Models for Battery Health Assessment: A Comparative Evaluation

Abstract

1. Introduction

2. Degradation and State Parameters

3. Battery State of Health Determination

4. Experimental Methods

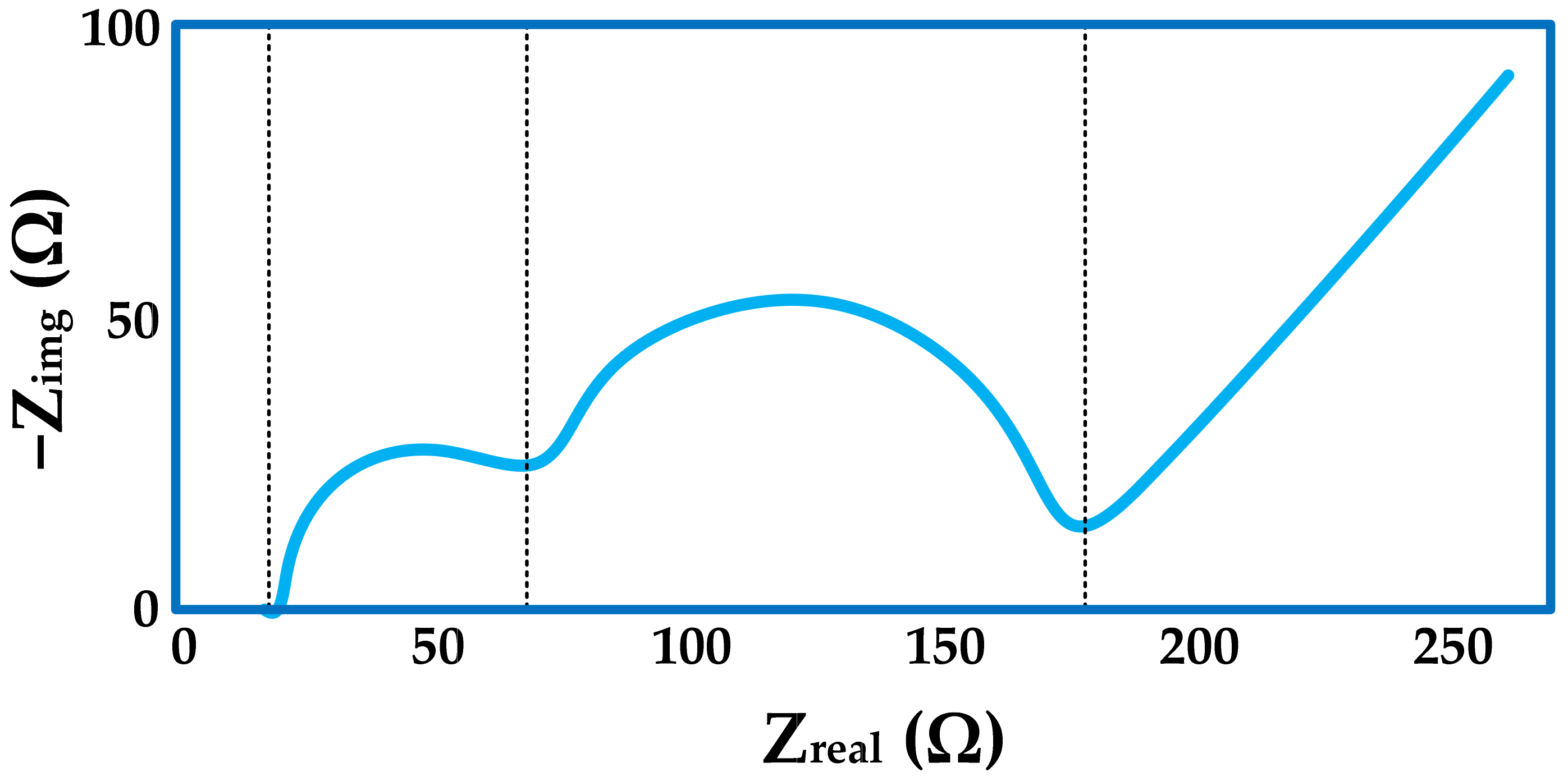

4.1. Electrochemical Impedance Spectroscopy

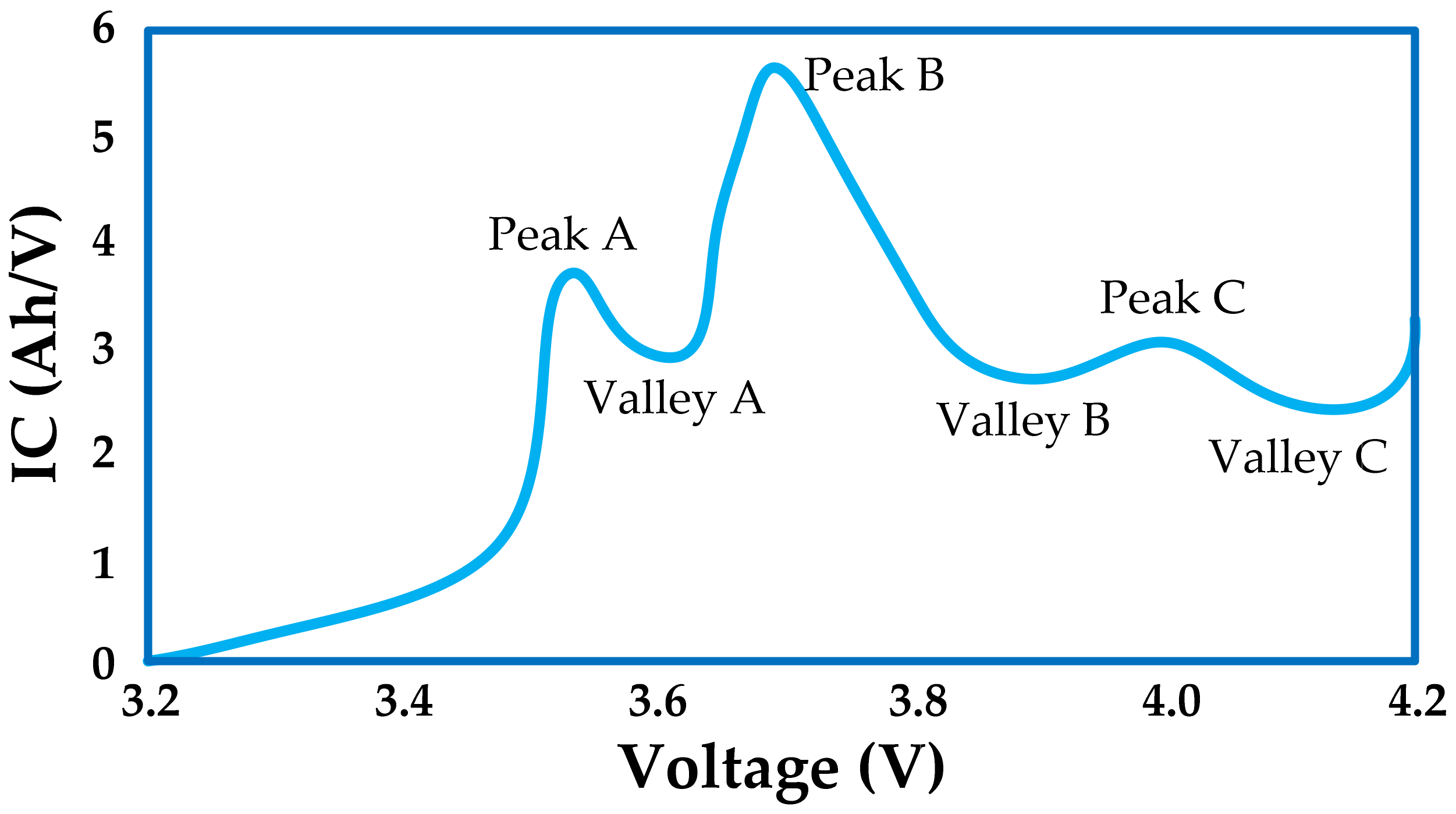

4.2. Incremental Capacity Analysis

5. Model-Based Methods

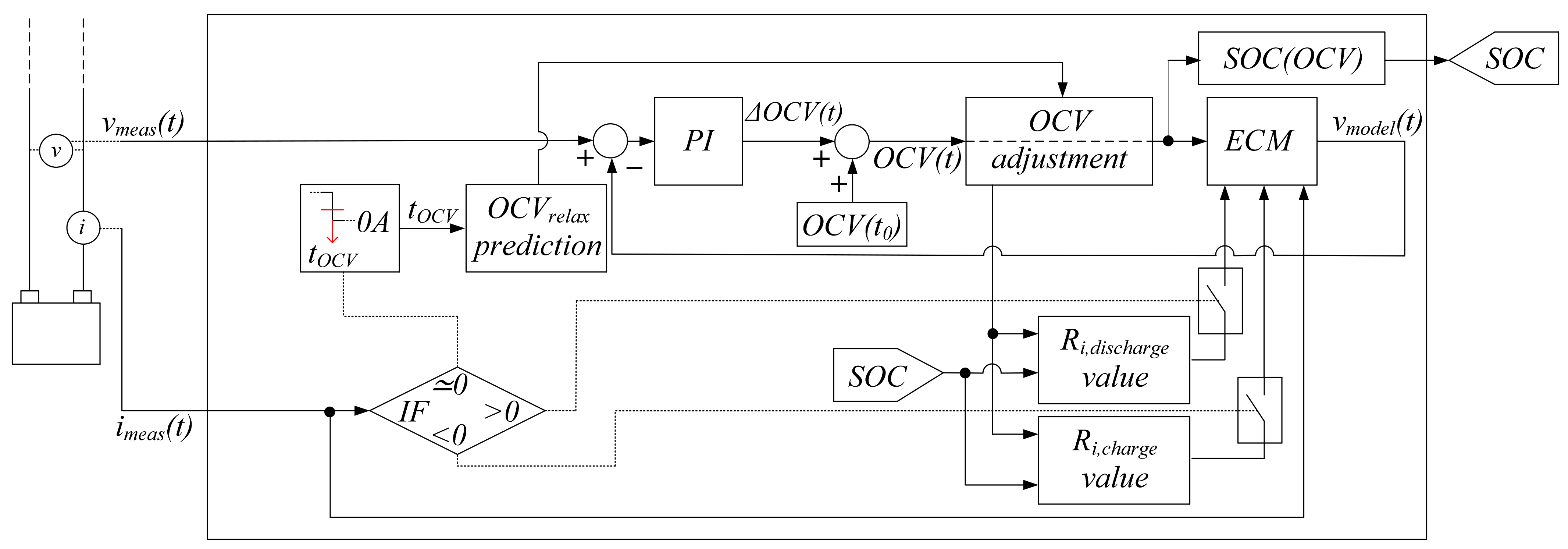

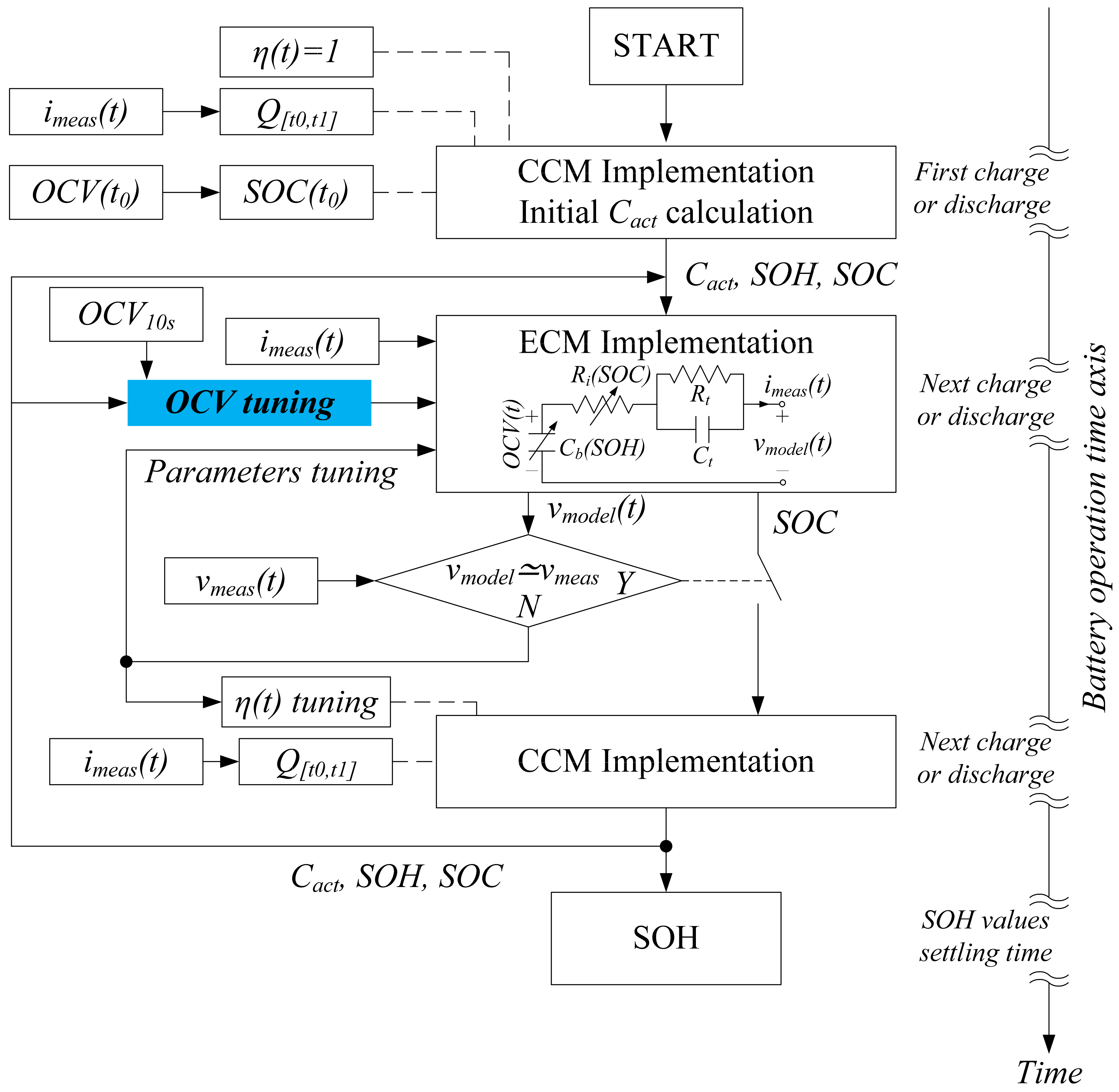

5.1. Equivalent Electric Circuit Models

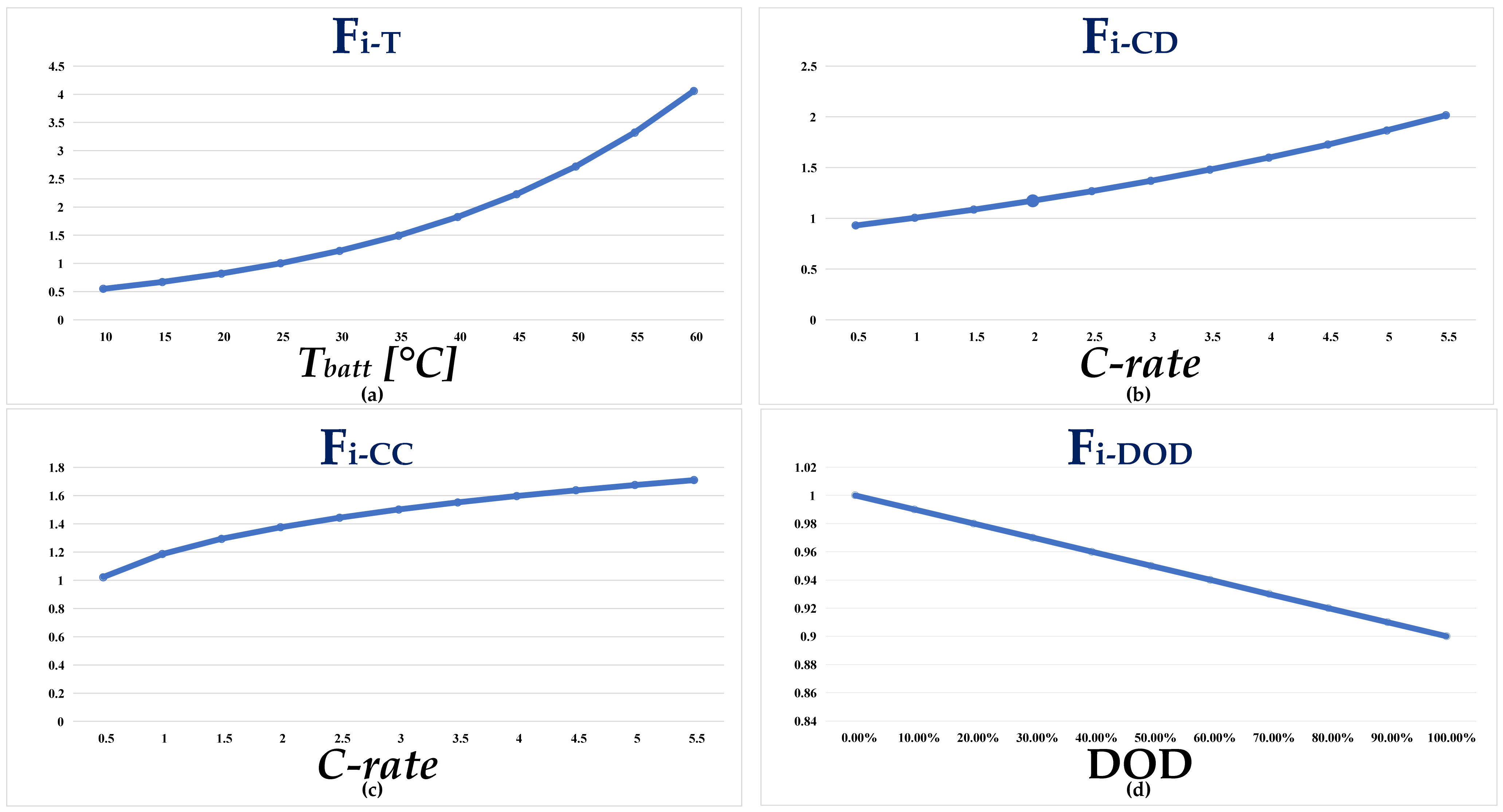

5.2. Aging Models

6. Data-Driven Methods

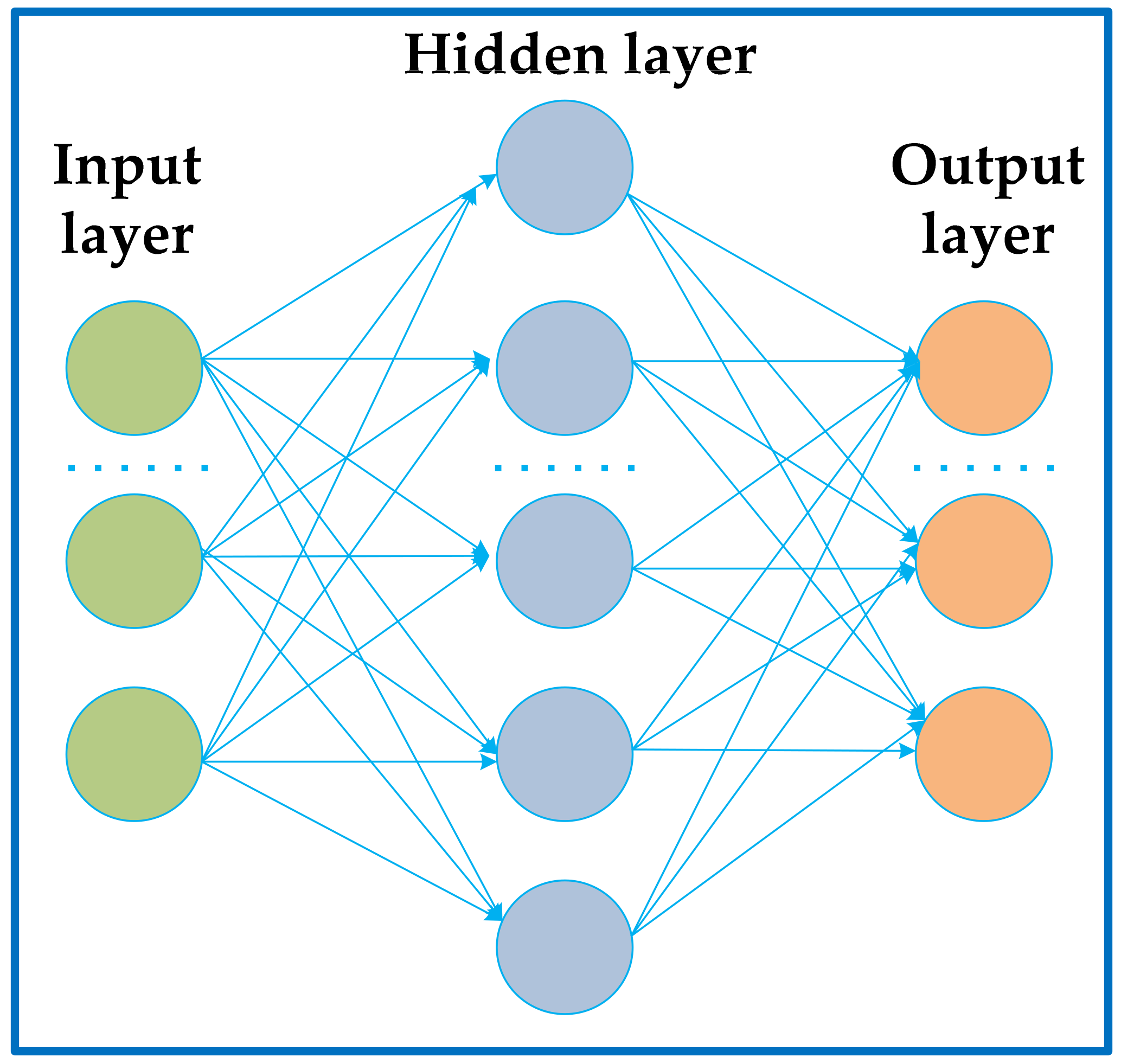

6.1. Neural Networks

6.2. Support Vector Regression

7. Discussion

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- The Nobel Prize. The Nobel Prize in Chemistry 2019. Available online: https://www.nobelprize.org/prizes/chemistry/2019/summary/ (accessed on 1 September 2022).

- Tsiropoulos, I.; Tarvydas, D.; Lebedeva, N. Li-ion Batteries for Mobility and Stationary Storage Applications; EUR 29440 EN; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Bloomberg, N.E.F. New Energy Outlook 2021. Available online: https://about.bnef.com/new-energy-outlook/ (accessed on 29 September 2022).

- United Nations. Resolution Adopted by the General Assembly on 25 September 2015. In Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015. [Google Scholar]

- IPCEI Batteries. Available online: https://www.ipcei-batteries.eu (accessed on 29 September 2022).

- Tian, H.; Qin, P.; Li, K.; Zhao, Z. A review of the state of health for lithium-ion batteries: Research status and suggestions. J. Clean. Prod. 2020, 261, 120813. [Google Scholar] [CrossRef]

- Hossain Lipu, M.S.; Hannan, M.A.; Hussain, A.; Hoque, M.M.; Ker, P.J.; Saad, M.H.M.; Ayob, A. A review of state of health and remaining useful life estimation methods for lithium-ion battery in electric vehicles: Challenges and recommendations. J. Clean. Prod. 2018, 205, 115–133. [Google Scholar] [CrossRef]

- Sarmah, S.B.; Kalita, P.; Garg, A.; Niu, X.; Zhang, X.; Peng, X.; Bhattacharjee, D. A Review of State of Health Estimation of Energy Storage Systems: Challenges and Possible Solutions for Futuristic Applications of Li-Ion Battery Packs in Electric Vehicles. J. Electrochem. Energy Convers. Storage 2019, 16, 040801. [Google Scholar] [CrossRef]

- Wang, Z.; Feng, G.; Zhen, D.; Gu, F.; Ball, A. A review on online state of charge and state of health estimation for lithium-ion batteries in electric vehicles. Energy Rep. 2021, 7, 5141–5161. [Google Scholar] [CrossRef]

- Noura, N.; Boulon, L.; Jemeï, S. A Review of Battery State of Health Estimation Methods: Hybrid Electric Vehicle Challenges. World Electr. Veh. J. 2020, 11, 66. [Google Scholar] [CrossRef]

- Rezvanizaniani, S.M.; Liu, Z.; Chen, Y.; Lee, J. Review and recent advances in battery health monitoring and prognostics technologies for electric vehicle (EV) safety and mobility. J. Power Sources 2014, 256, 110–124. [Google Scholar] [CrossRef]

- Tian, J.; Xiong, R.; Shen, W. A review on state of health estimation for lithium ion batteries in photovoltaic systems. eTransportation 2019, 2, 100028. [Google Scholar] [CrossRef]

- Xiong, R.; Li, L.; Tian, J. Towards a smarter battery management system: A critical review on battery state of health monitoring methods. J. Power Sources 2018, 405, 18–29. [Google Scholar] [CrossRef]

- Manoharan, A.; Begam, K.M.; Aparow, V.R.; Sooriamoorthy, D. Artificial Neural Networks, Gradient Boosting and Support Vector Machines for electric vehicle battery state estimation: A review. J. Energy Storage 2022, 55, 105384. [Google Scholar] [CrossRef]

- Rauf, H.; Khalid, M.; Arshad, N. Machine learning in state of health and remaining useful life estimation: Theoretical and technological development in battery degradation modelling. Renew. Sustain. Energy Rev. 2022, 156, 111903. [Google Scholar] [CrossRef]

- Sui, X.; He, S.; Vilsen, S.B.; Meng, J.; Teodorescu, R.; Stroe, D.J. A review of non-probabilistic machine learning-based state of health estimation techniques for Lithium-ion battery. Appl. Energy 2021, 300, 117346. [Google Scholar] [CrossRef]

- Berecibar, M.; Gandiaga, I.; Villarreal, I.; Omar, N.; Van Mierlo, J.; Van den Bossche, P. Critical review of state of health estimation methods of Li-ion batteries for real applications. Renew. Sustain. Energy Rev. 2016, 56, 572–587. [Google Scholar] [CrossRef]

- Lin, C.; Tang, A.; Wang, W. A Review of SOH Estimation Methods in Lithium-ion Batteries for Electric Vehicle Applications. Energy Procedia 2015, 75, 1920–1925. [Google Scholar] [CrossRef]

- Wang, Y.; Tian, J.; Sun, Z.; Wang, L.; Xu, R.; Li, M.; Chen, Z. A comprehensive review of battery modeling and state estimation approaches for advanced battery management systems. Renew. Sustain. Energy Rev. 2020, 131, 110015. [Google Scholar] [CrossRef]

- Yang, S.; Zhang, C.; Jiang, J.; Zhang, W.; Zhang, L.; Wang, Y. Review on state-of-health of lithium-ion batteries: Characterizations, estimations and applications. J. Clean. Prod. 2021, 314, 128015. [Google Scholar] [CrossRef]

- Waag, W.; Fleischer, C.; Sauer, D.U. Critical review of the methods for monitoring of lithium-ion batteries in electric and hybrid vehicles. J. Power Sources 2014, 258, 321–339. [Google Scholar] [CrossRef]

- Cuma, M.I.; Koroglu, T. A comprehensive review on estimation strategies used in hybrid and battery electric vehicles. Renew. Sustain. Energy Rev. 2015, 42, 517–531. [Google Scholar] [CrossRef]

- Dos Reis, G.; Strange, C.; Yadav, M.; Li, S. Lithium-ion battery data and where to find it. Energy AI 2021, 5, 100081. [Google Scholar] [CrossRef]

- Vasta, E.; Greco, D.; Scelba, G.; Cacciato, M.; De Benedetti, M.M.; Lanuzza, L.; Eberhardt, O.; Dugo, D.; Seminara, G. Design of a battery testing system with software/hardware interface. In Proceedings of the 2022 ELEKTRO Conference, Krakow, Poland, 23–26 May 2022; pp. 1–6. [Google Scholar]

- Gan, L.; Yang, F.; Shi, Y.F.; He, H.L. Lithium-ion battery state of function estimation based on fuzzy logic algorithm with associated variables. IOP Conf. Ser. Earth Environ. Sci. 2017, 94, 012133. [Google Scholar] [CrossRef]

- Bak, T.; Lee, S. Accurate Estimation of Battery SOH and RUL Based on a Progressive LSTM with a Time Compensated Entropy Index. In Proceedings of the 2019 Annual Conference of the PHM Society, Scottsdale, AR, USA, 23–26 September 2019; Volume 11. [Google Scholar]

- Cabrera-Castillo, E.; Niedermeier, F.; Jossen, A. Calculation of the state of safety (SOS) for lithium ion batteries. J. Power Sources 2016, 324, 509–520. [Google Scholar] [CrossRef]

- Nagulapati, V.M.; Lee, H.; Jung, D.W.; Paramanantham, S.S.S.; Brigljevic, B.; Choi, Y.; Lim, H. A novel combined multi-battery dataset based approach for enhanced prediction accuracy of data driven prognostic models in capacity estimation of lithium ion batteries. Energy AI 2021, 5, 100089. [Google Scholar] [CrossRef]

- Pannala, S.; Turner, J.A.; Allu, S.; Elwasif, W.R.; Kalnaus, S.; Simunovic, S.; Kumar, A.; Billings, J.J.; Wang, H.; Nada, J. Multiscale modeling and characterization for performance and safety of lithium-ion batteries. J. Appl. Phys. 2015, 118, 072017. [Google Scholar] [CrossRef]

- Carmeli, M.S.; Toscani, N.; Mauri, M. Electrothermal Aging Model of Li-Ion Batteries for Vehicle-to-Grid Services Evaluation. Electronics 2022, 11, 1042. [Google Scholar] [CrossRef]

- Li, X.; Wang, Z. State of health estimation for lithium-ion battery by combining incremental capacity analysis with gaussian process regression. arXiv 2019, arXiv:1903.07672. [Google Scholar]

- Caponetto, R.; Guarnera, N.; Matera, F.; Privitera, E.; Xibilia, M.G. Application of Electrochemical Impedance Spectroscopy for prediction of Fuel Cell degradation by LSTM neural networks. In Proceedings of the 2021 29th Mediterranean Conference on Control and Automation (MED), Bari, Italy, 22–25 June 2021; pp. 1064–1069. [Google Scholar]

- Gaberšček, M. Understanding Li-based battery materials via electrochemical impedance spectroscopy. Nat. Commun. 2021, 12, 6513. [Google Scholar] [CrossRef]

- Zappen, H.; Fuchs, G.; Gitis, A.; Sauer, D. In-Operando Impedance Spectroscopy and Ultrasonic Measurements during High-Temperature Abuse Experiments on Lithium-Ion Batteries. Batteries 2020, 6, 25. [Google Scholar] [CrossRef]

- Beiranvand, H.; Placzek, J.M.; Liserre, M.; Zampardi, G.; Brogioli, D.C.; La Mantia, F. Review of Power Converter Topologies for Electrochemical Impedance Spectroscopy of Lithium-Ion Batteries. In Proceedings of the 2022 24th European Conference on Power Electronics and Applications, Hannover, Germany, 5–9 September 2022; pp. 1–10. [Google Scholar]

- Middlemiss, L.A.; Rennie, A.J.R.; Sayers, R.; West, A.R. Characterisation of batteries by electrochemical impedance spectroscopy. Energy Rep. 2020, 6, 232–241. [Google Scholar] [CrossRef]

- Ezpeleta, I.; Freire, L.; Mateo-Mateo, C.; Nóvoa, X.R.; Pintos, A.; Valverde-Pérez, S. Characterisation of Commercial Li-Ion Batteries Using Electrochemical Impedance Spectroscopy. ChemistrySelect 2022, 7, e202104464. [Google Scholar] [CrossRef]

- Li, D.; Yang, D.; Li, L.; Wang, L.; Wang, K. Electrochemical Impedance Spectroscopy Based on the State of Health Estimation for Lithium-Ion Batteries. Energies 2022, 15, 6665. [Google Scholar] [CrossRef]

- Al-Zubaidi, R.; Smith, N.; Kasper, M.; Kumar, P.; Nilsson, D.; Mårlid, B.; Kienberger, F. Advanced Electrochemical Impedance Spectroscopy of Industrial Ni-Cd Batteries. Batteries 2022, 8, 50. [Google Scholar] [CrossRef]

- Meddings, N.; Heinrich, M.; Overney, F.; Lee, J.S.; Ruiz, V.; Napolitano, E.; Seitz, S.; Hinds, G.; Raccichini, R.; Gaberšček, M.; et al. Application of electrochemical impedance spectroscopy to commercial Li-ion cells: A review. J. Power Sources 2020, 480, 228742. [Google Scholar] [CrossRef]

- Waldmann, T.; Iturrondobeitia, A.; Kasper, M.; Ghanbari, N.; Aguesse, F.; Bekaert, E.; Daniel, L.; Genies, S.; Gordon, I.J.; Löble, M.W.; et al. Review—Post-mortem analysis of aged lithium-ion batteries: Disassembly methodology and physico-chemical analysis techniques. J. Electrochem. Soc. 2016, 163, A2149–A2164. [Google Scholar] [CrossRef]

- Bao, Y.; Chen, Y. Lithium-Ion Battery Real-Time Diagnosis with Direct Current Impedance Spectroscopy. Energies 2021, 14, 4396. [Google Scholar] [CrossRef]

- Stroe, D.I.; Schaltz, E. Lithium-Ion Battery State-of-Health Estimation Using the Incremental Capacity Analysis Technique. IEEE Trans. Ind. Appl. 2020, 56, 678–685. [Google Scholar] [CrossRef]

- Riviere, E.; Sari, A.; Venet, P.; Meniere, F.; Bultel, Y. Innovative Incremental Capacity Analysis Implementation for C/LiFePO4 Cell State-of-Health Estimation in Electrical Vehicles. Batteries 2019, 5, 37. [Google Scholar] [CrossRef]

- Bloom, I.; Jansen, A.N.; Abraham, D.P.; Knuth, J.; Jones, S.A.; Battaglia, V.S.; Henriksen, G.L. Differential voltage analyses of high-power, lithium-ion cells. J. Power Sources 2005, 139, 295–303. [Google Scholar] [CrossRef]

- Jenu, S.; Hentunen, A.; Haavisto, J.; Pihlatie, M. State of health estimation of cycle aged large format lithium-ion cells based on partial charging. J. Energy Storage 2022, 46, 103855. [Google Scholar] [CrossRef]

- Schaltz, E.; Stroe, D.I.; Nørregaard, K.; Ingvardsen, L.S.; Christensen, A. Incremental Capacity Analysis Applied on Electric Vehicles for Battery State-of-Health Estimation. IEEE Trans. Ind. Appl. 2021, 57, 1810–1817. [Google Scholar] [CrossRef]

- Lin, H.; Kang, L.; Xie, D.; Linghu, J.; Li, J. Online State-of-Health Estimation of Lithium-Ion Battery Based on Incremental Capacity Curve and BP Neural Network. Batteries 2022, 8, 29. [Google Scholar] [CrossRef]

- Li, Y.; Liu, K.; Foley, A.M.; Zülke, A.; Berecibar, M.; Nanini-Maury, E.; Van Mierlo, J.; Hoster, H.E. Data-driven health estimation and lifetime prediction of lithium-ion batteries: A review. Renew. Sustain. Energy Rev. 2019, 113, 109254. [Google Scholar] [CrossRef]

- Li, Y.; Abdel-Monem, M.; Gopalakrishnan, R.; Berecibar, M.; Nanini-Maury, E.; Omar, N.; van den Bossche, P.; Van Mierlo, J. A quick on-line state of health estimation method for Li-ion battery with incremental capacity curves processed by Gaussian filter. J. Power Sources 2018, 373, 40–53. [Google Scholar] [CrossRef]

- Lin, C.P.; Cabrera, J.; Yu, D.Y.W.; Yang, F.; Tsui, K.L. SOH Estimation and SOC Recalibration of Lithium-Ion Battery with Incremental Capacity Analysis & Cubic Smoothing Spline. J. Electrochem. Soc. 2020, 167, 090537. [Google Scholar]

- Weng, C.; Cui, Y.; Sun, J.; Peng, H. On-board state of health monitoring of lithium-ion batteries using incremental capacity analysis with support vector regression. J. Power Sources 2013, 235, 36–44. [Google Scholar] [CrossRef]

- Jiang, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Gao, Y.; Li, N. State of health estimation of second-life LiFePO4 batteries for energy storage applications. J. Clean. Prod. 2018, 205, 754–762. [Google Scholar] [CrossRef]

- Tang, X.; Zou, C.; Yao, K.; Chen, G.; Liu, B.; He, Z.; Gao, F. A fast estimation algorithm for lithium-ion battery state of health. J. Power Sources 2018, 396, 453–458. [Google Scholar] [CrossRef]

- Chen, C.H.; Planella, F.B.; O’regan, K.; Gastol, D.; Widanage, W.D.; Kendrick, E. Development of Experimental Techniques for Parameterization of Multi-scale Lithium-ion Battery Models. J. Electrochem. Soc. 2020, 167, 080534. [Google Scholar] [CrossRef]

- Zhou, W.; Zheng, Y.; Pan, Z.; Lu, Q. Review on the Battery Model and SOC Estimation Method. Processes 2021, 9, 1685. [Google Scholar] [CrossRef]

- Chaoui, H.; Mandalapu, S. Comparative Study of Online Open Circuit Voltage Estimation Techniques for State of Charge Estimation of Lithium-Ion Batteries. Batteries 2017, 3, 12. [Google Scholar] [CrossRef]

- Coleman, M.; Hurley, W.G.; Lee, C.K. An Improved Battery Characterization Method Using a Two-Pulse Load Test. IEEE Trans. Energy Convers. 2008, 23, 708–713. [Google Scholar] [CrossRef]

- Mousavi, S.M.; Nikdel, M. Various battery models for various simulation studies and applications. Renew. Sustain. Energy Rev. 2014, 32, 477–485. [Google Scholar] [CrossRef]

- Kai, S.; Qifang, S. Overview of the types of battery models. In Proceedings of the 2011 IEEE 30th Chinese Control Conference, Yantai, China, 22–24 July 2011; pp. 3644–3648. [Google Scholar]

- Achaibou, N.; Haddadi, M.; Malek, A. Lead acid batteries simulation including experimental validation. J. Power Sources 2008, 185, 1484–1491. [Google Scholar] [CrossRef]

- Sheperd, C.M. Design of Primary and Secondary Cells—Part II. An Equation Describing Battery Discharge. J. Electrochem. Soc. 1965, 112, 657–664. [Google Scholar]

- Hussein, A.; Batarseh, I. An Overview of Generic Battery Models. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–29 July 2011; pp. 1–6. [Google Scholar]

- Treptow, R.S. The lead-acid battery: Its voltage in theory and practice. J. Chem. Educ. 2002, 79, 334. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Einhorn, M.; Conte, F.V.; Kral, C.; Fleig, J. Comparison, Selection, and Parameterization of Electrical Battery Models for Automotive Applications. IEEE Trans. Power Electron. 2013, 28, 1429–1437. [Google Scholar] [CrossRef]

- Kularatna, N. Dynamics and Modeling of Rechargeable Batteries. IEEE Power Electron. Mag. 2014, 1, 23–33. [Google Scholar] [CrossRef]

- Schweighofer, B.; Raab, K.; Brasseur, G. Modeling of High Power Automotive Batteries by the Use of an Automated Test System. IEEE Trans. Instrum. Meas. 2003, 52, 1087–1091. [Google Scholar] [CrossRef]

- Li, J.; Mazzola, M. Accurate battery pack modeling for automotive applications. J. Power Sources 2013, 237, 215–228. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Guo, H.; Li, S. Comparison study on the battery models used for the energy management of batteries in electric vehicles. Energy Convers. Manag. 2012, 64, 113–121. [Google Scholar] [CrossRef]

- Wang, W.; Chung, H.; Zhang, J. Near-Real-Time Parameter Estimation of an Electrical Battery Model with Multiple Time Constants and SOC-Dependent Capacitance. IEEE Trans. Power Electron. 2014, 29, 5905–5920. [Google Scholar] [CrossRef]

- Seaman, A.; Dao, T.; McPhee, J. A survey of mathematical-based equivalent-circuit and electrochemical battery models for hybrid and electric vehicle simulation. J. Power Sources 2014, 256, 410–423. [Google Scholar] [CrossRef]

- Benini, L.; Castelli, G.; Macii, A.; Macii, E.; Poncino, M.; Scarsi, R. Discrete-Time Battery Models for System-Level Low-Power Design. IEEE Trans. Very Large Scale Integr. Syst. 2001, 9, 630–640. [Google Scholar] [CrossRef]

- Gold, S. A PSPICE Macromodel for Lithium-Ion Batteries. In Proceedings of the 1997 IEEE Battery Applications and Advances Conference, Long Beach, CA, USA, 31 March 1997; pp. 215–222. [Google Scholar]

- Chen, M.; Rincon-Mora, A. Accurate Electrical Battery Model Capable of Predicting Runtime and I–V Performance. IEEE Trans. Energy Convers. 2006, 21, 504–511. [Google Scholar] [CrossRef]

- Kroeze, R.; Krein, P. Electrical Battery Model for Use in Dynamic Electric Vehicle Simulations. In Proceedings of the 2008 IEEE Power Electronics Specialists Conference, Rhodes, Greece, 15–19 June 2008; pp. 1336–1342. [Google Scholar]

- Gao, L.; Liu, S.; Dougal, R.A. Dynamic Lithium-Ion Battery Model for System Simulation. IEEE Trans. Compon. Packag. Manuf. Technol. 2002, 25, 495–505. [Google Scholar]

- Li, S.; Ke, B. Study of Battery Modeling using Mathematical and Circuit Oriented Approaches. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–29 July 2011; pp. 1–8. [Google Scholar]

- Tremblay, O.; Dessaint, L. Experimental Validation of a Battery Dynamic Model for EV Applications. World Electr. Veh. J. 2009, 3, 289–298. [Google Scholar] [CrossRef]

- Jackey, R.A. A Simple, Effective Lead-Acid Battery Modeling Process for Electrical System Component Selection. SAE Trans. 2007, 116, 219–227. [Google Scholar]

- Bhangu, B.S.; Bingham, C.M.; Stone, D.A.; Bentley, P. Nonlinear Observer techniques for Prediction State-of-Charge and State-of-Health of Lead-Acid Batteries for Hybrid-Electric Vehicles. IEEE Trans. Veh. Technol. 2005, 54, 783–794. [Google Scholar] [CrossRef]

- Copetti, J.B.; Lorenzo, E.; Chenlo, F. A general battery model for PV system simulation. Prog. Photovolt.: Res. Appl. 1993, 1, 283–292. [Google Scholar] [CrossRef]

- Macomber, H.L.; Ruzek, J.B.; Costello, F.A. Photovoltaic Stand-Alone Systems: Preliminary Engineering-Design Handbook; United States Department of Energy: Washington, DC, USA, 1981.

- Salkind, A.; Singh, P.; Cannone, A.; Atwater, T.; Wang, X.; Reisner, D. Impedance modeling of intermediate size lead-acid batteries. J. Power Sources 2003, 116, 174–184. [Google Scholar] [CrossRef]

- Stroe, D.I.; Swierczynski, M.; Stroe, A.I.; Knap, V.; Teodorescu, R.; Andreasen, S.J. Evaluation of Different Methods for Measuring the Impedance of Lithium-Ion Batteries during Ageing. In Proceedings of the 2005 IEEE Ecological Vehicles and Renewable Energies International Conference, Monte Carlo, Monaco, 31 March–2 April 2005; pp. 1–8. [Google Scholar]

- Moubayed, N.; Kouta, J.; El-Ali, A.; Demayka, H.; Outbib, R. Parameter Identification of the Lead-Acid Battery Model. In Proceedings of the 2008 IEEE Photovoltaic Specialists Conference, San Diego, CA, USA, 11–16 May 2008; pp. 1–6. [Google Scholar]

- Ceraolo, M. New dynamical models of lead-acid batteries. IEEE Trans. Power Syst. 2000, 15, 1184–1190. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Li, G.; Li, M.; Jiang, Z.; Wang, X.; Zhao, Q. Third-order dynamic model of a lead acid battery for use in fuel cell vehicle simulation. In Proceedings of the 2011 IEEE Mechatronic Science, Electric Engineering and Computer Conference, Jilin, China, 19–22 August 2011; pp. 715–720. [Google Scholar]

- Yang, Q.; Xu, J.; Li, X.; Xu, D.; Cao, B. State-of-health estimation of lithium-ion battery based on fractional impedance model and interval capacity. Int. J. Electr. Power Energy Syst. 2020, 119, 105883. [Google Scholar] [CrossRef]

- Guo, R.; Shen, W. A Review of Equivalent Circuit Model Based Online State of Power Estimation for Lithium-Ion Batteries in Electric Vehicles. Vehicles 2021, 4, 1–29. [Google Scholar] [CrossRef]

- Tang, X.; Liu, B.; Lv, Z.; Gao, F. Observer based battery SOC estimation: Using multi-gain-switching approach. Appl. Energy 2017, 204, 1275–1283. [Google Scholar] [CrossRef]

- Du, J.; Liu, Z.; Wang, Y.; Wen, C. An adaptive sliding mode observer for lithium-ion battery state of charge and state of health estimation in electric vehicles. Control Eng. Pract. 2016, 54, 81–90. [Google Scholar] [CrossRef]

- Ning, B.; Cao, B.; Wang, B.; Zou, Z. Adaptive sliding mode observers for lithium-ion battery state estimation based on parameters identified online. Energy 2018, 153, 732–742. [Google Scholar] [CrossRef]

- Nobile, G.; Vasta, E.; Cacciato, M.; Scarcella, G.; Scelba, G.; Di Stefano, A.G.F.; Leotta, G.; Pugliatti, P.M.; Bizzarri, F. Integration of a relaxation voltage prediction function into a PI-based observer to improve the SOC estimation of battery packs in renewable energy applications. In Proceedings of the 2020 ELEKTRO Conference, Taormina, Italy, 11–15 May 2020; pp. 1–6. [Google Scholar]

- Amir, U.; Tao, L.; Zhang, X.; Saeed, M.; Hussain, M. A Novel SOC Estimation Method for Lithium Ion Battery Based On Improved Adaptive PI Observer. In Proceedings of the 2018 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Nottingham, UK, 7–9 November 2018; pp. 1–5. [Google Scholar]

- Rzepka, B.; Bischof, S.; Blank, T. Implementing an Extended Kalman Filter for SoC Estimation of a Li-Ion Battery with Hysteresis: A Step-by-Step Guide. Energies 2021, 14, 3733. [Google Scholar] [CrossRef]

- Zhi, L.; Peng, Z.; Zhifu, W.; Qiang, S.; Yinan, R. State of charge estimation for Li-ion battery based on extended Kalman filter. Energy Procedia 2017, 105, 3515–3520. [Google Scholar] [CrossRef]

- Jiang, N.; Pang, H. Study on Co-Estimation of SoC and SoH for Second-Use Lithium-Ion Power Batteries. Electronics 2022, 11, 1789. [Google Scholar] [CrossRef]

- Zeng, M.; Zhang, P.; Yang, Y.; Xie, C.; Shi, Y. SOC and SOH Joint Estimation of the Power Batteries Based on Fuzzy Unscented Kalman Filtering Algorithm. Energies 2019, 12, 3122. [Google Scholar] [CrossRef]

- Xiao, D.; Fang, G.; Liu, S.; Yuan, S.; Ahmed, R.; Habibi, S.; Emadi, A. Reduced-Coupling Coestimation of SOC and SOH for Lithium-Ion Batteries Based on Convex Optimization. IEEE Trans. Power Electron. 2020, 35, 12332–12346. [Google Scholar] [CrossRef]

- Nobile, G.; Vasta, E.; Cacciato, M.; Scarcella, G.; Scelba, G. Estimation of SOH for Battery Packs: A Real-Time Mixed Algorithm based on Coulomb Counting Method and Parameter-Varying Circuit Modeling. In Proceedings of the 2020 IEEE 11th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Dubrovnik, Croatia, 28 September–1 October 2020. [Google Scholar]

- Canals Casals, L.; Amante García, B.; González Benítez, M.M. Aging model for re-used electric vehicle batteries in second life stationary applications. In Project Management and Engineering Research AEPRO 2016; Springer: Berlin, Germany, 2017; pp. 139–151. [Google Scholar]

- Canals Casals, L.; Amante García, B.; Canal, C. Second life batteries lifespan: Rest of useful life and environmental analysis. J. Environ. Manag. 2019, 232, 354–363. [Google Scholar] [CrossRef]

- Vetter, J.; Novák, P.; Wagner, M.R.; Veit, C.; Möller, K.C.; Besenhard, J.O.; Winter, M.; Wohlfahrt-Mehrens, M.; Vogler, C.; Hammouche, A. Ageing mechanisms in lithium-ion batteries. J. Power Sources 2005, 147, 269–281. [Google Scholar] [CrossRef]

- Wang, J.; Liu, P.; Hicks-Garner, J.; Sherman, E.; Soukiazian, S.; Verbrugge, M.; Tataria, H.; Musser, J.; Finamore, P. Cycle-life model for graphite-LiFePO4 cells. J. Power Sources 2011, 196, 3942–3948. [Google Scholar] [CrossRef]

- Micari, S.; Foti, S.; Testa, A.; De Caro, S.; Sergi, F.; Andaloro, L.; Aloisio, D.; Napoli, G. Reliability assessment and lifetime prediction of Li-ion batteries for electric vehicles. Electr. Eng. 2022, 104, 165–177. [Google Scholar] [CrossRef]

- Omar, N.; Monem, M.A.; Firouz, Y.; Salminen, J.; Smekens, J.; Hegazy, O.; Gaulous, H.; Mulder, G.; Van den Bossche, P.; Coosemans, T.; et al. Lithium iron phosphate based battery—Assessment of the aging parameters and development of cycle life model. Appl. Energy 2014, 113, 1575–1585. [Google Scholar] [CrossRef]

- Capra, M.; Bussolino, B.; Marchisio, A.; Masera, G.; Martina, M.; Shafique, M. Hardware and Software Optimizations for Accelerating Deep Neural Networks: Survey of Current Trends, Challenges, and the Road Ahead. IEEE Access 2020, 8, 225134–225180. [Google Scholar] [CrossRef]

- Morgos, J.; Klčo, P.; Hrudkay, K. Artificial Neural Network Based MPPT Algorithm for Modern Household with Electric Vehicle. Communications. Sci. Lett. Univ. Zilina 2022, 24, C18–C26. [Google Scholar]

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Sahari, K.S.M.; Ker, P.J.; Muttaqi, K.M. State-of-Charge Estimation of Li-ion Battery in Electric Vehicles: A Deep Neural Network Approach. In Proceedings of the 2019 IEEE Industry Applications Society Annual Meeting, Baltimore, MD, USA, 29 September–3 October 2019; pp. 1–8. [Google Scholar]

- Nielsen, M.A. Neural Networks and Deep Learning; Determination Press: Washington, DC, USA, 2015. [Google Scholar]

- Sharma, S.; Sharma, S.; Athaiya, A. Activation functions in neural networks. Int. J. Eng. Appl. Sci. Technol. 2020, 4, 310–316. [Google Scholar] [CrossRef]

- Szandała, T. Review and Comparison of Commonly Used Activation Functions for Deep Neural Networks. In Bio-Inspired Neurocomputing. Studies in Computational Intelligence; Bhoi, A., Mallick, P., Liu, C.M., Balas, V., Eds.; Springer: Singapore, 2021; Volume 903, pp. 203–224. [Google Scholar]

- Lau, M.M.; Lim, K.H. Investigation of activation functions in deep belief network. In Proceedings of the 2017 2nd International Conference on Control and Robotics Engineering (ICCRE), Bangkok, Thailand, 1–3 April 2017; pp. 201–206. [Google Scholar]

- Zhu, D.; Campbell, J.J.; Cho, G. Battery Voltage Prediction Using Neural Networks. In Proceedings of the 2021 IEEE Transportation Electrification Conference & Expo (ITEC), Chicago, IL, USA, 21–25 June 2021; pp. 807–812. [Google Scholar]

- Darbar, D.; Bhattacharya, I. Application of Machine Learning in Battery: State of Charge Estimation Using Feed Forward Neural Network for Sodium-Ion Battery. Electrochem 2022, 3, 42–57. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Y.; Sun, J.; Cui, Z.; Wang, K. Stacked bidirectional LSTM RNN to evaluate the remaining useful life of supercapacitor. Int. J. Energy Res. 2022, 46, 3034–3043. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Maddikunta, P.K.R.; Meenakshisundaram, I.; Gadekallu, T.R.; Sharma, S.; Alkahtani, M.; Abidi, M.H. Deep neural networks based approach for battery life prediction. Cmc-Comput. Mater. Contin. 2021, 69, 2599–2615. [Google Scholar] [CrossRef]

- Shu, X.; Shen, S.; Shen, J.; Zhang, Y.; Li, G.; Chen, Z.; Liu, Y. State of health prediction of lithium-ion batteries based on machine learning: Advances and perspectives. iScience 2021, 24, 103265. [Google Scholar] [CrossRef]

- Jo, S.; Jung, S.; Roh, T. Battery State-of-Health Estimation Using Machine Learning and Preprocessing with Relative State-of-Charge. Energies 2021, 14, 7206. [Google Scholar] [CrossRef]

- Alwosheel, A.; van Cranenburgh, S.; Chorus, C.G. Is your dataset big enough? Sample size requirements when using artificial neural networks for discrete choice analysis. J. Choice Model. 2018, 28, 167–182. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.E.; Yang, Y. Advanced machine learning approach for lithium-ion battery state estimation in electric vehicles. IEEE Trans. Transp. Electrific. 2016, 2, 140–149. [Google Scholar] [CrossRef]

- Hossain Lipu, M.S.; Hannan, M.A.; Hussain, A.; Saad, M.H.; Ayob, A.; Uddin, M.N. Extreme learning machine model for state-of-charge estimation of lithium-ion battery using gravitational search algorithm. IEEE Trans. Ind. Appl. 2019, 55, 4225–4234. [Google Scholar] [CrossRef]

- Li, Y.; Li, K.; Liu, X.; Zhang, L. Fast battery capacity estimation using convolutional neural networks. Trans. Inst. Meas. 2020. [Google Scholar] [CrossRef]

- Yang, D.; Wang, Y.; Pan, R.; Chen, R.; Chen, Z. A Neural Network Based State-of-Health Estimation of Lithium-ion Battery in Electric Vehicles. Energy Procedia 2017, 105, 2059–2064. [Google Scholar] [CrossRef]

- Qianglong, L.; Xiaowei, Z.; Kun, Z.; Jianrui, S.; Kai, W. State of Health Estimation of Lithium-ion Battery Based on Ant Lion Optimization and Support Vector Regression. In Proceedings of the 2021 IEEE International Conference on Electrical Engineering and Mechatronics Technology (ICEEMT), Qingdao, China, 2–4 July 2021; pp. 334–337. [Google Scholar]

- Zhang, Y.; Liu, Y.; Wang, J.; Zhang, T. State-of-health estimation for lithium-ion batteries by combining model-based incremental capacity analysis with support vector regression. Energy 2022, 239, 121986. [Google Scholar] [CrossRef]

- Smola, A.J.; Schölkopf, B. A tutorial on support vector regression. Stat. Comput. 2004, 14, 199–222. [Google Scholar] [CrossRef]

- Weng, C.; Sun, J.; Peng, H. Model Parametrization and Adaptation Based on the Invariance of Support Vectors with Applications to Battery State-of-Health Monitoring. IEEE Trans. Veh. Technol. 2015, 64, 9. [Google Scholar] [CrossRef]

- Dubarry, M.; Svoboda, V.; Hwu, R.; Liaw, B.Y. Incremental capacity analysis and close-to equibrilium OCV measurements to quantify capacity fade in commercial rechargable lithium batteries. Electrochem. Solid-State Lett. 2006, 9, A454–A457. [Google Scholar] [CrossRef]

- Anseán, D.; García, V.M.; González, M.; Blanco-Viejo, C.; Viera, J.C.; Pulido, Y.F.; Sánchez, L. Lithium-ion battery degradation indicators via incremental capacity analysis. IEEE Trans. Ind. Appl. 2019, 55, 2992–3002. [Google Scholar] [CrossRef]

- Smola, A.; Scholkopf, B.; Ratsch, G. Linear programs for automatic accuracy control in regression. In Proceedings of the 1999 Ninth International Conference on Artificial Neural Networks (ICANN), Edinburgh, UK, 7–10 September 1999; Volume 2, pp. 575–580. [Google Scholar]

- Tan, X.; Zhan, D.; Lyu, P.; Rao, J.; Fan, Y. Online state-of-health estimation of lithium-ion battery based on dynamic parameter identification at multi timescale and support vector regression. J. Power Sources 2021, 484, 229–233. [Google Scholar] [CrossRef]

- Yang, D.; Wang, Y.; Pan, R.; Chen, R.; Chen, Z. State-of-health estimation for the lithium-ion battery based on support vector regression. Appl. Energy 2018, 227, 273–283. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, C.; Chen, Z. On-line battery state-of-charge estimation based on an integrated estimator. Appl. Energy 2017, 185, 2026–2032. [Google Scholar] [CrossRef]

- Wu, J.; Fang, L.; Meng, J.; Lin, M.; Dong, G. Optimized Multi-Source Fusion Based State of Health Estimation for Lithium-Ion Battery in Fast Charge Applications. IEEE Trans. Energy Convers. 2022, 37, 1489–1498. [Google Scholar] [CrossRef]

- Yang, R.; Zhang, X.; Liu, G.; Hou, S. State of Health Estimation for Power Battery Based on Support Vector Regression and Particle Swarm Optimization Method. In Proceedings of the 2021 40th Chinese Control Conference (CCC), Shanghai, China, 26–28 July 2021; pp. 6281–6288. [Google Scholar]

- Pastor-Fernández, C.; Uddin, K.; Chouchelamane, G.H.; Widanage, W.D.; Marco, J. A Comparison between Electrochemical Impedance Spectroscopy and Incremental Capacity-Differential Voltage as Li-ion Diagnostic Techniques to Identify and Quantify the Effects of Degradation Modes within Battery Management Systems. J. Power Sources 2017, 360, 301–318. [Google Scholar] [CrossRef]

- Andre, D.; Nuhic, A.; Soczka-Guth, T.; Sauer, D.U. Comparative study of a structured neural network and an extended Kalman filter for state of health determination of lithium-ion batteries in hybrid electricvehicles. Eng. Appl. Artif. Intell. 2013, 26, 951–961. [Google Scholar] [CrossRef]

- Obisakin, I.; Ekeanyanwu, C. State of Health Estimation of Lithium-Ion Batteries Using Support Vector Regression and Long Short-Term Memory. Open J. Appl. Sci. 2022, 12, 1366–1382. [Google Scholar] [CrossRef]

- Heinrich, F.; Klapper, P.; Pruckner, M. A comprehensive study on battery electric modeling approaches based on machine learning. Energy Inform. 2021, 4, 17. [Google Scholar] [CrossRef]

| Ref. | Error | Relevant Features | Chemistry | ||

|---|---|---|---|---|---|

| [47] | 0.85% RMSE | IC curve smoothed with moving average filter and Gaussian filter. Peak area as FOI. Second-degree polynomial curve fitted to the data to model the correlation. | Rate C/3 | LTO | |

| 1.58% RMSE | Rate 1C | ||||

| 1.57% RMSE | Rate 2C | ||||

| 1.37% RMSE | Rate C/3 | NMC | |||

| 1.60% RMSE | Rate 1C | ||||

| 4.72% RMSE | Rate 2C | ||||

| 2.12% RMSE | Rate C/3 | LFP | |||

| 2.33% RMSE | Rate 1C | ||||

| [48] | 1.33% RMSE 4.25% MAE | Comparison between cell and vehicle levels (battery pack). Rate C/2, position of peaks and valleys used as FOIs. | NMC | ||

| 2.92% RMSE 8.54% MAE | LMO | ||||

| [51] | <2.5% MAPE | Rate C/2. Linear regression function, established by using the Matlab curve fitting toolbox, used for associating FOIs (monotonic trends in the positions of peaks and valleys) with capacity fading. | NMC | ||

| [52] | 2.69% RMSE | Filtering with a robust cubic smoothing spline method. Robust linear regression with bisquare method used for associating FOIs with capacity fading. | Peak height ratio as FOI. RMSE of peak height ratio is 0.49% if low noise is introduced and 1.55% if high noise is introduced. | LFP | |

| 4.44% RMSE | Peak height value as FOI. | ||||

| 8.69% RMSE | Peak area as FOI. | ||||

| [53] | <1% MAPE (except for a few outliers) | SVR used for associating FOIs (peak heights) with capacity fading. | LFP | ||

| [54] | 1.41% RMSE | OLS method used for associating FOIs (peak height and peak area) with capacity fading. | LFP | ||

| 1.08% RMSE | Ridge regression used for associating FOIs (peak height and peak area) with capacity fading. | ||||

| 2.78% RMSE | Linear regression with Pearson’s product–moment correlation-based peak area selection method used for associating FOIs with capacity fading. | ||||

| Ref. | Error | Relevant Features | Chemistry |

|---|---|---|---|

| [125] | 1.1% RMSE | ELM-based GSA model, DST. | NMC |

| 1.4% RMSE | ELM-based GSA model, FUDS. | ||

| [126] | <2.93% RMSE | CNN (considering various combinations in the structure). | Li-ion Oxford Battery Degradation Dataset |

| <2.54% RMSE | LFP (dataset provided by the Toyota Research Institute) | ||

| 0.95% RMSE | CNN with four convolutional layers. | ||

| 1.72% RMSE | ANN. | ||

| 1.23–1.34% RMSE | DNN (error variation due to different number of hidden layers). | ||

| [127] | <5% MAE | Three-layer NN using a sigmoid activation function. | LFP |

| Ref. | Error | Relevant Features | Chemistry |

|---|---|---|---|

| [136] | 0.93–1.60% RMSE | PSO–LSSVR | LFP |

| 1.02–4.32% RMSE | LSSVR | ||

| 1.18–6% RMSE | NN | ||

| [138] | 0.5% MAE | GA–SVR | LFP |

| [139] | 0.41–1.45% MAE 0.56–1.59% RMSE | PSO–SVR | Li-ion (provided by NASA prognostic center of excellence) |

| 1.98–2.29% MAE 2.40–2.87% RMSE | SVR |

| Advantages | Disadvantages | |

|---|---|---|

| EXPERIMENTAL METHODS | ||

| EIS |

|

|

| ICA |

|

|

| MODEL-BASED METHODS | ||

| ECM |

|

|

| AM |

|

|

| DATA-DRIVEN METHODS | ||

| NN |

|

|

| SVR |

|

|

| OTHER SUPPORTIVE METHODS | ||

| CC |

|

|

| OCV |

|

|

| KF |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vasta, E.; Scimone, T.; Nobile, G.; Eberhardt, O.; Dugo, D.; De Benedetti, M.M.; Lanuzza, L.; Scarcella, G.; Patanè, L.; Arena, P.; et al. Models for Battery Health Assessment: A Comparative Evaluation. Energies 2023, 16, 632. https://doi.org/10.3390/en16020632

Vasta E, Scimone T, Nobile G, Eberhardt O, Dugo D, De Benedetti MM, Lanuzza L, Scarcella G, Patanè L, Arena P, et al. Models for Battery Health Assessment: A Comparative Evaluation. Energies. 2023; 16(2):632. https://doi.org/10.3390/en16020632

Chicago/Turabian StyleVasta, Ester, Tommaso Scimone, Giovanni Nobile, Otto Eberhardt, Daniele Dugo, Massimiliano Maurizio De Benedetti, Luigi Lanuzza, Giuseppe Scarcella, Luca Patanè, Paolo Arena, and et al. 2023. "Models for Battery Health Assessment: A Comparative Evaluation" Energies 16, no. 2: 632. https://doi.org/10.3390/en16020632

APA StyleVasta, E., Scimone, T., Nobile, G., Eberhardt, O., Dugo, D., De Benedetti, M. M., Lanuzza, L., Scarcella, G., Patanè, L., Arena, P., & Cacciato, M. (2023). Models for Battery Health Assessment: A Comparative Evaluation. Energies, 16(2), 632. https://doi.org/10.3390/en16020632