A Review of Powertrain Electrification for Greener Aircraft

Abstract

:1. Introduction

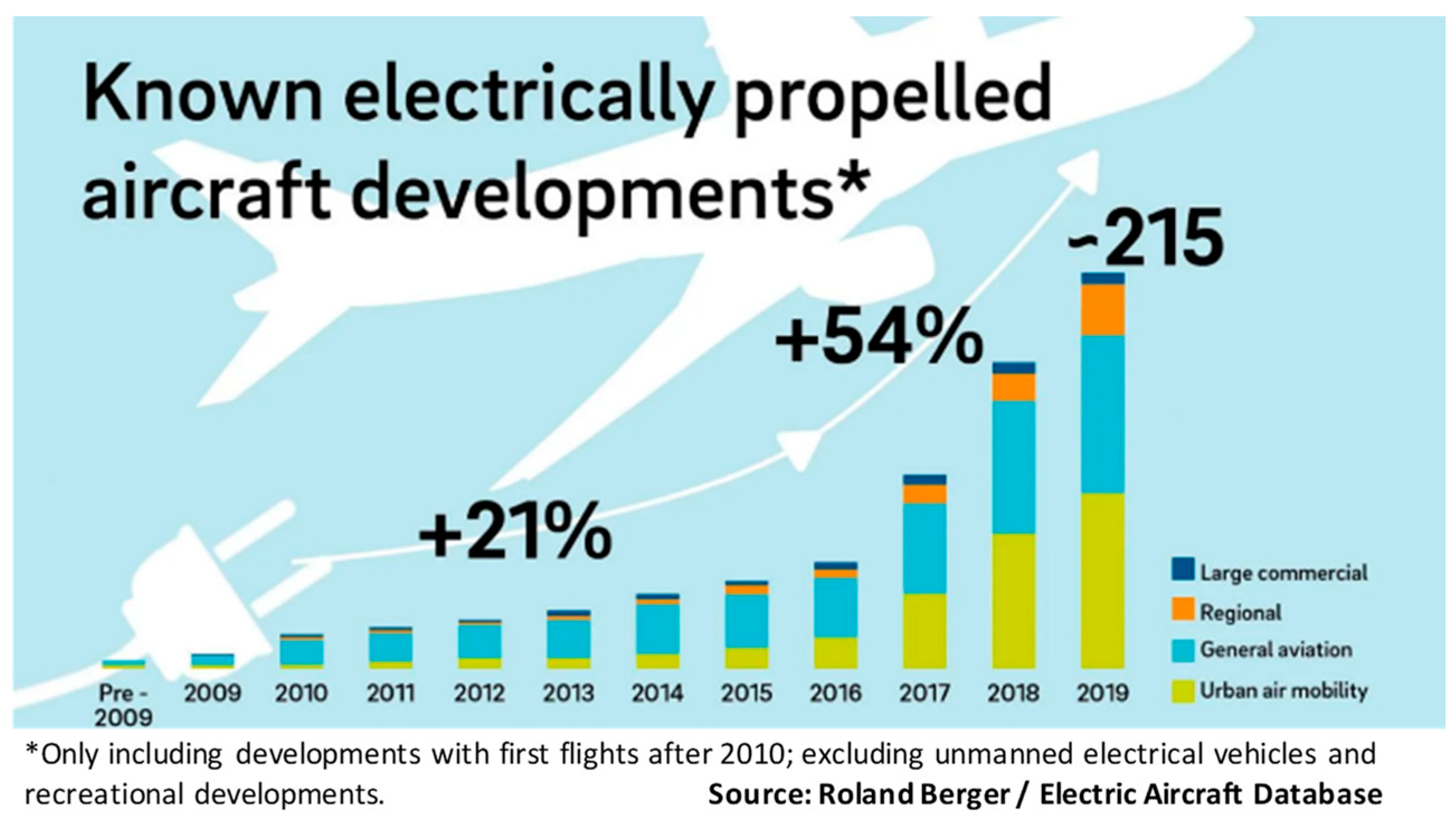

1.1. Literature Review on Electrically Propelled Aircraft

1.2. Main Issues in the Review

2. Context of Electrically Propelled Aircraft

2.1. Potential Benefits in Terms of Engine Optimization, Aerodynamics, and Energy Efficiency

- -

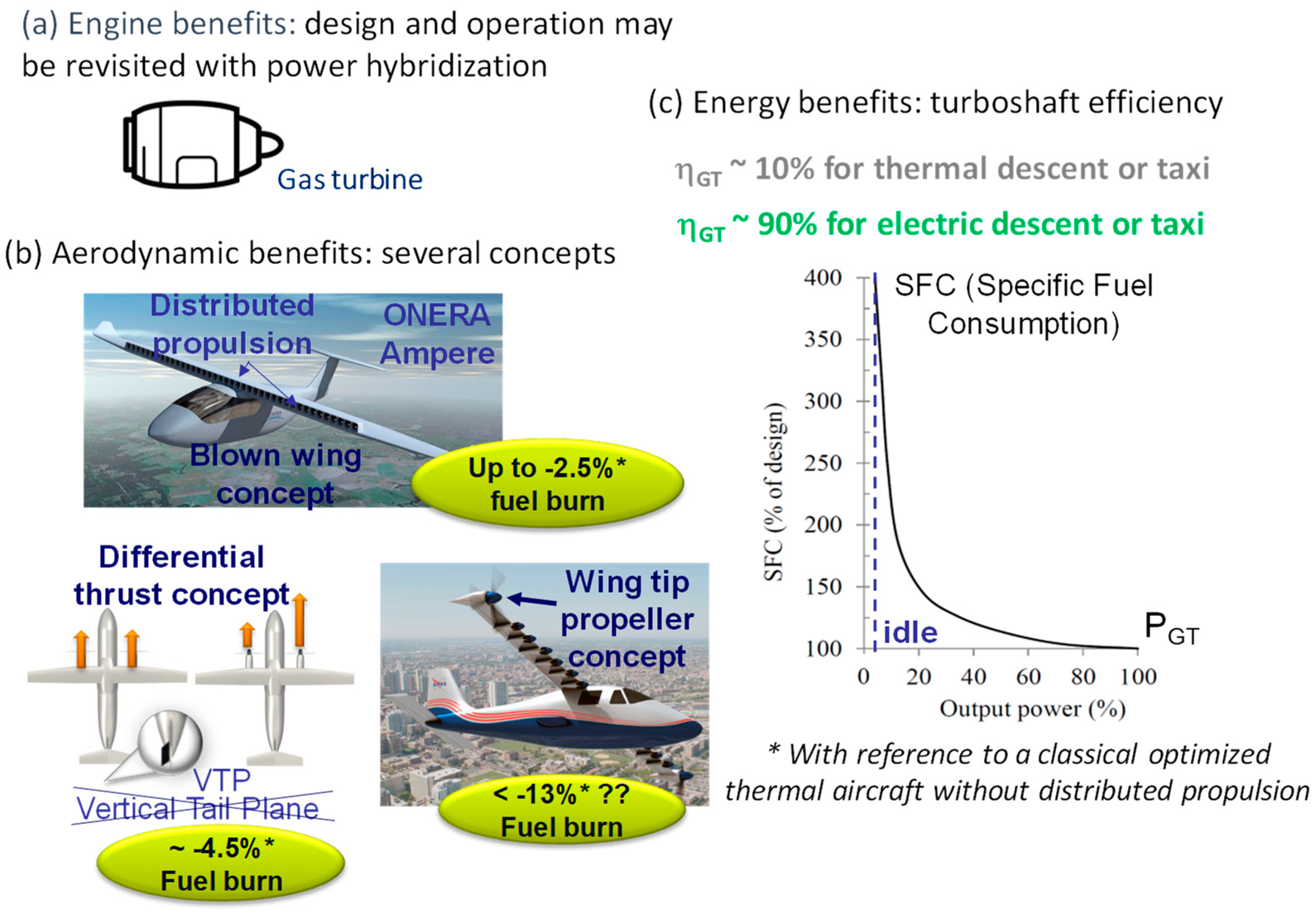

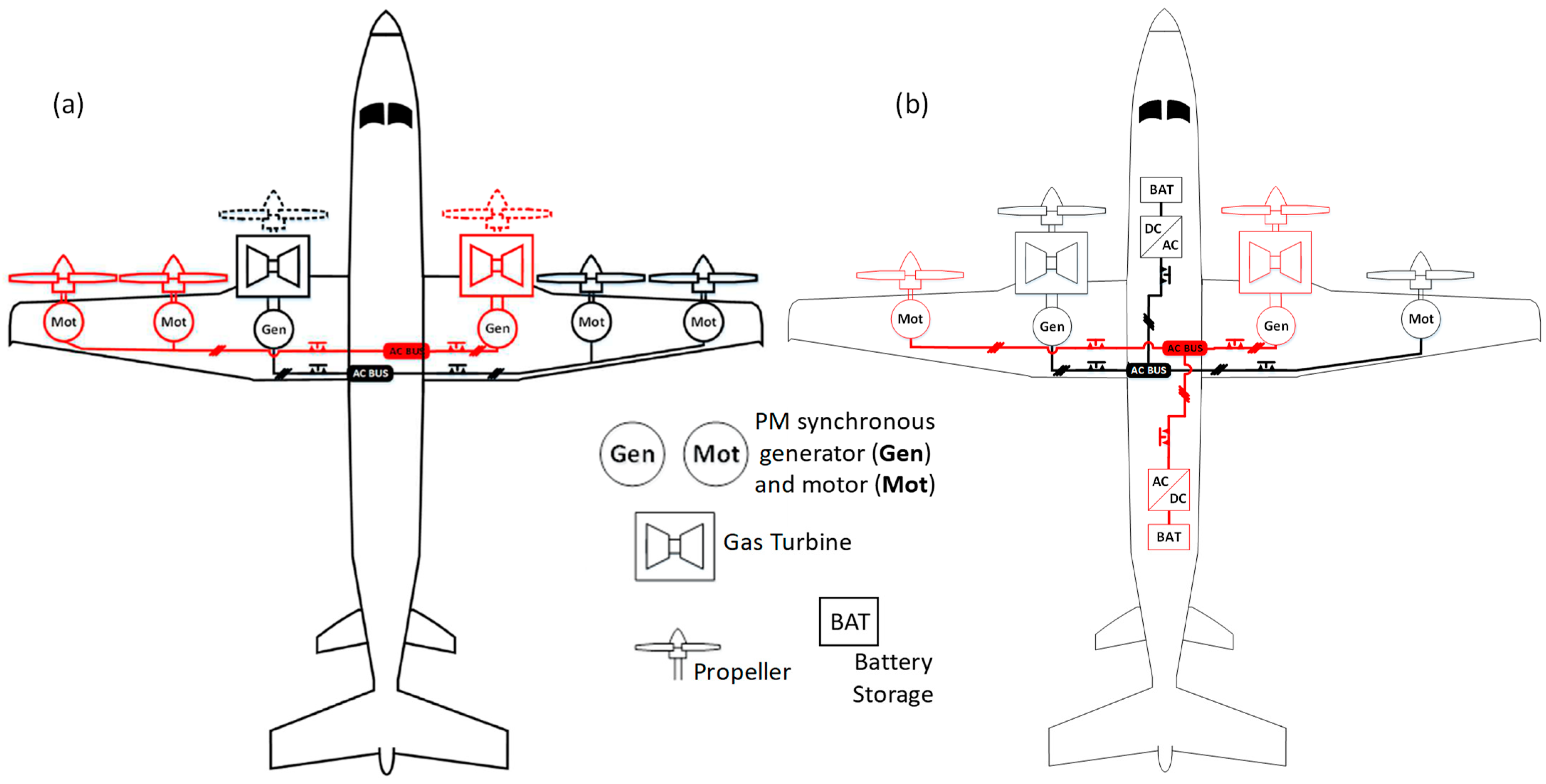

- The first benefit is related to the thermal engine design, as illustrated in Figure 7a, due to the degrees of freedom offered by the hybrid architectures. Indeed, the electric power boost capability can be useful in particular operation zones; it allows for optimizing the engine design with respect to conventional propulsion, where the gas turbine alone propels the aircraft.

- -

- Secondly, Figure 7 illustrates the aerodynamic benefits, which are studied in many projects but are not detailed in the examples of Section 3 and Section 4. However, distributed propulsion introduces, in the first place, potential gains allowing a reduction in wing surface (thus decreasing drag in flight) via the concept of “blown wing”, as proposed, for example, by NASA [11] and ONERA [12,13]. This concept consists, during the landing phase, of increasing the lift thanks to the blast effect caused by the distributed electric propellers. The high dynamics of electrically powered propellers also suggest the possibility of eliminating or reducing the rear vertical plane (reduction in weight and drag) via the concept of “differential thrust” [10]. Finally, some studies suggest that vortex effects can be reduced by adding propellers at the wingtips, for example, in the X57 concept [11]. Overall, coupling all aerodynamic benefits, Thauvin [10] estimates a net reduction of 15–20% in fuel consumption for a regional aircraft.

- -

- Finally, energy benefits due to hybrid-electric-powertrain optimization will be especially detailed in the example of Section 3. The example of Section 4 presents a typical hybrid architecture that mainly suppresses power electronics, thus obtaining energy gains by reducing the powertrain weight. These “energy gains” are the result of the trade-off between weight reduction and powertrain efficiency including the gas turbine operation over the flight mission. Indeed, increasing the efficiency of each conversion stage implies a reduced energy demand of the upstream stages in the propulsion chain, offering subsequent weight gains. Moreover, in the case of hybrid systems combining a main thermal source, typically a gas turbine, and auxiliary electrical sources (batteries or fuel cells), it is possible to reduce the fuel burn through a power management optimization of both sources to avoid operating the thermal engines in very-high-consuming regimes obtained at low power operation, as displayed in Figure 7c. Specific flight sequences such as taxiing or descent can thus be advantageously “electrified”.

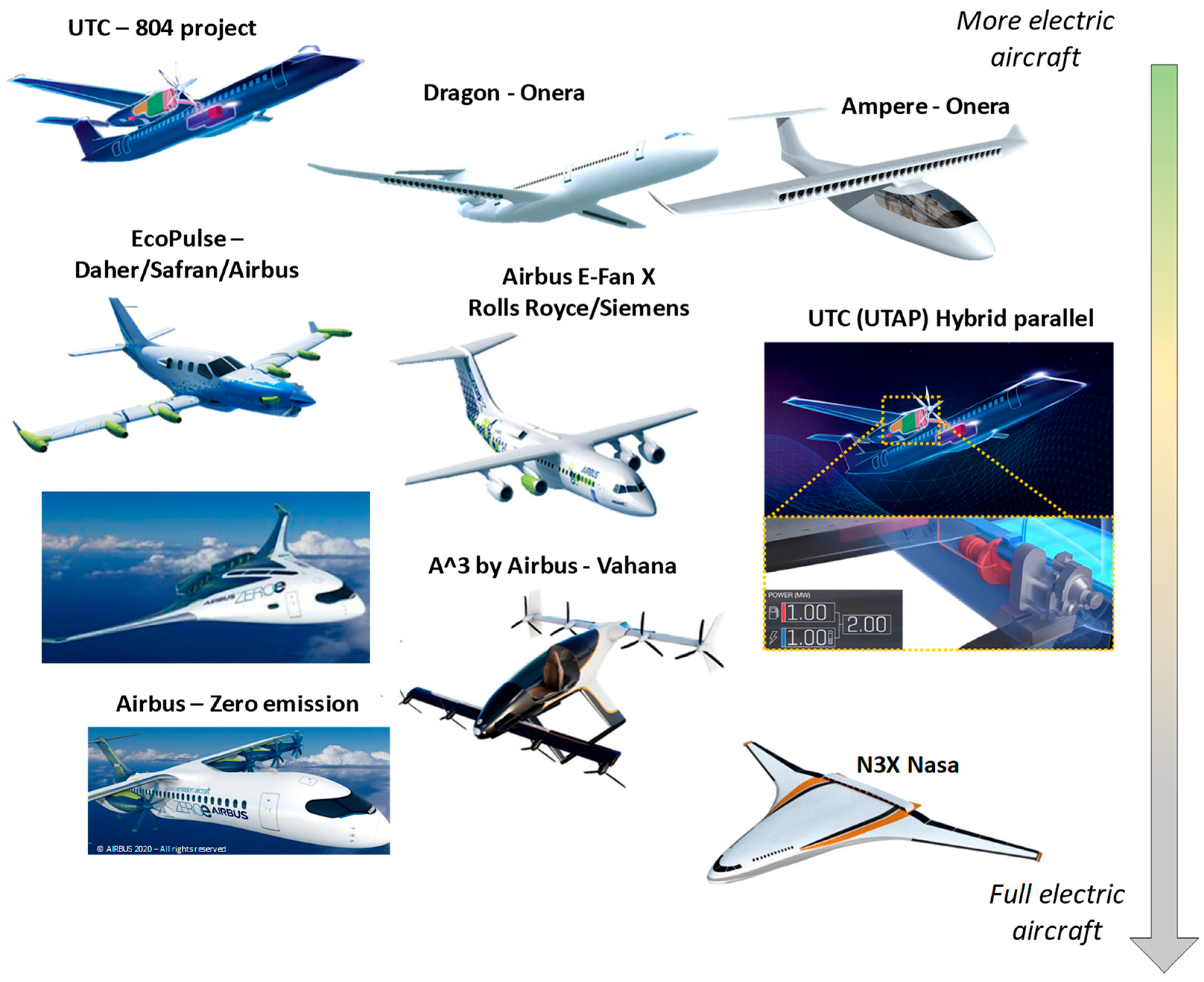

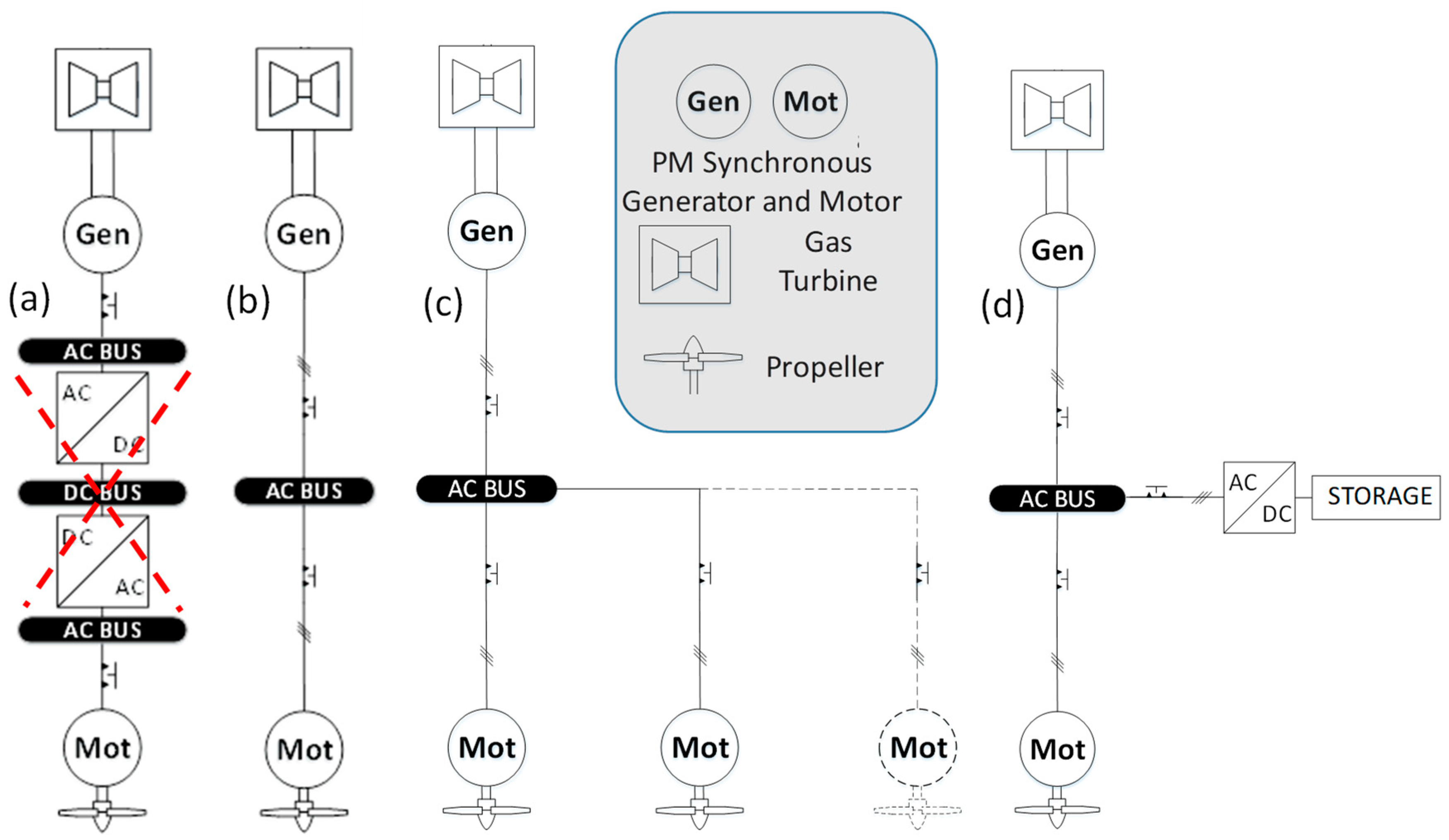

2.2. Hybrid-Electric and Full-Electric Architectures

- -

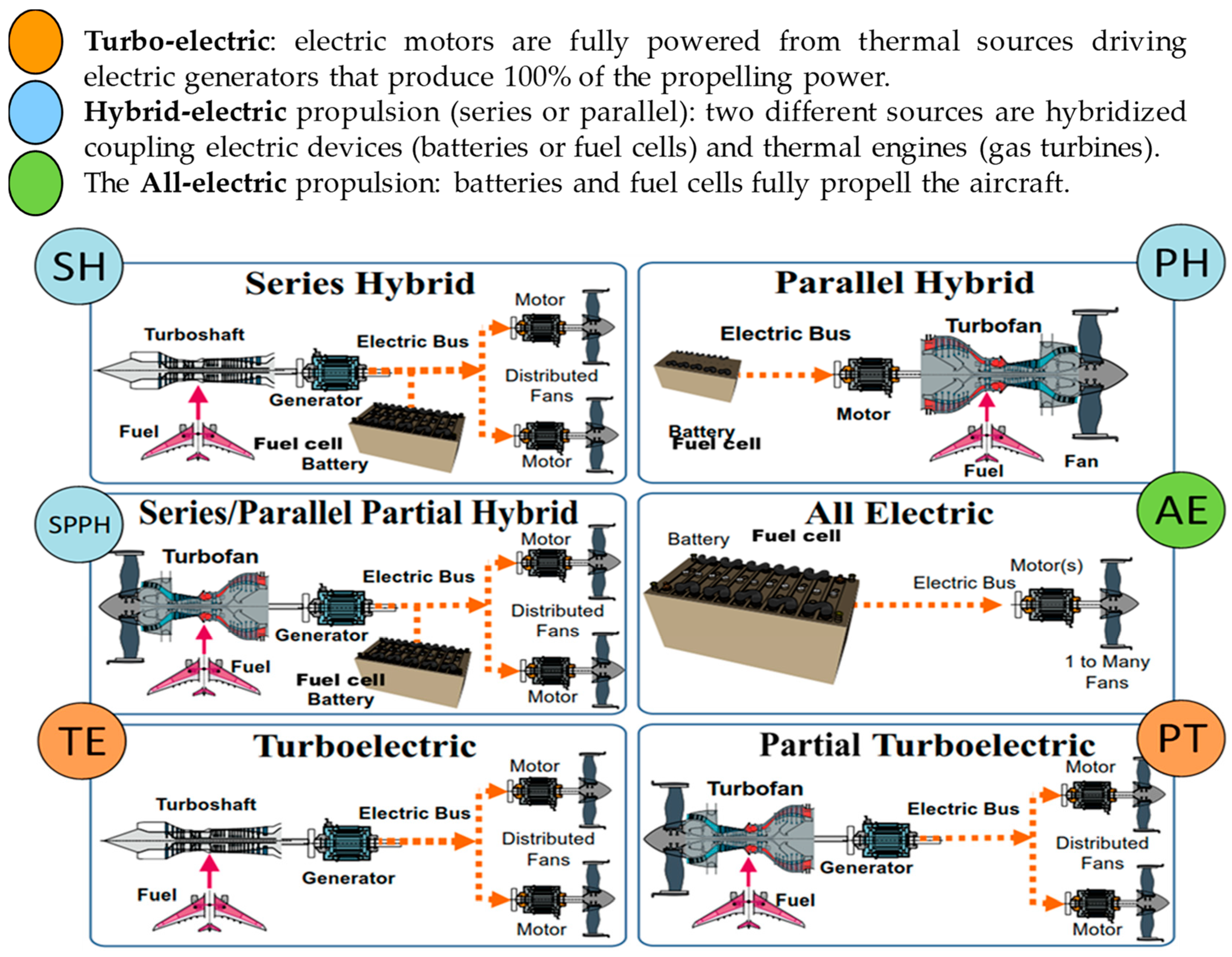

- Parallel hybrid architecture: In this structure, the conventional thermal engine is assisted by the eMotor during high-fuel-consumption-demand phases (low propulsive power demand), exactly as in an electric car. The weight addition due to the powertrain electrification is minimized compared to that of other hybrid architectures, and it was found in [10] to be the most promising in terms of fuel burn reduction rate. For example, the AMPAIRE start-up [55] built a prototype of a hybrid-electric parallel aircraft, which ran until its fly tests in California in 2019.

- -

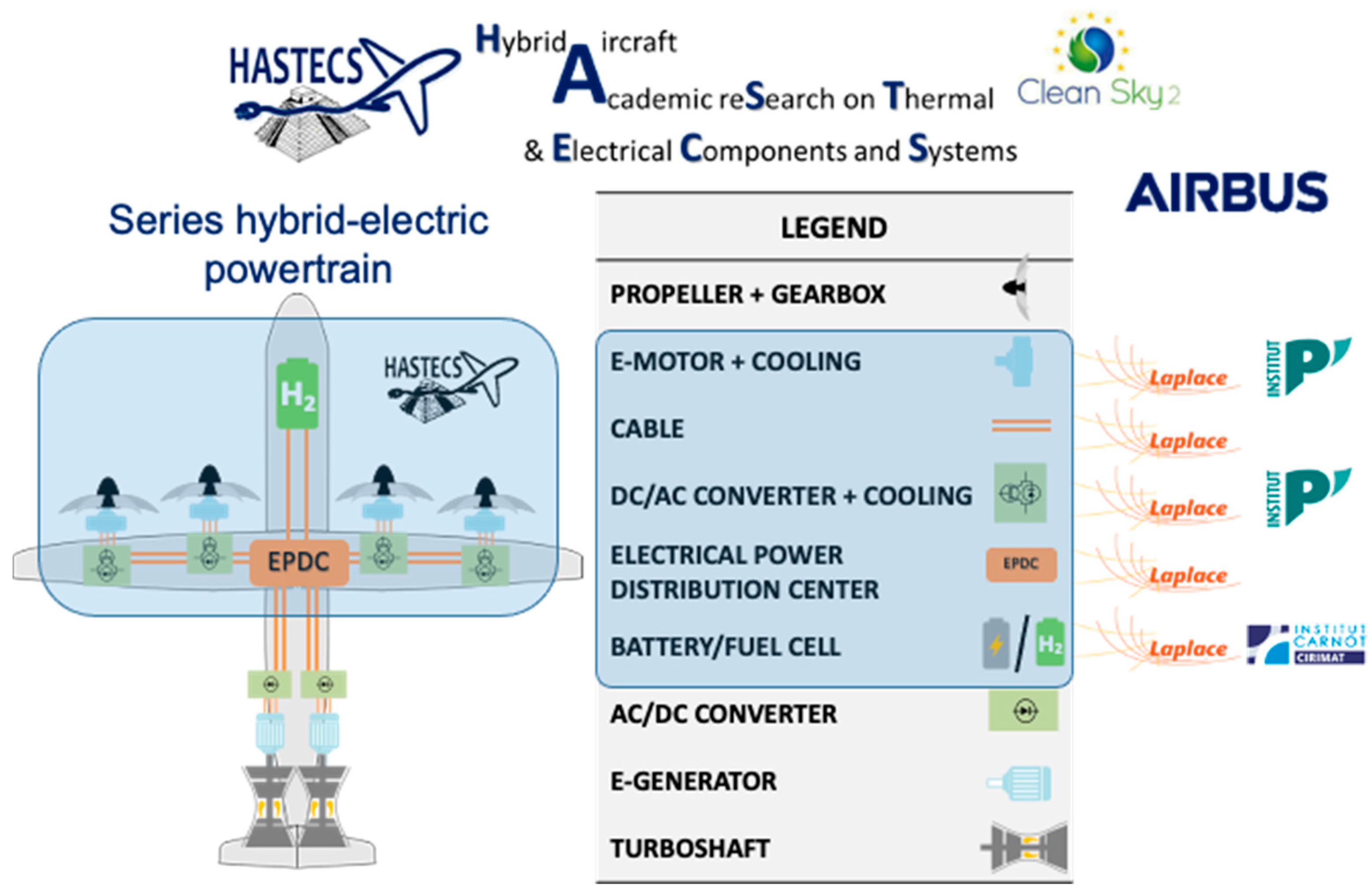

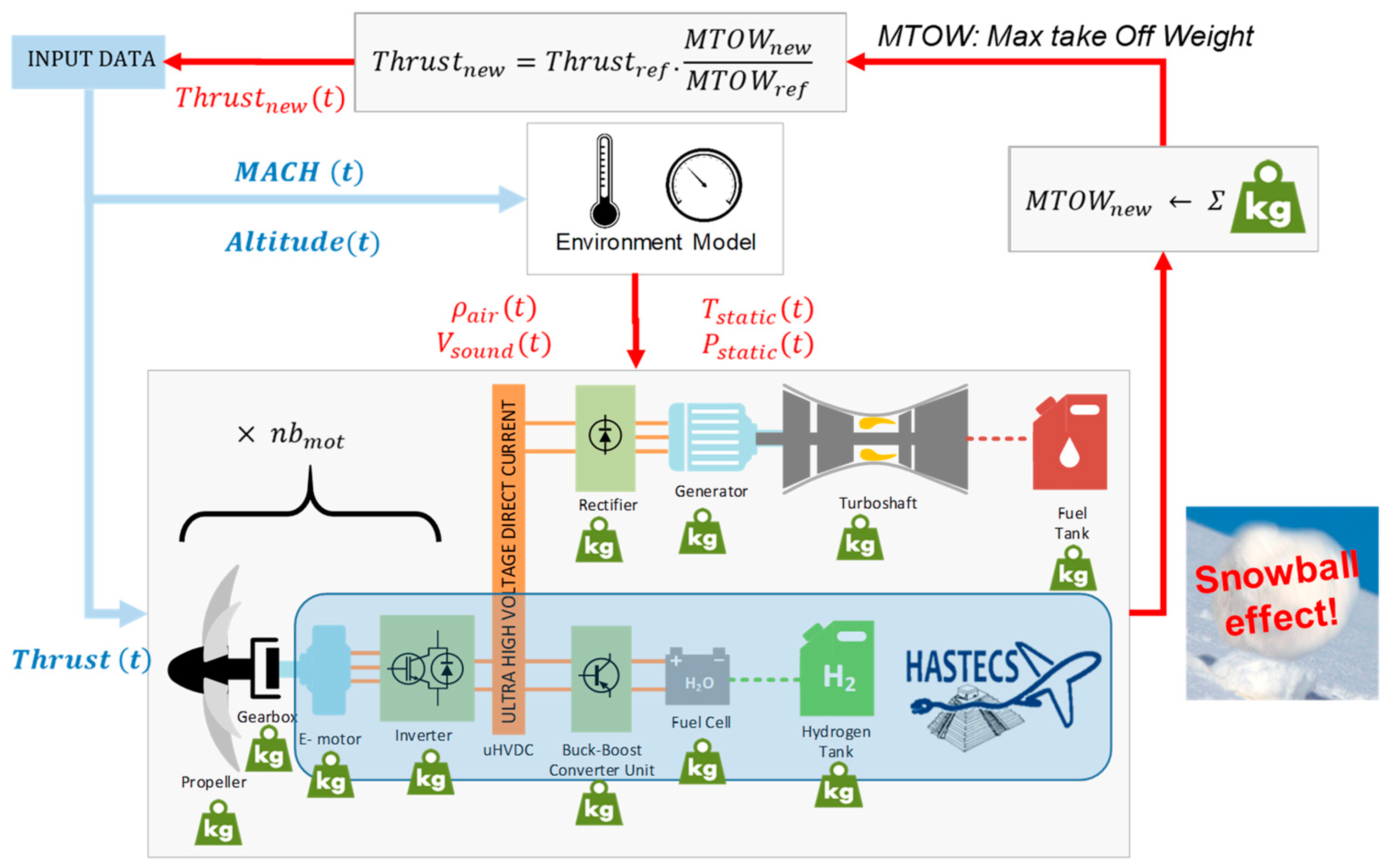

- Series hybrid architecture: With 100% electric propulsion, like “Turboelectric” and “All Electric” solutions, this structure is highly compelling and involves the most ambitious technological breakthroughs, involving high-power devices (cables, electric machines, power electronics) and “ultra HVDC bus voltage standards” with subsequent issues in terms of insulation (partial discharges) in aircraft environments, especially at low pressures. This is a reason why Airbus, as the topic leader in the EU Clean Sky 2 “HASTECS” project, has chosen to retain this architecture for a regional aircraft case study; this example is detailed in Section 3. Many other projects have made the same choice, starting with the American start-up Zunum Aero [56], supported by Boeing, that develops a family of series hybrid-electric small regional aircraft, the first being the ZA10 which is able to transport 10 Pax flying over a range of 600 nm. The aircraft concept uses either all-electric or hybrid-electric modes to extend the flight range. In cooperation with SAFRAN, which has provided a 500 kW gas turbine collected from an existing helicopter, the powertrain concept can switch either to an all-electric or a hybrid-electric powertrain to extend the aircraft mission. The series hybrid-electric propulsion can also be applied to VTOL and STOL (vertical and short take-off and landing aircraft) as for the Bell NEXUS [57]. Here, hybridization is necessary to extend the fight range.

- -

- The “SPPH” (series-parallel partial-hybrid) powertrain is an intermediate concept between series and parallel hybrid architectures. A turboshaft engine partly powers a generator that feeds electric motors driving propellers, which distribute thrust along the wings. The latter is associated with storage batteries. The aircraft thrust is generated both by electric and thermal engines; the French start-up “Cassio”, with Voltaero, and the “Ecopulse” project, comprising Daher, Safran, and Airbus, are among this family of concepts.

- -

- All-electric and zero-emission architecture: Flying all-electric powertrain is far from easy. Several concepts and prototypes have been proposed, starting with Siemens and its “Extra 330” concept, with an aircraft speed beyond 340 km/h. It especially embeds a very high specific power electric motor [58]. Such a specific power of 5 kW/kg has never been reached for an aircraft electric motor. Beyond that, Eviation is a young company in Israel that is also studying a full-electric concept. Their aircraft, able to transport nine pax by means of its 800 kW electric propulsion and powered by lithium-ion batteries, was presented at the Paris Air Show in 2019. Alongside these new generations of aircraft, VTOL and STOL aircraft are also in the “all-electric race”. Airbus has also proposed its “City Airbus”, a four-seat multi-copter concept. The market for VTOL and STOL aircraft is rapidly growing; aircraft manufacturers want to relieve road traffic congestion and make it more fluid. However, considering the limitations of battery-specific energy for current and medium-term solutions, the range of all-electric aircraft is still very limited. Thauvin [10] studied technology targets by assessing the required battery-specific energy to get an aircraft off the ground and have it fly over a certain range depending on its maximum take-off weight (MTOW) and its performance-level assessment. The technological assessment related to these entry-into-service (EIS) targets is summarized in Table 2. In Figure 11, based on the example of a 30-ton (t) MTOW (blue curves), a 100 nm (nautical miles) full-electric flight appears to be achievable with the battery technology prediction of “EIS2025” (EIS in 2025 with 280 Wh/kg for battery-specific energy target), while, in the longer term, the battery technology of “EIS2030+” (EIS beyond 2030 with 380 Wh/kg for battery-specific energy target) would enable the all-electric aircraft to fly nearly 200 nm, which is still strongly limited.

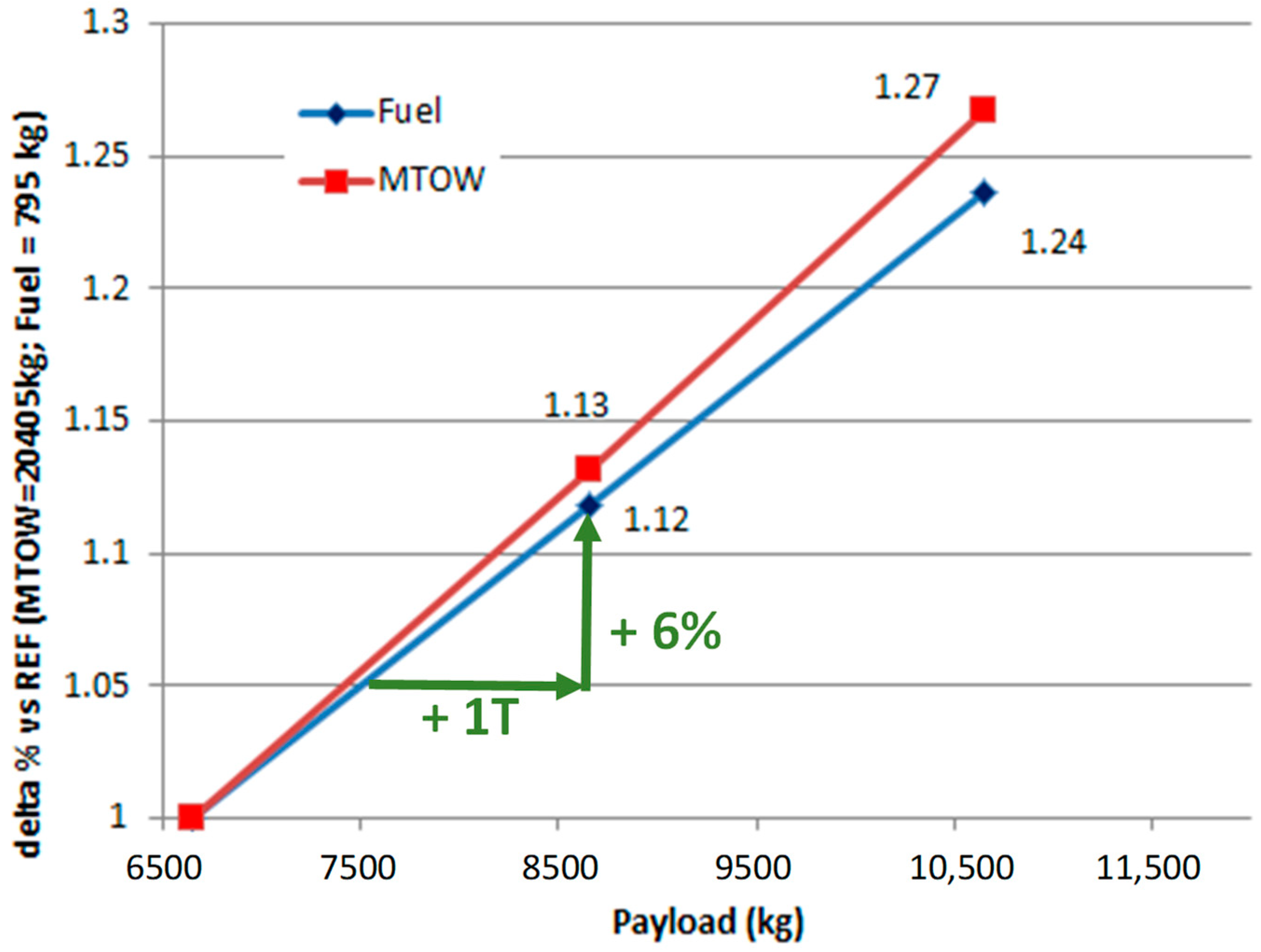

2.3. Electrified Powertrain Is Heavier Than Conventional Thermal Ones But “Technology Sensitive”

2.4. Literature Review on “Power Electronic-Less”-Electric and Hybrid-Electric Architectures

3. “HASTECS”, a Series Hybrid-Electric Powertrain for Regional Aircraft: From Technological Optimization to the MDO of the Whole Powertrain

3.1. The HASTECS Project

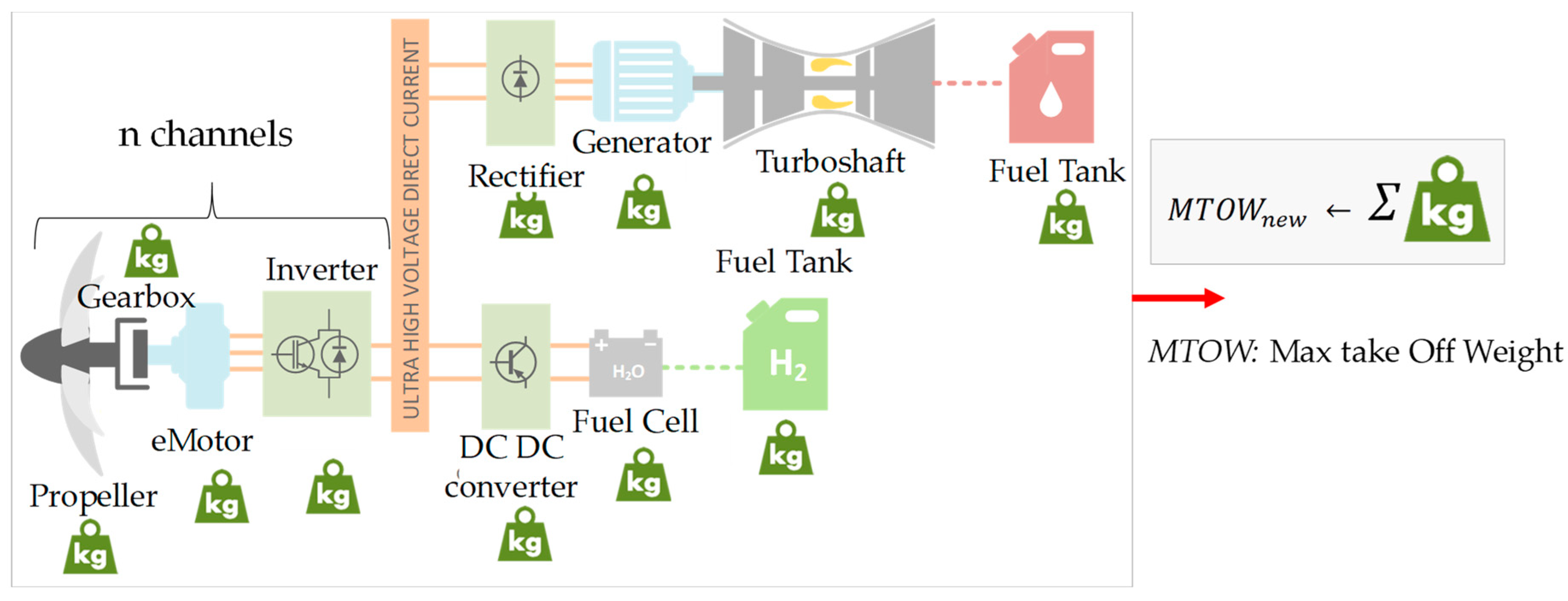

- -

- -

- -

- -

- Prospects towards high-energy-density batteries and fuel cells [52];

- -

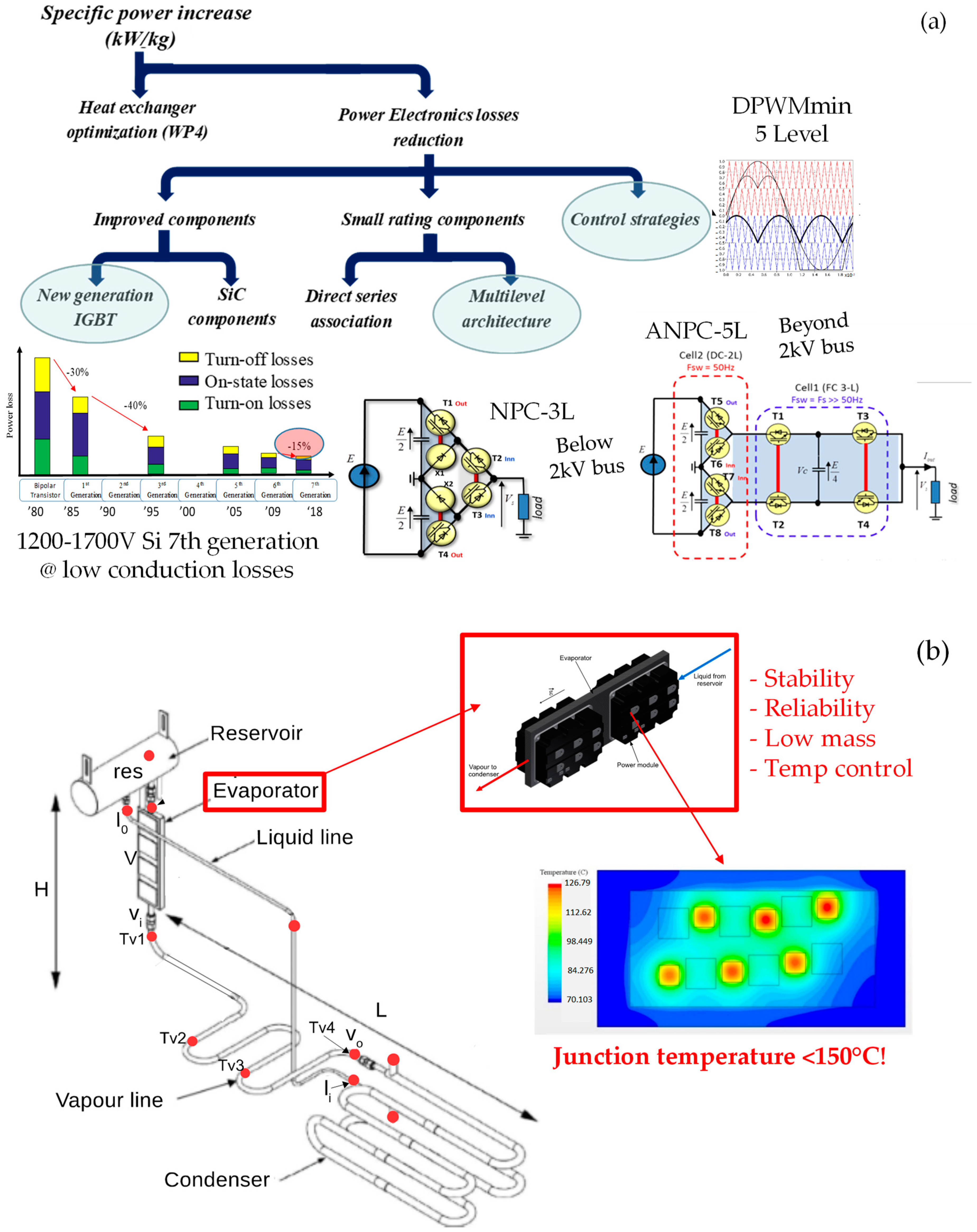

3.2. Local Optimization of Power Electronics

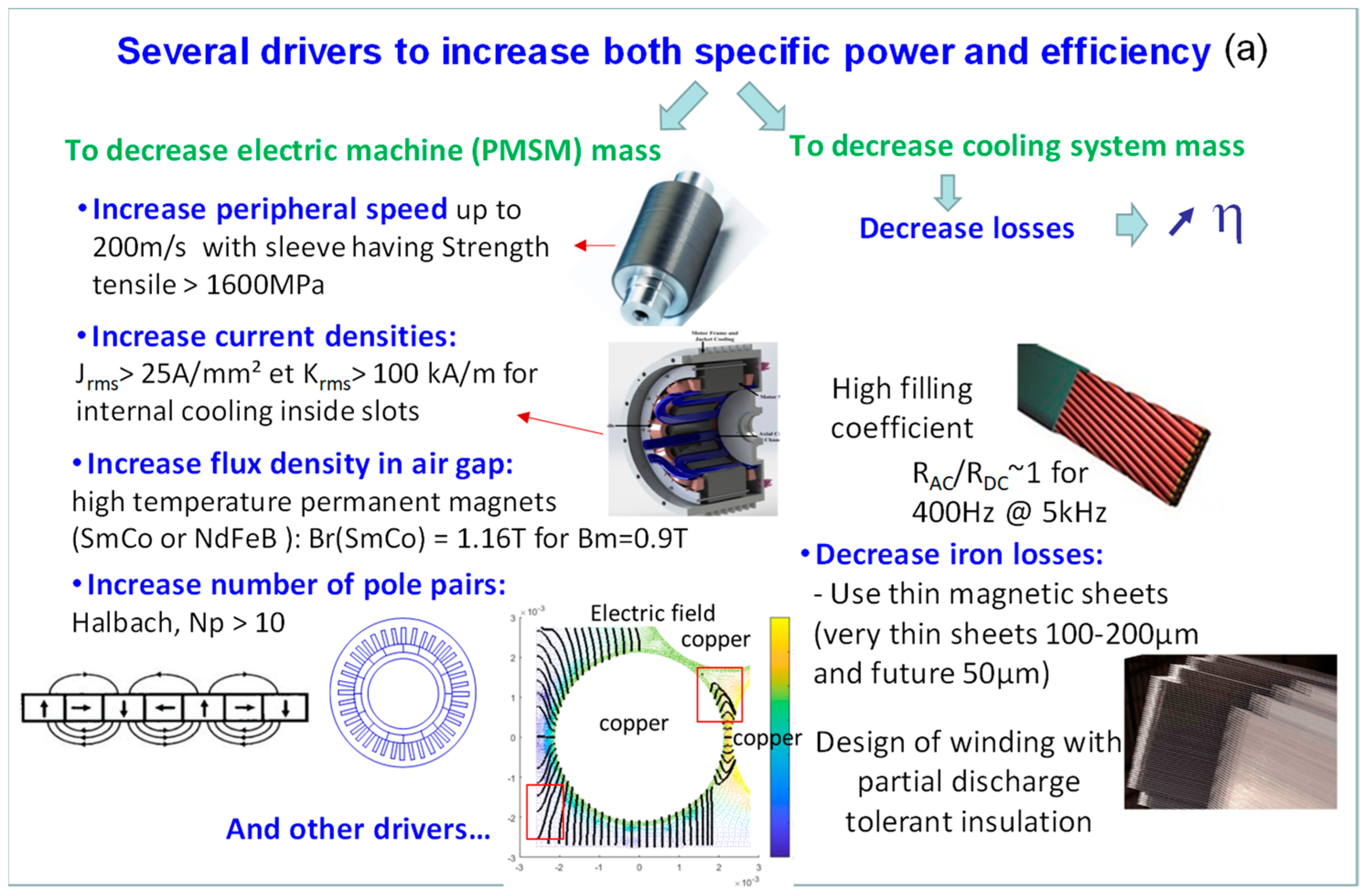

3.3. Local Optimization of the Electromechanical Actuator with Partial Discharge Tolerance

3.4. Prospective State of the Art and Modelling of High-Energy-Density Batteries vs. Fuel Cells

3.5. MDO of the Whole Hybrid-Electric Powertrain

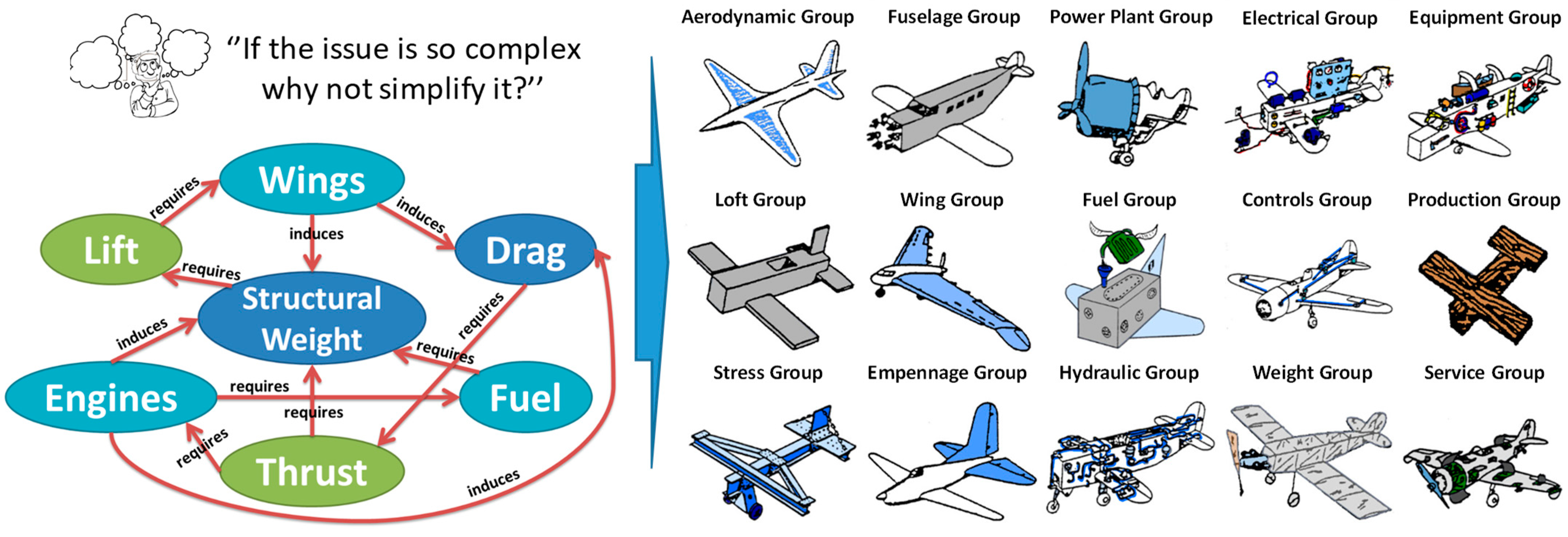

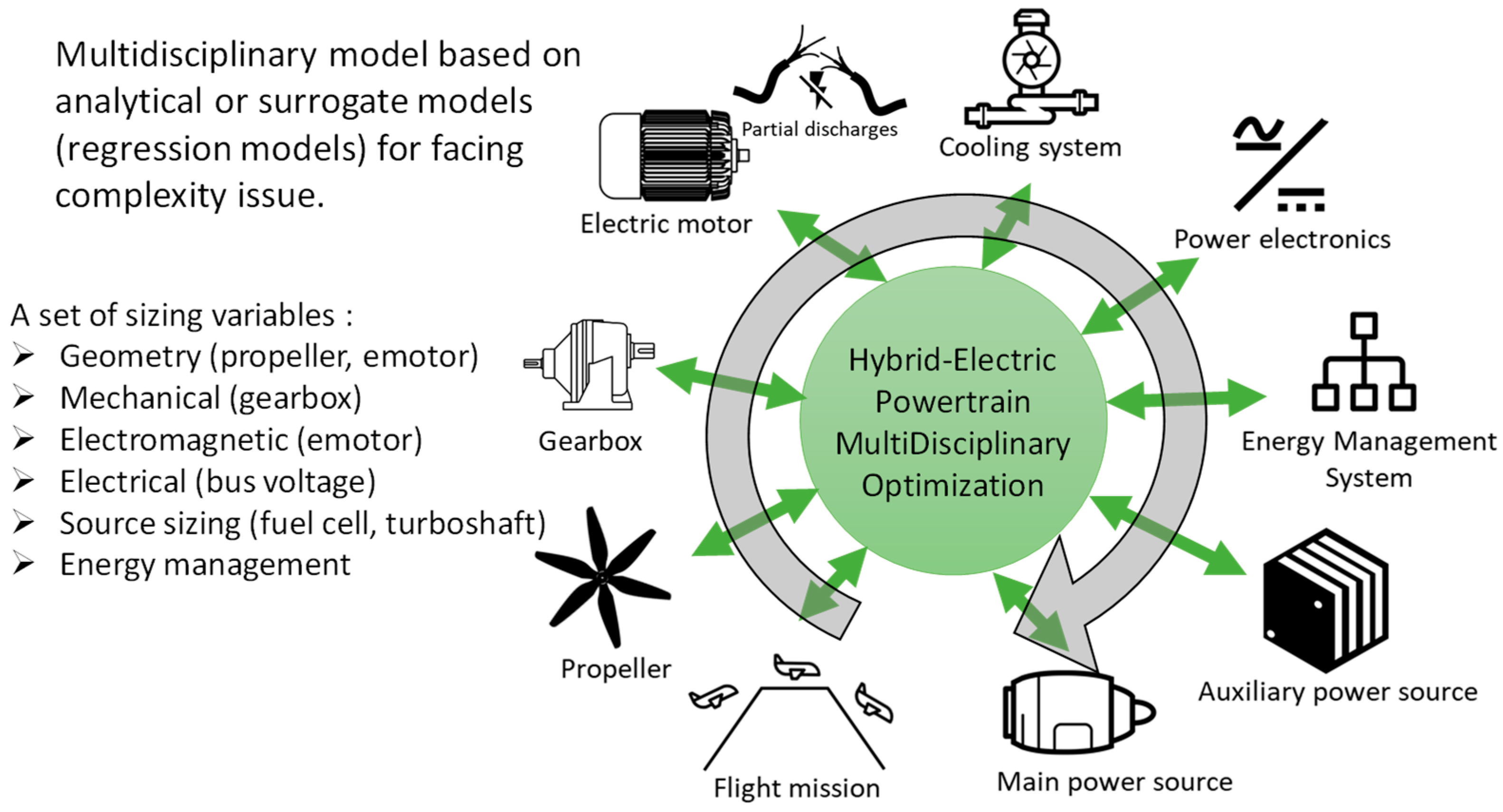

3.5.1. On the MDO Process Formulation

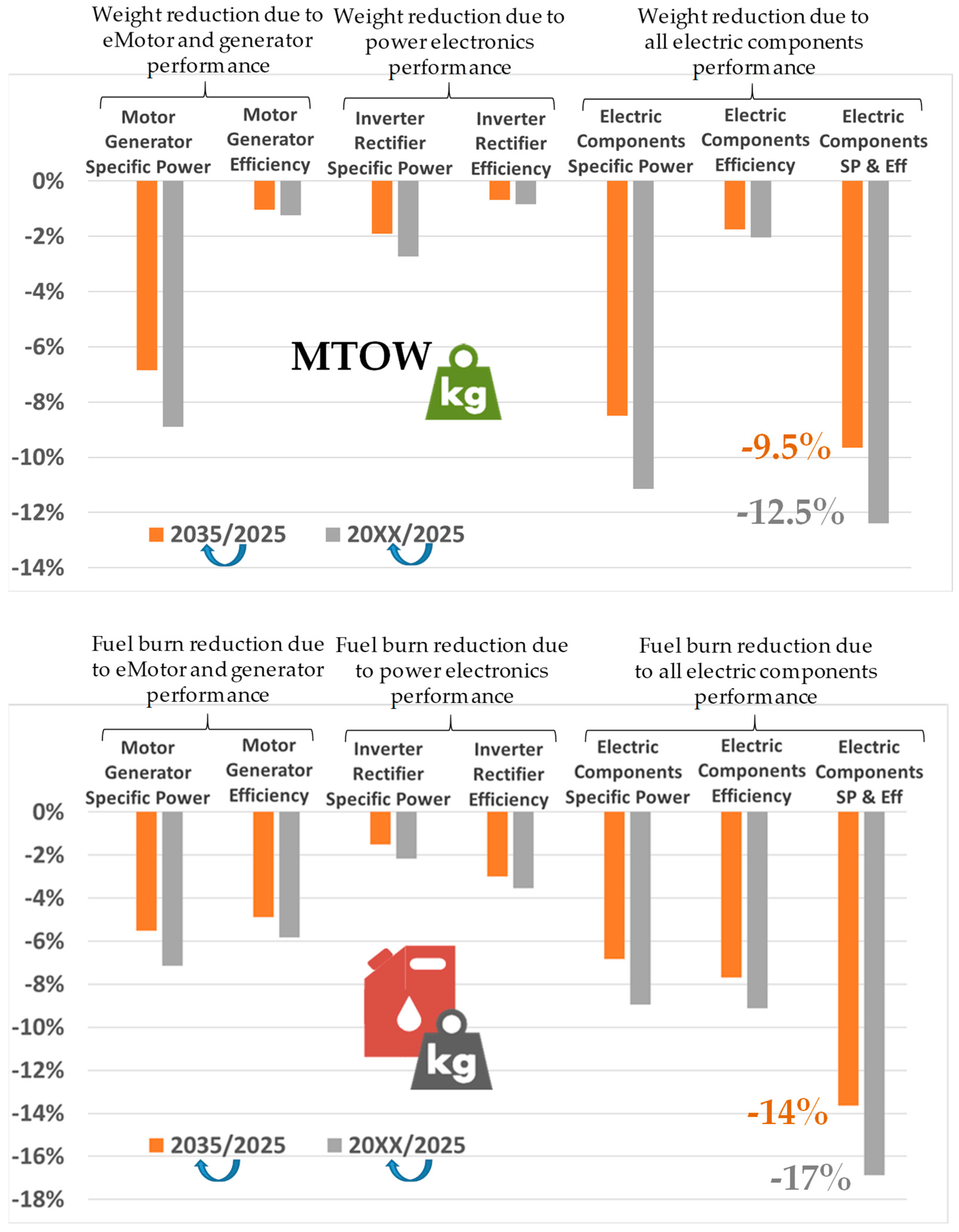

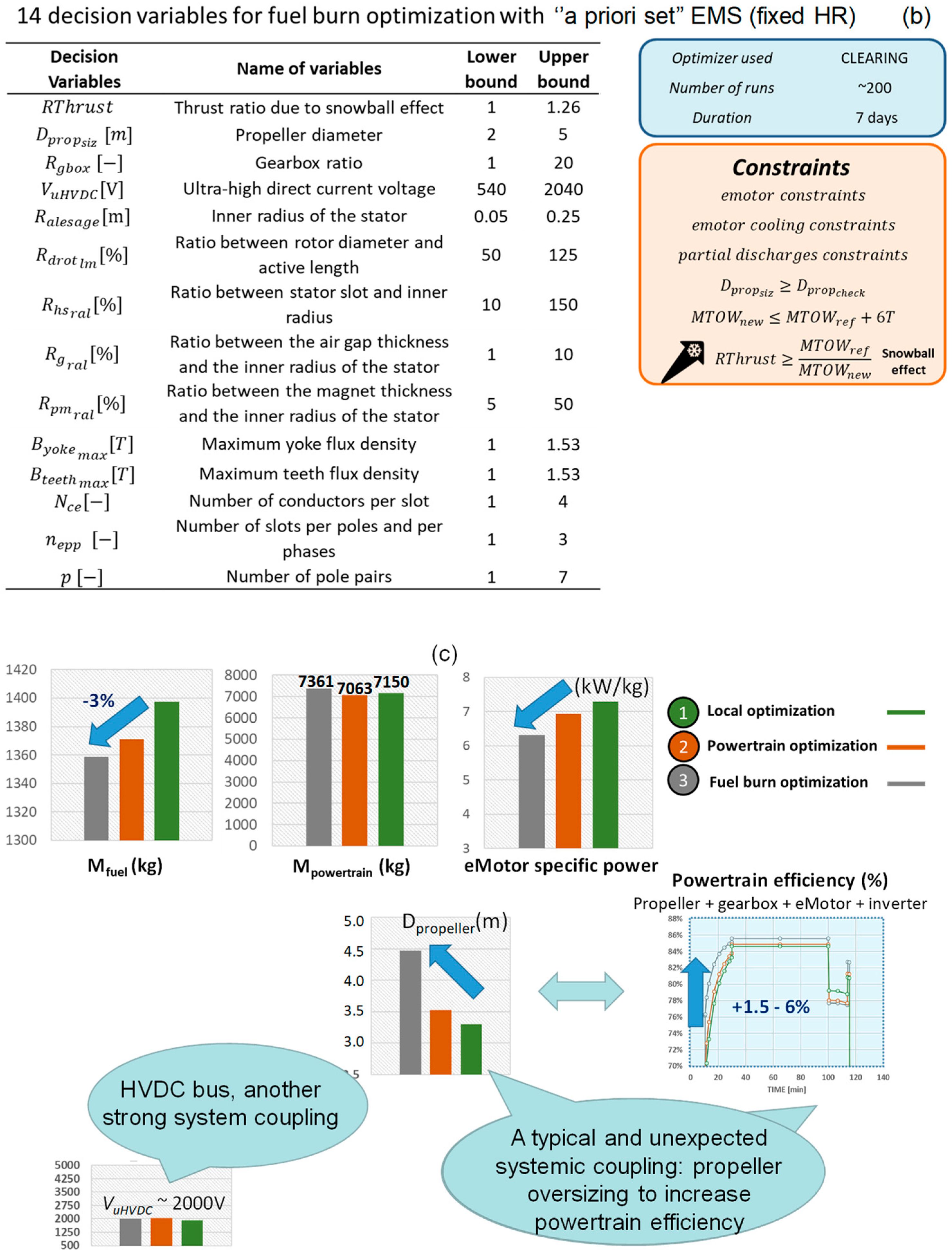

3.5.2. Optimization of the Whole Powertrain

- (1)

- A “local optimization” focusing on the eMotor weight minimization: in this case, other powertrain devices are considered with fixed ratings and the snowball effect is involved;

- (2)

- A first global optimization minimizing the whole electric powertrain weight;

- (3)

- A second global optimization minimizing the fuel burn of the overall hybrid-electric aircraft.

3.6. Final Trade-Off on Fuel Burn vs. Embedded Weight with Hybrid-Electric Architecture

4. “Power Electronic-Less” AC Architecture Stabilized by Hybridization: Another Solution for Electric Powertrain Weight Decrease

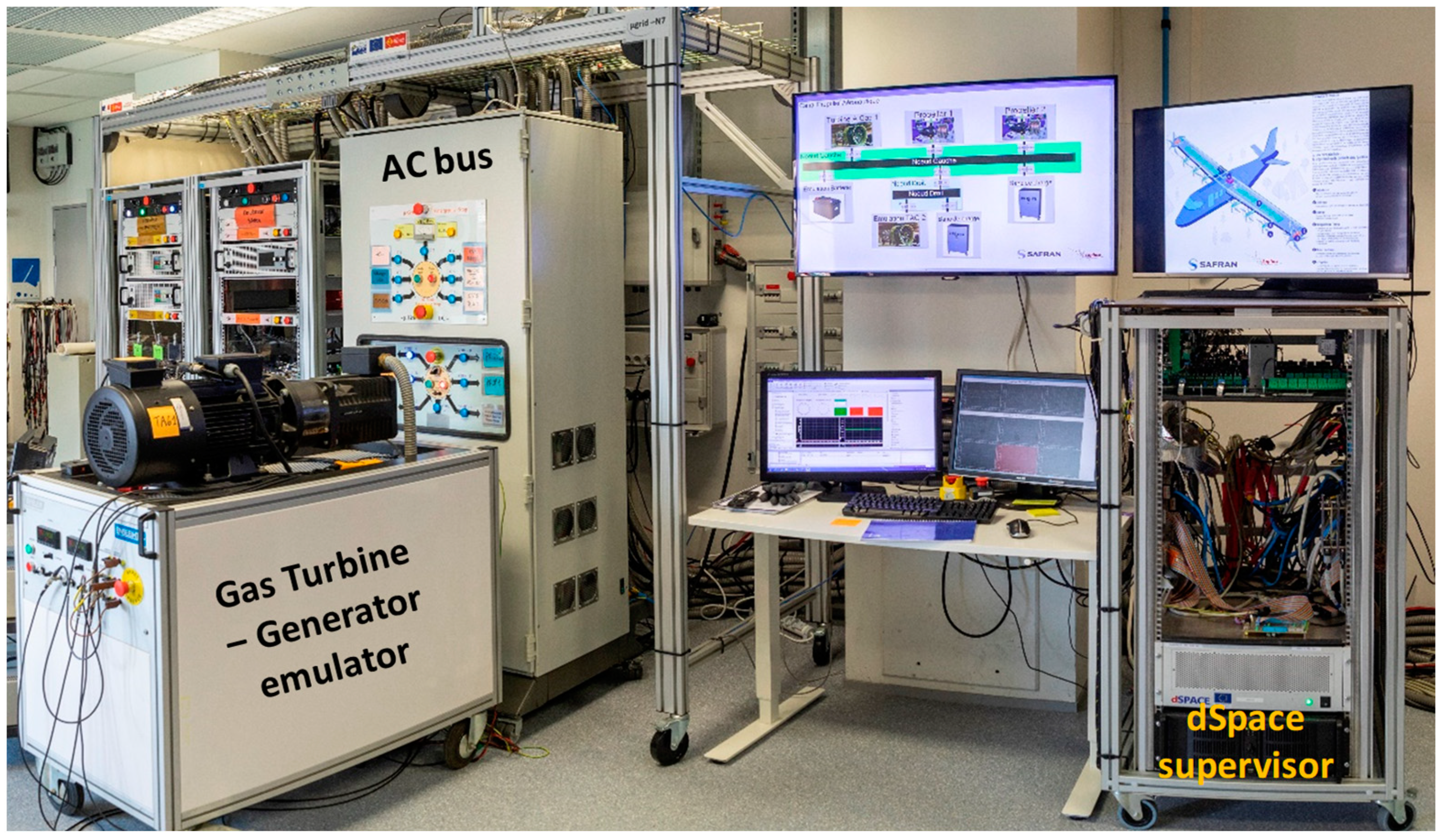

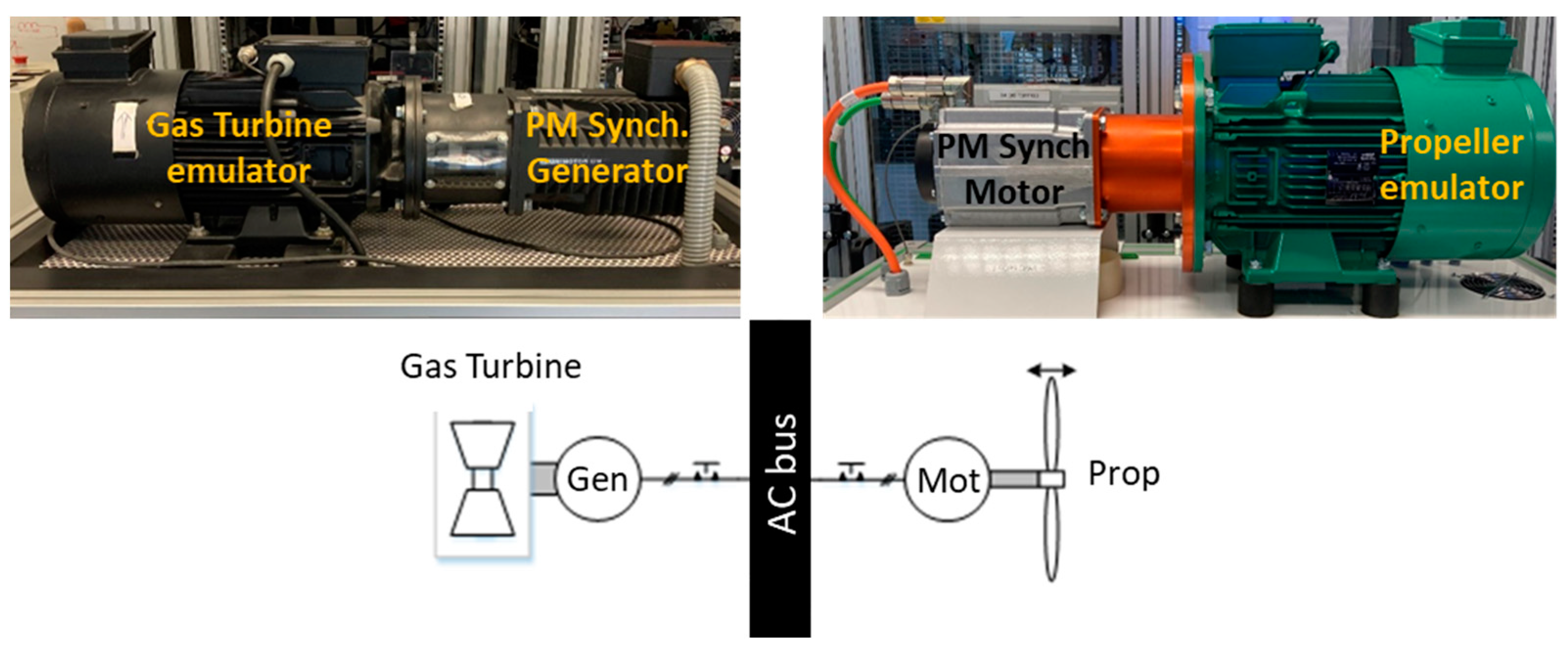

4.1. A “Power Electronic-Less” AC Architecture for Aircraft Propulsion

- -

- At the system input, the gas turbine controls the mechanical speed of the generator, then the AC bus frequency.

- -

- At the system output (propeller side), pitch control of blades adjusts the propulsive thrust with respect to the blade rotation speed.

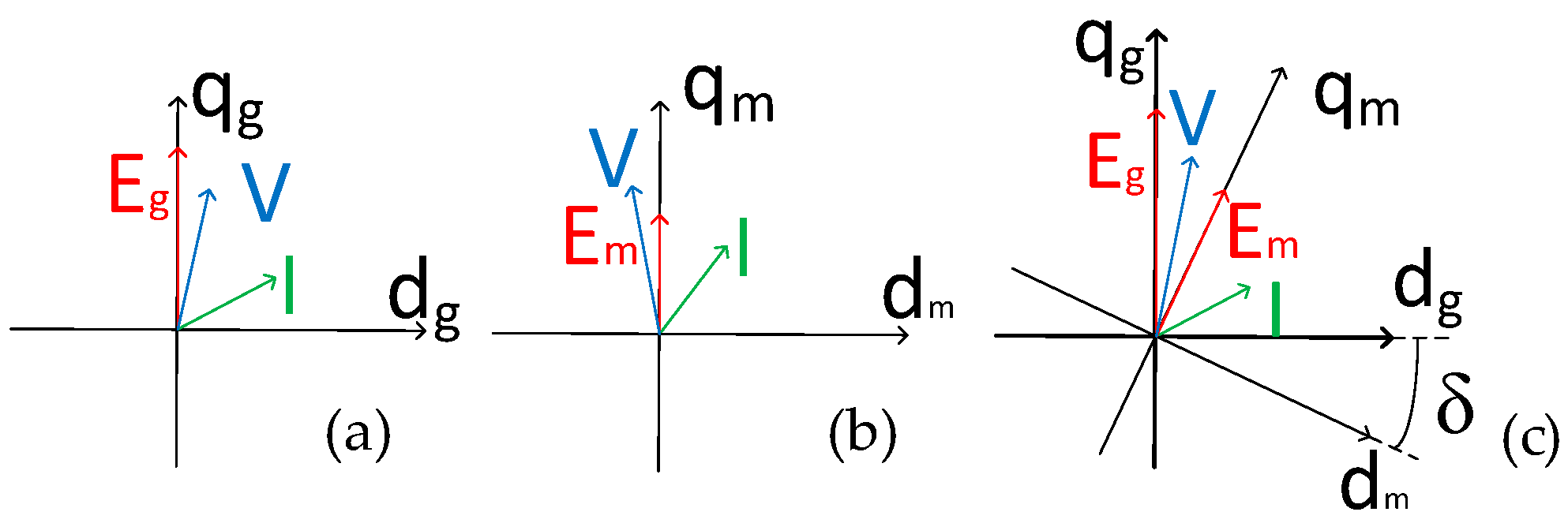

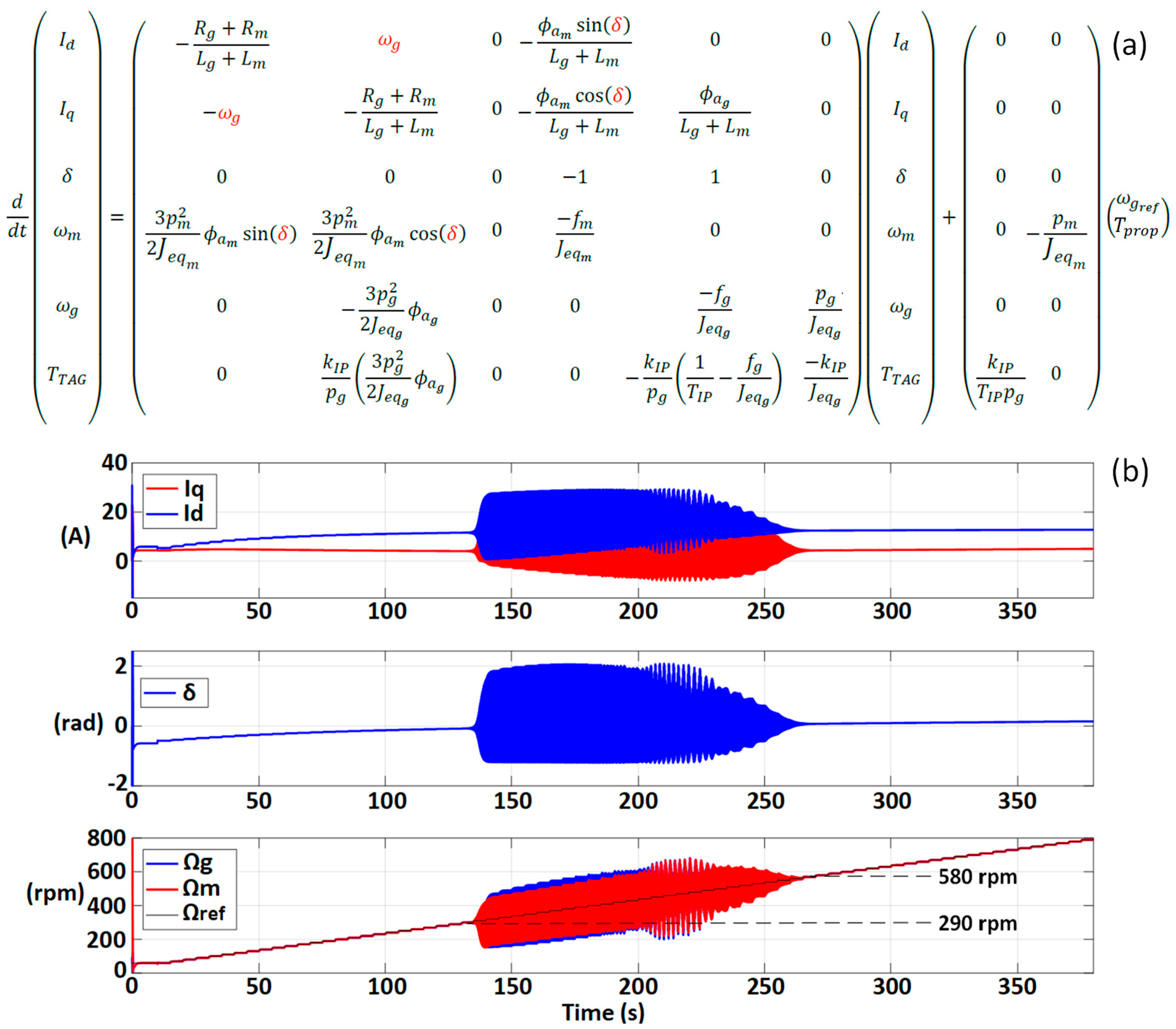

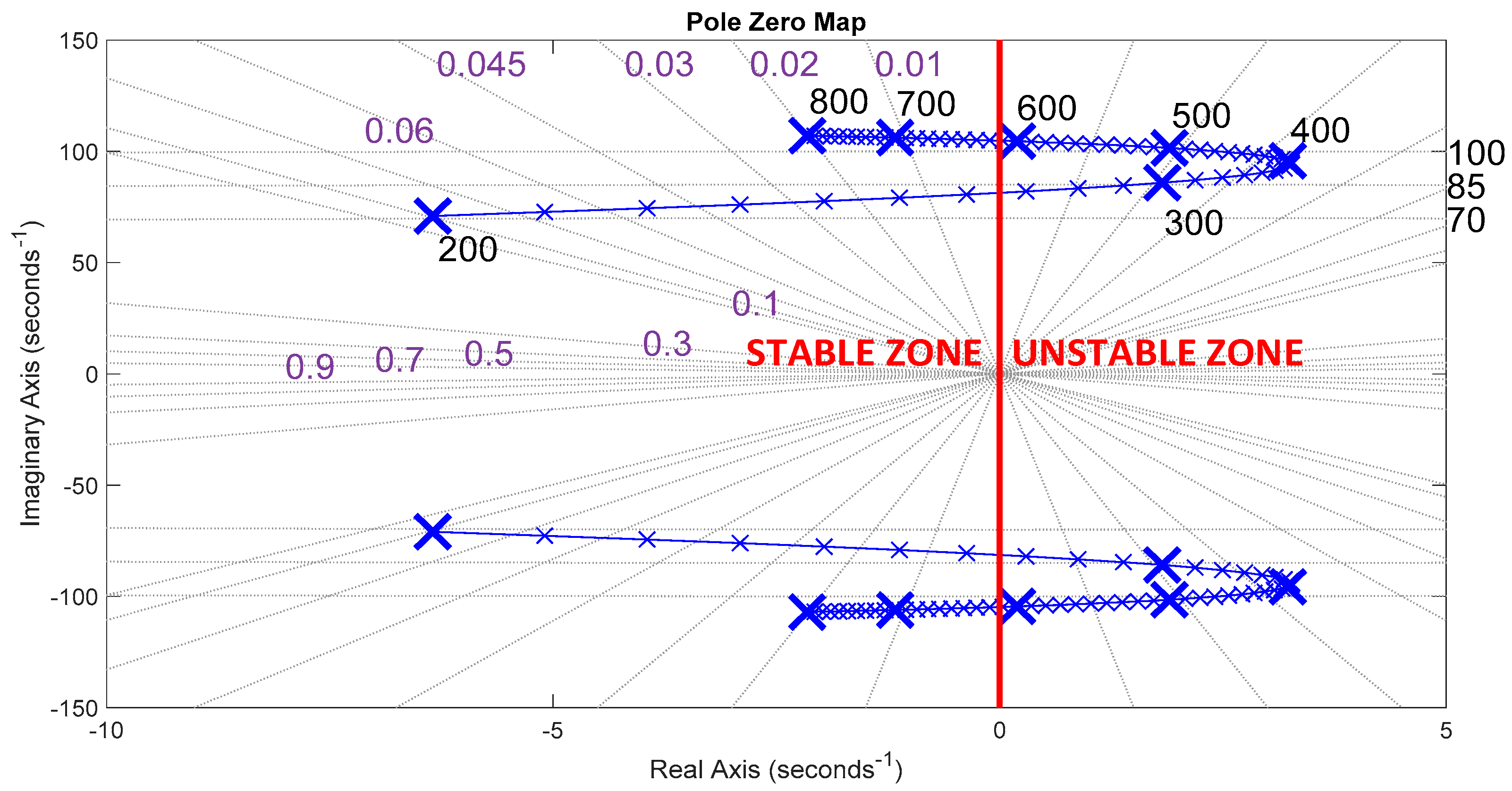

4.2. Stability Analysis of a “Power Electronic-Less” AC-Coupled Power Channel

- High stator inductances;

- Low electromotive forces (proportional to magnetic fluxes);

- High inertia of the motor set.

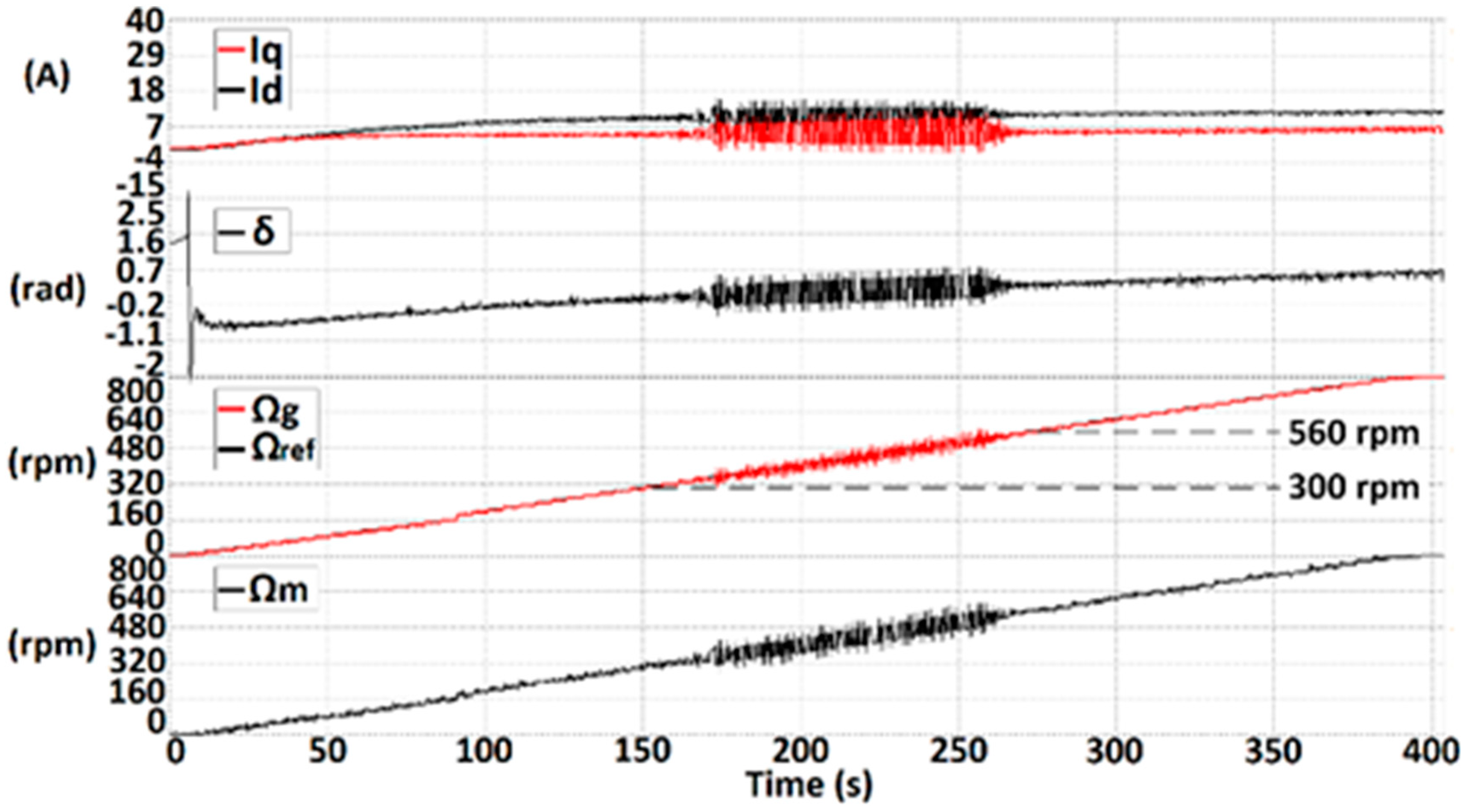

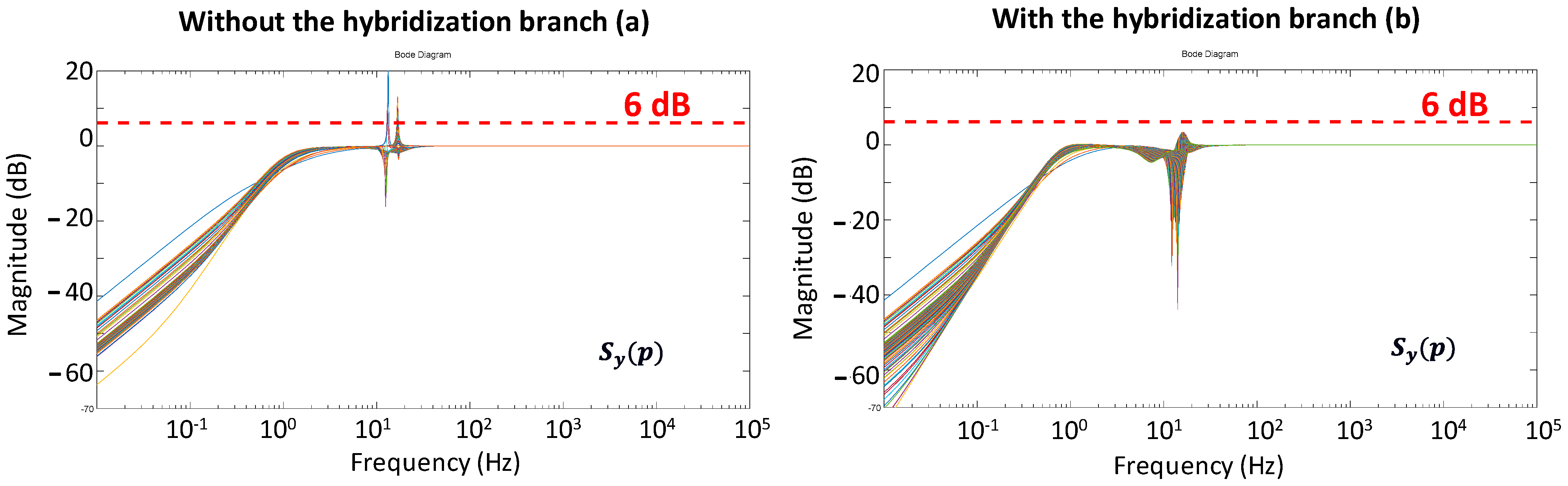

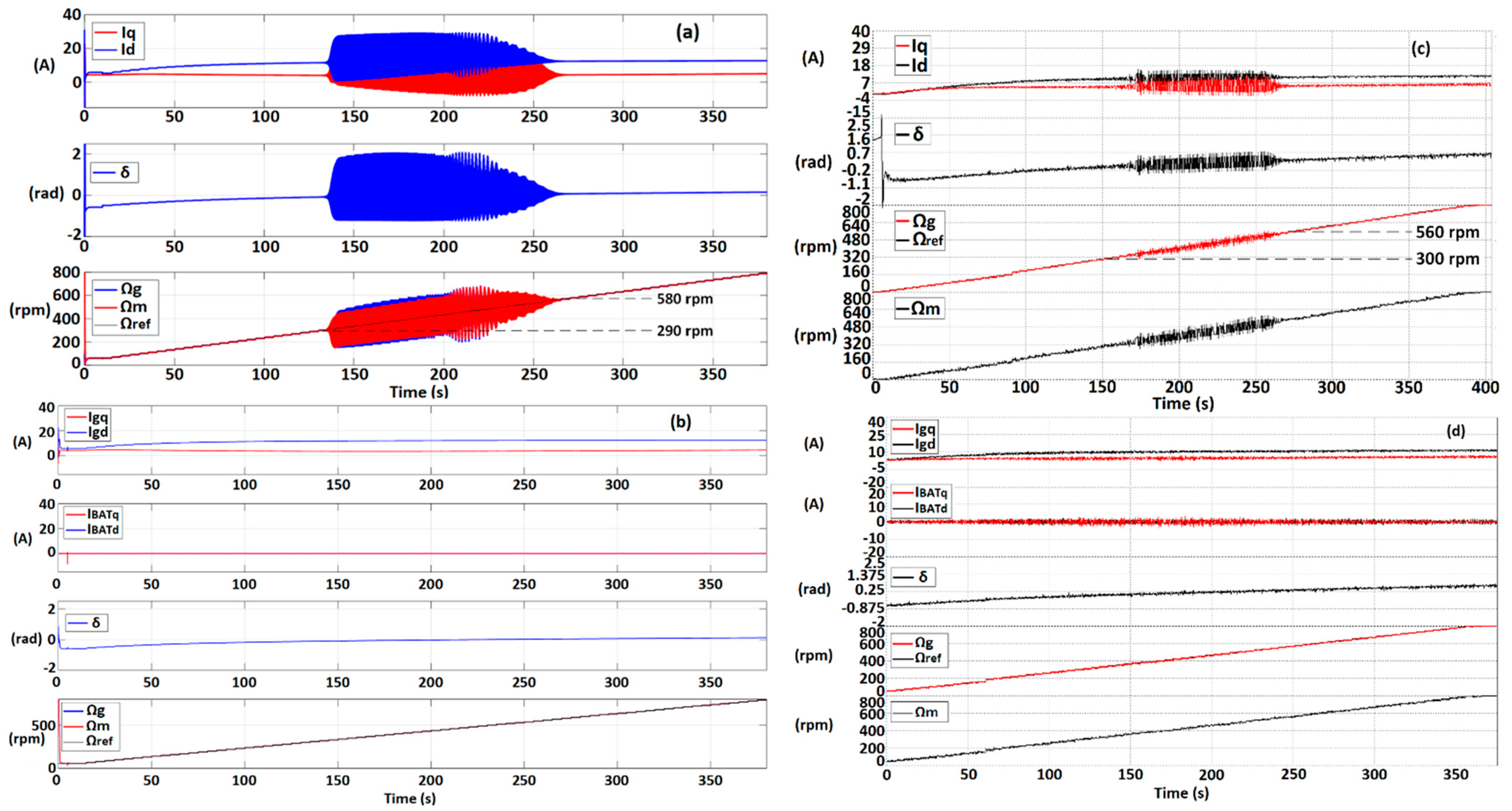

4.3. Power Hybridization of the Direct AC-Coupled Power Channel for Stable Operation

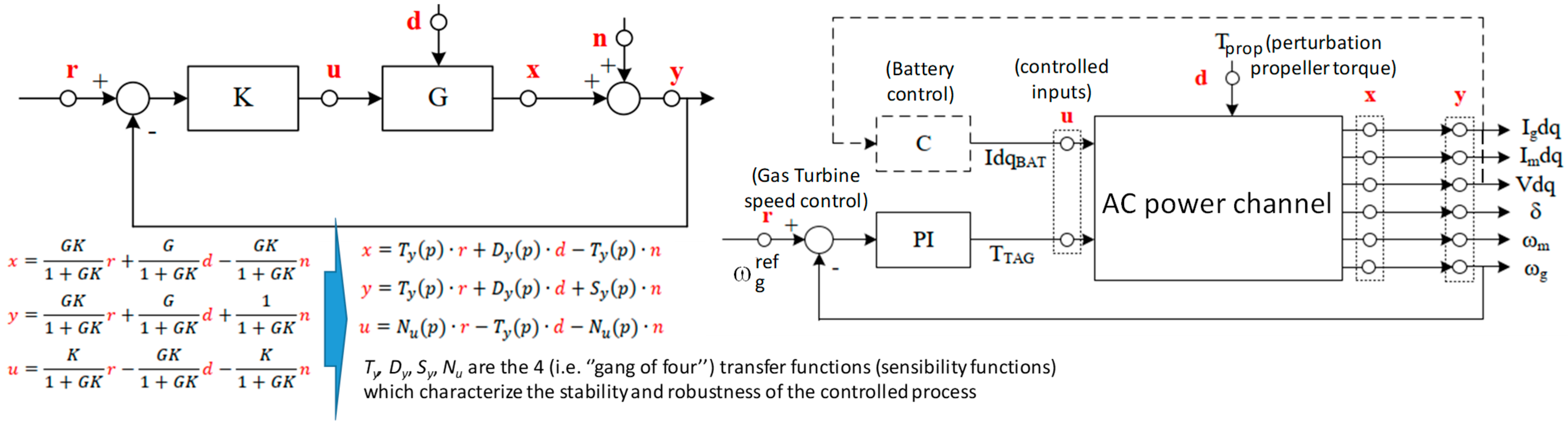

4.4. Control of the Hybridization Branch for System Stabilization

5. Conclusions and Future Directions

Funding

Data Availability Statement

Conflicts of Interest

References

- IATA. Global Outlook for Air Transport—Times of Turbulence. Report. 2022. Available online: https://www.iata.org/en/iata-repository/publications/economic-reports/airline-industry-economic-performance---june-2022---report (accessed on 3 March 2023).

- Eurocontrol, Eurocontrol Forecast Update 2021–2027. 2021. Available online: https://www.eurocontrol.int/publication/eurocontrol-forecast-update-2021-2027 (accessed on 1 March 2023).

- IATA. Aircraft Technology Roadmap to 2050. 2019. Available online: https://www.iata.org/contentassets/8d19e716636a47c184e7221c77563c93/Technology-roadmap-2050.pdf (accessed on 6 March 2023).

- Sarlioglu, B.; Morris, C.T. More Electric Aircraft: Review, Challenges, and Opportunities for Commercial Transport Aircraft. IEEE Trans. Transp. Electrif. 2015, 1, 54–64. [Google Scholar] [CrossRef]

- Berger, R. Electric Propulsion Is Finally on the Map. Available online: https://www.rolandberger.com/en/Insights/Publications/Electric-propulsion-is-finally-on-the-map.html (accessed on 18 March 2020).

- Pornet, C.; Isikveren, A. Conceptual design of hybrid-electric transport aircraft. Prog. Aerosp. Sci. 2015, 79, 114–135. [Google Scholar] [CrossRef]

- Epstein, A.H.; O’Flarity, S.M. Considerations for Reducing Aviation’s CO2 with Aircraft Electric Propulsion. J. Propuls. Power 2019, 35, 572–582. [Google Scholar] [CrossRef]

- Ansell, P.J.; Haran, K.S. Electrified Airplanes: A Path to Zero-Emission Air Travel. IEEE Electrif. Mag. 2020, 8, 18–26. [Google Scholar] [CrossRef]

- Madonna, V.; Giangrande, P.; Galea, M. Electrical Power Generation in Aircraft: Review, Challenges, and Opportunities. IEEE Trans. Transp. Electrif. 2018, 4, 646–659. [Google Scholar] [CrossRef]

- Thauvin, J. Exploring the Design Space for a Hybrid-Electric Regional Aircraft with Multidisciplinary Design Optimisation Methods. Ph.D. Thesis, Institut National Polytechnique de Toulouse (Toulouse INP), Toulouse, France, 2018. Available online: https://oatao.univ-toulouse.fr/23607/1/Thauvin_jerome.pdf (accessed on 1 September 2022).

- Clarke, S.; Redifer, M.; Papathakis, K.; Samuel, A.; Foster, T. X-57 Power and Command System Design. In Proceedings of the 2017 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 22–24 June 2017; pp. 393–400. [Google Scholar] [CrossRef]

- Hermetz, J.; Ridel, M.; Doll, C. Distributed electric propulsion for small business aircraft a concept-plane for key-technologies investigations. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Deajeon, Republic of Korea, 25–30 September 2016; pp. 1–10. [Google Scholar]

- Dillinger, E.; Döll, C.; Liaboeuf, R.; Toussaint, C.; Hermetz, J.; Verbeke, C.; Ridel, M. Handling qualities of ONERA’s small business concept plane with distributed electric propulsion. In Proceedings of the 30th Congress of the International Council of the Aeronautical Sciences, Belo Horizonte, Brazil, 9–14 September 2018; pp. 1–10. [Google Scholar]

- Pettes-Duler, M. Integrated Optimal Design of a Hybrid-Electric Aircraft Powertrain. Ph.D. Thesis, Institut National Polytechnique de Toulouse (Toulouse INP), Toulouse, France, 2021. Available online: https://oatao.univ-toulouse.fr/28350/1/Pettes_Duler_Matthieu_.pdf (accessed on 1 September 2022).

- Gao, Y.; Yang, T.; Bozhko, S.; Wheeler, P.; Dragicevic, T. Filter Design and Optimization of Electromechanical Actuation Systems Using Search and Surrogate Algorithms for More-Electric Aircraft Applications. IEEE Trans. Transp. Electrif. 2020, 6, 1434–1447. [Google Scholar] [CrossRef]

- Zhang, X.; Bowman, C.L.; O’Connell, T.C.; Haran, K.S. Large electric machines for aircraft electric propulsion. IET Electr. Power Appl. 2018, 12, 767–779. [Google Scholar] [CrossRef]

- Donateo, T.; De Pascalis, C.L.; Ficarella, A. Synergy Effects in Electric and Hybrid Electric Aircraft. Aerospace 2019, 6, 32. [Google Scholar] [CrossRef]

- Glassock, R.; Galea, M.; Williams, W.; Glesk, T. Hybrid Electric Aircraft Propulsion Case Study for Skydiving Mission. Aerospace 2017, 4, 45. [Google Scholar] [CrossRef]

- Brown, G.V. Weights and efficiencies of electric components of a turboelectric aircraft propulsion system. In Proceedings of the 49th AIAA Aerospace Sciences Meeting Including the New Horizons Forum and Aerospace Exposition, Orlando, FL, USA, 4–7 January 2011. [Google Scholar] [CrossRef]

- Antcliff, K.R.; Guynn, M.D.; Marien, T.; Wells, D.P.; Schneider, S.J.; Tong, M.J. Mission Analysis and Aircraft Sizing of a Hybrid-Electric Regional Aircraft. In Proceedings of the 54th AIAA Aerospace Sciences Meeting, San Diego, CA, USA, 4–6 January 2016; pp. 1–18. [Google Scholar] [CrossRef]

- Voskuijl, M.; Van Bogaert, J.; Rao, A.G. Analysis and design of hybrid electric regional turboprop aircraft. CEAS Aeronaut. J. 2018, 9, 15–25. [Google Scholar] [CrossRef]

- Ye, X.I.E.; Savvarisal, A.; Tsourdos, A.; Zhang, D.; Jason, G.U. Review of hybrid electric powered aircraft, its conceptual design and energy management methodologies. Chin. J. Aeronaut. 2021, 34, 432–450. [Google Scholar]

- Ribeiro, J.; Afonso, F.; Ribeiro, I.; Ferreira, B.; Policarpo, H.; Peças, P.; Lau, F. Environmental assessment of hybrid-electric propulsion in conceptual aircraft design. J. Clean. Prod. 2020, 247, 119477. [Google Scholar] [CrossRef]

- Rings, R.; Ludowicy, J.; Finger, D.F.; Braun, C. Sizing Studies of Light Aircraft with Parallel Hybrid Propulsion Systems; Deutsche Gesellschaft für Luft-und Raumfahrt-Lilienthal-Oberth eV: Bonn, Germany, 2018. [Google Scholar] [CrossRef]

- Brelje, B.J.; Martins, J.R. Electric, hybrid, and turboelectric fixed-wing aircraft: A review of concepts, models, and design approaches. Prog. Aerosp. Sci. 2018, 104, 1–19. [Google Scholar] [CrossRef]

- Janovec, M.; Čerňan, J.; Škultéty, F.; Novák, A. Design of batteries for a hybrid propulsion system of a training aircraft. Energies 2021, 15, 49. [Google Scholar] [CrossRef]

- Benzaquen, J.; He, J.; Mirafzal, B. Toward more electric powertrains in aircraft: Technical challenges and advancements. In CES Transactions on Electrical Machines and Systems; CES: Winchester, NV, USA, 2021; Volume 5. [Google Scholar] [CrossRef]

- Saias, C.A.; Goulos, I.; Roumeliotis, I.; Pachidis, V.; Bacic, M. Preliminary Design of Hybrid-Electric Propulsion Systems for Emerging Urban Air Mobility Rotorcraft Architectures. J. Eng. Gas Turbines Power 2021, 143, 111015. [Google Scholar] [CrossRef]

- Hoelzen, J.; Liu, Y.; Bensmann, B.; Winnefeld, C.; Elham, A.; Friedrichs, J.; Hanke-Rauschenbach, R. Conceptual Design of Operation Strategies for Hybrid Electric Aircraft. Energies 2018, 11, 217. [Google Scholar] [CrossRef]

- Martins, J.; Lambe, A.B. Multidisciplinary Design Optimization: A Survey of Architectures. AIAA J. 2013, 51, 2049–2075. [Google Scholar] [CrossRef]

- Iwaniuk, A.; Wiśniowski, W.; Żółtak, J. Multi-disciplinary optimisation approach for a light turboprop aircraft-engine integration and improvement. Aircr. Eng. Aerosp. Technol. 2016, 88, 348–355. [Google Scholar] [CrossRef]

- Lefebvre, T.; Schmollgruber, P.; Blondeau, C.; Carrier, G. Aircraft conceptual design in a multilevel, multifidelity, multidisciplinary optimization process. In Proceedings of the 28th International Congress of The Aeronautical Sciences, Brisbane, Australia, 23–28 September 2012; pp. 23–28. [Google Scholar]

- Gazaix, A.; Gallard, F.; Gachelin, V.; Druot, T.; Grihon, S.; Ambert, V.; Guénot, D.; Lafage, R.; Vanaret, C.; Pauwels, B.; et al. Towards the Industrialization of New MDO Methodologies and Tools for Aircraft Design. In Proceedings of the AIAA/ISSMO (18th Multidisciplinary Analysis and Optimization Conference—The American Institute of Aeronautics and Astronautics), Denver, CO, USA, 5–9 June 2017; pp. 1–23. [Google Scholar]

- Delbecq, S.; Budinger, M.; Ochotorena, A.; Reysset, A.; Defay, F. Efficient sizing and optimization of multirotor drones based on scaling laws and similarity models. Aerosp. Sci. Technol. 2020, 102, 105873. [Google Scholar] [CrossRef]

- De Giorgi, F.; Budinger, M.; Hazyuk, I.; Reysset, A.; Sanchez, F. Reusable Surrogate Models for the Preliminary Design of Aircraft Application Systems. AIAA J. 2021, 59, 2490–2502. [Google Scholar] [CrossRef]

- Liu, Y.; Elham, A.; Horst, P.; Hepperle, M. Exploring Vehicle Level Benefits of Revolutionary Technology Progress via Aircraft Design and Optimization. Energies 2018, 11, 166. [Google Scholar] [CrossRef]

- Brelje, B. Multidisciplinary Design Optimization of Electric Aircraft Considering Systems Modeling and Packaging. Ph.D. Thesis, Aerospace Engineering and Scientific Computing, University of Michigan, Ann Arbor, MI, USA, 2021. [Google Scholar]

- Finger, D.F. Methodology for Multidisciplinary Aircraft Design under Consideration of Hybrid-Electric Propulsion Technology. Ph.D. Thesis, RMIT University, Melbourne, VIC, USA, 2020. [Google Scholar]

- Prigent, S.; Maréchal, P.; Rondepierre, A.; Druot, T.; Belleville, M. A robust optimization methodology for preliminary aircraft design. Eng. Optim. 2016, 48, 883–899. [Google Scholar] [CrossRef]

- Lei, T.; Min, Z.; Gao, Q.; Song, L.; Zhang, X. The Architecture Optimization and Energy Management Technology of Aircraft Power Systems: A Review and Future Trends. Energies 2022, 15, 4109. [Google Scholar] [CrossRef]

- Pettes-Duler, M.; Roboam, X.; Sareni, B. Integrated Design Process and Sensitivity Analysis of a Hybrid Electric Propulsion System for Future Aircraft. In Lecture Notes in Electrical Engineering; Springer: Berlin/Heidelberg, Germany, 2020; Volume 1, pp. 71–85. [Google Scholar]

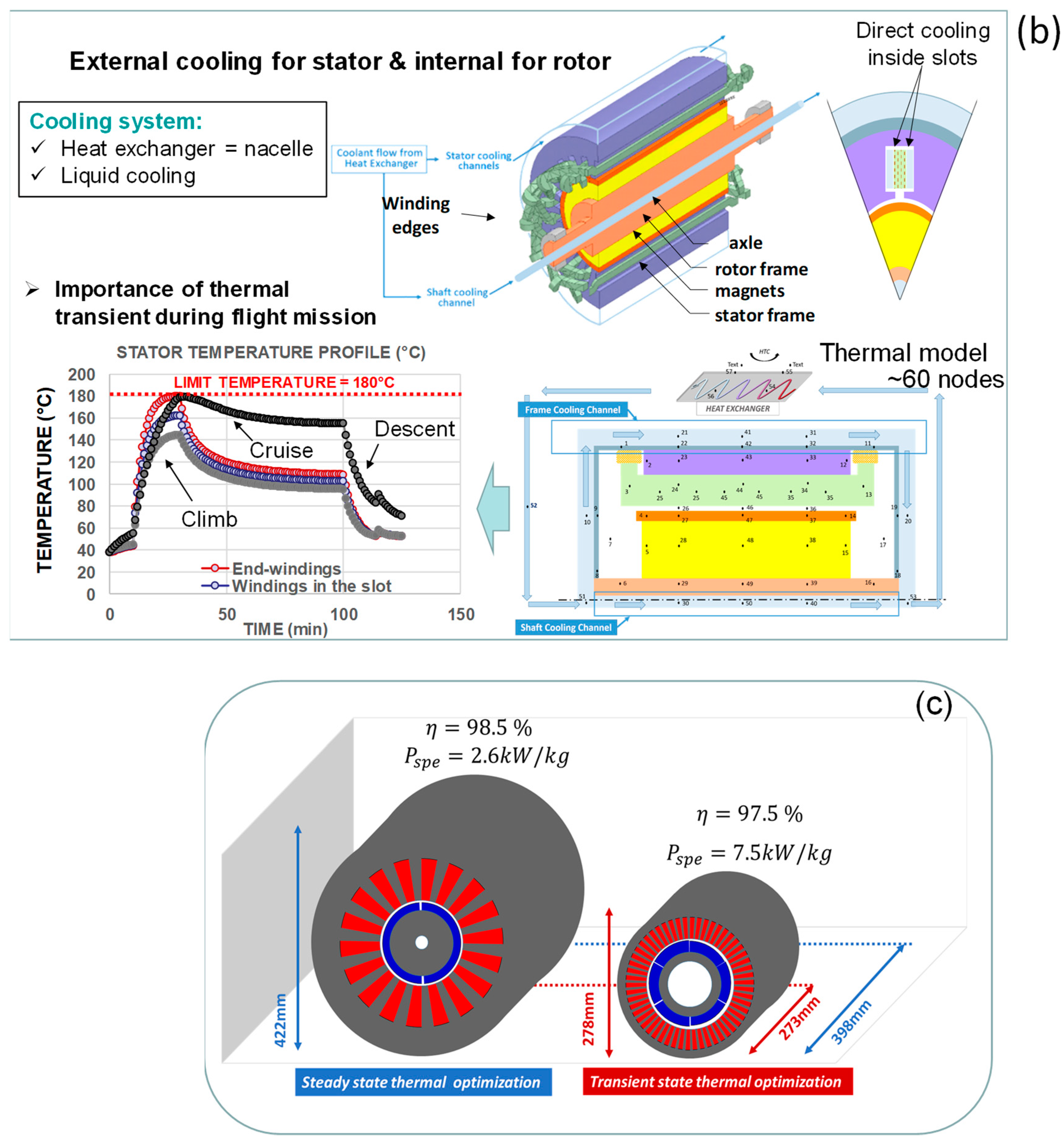

- Zeaiter, A. Thermal Modeling and Cooling of Electric Motors Application to the Propulsion of Hybrid Aircraft. Ph.D. Thesis, Ecole Nationale Supérieure de Mécanique et d’Aérotechnique (ENSMA), Chasseneuil-du-Poitou, France, 2020. Available online: https://tel.archives-ouvertes.fr/tel-03158868/document (accessed on 1 September 2022).

- Zeaiter, A.; Fenot, M. Thermal Sensitivity Analysis of a High Power Density Electric Motor for Aeronautical Application. In Proceedings of the 2018 IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles International Transportation Electrification Conference (ESARS-ITEC), Nottingham, UK, 7–9 November 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Touhami, S. Analytical Sizing Models to Assess the Performances of High Specific Power Electric Motors for Hybrid Aircraft. Ph.D. Thesis, Institut National Polytechnique de Toulouse (Toulouse INP), Toulouse, France, 2020. Available online: https://oatao.univ-toulouse.fr/28218/1/Touhami_Sarah.pdf (accessed on 1 September 2022).

- Touhami, S.; Zeaiter, A.; Fenot, M.; Lefèvre, Y.; Llibre, J.F.; Videcoq, E. Electrothermal models and design approach for high specific power electric motor for hybrid aircraft. In Proceedings of the Aerospace Europe Conference, Bordeaux, France, 25–28 February 2020. [Google Scholar]

- Collin, P. Design, Taking into Account the Partial Discharges Phenomena, of the Electrical Insulation System (EIS) of High Power Electrical Motors for Hybrid Electric Propulsion of Future Regional Aircraft. Ph.D. Thesis, Université de Toulouse, Toulouse, France, 2020. Available online: http://thesesups.ups-tlse.fr/4730/1/2020TOU30116.pdf (accessed on 1 September 2022).

- Collin, P.; Malec, D.; Lefèvre, Y. Tool to predict and avoid Partial Discharges in stator slot of rotating motors fed by inverter. In Proceedings of the Aerospace Europe Conference, Bordeaux, France, 25–28 February 2020. [Google Scholar]

- Erroui, N. Chaine de Conversion Forte Puissance Pour la Propulsion Aéronautique Hybride. Ph.D. Thesis, Toulouse INP, Toulouse, France, 2019. Available online: https://oatao.univ-toulouse.fr/25529/1/Erroui_najoua.pdf (accessed on 1 September 2022).

- Erroui, N.; Gateau, G.; Roux, N. Continuous-caliber semiconductor components. In Proceedings of the 2018 IEEE International Conference on Industrial Technology (ICIT), Lyon, France, 20–22 February 2018. [Google Scholar]

- Accorinti, F. Two-Phase Power Electronics Cooling Solution Design in Air Context Answer to the Objectives of the Hybrid Aircraft 2035. Ph.D. Thesis, Ecole Nationale Supérieure de Mécanique et d’Aérotechnique (ENSMA), Chasseneuil-du-Poitou, France, 2020. Available online: https://tel.archives-ouvertes.fr/tel-02993195/document (accessed on 1 September 2022).

- Accorinti, F.; Erroui, N.; Ayel, V.; Gateau, G.; Bertin, Y.; Roux, N.; Dutour, S.; Miscevic, M. High-efficiency cooling system for highly integrated power electronics for hybrid propulsion aircraft. In Proceedings of the 2019 IEEE 28th International Symposium on Industrial Electronics (ISIE), Vancouver, BC, Canada, 12–14 June 2019; pp. 870–877. [Google Scholar]

- Roboam, X.; Touhami, S.; Erroui, N.; Zeaiter, A.; Accorinti, F.; Collin, P.; Pettes-Duler, M. The HASTECS Book (Hastecs: Hybrid Aircraft: Research on Thermal and Electric Components and Systems). 2021. Available online: https://hal-univ-tlse3.archives-ouvertes.fr/hal-03407214 (accessed on 1 September 2022).

- Cavallo, A.; Canciello, G.; Russo, A. Integrated supervised adaptive control for the more Electric Aircraft. Automatica 2020, 117, 108956. [Google Scholar] [CrossRef]

- Akli, C.R. Conception Systémique d’une Locomotive Hybride Autonome. Application à la Locomotive Hybride de Démonstration et D’investigations en Energétique LHyDIE Développée par la SNCF. Ph.D. Thesis, Toulouse INP, Toulouse, France, 2008. Available online: https://oatao.univ-toulouse.fr/7710/1/akli.pdf (accessed on 25 May 2023). (In French).

- Ampaire Electric EELTM. Available online: https://www.ampaire.com/ (accessed on 25 May 2023).

- Zunum Aero. Available online: https://zunum.aero/ (accessed on 18 March 2020).

- Bell Nexus. Available online: https://fr.bellflight.com/products/bell-nexus (accessed on 10 March 2023).

- Anton, F. eAircraft: Hybrid-Elektrische Antriebe für Luftfahrzeuge. 2019. Available online: https://www.bbaa.de/fileadmin/user_upload/02-preis/02-02-preistraeger/newsletter-2019/02-2019-09/02_Siemens_Anton.pdf (accessed on 10 March 2023).

- Clean Hydrogen for Europe, H2 and the Future of Aircraft. 2022. Available online: https://hydrogeneurope.eu/h2-and-the-future-of-aircraft/ (accessed on 10 March 2023).

- Sadey, D.J.; Taylor, L.M.; Beach, R.F. Proposal and Development of a High voltage Variable Frequency alternating Current Power System for Hybrid Electric Aircraft. In Proceedings of the 14th International Energy Conversion Engineering Conference, Salt Lake City, UT, USA, 25–27 July 2016. [Google Scholar] [CrossRef]

- Sadey, D.J.; Bodson, M.; Csank, J.T.; Hunker, K.R.; Theman, C.J.; Taylor, L.M. Control Demonstration of Multiple Doubly-Fed Induction Motors for Hybrid Electric Propulsion. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar] [CrossRef]

- Himmelmann, R.A. Variable Speed AC Bus Powered Tail Cone Boundary Layer Ingestion Thruster. U.S. Patent US20180265206A1, 20 September 2018. [Google Scholar]

- Blackwelder, M.J.; Rancuret, P.M. Multiple Generator Synchronous Electrical Power Distribution System. U.S. Patent EP3197043A1, 26 July 2017. [Google Scholar]

- Armstrong, M.; Blackwelder, M. Combined AC and DC Turboelectric Distributed Propulsion System. U.S. Patent EP3318492A1, 9 May 2018. [Google Scholar]

- Armstrong, M.; Blackwelder, M.J.; Bollman, A.M. Synchronizing Motors for an Electric Propulsion System. U.S. Patent US20160365810A1, 15 December 2016. [Google Scholar]

- Bachmann, C.; Bergmann, D.; Bachmaier, G.; Gerlich, M.; Pais, G.; Vittorias, I. Propellerantrieb und Fahrzeug, Insbesondere Flugzeug. Germany Patent DE102015213580A1, 26 January 2017. [Google Scholar]

- Rougier, F.; Viguier, C. Système Electrique Pour Canal Propulsif Synchrone. France Patent FR3092948A1, 21 August 2020. [Google Scholar]

- Pettes-Duler, M.; Roboam, X.; Sareni, B.; Lefevre, Y.; Llibre, J.-F.; Fénot, M. Multidisciplinary Design Optimization of the actuation system of a hybrid electric aircraft powertrain. Electronics 2021, 10, 1297. [Google Scholar] [CrossRef]

- Petrowski, A. A clearing procedure as a niching method for genetic algorithms. In Proceedings of the IEEE International Conference on Evolutionary Computation, Nagoya, Japan, 20–22 May 1996; pp. 798–803. [Google Scholar] [CrossRef]

- Pettes-Duler, M.; Roboam, X.; Sareni, B. Integrated Optimal Design of a hybrid electric aircraft powertrain of future aircraft. Energies 2022, 15, 6719. [Google Scholar] [CrossRef]

- Richard, A. Conception D’architectures et Dimensionnement de Systèmes Propulsifs Aéronautiques, Etude des Canaux Propulsifs AC Synchrones. Ph.D. Thesis, Toulouse INP, Toulouse, France, 1 February 2023. (In French). [Google Scholar]

- Richard, A.; Roboam, X.; Rougier, F.; Roux, N.; Piquet, H. AC Electric Powertrain without Power Electronics for Future Hybrid Electric Aircraft: Architecture, Design and Stability Analysis. Appl. Sci. 2023, 13, 672. [Google Scholar] [CrossRef]

- Zimenko, K.; Polyakov, A.; Efimov, D.; Kremlev, A. Frequency Domain Analysis of Control System Based on Implicit Lyapunov Function. In Proceedings of the Chez IEEE—2016 European Control Conference (ECC), Aalborg, Denmark, 29 June–1 July 2016. [Google Scholar] [CrossRef]

- Airbus to Boost ‘Cold’ Technology Testing as Part of Its Decarbonisation Roadmap—Commercial Aircraft—Airbus. Available online: https://www.airbus.com/newsroom/press-releases/en/2021/03/airbus-to-boost-cold-technology-testing-as-part-of-its-decarbonisation-roadmap.html (accessed on 2 June 2021).

- Schneider, S. Some NASA Perspectives on H2. H2@Airports Workshop. 4 November 2020. Available online: https://www.energy.gov/sites/prod/files/2020/12/f81/hfto-h2-airports-workshop-2020-schneider.pdf (accessed on 25 May 2023).

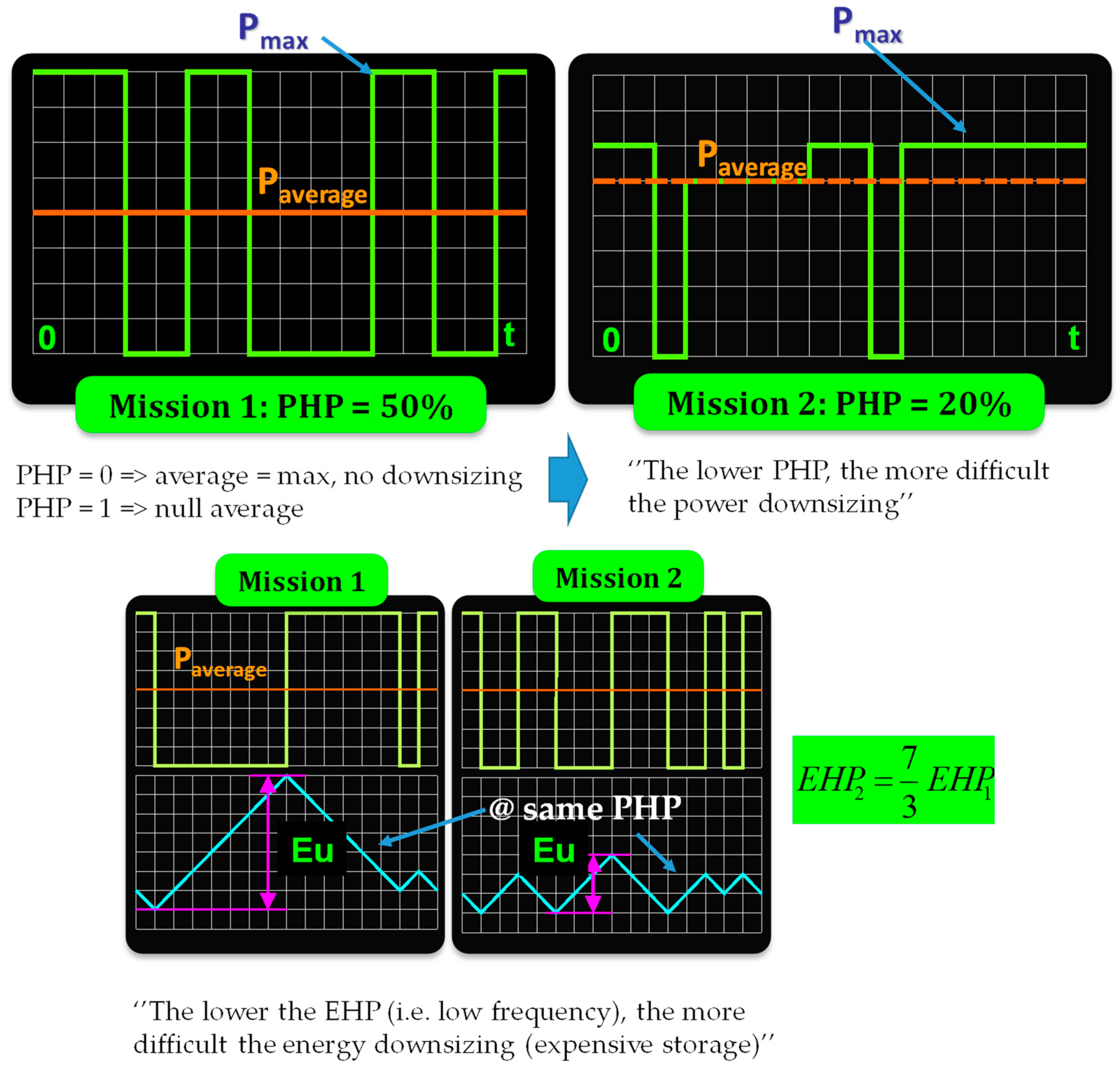

| Car | Train | Ship | Aircraft | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Urban | Rural Road | Motorway 150 km/h | Local Service | Switching | Urban Transport | Container | Passenger Ferry | Regional 200 nm | |

| PHP (%) | 94 | 85 | 74 | 65 | 83 | 91 | 43 | 63 | 33 |

| EHP (mHz) | 66 | 30 | 12 | 3 | 29 | 20 | n/a | n/a | 0.22 |

| EIS 2025 | EIS 2030+ | ||

|---|---|---|---|

| Electric machine | Specific power Efficiency | 7 kW/kg 96% | 11 kW/kg 98.5% |

| Power Electronics | Specific power | 15 kW/kg 99% | 20 kW/kg 99.5% |

| Battery | Specific energy Max charge/discharge (C rate) Efficiency | 280 Wh/kg 2/5 90% | 380 Wh/kg 2/5 95% |

| Cables | DC bus voltage | 540 V | 1500 V |

| 2025 Target | 2035 Target | 20XX Target | |

| eMotor/eGenerator | |||

| SP + cooling Efficiency | 5 kW/kg 96% | 10 kW/kg 98.5% | 15 kW/kg 99% |

| Power Electronics | |||

| SP + cooling Efficiency | 15 kW/kg 98% | 25 kW/kg 99.5% | 35 kW/kg 99.8% |

| Fuel Cell—Liquid H2 | |||

Auxiliary Stack | 3.3 kWh/kg 1.3 kW/kg 4 kW/kg | ||

| DC Bus | |||

| Ultra | 2000 V | ||

| LTO | NMC Solid State | FC System with Liquid H2 | ||

|---|---|---|---|---|

| Perspectives (5–10 years) | Cell level | ~180–200 Wh/kg | ~650 Wh/kg | ~1000 Wh/kg |

| System level | ~100 Wh/kg | ~325 Wh/kg | ~560 Wh/kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Roboam, X. A Review of Powertrain Electrification for Greener Aircraft. Energies 2023, 16, 6831. https://doi.org/10.3390/en16196831

Roboam X. A Review of Powertrain Electrification for Greener Aircraft. Energies. 2023; 16(19):6831. https://doi.org/10.3390/en16196831

Chicago/Turabian StyleRoboam, Xavier. 2023. "A Review of Powertrain Electrification for Greener Aircraft" Energies 16, no. 19: 6831. https://doi.org/10.3390/en16196831

APA StyleRoboam, X. (2023). A Review of Powertrain Electrification for Greener Aircraft. Energies, 16(19), 6831. https://doi.org/10.3390/en16196831