Energy and Exergy Analysis of Cascade Mixed Refrigerant Joule–Thomson System with the Application of a Precooler

Abstract

:1. Introduction

2. CMR J–T Cycle

2.1. Precooled CMR J–T Cycle

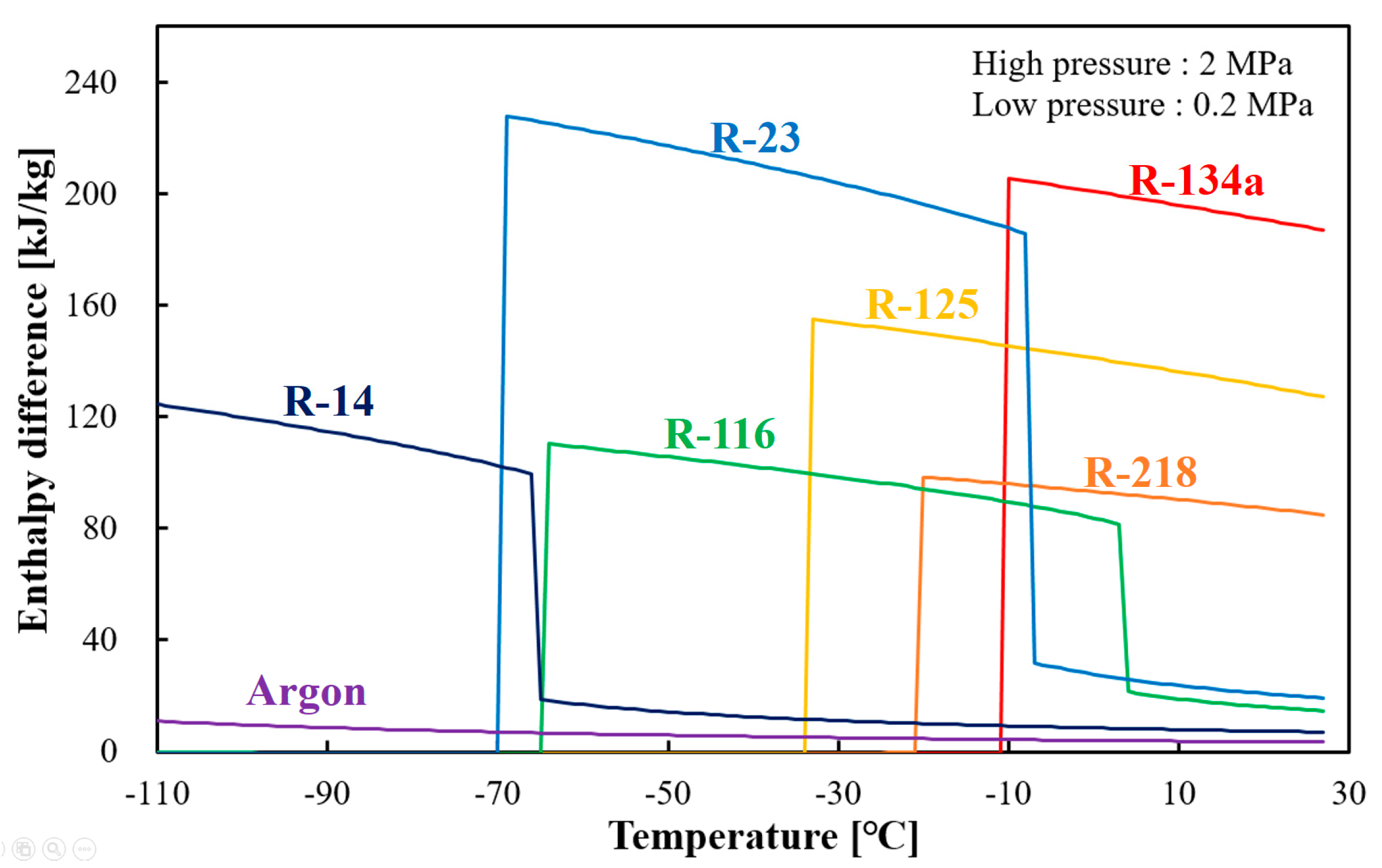

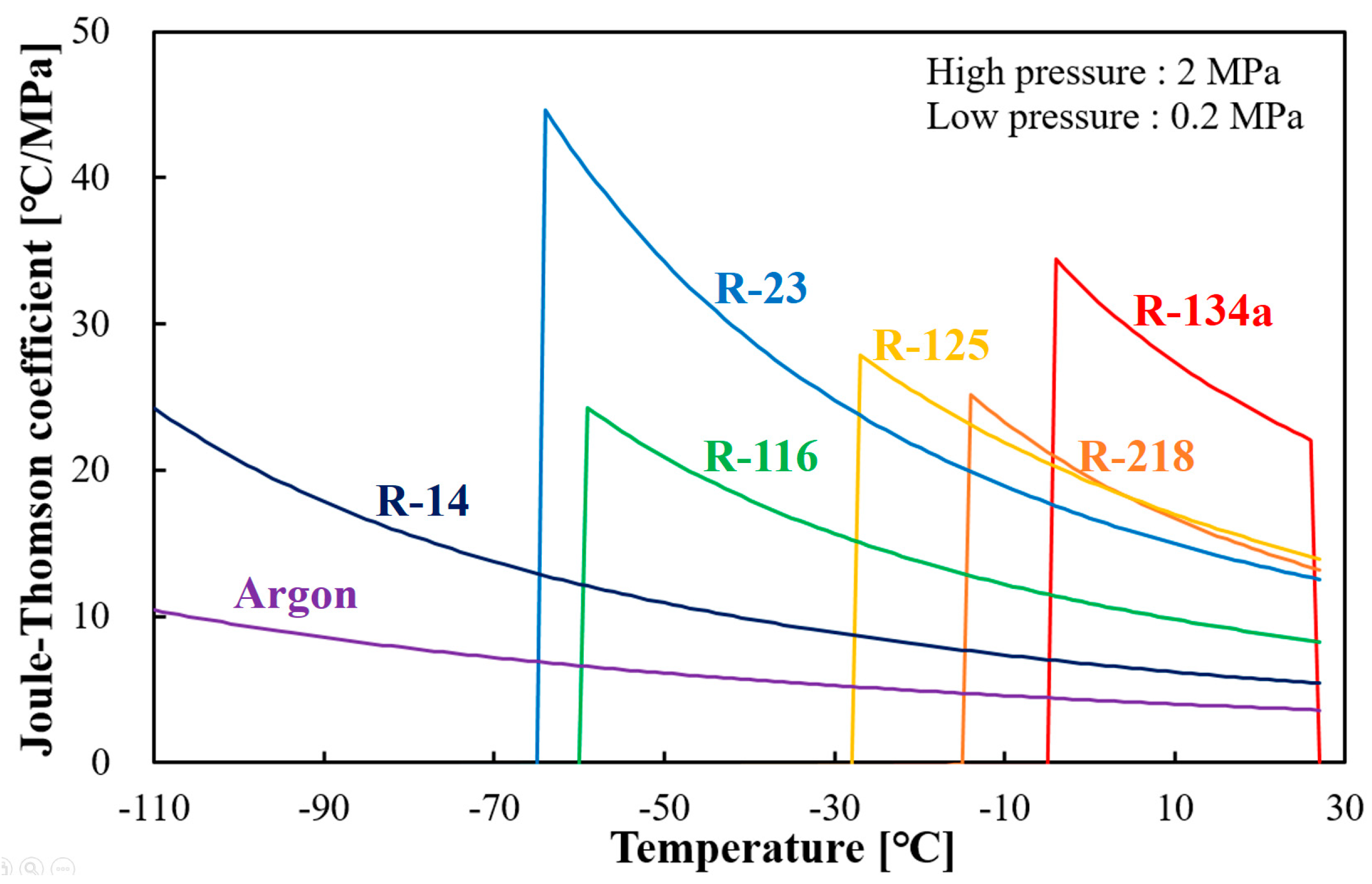

2.2. Working Fluids

2.3. Analysis Conditions

3. Thermodynamic Model

3.1. Energy Balance

3.2. Exergy Balance

4. Results and Discussion

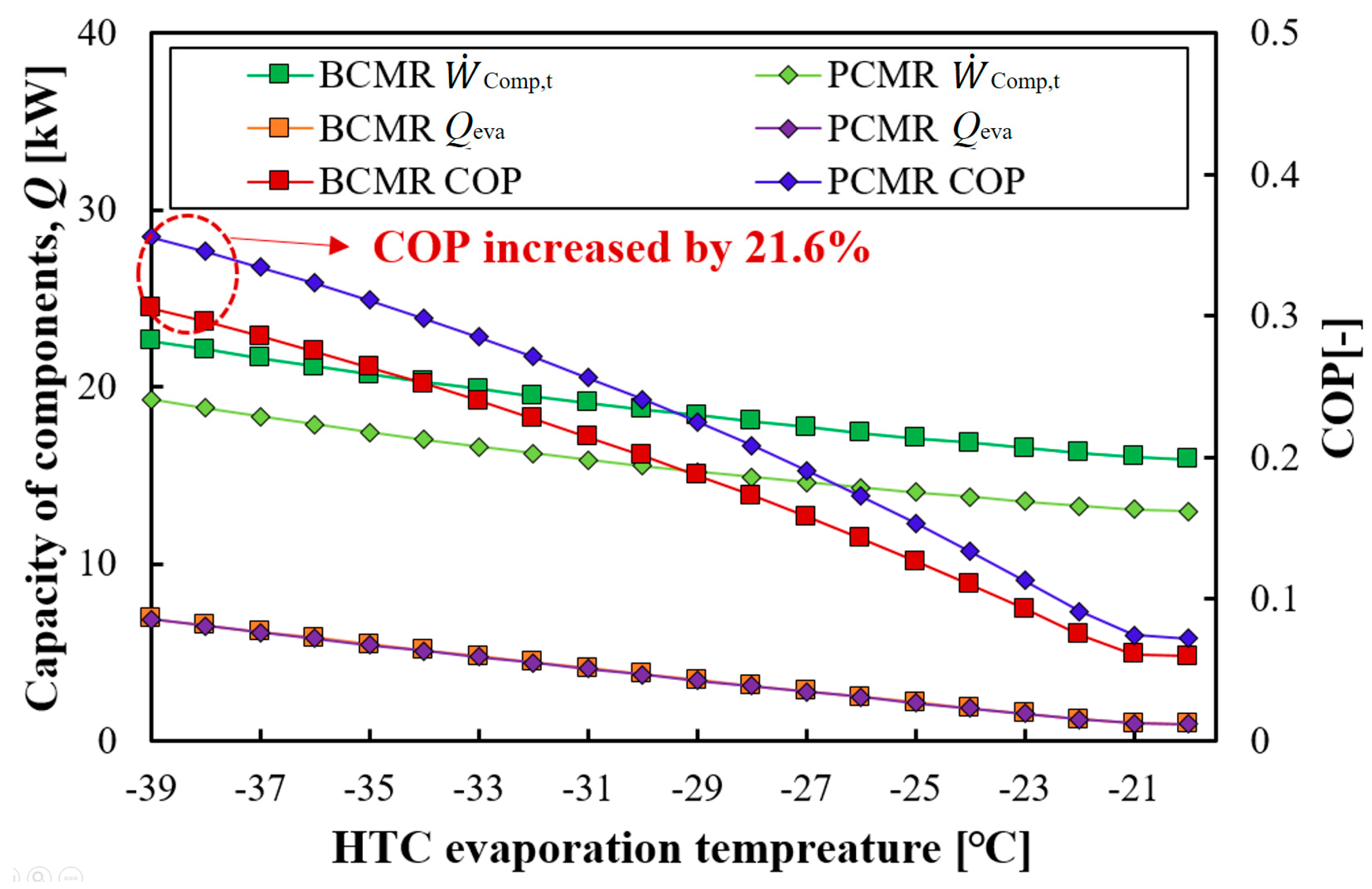

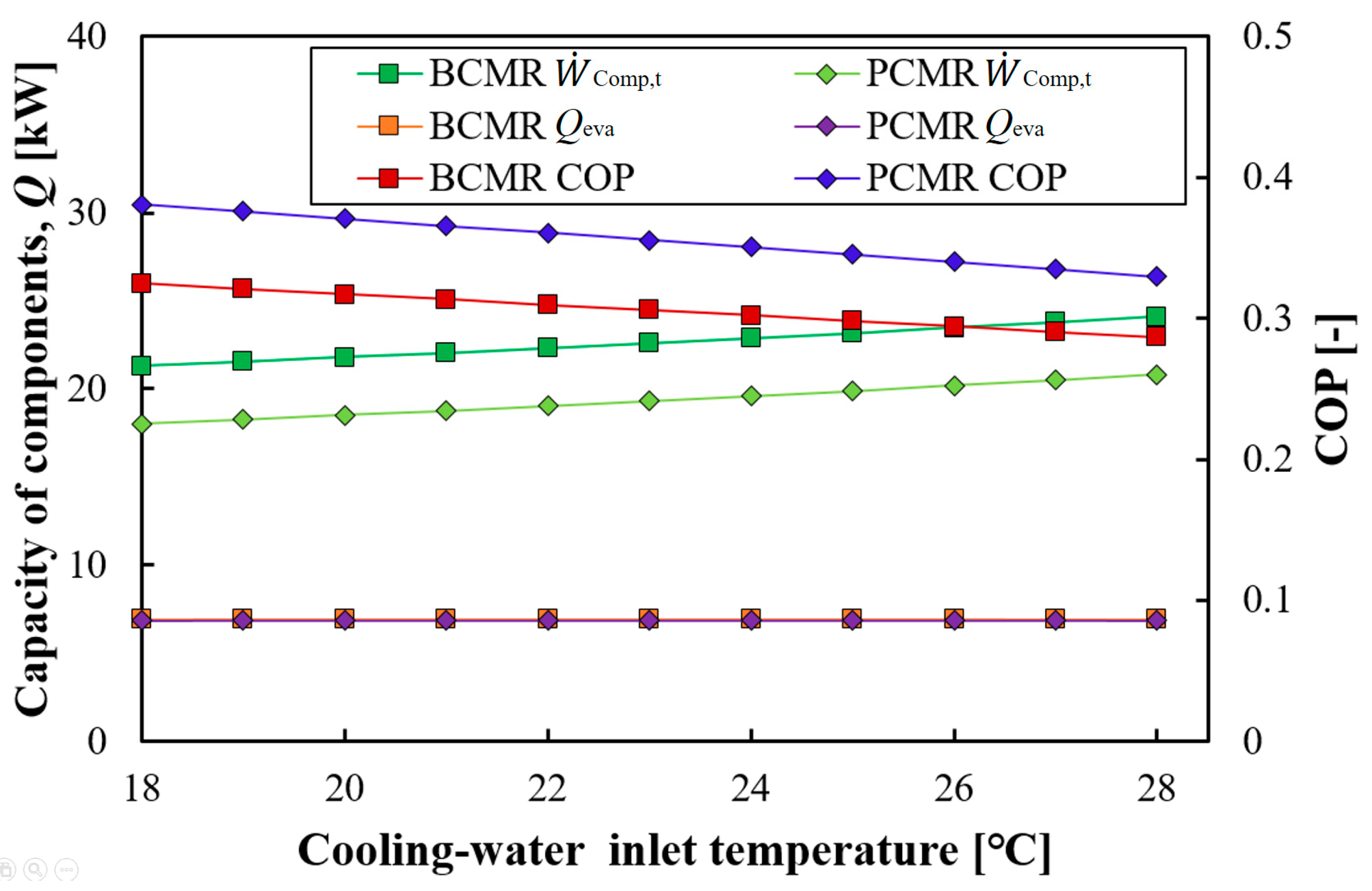

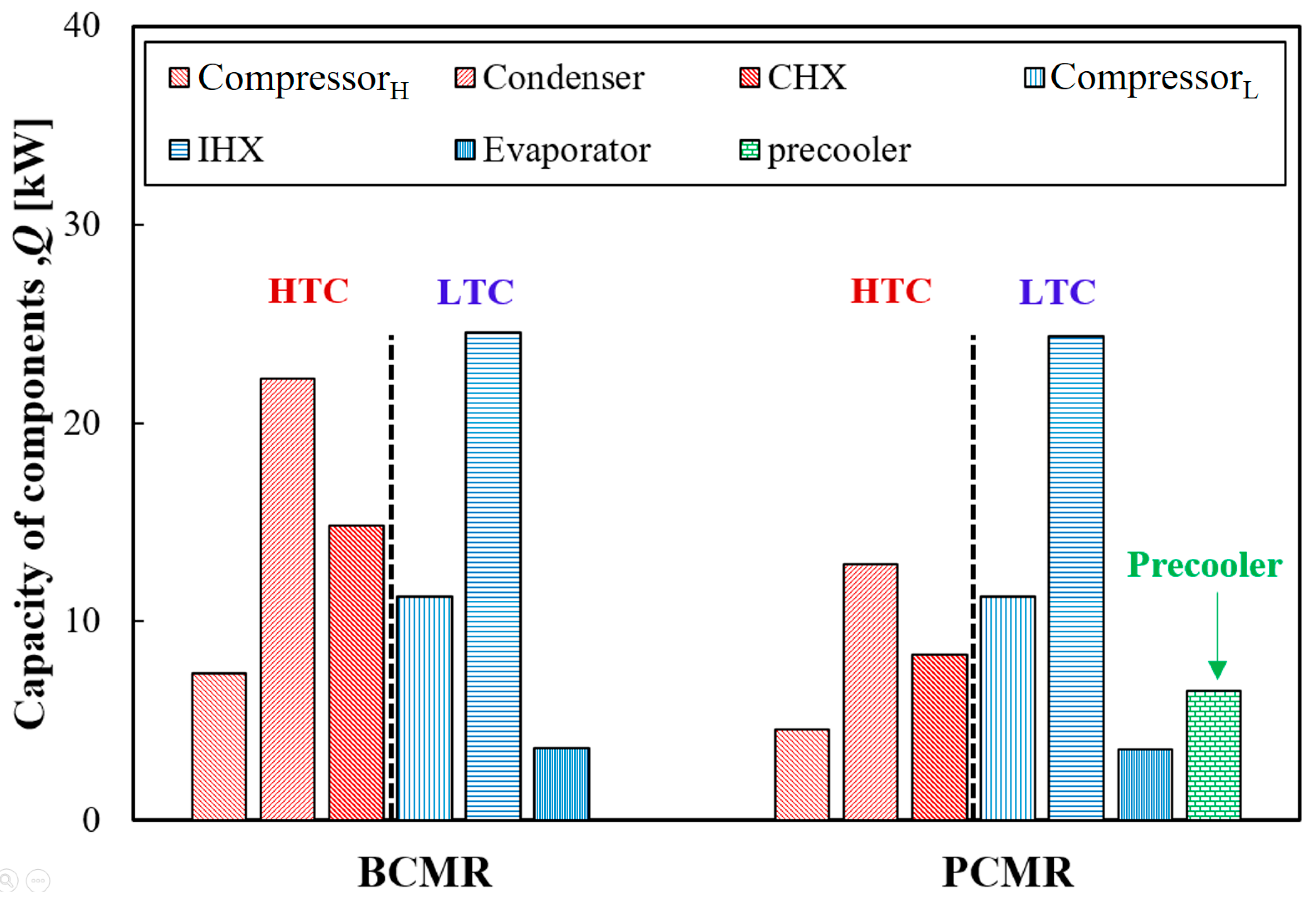

4.1. Energy Analysis of the CMR J–T System

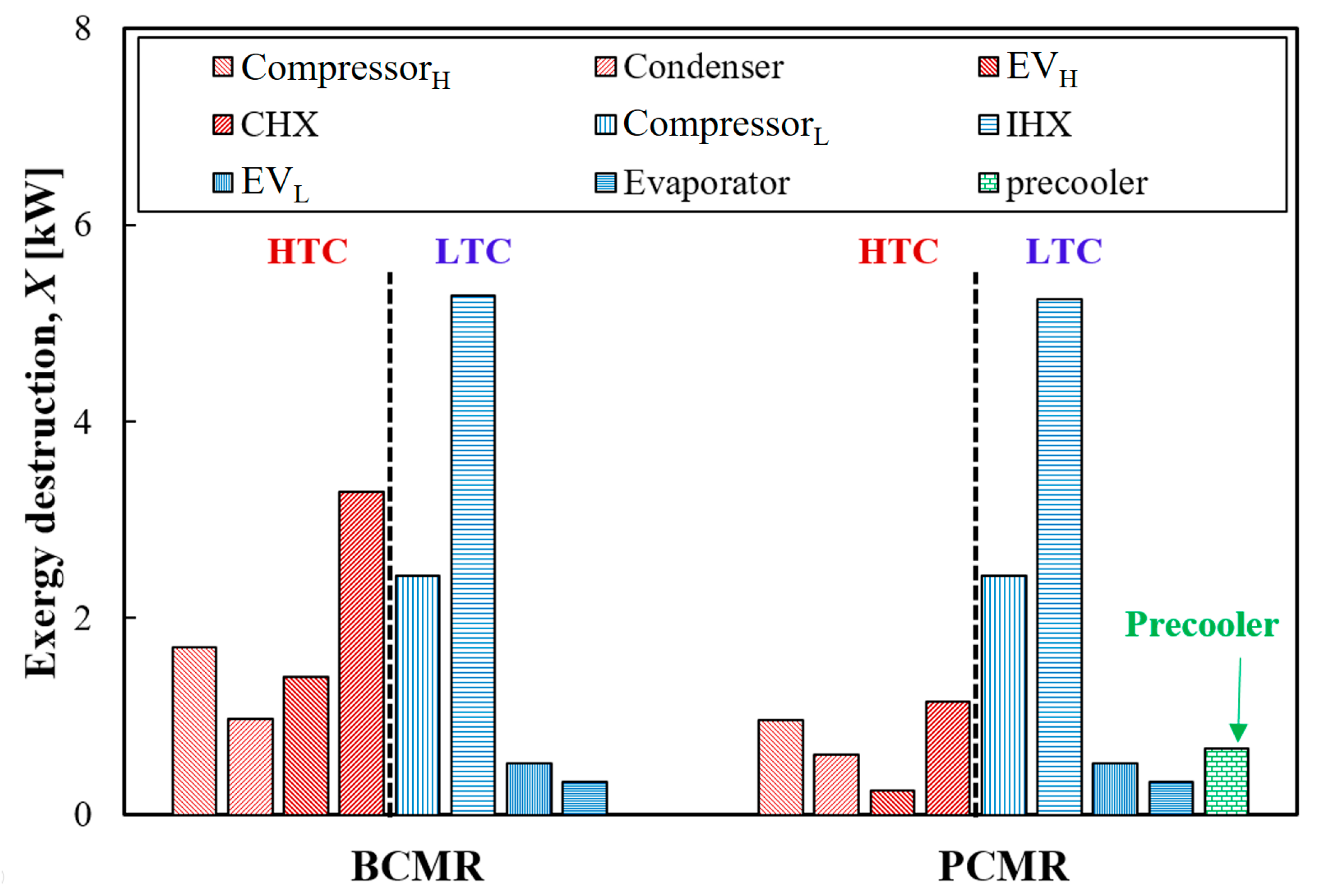

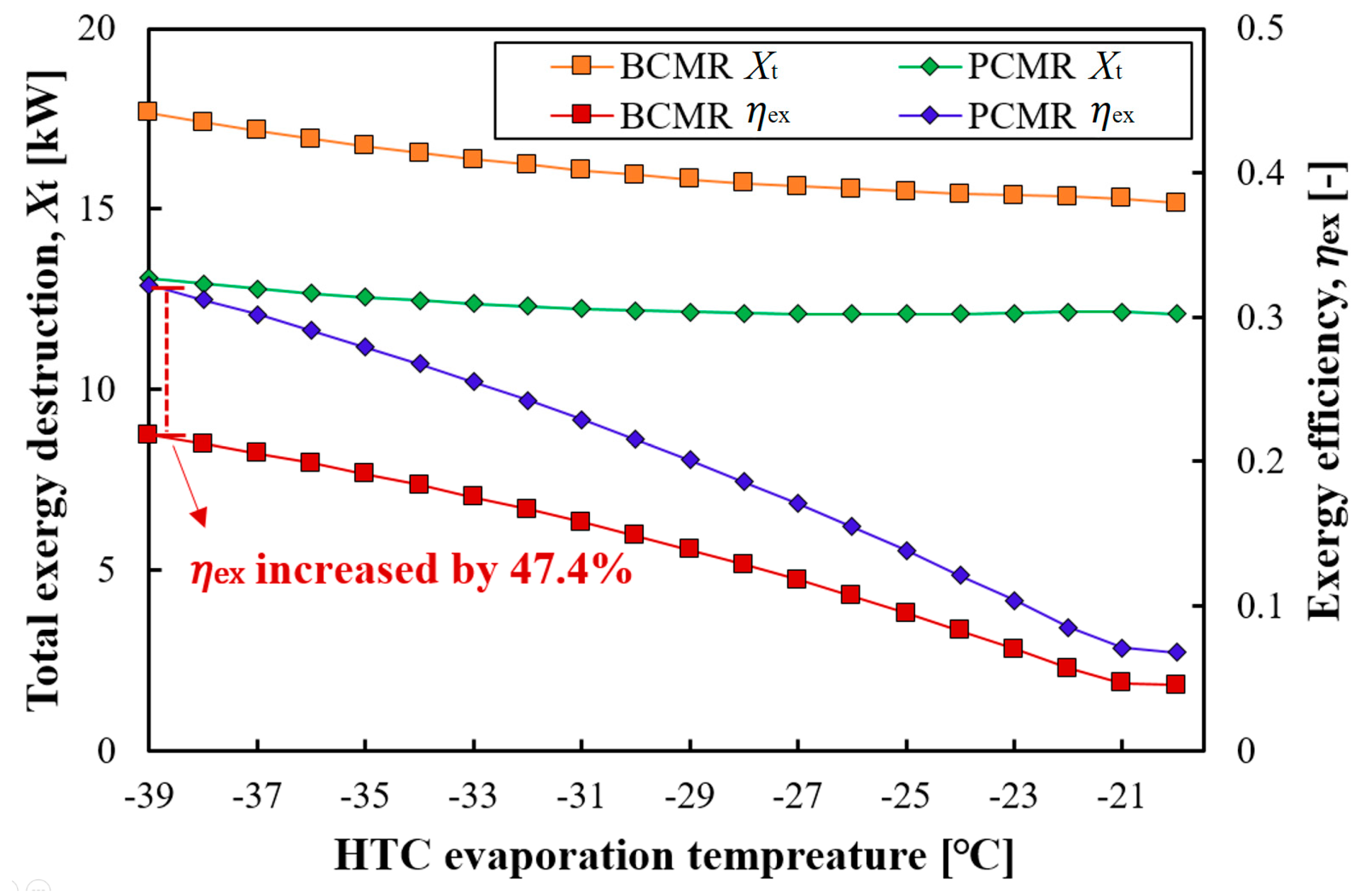

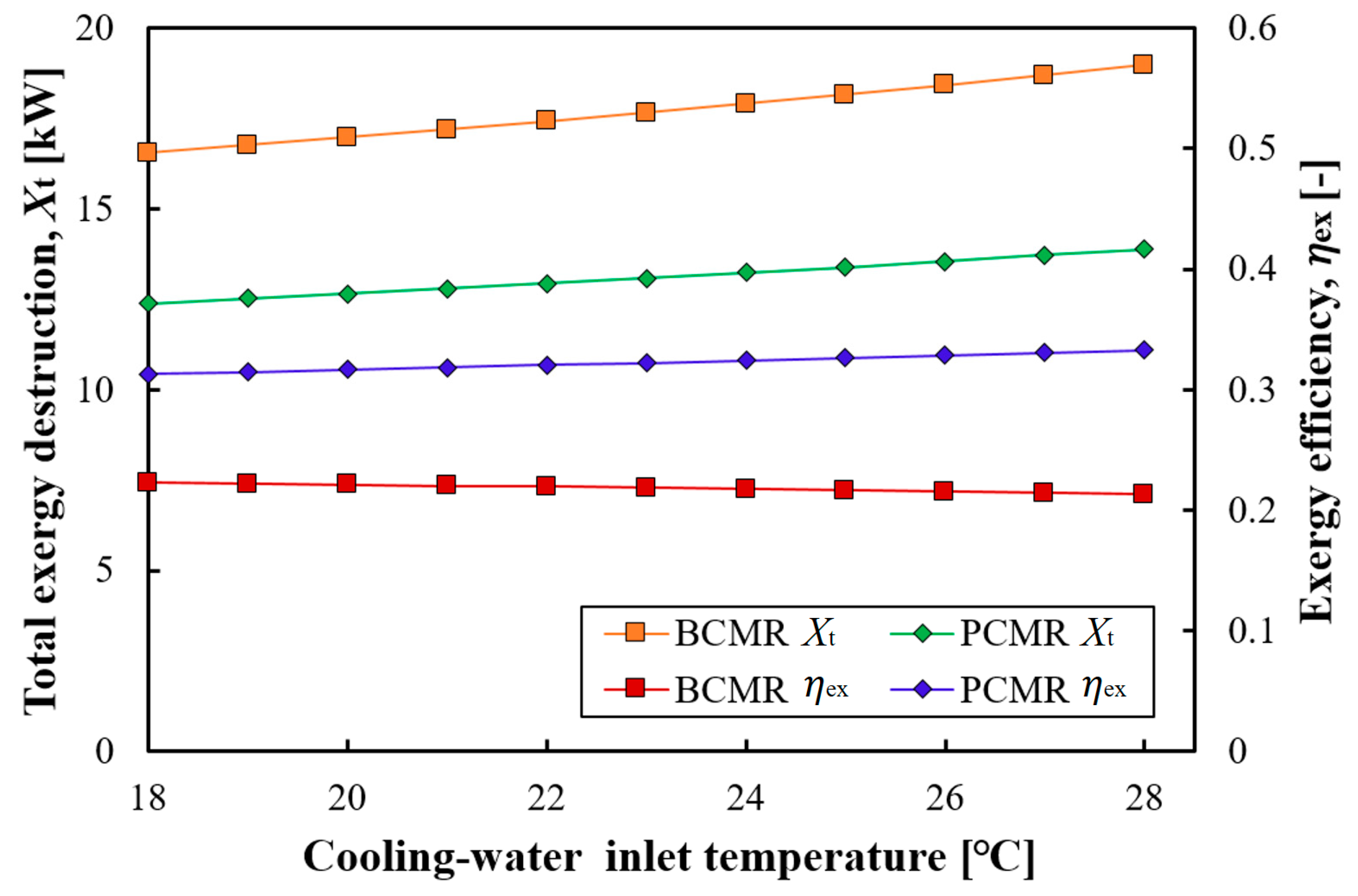

4.2. Exergy Analysis of CMR J–T

5. Conclusions

- The application of the precooler allows for partial handling of the cooling load of LTC, leading to a reduction in the cooling capacity of the HTC and enabling the downsizing of HTC components. Under the conditions considered in this study, the capacity of each component can be reduced by more than 40%. Utilizing this effect, device miniaturization and cost savings are anticipated.

- In CMR J–T systems, variations in the HTC evaporator temperature have a significant impact on the system’s COP. A lower evaporation temperature results in a higher COP, with a maximum increase of 21.6%. The main reason for this is that the previously mentioned non-azeotropic refrigerant undergoes phase changes within a certain pressure range based on temperature, affecting the achievable temperature, i.e., the cooling capacity of CMR J–T.

- Variations in cooling water temperature in CMR J–T systems can result in a 13% and 15% increase in COP for a BCMR and PCMR, respectively, under the specified conditions. A PCMR is more sensitive to these temperature variations because they affect the temperature and capacity that can be handled by the precooler, resulting in changes in the capacity of the CHX and other HTC components.

- From an exergy perspective, the evaporator temperature of HTC also has a significant impact. As the evaporator temperature decreases, there is an increasing trend in exergy destruction. However, exergy efficiency increases, albeit at a lower level compared to the increase in input energy (compressor power). Furthermore, the application of the precooler results in a maximum of 47.4% higher exergy efficiency within the analyzed range.

- An analysis of the variation in cooling water temperature reveals that, from an exergy perspective, the use of a PCMR results in lower exergy destruction and higher exergy efficiency compared to a BCMR. However, when considering energy analysis, lower cooling water temperatures lead to an increase in COP, but exergy efficiency decreases. This discrepancy can be attributed to the fact that the reduction in compressor input power outweighs the decrease in exergy destruction.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| MR: | Mixed refrigerant [-] |

| CMR: | Cascade mixed refrigerant [-] |

| J–T: | Joule–Thomson [-] |

| HTC: | High-temperature cycle [-] |

| LTC: | Low-temperature cycle [-] |

| Q: | Heat capacity [kW] |

| : | Mass flow rate [kg/s] |

| Cp: | Specific heat capacity [kJ/kg∙K] |

| T: | Temperature [K] |

| ΔT: | Temperature difference [K] |

| : | Compressor work [kW] |

| ΔT: | Temperature difference [K] |

| h: | Specific enthalpy [kJ/kg] |

| s: | Specific entropy [kJ/kg∙K] |

| X: | Exergy destruction [-] |

| : | Efficiency [-] |

| Subscripts | |

| Eva: | Evaporator |

| Comp: | Compressor |

| Cond: | Condenser |

| EV: | Expansion valve |

| CHX: | Cascade heat exchanger |

| Pre: | Precooler |

| IHX: | Intermediate heat exchanger |

| CW: | Cooling water |

| P: | Pressure |

| T: | Temperature |

| t: | Total |

| in: | Inlet |

| out: | Outlet |

| H: | High-temperature cycle |

| L: | Low-temperature cycle |

| 0: | Reference state |

| s: | specific entropy |

| ex: | Exergy |

| ave: | Average |

| eff: | Efficiency |

References

- Rodriguez-Criado, J.C.; Expósito-Carrillo, J.A.; Peris Pérez, B.; Dominguez-Muñoz, F. Experimental performance analysis of a packaged R290 refrigeration unit retrofitted with R170 for ultra-low temperature freezing. Int. J. Refrig. 2022, 134, 105–114. [Google Scholar] [CrossRef]

- Liu, Z.; Bai, M.; Tan, H.; Ling, Y.; Cao, Z. Experimental test on the performance of a −80 °C cascade refrigeration unit using refrigerants R290-R170 for COVID-19 vaccines storage. J. Build. Eng. 2023, 63, 105537. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, M.; Gehl, A.; Fricke, B.; Nawaz, K.; Gluesenkamp, K.; Shen, B.; Munk, J.; Hagerman, J.; Lapsa, M. COVID 19 vaccine distribution solution to the last mile challenge: Experimental and simulation studies of ultra-low temperature refrigeration system. Int. J. Refrig. 2022, 133, 313–325. [Google Scholar] [CrossRef] [PubMed]

- Kochunni, S.K.; Chowdhury, K. Use of dual pressure Claude liquefaction cycles for complete and energy-efficient reliquefaction of boil-off gas in LNG carrier ships. Energy 2020, 198, 117345. [Google Scholar] [CrossRef]

- Romero Gómez, J.; Romero Gómez, M.; Lopez Bernal, J.; Baaliña Insua, A. Analysis and efficiency enhancement of a boil-off gas reliquefaction system with cascade cycle on board LNG carriers. Energy Convers. Manag. 2015, 94, 261–274. [Google Scholar] [CrossRef]

- Liu, S.; Bai, T.; Wei, Y.; Yu, J. Performance analysis of a modified ejector-enhanced auto-cascade refrigeration cycle. Energy 2023, 265, 126334. [Google Scholar] [CrossRef]

- Chakravarthy, V.S.; Shah, R.K.; Venkatarathnam, G. A review of refrigeration methods in the temperature range 4–300 K. J. Therm. Sci. Eng. Appl. 2011, 3, 020801. [Google Scholar] [CrossRef]

- Radebaugh, R. Refrigeration for Superconductors. Proc. IEEE 2004, 92, 1719–1734. [Google Scholar] [CrossRef]

- Venkatarathnam, G.; Kumar, P.; Murthy, S. Performance of a Throttle Cycle Refrigerator with Nitrogen-Hydrocarbon and Argon-Hydrocarbon Mixtures. In AIP Conference Proceedings; American Institute of Physics: College Park, MD, USA, 2004; Volume 710. [Google Scholar] [CrossRef]

- Gong, M.Q.; Wu, J.F.; Luo, E.G. Performances of the mixed-gases Joule-Thomson refrigeration cycles for cooling fixed-temperature heat loads. Cryogenics 2004, 44, 847–857. [Google Scholar] [CrossRef]

- Longsworth, R.C.; Boiarski, M.J.; Klusmier, L.A. 80 K Closed-Cycle Throttle Refrigerator BT-Cryocoolers 8; Ross, R.G., Ed.; Springer: Boston, MA, USA, 1995; pp. 537–541. ISBN 978-1-4757-9888-3. [Google Scholar]

- Little, W.A.; Sapozhnikov, I. Development of a Low Cost, Cryogenic Refrigeration System for Cooling of Cryoelectronics BT-Advances in Cryogenic Engineering; Kittel, P., Ed.; Springer: Boston, MA, USA, 1994; pp. 1467–1474. ISBN 978-1-4615-2522-6. [Google Scholar]

- Radebaugh, R. Cryocoolers: The state of the art and recent developments. J. Phys. Condens. Matter 2009, 21, 164219. [Google Scholar] [CrossRef]

- Bychkov, E.G. An analytical method for ensuring the optimal circulating composition of the multicomponent refrigerant mixture in a steady-state operation mode of the Joule-Thomson refrigerator operating with mixtures. Int. J. Refrig. 2021, 130, 356–369. [Google Scholar] [CrossRef]

- Sreenivas, B.; Nayak, H.G.; Venkatarathnam, G. Relationship between composition of mixture charged and that in circulation in an auto refrigerant cascade and a JT refrigerator operating in liquid refrigerant supply mode. Cryogenics 2017, 81, 42–46. [Google Scholar] [CrossRef]

- Rozhentsev, A. Refrigerating machine operating characteristics under various mixed refrigerant mass charges. Int. J. Refrig. 2008, 31, 1145–1155. [Google Scholar] [CrossRef]

- Wang, H.C.; Chen, G.F.; Dong, X.Q.; Zhao, Y.X.; Guo, H.; Gong, M.Q. Performance comparison of single-stage mixed-refrigerant Joule–Thomson cycle and pure-gas reverse Brayton cycle at fixed-temperatures from 80 to 180 K. Int. J. Refrig. 2017, 80, 77–91. [Google Scholar] [CrossRef]

- Bai, T.; Li, D.; Xie, H.; Yan, G.; Yu, J. Experimental research on a Joule-Thomson refrigeration cycle with mixture R170/R290 for −60 °C low-temperature freezer. Appl. Therm. Eng. 2021, 186, 116476. [Google Scholar] [CrossRef]

- Lu, X.; Rui, S.; He, T. Experimental investigation of cycle characteristics of a R23 and R600a based Joule-Thomson refrigerator. Heat Mass Transf. 2019, 55, 1439–1446. [Google Scholar] [CrossRef]

- Jerome, S.; Venkatarathnam, G. Performance of a Linde-Hampson refrigerator operating from −120 °C to −60 °C with optimised R14-hydrocarbon mixtures exhibiting vapour-liquid-liquid equilibria. Heat Mass Transf. 2020, 56, 1523–1535. [Google Scholar] [CrossRef]

- Walimbe, N.S.; Narayankhedkar, K.G.; Atrey, M.D. Experimental investigation on mixed refrigerant Joule–Thomson cryocooler with flammable and non-flammable refrigerant mixtures. Cryogenics 2010, 50, 653–659. [Google Scholar] [CrossRef]

- Podtcherniaev, O.; Boiarski, M.; Lunin, A. Comparative Performance of Two-Stage Cascade and Mixed Refrigerant Systems in a Temperature Range from–100C to–70C. 2002. International Refrigeration and Air Conditioning Conference. Paper 618. Available online: http://docs.lib.purdue.edu/iracc/618 (accessed on 3 September 2023).

- Liu, J.; Liu, Y.; Yu, J.; Yan, G. Thermodynamic analysis of a novel vapor-injection Joule-Thomson refrigeration cycle with a binary hydrocarbon mixture for −86 °C freezer. Appl. Therm. Eng. 2023, 230, 120835. [Google Scholar] [CrossRef]

- Podtcherniaev, O. Performance of throttle-cycle coolers operating with mixed refrigerants designed for industrial applications in a temperature range 110 to 190 K. In AIP Conference Proceedings; AIP: Woodbury, NY, USA, 2002; Volume 613, pp. 863–872. [Google Scholar]

- Pan, M.; Zhao, H.; Liang, D.; Zhu, Y.; Liang, Y.; Bao, G. A review of the cascade refrigeration system. Energies 2020, 13, 2254. [Google Scholar] [CrossRef]

- Yoon, J.-I.; Son, C.-H.; Seol, S.-H.; Yoon, J.-H. Perspective Chapter: Ultra-Low Temperature Chillers for Semiconductor Manufacturing Process; Vizureanu, P., Ed.; IntechOpen: Rijeka, Croatia, 2021; p. Ch. 3. ISBN 978-1-80355-610-9. [Google Scholar]

- Lee, J.; Hwang, G.; Jeong, S.; Park, B.J.; Han, Y.H. Design of high efficiency mixed refrigerant Joule–Thomson refrigerator for cooling HTS cable. Cryogenics 2011, 51, 408–414. [Google Scholar] [CrossRef]

- Almeida-Trasvina, F.; Smith, R. Design and optimisation of novel cascade mixed refrigerant cycles for LNG production–Part I: Benchmark cascade cycles. Chem. Eng. Res. Des. 2023, 190, 619–633. [Google Scholar] [CrossRef]

- Almeida-Trasvina, F.; Smith, R. Design and optimisation of novel cascade mixed refrigerant cycles for LNG production–Part II: Novel cascade configurations. Energy 2023, 266, 126404. [Google Scholar] [CrossRef]

- Lee, K.S.; Yoon, J.I.; Son, C.H.; Lee, J.H.; Moon, C.G.; Yoo, W.J.; Lee, B.C. Performance Characteristics of a Joule–Thomson Refrigeration System with Mixed Refrigerant Composition. Heat Transf. Eng. 2021, 42, 1087–1096. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, Y.; Wang, H.; Gong, M. The effective refrigeration temperature zone expressed by partial molar enthalpy difference of each component in mixed-refrigerant Joule-Thomson refrigerators. Cryogenics 2022, 128, 103590. [Google Scholar] [CrossRef]

- Aspen HYSYS V12; Aspen Technology Inc.: Bedford, MA, USA, 2023.

- Ardhapurkar, P.M.; Atrey, M.D. Performance optimization of a miniature Joule-Thomson cryocooler using numerical model. Cryogenics 2014, 63, 94–101. [Google Scholar] [CrossRef]

- Lakshmi Narasimhan, N.; Venkatarathnam, G. A method for estimating the composition of the mixture to be charged to get the desired composition in circulation in a single stage JT refrigerator operating with mixtures. Cryogenics 2010, 50, 93–101. [Google Scholar] [CrossRef]

- Mota-Babiloni, A.; Navarro-Esbrí, J.; Barragán, Á.; Molés, F.; Peris, B. Theoretical comparison of low GWP alternatives for different refrigeration configurations taking R404A as baseline. Int. J. Refrig. 2014, 44, 81–90. [Google Scholar] [CrossRef]

- Bayrakçi, H.C.; Özgür, A.E. Energy and exergy analysis of vapor compression refrigeration system using pure hydrocarbon refrigerants. Int. J. Energy Res. 2009, 33, 1070–1075. [Google Scholar] [CrossRef]

- Yan, G.; Chen, J.; Yu, J. Energy and exergy analysis of a new ejector enhanced auto-cascade refrigeration cycle. Energy Convers. Manag. 2015, 105, 509–517. [Google Scholar] [CrossRef]

- Yang, M.H.; Yeh, R.H. Performance and exergy destruction analyses of optimal subcooling for vapor-compression refrigeration systems. Int. J. Heat Mass Transf. 2015, 87, 1–10. [Google Scholar] [CrossRef]

| Type | Refrigerant | Normal Boiling Point [°C] | Global Warming Potential | Ozone Depletion Potential | Safety Group |

|---|---|---|---|---|---|

| Hydrofluorocarbon | R-134a | −26.3 | 1430 | 0 | A1 |

| Perfluorocarbon | R-218 | −36.7 | 8830 | 0 | A1 |

| Hydrofluorocarbon | R-125 | −48.5 | 3170 | 0 | A1 |

| Perfluorocarbon | R-116 | −78.2 | 12,200 | 0 | A1 |

| Hydrofluorocarbon | R-23 | −82.1 | 14,800 | 0 | A1 |

| Perfluorocarbon | R-14 | −127.8 | 7390 | 0 | A1 |

| - | Argon | −185.85 | 0 | 0 | A1 |

| Design Parameter | Values | |

|---|---|---|

| Cooling water | Supply temperature | 18~28 °C |

| Flow rate | 1 kg/s | |

| HTC | Condensation temperature | Δ10 (from cooling-water inlet temperature) °C |

| Evaporator inlet temperature | −39~−20 °C | |

| Superheat and subcool temperatures | 5 °C | |

| Working fluid | R-404A | |

| LTC | Precooler outlet temperature | Δ3 (from cooling-water inlet temperature) °C |

| Evaporator temperature | −110 °C | |

| IHX minimum approach | 4.829 °C | |

| Discharge pressure | 2 MPa | |

| Suction pressure | 0.2 MPa | |

| Compressor work | 11.25 kW | |

| Working fluid | Mixed refrigerants (R-218, R-23, R-14, Ar) | |

| Heat exchanger | Pressure drop in heat exchanger (refrigerant side/water side) | 30/20 kPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yoon, J.-H.; Yoon, J.-I.; Son, C.-H.; Seol, S.-H. Energy and Exergy Analysis of Cascade Mixed Refrigerant Joule–Thomson System with the Application of a Precooler. Energies 2023, 16, 6991. https://doi.org/10.3390/en16196991

Yoon J-H, Yoon J-I, Son C-H, Seol S-H. Energy and Exergy Analysis of Cascade Mixed Refrigerant Joule–Thomson System with the Application of a Precooler. Energies. 2023; 16(19):6991. https://doi.org/10.3390/en16196991

Chicago/Turabian StyleYoon, Ji-Hoon, Jung-In Yoon, Chang-Hyo Son, and Sung-Hoon Seol. 2023. "Energy and Exergy Analysis of Cascade Mixed Refrigerant Joule–Thomson System with the Application of a Precooler" Energies 16, no. 19: 6991. https://doi.org/10.3390/en16196991

APA StyleYoon, J.-H., Yoon, J.-I., Son, C.-H., & Seol, S.-H. (2023). Energy and Exergy Analysis of Cascade Mixed Refrigerant Joule–Thomson System with the Application of a Precooler. Energies, 16(19), 6991. https://doi.org/10.3390/en16196991