A Study on Utilization of High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies

Abstract

1. Introduction

2. Materials and Methods

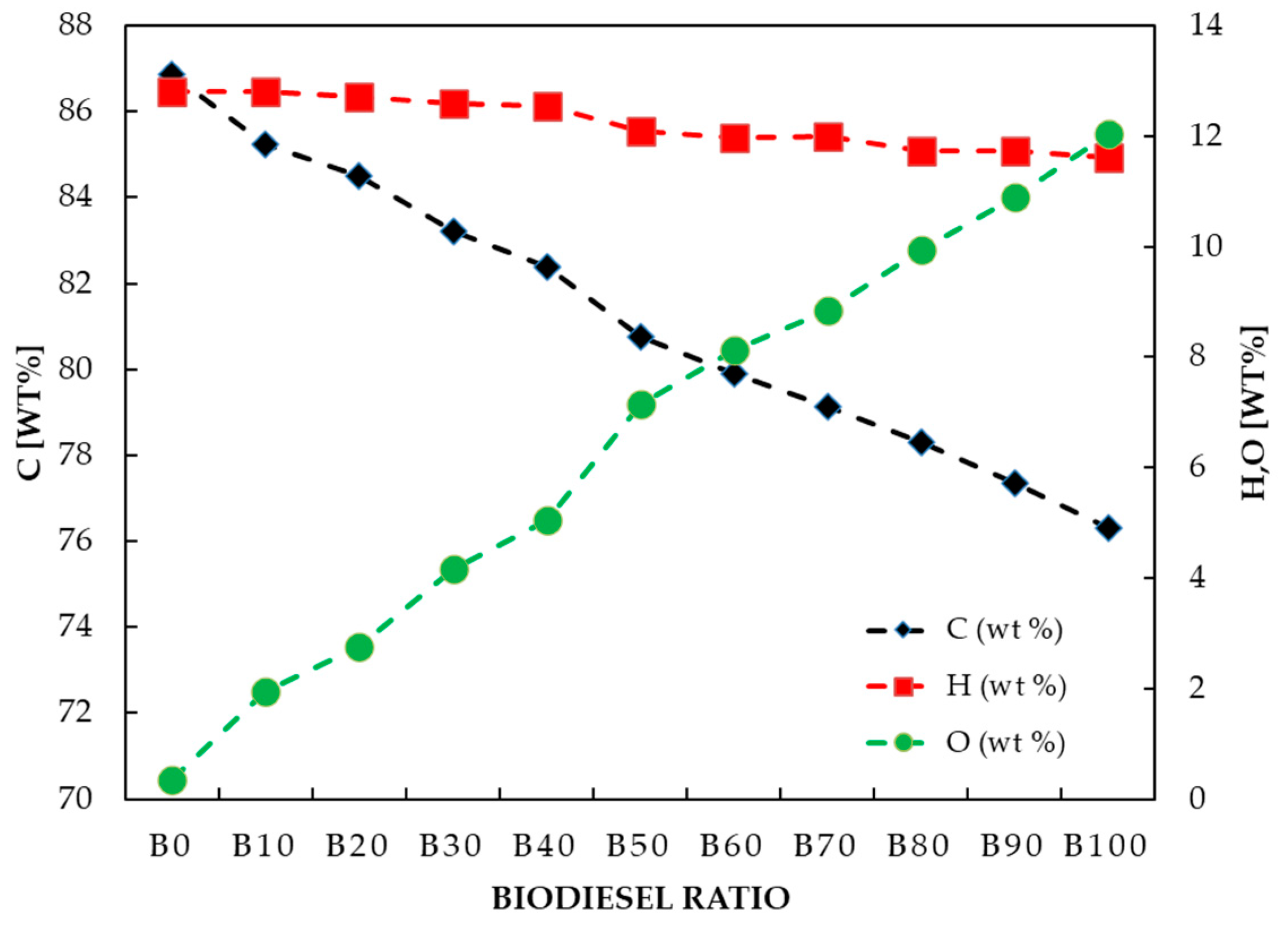

2.1. Tested Fuel

2.2. Tested Vehicle

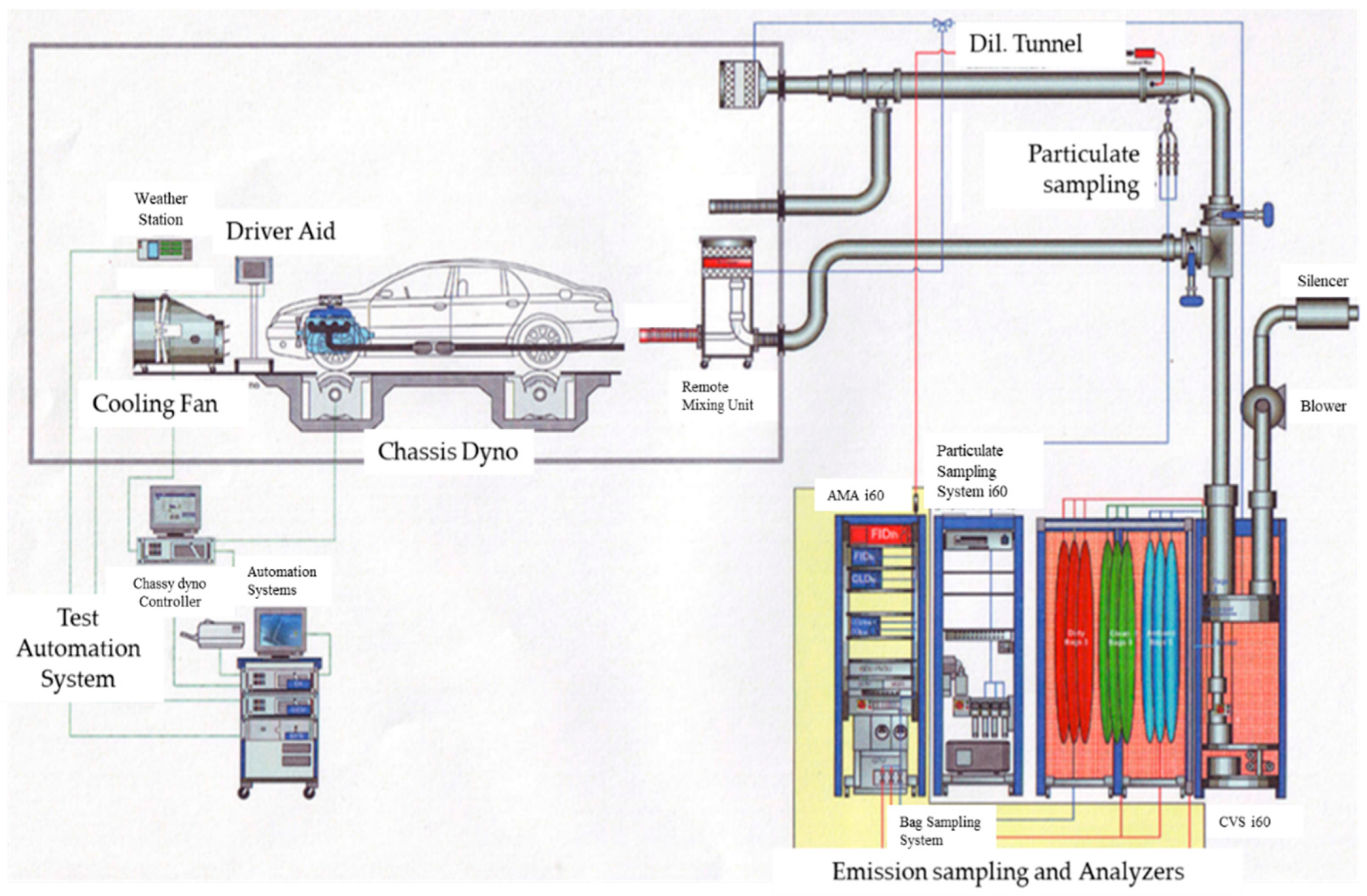

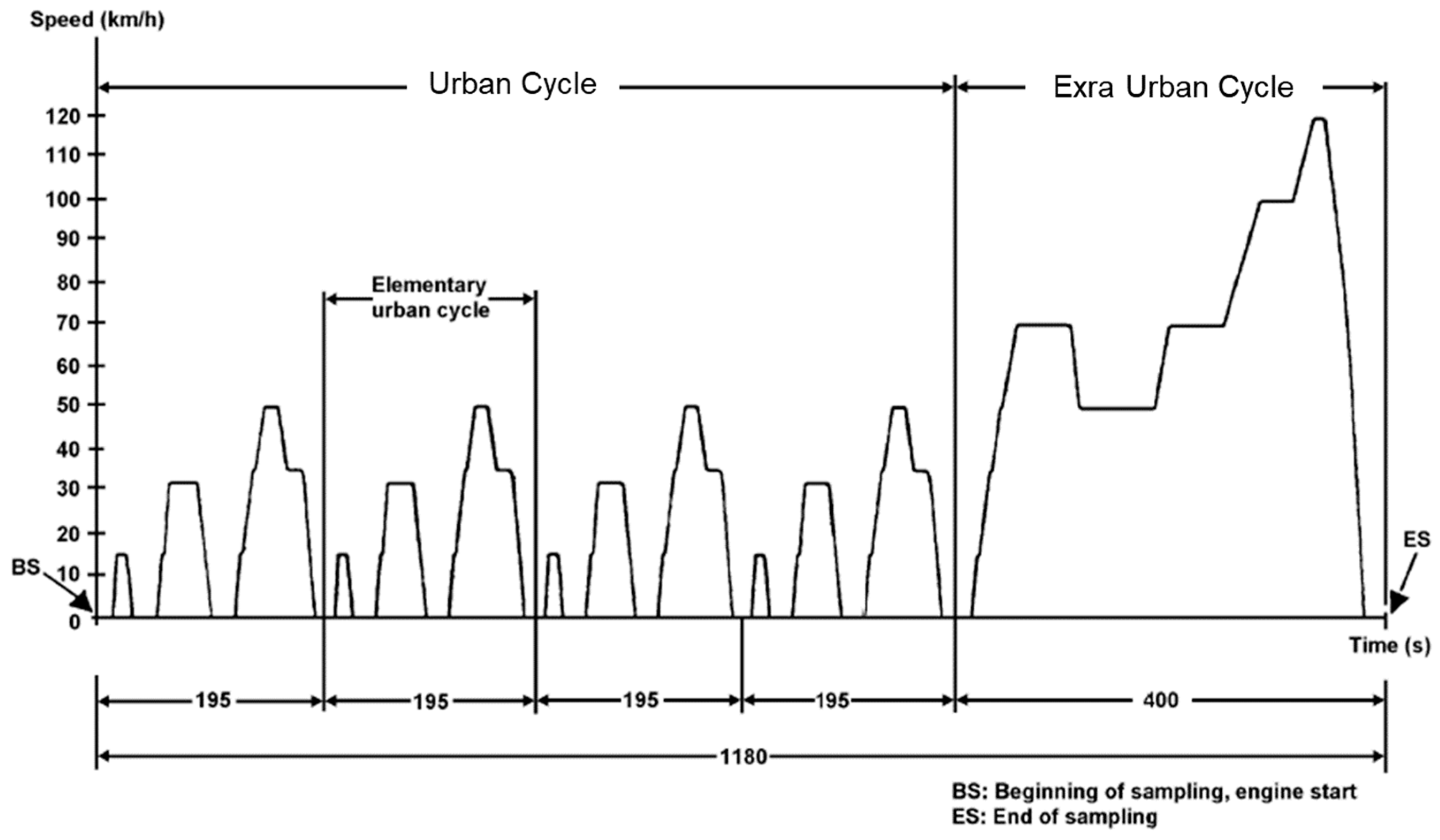

2.3. Testing Equipment and Cycle

3. Results and Discussion

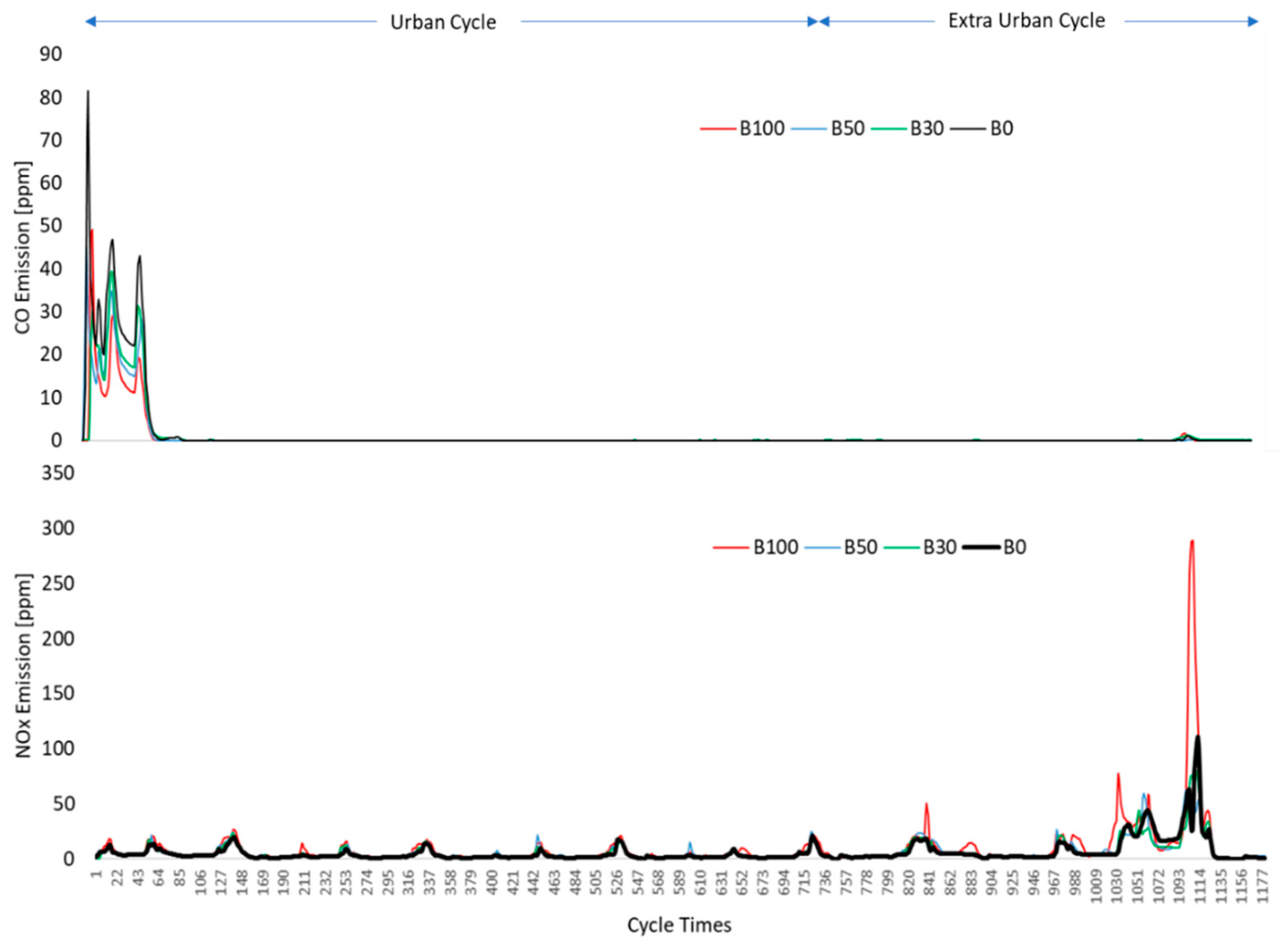

3.1. Emissions Test Result

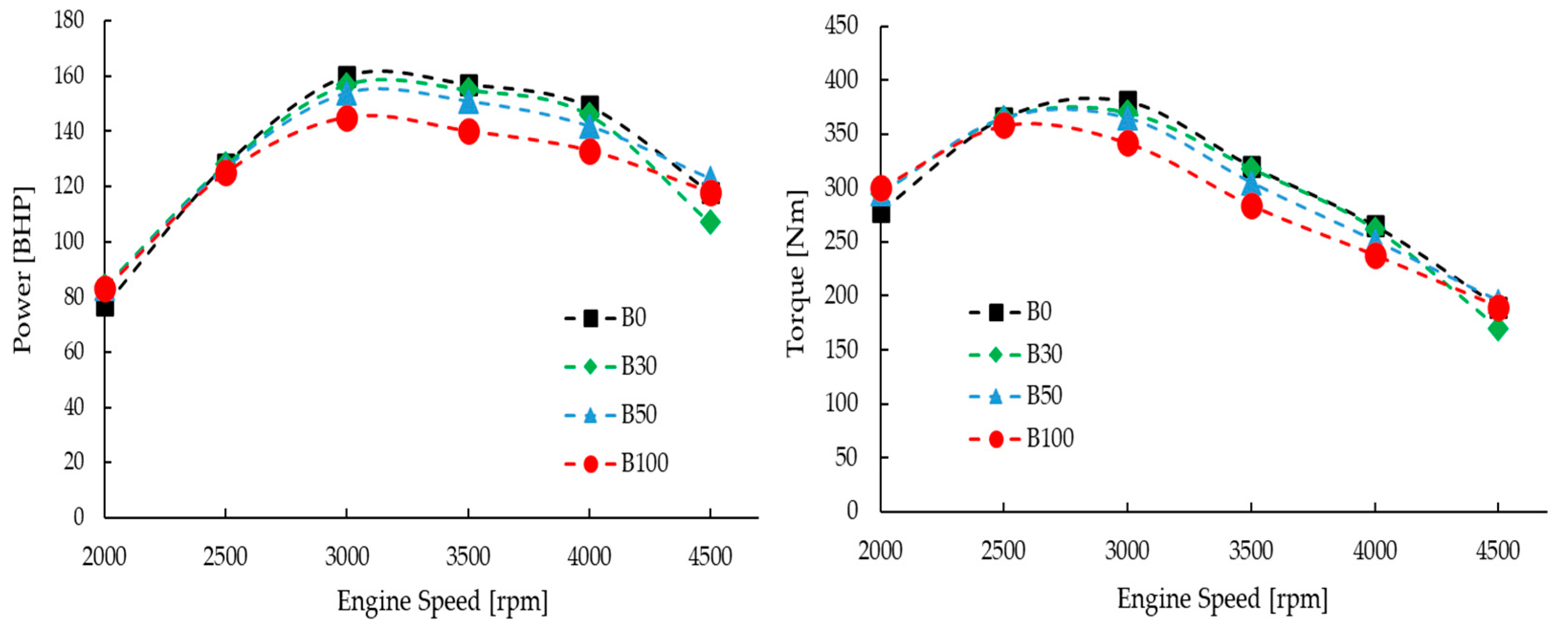

3.2. Power and Torque

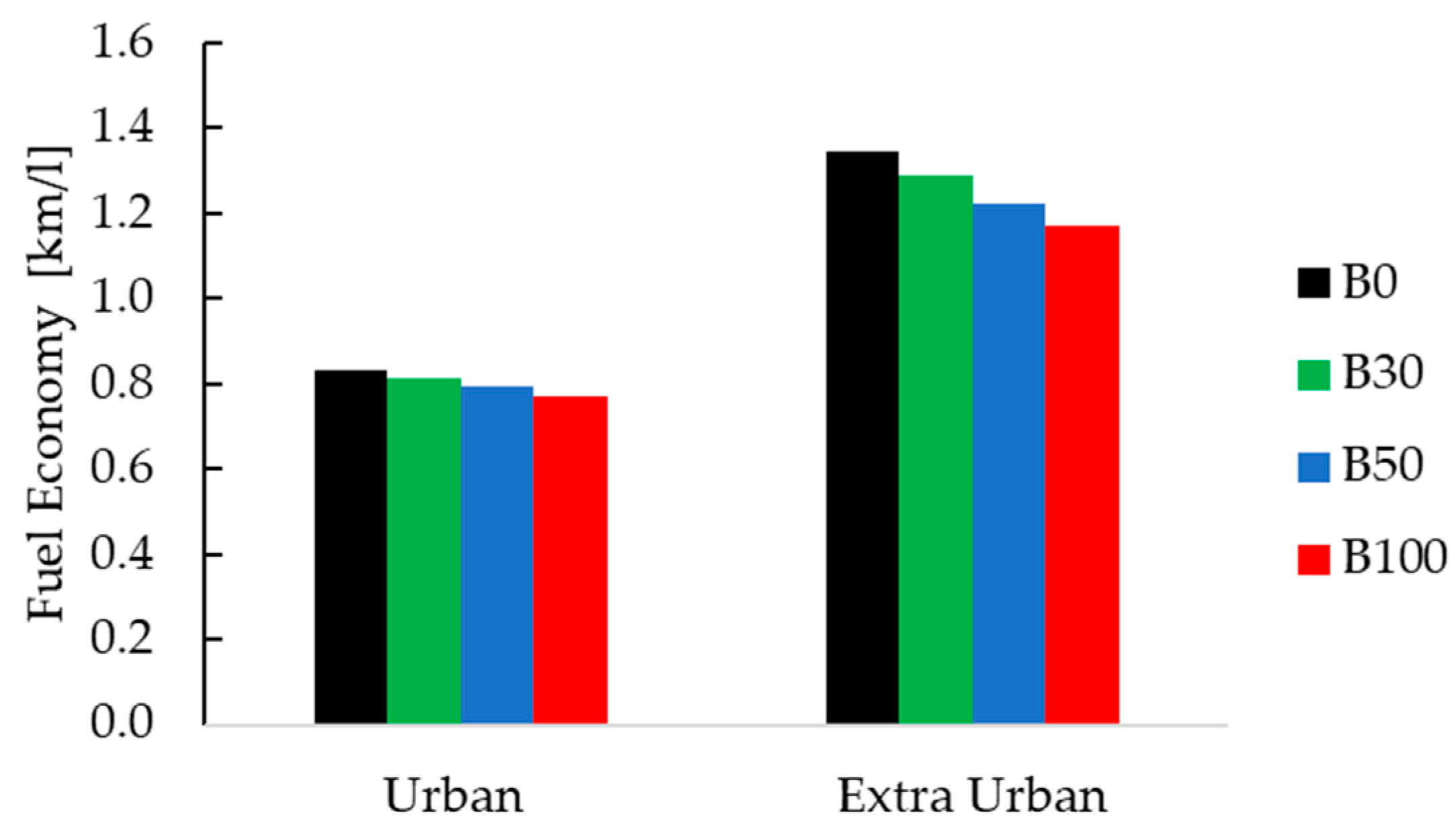

3.3. Fuel Economy

- FE: Fuel Economy in km/liter

- D: Tested Fuel Density in gr/cm3

- mHC: Measured HC emissions in gr/km

- mCO: Measured CO emissions in gr/km

- mCO2: Measured CO2 emissions in gr/km

4. Conclusions

- The use of high-ratio biodiesel and pure biodiesel leads to a decrease in emissions of CO, HC and Particulates. Here, B100 could suppress particulate emissions by up to 80%. Conversely, NOx emissions increased with increasing biodiesel ratio. In this study, tests with a Euro4-compliant vehicle showed that emissions of CO, HC, NOx and particulates using the B0, B30, B50 and B100 fuels were all below the limits imposed by the Euro4 standard.

- The power output of the vehicle tested at wide-open throttle and fueled by B30, B50 and B100 was 3%, 4% and 10% lower than that of a diesel-fueled vehicle, respectively.

- The fuel economy using high-ratio biodiesel and pure biodiesel should be calculated by a new formula of carbon balance factoring in the carbon-to-hydrogen ratio instead of the standard R101 carbon balance formula. Using the modified carbon balance formula with the New European Driving Cycle (NEDC) showed that the FE with B30, B30 and B100 was 3%, 7% and 11% lower than with diesel fuel, respectively.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Reksowardojo, I.K.; Setiapraja, H.; Fajar, R.; Wibowo, E.; Kusdiana, D. An Investigation of Laboratory and Road Test of Common Rail Injection Vehicles Fueled with B20 Biodiesel. Energies 2020, 13, 6118. [Google Scholar] [CrossRef]

- Groom, B.; Palmer, C.; Sileci, L. Carbon emissions reductions from Indonesia’s moratorium on forest concessions are cost-effective yet contribute little to Paris pledge. Proc. Natl. Acad. Sci. USA 2022, 119, e21026131. [Google Scholar] [CrossRef] [PubMed]

- Du, H.; Huque, Z.; Kommalapati, R.R. Impacts of Biodiesel Applied to the Transportation Fleets in the Greater Houston Area. J. Renew. Energy 2018, 2018, 7350715. [Google Scholar] [CrossRef]

- Anderson, L.G. Effects of Biodiesel Fuels Use on Vehicle Emissions. J. Sustain. Energy Environ. 2012, 3, 35–47. [Google Scholar] [CrossRef]

- McCormick, R.L.; Tennant, C.J.; Hayes, R.R.; Black, S.; Ireland, J.; McDaniel, T.; Williams, A.; Frailey, M.; Sharp, C.A. Regulated Emissions from Biodiesel Tested in Heavy-Duty Engines Meeting 2004 Emission Standards. In Proceedings of the the 2005 SAE Brasil Fuels & Lubricants Meeting, Rio de Janiero, Brazil, 11 May 2005. [Google Scholar]

- Hoang, A.T.; Le, M.X.; Nižetić, S.; Huang, Z.; Ağbulut, Ü.; Veza, I.; Said, Z.; Le, A.T.; Tran, V.D.; Nguyen, X.P. Understanding behaviors of compression ignition engine running on metal nanoparticle additives-included fuels: A control comparison between biodiesel and diesel fuel. Fuel 2022, 326, 124981. [Google Scholar] [CrossRef]

- Volpato, C.E.S.; Conde, A.d.P.; Barbosa, J.A.; Salvador, N. Performance of Cycle Diesel Engine Using Biodiesel of Olive Oil (B100). Ciência E Agrotecnologia 2012, 36, 348–353. [Google Scholar] [CrossRef]

- Tziourtzioumis, D.N.; Stamatelos, A.M. Experimental Investigation of the Effect of Biodiesel Blends on a DI Diesel Engine’s Injection and Combustion. Energies 2017, 10, 970. [Google Scholar] [CrossRef]

- Noukpo, M.L.; Abbe, C.V.N.; Anyi, J.N.; Essola, D.; Mezoue, C.; Mouangue, R.; Nzengwa, R. Experimental and Numerical Investigation on the Influence of the Rate of Injection (Roi) on Engine Performance for B100 Fuel Control Strategy in Diesel Engines. J. Eng. 2020, 2020, 8884754. [Google Scholar] [CrossRef]

- Suthisripok, T.; Semsamran, P. The impact of biodiesel B100 on a small agricultural diesel engine. Tribol. Int. 2018, 128, 397–404. [Google Scholar] [CrossRef]

- Chiavola, O.; Recco, E. Emission Performance of a Diesel Engine Fuelled with Petrol Diesel, Green Diesel, and Waste Cooking Oil Blends. J. Combust. 2018, 2018, 4819175. [Google Scholar] [CrossRef]

- Abu-Hamdeh, N.H.; Alnefaie, K.A. A Comparative Study of Almond Biodiesel-Diesel Blends for Diesel Engine in Terms of Performance and Emissions. BioMed Res. Int. 2015, 2015, 529808. [Google Scholar] [CrossRef]

- Tutunea, D.; Dumitru, I. Analysis of performance and emissions of diesel engine using sunflower biodiesel. IOP Conf. Series Mater. Sci. Eng. 2017, 252, 012085. [Google Scholar] [CrossRef]

- Islam, M.S.; Ahmed, A.S.; Islam, A.; Aziz, S.A.; Xian, L.C.; Mridha, M. Study on Emission and Performance of Diesel Engine Using Castor Biodiesel. J. Chem. 2014, 2014, 451526. [Google Scholar] [CrossRef]

- Kaya, T.; Kutlar, O.A.; Taskiran, O.O. Evaluation of the Effects of Biodiesel on Emissions and Performance by Comparing the Results of the New European Drive Cycle and Worldwide Harmonized Light Vehicles Test Cycle. Energies 2018, 11, 2814. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Duong, M.Q.; Nguyen, K.T.; Pham, T.V.; Pham, P.X. An extensive analysis of biodiesel blend combustion characteristics under a wide range of thermal conditions of a cooperative fuel research engine. Sustainability 2020, 12, 7666. [Google Scholar] [CrossRef]

- Rojas, J.C.P.; Miguel, C.R.T.S.; Medina, R.V.; Naranjo, J.A.L.; Hernàndez, F.E.O.; Castelló, R.C. Pollutant Emissions and Combustion Efficiency Assessment of Engines Using Biodiesel. Appl. Sci. 2020, 10, 8646. [Google Scholar] [CrossRef]

- Ge, J.C.; Choi, N.J. Soot Particle Size Distribution, Regulated and Unregulated Emissions of a Diesel Engine Fueled with Palm Oil Biodiesel Blends. Energies 2020, 13, 5736. [Google Scholar] [CrossRef]

- Lu, J.-H.; Ku, Y.-Y.; Liao, C.-F. The effects of biodiesel on the performance and the durability of diesel engine active-DPF. In Proceedings of the SAE 2012 World Congress & Exhibition, Detroit, MI, USA, 24–26 April 2012. [Google Scholar] [CrossRef]

- Li, Y.X.; McLaughlin, N.B.; Patterson, B.S.; Burtt, S.D. Fuel efficiency and exhaust emissions for biodiesel blends in an agricultural tractor. In Proceedings of the CSAE/SCGR 2005 Meeting, Winnipeg, MB, Canada, 26–29 June 2005; Volume 48. [Google Scholar]

- Puškár, M.; Kopas, M.; Sabadka, D.; Kliment, M.; Šoltésová, M. Reduction of the Gaseous Emissions in the Marine Diesel Engine Using Biodiesel Mixtures. J. Mar. Sci. Eng. 2020, 8, 330. [Google Scholar] [CrossRef]

- Rajaeifara MATabatabaei, M.; Aghbashloe, M.; Nizamif, A.-S.; Heidrich, O. Emissions from urban bus fleets running on biodiesel blends under realworld operating conditions: Implications for designing future case studies. Renew. Sustain. Energy Rev. 2019, 111, 276–292. [Google Scholar] [CrossRef]

- Fernández-Yáñez, P.; Soriano, J.A.; Soto, F.; Armas, O.; Pla, B.; Bermúdez, V. Pollutant emissions from Euro 6 light duty vehicle tested under steady state and transient operation on a roller test bench with hydrogenated paraffinic and biodiesel fuels. Fuel 2022, 323, 124173. [Google Scholar] [CrossRef]

- Godiño, J.A.V.; García, M.T.; Aguilar, F.J.J.-E. Experimental analysis of late direct injection combustion mode in a compression-ignition engine fuelled with biodiesel/diesel blends. Energy 2022, 239, 121895. [Google Scholar] [CrossRef]

- Fontana, G.; Galloni, E.; Ianniello, R.; Lanni, D.; Beatrice, C.; Di Blasio, G. Numerical analyses of spray development and combustion process with dieselgasoline-ethanol mixtures in compression-ignition engines. AIP Conf. Proc. 2019, 2191, 020078. [Google Scholar] [CrossRef]

- Chojnowski, J.; Karczewski, M. Influence of the working parameters of the chassis dynamometer on the assessment of tuning of dual-fuel systems. Energies 2022, 15, 4869. [Google Scholar] [CrossRef]

- Khan, M.M.; Sharma, R.P.; Kadian, A.K.; Hasnain, S.M.M. An assessment of alcohol inclusion in various combinations of biodiesel diesel on the performance and exhaust emission of modern day compression ignition engines—A review. Mater. Sci. Energy Technol. 2022, 5, 81–98. [Google Scholar] [CrossRef]

- Kumagai, T. Improving the Accuracy of Fuel Consumption Measurement in CVS System. Technical Journal Readout English Edition; Horiba: Tokyo, Japan, 2014. [Google Scholar]

| No | Parameter | Unit | Diesel Fuel (B0) | Limit *1 | FAME (B100) | Limit *2 | ||

|---|---|---|---|---|---|---|---|---|

| Min | Max | Min | Max | |||||

| 1 | Cetane Number | - | 49.2 | 51 | - | 63 | 51 | - |

| 2 | Index Cetane | - | 48.8 | 48 | - | 58.3 | - | - |

| 3 | Density at 15 °C | kg/m3 | 828.5 | 810 | 850 | 873.5 | 810 | 850 |

| 4 | Viscosity at 40 °C | mm2/s | 2.26 | 2 | 4.5 | 4.37 | 2.3 | 6 |

| 5 | Sulfur Content | ppm | 10 | - | 50 | 16 | - | 10 |

| 6 | Distillation | |||||||

| IBP | °C | 190 | - | - | 316 | - | - | |

| 90% vol | °C | 344 | - | - | 334 | - | - | |

| 95% vol | °C | 363 | - | 370 | 337 | - | 360 | |

| FBP | °C | 371 | - | - | 341 | - | - | |

| 7 | Flash Point | °C | 74 | - | 55 | 174 | - | 130 |

| 8 | Pour Point | °C | -24 | - | 18 | 15 | - | - |

| 9 | Carbon Residue | % m/m | nil | - | 0.1 | 0.045 | - | 0.05 |

| 10 | Water Content | mg/kg | 18 | - | 280 | 62 | - | 350 |

| 11 | Oxidation Stability | g/m3 | >48 | - | - | 16 | - | - |

| 12 | Cu Strip Corrosion | merit | 1B | - | 1A | 1A | - | 1A |

| 13 | Ash Content | % m/m | 0.005 | - | 0.01 | 0.002 | - | 0.02 |

| 14 | Sediment Content | % m/m | 0.005 | - | 0.01 | 0.002 | - | 0.01 |

| 15 | Total Acid Number | mg KOH/g | 0.07 | - | 0.3 | 0.18 | - | 0.4 |

| 16 | Lubricity (HFRR wear scar diameter @60 °C) | micron | 600 | - | 460 | 203 | - | - |

| No | Parameter | Unit | B0 | B30 | B50 | B100 |

|---|---|---|---|---|---|---|

| 1 | Density at 15 °C | kg/m3 | 841.7 | 851.3 | 867.5 | 873.5 |

| 2 | Lower Heating Value | MJ/kg | 45.5 | 43.8 | 42.8 | 40.1 |

| No. | Items | Specifications |

|---|---|---|

| 1 | Engine Displacement (cc) | 2755 |

| 2 | Maximum Power Output (HP/rpm) | 174/3400 |

| 3 | Maximum Torque (Nm/rpm) | 450/1600-2400 |

| 4 | Number of Cylinders | 4 |

| 5 | Valve System | In-line 16 valve DOHC |

| 6 | Intake system | Variable Turbo Charger with Intercooler |

| 7 | Fuel Supply | Common Rail Injection Systems |

| 8 | Exhaust After Treatment | Diesel Oxidation Catalyst |

| 9 | Vehicle Emissions Category | Euro4 |

| Fuel | Weighing [km/L] | R101 [km/L] | Modified R101 [km/L] | Difference of R101 & Modified R101 [%] | Difference of R101 & Weighing [%] | Difference of Modified R101 & Weighing [%] |

|---|---|---|---|---|---|---|

| B0 | 10.92 | 11 | 10.97 | 0.27 | 0.73 | 0.46 |

| B30 | 10.42 | 11.04 | 10.61 | 3.89 | 5.62 | 1.79 |

| B50 | 10.34 | 10.96 | 10.26 | 6.39 | 5.66 | −0.78 |

| B100 | 9.55 | 11.11 | 9.81 | 11.70 | 14.04 | 2.65 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reksowardojo, I.K.; Setiapraja, H.; Mokhtar; Yubaidah, S.; Mansur, D.; Putri, A.K. A Study on Utilization of High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies. Energies 2023, 16, 718. https://doi.org/10.3390/en16020718

Reksowardojo IK, Setiapraja H, Mokhtar, Yubaidah S, Mansur D, Putri AK. A Study on Utilization of High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies. Energies. 2023; 16(2):718. https://doi.org/10.3390/en16020718

Chicago/Turabian StyleReksowardojo, Iman K., Hari Setiapraja, Mokhtar, Siti Yubaidah, Dieni Mansur, and Agnes K. Putri. 2023. "A Study on Utilization of High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies" Energies 16, no. 2: 718. https://doi.org/10.3390/en16020718

APA StyleReksowardojo, I. K., Setiapraja, H., Mokhtar, Yubaidah, S., Mansur, D., & Putri, A. K. (2023). A Study on Utilization of High-Ratio Biodiesel and Pure Biodiesel in Advanced Vehicle Technologies. Energies, 16(2), 718. https://doi.org/10.3390/en16020718