Energy Harvesting and Storage Devices through Intelligent Flexographic Technology: A Review Article

Abstract

1. Introduction

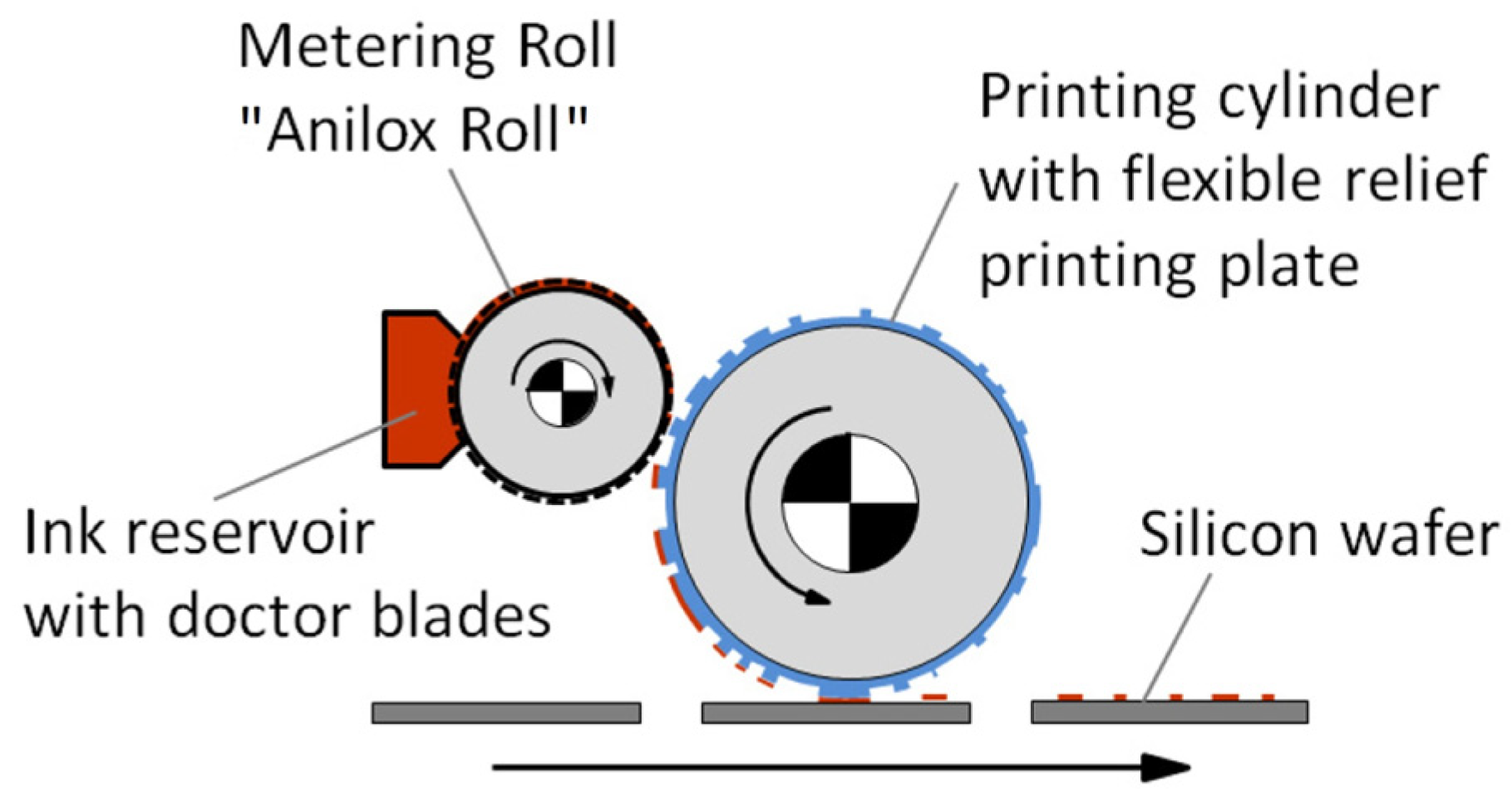

2. Potentials of Flexographic Printing for Silicon-Based Solar Cell Fabrication

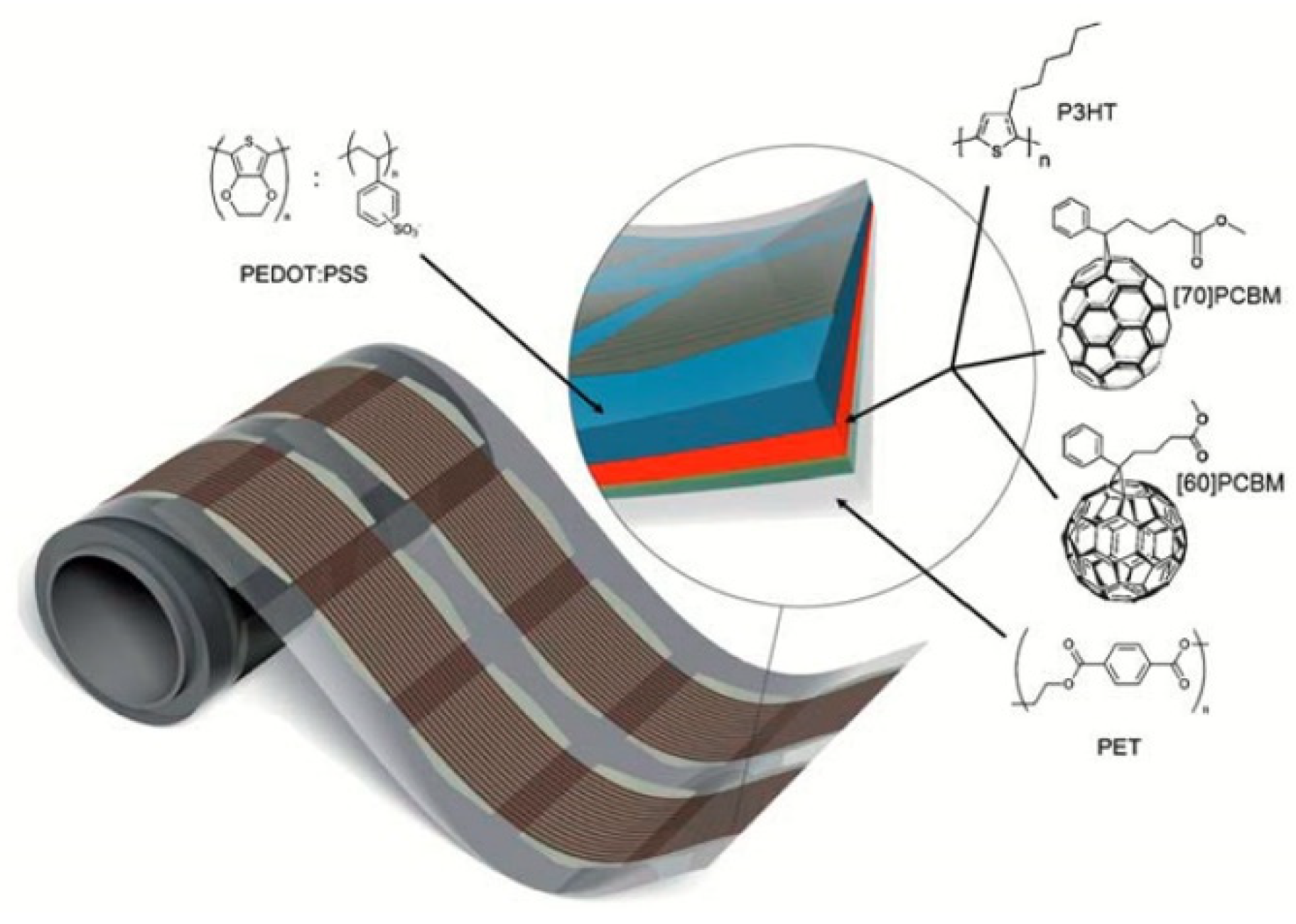

3. Polymer Solar Cell

4. Energy Storage Application

5. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bagher, A.M.; Vahid, M.M.A.; Mohsen, M. Types of solar cells and application. Am. J. Opt. Photonics 2015, 3, 94–113. [Google Scholar] [CrossRef]

- Platzer, M.D. US Solar Photovoltaic Manufacturing: Industry Trends, Global Competition, Federal Support; Congressional Research Service; Library of Congress: Washington, DC, USA, 2012. [Google Scholar]

- Sharma, S.; Jain, K.K.; Sharma, A. Solar cells: In research and applications—A review. Mater. Sci. Appl. 2015, 6, 1145. [Google Scholar] [CrossRef]

- Archer, M.D.; Green, M.A. (Eds.) . Clean Electricity from Photovoltaics; World Scientific: Singapore, 2014; Volume 4. [Google Scholar]

- Mahesh, D.; Rajesh, J. TiO2 microstructure, fabrication of thin film solar cells and introduction to dye sensitized solar cells. Res. J. Recent Sci. 2012, 2, 25–29. [Google Scholar]

- Li, G.; Zhu, R.; Yang, Y. Polymer solar cells. Nat. Photonics 2012, 6, 153–161. [Google Scholar] [CrossRef]

- Zhang, L.; Jia, T.; Pan, L.; Wu, B.; Wang, Z.; Gao, K.; Cao, Y. 15.4% Efficiency all-polymer solar cells. Sci. China Chem. 2021, 64, 408–412. [Google Scholar] [CrossRef]

- Ahn, N.; Son, D.Y.; Jang, I.H.; Kang, S.M.; Choi, M.; Park, N.G. Highly reproducible perovskite solar cells with average efficiency of 18.3% and best efficiency of 19.7% fabricated via Lewis base adduct of lead (II) iodide. J. Am. Chem. Soc. 2015, 137, 8696–8699. [Google Scholar] [CrossRef]

- Zhang, Y.; Yi, H.; Iraqi, A.; Kingsley, J.; Buckley, A.; Wang, T.; Lidzey, D.G. Comparative indoor and outdoor stability measurements of polymer based solar cells. Sci. Rep. 2017, 7, 1305. [Google Scholar] [CrossRef]

- Li, B.; Wang, L.; Kang, B.; Wang, P.; Qiu, Y. Review of recent progress in solid-state dye-sensitized solar cells. Sol. Energy Mater. Sol. Cells 2006, 90, 549–573. [Google Scholar] [CrossRef]

- Graetzel, M.; Janssen, R.A.; Mitzi, D.B.; Sargent, E.H. Materials interface engineering for solution-processed photovoltaics. Nature 2012, 488, 304–312. [Google Scholar] [CrossRef] [PubMed]

- Suhaimi, S.; Shahimin, M.M.; Alahmed, Z.A.; Chyský, J.; Reshak, A.H. Materials for enhanced dye-sensitized solar cell performance: Electrochemical application. Int. J. Electrochem. Sci. 2015, 10, 2859–2871. [Google Scholar]

- Liang, M.; Xu, W.; Cai, F.; Chen, P.; Peng, B.; Chen, J.; Li, Z. New triphenylamine-based organic dyes for efficient dye-sensitized solar cells. J. Phys. Chem. C 2007, 111, 4465–4472. [Google Scholar] [CrossRef]

- Shah, D.K. A Study on the Surface Texturing and Antireflection Coating with Nanomaterials for Crystalline Silicon Solar Cell. Master’s Thesis, Jeonbuk National University, Jeonju, Republic of Korea, 2022. [Google Scholar]

- Ebong, A.; Chen, N. Metallization of crystalline silicon solar cells: A review. In High Capacity Optical Networks and Emerging/Enabling Technologies; IEEE: New York, NY, USA, 2012; pp. 102–109. [Google Scholar]

- Mayer, A.; Scully, S.; Hardin, B.; Rowell, M.; McGehee, M. Polymer-based solar cells. Mater. Today 2007, 10, 28. [Google Scholar] [CrossRef]

- Sampaio, P.G.V.; Gonzalez, M.O.A.; de Oliveira Ferreira, P.; da Cunha Jacome Vidal, P.; Pereira, J.P.P.; Ferreira, H.R.; Oprime, P.C. Overview of printing and coating techniques in the production of organic photovoltaic cells. Int. J. Energy Res. 2020, 44, 9912–9931. [Google Scholar] [CrossRef]

- Brabec, C.J.; Shaheen, S.E.; Winder, C.; Sariciftci, N.S.; Denk, P. Effect of LiF/metal electrodes on the performance of plastic solar cells. Appl. Phys. Lett. 2002, 80, 1288–1290. [Google Scholar] [CrossRef]

- Ur Rehman, A.; Lee, S.H. Crystalline silicon solar cells with nickel/copper contacts. In Solar Cells-New Approaches and Reviews; InTech Open: Rijeka, Croatia, 2015. [Google Scholar]

- Brunetti, F.; Operamolla, A.; Castro-Hermosa, S.; Lucarelli, G.; Manca, V.; Farinola, G.M.; Brown, T.M. Printed solar cells and energy storage devices on paper substrates. Adv. Funct. Mater. 2019, 29, 1806798. [Google Scholar] [CrossRef]

- Huddy, J.E.; Ye, Y.; Scheideler, W.J. Precursor Ink Design for Scalable Fabrication of Perovskite Solar Cells via High-Speed Flexography. In Proceedings of the 2022 IEEE 49th Photovoltaics Specialists Conference (PVSC), San Juan, Puerto Rico, 11–16 June 2022; p. 0028. [Google Scholar]

- Samantaray, N.; Parida, B.; Soga, T.; Sharma, A.; Kapoor, A.; Najar, A.; Singh, A. Recent Development and Directions in Printed Perovskite Solar Cells. Phys. Status Solidi 2022, 219, 2100629. [Google Scholar] [CrossRef]

- Tomašegović, T.; Mahović Poljaček, S.; Strižić Jakovljević, M.; Urbas, R. Effect of the common solvents on UV-modified photopolymer and EPDM flexographic printing plates and printed ink films. Coatings 2020, 10, 136. [Google Scholar] [CrossRef]

- Ljevak, I.; Bilalli, A. Correlation between Ink Thickness and" Shrink Sleeve" Flexographic Print Quality at a Stable Friction Coefficient. Teh. Glas. 2021, 15, 366–370. [Google Scholar]

- Hösel, M.; Krebs, F.C. Large-scale roll-to-roll photonic sintering of flexo printed silver nanoparticle electrodes. J. Mater. Chem. 2012, 22, 15683–15688. [Google Scholar] [CrossRef]

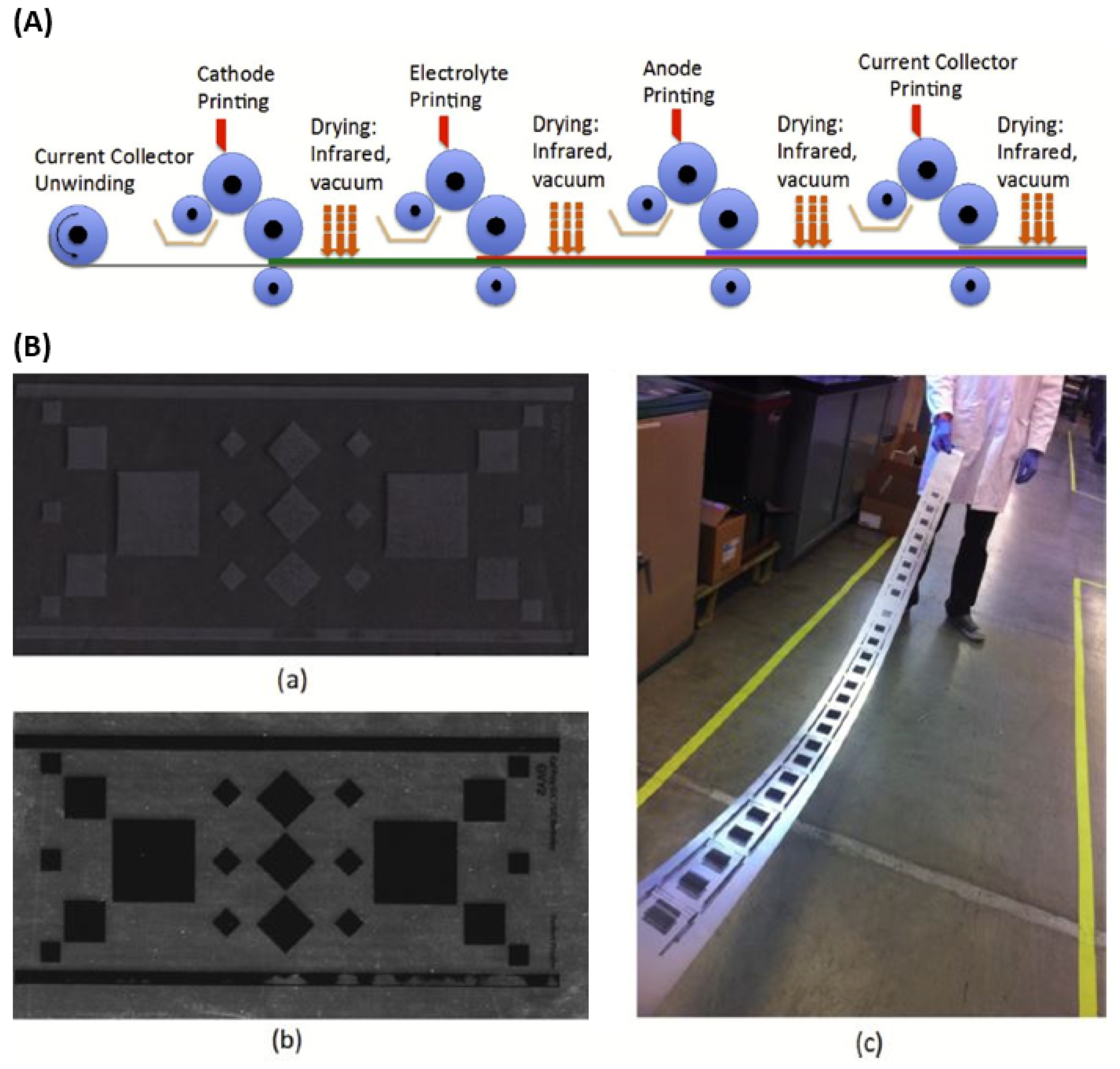

- Wang, Z.; Winslow, R.; Madan, D.; Wright, P.K.; Evans, J.W.; Keif, M.; Rong, X. Development of MnO2 cathode inks for flexographically printed rechargeable zinc-based battery. J. Power Sources 2014, 268, 246–254. [Google Scholar] [CrossRef]

- Krebs, F.C.; Fyenbo, J.; Jørgensen, M. Product integration of compact roll-to-roll processed polymer solar cell modules: Methods and manufacture using flexographic printing, slot-die coating and rotary screen printing. J. Mater. Chem. 2010, 20, 8994–9001. [Google Scholar] [CrossRef]

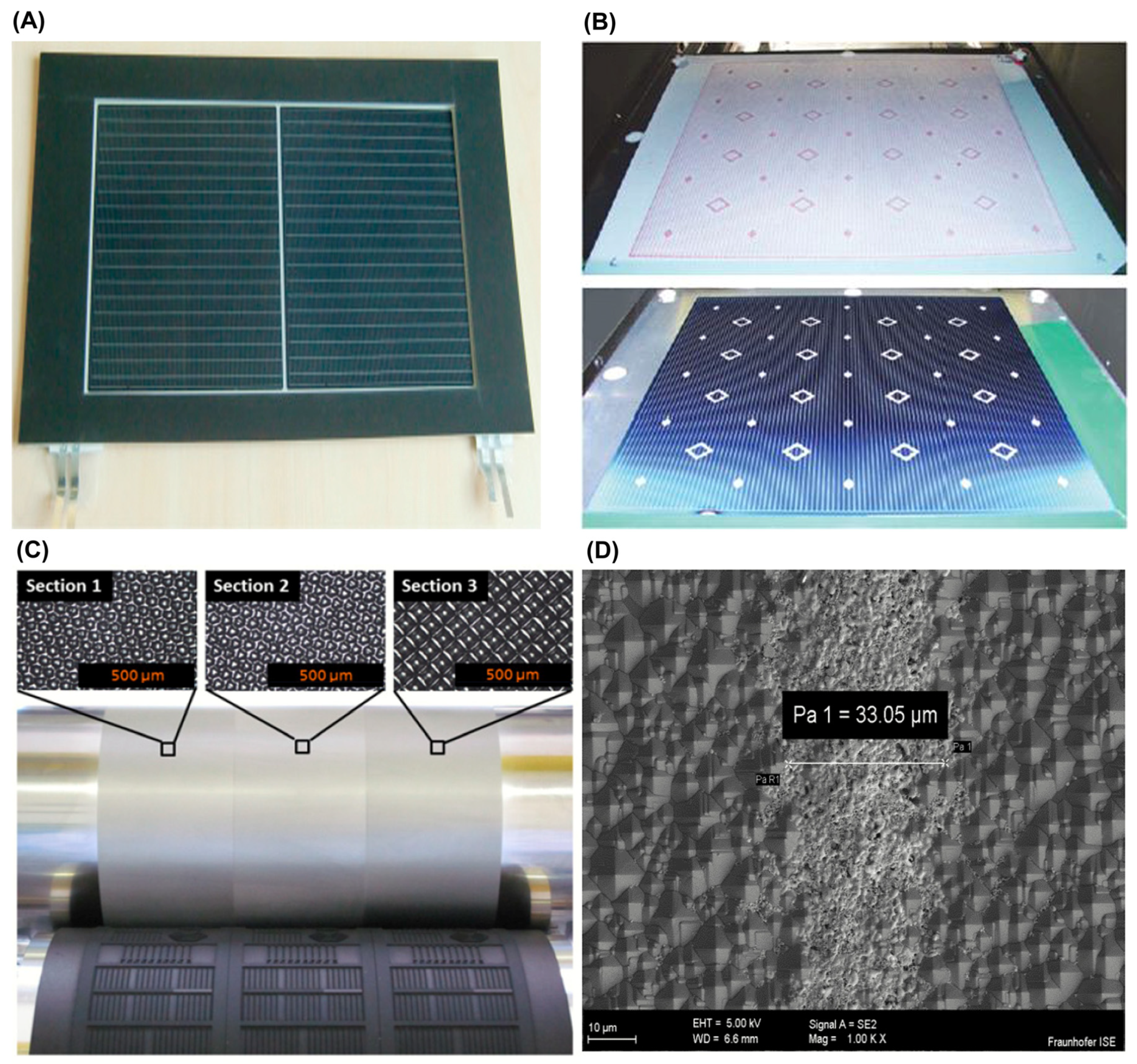

- Lorenz, A.; Senne, A.; Rohde, J.; Kroh, S.; Wittenberg, M.; Krüger, K.; Biro, D. Evaluation of flexographic printing technology for multi-busbar solar cells. Energy Procedia 2015, 67, 126–137. [Google Scholar] [CrossRef]

- Assaifan, A.K.; Al Habis, N.; Ahmad, I.; Alshehri, N.A.; Alharbi, H.F. Scaling-up medical technologies using flexographic printing. Talanta 2020, 219, 121236. [Google Scholar] [CrossRef] [PubMed]

- Zhong, Z.W.; Ee, J.H.; Chen, S.H.; Shan, X.C. Parametric investigation of flexographic printing processes for R2R printed electronics. Mater. Manuf. Process. 2020, 35, 564–571. [Google Scholar] [CrossRef]

- Lorenz, A.; Klawitter, M.; Linse, M.; Tepner, S.; Röth, J.; Wirth, N.; Clement, F. The project» Rock-Star «: The evolution of rotary printing for solar cell metallization. In AIP Conference Proceedings; AIP Publishing LLC: Long Island, NY, USA, 2021; Volume 2367, p. 020008. [Google Scholar]

- Lorenz, A.; Kalio, A.; Hofmeister, G.T.; Nold, S.; Kraft, A.; Bartsch, J.; Biro, D. Flexographic printing–high throughput technology for fine line seed layer printing on silicon solar cells. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, EUPVSEC, Paris, France, 30 September–4 October 2013; Volume 30, pp. 1017–1023. [Google Scholar]

- Thibert, S.; Jourdan, J.; Bechevet, B.; Mialon, S.; Beneventi, D.; Chaussy, D.; Reverdy-Bruas, N. Flexographic Process for Front Side Metallization of Silicon Solar Cell. In Proceedings of the 28th European Photovoltaic Solar Energy Conference and Exhibition, EUPVSEC, Paris, France, 30 September–4 October 2013; Volume 30, pp. 1013–1016. [Google Scholar]

- Wegener, M.; Spiehl, D.; Sauer, H.M.; Mikschl, F.; Liu, X.; Kölpin, N.; Schmidt, M.; Jank, M.P.; Dörsam, E.; Roosen, A. Flexographic printing of nanoparticulate tin-doped indium oxide inks on PET foils and glass substrates. J. Mater. Sci. 2016, 51, 4588–4600. [Google Scholar] [CrossRef]

- Hwang, M.; Kim, S.; Lee, K.; Moon, I.; Lim, J.; Lee, J.; Cho, E. Fine and high aspect ratio front electrode formation for improving efficiency of the multicristalline silicon solar cells. In Proceedings of the 25th European Photovoltaic Solar Energy Conference, Valencia, Spain, 6–10 September 2010; pp. 1792–1795. [Google Scholar]

- Frey, M.; Clement, F.; Dilfer, S.; Erath, D.; Biro, D. Front-side metalization by means of flexographic printing. Energy Procedia 2011, 8, 581–586. [Google Scholar] [CrossRef]

- Thibert, S.; Chaussy, D.; Beneventi, D.; Reverdy-Bruas, N.; Jourdan, J.; Bechevet, B.; Mialon, S. Silver ink experiments for silicon solar cell metallization by flexographic process. In Proceedings of the 2012 38th IEEE Photovoltaic Specialists Conference, Austin, TX, USA, 3–8 June 2012; pp. 002266–002270. [Google Scholar]

- Thibert, S.; Jourdan, J.; Bechevet, B.; Mialon, S.; Chaussy, D.; Reverdy-Bruas, N.; Beneventi, D. Study of the high throughput flexographic process for silicon solar cell metallisation. Prog. Photovolt. Res. Appl. 2016, 24, 240–252. [Google Scholar] [CrossRef]

- Mette, A. New concepts for front side metallization of industrial silicon solar cells. Doctoral Thesis, Albert-Ludwigs-Universität, Freiburg im Breisgau, Germany, 2007. [Google Scholar]

- Lorenz, A.; Kraft, A.; Gredy, C.; Filipovic, A.; Binder, S.; Krüger, K.; Bartsch, J.; Clement, F.; Biro, D.; Preu, R.; et al. Comprehensive Comparison of Different Fine Line Printing Technologies Adressing the Seed and Plate Approach with Ni-Cu-Plating. Proc. 30th EUPVSEC 2015, 732–736. [Google Scholar]

- Kalio, A.; Richter, A.; Hörteis, M.; Glunz, S.W. Metallization of n-type silicon solar cells using fine line printing techniques. Energy Procedia 2011, 8, 571–576. [Google Scholar] [CrossRef]

- Kray, D.; Aleman, M.; Fell, A.; Hopman, S.; Mayer, K.; Mesec, M.; Richerzhagen, B. Laser-doped silicon solar cells by laser chemical processing (LCP) exceeding 20% efficiency. In Proceedings of the 2008 33rd IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 1–3. [Google Scholar]

- Tous, L.; Lerat, J.F.; Emeraud, T.; Negru, R.; Huet, K.; Uruena, A.; Mertens, R. Nickel silicide contacts formed by excimer laser annealing for high efficiency solar cells. Prog. Photovolt. Res. Appl. 2013, 21, 267–275. [Google Scholar] [CrossRef]

- Lorenz, A.; Gredy, C.; Beyer, S.; Yao, Y.; Papet, P.; Ufheil, J.; Clement, F. Flexographic printing–towards an advanced front side metallization approach with high throughput and low silver consumption. Sol. Energy Mater. Sol. Cells 2016, 157, 550–557. [Google Scholar] [CrossRef]

- Mette, A.; Richter, P.L.; Hörteis, M.; Glunz, S.W. Metal aerosol jet printing for solar cell metallization. Prog. Photovolt. Res. Appl. 2007, 15, 621–627. [Google Scholar] [CrossRef]

- Lorenz, A.; Gredy, C.; Senne, A.; Beyer, S.; Yao, Y.; Papet, P.; Clement, F. Flexoprinted busbarless solar cells for multi-wire interconnection. Energy Procedia 2016, 98, 46–60. [Google Scholar] [CrossRef]

- Nuhash, M.M.; Alam, I.; Islam, A.N.U. Manufacturing Processes of Solution-processed Organic Solar cells and Recent Advances. In Proceedings of the Third International Conference on Industrial & Mechanical Engineering and Operations Management (IMEOM), Dhaka, Bangladesh, 26–27 December 2020; p. 217. [Google Scholar]

- Søndergaard, R.; Hösel, M.; Angmo, D.; Larsen-Olsen, T.T.; Krebs, F.C. Roll-to-roll fabrication of polymer solar cells. Mater. Today 2012, 15, 36–49. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Wang, Y.; Cheng, T.; Yao, L.Q.; Li, X.; Lai, W.Y.; Huang, W. Printed supercapacitors: Materials, printing and applications. Chem. Soc. Rev. 2019, 48, 3229–3264. [Google Scholar] [CrossRef] [PubMed]

- Krebs, F.C.; Nielsen, T.D.; Fyenbo, J.; Wadstrøm, M.; Pedersen, M.S. Manufacture, integration and demonstration of polymer solar cells in a lamp for the “Lighting Africa” initiative. Energy Environ. Sci. 2010, 3, 512–525. [Google Scholar] [CrossRef]

- Krebs, F.C.; Jørgensen, M.; Norrman, K.; Hagemann, O.; Alstrup, J.; Nielsen, T.D.; Kristensen, J. A complete process for production of flexible large area polymer solar cells entirely using screen printing—First public demonstration. Sol. Energy Mater. Sol. Cells 2009, 93, 422–441. [Google Scholar] [CrossRef]

- Xue, P.; Cheng, P.; Han, R.P.; Zhan, X. Printing fabrication of large-area non-fullerene organic solar cells. Mater. Horiz. 2022, 9, 194–219. [Google Scholar] [CrossRef]

- Hübler, A.; Trnovec, B.; Zillger, T.; Ali, M.; Wetzold, N.; Mingebach, M.; Dyakonov, V. Printed paper photovoltaic cells. Adv. Energy Mater. 2011, 1, 1018–1022. [Google Scholar] [CrossRef]

- Yip, H.L.; Hau, S.K.; Jen, A.K.Y. Interface engineering of stable, efficient polymer solar cells. Sol. Altern. Energy 2009. [CrossRef]

- Hsueh, T.J.; Hsu, C.L. Fabrication of gas sensing devices with ZnO nanostructure by the low-temperature oxidation of zinc particles. Sens. Actuators B Chem. 2008, 131, 572–576. [Google Scholar] [CrossRef]

- Radhakrishnan, S.; Saini, D.R. Electrical properties of polyester elastomer composites containing metallic fillers. J. Mater. Sci. 1991, 26, 5950–5956. [Google Scholar] [CrossRef]

- Oosterhout, S.D.; Wienk, M.M.; Van Bavel, S.S.; Thiedmann, R.; Koster, L.J.A.; Gilot, J.; Janssen, R.A. The effect of three-dimensional morphology on the efficiency of hybrid polymer solar cells. Nat. Mater. 2009, 8, 818–824. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.P.; Chen, Y.D.; Chuang, S.C. High-performance and highly durable inverted organic photovoltaics embedding solution-processable vanadium oxides as an interfacial hole-transporting layer. Adv. Mater. 2011, 23, 3859–3863. [Google Scholar] [CrossRef] [PubMed]

- Zilberberg, K.; Trost, S.; Meyer, J.; Kahn, A.; Behrendt, A.; Lützenkirchen-Hecht, D.; Frahm, R.; Riedl, T. Inverted organic solar cells with sol–gel processed high work-function vanadium oxide hole-extraction layers. Adv. Funct. Mater. 2011, 21, 4776–4783. [Google Scholar] [CrossRef]

- Hajzeri, M.; Vuk, A.Š.; Perše, L.S.; Čolović, M.; Herbig, B.; Posset, U.; Orel, B. Sol–gel vanadium oxide thin films for a flexible electronically conductive polymeric substrate. Sol. Energy Mater. Sol. Cells 2012, 99, 62–72. [Google Scholar] [CrossRef]

- Kololuoma, T.; Lu, J.; Alem, S.; Graddage, N.; Movileanu, R.; Moisa, S.; Tao, Y. Flexo printed sol-gel derived vanadium oxide films as an interfacial hole-transporting layer for organic solar cells. In Oxide-Based Materials and Devices VI.; International Society for Optics and Photonics: Belligham, WA, USA, 2015; Volume 9364, p. 93640K. [Google Scholar]

- Zilberberg, K.; Trost, S.; Schmidt, H.; Riedl, T. Solution processed vanadium pentoxide as charge extraction layer for organic solar cells. Adv. Energy Mater. 2011, 1, 377–381. [Google Scholar] [CrossRef]

- Huang, J.S.; Chou, C.Y.; Liu, M.Y.; Tsai, K.H.; Lin, W.H.; Lin, C.F. Solution-processed vanadium oxide as an anode interlayer for inverted polymer solar cells hybridized with ZnO nanorods. Org. Electron. 2009, 10, 1060–1065. [Google Scholar] [CrossRef]

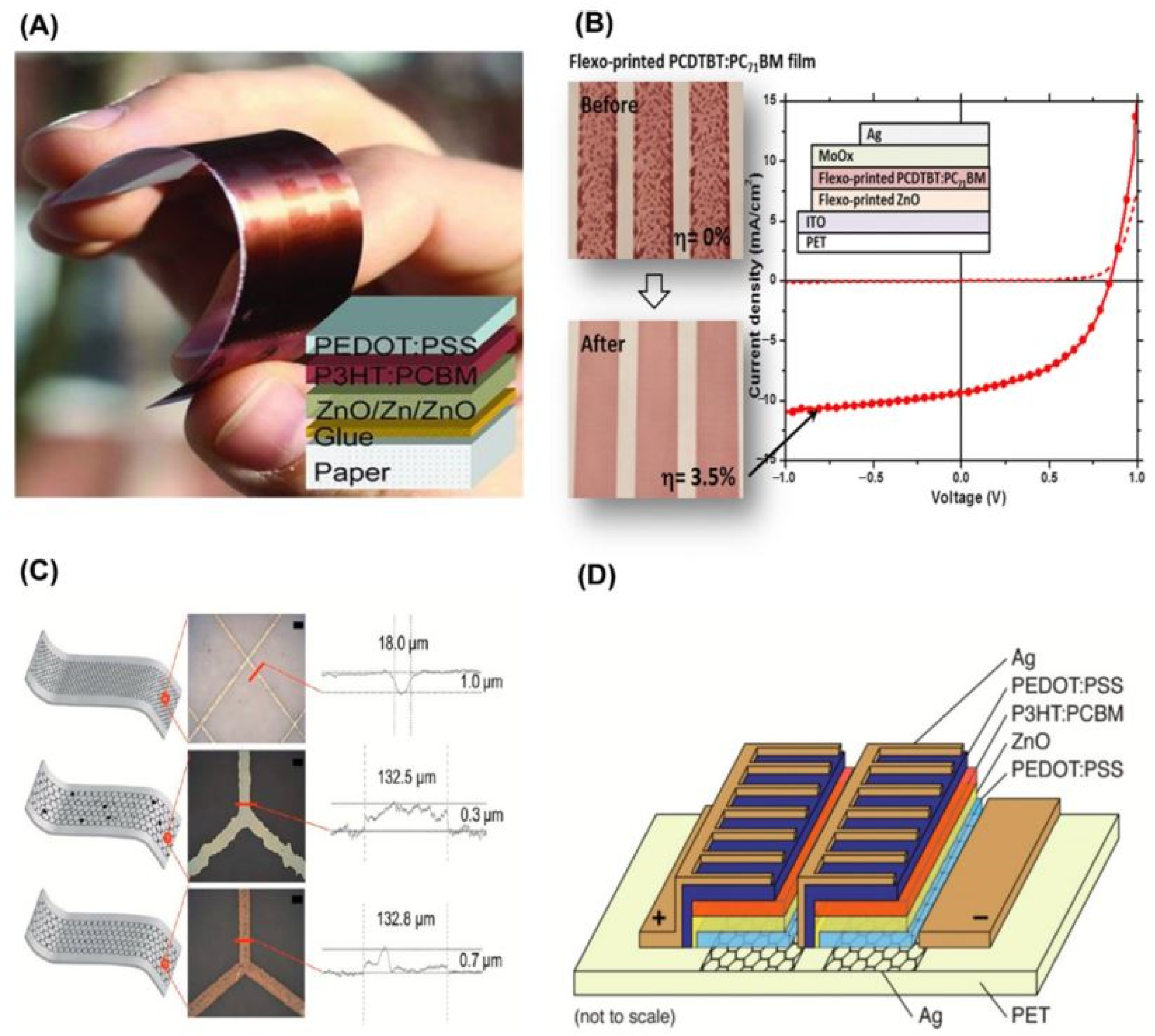

- Alem, S.; Graddage, N.; Lu, J.; Kololuoma, T.; Movileanu, R.; Tao, Y. Flexographic printing of polycarbazole-based inverted solar cells. Org. Electron. 2018, 52, 146–152. [Google Scholar] [CrossRef]

- Castro, M.F.; Mazzolini, E.; Sondergaard, R.R.; Espindola-Rodriguez, M.; Andreasen, J.W. Flexible ITO-free roll-processed large-area nonfullerene organic solar cells based on P3HT: O-IDTBR. Phys. Rev. Appl. 2020, 14, 034067. [Google Scholar] [CrossRef]

- Galagan, Y.; Zimmermann, B.; Coenen, E.W.; Jørgensen, M.; Tanenbaum, D.M.; Krebs, F.C.; Andriessen, R. Current Collecting Grids for ITO-Free Solar Cells. Adv. Energy Mater. 2012, 2, 103–110. [Google Scholar] [CrossRef]

- Galagan, Y.; de Vries, I.G.; Langen, A.P.; Andriessen, R.; Verhees, W.J.; Veenstra, S.C.; Kroon, J.M. Technology development for roll-to-roll production of organic photovoltaics. Chem. Eng. Process. Process Intensif. 2011, 50, 454–461. [Google Scholar] [CrossRef]

- Galagan, Y.; Coenen, E.W.; Sabik, S.; Gorter, H.H.; Barink, M.; Veenstra, S.C.; Blom, P.W. Evaluation of ink-jet printed current collecting grids and busbars for ITO-free organic solar cells. Sol. Energy Mater. Sol. Cells 2012, 104, 32–38. [Google Scholar] [CrossRef]

- Yu, J.S.; Kim, I.; Kim, J.S.; Jo, J.; Larsen-Olsen, T.T.; Søndergaard, R.R.; Krebs, F.C. Silver front electrode grids for ITO-free all printed polymer solar cells with embedded and raised topographies, prepared by thermal imprint, flexographic and inkjet roll-to-roll processes. Nanoscale 2012, 4, 6032–6040. [Google Scholar] [CrossRef]

- Hösel, M.; Søndergaard, R.R.; Angmo, D.; Krebs, F.C. Comparison of Fast Roll-to-Roll Flexographic, Inkjet, Flatbed, and Rotary Screen Printing of Metal Back Electrodes for Polymer Solar Cells. Adv. Eng. Mater. 2013, 15, 995–1001. [Google Scholar] [CrossRef]

- Ahn, D.B.; Lee, S.S.; Lee, K.H.; Kim, J.H.; Lee, J.W.; Lee, S.Y. Form factor-free, printed power sources. Energy Storage Mater. 2020, 29, 92–112. [Google Scholar] [CrossRef]

- Karpinski, A.P.; Makovetski, B.; Russell, S.J.; Serenyi, J.R.; Williams, D.C. Silver–zinc: Status of technology and applications. J. Power Sources 1999, 80, 53–60. [Google Scholar] [CrossRef]

- Ho, C.C.; Evans, J.W.; Wright, P.K. Direct write dispenser printing of a zinc microbattery with an ionic liquid gel electrolyte. J. Micromechanics Microengineering 2010, 20, 1040. [Google Scholar] [CrossRef]

- Humble, P.H.; Harb, J.N.; LaFollette, R. Microscopic nickel-zinc batteries for use in autonomous microsystems. J. Electrochem. Soc. 2001, 148, A1357. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, H.; Zhang, W.K.; Gan, Y.P.; Wang, C.T. Effects of conductive ceramic on the electrochemical performance of ZnO for Ni/Zn rechargeable battery. Electrochim. Acta 2008, 53, 5386–5390. [Google Scholar] [CrossRef]

- Higgins, R.L.; Erisman, L.R. Applications of the Lithium-Carbon Mono-Fluoride Battery. In Proceedings of the 28th Power Sources Symposium, Atlantic City, NJ, USA, 12–15 June 1978; pp. 208–210. [Google Scholar]

- Xu, C.; Du, H.; Li, B.; Kang, F.; Zeng, Y. Reversible insertion properties of zinc ion into manganese dioxide and its application for energy storage. Electrochem. Solid State Lett. 2009, 12, A61. [Google Scholar] [CrossRef]

- Kordesh, K.; Weissenbacher, M. Rechargeable alkaline manganese dioxide/zinc batteries. J. Power Sources 1994, 51, 61–78. [Google Scholar] [CrossRef]

- Ross, P.N., Jr. Zinc Electrode and Rechargeable Zinc-Air Battery; (No. US 4842963); Lawrence Berkeley National Lab. (LBNL): Berkeley, CA, USA, 1989. [Google Scholar]

- Müller, S.; Holzer, F.; Haas, O. Optimized zinc electrode for the rechargeable zinc–air battery. J. Appl. Electrochem. 1998, 28, 895–898. [Google Scholar] [CrossRef]

- McLarnon, F.R.; Cairns, E.J. The secondary alkaline zinc electrode. J. Electrochem. Soc. 1991, 138, 645. [Google Scholar] [CrossRef]

- Wang, Z. Flexographically printed rechargeable zinc-based battery for grid energy storage. Doctoral Thesis, UC Berkeley, Berkeley, CA, USA, 2013. [Google Scholar]

| Application | Substrate | Ink | Result | Reference |

|---|---|---|---|---|

| Using rheology characterization to study viscoelastic properties of a diluted screen-printing silver paste and to adapt such a paste to the flexographic printing process for depositing a seed layer. | Monocrystalline silicon wafer after alkaline texturization | (A0) Screen-printing silver paste ink containing 5, 7, 10, 15, and 20 wt% of the solvent | Deposit 30 μm in the width of the silver seed layer | [37] |

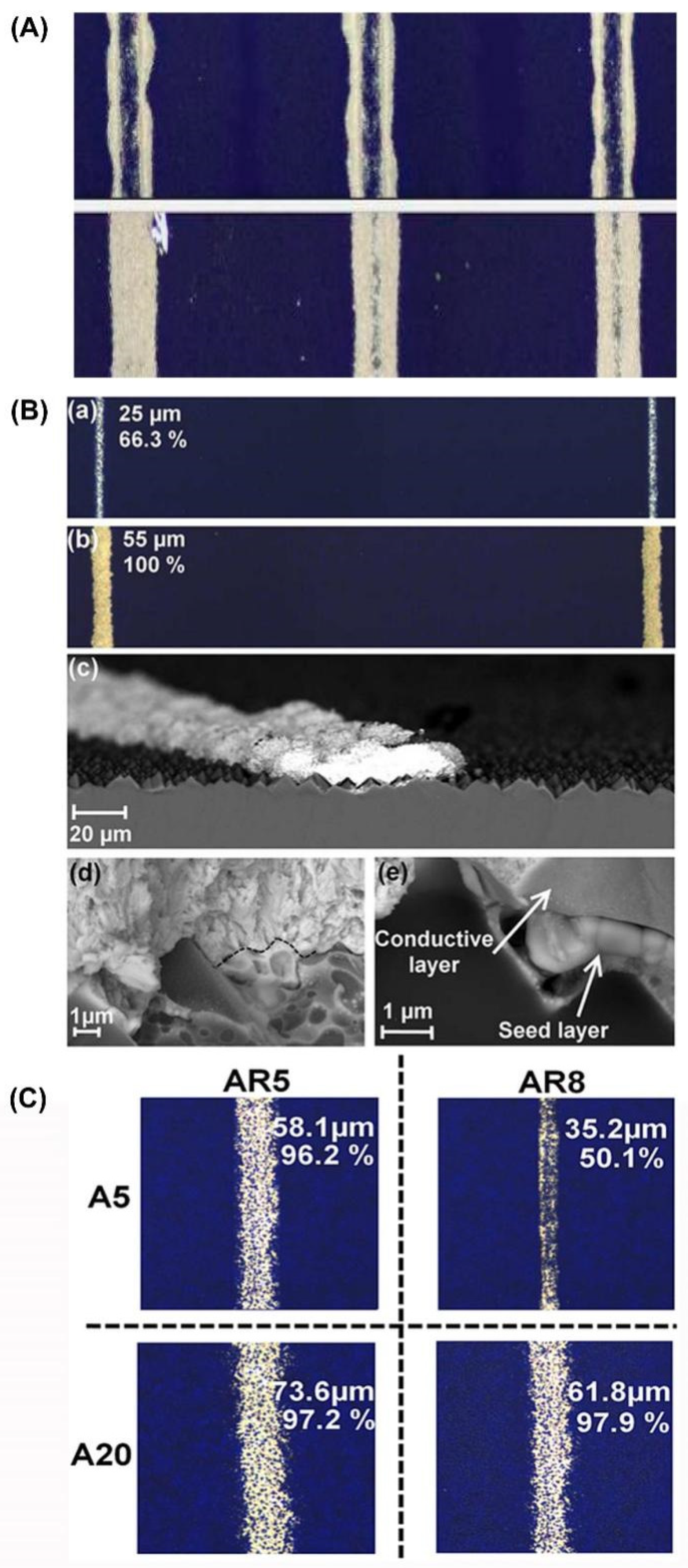

| Print fine lines on the front-side metallization of silicon solar cells. | P-type, textured Cz-Si (Czrochalski-grown silicon) | Silver paste A with particle size ranging between 0.5 and 1 μm, and is diluted by 5, 10, 15, and 20 wt% of 2-(2-butoxyethoxy) ethanol to formulate A5, A10, A15, and A20. | Encouraging 17.9% efficiency on Cz-Si solar cell | [38] |

| Fabrication of the 1st busbarless solar cell with flexo-printed front-side metallization. | Wafer material of Cz-Si p-type solar cell up to anti-reflection coating (precursors) with an edge length of 156 mm | Two types of silver-based inks (Ag-inks). Ink A: aerosol jet optimization ink. Ink B: diluted screen-printing Ag-paste | Achieving an average conversion efficiency of | [44] |

| Printing of the front-side metallization of busbarless Al BSF solar cells with multi-wire interconnection. | Silicon wafer p-type Cz-Si precursors. | Silver ink (Ag-ink) | Achieving an average conversion efficiency of | [46] |

| Front-side metallization of multi-busbar solar cells. | Silicon wafer | Silver-based ink (aerosol ink SISC) | Producing a fine-line metallization of multi-busbar solar cells with 33 µm contact finger width | [28] |

| Application | Substrate | Ink | Results | Reference |

|---|---|---|---|---|

| Printing 5 mm wide lines of ZnO, P3HT: [60/70] PCBM, PEDOT:PSS, and silver. | ITO-PET | Layer of n-octanol | 2.75% power conversion efficiency | [27] |

| A novel layer structure (paper/Zn/ZnO/photoactive layer/PEDOT:PSS) for polymer/fullerene-based flexible photovoltaic cell. | Paper | PEDOT: PSS (1.5 wt% PEDOT PH1000 and 0.35 wt% PEDOT F010) in water including some surfactant mixture. | 1.31% power conversion efficiency | [53] |

| Printing a hole-transporting layer (HTLs) for inverted OPV (ITO/ZnO/PCDTBT:PC70BM/VOx/Ag). | ITO-coated glass and PET | Vanadium oxide precursor | 3.5–4.5% power conversion efficiencies | [61] |

| A photoactive layer of BHJ solar cells. | Indium tin oxide (ITO) 130 nm thickness coated PET with125 µm thickness | ZnO nanoparticles and sol-gel-based vanadium oxide inks. PCDTBT:PC71BM ink | 3.5% conversion efficiency | [64] |

| Comparing three types of printing of the front conductive grid of (ITO) free polymer solar cells and raised topographies. | PEDOT:PSS PET | Water-based silver nanoparticle inks | 1.72% conversion efficiency | [69] |

| Comparing four different R2R printing methods for printing back electrodes for polymer solar cell modules based on the Ione process. | PEDOT:PSS | Water-based silver inks | - | [70] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al Habis, N.; Khushaim, M.; Nabat Al-Ajrash, S.M. Energy Harvesting and Storage Devices through Intelligent Flexographic Technology: A Review Article. Energies 2023, 16, 869. https://doi.org/10.3390/en16020869

Al Habis N, Khushaim M, Nabat Al-Ajrash SM. Energy Harvesting and Storage Devices through Intelligent Flexographic Technology: A Review Article. Energies. 2023; 16(2):869. https://doi.org/10.3390/en16020869

Chicago/Turabian StyleAl Habis, Nuha, Muna Khushaim, and Saja M. Nabat Al-Ajrash. 2023. "Energy Harvesting and Storage Devices through Intelligent Flexographic Technology: A Review Article" Energies 16, no. 2: 869. https://doi.org/10.3390/en16020869

APA StyleAl Habis, N., Khushaim, M., & Nabat Al-Ajrash, S. M. (2023). Energy Harvesting and Storage Devices through Intelligent Flexographic Technology: A Review Article. Energies, 16(2), 869. https://doi.org/10.3390/en16020869