Abstract

Mitigating CO2 emissions from long-haul commercial trucking is a major challenge that must be addressed to achieve substantial reductions in greenhouse gas (GHG) emissions from the transportation sector. Extensive recent research and development programs have shown how significant near-term reductions in GHGs from commercial vehicles can be achieved by combining technological advances. This paper reviews progress in technology for engine efficiency improvements, vehicle resistance and drag reductions, and the introduction of hybrid electric powertrains in long-haul trucks. The results of vehicle demonstration projects by major vehicle manufacturers have shown peak brake thermal efficiency of 55% in heavy-duty diesel engines and have demonstrated freight efficiency improvements of 150% relative to a 2009 baseline in North America. These improvements have been achieved by combining multiple incremental improvements in both engine and vehicle technologies. Powertrain electrification through hybridization has been shown to offer some potential reductions in fuel consumption. These potential benefits depend on the vehicle use, the details of the powertrain design, and the duty cycle. To date, most papers have focused on standard drive cycles, leaving a research gap in how hybrid electric powertrains would be designed to minimize fuel consumption over real-world drive cycles, which are essential for a reliable powertrain design. The results of this paper suggest that there is no “one-size-fits-all” solution to reduce the GHGs in long-haul trucking, and a combination of technologies is required to provide an optimum solution for each application.

1. Introduction

On-road transportation of freight is central to modern economic activity. However, current on-road freight vehicles emit significant amounts of greenhouse gas emissions (GHGs), on the order of 7% of global anthropogenic emissions [1], along with significant amounts of local and regional air pollutants. The GHG emissions from commercial trucking in developed economies have been increasing over the last decades due to an increasing road freight transport demand. In North America (NA), for example, GHG emissions from heavy-duty vehicles (HDVs) have doubled over the past 25 years despite significant improvements in fuel economy (FE) [2]. Eliminating these emissions is critical to meeting global commitments to net-zero GHG emissions but must be achieved without imposing unacceptable costs on the economic activity that freight transportation underpins. This work reviews recent advances in vehicle and engine technology and powertrain electrification as approaches to reducing GHG emissions from the long-haul (LH) trucking sector.

The urgent need to reduce GHG emissions in commercial vehicles has led to the development of increasingly stringent GHG/CO2 regulations for those vehicles [3,4,5]. A focus of regulatory activity has been on heavy-duty (HD) and long-haul trucks (LHTs), with gross vehicle weight ratings (GVWR) exceeding 15 tons (33,000 lbs) and daily mileage of 300 mi to 500 mi. Moreover, regional-haul trucks (RHTs), which have lower daily mileage (50 mi to 300 mi), face the same challenges as LHTs in terms of high levels of GHGs. While LHTs are numerically a small proportion of the HDV fleet, they produce a substantial fraction of total GHGs (50% to 65%) and criteria pollutants emitted by HDVs [6,7,8]. In response, the European Commission (EC), the United States Environmental Protection Agency (EPA), and the California Air Resources Board (CARB) have implemented increasingly stringent regulations on GHG emissions from LHTs. In 2023, the European Union (EU) finalized rules to reduce CO2 emissions from LHTs relative to a 2019 baseline of 45% by 2030, 65% by 2035, and 90% by 2040 [3,4]. In the United States (U.S.), the EPA has published Phase 3 GHG regulations that require 25% CO2 reductions in LHTs from 2027 to 2032 [5]. Engine and aftertreatment system efficiency improvements and vehicle technologies are required to meet these emission requirements. However, GHG mitigation strategies in diesel engines must be NOx neutral or even be able to diminish NOx amounts due to recently announced tight NOx limits [9]. This paper will evaluate the current advances in LHTs by summarizing the recent developments in engine, powertrain, and vehicle sides.

Current HDV technology is advancing rapidly because of regulatory push and fuel costs, with improvements in engine efficiency, advances in the powertrain, and enhancement of the vehicle side technologies to reduce road resistance forces. Considerable efforts have been expended on developing commercially feasible technologies for LHTs. In North America, the U.S. Department of Energy (DOE) collaborated with major vehicle original equipment manufacturers (OEMs) in three phases of the “SuperTruck” program to improve efficiency in long-haul trucking. Manufacturers have reported 150% improvements in freight efficiency (measure of fuel consumed to carry a unit payload over a unit distance, i.e., kg·km/L or ton-mile per gallon) using technologies with commercially viable payback periods on the order of 2 years [10,11]. The approaches have included engine advances, vehicle improvements (weight, aerodynamic drag, rolling resistance), and powertrain advances.

Electrifying the powertrain has been receiving much attention recently, particularly in light-duty vehicles (LDVs). A hybrid powertrain with an electric drive system coupled to the powertrain can capture some of the energy currently lost as heat through traditional friction brakes and store it in a battery (regenerative braking), leading to fuel consumption (FC) mitigation. Hybrid electric powertrains cover a wide range, from an oversized starter motor/alternator (mild-hybrid) to a fully electric drive system where an internal combustion engine (ICE) is used to maintain the charge in the battery (full hybrid). Hybrid powertrain systems have been increasingly penetrating the LDV market and medium-duty vehicles such as vocational trucks and buses in urban operation due to the prevalence of stop-and-go traffic in urban cycles and the hybrid powertrain’s ability to recover energy. For heavy trucks in long-haul applications, systems to date have focused on mild-hybrid applications, where a 48 V system is used to electrify auxiliaries, reduce the need for engine idling, and provide limited energy recovery [12,13]. A key challenge for LHT propulsion systems is the need for sustained high torques when heavy payloads are combined with long uphill grades and long daily driving distances.

The scope of this review includes current advances in the engine, powertrain, and vehicle of LHTs and RHTs. However, this study does not include light HDVs (e.g., HD pickups) and medium HDVs, such as school and transit buses and vocational trucks. The HDV fleet is very diverse in terms of GVWR, daily mileage, operating characteristics, and drive cycles; however, this study only focuses on LHTs and RHTs. The detailed description of these two classes is in Table 1. Moreover, hydrogen-fuelled engines and fuel cell trucks are not covered in this paper. Finally, the cost analysis and life cycle assessment of the studied technologies are out of the scope of this study.

Table 1.

The studied trucks are included in the scope of this review.

This paper is organized as follows: First, the LHTs’ make-up and market will be shown. Second, the current regulations on GHGs will be presented. Third, recent technological developments in the engine, vehicle, and powertrain will be reviewed. Subsequently, the electrified powertrains will be scrutinized, considering the long-haul trucking application. Finally, the standard and experimental drive cycles and their importance in designing hybrid powertrains will be discussed, highlighting existing research gaps. Finally, the topics that will be discussed in this paper are summarized in Figure 1.

Figure 1.

Structure and key topics for long-haul truck powertrain technologies are reviewed in this paper.

2. LHTs Make-Up and Market

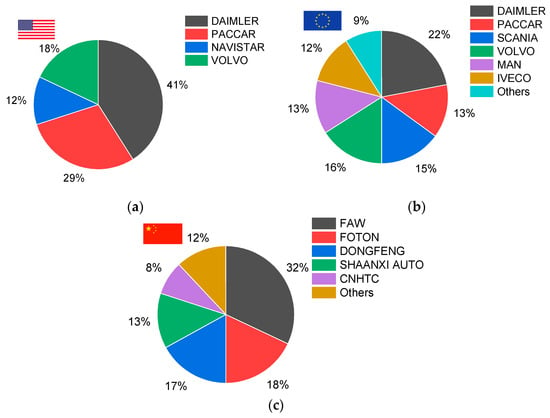

Road freight transport is a critical part of economic activity worldwide. It generates a turnover of more than €334 billion in Europe and provides jobs for 3.2 million Europeans [15]. In North America, trucks are responsible for 66% of the trade between the U.S., Canada, and Mexico. All other modes, like air and rail, handle the remaining 34% of the freight [16,17]. To meet these demands, annual commercial vehicle production globally is on the order of 10 M units. Manufacturers are primarily based in China (42% of global truck and bus production from 2016 to 2022), 21% in Europe, and 13% in the U.S. [18]. There are relatively few OEMs for LHTs in all the main markets, as summarized in Figure 2 [18,19,20]. Some of the main OEMs are active in both Europe and North America, including PACCAR (DAF and Leyland in Europe; Peterbilt and Kenworth in NA); Daimler (Freightliner and Western Star in NA); and Volvo (Mack in NA).

Figure 2.

LHT OEM market share in (a) the U.S. (2021), (b) Western Europe (2017), and (c) China (2016) [18,19,20,21].

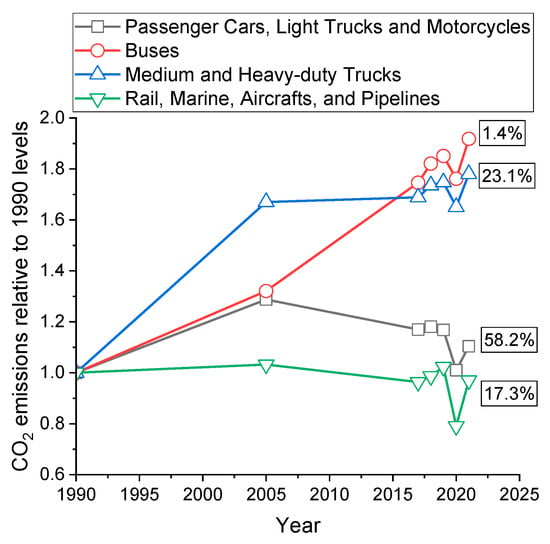

The carbon footprint of HDVs has increased considerably compared to other transportation sections. For example, in the U.S. (and similarly in Canada), as shown in Figure 3, the CO2 has almost doubled since 1990 for HDVs, showing that despite vehicle efficiency improvements, the total fuel consumption has risen due to an increasing road freight transport demand. Buses also showed a similar trend, although the GHG level of the light-duty sector has been almost stable since 1990. In Europe, CO2 emissions from HDVs increased by 25% between 1990 and 2016, stemming from growing road transport demand [21].

Figure 3.

CO2 emissions in the transportation sector in the U.S. relative to 1990; the values in the box show the 2021 CO2 share in transportation—data obtained from [22,23].

HDVs are categorized as light heavy-duty (GVWR of 8500 to 19,500 lbs), medium heavy-duty (GVWR of 19,501 to 33,000 lbs), and heavy heavy-duty (LHTs with GVWR exceeding 33,000 lbs). As seen in Table 2, HDVs form only 2% of vehicles on the road in Europe and are responsible for one-fourth of the road transport CO2 in the EU (and almost 6% of total EU GHG) and 31% of transport-related NOx emissions [3,21,24]. HDVs show a similar GHG share in the U.S. [25], and although they represent only 7.8% of the total road transport market, HDVs in China are responsible for 74% of transport NOx, 52.4% of road PM and 6.1% of all GHG emissions [26].

Table 2.

HDV share in road transportation emissions [6,8,25,26].

Although light commercial vehicles in HDVs account for the largest market share, tractor–trailers, or LHTs, emit a major part of GHG and NOx emissions. For example, LHTs form 9% of the HDV fleet in the U.S. but emit almost half of the NOx emissions and half of the GHGs. Similarly, RHTs make up 5% of the HDV fleet and are responsible for 12% and 13% of the GHGs and NOx emissions, respectively [8]. Moreover, in particular, LHTs emit 65% of the CO2 emissions within HDVs in Europe [6,7].

Moreover, LHTs are responsible for hauling almost 65% of goods (regarding the weight of the shipment) [27] in the U.S. while using 28 billion gallons of fuel per year (22% of total transportation energy usage). Also, HDVs’ GHG emissions in the U.S. are almost 430 MMT CO2 equivalent per year. Similarly, in Europe, these trucks account for almost two-thirds of road freight transport in vehicle kilometers [28]. As a result, there is a significant opportunity for technology improvement to reduce emissions and fuel costs in this key sector. One of the main driving factors for these engine, powertrain, and vehicle parts improvements is stringent emission regulations, which will be discussed in the next section.

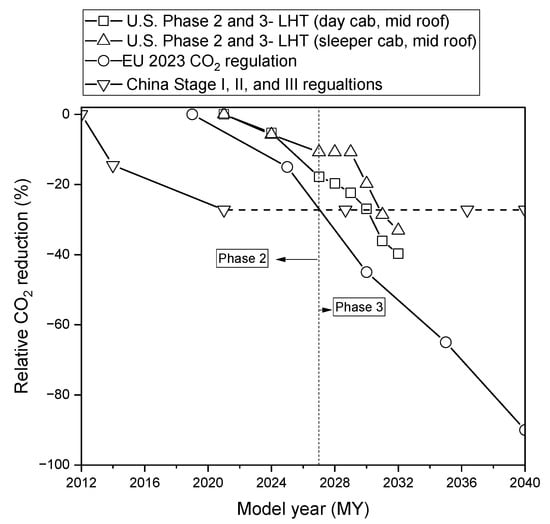

3. Drivers of LHT Fuel Consumption Reduction

Regulatory push and cost savings from fuel consumption reduction are the main drivers for the technology upgrades in commercial vehicles. The emission regulations for LHTs are categorized as GHG and meet the criteria for pollutant emissions. Regulatory limits aiming to reduce GHG emissions in LHTs vary between jurisdictions. Requirements for the U.S., EU, and China are summarized in Figure 4. The U.S. Phase 2 and 3 regulations, when combined, require an almost 40% CO2 reduction in LHTs in 2032 compared to 2021 levels [5]. In February 2023, the European Union announced more ambitious fleet average targets for CO2 reduction in HDVs, with 45% in 2030, 65% in 2035, and 90% in 2040 compared to 2019 levels [3,4]. Finally, China is in phase 3 of the fuel consumption standard, which applies to all new 2021 heavy commercial vehicles with a 15% lower fuel consumption limit than the previous phase.

Figure 4.

Overview of GHG regulations in different jurisdictions—data obtained from [3,5,29].

In all cases, the regulations target vehicle tailpipe (not fuel-cycle) emissions reductions and are based on manufacturer sales-weighted annual new vehicle averages. The wide variety of HDVs means that type approval for individual vehicles, common in LDVs, would be prohibitively expensive. Instead, regulations combine ICE emissions and performance test results with vehicle simulations to provide consistent assessments across HDV platforms. European regulation uses a modeling tool called the Vehicle Energy Consumption Calculation Tool (VECTO), while in the U.S., the EPA uses the Greenhouse Gas Emissions Model (GEM). Although details differ, both tools combine ICE performance and emissions maps with powertrain (transmission, etc.) and vehicle configuration (load/weight, rolling resistance, drag) data over a series of defined drive cycles. GHG restrictions can be based on vehicle configuration: VECTO includes over 15 different classes of LHTs, while the EPA regulates different standards based on weight and vehicle configuration (e.g., day cab vs. sleeper cab). In the U.S., GHG emissions include tailpipe CO2 as well as other GHGs (including CH4 and N2O). In the EU, the regulations are for tailpipe CO2 only; emissions of other GHGs are captured under air pollutant emissions limits.

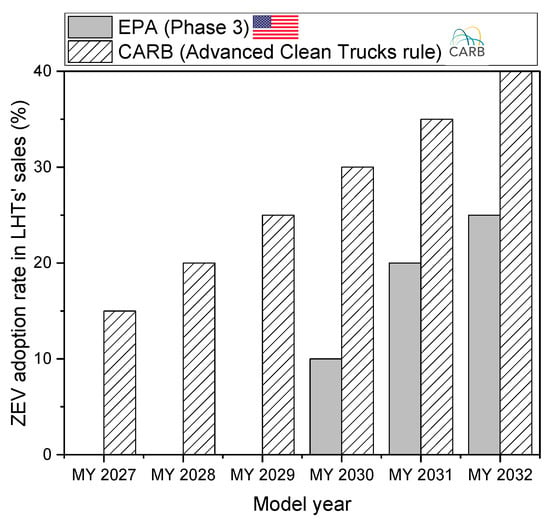

Along with fleet average GHG/CO2 reductions, regulators are also implementing requirements for a fraction of new HDV sales of zero-emission vehicles (ZEVs). In NA, CARB is implementing ZEV requirements, as shown in Figure 5, and the EPA estimated ZEV adoption rates as one potential technology pathway to meet the CO2 standards [12,30]. Similarly, in the European context, there is flexibility to comply with the CO2 regulations determined by the zero- and low-emission vehicle (ZLEV) factor to reduce the manufacturer’s target by 3% depending on the number of produced ZLEVs [31]. Moreover, the International Energy Agency (IEA) has projected that the share of battery electric trucks needs to be 25% by 2030 to comply with the Net Zero Emissions by 2050 Scenario (NZE) [32]. Similarly, the share of battery electric vehicles in the medium and HD sectors is envisioned to reach 40% by 2040, based on the BloombergNEF report [33]. It is significant to consider the required infrastructure and life-cycle implications of full powertrain electrification. Moreover, different factors, such as battery weight/size and their impact on cargo capacity and charging time, need to be better evaluated in ZEVs regarding long-haul trucking applications. According to the abovementioned optimistic ZEV adoption rates, the majority of new HDVs will still include an internal combustion engine as a key part of the propulsion system. Therefore, continuous work to improve efficiency and reduce GHG emissions from these vehicles is imperative in addressing climate change in the near term.

Figure 5.

EPA projected the adoption of ZEV in LHTs, along with ZEV rates in California’s Advanced Clean Trucks rule [34,35].

4. Technology Systems for Efficiency Improvement in LHTs

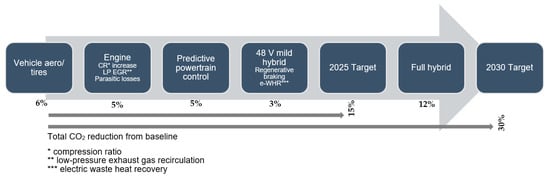

Commercial vehicles must meet stringent emission and CO2 regulations alongside FE improvements to lower operational costs. Fuel-saving technologies for HDVs can be generally classified as engine, powertrain, or vehicle efficiency improvements. There are significant interactions: downspeeding, for example, leads to lower friction losses and hence higher engine efficiency but is only achievable through a combination of engine design to improve torque at low rotational speeds, combined with advanced transmissions incorporating more reactive shift strategies and a reoptimized final-drive ratio. To meet emissions targets, incremental technology improvements across all aspects of the LHT will be required. A good example of combining different technology pathways is a study by Pischinger et al. [36] to reach the European 2030 CO2 target defined in 2019 (note that this does not address the current, more aggressive restrictions from 2023). Different engine, driveline, and vehicle technologies are incorporated in the analysis as shown in Figure 6; hybridization is recognized as a potential contributor, along with vehicle, engine, and powertrain control improvements.

Figure 6.

Technology pathways to meet European 2025 and 2030 CO2 regulations on LHTs [36,37], adapted from Pischinger et al. [36] and Joshi [12]. CO2 reductions are relative to a 2019 baseline. Studies were conducted prior to 2023 EU standards, so they do not incorporate the most aggressive CO2 reductions.

Combining engine, driveline, and vehicle technologies is the key consideration in fuel economy improvement, as different papers showed a 20% to 40% FC reduction by combining these technologies. The long-term role of ICE and its centric role in hybrid systems are also highlighted in different studies due to progressive efficiency improvements [38,39]. Buysse et al. [38] underscored HD diesel engines’ crucial role in U.S. long-haul trucking using efficient technology systems. Their analysis showed a 24% CO2 emissions reduction beyond the 2027 standard using a 55% brake thermal efficiency (BTE) engine, advanced predictive cruise control, and low-rolling resistance (LRR) tires. Also, further utilizing engine downspeeding, downsizing, and mild hybrids can reduce CO2 emissions to 34% lower than the Phase II standard. Delgado and Lutsey [40], simulating an LHT, showed that FE could be doubled by utilizing aerodynamic improvement, higher tire efficiency, downspeeding, downsizing, WHR, and hybridization. In a similar study, Delgado et al. [41] evaluated the FE benefits of different technology packages in the 2020–2030 time frame by modeling an LHT. The results showed a potential 27% reduction in fuel consumption using commercialized technologies, such as low-rolling-resistance tires, aerodynamics, engine friction improvement, turbocompounding, and downspeeding. Also, implementing a 55% BTE engine model equipped with WHR and hybridization showed a further reduction in fuel consumption, i.e., 43% from the baseline.

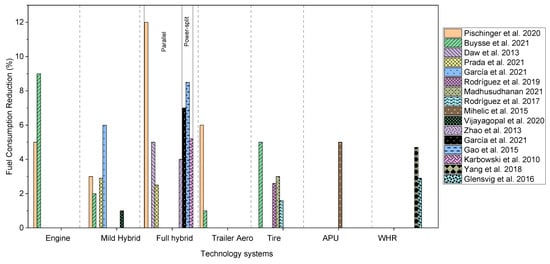

By reviewing the literature on LHTs, the general contribution of engine, powertrain, and vehicle technologies to FE improvement is comparable with the results of Pischinger et al. This alignment is shown in Figure 7, which illustrates an overview of the current FE improvements in LHTs. Figure 7 results are from research papers evaluating different technology features in LHTs in the U.S. and Europe; the papers relied on simulation to assess FE benefits and selected different baseline LHTs. The details of engine, vehicle, and powertrain technologies will be discussed in the next sections.

Figure 7.

FE contributors in the literature, based on simulation results for LHTs in the U.S. and Europe with different baselines [36,38,42,43,44,45,46,47,48,49,50,51,52,53,54,55].

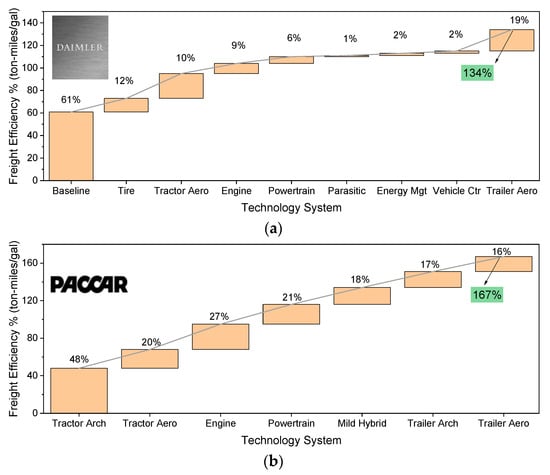

Similarly, in the SuperTruck II program, the participating OEMs have claimed freight efficiency (payload carried multiplied by distance covered divided by fuel consumed, i.e., ton-mil/gallon) improvements of more than 100%. These have been achieved by combining incremental improvements to multiple technology elements relating to the engine, powertrain, and vehicle, as shown in Figure 8.

Figure 8.

OEM’s claimed efficiency benefits from technology elements as a share in freight efficiency improvement in the SuperTruck II program relative to the 2009 baseline vehicle for (a) DAIMLER and (b) PACCAR [56,57].

The overview of the technological features of all the involved OEMs is summarized in Table 3 [11]. The developed technologies range from improved engine efficiency to reduced weight and drag, along with enhancing powertrain efficiency by recuperating dissipated heat via a WHR system and converting that to electricity to be stored in the battery pack. As shown in Figure 8, there is no single technology element that predominates the reported improvements in freight efficiency. Rather, incremental improvements are achieved across a wide range of system components. The details of the selected technologies vary between OEMs, but engine efficiency, powertrain optimization, and vehicle resistance reductions all make important contributions for all the project teams. The primary benefit is to reduce vehicle resistance and fuel consumption through efficiency improvements and system optimization. Weight reduction to increase payload within permitted gross vehicle weights has a secondary effect on the overall freight efficiency improvements. The details of the engine, powertrain, and vehicle side improvements will be discussed in the next sections.

Table 3.

Technology systems in the DOE SuperTruck II Program [10,12,56,57,58,59,60,61,62].

5. Engine Technology Systems

Engine technology systems range from a higher compression ratio to better recuperation of dissipated energy using the WHR system. Different technological features are summarized in Table 4, showing the related fuel-saving benefits. Understanding how the different technology blocks can be combined to achieve real CO2 reductions is important. In the European context, Pischinger et al. [36,37] investigated the technology packages for LHTs to comply with the European 2025 and 2030 GHG regulations. In their work, engine efficiency improvement was essential to meeting future standards. The analysis focused on combustion efficiency, air management efficiency, parasitic loss reduction, and WHR as the main tools to reach almost 54% of peak engine efficiency. Increasing the compression ratio and using high-flow fuel injectors increased combustion efficiency. Air management included a highly efficient turbo, Miller valve timing, and low-pressure EGR.

Table 4.

Advanced engine technology systems in commercial vehicles [12,40,41,47,63,64,65,66,67,68,69,70,71,72,73].

SuperTruck II kicked off in 2016, adding PACCAR with more ambitious targets, including demonstrating: (1) greater than 100% improvement in vehicle freight efficiency (payload and distance carried divided by the fuel consumed) relative to a 2009 baseline for a long-haul freight application; (2) minimum 55% engine BTE (peak value) under engine conditions for 65 mph (104 km/h) on an engine dynamometer; and (3) cost-effectiveness of the selected technologies with payback periods on the order of 2 years [11].

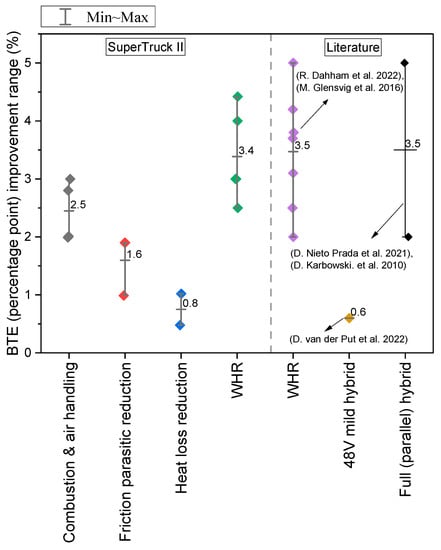

The program utilized different engine technologies contributing to higher BTE, as shown in Figure 9, where engine combustion and air management improvements included higher CR and PCP, bowl optimization, LIVC Miller cycle, high-temperature piston, and thermal barrier, optimized two-stage turbocharger, interstage cooling, and two-stage EGR cooling. Reducing friction was possible via low friction rings and liners, improved bearing, low viscosity oil, and an e-EGR pump. Also, heat loss reduction was obtained using cylinder head and exhaust port insulation and a high-temperature piston. Regarding aftertreatment system development, all teams have utilized closed-coupled SCR and a 48 V E-heated catalyst [10,12,56,57,58,59,62]. Overall, no one technological breakthrough dominates the reported engine efficiency improvements. A series of significant improvements, based on improving the overall in-cylinder combustion process while reducing losses in the engine system, can produce significant net additive benefits.

Figure 9.

Range of brake thermal efficiency improvements for selected engines and powertrain system advances. Changes are absolute (percentage point) improvements in BTE over the various studies referenced. Results from the SuperTuck program based on OEM reports to sponsor DOE [56,57,58,59,60,61,62] are separated from selected other studies [43,53,55,66,67].

5.1. Engine Aftertreatment System (EATS)

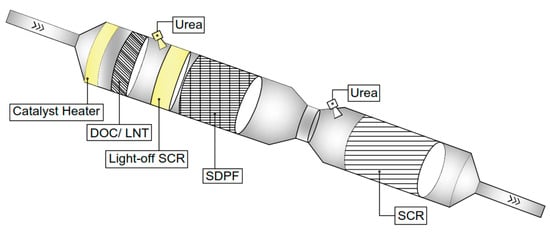

A key element of future LHTs will be the ability to meet ultra-low NOx emissions, including CARB’s recently imposed 0.02 g/bhph standard and the anticipated EURO VII level (350 mg/kWh), while simultaneously improving efficiency/reducing CO2 emissions. SuperTruck II teams utilized closed-coupled SCR and electric heater in the aftertreatment system, and PACCAR has demonstrated a CARB ultra-low NOx limit. Moreover, Boger et al. [74] have suggested an aftertreatment system for meeting the EU VII regulation, as depicted in Figure 10. The highlighted components are considered new items necessary for meeting the tight limits of the EU VII standard [74]. A recent study by Meruva et al. [75] showed that a 7 kW catalyst heater can meet the ultra-low NOx 2027 regulation when combined with a closed-coupled light-off SCR.

Figure 10.

Potential aftertreatment architecture to comply with the Euro VII regulation adapted from [74]. LNT and SDPF stand for lean NOx trap and SCR-catalyzed diesel particulate filter (a DPF with SCR coating), respectively.

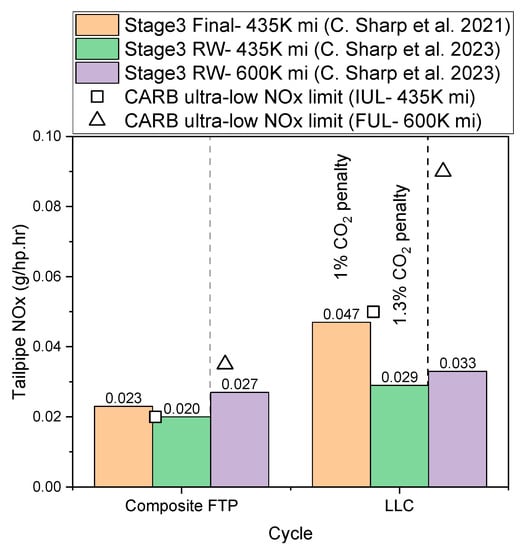

In a recent work by Sharp et al. [76] from Southwest Research Institute (SwRI), the authors showed that they achieved CARB ultra-low NOx MY 2027+ limits by modifying the aftertreatment system over composite (cold and warm starts) Federal Test Procedure (FTP) and low load cycle (LLC). The authors compared the results with both CARB intermediate useful life (IUL) and full useful life (FUL) limits in each cycle. However, in some modes, there is an added CO2 penalty. The summarized results for stage 3 (previous work by the authors [77]) and stage 3 RW (rework) are shown in Figure 11.

Figure 11.

Demonstration of CARB ultra-low NOx emission MY 2027+ limits by the work conducted in SwRI [76]. The authors have compared the results of their current work [76] and previous work [77] with CARB ultra-low NOx limits.

5.2. Waste Heat Recovery

Despite all the efficiency improvements in diesel engines for LHTs, a significant amount of the fuel chemical energy is still dissipated as enthalpy in the exhaust stream. As a result, WHR remains interested in making use of an energy stream that is currently dissipated. The sustained stability and high-load operation of a typical LHT provide good conditions for WHR. Current approaches are focused on ORC, where the working fluid absorbs heat from different engine heat sources and generates work in the expansion process within the turbine [78].

Quantifying the engine efficiency and fuel consumption benefits of the WHR system is essential. All SuperTruck teams considered WHR an important factor in reaching the desired BTE; however, actual implementation in production is uncertain, and more research is needed to evaluate the WHR’s commercial viability. As discussed earlier (Figure 9), WHR has the maximum potential for BTE improvement between 2% and 4.5%. Working fluids include cyclopentane and a water/ethanol mixture (Daimler uses a phase change cooling system), and heat sources include coolant, charge air, exhaust gas, and EGR. Volvo showed that exhaust energy recovery could improve BTE by 2%, with a further 1% by including energy from the engine cooling system [61]. Navistar and PACCAR showed similar results, with 3.6% and 4% improvements in BTE, respectively [57,62]. By adding phase-change cooling, Daimler suggested a 4.4% BTE improvement was possible [60]. The results of the SuperTruck II studies for WHR are summarized in Table 3. One of the main reasons for WHR’s applicability in the SuperTruck II program relates to the long-haul drive cycle. Highway drive cycles are considered suitable for WHR applications since they provide stable exhaust temperatures compared to urban drive cycles with lower engine loads. Gao et al. [79] analyzed the applicability of the WHR system in various drive cycles. The results showed that urban conditions are unsuitable due to the low engine exhaust temperature and the low work output from WHR. The results showed −0.18% to 0.16% in energy savings over urban cycles, while in the suburbs and highways, WHR led to an energy-saving rate of 3.36% to 10.60%.

Several studies have inspected WHR through simulation tools to assess the fuel consumption benefit. GT-Power, MATLAB/SIMULINK, and AVL Cruise are the most used simulation tools in this regard. The simulation results show that the fuel consumption benefit is between 3% and 4%. Villani and Tribioli [80] utilized GT-Power to quantify the output power of WHR in an LHT; the results over the Heavy Heavy-Duty Diesel Truck (HHDDT) cycle showed 3.9 kW in the WHR output, which can be stored in the battery pack. Similarly, using GT-Power simulation, Yang et al. [54] achieved a 4.7% fuel consumption reduction in a WHR-integrated system in a 12.4 L diesel engine. Moreover, Glensvig et al. [55] explored WHR applicability in an LHT by engine testing and showed a 6.5 g/kWh brake-specific fuel consumption (BSFC) improvement in the 1100–1200 rpm range. On-road tests on the highway showed a 2.9% fuel consumption reduction.

WHR can also be integrated into hybrid powertrains to store the generated work in the battery pack. Some studies evaluated WHR integrated into the hybrid system; Villani et al. [81] chose a series hybrid for an LHT equipped with a 12.6 L engine to assess the FE benefit using GT-Power simulation. The full hybrid+ WHR retrofit had the potential for a maximum of 17% FC reduction. Galuppo et al. [82] evaluated the application of WHR integrated into the 48 V mild hybrid (PTO) on an LHT. The amount of energy from the WHR compared to the total recovered energy (WHR plus regenerative braking energy) was about 60%. Another benefit when WHR and hybrid powertrains are integrated is that the battery size could be reduced since some of the electric power would be supplied by WHR. Another important factor in WHR implementation is its optimized operation when integrated with ICE. Recent papers have discussed the need to design an efficient control framework for the optimum ICE and WHR operation to minimize the FC and meet the exhaust gas temperature constraints for the aftertreatment system [83,84].

6. Transmission Technologies

Transmission systems play a crucial role in converting engine-generated power into tractive force at the wheels. Historically, manual transmissions (MTs) were primarily used in HDV segments. However, transmissions that automate speed selection and gear shifting can significantly reduce fuel consumption by optimizing engine operation according to road load and power demands. This optimization generally involves decreasing engine speed and enhancing torque output, which helps lessen engine friction and pumping losses. Three technologies that have begun to replace traditional MTs are automated manual transmission (AMT), automatic transmission (AT), and dual-clutch transmission (DCT) [47].

Both AMTs and MTs operate on similar principles, but in AMTs, clutch operation and gear selection are automatically controlled. AMTs have gradually been replacing MTs in the U.S. since 2006, with a 28% market penetration of LHTs in 2015. In Europe, AMTs were found in 70% of new LHTs in 2015, whereas in China, AMTs were only present in 3% of new LHTs [47]. The FE of AMTs is largely contingent on the driver and their driving style over the same route, with the AMT offering more consistency by removing a degree of driver discretion to select the optimal gear and gear-shift strategy. The U.S. EPA and National Highway Traffic Safety Administration (NHTSA) approximate a 2% FE advantage when switching from MTs to AMTs in LHTs [85].

In contrast, Ats significantly differ from MTs in their design and functionality, with the engine and gearbox coupling happening via a hydraulic torque converter. The U.S. is the primary market for heavy-duty Ats, with about 5% of LHTs equipped with Ats, compared to less than 0.5% in the European Union.

DCTs are essentially AMTs that allow for uninterrupted power during gear shifts. This nonstop torque during gear changes decreases the number of transient events and expands the possibilities of downspeeding as a fuel-saving technique. According to the EPA and NHTSA, the FE gains of AMTs and DCTs are comparable. DCTs constituted roughly 0.5% of new HDVs in Europe and were not featured in LHTs in the U.S. or China. However, by 2027, the EPA and NHTSA anticipate a 10% market adoption of DCTs in LHTs [47,85]. While the DCT offers some efficiency benefits over other transmissions, the most important transmission optimization is to allow engine and vehicle operation improvements and ensure consistency in vehicle fuel consumption between drivers.

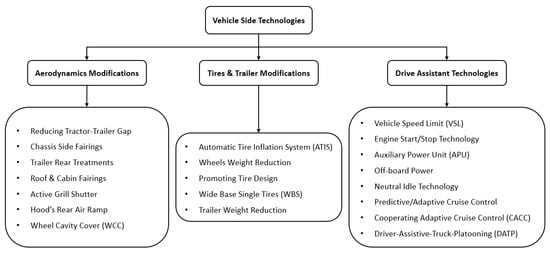

7. Vehicle Side Technologies

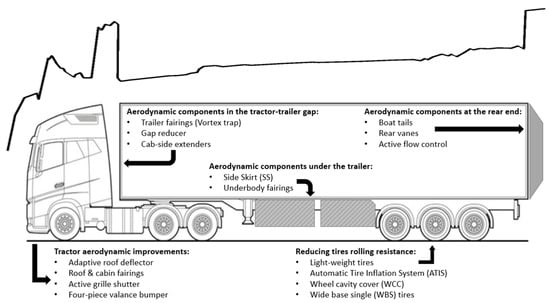

In addition to advancing engine-side technologies aimed at improving FE and reducing emissions in LHTs, various vehicle-side modifications can be implemented apart from engine-related changes. These vehicle-side technologies encompass a range of enhancements, including aerodynamic modifications, tire and trailer weight modifications, and drive assistant technologies, as shown in Figure 12. Vehicle side improvements are essential in enhancing tractor–trailer efficiency, which has been reflected in U.S. Phase 2 GHG regulation [86,87]. Although the CO2 emission of the trailer by itself is zero, its design greatly impacts the fuel consumption of LHTs. The most substantial resisting force for LHTs during highway driving at 0 grade is aerodynamic resistance. The aerodynamic resisting force is proportional to the second power of velocity, and it accounts for up to 25% of LHTs’ fuel consumption [88,89,90]. However, the impact of aerodynamic drag forces can be minimized by enhancing aero features on both the tractor and trailer sides [45,86]. The critical areas in an LHT on which the aerodynamic drag affects are: (1) the front surface and roof of the tractor; (2) the tractor–trailer gap; (3) the rear end of the trailer; and (4) the side and under-body of the trailer.

Figure 12.

Combination of vehicle-side technologies for reducing the fuel consumption and GHG emissions of LHTs.

By implementing appropriate modifications in the mentioned critical aerodynamic areas, it is possible to reduce fuel consumption by up to 6.3% over the long-haul cycles and 3.6% over the regional delivery ones [45,87,91]. Wind tunnel testing indicated that basic aerodynamic improvements, including a roof deflector, trailer side skirts (SS), and tractor–trailer gap reducer to the LHT, can reduce the drag coefficient by 8% at highway speeds [46]. Wood et al. [92] focused on estimating the under-body aerodynamic drag reduction by installing SS and wheel cavity cover (WCC). They examined various installation modes for SS and WCC and proved that 5% fuel savings could be achieved for LHTs over the highway. The trailer frontal splitter (vortex generator) has zero impact on fuel consumption, and external side mirrors increase the drag coefficient by 3.23% [92,93,94]. Trailer SS was the most dominant aerodynamic technology in the U.S. prior to 2016 [47]. A multi-parametric optimization approach for designing SS and boat tails (angle and length of the panel) in LHTs is yielding up to 13% drag coefficient reduction over the highway [91,95]. Using adjustable roof deflectors and tractor–trailer gap reducers can decrease the drag coefficient by up to 16.3% [96]. Buscariolo et al. [88] compared drag coefficient reduction among various body styles for an LHT by utilizing a full aerodynamic package. The internal flow rate from the grille into the radiator can be modified by using an active grille shutter [45,47,94]. Active grille shutter has been one of the most dominant technologies in Europe since 2013, and it could improve the FE of LHTs by 1.6%, while this technology has not been adopted highly in the U.S. and China. The market penetration of active grille shutters for LHTs in the U.S. has been intensified in the SuperTruck program [47]. Overall, the main challenges for aerodynamic improvements to LHTs are the need to match the tractor to multiple trailers, the marginal improvements of each aerodynamic feature on its own, and the fact that much of the FE improvement is a result of trailer improvements, whose owners may not be directly paying for the fuel costs and hence do not see a direct financial benefit from any trailer aerodynamic improvements.

Further vehicle fuel consumption and GHG emission savings can be achieved by lightening the vehicle and reducing the rolling resistance of the tires [45,86]. The rolling resistance can be decreased by promoting the tire design, reducing wheel weight, using wide-base-single (WBS) tires, and regulating the inside tire pressure. The mentioned tire modifications can improve the truck’s FE by 4.4% over the long-haul cycles and 2.6% over the regional-haul cycles [45,90]. Using new composites and alternative materials in both trailers and wheels yields lighter structures. Based on the current technologies, a 15% weight reduction is achievable in empty trailers, leading to 1.6% and 2.4% fuel savings over long-haul cycles and regional delivery ones, respectively [85]. Simulation results show that adding single-wide tires to lightweight trailers can reduce the chassis weight by up to 1350 kg, and fuel consumption can be reduced by 3 to 5% over long-haul cycles [46]. Until 2015, the U.S. used wide single-tire technology to design LHTs more than China and Europe. However, market penetration of tire pressure monitoring and tire inflation systems in Europe has been higher than in the U.S. and China since 2015. Based on the prediction up to 2027, the market dominance of automatic tire inflation systems (ATIS) will reach approximately 30% in the U.S. [47].

Combining the vehicle-side technologies, including aerodynamics, tires, and total weight reduction, 11.9% and 8.4% fuel savings can be achievable over the long-haul and regional delivery cycles, respectively. Also, the drag coefficient can be decreased by up to 21% over the long-haul cycles [45,86,87,90,93,97]. The schematic of the technologies to reduce the aerodynamic and tire rolling resistances in both tractor and trailer sides is shown in Figure 13. The contribution of using aerodynamics, tires, and weight reduction modifications in the research literature to mitigate both the drag coefficient and fuel consumption of LHTs over the highway has been shown in Table 5.

Figure 13.

Representative schematic of a European cab-over tractor–trailer configuration for an LHT with indicative areas of aerodynamic drag and rolling resistance reductions. The trend line represents qualitatively the net contributions of each segment to the overall vehicle drag.

Table 5.

Contribution of various aerodynamic and tire rolling resistance technologies to reduce both the drag coefficient and fuel consumption of LHTs in the literature.

In addition, drive-assistant technologies play a crucial role in reducing the fuel consumption of LHTs, even at lower speeds [90,98]. The widely used drive assistant technologies are depicted in Figure 12. The vehicle speed limit (VSL) is an electronic system that controls the maximum vehicle speed through the engine controller, leading to better freight efficiency, especially on the highway [47]. The start/stop engine system can reduce idling time during short stops, although it has low advantages for LHTs as they are mostly driven over highways. The Auxiliary Power Unit (APU) is a compact and efficient motor that generates sufficient power to operate the heating or cooling system and interior appliances, eliminating the need to run the truck engine in idle mode during breaks and rest periods. APU supplies the auxiliary power demands from an electrical source like a small battery [48]. The key distinction between APU and micro-hybrid systems lies in their operational scope: the latter can supply non-propulsion demands when the truck is in motion and at a standstill, whereas the former can only be utilized during stationary situations [99]. Neutral idle technology disconnects the engine output shaft from the torque coupler during short stops, reducing transmission power losses [45,90]. Driver-Assistive Truck Platooning (DATP) and adaptive/predictive cruise control are classified as advanced drive-assistive technologies that are still being developed [47]. The market penetration of predictive cruise control (PCC) and DATP systems is expected to increase to 40% by 2027 in both the U.S. and Europe [47].

Platooning reduces fuel consumption and emissions and improves traffic safety [100,101]. In the U.S., 65% of HD truck miles can be driven in platooning mode [100]. Multiple studies have shown that platooning can reduce the fuel consumption of LHTs between 4% and 17%, specifically for the following truck. Platooning has a lower impact on reducing the drag coefficient of the lead truck, resulting in a comparatively smaller FE improvement compared to the following trucks, typically ranging between zero and 5% [100,101,102,103]. The drag coefficient of the following truck decreases with shorter separation from the lead truck, but road safety and braking are limiting factors for the inter-vehicle distance [104,105,106,107]. Speed of platooning trucks, trajectory, spacing, and lane changing also affect fuel consumption [100,101,108]. Long combination vehicles (LCVs) have better drag reduction compared to platooning trucks and single configurations [48]. Cooperative adaptive cruise control (CACC) maintains speed and distance for better fuel reduction in LHTs [103,106]. In platooning, solely relying on CACC over high-grade sections results in a negative FE impact for the following trucks. Because trailing trucks struggle to maintain the target distance from the lead truck, this leads to increased acceleration for re-engaging [109]. The integration of CACC with DATP systems, including predictive cruise control and neutral coasting, yields at least a 4% FE improvement for platooning trucks in high-grade hilly sections compared to CACC alone without DATP [109,110]. Further investigation is needed to determine the exact fuel savings for lead and following trucks during platooning [103,111,112].

Contrary to the varied outcomes when evaluating how platooning affects fuel usage and emissions in lead and follower trucks, real-world challenges exist to actually implementing truck platooning systems. These challenges mostly relate to the infrastructure needed, the necessary policies, and the technology itself [113,114]. Achieving higher levels of platooning automation (referred to as level 3 and above), necessitating enhanced precision in longitudinal and lateral control, as well as advancements in on-board technologies and human-machine systems, remains unequivocally imperative. However, such advancements are unlikely in short-term deployments preceding 2035 [113,115,116].

Overall, technologies focused on both tractors and trailers, combined with advanced drive assistant technologies, led to a fuel consumption reduction of more than 20% in the case of LHTs over highways. As with engine technologies, these advances are not generally based on technological breakthroughs. Selection of better materials, improved designs using better analytical and modeling tools, combined with increased on-vehicle computational power allowing for new ways of using the vehicle, all contribute to improving the overall vehicle efficiency, leading to lower fuel consumption per unit payload and distance driven.

8. Powertrain Electrification and Its Opportunities for LHTs

Alongside the advancing engine and vehicle-side technologies, electrification emerges as a potential solution to address the increasingly demanding fuel consumption and GHG emission standards for LHTs [117,118]. While the substantial impact of electrification on LD vehicles has been demonstrated, further investigation is warranted to assess its effects specifically on HD vehicles. Registration of electric HD trucks in the U.S., Europe, and China doubled in 2021 compared to 2020 [119,120]. Although the portion of battery electric and plug-in hybrid trucks sold in 2021 was less than 0.3% of the total number of registrations for medium-duty (MD) and HD trucks worldwide, and this portion is only 0.1% for non-plug-in hybrid trucks, the number is expected to increase to 10% of total sales by 2030 as a part of the net zero-emission program [117,121]. Techniques to reduce fuel consumption and GHG emissions for LHTs cover a broad range, from idle elimination to full electric drive.

This work is focused on the potential of hybrid electric powertrains, where an internal combustion engine is combined with a drivetrain that includes both electrical energy storage and an electric motor/generator that can be used to enhance the performance of the overall engine system. Full electrification of LHTs, with energy provision from either battery or hydrogen fuel cells, is an area of great interest but outside the scope of this paper.

8.1. Impact of Various Electrified Configurations on FE Improvement in LHTs

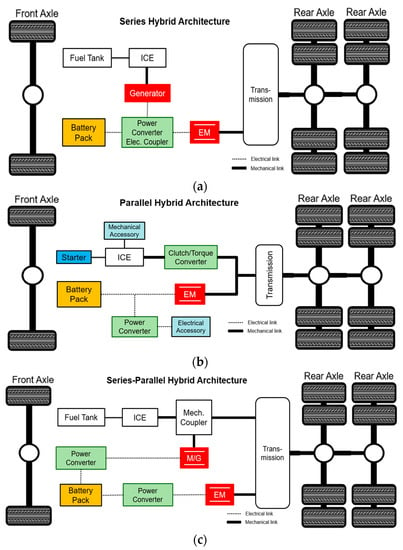

Hybrid electric trucks (HETs) utilize multiple power sources: ICE and an electric motor [122]. The inclusion of electric components such as motors and batteries allows for various hybrid architectures with different motor, transmission, and clutch placements [123]. HETs can generally be subdivided into four categories based on the level of electrification: micro (Micro-HETs), mild (Mild-HETs), full (Full-HETs), and plug-in (PHETs). Full-HETs can be further classified based on the powertrain configuration, including series hybrids, parallel hybrids, and series-parallel (power-split) hybrids [124]. This section examines the powertrain architectures and potential benefits of HETs for use in long-haul applications.

8.1.1. Mild-Hybrid Configuration for LHTs (Mild-LHT)

A medium voltage range (~48 V) is utilized in a mild-hybrid configuration, incorporating a small electric motor and battery. The motor/generator can be positioned as an integrated starter generator (ISG) at the front of the engine, replacing the conventional starter and alternator, or directly connected to the crankshaft between the engine and the clutch via a belt [125,126]. The small electric motor and battery serve several functions in a mild-hybrid configuration, including engine start/stop during idling, regenerative brake energy recovery, drivetrain torque enhancement, and powering electrical accessories [106]. Micro-hybrids, a subset of mild-hybrid configurations, encompass all the mild-hybrid functions, excluding powertrain torque enhancement due to lower operating voltage and electric motor power, making them less applicable for commercial trucks [127].

All SuperTruck II teams utilized 48 V mild hybrid using ISG mounted on the rear power take-off (PTO) as long-haul trucking, implying no need for aggressive hybridization due to the less regenerative braking potential in highway drive cycles. Moreover, mild hybridization needs fewer changes in the main engine and transmission configuration and less battery cost and weight (subsequently, less impact on the cargo payload). In the SuperTruck II program, the electric motor ranged from 15 kW to 30 kW for the mild hybrid powertrain, and Li-ion batteries were 48 V, 7–14 kWh [56,57,58,59,60,61,62]. Furthermore, the mild-hybrid configuration enables the usage of 48 V accessory systems in the engine, such as the e-turbo, e-heater, e-EGR pump, and e-coolant/oil pump [44,128]. The limitations of using the mild-hybrid configuration in long-haul applications include an approximately zero pure electric range due to the small size of the electric motor and large, demanding torque at wheels, constraints on auxiliary load during engine-off situations, and a limited battery capacity for storing regenerative brake energy [117].

According to the literature, the FE improvement of Mild-LHTs compared to the conventional baseline is small in long-haul drive cycles but significant in more transient urban cycles since braking is more frequent in transient cycles, leading to more braking energy recuperation. A total of 2.9% and 4.4% improvements were reported over standard HHDDT-65 and HHDDT-Cruise drive cycles under 100% cargo load. Additionally, the FE improvement over standard urban drive cycles, such as HHDDT-Transient and Urban Dynamometer Driving Schedule (UDDS)-Truck, was reported as 10.7% and 11.1%, respectively [53]. Prada et al. [43] demonstrated that the FE improvement of a Mild-LHT over the EPA-55 standard highway drive cycle with 100% cargo load is 2.9% compared to the conventional baseline. Vijayagopal et al. [49] concluded that the FE improvement of a fully loaded Mild-LHT over the EPA-65 standard highway drive cycle is less than 1% compared to the conventional baseline. Moreover, the FE improvement over the standard ARB-Transient drive cycle with 100% cargo load was shown as 3% compared to the conventional baseline.

8.1.2. Full Hybrid—Series Hybrid Configuration for LHTs (SH-LHT)

In the series hybrid (SH) configuration, the electric motor drives the wheels, and the ICE powers a generator to recharge the battery, as depicted in Figure 14a. The ICE can be controlled to operate at high-efficiency steady-state conditions as it does not need to meet the instantaneous load demand [124]. The mechanical energy generated by the ICE is converted to electrical energy by the generator, which can both charge the battery and power the traction motor for propulsion [117]. A gearbox can be utilized to maintain crawling ability at lower speeds comparable to the conventional baseline [129].

Figure 14.

Representative configurations of (a) Series hybrid (SH), (b) parallel hybrid (PH), and (c) power-split hybrid (PSH) long-haul truck (LHT). Note that within each class, there can be variations in location, type, and number of individual components.

The series hybrid configuration has two modes: (1) pure electric mode with the ICE off and the battery powering the traction motor for propulsion, and (2) range-extender mode with the ICE providing power through the generator to the traction motor and wheels [130,131]. For LHTs, operating in the first mode enables better FE and emissions by relying solely on battery power. However, in power-demanding situations like highway driving with limited regenerative brake opportunities, SH-LHTs cannot sustain pure electric mode for long distances, resulting in rapid battery charge depletion [117,132]. In range-extender mode, the ICE must remain active to charge the battery or power the traction motor. The lack of mechanical connection between the ICE and wheels leads to a multi-step energy conversion process: fuel energy is converted into mechanical (shaft) work, which is then converted into electrical energy, which is then converted back into mechanical power delivered to the wheels [124].

For LHTs, in highway use, the high efficiency of the conventional ICE negates the potential BTE improvements from optimized operation as a range extender. As a result, the additional energy conversion losses combined with limited regenerative brake opportunities lead to limited FE improvements [88,133]. Various studies have shown fuel economy penalties of between 5% and 16% with high loads on highway drive cycles [51,52]. An SH-LHT in urban driving does show significant potential, with up to 18% fuel economy improvements, due to the greater opportunities for regenerative braking and lower average load demand on the engine [133]. As most fuel consumption and GHG emissions for LHTs are from highway driving, the efficiency penalty of the SH configuration under these conditions makes it unsuitable for LH applications.

8.1.3. Full Hybrid—Parallel Hybrid Configuration for LHTs (PH-LHT)

In a parallel hybrid (PH) design, both the ICE and electric motor have mechanical connections to the transmission and wheels (Figure 14b). The ICE serves as the primary power source, while the electrical machine assists during acceleration and recovers energy during dynamic braking [134]. Compared to the series hybrid design, a PH typically has a smaller battery and electric motor as it does not need to meet the full load demand. This offers operating flexibility, including ICE-only, purely electric, and hybrid modes [135].

For LHTs, the PH configuration performs better on highways than on an SH because the ICE power can directly transmit to the wheels without two-stage energy conversion or needing a heavy generator [135,136]. A PH requires sophisticated control strategies to keep the ICE operating in high-efficiency zones [134]. The battery state of charge (SOC) level should be maintained at the same level at the beginning and end of the trip by recovering the regenerative brake energy or getting charged from the ICE [137].

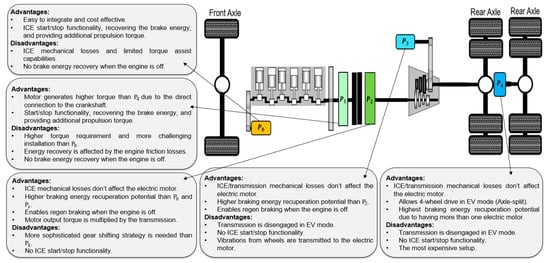

Parallel hybrid configurations include a range of different electric motor sizes and locations. They can be classified into four sub-groups based on the electric motor placement: , , , , and as shown in Figure 15 [138]. In configuration, the alternator, and starter in the conventional baseline are replaced with a small electric motor acting as an ISG or belt assistant starter (BAS) in the form of a micro-hybrid, which is relatively easy to integrate into the powertrain [117,139]. In setup, which is mostly used in mild-hybrid configurations, the electric motor is directly connected to the crankshaft [117,140]. In the design, the electric motor can either be side-attached using a belt or integrated into the transmission’s input shaft. It is also known as a pre-transmission parallel hybrid configuration [134,141]. In , the electric motor is installed on the output shaft of the transmission and is also named the post-transmission parallel hybrid configuration [117,142]. In , the electric motor is placed separately on the rear axle as an e-drive system [117,138].

Figure 15.

Schematic of various parallel hybrid setups (, , , and ) based on the electric motor placement for LHTs and key advantages and disadvantages for each configuration.

These PH configurations have advantages and disadvantages, summarized in Figure 15. In general, and are the most commonly used parallel hybrid designs for HDVs. has two disadvantages compared to : (1) the transmission is disengaged during the purely electric mode, and (2) the vibrations from wheels are directly transmitted to the electric motor, making the design less durable. The main advantage of over is that the performance of electric motors in is highly reliant on the gearbox ratio and shifting strategy [117,140]. In terms of LHTs, which are mostly driven over highways, the fuel consumption of and is very close to each other because transmission is often engaged in lower gear ratios during cruising speed, and gear shifting is not conducted frequently compared to urban driving conditions [134].

Several studies have focused on estimating the FE improvement of PH-LHTs. The results show that the hybrid powertrain leads to more fuel savings over urban drive cycles than highway cycles since, over the highway, the opportunity for regenerative brake energy is negligible, and a large portion of engine power should be sent to the battery for sustaining the SOC level at the beginning and end of the trip. Prada et al. [43] showed that the pre-transmission PH-LHT brings only a 2.5% FE improvement over the standard highway drive cycles under fully loaded conditions compared to the conventional baseline. A total of 24% and 4% FE improvements were achieved via pre-transmission PH-LHTs in regional-haul trucks over urban and highway drive cycles, respectively [50]. Similarly, Gao et al. [133] concluded that pre-transmission PH-LHT brings 27.5% and 2.1% FE improvement over the experimental urban and highway drive cycles, respectively, compared to the conventional baseline. Vijayagopal et al. [49] indicated that without downsizing the engine, PH-LHT does not bring any FE benefit compared to the conventional baseline over the highway under 100% cargo load because of the energy that ICE should consume to maintain the battery SOC at the beginning and end of the trip. Simulation results by Daw et al. [42] showed a 5% FE benefit in the configuration for an LHT.

The fuel-saving potential of PH-LHTs depends strongly on the powertrain configuration, the driving/duty cycle, the payload, and the details of the control strategies used. For PH-LHTs under 100% cargo load over experimental long-haul drive cycles, including road gradients, FE can be 3% worse or as much as 8% better than a non-hybrid baseline. Much of this benefit is control optimized to operate the engine in high BTE regions, which can improve cycle-average engine BTE by 2–5 percentage points (absolute value) over long-haul drive cycles [43,53]. The truck’s trajectory path can be predicted through advanced optimization-based control strategies, and the energy consumed by the ICE to maintain battery charge would be minimized by maximizing the opportunities for regenerative braking along the trip [132].

8.1.4. Full Hybrid—Power-Split Hybrid Configuration for LHTs (PSH-LHT)

The power-split hybrid (PSH) configuration combines the advantages of series and parallel hybrids. Toyota introduced this architecture as the Toyota Hybrid System (THS) in 1999 [143]. PSH utilizes a planetary gearset as a lighter and more compact speed coupling device with greater speed ratios; however, designing a durable large planetary gearset for LHTs capable of operating under high torque and power ratios is challenging [144]. Typical LD PSH configurations include two electric motors to allow enhanced optimization of both ICE and vehicle operation [135,145]. Figure 14c depicts the schematic view of PSH.

In the available proposed PSH-LHT designs in the literature, the ICE is connected to the carrier, M/G is linked to the sun gear, and the traction motor is connected to the ring gear [144]. The planetary gearset divides engine power into two paths: one electrical and two mechanical paths [135]. In the electrical path, a portion of the ICE power is transmitted to the M/G for storage in the battery or transferred to the traction motor for propulsion. In the mechanical path, the remaining power is sent to the driveline through the transmission output [117,135]. This architecture enables the independent operation of the ICE, allowing it to operate in its high-efficiency region regardless of wheel speed [146,147]. The clutch can be opened at low speeds for series mode, while parallel mode is used during cruising speeds [117,148]. Both electric motors in PSH contribute to brake energy regeneration, resulting in more efficient regeneration compared to parallel and series hybrids [135,146]. However, additional components such as electric motors and converters add cost and require more sophisticated control strategies than parallel and series hybrids [149].

The fuel consumption benefits of the PSH have been assessed for LHTs under various driving conditions. Net FE benefits when fully loaded on a highway cycle have been estimated at between 5.2% and 13% compared to the conventional baseline. Under transient driving conditions of an urban cycle, FE benefits approaching 38% have been predicted [51,52,53]. Compared to the parallel hybrid configuration over long-haul drive cycles, the PSH design exhibits 0.5% to 2% higher FE improvement and 2% to 3% better engine BTE [132,140,141].

8.1.5. Full Hybrid—Plug-in Hybrid Configuration for LHTs (Plug-in-LHT)

This architecture is a step towards fully electric vehicles (FEVs). The most significant feature of plug-in systems is the ability to charge the battery from the electrical grid [150,151]. Larger batteries and electric motors in plug-in hybrid designs enable the ICE to operate in high-efficiency regions, resulting in reduced fuel consumption and tailpipe GHG emissions [117,152]. Although increasing electric range, larger batteries incur added weight and cost [43,153]. Two potential plug-in hybrid architectures for LHTs include series plug-in-LHT and series-parallel (power-split) plug-in-LHTs. These two architectures are similar to series and power-split hybrids, with the difference that the battery size becomes larger and can be charged off-board to sustain the vehicle more in pure electric mode [43,49]. The operational and control system complexity of PSH plug-in-LHTs is higher than that of series configuration, but it offers greater FE improvement, as discussed in Section 8.1.4 [135,154].

The combination of a large-capacity battery and a traction motor that can propel the vehicle typically provides a greater all-electric range (AER) across multiple applications compared to other hybrid configurations. They also offer the potential to downsize the engine without sacrificing performance in many situations, offering engine cost and weight reductions. These can partially offset the weight and cost penalties of the PHET configuration and can help improve efficiency through lower friction [43,49]. Selecting a battery size for a plug-in LHT is complex; one approach taken by LD vehicles is to cover half of the 90th percentile of the daily driving range in pure electric mode [43]. The route specifications of LHTs between two cargo depots can be determined to determine the share of electric miles and the appropriate engine and battery size for a given application.

Few papers explored plug-in-LHTs’ fuel-saving potential. Vijayagopal et al. [49] proposed a downsized diesel engine in a plug-in-LHT. They considered blended mode as the battery charge-depleting strategy, achieving a 40% equivalent FE improvement over the EPA-55 highway drive cycle under full cargo load, considering both electrical and chemical (fuel) energy supplied to the vehicle. Over the ARB-Transient driving cycle, FE improvement reached ~50%. In plug-in-LHTs, the blended charge depletion strategy in which the ICE participates in providing the vehicle’s demanding power at the same time as the battery is depleted leads to better fuel consumption results than the charge sustaining (CS) mode, in which the battery is fully depleted first, then the ICE is involved in sustaining the charge of the battery at the minimum SOC level [151]. Prada et al. [43] found the CS mode-only plug-in-LHT fuel economy over the highway to be 26% worse than the conventional baseline under 100% cargo load. Series plug-in-LHT shows 1.5% to 2% engine BTE improvement over long-haul drive cycles compared to conventional (non-plug-in) PH-LHTs, or 4%−8% compared to the conventional baseline.

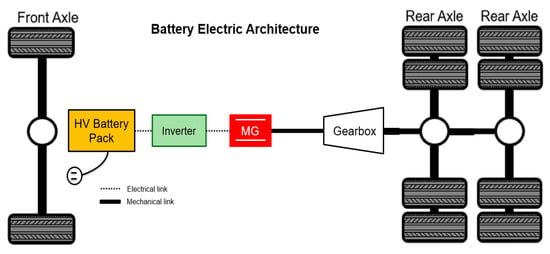

8.1.6. Battery Electric Configuration for LHTs (BE-LHT)

In a battery electric configuration, the rechargeable battery provides power to the electric motor(s) for vehicle propulsion without relying on an ICE [155]. It resembles the series plug-in-LHTs but eliminates the ICE, as shown in Figure 16. The net emissions of BE-LHTs depend on the electrical energy source. The BE configuration has a simple design; however, the battery size limits the expected vehicle range [156]. Adopting BE-LHTs faces economic and technical challenges despite regulations aiming to reduce fuel consumption and emissions in many countries in the future [119,157]. BE-LHTs travel long distances at high speeds, requiring more electric energy from the battery due to the higher vehicle weight, diverse road conditions, and greater road resistive forces compared to light-duty electric cars [158]. Therefore, a larger battery pack is required, substantially reducing the truck’s total cargo capacity to maintain a similar GVWR as the conventional baseline [49]. Limited charging infrastructure, longer charging times, and high battery system costs are major obstacles for BE-LHTs [121,159,160].

Figure 16.

Schematic diagram of battery electric (BE) configuration for LHTs.

Due to the limitations in estimating the accurate battery penalty weight, battery charging time, and design payback period, there is limited literature on designing and evaluating BE-LHTs. Zhao et al. [50] indicated that by considering the pure electric range as 120 miles, the BE-LHT configuration could improve the equivalent FE (on an energy-equivalent basis) up to 120% compared to the conventional baseline over an experimental highway drive cycle under 100% cargo load. Vijayagopal et al. [49], assuming a daily driving range (DDR) of 500 miles for sleeper LHTs, showed that the battery electric configuration leads to more than 100% equivalent FE improvement compared to the conventional baseline over the EPA-55 standard drive cycle under fully loaded conditions. Estimating the penalty weight of high voltage batteries and the required fast charging infrastructures still needs more research to check the feasibility of using BE-LHTs over highways.

8.1.7. Benchmarking of the Available Electrified LHTs in the Literature

To compare the fuel-saving potential of the electrified powertrain in LHTs, a benchmark of the reviewed hybrid and electrified configurations in the literature has been shown in Table 6. The fuel-saving potential of the proposed electrified configurations is shown compared to the conventional baseline. Moreover, the types of drive cycles, either experimental, including the road gradient, or standard without the road gradient, are indicated in the table. Finally, engine downsizing implementation for each proposed design in the literature is also shown in the last column.

Table 6.

Benchmarking of the available hybrid electric LHTs in the research literature. These are all based on modeling results.

8.2. Drive Cycles for Evaluating the FE of LHTs

Comparing the fuel consumption of different LHT powertrain configurations depends strongly on the drive cycle used. These drive cycles can be divided into two categories: (1) standard/regulatory drive cycles and (2) real-world experimental drive cycles [43]. The first group ignores the road grade profile, while the latter group incorporates the road gradient.

A common method to estimate the whole-body performance of a designed vehicle, either conventional or electrified, is to use the standard/regulatory driving cycles that encompass all operating modes, including acceleration, deceleration, idling, and cruise [43]. A summative classification of the standard driving cycles of LHTs in both urban and highway cycles is shown in Table 7 [161,162]. Highway-dominant cycles include higher cruising times than urban-dominant ones, while the percentage of idling and decelerating times is higher in urban drive cycles. The presence of extended deceleration periods in urban drive cycles, as opposed to predominantly highway-based cycles, amplifies the potential for regenerative braking in hybrid powertrains. Conversely, during highway drive cycles, characterized by reduced braking efficiency and elevated torque requirements at high velocities, the reliance of hybrid LHTs on the electric propulsion system becomes limited. Thus, as indicated in Table 7, non-plug-in hybrid LHTs exhibit modest FE enhancements over highways in comparison to the conventional baseline. It is important to highlight that the increased GVWR of class 8 LHTs, which drives greater torque and power prerequisites for the propulsion system, yields a diminished ratio of recaptured regenerative brake energy to total demanded propulsion energy at wheels compared to lower GVWR classes like class 6 and 7, even in urban driving cycles [158,163].

Table 7.

Standard drive cycles for evaluating the FE in LHTs.

Except for that long-haul VECTO drive cycle, which incorporates the road grade profile, the other listed standard drive cycles for LHTs do not include road inclination. The road gradient continuously changes per distance in real-world driving conditions, imposing more speed and torque transients on the propulsion system. Therefore, it is highly important to provide and use real-world drive cycles taking the road gradient into account to mimic the transient behavior of engine torque and speed to accurately evaluate the FE of newly designed electrified configurations. Total distance can also be important as a hybrid powertrain’s battery state of charge can vary over short distances, even when the battery SOC is maintained at a constant level over longer durations. For plug-in hybrid LHTs, the total driving distance between charges is very important and is normally much longer than the proscribed distance in typical regulatory standards. Concatenating multiple iterations of the same cycle influences FE results [49,151].

9. Conclusions

Near-term reductions and long-term elimination of GHG emissions from long-distance on-road goods transportation are critical challenges. Regulations are pushing manufacturers to reduce GHG emissions while developing new zero-emission technologies. Different applications have a diverse range of vehicle requirements, including range, payload, and performance on a grade. As a result, there is no “one-size-fits-all” solution, and the combination of engine, powertrain, and vehicle technologies is essential in reducing GHGs. This paper showed that engine and vehicle-side improvements could achieve realistic and significant GHG reductions. On the other hand, powertrain electrification has seen significant investigation for commercial vehicles but has not yet achieved widespread market penetration, and its infrastructure, associated costs, and life-cycle implications need to be better understood. The key findings from this review were:

- Long-haul trucks make up a relatively small proportion of commercial vehicles (9% to 16%) but contribute disproportionately to GHG emissions (25% to 50%) from commercial transport due to long travel distances and heavy payloads.

- Current and upcoming GHG standards are driving substantial improvements in vehicle efficiency and the development of zero-emission vehicles in the commercial market. Simultaneously, further restrictions on NOx emissions are forcing further technological advances for internal combustion engine-powered vehicles.

- Substantial improvements in engine, powertrain, and vehicle design and operation are achieving substantial reductions in fuel consumption so that freight efficiency—fuel used to transport a given mass of payload over a given distance—has been increased by 100–150% compared to the 2009 baseline in commercial demonstrations.

- The peak brake thermal efficiency of internal combustion engines used in long-haul trucks is approaching 50% for in-service engines, with near-term technology pathways reaching 50% or higher. The addition of waste heat recovery has been shown to enable an engine system to reach a peak of 55% brake thermal efficiency at conditions typically encountered in loaded cruising.

- Near-term vehicle improvements, including better aerodynamics, low rolling resistance tires, and vehicle weight reduction, offer between 12% and 14% fuel economy improvements over long-haul driving conditions.

- Hybridizing a long-haul truck involves adding electrical energy storage, a motor/generator combination, and a diesel engine. There is a general lack of experimental studies demonstrating such hybrid commercial vehicles, with most studies being based on numerical models of varying fidelity. Results vary depending on the vehicle configuration and duty cycle. However, long-haul on-highway trucking generally shows substantially smaller benefits than more transient and lower-load urban operations.

- Of the different hybrid configurations, mild-hybrid approaches have the lowest cost and complexity and offer some brake energy recovery potential with limited net potential benefits in long-haul trucking. Series hybrids also show limited or no benefit due to the energy conversion losses between the engine and the drive under high-load cruising conditions. Power-split and pre-transmission parallel hybrid designs exhibit the highest fuel-saving potential for on-highway use, but the benefits strongly depend on the drive cycle.

- Plug-in long-haul truck studies in the literature have suggested significant fuel-saving potential: up to 43% on highways with a 100% cargo load compared to the conventional baseline. Uncertainties surrounding their adoption in the HD market include a high battery weight-to-energy capacity ratio, higher powertrain costs, longer charging times, and inadequate fast-charging infrastructure.

- Understanding the drive cycle to be used is of critical importance in designing electrified powertrains. Most papers have focused on standard drive cycles, while it is significant to consider experimental cycles with higher road grades to design a reliable electrified powertrain.

In conclusion, engine, vehicle, and powertrain technologies that offer pathways to reduce the GHG emissions from LH trucking are urgently needed. Mild hybridization for LH trucking, including start-stop/ISG with the electrification of auxiliaries and thermal aftertreatment management, is likely in the near future. Full hybridization offers limited benefits in the LH segment as the high power use minimizes chances for regenerative braking, and the high efficiency of diesel engines in typical highway driving conditions limits the ability to re-optimize the engine for improved efficiency. However, reducing engine transients by a hybrid powertrain leads to substantially low engine-out (e.g., NOx) emissions. Other benefits include allowing electric operation in regions where only zero emissions are permitted, such as green zones in certain urban regions. Powertrain full electrification offers one approach that needs to be better understood regarding real driving range, battery weight/size, and its impact on cargo capacity, charging time, the required infrastructure, and life-cycle implications.

Author Contributions

Writing—original draft preparation, N.B.M. and S.M. (Sina Moghadasi); writing—review and editing, and supervision, G.M.-C., M.S. and S.M. (Sandeep Munshi). All authors have read and agreed to the published version of the manuscript.

Funding

Research was funded by the Natural Sciences and Engineering Research Council of Canada (Alliance program, grant ID #551990) in partnership with Westport Fuel Systems Inc.

Data Availability Statement

No new data was created or analyzed in this study. Dataset sharing is not applicable to this article.

Conflicts of Interest

The authors declare no conflict of interest. The funders did not contribute to the writing of the article and had no input on the inclusion or exclusion of certain studies or results. The work presented here is entirely the view of the authors and does not represent the view of any organization or commercial entity.

Nomenclature

| AER | all-electric range |

| AMT | automated manual transmission |

| APU | auxiliary power unit |

| AT | automatic transmission |

| ATIS | automatic tire inflation systems |

| BAS | belt assistant starter |

| BE | battery electric |

| BSFC | brake-specific fuel consumption |

| BSG | belt starter generator |

| CAC | charge air cooler |

| CARB | California Air Resources Board |

| CC | close-coupled |

| CR | compression ratio |

| CS | charge sustaining |

| DCT | dual-clutch transmission |

| DATP | driver-assistive-truck-platooning |

| DEF | diesel exhaust fluid |

| DDR | daily driving range |

| DOC | diesel oxidation catalyst |

| DPF | diesel particulate filter |

| DOE | Department of Energy |

| EC | European Commission |

| EPA | Environmental Protection Agency |

| EV | electric vehicle |

| FE | fuel economy |

| FEV | full electric vehicle |

| FTP | Federal Test Procedure |

| FUL | full useful life |

| GCI | gasoline compression ignition |

| GEM | greenhouse gas emissions model |

| PSH | power-split hybrid |

| RHT | regional-haul trucks |

| SCR | selective catalytic reduction |

| SDPF | SCR-catalyzed diesel particulate filter |

| SH | series hybrid |

| SOC | state of charge |

| SS | side skirt |

| THS | Toyota Hybrid System |

| UDDS | Urban Dynamometer Driving Schedule |

| GHG | greenhouse gas emissions |

| GVWR | gross vehicle weight ratings |

| HD | heavy-duty |

| HDV | heavy-duty vehicle |

| HHDDT | Heavy Heavy-Duty Diesel Truck |

| HET | hybrid electric trucks |

| HP | high pressure |

| HT | high temperature |

| IEA | International Energy Agency |

| IUL | intermediate useful life |

| LCV | long combination vehicle |

| LEVO | late exhaust valve opening |

| LHT | long-haul truck |

| LIVC | late intake valve closing |

| LNT | lean NOx trap |

| LRR | low-rolling resistance |

| LT | low temperature |

| MD | medium-duty |

| MGU | motor generator unit |

| MT | manual transmission |

| NA | North America |

| NHTSA | National Highway Traffic Safety Administration |

| NZE | net zero emissions |

| ND | not disclosed |

| OEM | original equipment manufacturer |

| ORC | Organic Rankine Cycle |

| PCC | predictive cruise control |

| PCP | peak cylinder pressure |

| PH | parallel hybrid |

| PTO | power take-off |

| VGT | variable geometry turbine |

| VSL | vehicle speed limit |

| VVA | variable valve actuation |

| WBS | wide-base-single |

| WCC | wheel cavity cover |

| WHR | waste heat recovery |

| ZEV | zero-emission vehicle |

| ZLEV | zero- and- low emission vehicle |

References

- Crippa, M.; Guizzardi, D.; Banja, M.; Solazzo, E.; Muntean, M.; Schaaf, E.; Pagani, F.; Monforti-Ferrario, F.; Olivier, J.; Quadrelli, R.; et al. CO2 Emissions of All World Countries. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC130363 (accessed on 27 July 2023).

- Environment and Climate Change Canada. Greenhouse Gas Sources and Sinks in Canada: Executive Summary. 2022. Available online: https://www.canada.ca/en/environment-climate-change/services/climate-change/greenhouse-gas-emissions/sources-sinks-executive-summary-2022.html (accessed on 15 January 2023).

- CO2 Emission Standards for Heavy-Duty Vehicles. Available online: https://ec.europa.eu/commission/presscorner/detail/en/qanda_23_763 (accessed on 20 February 2023).