Comprehensive Analysis of Solid Oxide Fuel Cell Performance Degradation Mechanism, Prediction, and Optimization Studies

Abstract

1. Introduction

2. SOFC Degradation Mechanism Analysis

2.1. Stack Performance Degradation

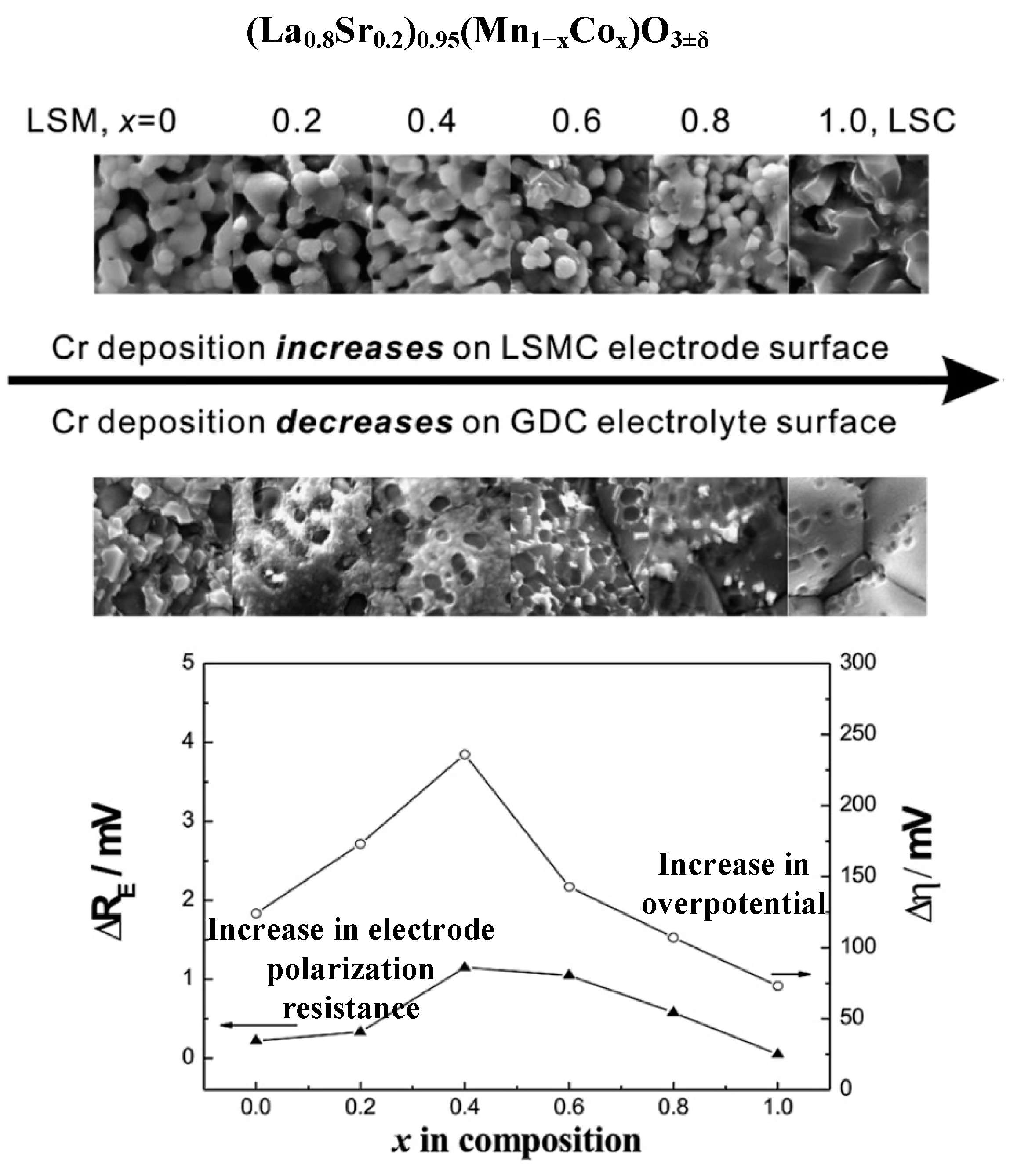

2.1.1. Cathode Performance Degradation

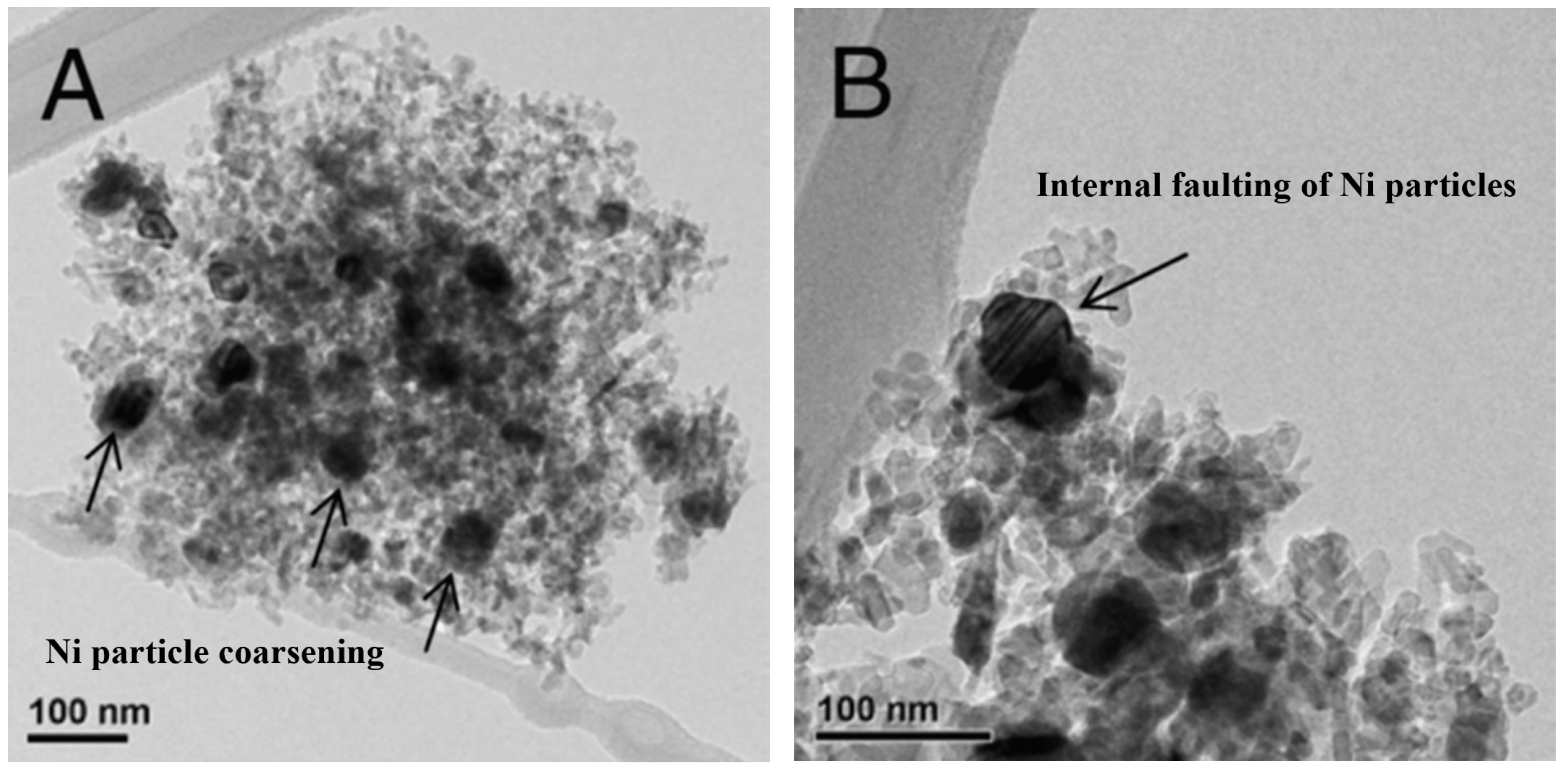

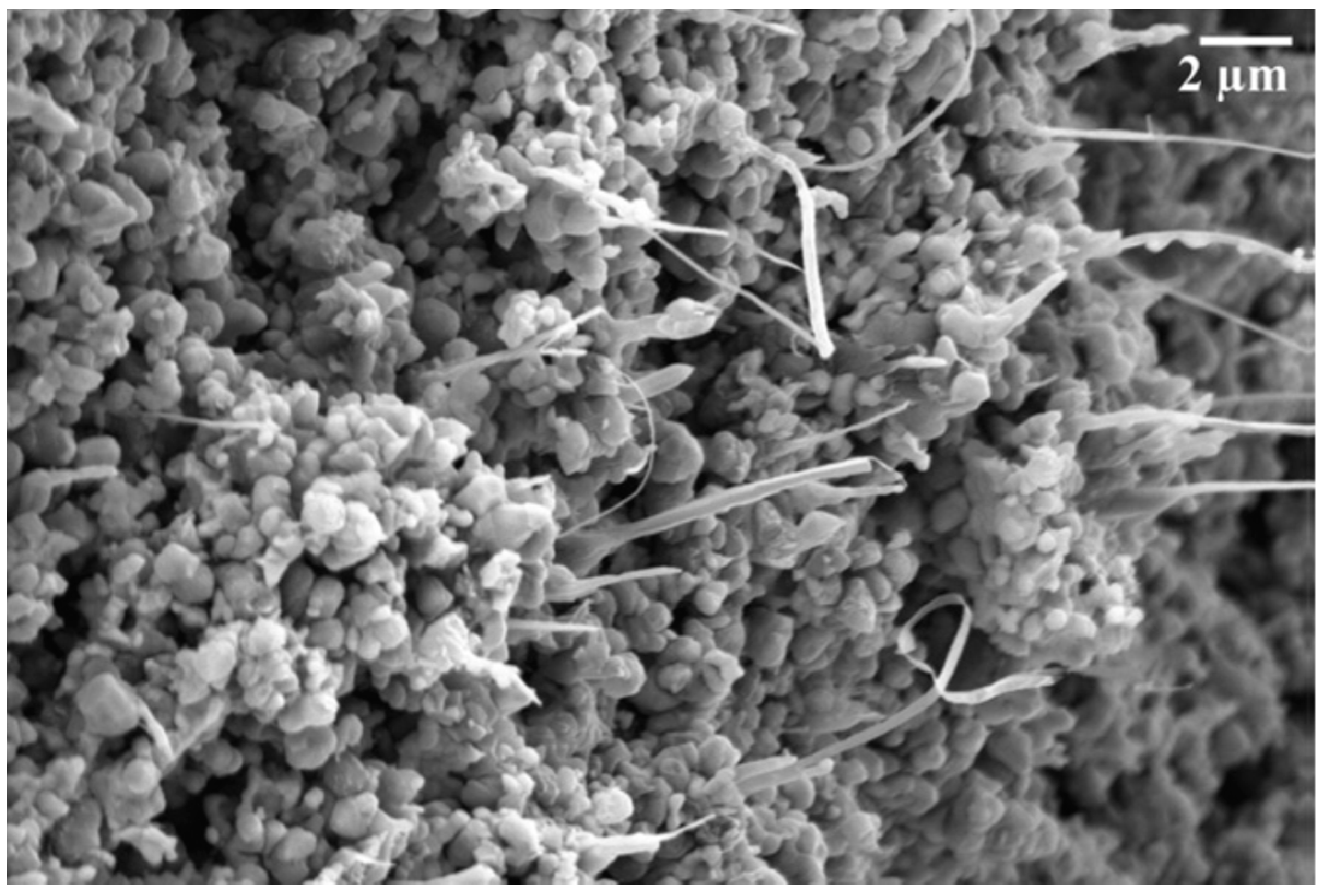

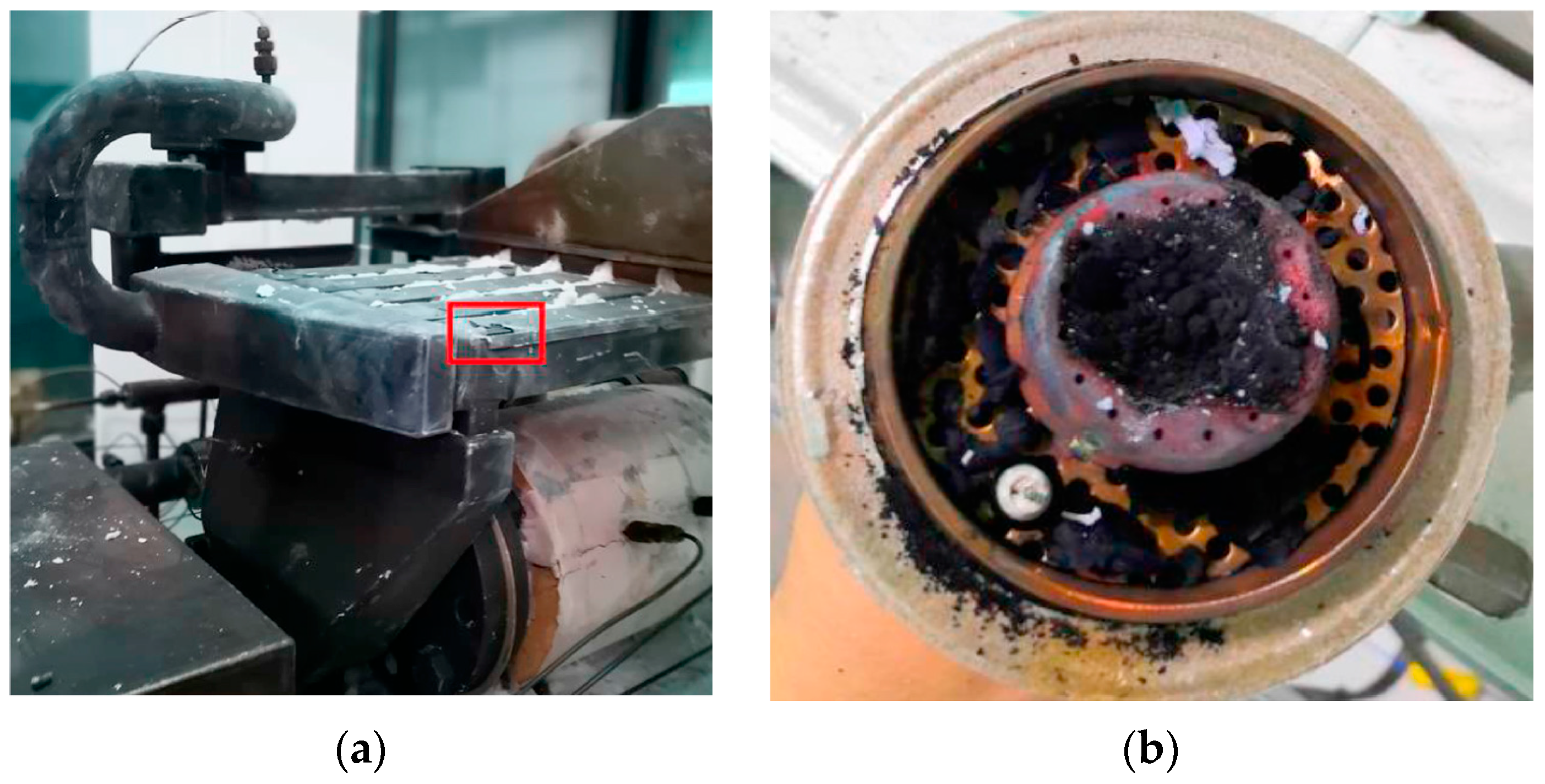

2.1.2. Anode Performance Degradation

2.1.3. Electrolyte Performance Degradation

2.1.4. Interconnect Performance Degradation

2.1.5. Sealing Material Performance Degradation

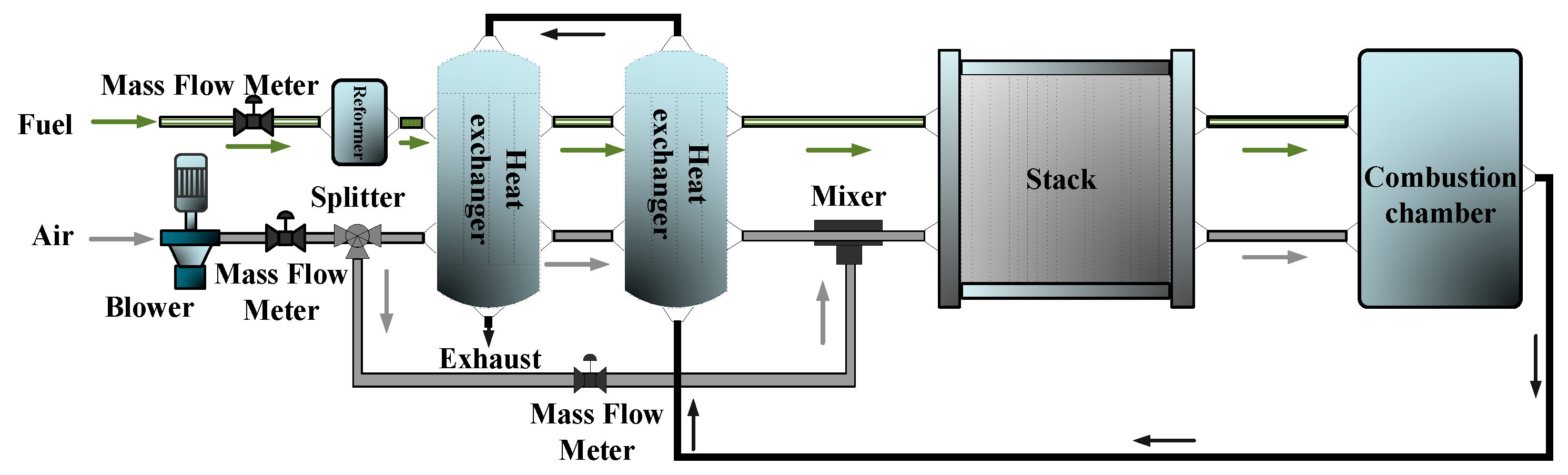

2.2. System-Level Performance Degradation

3. SOFC Degradation Performance Prediction

3.1. Model-Based Degradation Performance Prediction

3.2. Data-Based Degradation Performance Prediction

3.3. EIS-Based Degradation Performance Prediction

3.4. Image-Based Degradation Performance Prediction

4. SOFC Performance Optimization Scheme

4.1. System Material and Structure Improvement

4.2. Health Controller Design

5. Conclusions and Future Remarks

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Boldrin, P.; Brandon, N.P. Progress and Outlook for Solid Oxide Fuel Cells for Transportation Applications. Nat. Catal. 2019, 2, 571–577. [Google Scholar] [CrossRef]

- Peng, J.; Huang, J.; Jiang, C.; Xu, Y.-W.; Wu, X.-L.; Li, X. Generalized Spatial-Temporal Fault Location Method for Solid Oxide Fuel Cells Using LSTM and Causal Inference. IEEE Trans. Transp. Electrif. 2022, 8, 4. [Google Scholar] [CrossRef]

- Peng, J.; Huang, J.; Wu, X.L.; Xu, Y.W.; Chen, H.; Li, X. Solid Oxide Fuel Cell (SOFC) Performance Evaluation, Fault Diagnosis and Health Control: A Review. J. Power Sources 2021, 505, 230058. [Google Scholar] [CrossRef]

- Skafte, T.L.; Hjelm, J.; Blennow, P.; Graves, C.R. Quantitative Review of Degradation and Lifetime of Solid Oxide Cells and Stacks. In Proceedings of the 12th European SOFC & SOE Forum, Lucerne, Switzerland, 5–8 July 2016; pp. 8–27. [Google Scholar]

- Tu, H.; Stimming, U. Advances, Aging Mechanisms and Lifetime in Solid-Oxide Fuel Cells. J. Power Sources 2004, 127, 284–293. [Google Scholar] [CrossRef]

- Sreedhar, I.; Agarwal, B.; Goyal, P.; Agarwal, A. An Overview of Degradation in Solid Oxide Fuel Cells-Potential Clean Power Sources. J. Solid State Electrochem. 2020, 24, 1239–1270. [Google Scholar] [CrossRef]

- Anwar, M.; Abdul, M.A.S.; Khan, U.M.; Hassan, M.; Khoja, A.H.; Muchtar, A. A Review of X-ray Photoelectron Spectroscopy Technique to Analyze the Stability and Degradation Mechanism of Solid Oxide Fuel Cell Cathode Materials. Materials 2022, 15, 2540. [Google Scholar] [CrossRef]

- Subotić, V.; Hochenauer, C. Analysis of Solid Oxide Fuel and Electrolysis Cells Operated in a Real-System Environment: State-of-the-Health Diagnostic, Failure Modes, Degradation Mitigation and Performance Regeneration. Prog. Energy Combust. Sci. 2022, 93, 101011. [Google Scholar] [CrossRef]

- Dolenc, B.; Boškoski, P.; Stepančič, M.; Pohjoranta, A.; Juričić, Đ. State of Health Estimation and Remaining Useful Life Prediction of Solid Oxide Fuel Cell Stack. Energy Convers Manag. 2017, 148, 993–1002. [Google Scholar] [CrossRef]

- Wu, X.; Xu, L.; Wang, J.; Yang, D.; Li, F.; Li, X. A Prognostic-Based Dynamic Optimization Strategy for a Degraded Solid Oxide Fuel Cell. Sustain. Energy Technol. Assess. 2020, 39, 100682. [Google Scholar] [CrossRef]

- Vrečko, D.; Nerat, M.; Vrančić, D.; Dolanc, G.; Dolenc, B.; Pregelj, B.; Meyer, F.; Au, S.F.; Makkus, R.; Juričić, Đ. Feedforward-Feedback Control of a Solid Oxide Fuel Cell Power System. Int. J. Hydrog. Energy 2018, 43, 6352–6363. [Google Scholar] [CrossRef]

- Åström, K.; Fontell, E.; Virtanen, S. Reliability Analysis and Initial Requirements for FC Systems and Stacks. J. Power Sources 2007, 171, 46–54. [Google Scholar] [CrossRef]

- Wilson, J.R.; Cronin, J.S.; Duong, A.T.; Rukes, S.; Chen, H.Y.; Thornton, K.; Mumm, D.R.; Barnett, S. Effect of Composition of La0.8Sr0.2MnO3-Y2O 3-Stabilized ZrO2 Cathodes. Correlating Three-Dimensional Microstructure and Polarization Resistance. J. Power Sources 2010, 195, 1829–1840. [Google Scholar] [CrossRef]

- Yokokawa, H. Understanding Materials Compatibility. Annu. Rev. Mater Res. 2003, 33, 581–610. [Google Scholar] [CrossRef]

- Fang, Q.; Blum, L.; Stolten, D. Electrochemical Performance and Degradation Analysis of an SOFC Short Stack Following Operation of More than 100,000 Hours. J. Electrochem. Soc. 2019, 166, F1320–F1325. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, L.; Liu, E.; Jiang, S.P. A Fundamental Study of Chromium Deposition and Poisoning at (La 0.8Sr0.2)0.95(Mn1-XCo x)O3 ± δ (0.0≤ x ≤1.0) Cathodes of Solid Oxide Fuel Cells. Int. J. Hydrog. Energy 2011, 36, 805–821. [Google Scholar] [CrossRef]

- Riegraf, M.; Schiller, G.; Costa, R.; Friedrich, K.A.; Latz, A.; Yurkiv, V. Lifetime and Performance Prediction of SOFC Anodes Operated with Trace Amounts of Hydrogen Sulfide. ECS Trans. 2015, 68, 1373. [Google Scholar] [CrossRef]

- Dees, D.; Claar, T.; Easler, T.; Fee, D.; Mrazek, F. Conductivity of Porous Ni/ZrO2-Y2O3 Cermets. J. Electrochem. Society 1987, 134, 9. [Google Scholar] [CrossRef]

- Khan, M.Z.; Song, R.-H.; Lee, S.-B.; Lim, T.-H. Lifetime Prediction of Anode-Supported Solid Oxide Fuel Cell on the Basis of Individual Components Degradation. ECS Trans. 2019, 91, 621–627. [Google Scholar] [CrossRef]

- Sehested, J.; Gelten, J.A.P.; Helveg, S. Sintering of Nickel Catalysts: Effects of Time, Atmosphere, Temperature, Nickel-Carrier Interactions, and Dopants. Appl. Catal. A Gen. 2006, 309, 237–246. [Google Scholar] [CrossRef]

- Klemensø, T.; Appel, C.C.; Mogensen, M. In Situ Observations of Microstructural Changes in SOFC Anodes during Redox Cycling. Electrochem. Solid-State Lett. 2006, 9, A403. [Google Scholar] [CrossRef]

- Lanzini, A.; Leone, P.; Guerra, C.; Smeacetto, F.; Brandon, N.P.; Santarelli, M. Durability of Anode Supported Solid Oxides Fuel Cells (SOFC) under Direct Dry-Reforming of Methane. Chem. Eng. J. 2013, 220, 254–263. [Google Scholar] [CrossRef]

- Sezer, H.; Mason, J.H.; Celik, I.B.; Yang, T. Three-Dimensional Modeling of Performance Degradation of Planar SOFC with Phosphine Exposure. Int. J. Hydrog. Energy 2021, 46, 6803–6816. [Google Scholar] [CrossRef]

- Yoshizumi, T.; Taniguchi, S.; Shiratori, Y.; Sasaki, K. Sulfur Poisoning of SOFCs: Voltage Oscillation and Ni Oxidation. J. Electrochem. Soc. 2012, 159, F693–F701. [Google Scholar] [CrossRef]

- Haering, C.; Roosen, A.; Schichl, H. Degradation of the Electrical Conductivity in Stabilised Zirconia Systems Part I: Yttria-Stabilised Zirconia. Solid State Ion. 2005, 176, 253–259. [Google Scholar] [CrossRef]

- Geng, S.; Li, Y.; Ma, Z.; Zhu, S.; Wang, F. Sputtered Nanocrystalline Coating of a Low-Cr Alloy for Solid Oxide Fuel Cell Interconnects Application. J. Power Sources 2013, 232, 66–73. [Google Scholar] [CrossRef]

- Chen, S.; Lin, J.; Yang, H.; Tang, D.; Zhang, T. Controlling the Redox Reaction at the Interface between Sealing Glasses and Cr-Containing Interconnect: Effect of Competitive Reaction. J. Power Sources 2014, 267, 753–759. [Google Scholar] [CrossRef]

- Chou, Y.S.; Stevenson, J.W.; Singh, P. Thermal Cycle Stability of a Novel Glass-Mica Composite Seal for Solid Oxide Fuel Cells: Effect of Glass Volume Fraction and Stresses. J. Power Sources 2005, 152, 168–174. [Google Scholar] [CrossRef]

- Nakajo, A.; Mueller, F.; McLarty, D.; Brouwer, J.; van herle, J.; Favrat, D. The Effects of Dynamic Dispatch on the Degradation and Lifetime of Solid Oxide Fuel Cell Systems. J. Electrochem. Soc. 2011, 158, B1329. [Google Scholar] [CrossRef]

- Wu, X.L.; Xu, Y.W.; Xue, T.; Zhao, D.Q.; Jiang, J.; Deng, Z.; Fu, X.; Li, X. Health State Prediction and Analysis of SOFC System Based on the Data-Driven Entire Stage Experiment. Appl. Energy 2019, 248, 126–140. [Google Scholar] [CrossRef]

- Xiao-Long, W.; Yuanwu, X.; Tao, X.; Dongqi, Z.; Jianhua, J.; Zhonghua, D.; Xiaowei, F.; Xi, L. Standby and Shutdown Cycles Modeling of SOFC Lifetime Prediction. Energy Procedia 2019, 158, 1573–1578. [Google Scholar] [CrossRef]

- Tucker, D.; Abreu-Sepulveda, M.; Harun, N.F. SOFC Lifetime Assessment in Gas Turbine Hybrid Power Systems. J. Fuel Cell Sci. Technol. 2014, 11, 14–1052. [Google Scholar] [CrossRef]

- Gemmen, R.S.; Williams, M.C.; Gerdes, K. Degradation Measurement and Analysis for Cells and Stacks. J. Power Sources 2008, 184, 251–259. [Google Scholar] [CrossRef]

- Mason, J.; Celik, I.; Lee, S.; Abernathy, H.; Hackett, G. Performance Degradation Predictions Based on Microstructural Evolution Due to Grain Coarsening Effects in Solid Oxide Fuel Cell Electrodes. J. Electrochem. Soc. 2018, 165, F64–F74. [Google Scholar] [CrossRef]

- Zaccaria, V.; Tucker, D.; Traverso, A. A Distributed Real-Time Model of Degradation in a Solid Oxide Fuel Cell, Part I: Model Characterization. J. Power Sources 2016, 311, 175–181. [Google Scholar] [CrossRef]

- Fu, Q.; Li, Z.; Wei, W.; Liu, F.; Xu, X.; Liu, Z. Performance Degradation Prediction of Direct Internal Reforming Solid Oxide Fuel Cell Due to Ni-Particle Coarsening in Composite Anode. Energy Convers. Manag. 2021, 233, 113902. [Google Scholar] [CrossRef]

- Zhu, P.; Wu, Z.; Wang, H.; Yan, H.; Li, B.; Yang, F.; Zhang, Z. Ni Coarsening and Performance Attenuation Prediction of Biomass Syngas Fueled SOFC by Combining Multi-Physics Field Modeling and Artificial Neural Network. Appl. Energy 2022, 322, 119508. [Google Scholar] [CrossRef]

- Khan, M.Z.; Mehran, M.T.; Song, R.H.; Lee, J.W.; Lee, S.B.; Lim, T.H. A Simplified Approach to Predict Performance Degradation of a Solid Oxide Fuel Cell Anode. J. Power Sources 2018, 391, 94–105. [Google Scholar] [CrossRef]

- Fang, X.; Lin, Z. Numerical Study on the Mechanical Stress and Mechanical Failure of Planar Solid Oxide Fuel Cell. Appl. Energy 2018, 229, 63–68. [Google Scholar] [CrossRef]

- Hardjo, E.; Monder, D.S.; Karan, K. Numerical Modeling of Nickel-Impregnated Porous YSZ-Supported Anodes and Comparison to Conventional Composite Ni-YSZ Electrodes. ECS Trans. 2011, 35, 1823–1832. [Google Scholar] [CrossRef]

- Nakajo, A.; Mueller, F.; Brouwer, J.; van Herle, J.; Favrat, D. Mechanical Reliability and Durability of SOFC Stacks. Part I: Modelling of the Effect of Operating Conditions and Design Alternatives on the Reliability. Int. J. Hydrogen Energy 2012, 37, 9249–9268. [Google Scholar] [CrossRef]

- Rao, M.; Wang, L.; Chen, C.; Xiong, K.; Li, M.; Chen, Z.; Dong, J.; Xu, J.; Li, X. Data-Driven State Prediction and Analysis of SOFC System Based on Deep Learning Method. Energies 2022, 15, 99. [Google Scholar] [CrossRef]

- Chi, Y.; Qiu, Y.; Lin, J.; Song, Y.; Hu, Q.; Li, W.; Mu, S. Online Identification of a Link Function Degradation Model for Solid Oxide Fuel Cells under Varying-Load Operation. Int. J. Hydrogen Energy 2022, 47, 2622–2646. [Google Scholar] [CrossRef]

- Wu, X.; Ye, Q. Fault Diagnosis and Prognostic of Solid Oxide Fuel Cells. J. Power Sources 2016, 321, 47–56. [Google Scholar] [CrossRef]

- Zu, Y.; Jiang, J.; Li, X. A Hybrid Prediction Method for SOFC Degradation Prediction. In Proceedings of the 2021 China Automation Congress, CAC 2021, Beijing, China, 22–24 October 2021; pp. 6532–6536. [Google Scholar]

- Zheng, Y.; Wu, X.L.; Zhao, D.; Xu, Y.W.; Wang, B.; Zu, Y.; Li, D.; Jiang, J.; Jiang, C.; Fu, X.; et al. Data-Driven Fault Diagnosis Method for the Safe and Stable Operation of Solid Oxide Fuel Cells System. J. Power Sources 2021, 490. [Google Scholar] [CrossRef]

- Yang, K.; Liu, J.; Wang, Y.; Shi, X.; Wang, J.; Lu, Q.; Ciucci, F.; Yang, Z. Machine-Learning-Assisted Prediction of Long-Term Performance Degradation on Solid Oxide Fuel Cell Cathodes Induced by Chromium Poisoning. J. Mater. Chem. A 2022, 10, 23683–23690. [Google Scholar] [CrossRef]

- Li, M.; Wu, J.; Chen, Z.; Dong, J.; Peng, Z.; Xiong, K.; Rao, M.; Chen, C.; Li, X. Data-Driven Voltage Prognostic for Solid Oxide Fuel Cell System Based on Deep Learning. Energies 2022, 15, 6294. [Google Scholar] [CrossRef]

- Pahon, E.; Yousfi Steiner, N.; Jemei, S.; Hissel, D.; Péra, M.C.; Wang, K.; Moçoteguy, P. Solid Oxide Fuel Cell Fault Diagnosis and Ageing Estimation Based on Wavelet Transform Approach. Int. J. Hydrog. Energy 2016, 41, 13678–13687. [Google Scholar] [CrossRef]

- Ma, R.; Yang, T.; Breaz, E.; Li, Z.; Briois, P.; Gao, F. Data-Driven Proton Exchange Membrane Fuel Cell Degradation Predication through Deep Learning Method. Appl. Energy 2018, 231, 102–115. [Google Scholar] [CrossRef]

- Marra, D.; Sorrentino, M.; Pianese, C.; Iwanschitz, B. A Neural Network Estimator of Solid Oxide Fuel Cell Performance for On-Field Diagnostics and Prognostics Applications. J. Power Sources 2013, 241, 320–329. [Google Scholar] [CrossRef]

- Cuneo, A.; Zaccaria, V.; Tucker, D.; Traverso, A. Probabilistic Analysis of a Fuel Cell Degradation Model for Solid Oxide Fuel Cell and Gas Turbine Hybrid Systems. Energy 2017, 141, 2277–2287. [Google Scholar] [CrossRef]

- Ploner, A.; Hagen, A.; Hauch, A. Classical Statistical Methodology for Accelerated Testing of Solid Oxide Fuel Cells. J. Power Sources 2018, 395, 379–385. [Google Scholar] [CrossRef]

- Boigues Muñoz, C.; Pumiglia, D.; Santoni, F.; McPhail, S.J.; Comodi, G.; Carlini, M. Performance Degradation Prediction of a Low-Temperature SOFC via Impedance Spectroscopy and CFD Modelling. ECS Trans. 2015, 68, 2227–2235. [Google Scholar] [CrossRef]

- Gallo, M.; Polverino, P.; Mougin, J.; Morel, B.; Pianese, C. Coupling Electrochemical Impedance Spectroscopy and Model-Based Aging Estimation for Solid Oxide Fuel Cell Stacks Lifetime Prediction. Appl. Energy 2020, 279, 115718. [Google Scholar] [CrossRef]

- Gazzarri, J.I.; Kesler, O. Non-Destructive Delamination Detection in Solid Oxide Fuel Cells. J. Power Sources 2007, 167, 430–441. [Google Scholar] [CrossRef]

- Ananyev, M.; Steinberger-Wilckens, R. SOFC degradation quantification using image analysis. In Proceedings of the 15th European Fuel Cell Forum, Lucerne, Switzerland, 28 June–1 July 2011; pp. 21–34. [Google Scholar]

- Simwonis, D.; Tietz, F.; Stöver, D. Nickel Coarsening in Annealed Ni/8YSZ Anode Substrates for Solid Oxide Fuel Cells. Solid State Ion. 2000, 132, 241–251. [Google Scholar] [CrossRef]

- Yan, D.; Zhang, C.; Liang, L.; Li, K.; Jia, L.; Pu, J.; Jian, L.; Li, X.; Zhang, T. Degradation Analysis and Durability Improvement for SOFC 1-Cell Stack. Appl. Energy 2016, 175, 414–420. [Google Scholar] [CrossRef]

- Qi, Q.; Wang, L.; Liu, Y.; Huang, Z. Effect of TiC Particles Size on the Oxidation Resistance of TiC/Hastelloy Composites Applied for Intermediate Temperature Solid Oxide Fuel Cell Interconnects. J. Alloy. Compd. 2019, 778, 811–817. [Google Scholar] [CrossRef]

- Falk-Windisch, H.; Claquesin, J.; Sattari, M.; Svensson, J.E.; Froitzheim, J. Co- and Ce/Co-Coated Ferritic Stainless Steel as Interconnect Material for Intermediate Temperature Solid Oxide Fuel Cells. J. Power Sources 2017, 343, 1–10. [Google Scholar] [CrossRef]

- Cheng, C.H.; Chang, Y.W.; Hong, C.W. Multiscale Parametric Studies on the Transport Phenomenon of a Solid Oxide Fuel Cell. J. Fuel Cell Sci. Technol. 2005, 2, 219–225. [Google Scholar] [CrossRef]

- Chen, D.; Bi, W.; Kong, W.; Lin, Z. Combined Micro-Scale and Macro-Scale Modeling of the Composite Electrode of a Solid Oxide Fuel Cell. J. Power Sources 2010, 195, 6598–6610. [Google Scholar] [CrossRef]

- Aphale, A.N.; Ravi Narayan, L.; Hu, B.; Pandey, A.; Singh, P. Surface Pretreatment of Alumina Forming Alloy and Its Implication on Cr Evaporation. ECS Trans. 2018, 85, 57–63. [Google Scholar] [CrossRef]

- Hwang, B.; Kwon, H.; Ko, J.; Kim, B.K.; Han, J.W. Density Functional Theory Study for the Enhanced Sulfur Tolerance of Ni Catalysts by Surface Alloying. Appl. Surf. Sci. 2018, 429, 87–94. [Google Scholar] [CrossRef]

- Jiang, S.P. Sintering Behavior of Ni/Y2O3-ZrO2 Cermet Electrodes of Solid Oxide Fuel Cells. J. Mater. Sci. 2003, 18, 3775–3782. [Google Scholar] [CrossRef]

- Busawon, A.N.; Sarantaridis, D.; Atkinson, A. Ni Infiltration as a Possible Solution to the Redox Problem of SOFC Anodes. Electrochem. Solid-State Lett. 2008, 11, B186. [Google Scholar] [CrossRef]

- Schluckner, C.; Subotić, V.; Preißl, S.; Hochenauer, C. Numerical Analysis of Flow Configurations and Electrical Contact Positions in SOFC Single Cells and Their Impact on Local Effects. Int. J. Hydrog. Energy 2019, 44, 1877–1895. [Google Scholar] [CrossRef]

- Canavar, M.; Mat, A.; Celik, S.; Timurkutluk, B.; Kaplan, Y. Investigation of Temperature Distribution and Performance of SOFC Short Stack with/without Machined Gas Channels. Int. J. Hydrogen Energy 2016, 41, 10030–10036. [Google Scholar] [CrossRef]

- Seo, K.D.; Kim, Y.J.; Park, J.Y.; Lim, H.T. Investigating the Effect of Current Collecting Conditions on Solid Oxide Fuel Cell (SOFC) Performance with Additional Voltage Probes. Int. J. Hydrogen Energy 2018, 2349–2358. [Google Scholar] [CrossRef]

- Chen, B.; Xu, H.; Ni, M. Modelling of Finger-like Channelled Anode Support for SOFCs Application. Sci. Bull. 2016, 61, 1324–1332. [Google Scholar] [CrossRef]

- Nguyen, X.V.; Chang, C.T.; Jung, G.B.; Chan, S.H.; Yeh, C.C.; Yu, J.W.; Lee, C.Y. Improvement on the Design and Fabrication of Planar SOFCs with Anode–Supported Cells Based on Modified Button Cells. Renew Energy 2018, 129, 806–813. [Google Scholar] [CrossRef]

- Kong, W.; Han, Z.; Lu, S.; Gao, X.; Wang, X. A Novel Interconnector Design of SOFC. Int. J. Hydrogen Energy 2020, 45, 20329–20338. [Google Scholar] [CrossRef]

- Jiang, J.; Shen, T.; Deng, Z.; Fu, X.; Li, J.; Li, X. High Efficiency Thermoelectric Cooperative Control of a Stand-Alone Solid Oxide Fuel Cell System with an Air Bypass Valve. Energy 2018, 152, 13–26. [Google Scholar] [CrossRef]

- Nakajo, A.; Mueller, F.; Brouwer, J.; van Herle, J.; Favrat, D. Progressive Activation of Degradation Processes in Solid Oxide Fuel Cells Stacks: Part I: Lifetime Extension by Optimisation of the Operating Conditions. J. Power Sources 2012, 216, 449–463. [Google Scholar] [CrossRef]

- Spivey, B.J.; Hedengren, J.D.; Edgar, T.F. Constrained Control and Optimization of Tubular Solid Oxide Fuel Cells for Extending Cell Lifetime. In Proceedings of the American Control Conference, Montreal, QC, Canada, 27–29 June 2012; pp. 1356–1361. [Google Scholar]

- Parhizkar, T.; Hafeznezami, S. Degradation Based Operational Optimization Model to Improve the Productivity of Energy Systems, Case Study: Solid Oxide Fuel Cell Stacks. Energy Convers. Manag. 2018, 158, 81–91. [Google Scholar] [CrossRef]

- Wu, X.; Gao, D. Fault Tolerance Control of SOFC Systems Based on Nonlinear Model Predictive Control. Int. J. Hydrogen Energy 2017, 42, 2288–2308. [Google Scholar] [CrossRef]

- Sangtongkitcharoen, W.; Assabumrungrat, S.; Pavarajarn, V.; Laosiripojana, N.; Praserthdam, P. Comparison of Carbon Formation Boundary in Different Modes of Solid Oxide Fuel Cells Fueled by Methane. J. Power Sources 2005, 142, 75–80. [Google Scholar] [CrossRef]

- Mueller, F.; Jabbari, F.; Brouwer, J. On the Intrinsic Transient Capability and Limitations of Solid Oxide Fuel Cell Systems. J. Power Sources 2009, 187, 452–460. [Google Scholar] [CrossRef]

- Pohjoranta, A.; Halinen, M.; Pennanen, J.; Kiviaho, J. Model Predictive Control of the Solid Oxide Fuel Cell Stack Temperature with Models Based on Experimental Data. J. Power Sources 2015, 277, 239–250. [Google Scholar] [CrossRef]

- Fardadi, M.; Mueller, F.; Jabbari, F. Feedback Control of Solid Oxide Fuel Cell Spatial Temperature Variation. J. Power Sources 2010, 195, 4222–4233. [Google Scholar] [CrossRef]

- Wu, X.; Yang, D.; Wang, J.; Li, X. Temperature Gradient Control of a Solid Oxide Fuel Cell Stack. J. Power Sources 2019, 414, 345–353. [Google Scholar] [CrossRef]

| Stack Components | Reasons for Degradation |

|---|---|

| Cathode | Oxidation of LSM cathode, Cr poisoning, poisoning due to gas impurities |

| Anode | Ni particle coarsening, Ni redox, carbon deposition, poisoning due to gas impurities |

| Electrolytes | Decrease in ionic conductivity of YSZ |

| Interconnect | High-temperature oxidation of metal interconnects |

| Sealing material | The chemical reaction between glass sealing material and electrode material, mica seal leakage |

| Prediction Method | Predicted Objects | Models | Ref. |

|---|---|---|---|

| Model-based approach | Predicting future degradation trends and remaining service life of SOFC stack. | Nonlinear SOFC power stack integration model | [9] |

| Model-based approach | Predicting the long-term performance degradation process of SOFC stack under accelerated operating conditions. | SOFC multi-physics field degradation model | [19] |

| Model-based approach | Predicting cell performance degradation due to fuel contaminant phosphine. | Transient 3D planar SOFC model | [23] |

| Model-based approach | Predicting the impact of scheduling methods on SOFC system performance. | Degradation model of each SOFC component | [29] |

| Model-based approach | Predicting the performance degradation of the stack when coal syngas is the fuel. | A mechanistic model of the stack | [33] |

| Model-based approach | Predicting performance degradation caused by electrode coarsening. | SOFC multi-physics field model | [34] |

| Model-based approach | Predicting the effect of operating parameters on SOFC output voltage in the presence of degradation. | 1D real-time SOFC model | [35] |

| Model-based approach | Predicting degradation of direct methane reforming (DIR) SOFC performance due to Ni particle coarsening. | SOFC multi-physics field model | [36] |

| Model-based approach | Predicting the effect of Ni coarsening on SOFC performance. | Transient multi-physics field model for SOFC | [37] |

| Model-based approach | Predicting the degradation of the electrochemical performance of SOFC anodes due to Ni grain growth. | SOFC anode degradation prediction model | [38] |

| Model-based approach | Predicting SOFC performance degradation caused by nickel content, oxidation state, and temperature. | Multi-physics field model of SOFC stack | [39] |

| Prediction Method | Predicted Objects | Algorithm | Ref. |

|---|---|---|---|

| Data-based Approach | Predicting the degradation performance of SOFC systems. | Double-layer LSTM model | [42] |

| Data-based Approach | Predicting long-term degradation trends in SOFC. | Link function, great likelihood algorithm | [43] |

| Data-based Approach | Identifying the SOFC fault types and predicting the remaining SOFC lifetime under the faults. | Least squares support vector machine, semi-hidden Markov algorithm | [44] |

| Data-based Approach | Predicting heat exchanger rupture failures in SOFC systems. | SVM algorithm | [46] |

| Data-based Approach | Predicting the SOFC performance degradation caused by Cr poisoning. | Machine learning combined with relaxation time (DRT) distribution | [47] |

| Data-based Approach | Predicting the SOFC system’s degradation performance. | A state prediction model based on encoder-decoder RNN | [48] |

| Data-based Approach | Finding the effective characteristic quantity for judging the abnormal operation status and predicting the remaining lifetime of SOFC. | Wavelet transform algorithm | [49] |

| Data-based Approach | Forecasting performance degradation of proton exchange membrane fuel cells (PEMFC). | Grid long and short-term memory, recursive neural network | [50] |

| Data-based Approach | Predicting the output voltage trajectory of SOFC. | Neural network (NN) algorithm | [51] |

| Data-based Approach | Predicting the impact of uncertainty in SOFC during degradation. | An approximate randomized algorithm based on Taylor series expansion | [52] |

| Data-based Approach | Predicting SOFC performance degradation at seven different temperatures and four different fuel operating conditions. | The semi-empirical degenerate prediction algorithm | [53] |

| Optimized Solutions | Degradation Type | Improvement Methods | Ref. |

|---|---|---|---|

| Material Improvement | Interconnect oxidation | TiC/Hastelloy alloy composites are used to develop the interconnects. | [60] |

| Material Improvement | Creep and rupture of interconnects | Crofer 22APU high-temperature ferritic stainless steel is used to develop the interconnects. | [61] |

| Material Improvement | Decrease in electrolyte YSZ ionic conductivity | Changing the doping concentration of Y2O3. | [62] |

| Material Improvement | Anode Ni particle coarsening | An interstitial layer consisting of nanoparticles is added to the composite electrode. | [66] |

| Material Improvement | Cathode Cr poisoning | A dense and uniform alumina protective layer is generated on the surface of the interconnect to reduce the evaporation of Cr. | [64] |

| Material Improvement | Anode sulfur poisoning | Transition metals such as Cu, Pd, Au, Ag, and Rh are doped in Ni anodes to reduce anode sulfur poisoning. | [65] |

| Material Improvement | Redox of anode Ni | Nickel is infiltrated into the prefabricated porous yttrium oxide stabilized zirconia structure. | [67] |

| Optimized Solutions | Improvement Program | Improvement Effect | Ref. |

|---|---|---|---|

| Structural improvement | The gas flow path of the stack uses a cross-flow structure. | It can make the current density and temperature distribution of the whole SOFC stack more uniform, which helps to extend the life of the SOFC stack. | [68] |

| Structural improvement | Adopting the anode flow channel layout based on the woven structure of nickel mesh. | The fuel flow in the stack is more uniformly distributed. The stack peak temperature is lower. | [69] |

| Structural improvement | Adding platinum-based contact paste to the electrical contact points. | The output performance of the stack becomes more stable. | [70] |

| Structural improvement | Finger-shaped anode support structure is adopted as the air channel shape for micro SOFC. | The finger-shaped anode support structure is more conducive to improving the stack performance. | [71] |

| Structural improvement | Adding coin cell batteries to SOFC systems. | The coin cell can assist in the thermal conversion of the stack and can effectively improve the dynamic performance of the SOFC system. | [72] |

| Structural improvement | X-shaped column interconnects. | It can significantly increase the oxygen concentration of the porous cathode under the rib, reduce the cathode concentration difference polarization loss, and improve the performance of the stack. | [73] |

| Structural improvement | Applying an air bypass valve to the air input side of the stack. | It is sufficient to increase the adjustment range of air input, which in turn increases the adjustment range of system temperature and improves the overall system performance. | [74] |

| Control Purpose | Control Solutions | Control Effect | Ref. |

|---|---|---|---|

| Quantitatively extending the lifetime of SOFC under nickel roughening and oxidative degradation mechanisms. | Control strategy combining prediction and dynamic optimization | It can effectively extend the life of SOFC without significantly reducing the efficiency of power generation. | [10] |

| Optimizing the performance degradation of SOFC in terms of lifetime and electrical efficiency. | Operation parameter optimization strategy | Operating at a lower system-specific power and higher stack temperature can extend the lifetime by 10 times. | [75] |

| Extending fuel cell life by controlling minimum cell temperature and maximum radial thermal gradient. | Constrained control method for the lifetime of tubular SOFC | This method extends SOFC operating life by reducing the thermal stress inside the stack and reduces operating costs by 5%. | [76] |

| Finding the optimal operating conditions for the target operating time of the anode-supported SOFC. | Degradation-based optimization (DBO) framework | The target life has a significant impact on system productivity, optimal operating temperature, and current density. | [77] |

| Implementing load tracking and temperature safety for SOFC systems. | Neural network-based predictive controller | Load tracking and temperature safety are achieved under different fault states. | [78] |

| Reducing the formation of carbon deposits by controlling the proportion of water vapor in the fuel in the SOFC system. | SOFC system water-to-carbon ratio controller | When the ratio of water vapor to methane in the fuel is higher than 1.6, carbon deposition on the surface of the anode Ni particles can be avoided. | [79] |

| Preventing fuel deficits. | Control method based on constant fuel utilization | Successfully preventing fuel deficits by limiting fluctuations in fuel utilization under instantaneous power demand. | [80] |

| Reducing the thermal stress in the stack. | Model predictive controller based on the generalized predictive control algorithm | The controller can regulate and control the temperature difference of the cells in the SOFC stack to reduce the thermal stress in the stack. | [81] |

| Minimizing SOFC stack space temperature. | H-infinity-based feedback control strategy | The control strategy achieves load following and space temperature minimization under fast and large load disturbances by controlling the air flow rate and the cathode inlet temperature. | [82] |

| Controlling the temperature gradient inside the SOFC stack. | Composite nonlinear controller based on higher-order sliding mode observer | The temperature inside the stack can be observed by the observer and the temperature gradient can be adjusted. | [83] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, J.; Zhao, D.; Xu, Y.; Wu, X.; Li, X. Comprehensive Analysis of Solid Oxide Fuel Cell Performance Degradation Mechanism, Prediction, and Optimization Studies. Energies 2023, 16, 788. https://doi.org/10.3390/en16020788

Peng J, Zhao D, Xu Y, Wu X, Li X. Comprehensive Analysis of Solid Oxide Fuel Cell Performance Degradation Mechanism, Prediction, and Optimization Studies. Energies. 2023; 16(2):788. https://doi.org/10.3390/en16020788

Chicago/Turabian StylePeng, Jingxuan, Dongqi Zhao, Yuanwu Xu, Xiaolong Wu, and Xi Li. 2023. "Comprehensive Analysis of Solid Oxide Fuel Cell Performance Degradation Mechanism, Prediction, and Optimization Studies" Energies 16, no. 2: 788. https://doi.org/10.3390/en16020788

APA StylePeng, J., Zhao, D., Xu, Y., Wu, X., & Li, X. (2023). Comprehensive Analysis of Solid Oxide Fuel Cell Performance Degradation Mechanism, Prediction, and Optimization Studies. Energies, 16(2), 788. https://doi.org/10.3390/en16020788