Research on Transformation of Connate Water to Movable Water in Water-Bearing Tight Gas Reservoirs

Abstract

:1. Introduction

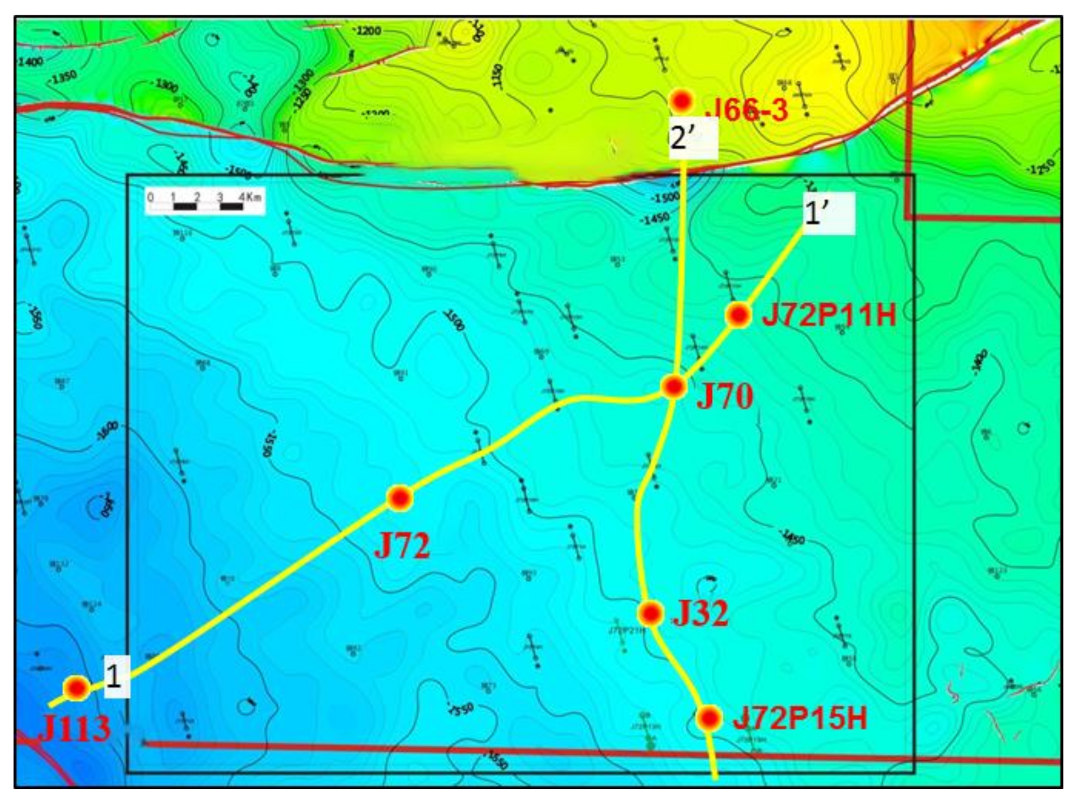

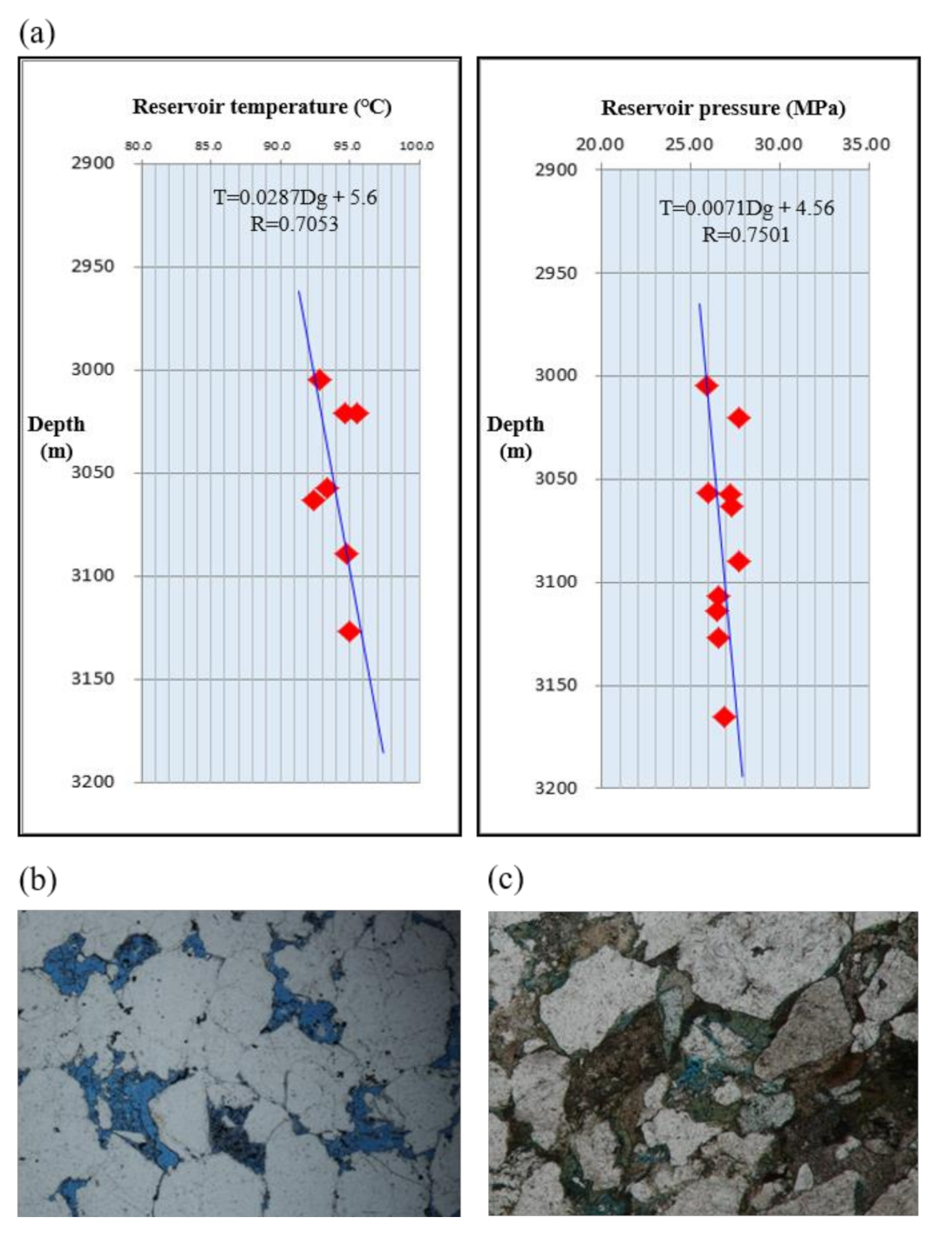

2. Overview of Study Area

2.1. Geological Characteristics

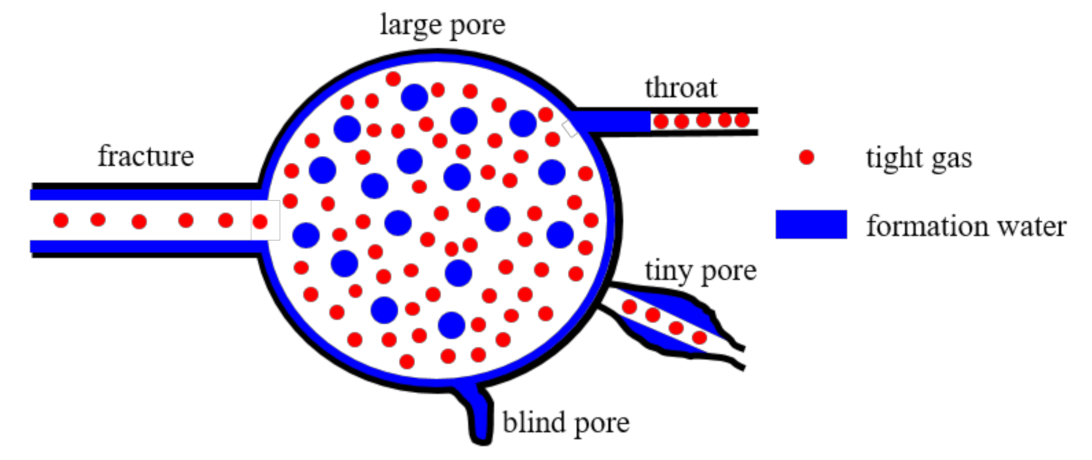

2.2. Pore-Throat Characteristics

2.3. Formation Water Occurrence Characteristics

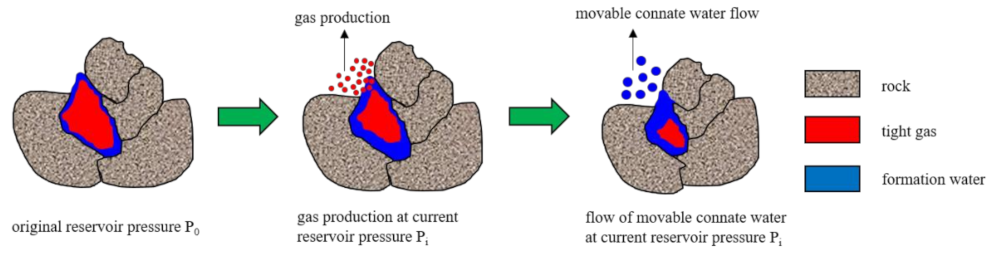

3. Transformation Mechanism of Connate Water to Movable Water

3.1. Transformation Mechanism

3.2. Theoretical Analysis

3.2.1. Model Assumptions

3.2.2. Change of Water Saturation during the Depressurization Process

3.2.3. Evaluation of the Connate Water Transition to Movable Water

4. Experimental Methodology

4.1. Formation Water Expansion Tests

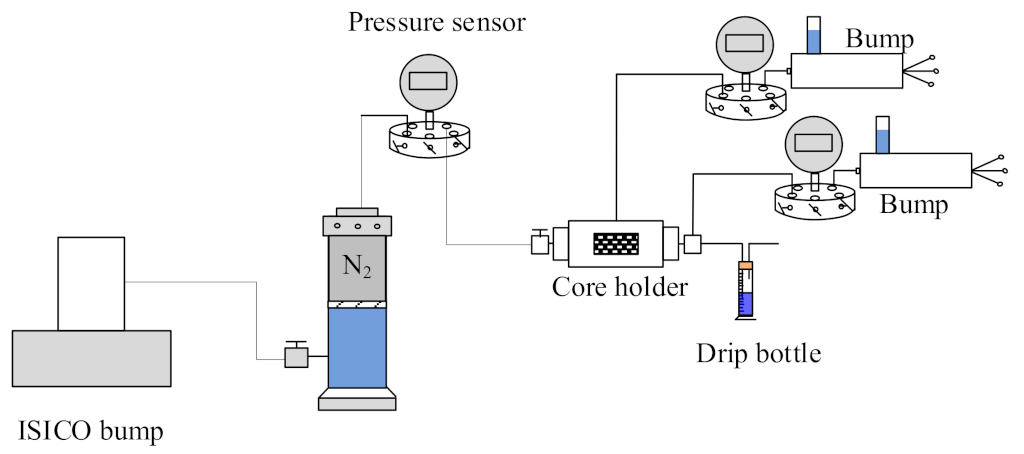

4.2. Connate Water Tests

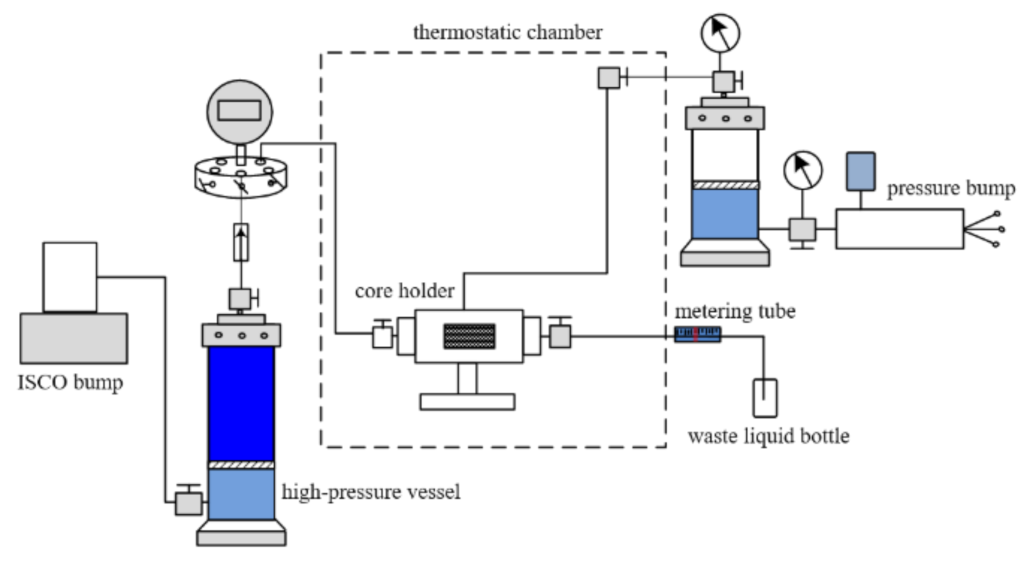

4.3. Porosity Stress Sensitivity Tests

5. Results and Discussion

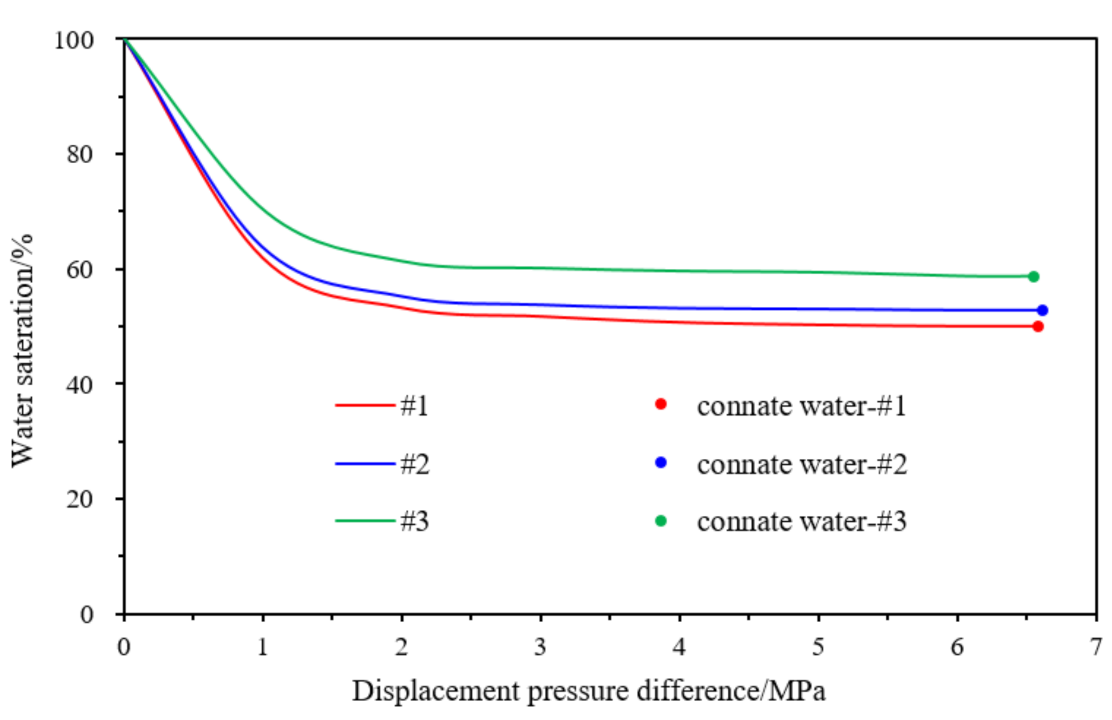

5.1. The Results of the Connate Water Test

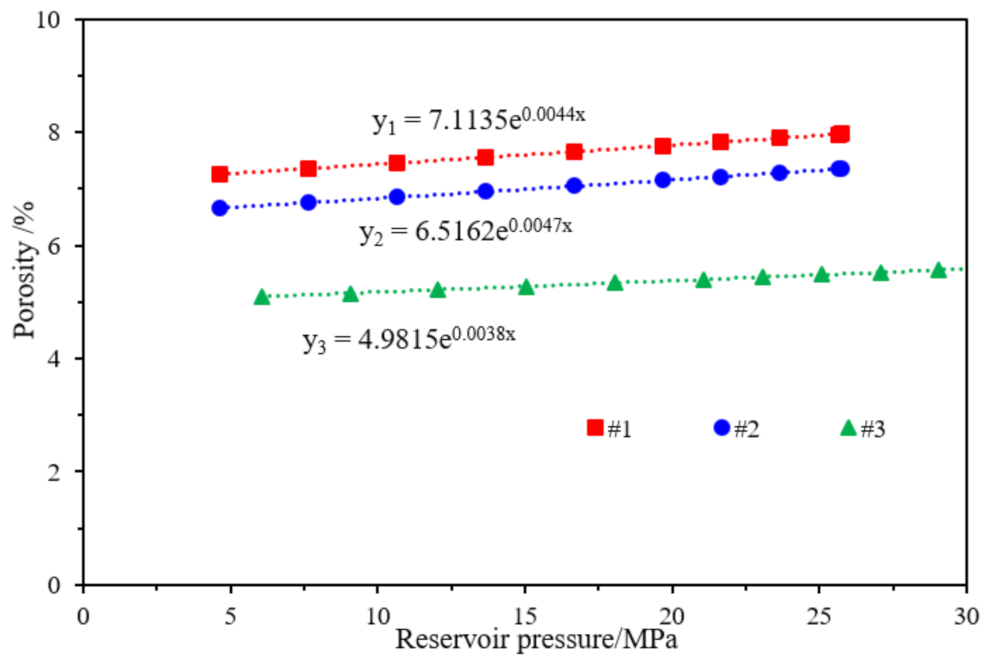

5.2. The Results of Porosity Stress Sensitivity

5.3. Analysis of the Connate Water Transition to Movable Water

6. Conclusions

- (1)

- The transformation mechanism of connate water into movable water involves the expansion of connate water films and the compression of pore volume due to the reduction of reservoir pressure. Both processes collectively promote the conversion of connate water to movable water;

- (2)

- Gas-water displacement experiments under reservoir conditions indicate that the Dongsheng gas field in the Ordos Basin exhibits high connate water saturation characteristics, with a connate water saturation ranging from 50.09% to 58.5%. For reservoir rocks, the sensitivity of porosity stress to pressure follows an exponential relationship during the realistic simulation of pressure reduction in production;

- (3)

- By combining laboratory experiments and theoretical calculations, an evaluation method for the transformation of connate water into movable water was established. During the development process, the range of increased movable water saturation is between 6.1% and 8.4%. Moreover, the poorer the pore-permeability characteristics, the more pronounced the variations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Akilu, S.; Padmanabhan, E.; Sun, Z. A review of transport mechanisms and models for unconventional tight shale gas reservoir systems. Int. J. Heat Mass Transf. 2021, 175, 121125. [Google Scholar] [CrossRef]

- Hu, X.; Wang, J.; Zhang, L.; Xiong, H.; Wang, Z.; Duan, H.; Yao, J.; Sun, H.; Zhang, L.; Song, W.; et al. Direct Visualization of Nanoscale Salt Precipitation and Dissolution Dynamics during CO2 Injection. Energies 2022, 15, 9567. [Google Scholar] [CrossRef]

- Ding, J.; Yang, S.; Nie, X.; Wang, Z. Dynamic threshold pressure gradient in tight gas reservoir. J. Nat. Gas Sci. Eng. 2014, 20, 155–160. [Google Scholar] [CrossRef]

- Asghar, Z.; Ali, N.; Javid, K.; Waqas, M.; Khan, W.A. Dynamical interaction effects on soft-bodied organisms in a multi-sinusoidal passage. Eur. Phys. J. Plus 2021, 136, 693. [Google Scholar] [CrossRef]

- Wang, L.; Wang, S.; Zhang, R.; Wang, C.; Xiong, Y.; Zheng, X.; Li, S.; Jin, K.; Rui, Z. Review of multi-scale and multi-physical simulation technologies for shale and tight gas reservoirs. J. Nat. Gas Sci. Eng. 2017, 37, 560–578. [Google Scholar] [CrossRef]

- Wang, Z.; Ding, K.; Liu, T.; Yao, J.; Sun, H.; Yang, Y.; Zhang, L.; Song, W.; Zhang, K.; Zhong, J. Minireview of Microscopic CO2 Interactions with Fluids and Minerals in Shale: Advances and Outlook. Energy Fuels 2023, 37, 9895–9913. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; He, D.; Wei, Y.; Li, J.; Jia, A.; Chen, J.; Zhao, Q.; Li, Y.; Yang, S. Theory, technology and prospects of conventional and unconventional natural gas. Pet. Explor. Dev. 2018, 45, 575–587. (In Chinese) [Google Scholar] [CrossRef]

- Qin, S.; Li, F.; Li, W.; Zhou, Z.; Zhou, G. Formation mechanism of tight coal-derived-gas reservoirs with medium-low abundance in Xujiahe Formation, central Sichuan Basin, China. Mar. Pet. Geol. 2018, 89, 144–154. [Google Scholar] [CrossRef]

- Jia, A.; Wei, Y.; Guo, Z.; Wang, G.; Meng, D.; Huang, S. Development status and prospect of tight sandstone gas in China. Nat. Gas Ind. 2022, 42, 83–92. (In Chinese) [Google Scholar] [CrossRef]

- Wang, H.; Cui, Y.; Liu, X.; Qiang, Z.; Wang, S. Multi-layer horizontal wells development for tight sandstone gas reservoir: Case study of tight gas reservoir model zone in Ordos Basin. Nat. Gas Geosci. 2021, 32, 472–480. (In Chinese) [Google Scholar]

- Gao, J.; Ma, B.; Lu, Y.; Zhang, W.; Cao, Q. Origin of authigenic kaolinite with implications for Permian tight gas sandstone reservoirs in the northern Ordos Basin, central China. J. Nat. Gas Sci. Eng. 2022, 99, 104429. [Google Scholar] [CrossRef]

- Tian, J.; Qin, C.; Kang, Y.; You, L.; Jia, N.; Song, J. Reasons for low flowback behaviors of water-based fluids in tight sandstone gas reservoirs. J. Pet. Sci. Eng. 2023, 220, 111152. [Google Scholar] [CrossRef]

- Wang, R.; Liu, K.; Shi, W.; Qin, S.; Zhang, W.; Qi, R.; Xu, L. Reservoir Densification, Pressure Evolution, and Natural Gas Accumulation in the Upper Paleozoic Tight Sandstones in the North Ordos Basin, China. Energies 2022, 15, 1990. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; He, Z.; Wang, Y.; Guo, M.; Zhu, G.; Cai, D.; Lu, S.; Xiao, D.; Li, Y.; et al. Characteristics of heterogeneous diagenesis and modification to physical properties of Upper Paleozoic tight gas reservoir in eastern Ordos Basin. J. Pet. Sci. Eng. 2022, 208, 109243. [Google Scholar] [CrossRef]

- Zheng, D.; Pang, X.; Jiang, F.; Liu, T.; Shao, X.; Huyan, Y. Characteristics and controlling factors of tight sandstone gas reservoirs in the Upper Paleozoic strata of Linxing area in the Ordos Basin, China. J. Nat. Gas Sci. Eng. 2020, 75, 103135. [Google Scholar] [CrossRef]

- Yin, X.; Jiang, S.; Chen, S.; Wu, P.; Gao, W.; Gao, J.; Shi, X. Impact of rock type on the pore structures and physical properties within a tight sandstone reservoir in the Ordos Basin, NW China. Pet. Sci. 2020, 17, 896–911. [Google Scholar] [CrossRef]

- Liu, G.; Xie, S.; Tian, W.; Wang, J.; Li, S.; Wang, Y.; Yang, D. Effect of pore-throat structure on gas-water seepage behaviour in a tight sandstone gas reservoir. Fuel 2022, 310, 121901. [Google Scholar] [CrossRef]

- Zhou, S.; Zhou, Y.; Shi, J.; Zhu, Y.; Xiao, W.; Zhang, R. Micropore structure and water driving characteristics of tight sandstone reservoirs in Ordos Basin. J. Pet. Explor. Prod. Technol. 2022, 12, 601–612. [Google Scholar] [CrossRef]

- Xiangdong, Y.; Jiang, S.; YanLu, L.; Wei, G.; Jungang, L.; Peng, W.; Litao, M. Impact of pore structure and clay content on the water-gas relative permeability curve within tight sandstones: A case study from the LS block, eastern Ordos Basin, China. J. Nat. Gas Sci. Eng. 2020, 81, 103418. [Google Scholar] [CrossRef]

- Wu, W.; Wei, X.; Zhao, X.; Li, N.; Lu, X.; Chen, J. Controlling Factors of Gas-Bearing Properties in Permian Tight Sandstone Based on Sealing Corings, Sulige Gas Field, Ordos Basin, Northern China. Front. Phys. 2022, 10, 833691. [Google Scholar] [CrossRef]

- Cai, J.; Zhao, L.; Zhang, F.; Wei, W. Advances in multiscale rock physics for unconventional reservoirs. Adv. Geo-Energy Res. 2022, 6, 271–275. [Google Scholar] [CrossRef]

- Ren, D.; Wang, X.; Kou, Z.; Wang, S.; Wang, H.; Wang, X.; Tang, Y.; Jiao, Z.; Zhou, D.; Zhang, R. Feasibility evaluation of CO2 EOR and storage in tight oil reservoirs: A demonstration project in the Ordos Basin. Fuel 2023, 331, 125652. [Google Scholar] [CrossRef]

- Gao, Q.; Han, S.; Cheng, Y.; Shi, X.; Yan, C.; Han, Z. Flow-coupled-geomechanical modelling of CO2 transport in depleted shale from a microscopic perspective. Energy 2022, 257, 124727. [Google Scholar] [CrossRef]

- Wu, X.; Pu, H.; Zhu, K.; Lu, S. Formation damage mechanisms and protection technology for Nanpu nearshore tight gas reservoir. J. Pet. Sci. Eng. 2017, 158, 509–515. [Google Scholar] [CrossRef]

- Wang, W.; Yue, D.; Eriksson, K.A.; Liu, X.; Liang, X.; Qu, X.; Xie, Q. Qualitative and quantitative characterization of multiple factors that influence movable fluid saturation in lacustrine deep-water gravity-flow tight sandstones from the Yanchang Formation, southern Ordos Basin, China. Mar. Pet. Geol. 2020, 121, 104625. [Google Scholar] [CrossRef]

- Meng, M.; Shen, Y.; Ge, H.; Xu, X.; Wu, Y. The Effect of Fracturing Fluid Saturation on Natural Gas Flow Behavior in Tight Reservoirs. Energies 2020, 13, 5278. [Google Scholar] [CrossRef]

- Liu, D.; Sun, W.; Ren, D. Experimental Investigation of Pore Structure and Movable Fluid Traits in Tight Sandstone. Processes 2019, 7, 149. [Google Scholar] [CrossRef]

- Gao, H.; Li, H.A. Pore structure characterization, permeability evaluation and enhanced gas recovery techniques of tight gas sandstones. J. Nat. Gas Sci. Eng. 2016, 28, 536–547. [Google Scholar] [CrossRef]

- Wu, J.; Yang, S.; Gan, B.; Cao, Y.; Zhou, W.; Kou, G.; Wang, Z.; Li, Q.; Dong, W.; Zhao, B. Pore Structure and Movable Fluid Characteristics of Typical Sedimentary Lithofacies in a Tight Conglomerate Reservoir, Mahu Depression, Northwest China. ACS Omega 2021, 6, 23243–23261. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, D.; Wang, X.; Wang, Z.; Zhang, W.; Sun, W.; Ma, M.; Liu, D. Characterization of Movable Fluid Distribution in Tight Oil Reservoirs by NMR and Centrifugation. Geofluids 2023, 2023, 1668663. [Google Scholar] [CrossRef]

- Su, Y.; Li, D.; Li, L.; Gao, X.; Zhuang, X.; Fu, J. Formation Water Mobility and Influencing Factors in Tight Sandstone Gas Reservoir. Spec. Oil Gas Reserv. 2020, 27, 118–122. (In Chinese) [Google Scholar]

- Zhang, J.; Li, X.; Shen, W.; Gao, S.; Liu, H.; Ye, L.; Fang, F. Study of the Effect of Movable Water Saturation on Gas Production in Tight Sandstone Gas Reservoirs. Energies 2020, 13, 4645. [Google Scholar] [CrossRef]

- Su, Y.; Fu, J.; Li, L.; Wang, W.; Zafar, A.; Zhang, M.; Ouyang, W. A new model for predicting irreducible water saturation in tight gas reservoirs. Pet. Sci. 2020, 17, 1087–1100. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, C.; Zhu, L. A fractal irreducible water saturation model for capillary tubes and its application in tight gas reservoir. J. Pet. Sci. Eng. 2017, 159, 731–739. [Google Scholar] [CrossRef]

- Fang, J.; Guo, P.; Xiao, X.; Du, J.; Dong, C.; Xiong, Y.; Long, F. Gas-water relative permeability measurement of high temperature and high pressure tight gas reservoirs. Pet. Explor. Dev. 2015, 42, 92–96. [Google Scholar] [CrossRef]

| Ion Content (mg/L) | Salinity (mg/L) | Density (g/cm3) | Water Type | |||||

|---|---|---|---|---|---|---|---|---|

| Na+ and K+ | Ca2+ | Mg2+ | Cl− | HCO3− | SO42− | |||

| 7615.38 | 8301.89 | 277.9 | 24,202.52 | 156.92 | 439.61 | 41,714.96 | 1.04 | CaCl2 |

| Core Number | Length/cm | Diameter/cm | Porosity/% | Permeability/mD | Overlying Rock Pressure/MPa | Reservoir Pressure/MPa |

|---|---|---|---|---|---|---|

| #1 | 5.513 | 2.459 | 7.967 | 0.0613 | 59.65 | 25.75 |

| #2 | 5.589 | 2.468 | 7.351 | 0.0417 | 59.65 | 25.75 |

| #3 | 4.933 | 2.482 | 5.597 | 0.0075 | 61.03 | 30.71 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, F.; Wang, Z.; Fu, S.; Li, A.; Zhong, J. Research on Transformation of Connate Water to Movable Water in Water-Bearing Tight Gas Reservoirs. Energies 2023, 16, 6961. https://doi.org/10.3390/en16196961

Chen F, Wang Z, Fu S, Li A, Zhong J. Research on Transformation of Connate Water to Movable Water in Water-Bearing Tight Gas Reservoirs. Energies. 2023; 16(19):6961. https://doi.org/10.3390/en16196961

Chicago/Turabian StyleChen, Fuhu, Zengding Wang, Shuaishi Fu, Aifen Li, and Junjie Zhong. 2023. "Research on Transformation of Connate Water to Movable Water in Water-Bearing Tight Gas Reservoirs" Energies 16, no. 19: 6961. https://doi.org/10.3390/en16196961

APA StyleChen, F., Wang, Z., Fu, S., Li, A., & Zhong, J. (2023). Research on Transformation of Connate Water to Movable Water in Water-Bearing Tight Gas Reservoirs. Energies, 16(19), 6961. https://doi.org/10.3390/en16196961