1. Introduction

There has been considerable attention in recent years towards environmental concerns from both the academia and industry ([

1,

2,

3,

4]). These concerns have given birth to pressures emanating from the global competitive markets, while environmental regulations as well as customers are forcing firms worldwide to thoroughly think about the environmental footprints arising from their business operations. Therefore, industries have since embarked on a journey to reduce their environmental impacts through the adoption of newer business and management paradigms instead of their traditional practices [

5].

GSCM is a management paradigm that incorporates “green” philosophy in manufacturing, distribution, procurement and logistics [

6]. GSCM involves a set of managerial activities that firms adapt to in order to reduce pollution and energy consumption in an effort to attain sustainability. Arguably, competitive advantage is achieved due to the implementation of these practices [

7]. In other words, GSCM buttresses on the integration of environmental aspects into different facets of supply chain management [

8].

GSCM practices (GSCMPs) are a group of activities or actions that lead to the implementation of GSCM, which is characterized by reduction of environmental deterioration and pollution while improving performance, leading to customer and stakeholder satisfaction [

2]. Through a critical review of the literature, Ref. [

5] have found that internal environmental management, investment recovery, green procurement, cooperation with customers, reverse logistics, eco-design, and the design of packaging are the most important GSCM practices mentioned by researchers.

Furthermore, the development and adoption of digital technologies have since become a trendy area of discussion in the academia as well as the industry with the Industry 4.0 (I 4.0), or the fourth industrial revolution, facilitating digital transformation that is continuously gaining attention from industrialists and governments [

9,

10,

11]. One of the merits of I 4.0 technologies is making manufacturing systems and operations efficient, sustainable and autonomous while building a smart system that integrates digital technologies and physical objects [

12]. With the help of I 4.0, supply chain processes can efficiently and effectively be managed by making real-time data available in the presence of intelligent systems and devices [

9].

That is why researchers were found in the extant literature to have exhibited interest in researching on the ways in which different digital technologies like I 4.0 could be used as tools for achieving efficiency in terms of manufacturing and engineering management. For example, Ref. [

13] reviewed literature and in an indirect coverage of the GSCM looked at the role of I 4.0 in enhancing LARG (Lean, Agile, Resilient and Green) manufacturing, Ref. [

14] focused on the role of machine learning in GSCM and Ref. [

15] studied the role of Big Data Analytics in terms of linking GSCMP and competitiveness during COVID-19.

In recent times, the world is gradually seen to resort to renewable energy (RE) sources as the most effective alternatives to fossil fuels while trying to solve the global energy security challenges, but a major challenge also arises in the RE systems selection as the RE technologies arguably face sustainability challenges [

16]. That is why this research aims to review the literature on these challenges within the renewable energy sector (RES) and critically discusses an I 4.0 powered GSCM to tackling such problems.

Renewable sources of energy are the sources in which clean energy is naturally regenerated directly from the sun in the form of thermal, photochemical and photoelectric energies, or through wind, hydropower and biomass [

17], or through other environmental mechanisms and natural movements [

18]. In other words, RE sources could be referred to as domestic resources that provide energy with little or no emissions in terms of greenhouse gases or pollutants [

19].

Different researchers have studied the combination of supply chain management with different aspects of digitalisation and, in the course of that, various terminologies have been developed [

20]. For instance, Smart GSCM [

20], the fourth industrial revolution of supply chains or supply chain 4.0 [

21,

22], digitally enabled sustainable supply chains [

23], and I 4.0-enabled sustainable supply chain [

24] were used among others. Despite these efforts by scholars, the smartness of supply chains and sustainability have been studied disjointedly in recent years and, to this end, there is no consensus among scholars with regard to a framework of integrating smart supply chains with sustainability [

25].

Based on the reviewed literature, no review paper was found that focused on a combined construct of GSCM and I 4.0 to tackle sustainability and supply chain problems in the RES.

Therefore, the current research is aimed at systematically reviewing the literature on GSCM, I 4.0 and RES. In other words, the objectives of this research are to ascertain state-of-the-art practices in GSCM literature in order to review the literature about GSCM and the I 4.0 combined construct while highlighting assertions made by researchers with regard to the role of I 4.0 technologies in the adoption and successful implementation of GSCM. Moreover, this research is aimed at highlighting the RE supply chain challenges and the role of I 4.0-powered GSCM in tackling such challenges. Furthermore, the extant literature presents GSCMP unsystematically, generally without proper categorization of what GSCMP falls in what category for easier mapping of these practices, thereby enhancing adoption in a smoother manner. The current study therefore works on filling that gap by categorizing these GSCMP based on where they fall in a given value chain.

The rest of this article is structured as follows:

Section 2 provides background on GSCM, I 4.0 and RES,

Section 3 highlights the methodology of systematic literature review followed in this article,

Section 4 presents results and analysis, and

Section 5 presents the conclusion and future research directions.

2. Green Supply Chain Management, Industry 4.0 and the Renewable Energy Sector: Background

In the early 1990s, the concept of GSCM was first introduced [

26], although it only became popular around the 2000s as evidenced by surging empirical publications ([

27,

28]). GSCM is among the numerous concepts of sustainability and sustainable practices; GSCM encapsulates the entire activities of delivering products and services from raw materials to disposal or end of life [

29]. GSCM is a fundamental derivative of supply chain management, which is linked to strategically integrating environmental considerations through the implementation of a set of environmental practices, such as green design, green manufacturing, reverse logistics, waste management, green operations, among others, across the supply chain in an effort to minimize adverse environmental footprints [

30].

It has been asserted by [

6] that GSCM, which involves the integration of green philosophy into manufacturing, procurement, distribution and reverse logistics, arguably enhances environmental performance and sustainability of firms. According to [

31], GSCM increases companies’ competitive advantage and economic performance. They added that enhanced reputation, efficiency, effectiveness and revenue growth can also be achieved as a result of successful GSCMP implementation. This assertion by [

32] holds an overly positivist view towards GSCM, while [

33] refute what they call the fallacy of profitable GSCM and added that GSCM might present a trade-off when it comes to the nexus between economic performance and GSCM.

I 4.0 encapsulates different intelligent and innovative technologies like the Internet of things (IoT), cloud computing and big data analytics, which collectively facilitate seamless connectivity, communication and automation. Also, these technologies are useful in terms of data collection and information sharing across supply chains with regard to material quality, product life cycle and operations [

9]. Furthermore, Ref. [

12] asserted that I 4.0 technologies possess an embedded capability of drastically reducing set-up times, labour and material costs, and lead times, which can also increase design and production flexibility, thereby enhancing customization and productivity. In a different research, it was found that big data analytics, which is one of the I 4.0 technologies, could allow firms to make successful and informed decisions on green operations across supply chains [

34].

The generic notion behind I 4.0 is that of the fourth industrial revolution brought about by the recent rapid technological advancements. Ref. [

10] asserted that I 4.0 embeds computerisation and interconnection into the traditional mainstream industry. The authors added that the main objectives of I 4.0 are centred around providing IT-enabled mass customization of manufactured products to enable the efficient tracking of parts and products, to facilitate the flexible adaptation and automation of production process, to enable effective communication among components, parts and machines, and to bring to the fore new types of business models and services for interaction along value chains. To buttress on the effectiveness of I 4.0 technologies, Ref. [

35] asserted that a survey of 300 leading companies in Southeast Asia showed that nine out of ten respondents believed in the effectiveness of I 4.0 technologies.

Green government and institutional policies, among many other reasons, have brought about a boost in RES with the global production and installed capacity of RE technologies continuing to spread worldwide in a substantially increasing manner [

36]. Therefore, this research covers the interaction between GSCM, I 4.0 and the RES. In other words, this research work studies the literature on I 4.0 powered GSCM to tackle sustainability- and supply chain-related problems within the RES.

Figure 1 depicts the interaction between the different constructs.

3. Methodology

In this section, the methodology used in this literature review is described. The seven-step methodology adopted from [

37] was chosen. The latter was selected due to its robustness and rigour in terms of filtering research resources so also its elaboratively comprehensive nature.

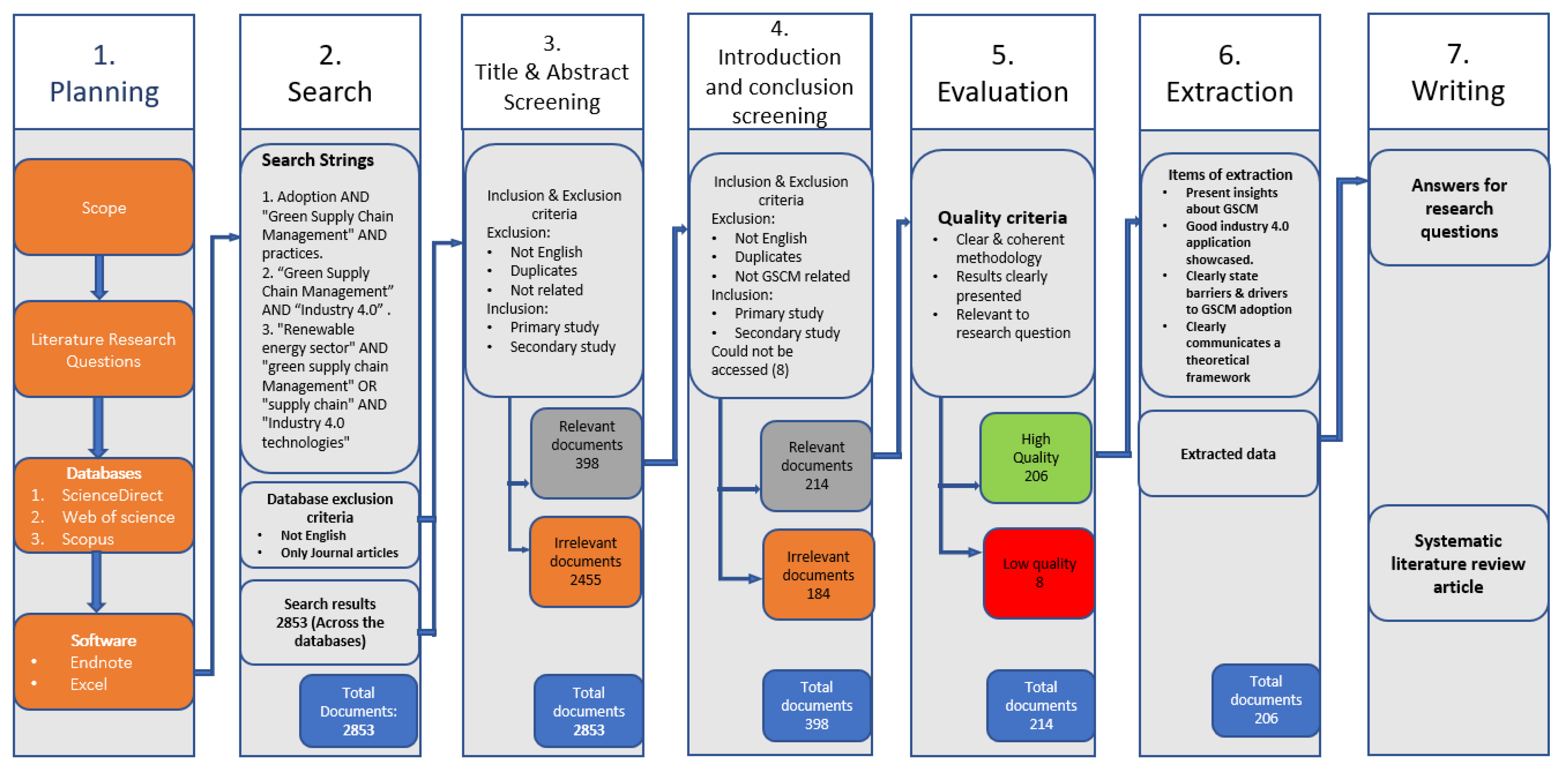

Figure 2 shows the steps involved and explains the steps taken in each stage.

3.1. Step 1 (Planning)

The initial stage is aimed at determining the constructs, which this literature review covers. Therefore, this study is scoped to focus on the combined constructs of GSCM and I 4.0. Interestingly, despite the fact that the literature on GSCM is growing exponentially [

5], the answers to the following research questions this paper aims to answer are scarce. The following questions were coined for this systematic literature review:

Q1. What are the current state of the art practices in the GSCM literature?

The goal of this question is to ascertain the GSCMP found by researchers in different areas of focus and industries.

Q2. What is the role of I 4.0 technologies in the adoption of GSCMP?

The goal of this question is to examine the level of application of industry 4.0 technologies in driving the adoption of GSCM. So also, to ascertain the facets of I 4.0 that can be applied in what strata of Green Supply Chains.

Q3. What are the sustainability and supply chain related problems within the RES?

This is aimed at obtaining sustainability and supply chain related problems within the literature reviewed.

Q4. How can the combination of GSCMP and I 4.0 solve supply chain related problems in the RES?

The aim of this question is to ascertain the supply chain- and sustainability-related issues in the RE supply chain, and the ways in which I 4.0-powered GSCM will tackle these challenges.

ScienceDirect, Web of Science and Scopus were the databases identified for search purposes, and they were particularly chosen because of their wide coverage of articles. Microsoft Excel was used as the data extraction tool where a literature matrix was created. Endnote was used as the reference management software because of its versatility and unique features.

3.2. Step 2 (Search)

To conduct the literature search on the databases identified in Step 1, a set of search strings was designed after a prior literature search and consultation with a senior librarian in order to obtain robust search strings that are representative of the research questions. Each of the three strings mentioned below were searched independently in each of the three databases identified above;

Adoption AND “Green Supply Chain Management” AND practices

“Green Supply Chain Management” AND “Industry 4.0”

“Renewable energy sector” AND “green supply chain Management” OR “supply chain” AND “Industry 4.0 technologies”

The search was conducted on 09/11/2022 and on 04/03/2023. Another search of search string 3 (enhanced: (“Renewable energy”) AND (“green supply chain”) AND (“Industry 4.0” OR “Digital technologies”) above was conducted on 22 September 2023 to make sure no valuable resources are left behind and to obtain up-to-date results. Nine (9) additional articles were obtained and reviewed alongside the initial 206, totalling 215. The search was carried out to look for relevant results that contain the elements of the search strings in their titles, abstracts and keywords. The exclusion criteria applied at this stage were:

Not in English

Only journal articles

3.3. Step 3 (Title and Abstract Screening)

At this stage, the results were imported into the reference management software (Endnote 20 Desktop) where duplicates were removed and the eligibility of papers was decided by screening and glancing through their titles and abstracts. Due to the high number of initial search results, it is practically impossible to read every article fully to decide on its inclusion, so filtration stages have to be in place, which is why we conducted our search in this way.

3.4. Step 4 (Introduction and Conclusion Screening)

After the title and abstract screening, a more in-depth reading was performed at this stage to reliably decide the suitability of resources for the systematic literature review. This stage is guided by inclusion and exclusion criteria, which include language clarity and relevance to the major constructs the research covers.

3.5. Step 5 (Evaluation)

More rigorous reading was performed here to finally decide on the quality of resources to work with. The following quality criteria were set:

- -

Clarity of methodology

- -

Results are discussed succinctly

- -

The resource is relevant to the research questions.

3.6. Step 6 (Extraction)

A thorough reading was carried out to extract answers to the identified research questions. Microsoft Excel was used to generate a literature matrix that served as the repository of all relevant data extracted from the resources used. Information relevant to research questions were appended to the matrix, as they appear in the article against each article’s title on the same row. These gathered assertions by different researchers were extracted, synthesized and presented in this paper.

5. Discussion

Based on this review, the following are the main findings: first, state-of-the-art GSCMP were obtained. Although, there is no consensus among researchers on an agreed upon framework of GSCMP that encapsulates business function peculiarities, sector and value chain specific GSCMP, this study has elaboratively categorized GSCMP based on business functions and where the practices fall in a given value chain. With regard to GSCMP adoption, this categorization presents a simplistic streamlined guide for managers and policy makers on mapping out how and what business functions should comply with sustainable practices within their organisations.

Second, this research has identified the role of I 4.0 technologies in GSCM adoption and carefully synthesized how I 4.0 goes hand in hand with GSCM by increasing effectiveness and efficiency of executing GSCMP. Furthermore, the major I 4.0 technologies were identified and their applicability in business contexts were highlighted with the citations of relevant use cases that practically depict the significance of the incorporation of the disruptive technologies with GSCM. This serves as a guide towards leveraging such technologies for more sustainable and efficient business functions.

Third, this review covered an overview of sustainability and supply chain-related challenges in the RES, which are found to be existent along the RES supply chains from upstream to downstream. Also, the literature has been reviewed on the I 4.0-GSCM makeup to tackle the identified challenges. A lot of the challenges for instance have to do with the procurement and sourcing of raw materials for the fact that most of the latter are sourced from conflict locations with high-risk factors bordering around issues of slavery and child labour, among others. It was succinctly portrayed that an I 4.0-powered GSCM will provide a traceability and transparency-enabled sustainable supply chain that has reduced risk factors. Other challenges identified are operational and end-of-life management-related challenges.

The outcome of this literature review provides an insight for researchers and industry practitioners on a wide range of GSCM practices that are implementable in different business functions, and I 4.0 technologies and their use cases in terms of achieving sustainability by leveraging such disruptive technologies to enhance the adoption GSCM, thereby achieving corporate sustainability in the RES. Moreover, the role of the proposed I 4.0-powered GSCM in tackling sustainability and supply chain-related issues, most especially in the RES, were critically discussed. In a nutshell, this work would provide managers with the wherewithal of GSCM implementation and I 4.0 integration with GSCM to achieve robust business problem solving. The current research also presents, for policy makers and managers within the RES, an overview of the I 4.0-GSCM approach to tackling numerous sustainability and supply chain issues within the RES.

6. Conclusions and Future Research

Main contributions of this article are based on its findings in response to the aim ad objectives of this review. This study aimed at systematically reviewing the literature on GSCM, I 4.0 and RES. The objectives of this research were to ascertain state-of-the-art practices in GSCM literature in order to review the literature about GSCM and the I 4.0-combined construct while highlighting assertions made by researchers with regard to the role of I 4.0 technologies in the adoption and successful implementation of GSCM. Moreover, this research aimed at highlighting the RE supply chain challenges and the role of I 4.0-powered GSCM in tackling such challenges.

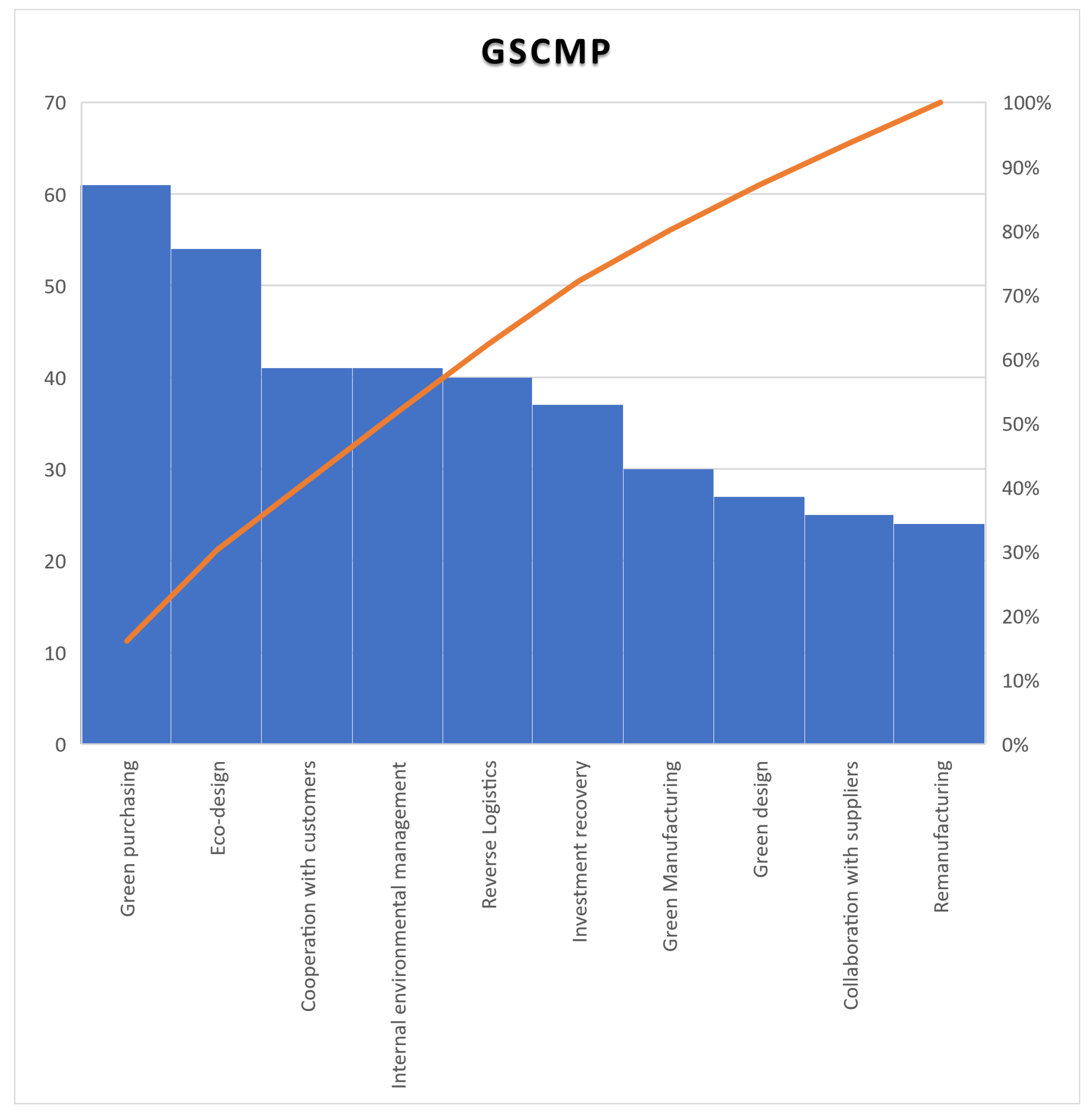

A total of 215 systematically selected empirical and review research papers were reviewed in this study to obtain an up-to-date knowledge about GSCM and the I 4.0-combined construct. In line with the first objective of this research (Q1), different state-of-the-art GSCM practices in various areas of focus, countries and industries were obtained, and these practices were identified and categorized as being related to manufacturing, corporate relationship, procurement and sourcing, product design, logistics and transportation, waste and pollution management and organisational culture or strategy. We found that the ten most important GSCMPs mentioned by researchers are Green purchasing, Eco-design, Cooperation with customers, Internal Environmental Management, Reverse logistics, Investment recovery, Green manufacturing, Green design, Collaboration with suppliers and Remanufacturing.

In line with the second objective (Q2) of this literature review, the studies on the combined constructs of GSCM and I 4.0 technologies were identified and discussed. According to the findings of this literature review, there are limited studies conducted on the combined construct of I 4.0 and GSCM, specifically on the role and application of I 4.0 technologies in the implementation of GSCM. To fulfil the third objective (Q3) of this study, supply chain- and sustainability-related challenges in the RE sector were identified, and based on the fourth objective (Q4), a critical discussion around solving them using Industry 4.0-GSCM integration was presented.

Future research work may be focussed on developing models of I 4.0-powered GSCMP implementation that succinctly identify sector-by-sector implementation roadmaps. This can be best achieved through studies that empirically develop the I 4.0-powered GSCMP framework and test that for a practical appraisal by industrial actors. Further studies on the combined construct of I 4.0 and GSCM are also needed because the extant literature provides scant studies in this regard. Significantly, research communities should work towards building comprehensive models of GSCMP, as there is no consensus among researchers on what constitutes GSCMP. In other words, there is a need for a unanimous categorization of GSCMP according to industry type and sector, so empirical studies on larger scales can be conducted.