The Effect of Dust Deposition on the Performance of Photovoltaic Panels

Abstract

1. Introduction

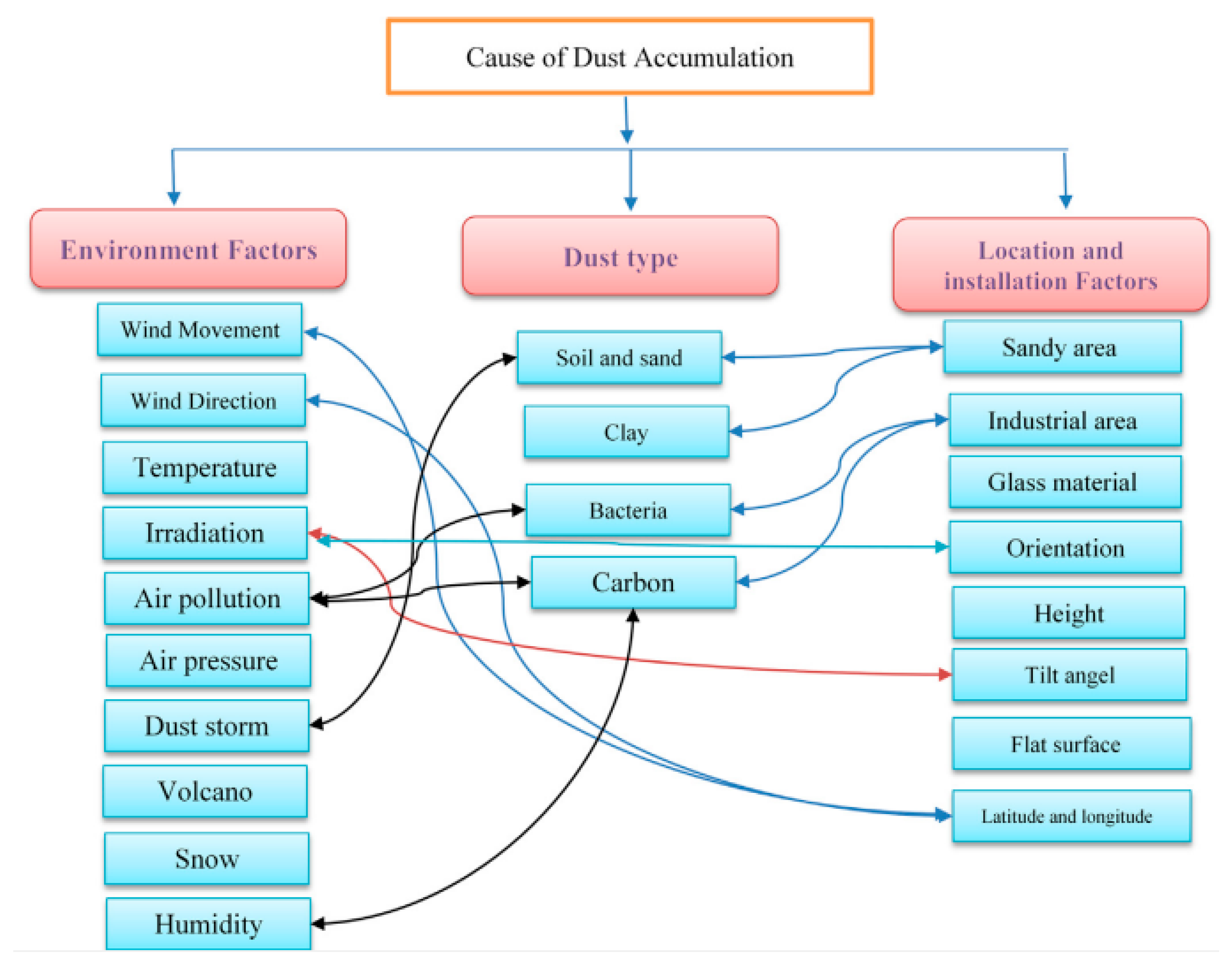

2. The Causes of Dust Accumulation on the Surface of Solar Panels

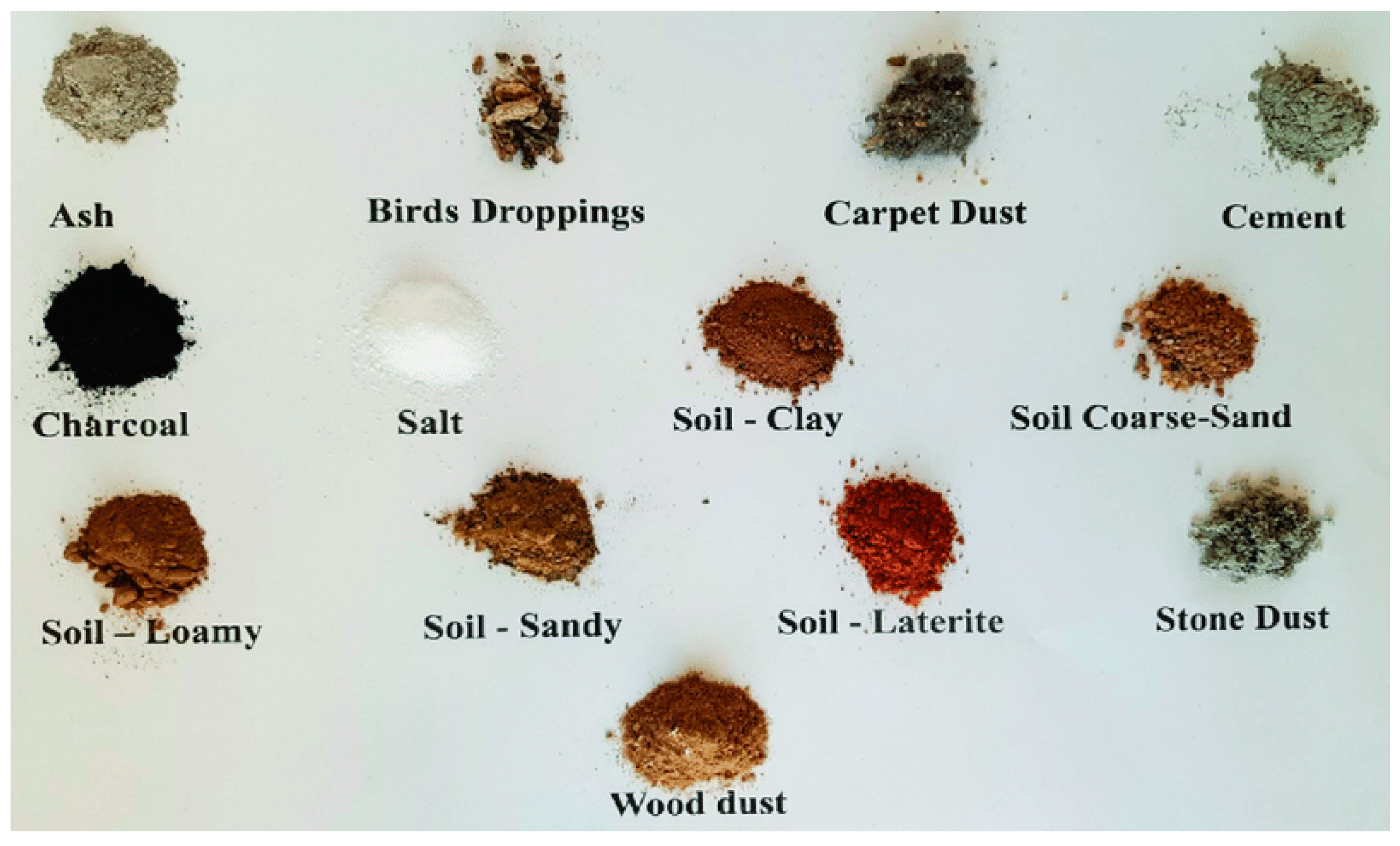

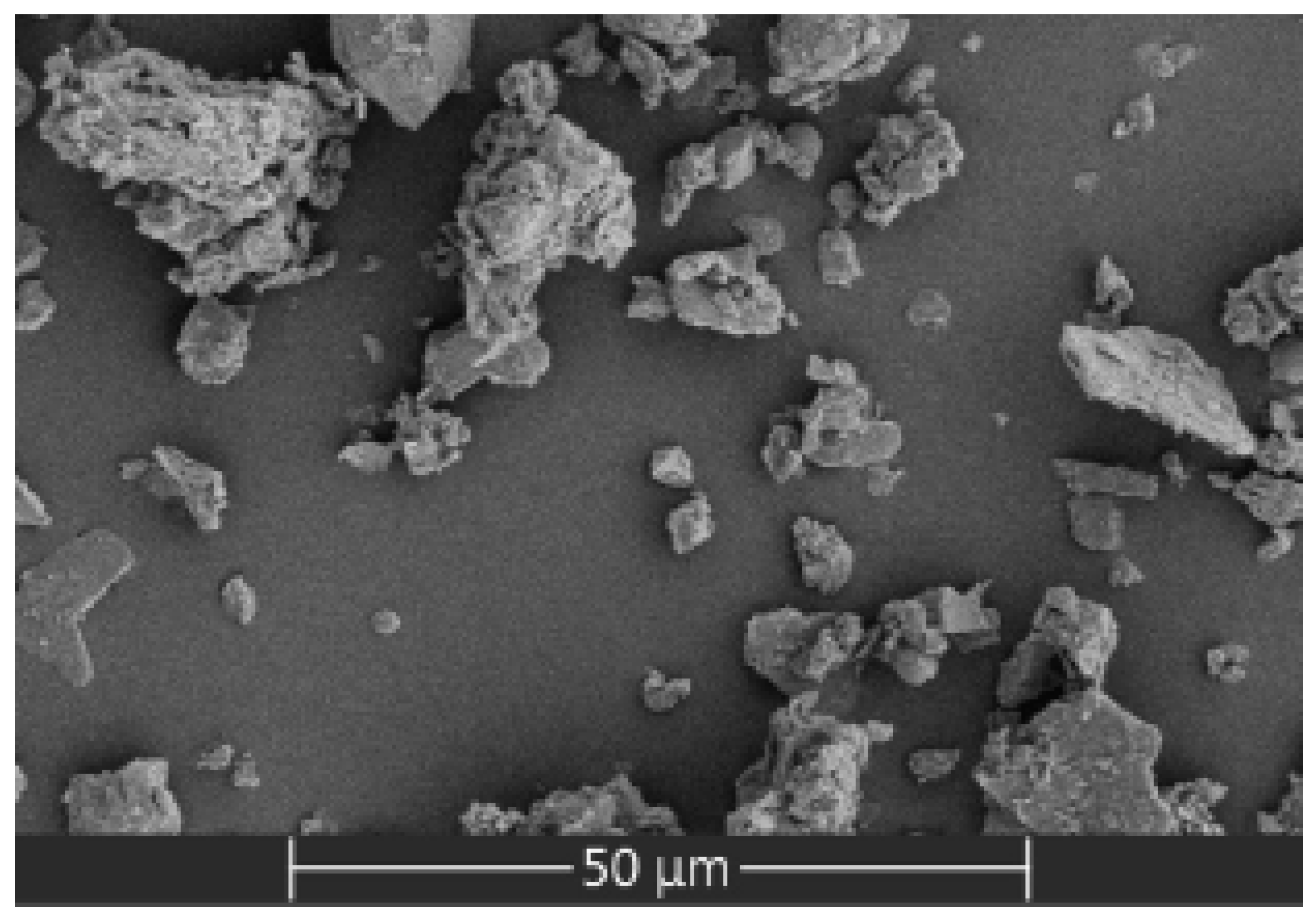

3. The Composition of the Dust Deposited on the Surface of Photovoltaic Panels

4. The Effect of Temperature on the Output Power of the Photovoltaic Mode

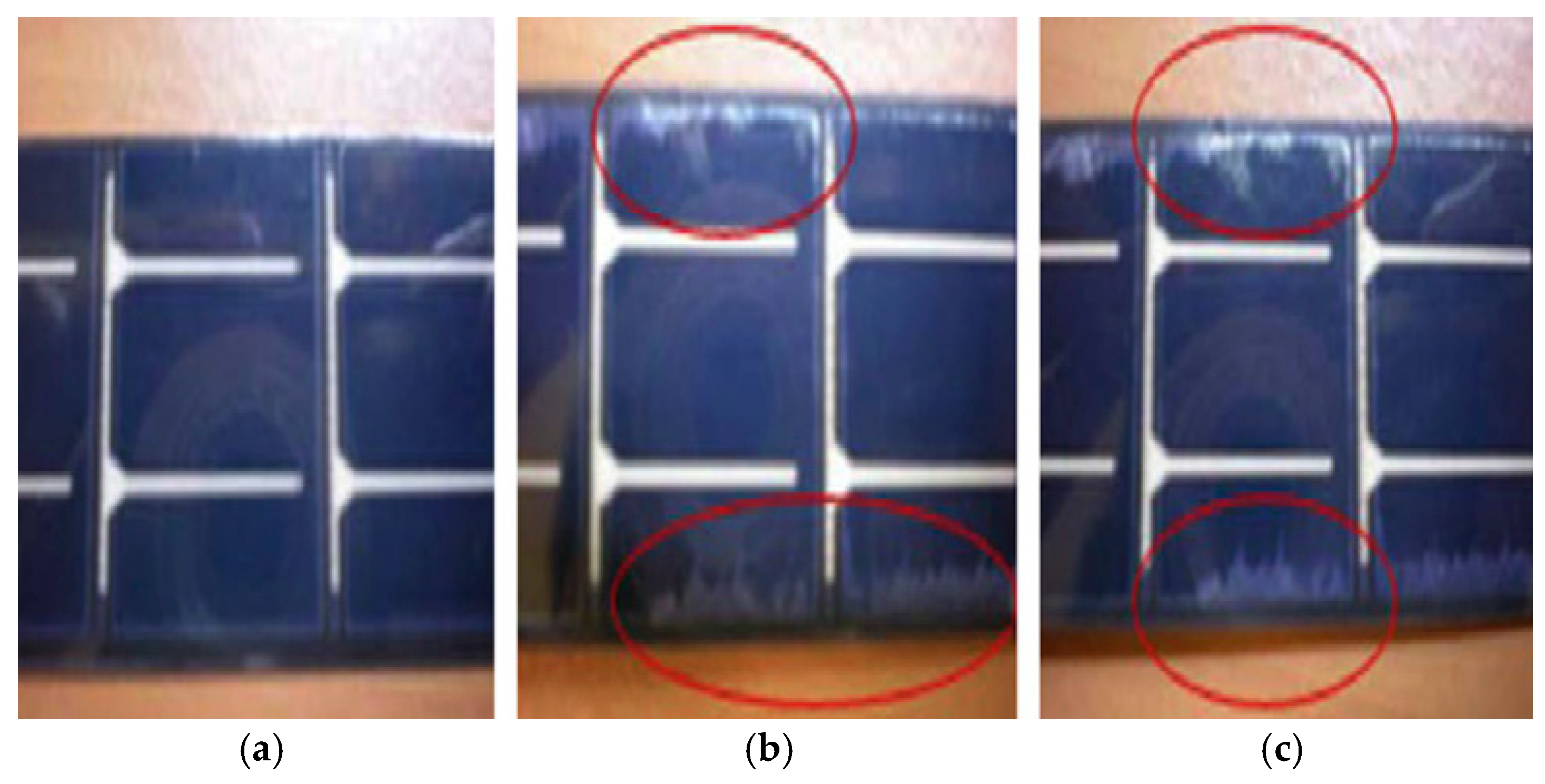

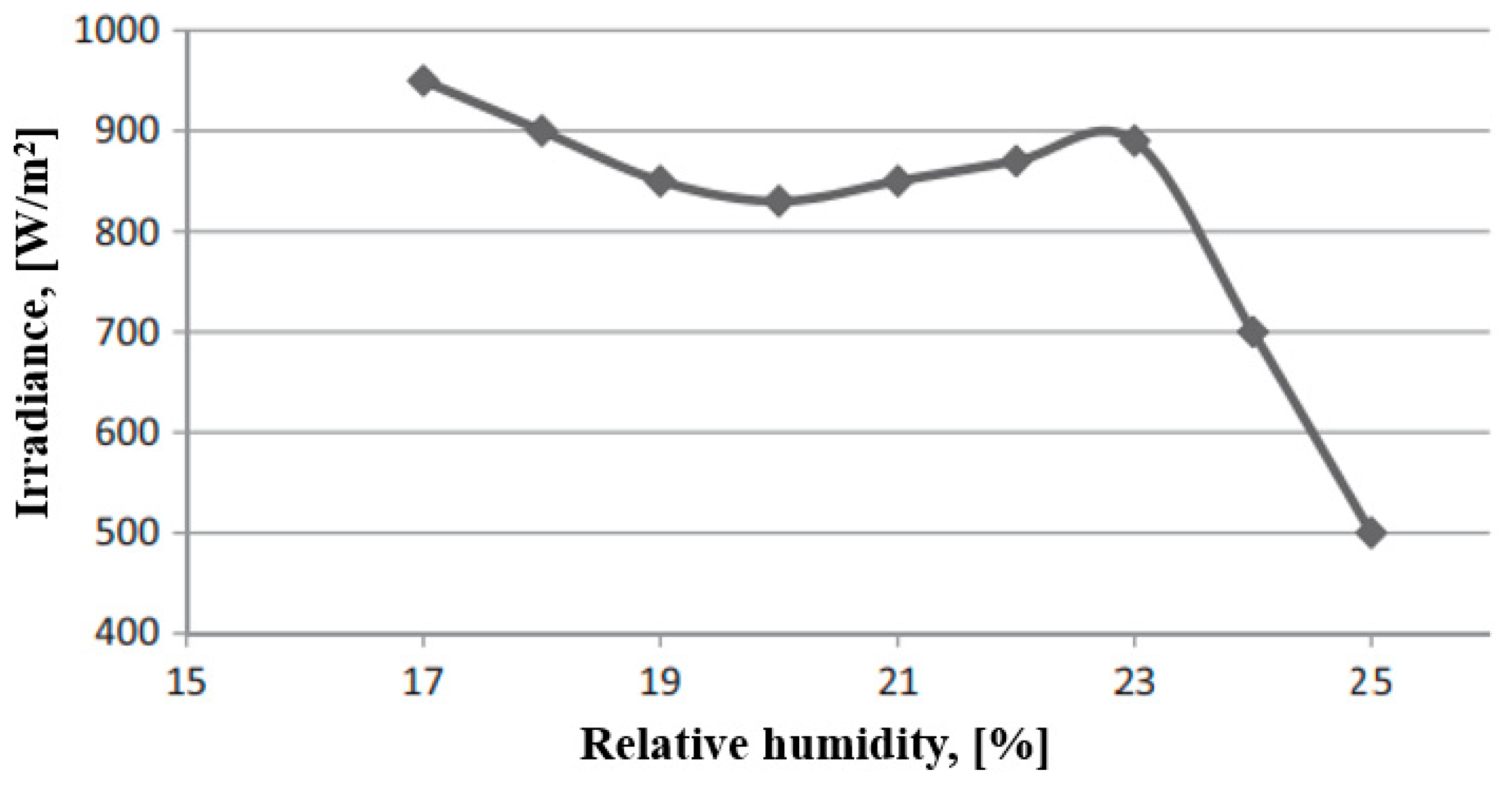

5. The Impact of Humidity on the Performance of Photovoltaic Cells

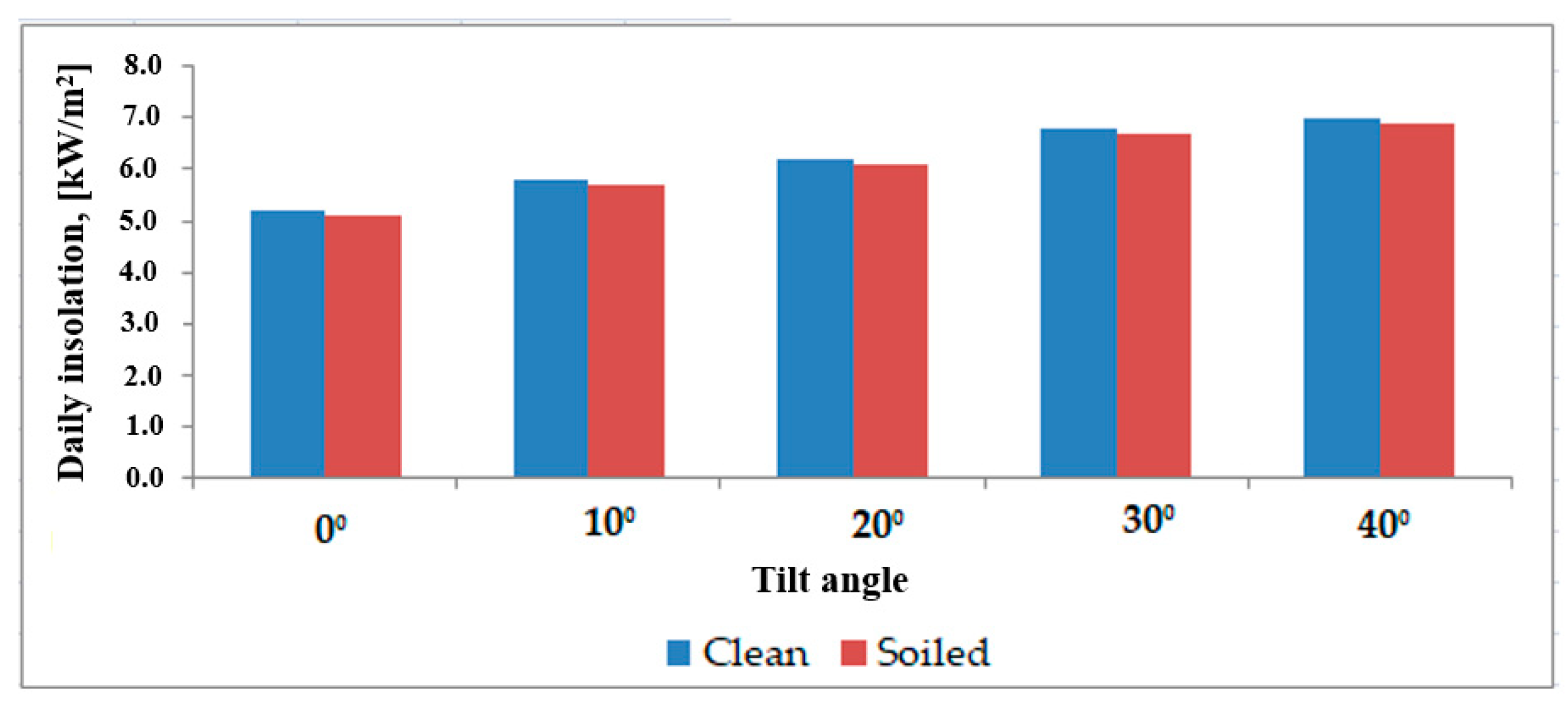

6. The Influence of the Tilt Angles of the Photovoltaic Panels on the Dust Deposition Rate

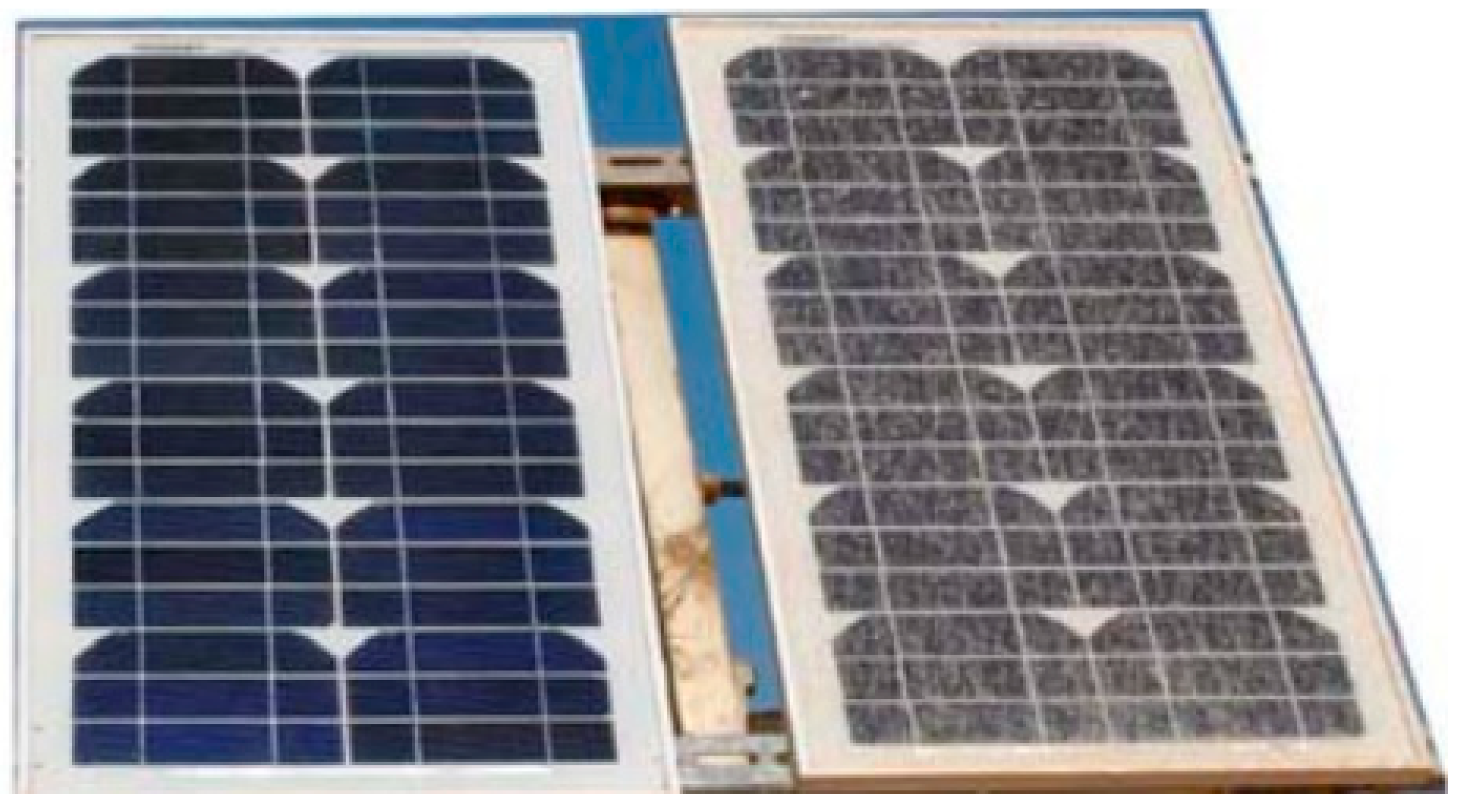

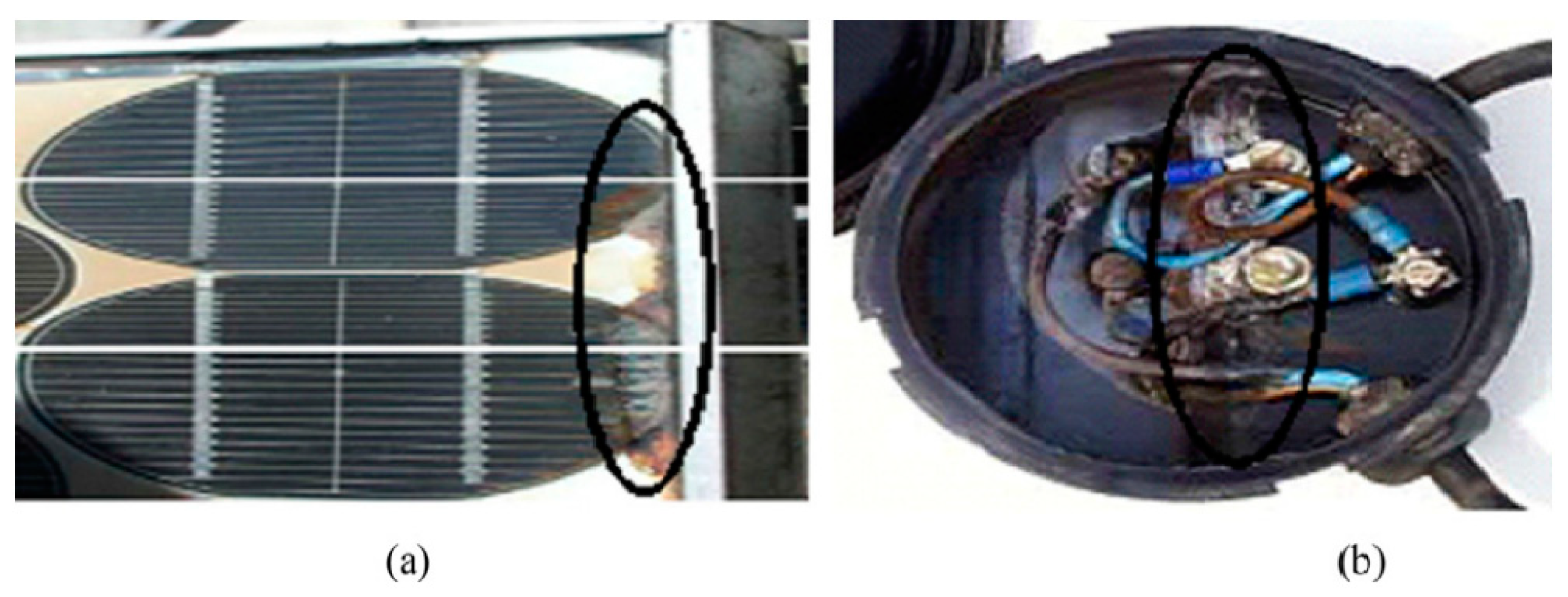

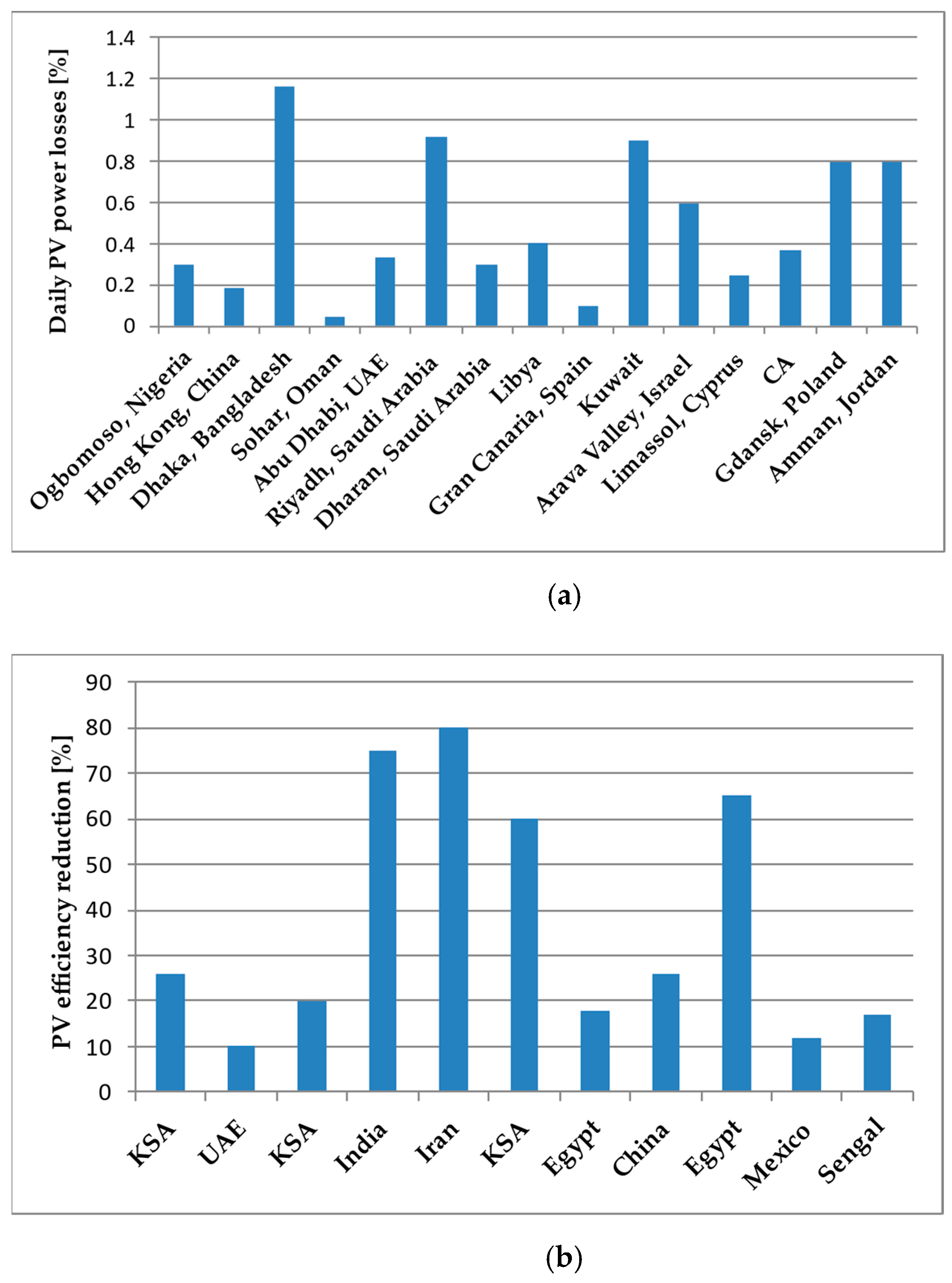

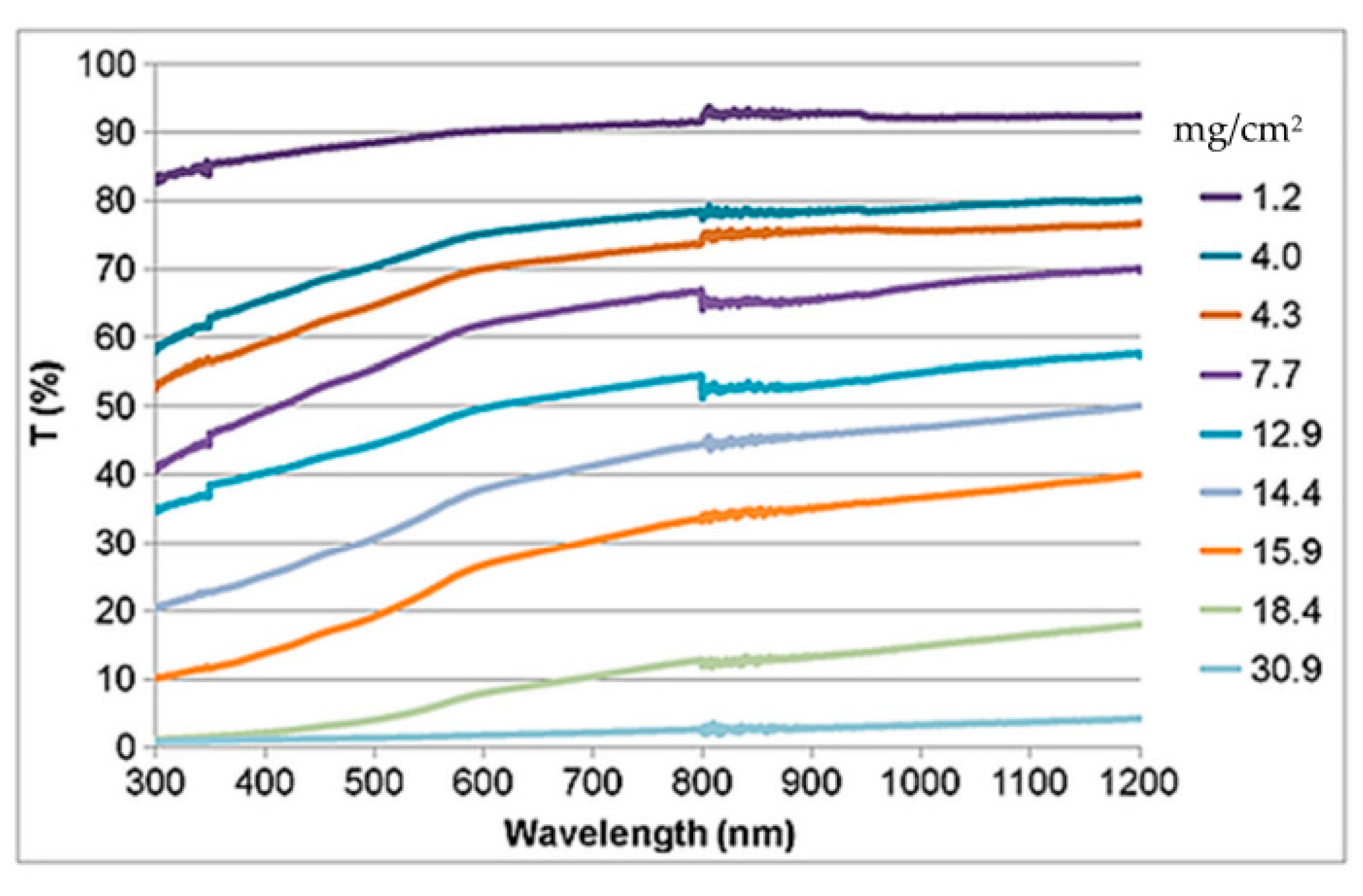

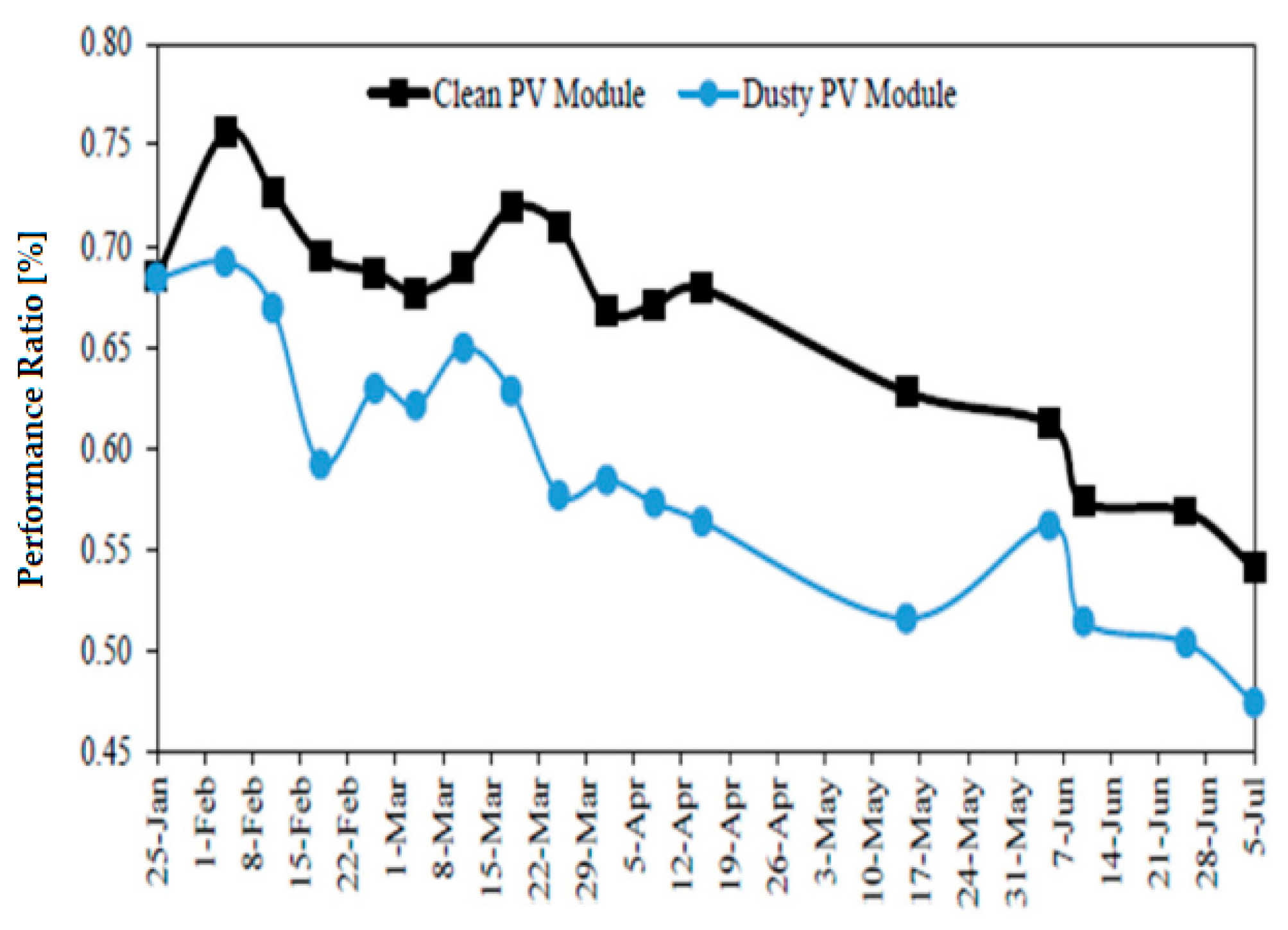

7. The Effect of Dust Accumulation on the Performance of Photovoltaic Panels

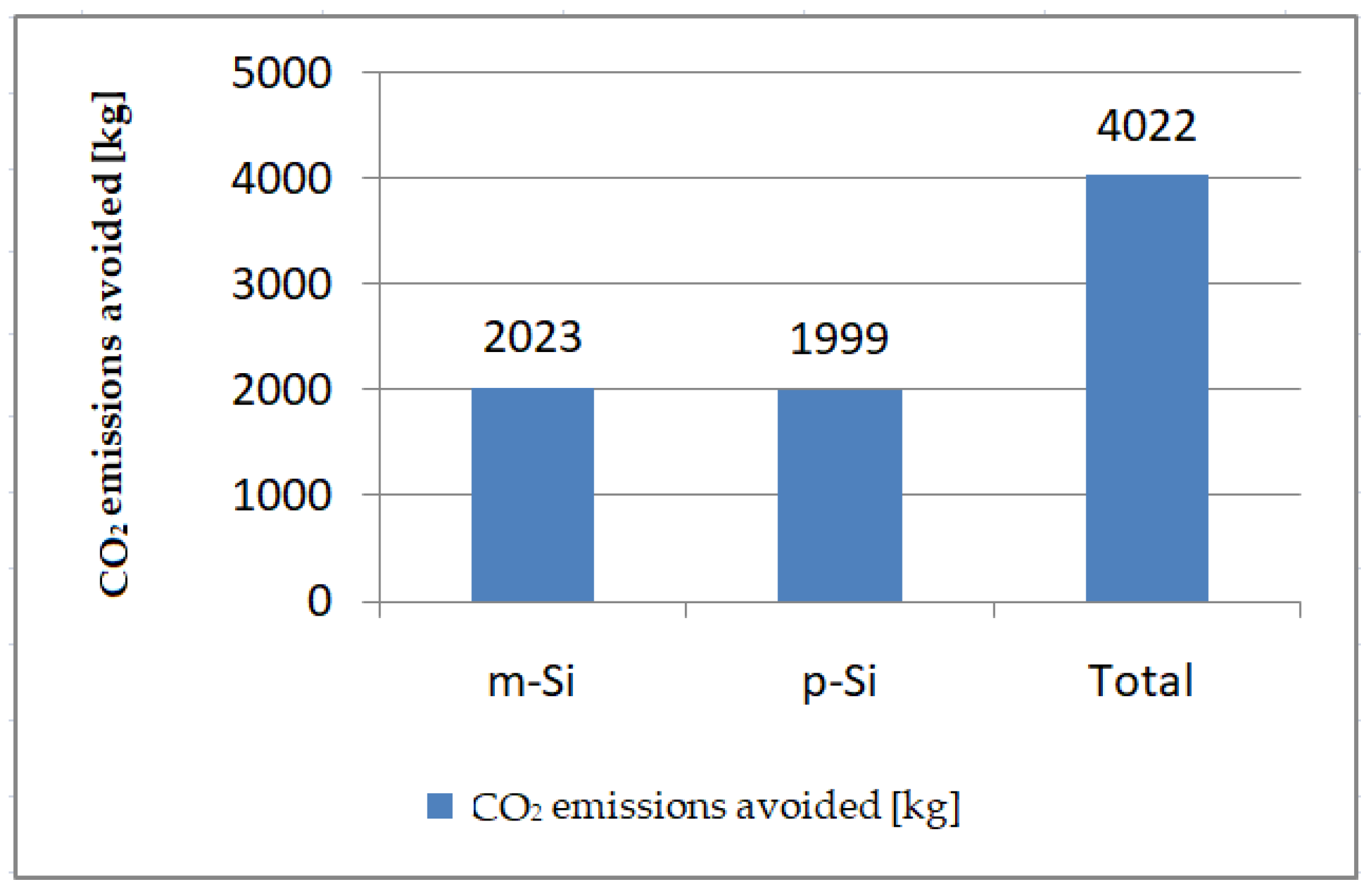

8. Reduction in CO2 Emissions

9. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Emisii de gaze cu efect de seră pe țări și sectoare (infografic)|Actualitate|Parlamentul European. Available online: https://www.europarl.europa.eu/news/ro/headlines/society/20180301STO98928/emisii-de-gaze-cu-efect-de-sera-pe-tari-si-sectoare-infografic (accessed on 19 December 2022).

- Shenouda, R.; Abd-Elhady, M.S.; Kandil, H.A. A review of dust accumulation on PV panels in the MENA and the Far East regions. J. Eng. Appl. Sci. 2022, 69, 8. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Alghoul, M.A.; Alawadhi, H. Experimental investigation of dust pollutants and the impact of environmental parameters on PV performance: An experimental study. Environ. Dev. Sustain. 2018, 20, 155–174. [Google Scholar] [CrossRef]

- Verma, A.; Singhal, S. Solar PV Performance Parameter and Recommendation for Optimization of Performance in Large Scale Grid Connected Solar PV Plant—Case Study. J. Energy Power Sources 2015, 2, 40–53. [Google Scholar]

- Quan, Z.; Lu, H.; Zhao, W.; Zheng, C.; Zhu, Z.; Qin, J.; Yue, M. A Review of Dust Deposition Mechanism and Self-Cleaning Methods for Solar Photovoltaic Modules. Coatings 2023, 13, 49. [Google Scholar] [CrossRef]

- Rao, A.; Pillai, R.; Mani, M.; Ramamurthy, P. Influence of dust deposition on photovoltaic panel performance. Energy Procedia 2014, 54, 690–700. [Google Scholar] [CrossRef]

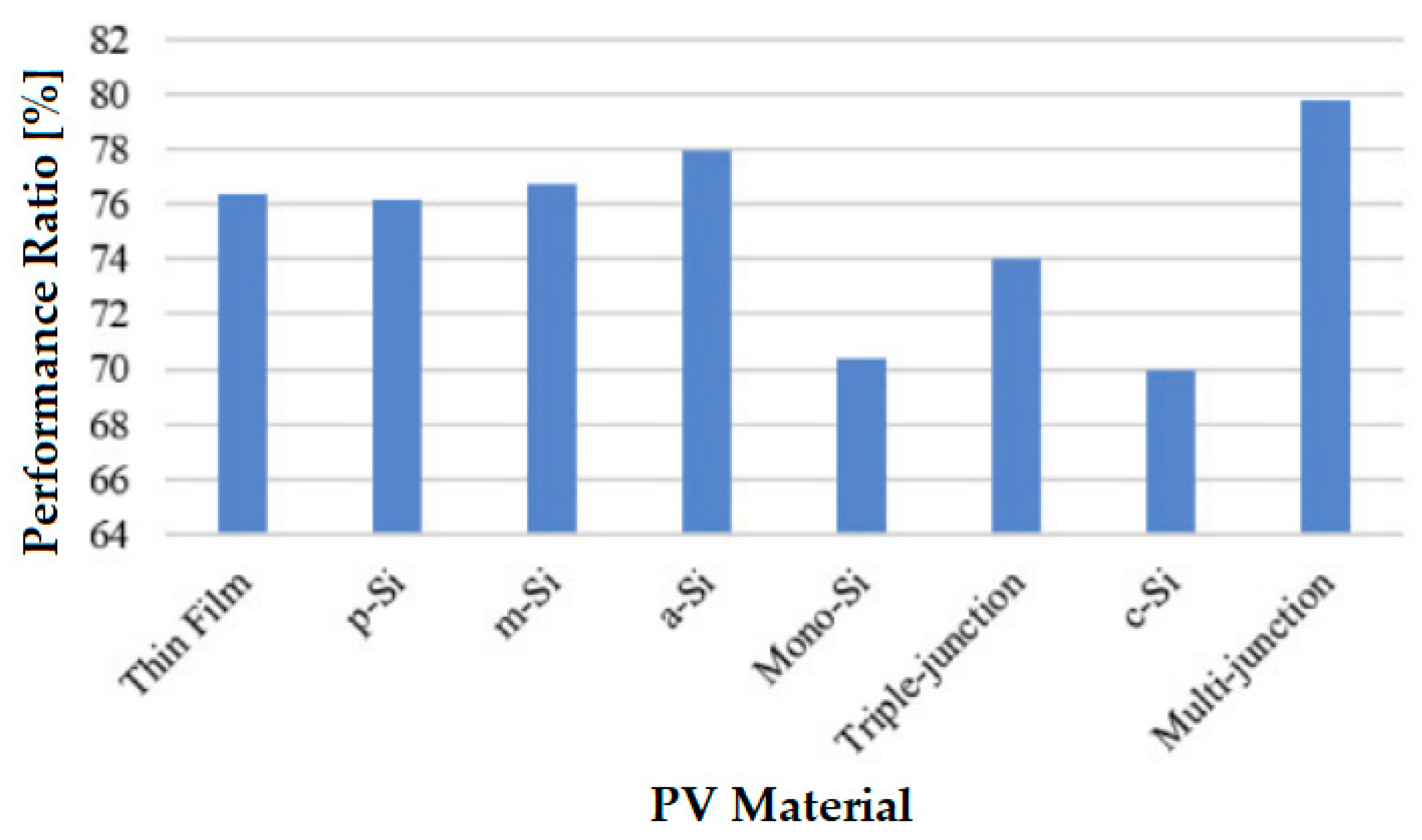

- Urrejola, E.; Antonanzas, J.; Ayala, P.; Salgado, M.; Ramírez-Sagner, G.; Corte’s, C.; Escobar, R. Effect of soiling and sunlight exposure on the performance ratio of photovoltaic technologies in Santiago, Chile. Energy Convers. Manag. 2016, 114, 338–347. [Google Scholar] [CrossRef]

- Mihai, M.I.; Tanasiev, V.; Badea, A.; Vidu, R. The influence of climatic factors on the performance of photovoltaic panels. In Proceedings of the The 39th ARA Proceedings, Rome, Italy, 28–31 July 2015. [Google Scholar]

- Kaldellis, J.K.; Fragos, P.; Kapsali, M. Systematic experimental study of the pollution deposition impact on the energy yield of photovoltaic installations. Renew. Energy 2011, 36, 2717–2724. [Google Scholar] [CrossRef]

- Kumar, S.; Chaurasia, P. Experimental study on the effect of dust deposition on solar photovoltaic panel in Jaipur. Int. J. Sci. Res. 2014, 3, 1690–1693. [Google Scholar]

- Castrillón-Mendoza, R.A.; Manrique-Castillo, P.A.; Rey-Hernández, J.; Rey-Martínez, F.; González-Palomino, G. PV Energy Performance in a Sustainable Campus. Electronics 2020, 9, 1874. [Google Scholar] [CrossRef]

- Molki, A. Dust affects solar-cell efficiency. Phys. Educ. 2010, 45, 456–458. [Google Scholar] [CrossRef]

- Saravanan, V.S.; Darvekar, S.K. Solar Photovoltaic Panels Cleaning Methods A Review. Int. J. Pure Appl. Math. 2018, 118, 1–17. [Google Scholar]

- Khan, T.M.Y.; Soudagar, M.E.M.; Kanchan, M.; Afzal, A.; Banapurmath, N.R.; Akram, N.; Mane, S.D.; Shahapurkar, K. Optimum location and infuence of tilt angle on performance of solar PV panels. J. Therm. Anal. Calorim. 2020, 141, 511–532. [Google Scholar] [CrossRef]

- Klugmann-Radziemska, E. Degradation of electrical performance of a crystalline photovoltaic module due to dust deposition in northern Poland. Renew. Energy 2015, 78, 418–426. [Google Scholar] [CrossRef]

- Chanchangi, Y.; Ghosh, A.; Sundaram, S.; Malick, T.K. Dust and PV Performance in Nigeria: A review. Renew. Sustain. Energy Rev. 2020, 121, 109704. [Google Scholar] [CrossRef]

- McTainsh, G.H.; Nickling, W.G.; Lynch, A.W. Dust deposition and particle size in Mali, West Africa. Catena 1997, 29, 307. [Google Scholar] [CrossRef]

- Fujiwara, F.; Rebagliati, R.J.; Dawidowski, L.; Gomez, D.; Polla, G.; Pereyra, V.; Smichowski, P. Spatial and chemical patterns of size fractionated road dust collected in a megacity. Atmos. Environ. 2011, 45, 1497. [Google Scholar] [CrossRef]

- Beattie, N.S.; Moir, R.S.; Chacko, C.; Buffoni, G.; Roberts, S.H.; Pearsall, N.M. Understanding the effects of sand and dust accumulation on photovoltaic modules. Renew. Energy 2012, 48, 448. [Google Scholar] [CrossRef]

- Kaldellis, J.; Kokala, A. Quantifying the decrease of the photovoltaic panels’ energy yield due to phenomena of natural air pollution disposal. Energy 2010, 35, 4862–4869. [Google Scholar] [CrossRef]

- Prasad, A.A.; Nishant, N.; Kay, M. Dust cycle and soiling issues affecting solar energy reductions in Australia using multiple datasets. Appl. Energy 2022, 310, 118626. [Google Scholar] [CrossRef]

- Adinoyi, M.J.; Said, S.A.M. Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renew. Energy 2013, 60, 633–636. [Google Scholar] [CrossRef]

- Cabanillas, R.E.; Munguía, H. Dust accumulation effect on efficiency of Si photovoltaic modules. J. Renew. Sustain. Energy 2011, 3, 043114. [Google Scholar] [CrossRef]

- Maghami, M.R.; Hizam, H.; Gomes, C.; Radzi, M.A.; Rezadad, M.I.; Hajighorbani, S. Power loss due to soiling on solar panel: A review. Renew. Sustain. Energy Rev. 2016, 59, 1307–1316. [Google Scholar] [CrossRef]

- Chanchangi, Y.; Ghosh, A.; Sundaram, S.; Mallick, T. An analytical indoor experimental study on the effect of soiling on PV, focusing on dust properties and PV surface material. Sol. Energy 2020, 203, 46–68. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T. Experimental analysis of the effect of dust’s physical properties on photovoltaic modules in Northern Oman. Sol. Energy 2016, 139, 68–80. [Google Scholar] [CrossRef]

- Kumar, E.S.; Sarkar, B.D.B. Soiling and dust impact on the efficiency and the maximum power point in the photovoltaic modules. Int. J. Eng. Res. Technol. 2013, 2, 1–8. [Google Scholar]

- Kazem, H.; Chaichan, M.; Al-Waeli, A.A.; Sopian, K. A review of dust accumulation and cleaning methods for solar photovoltaic systems. J. Clean. Prod. 2020, 276, 123187. [Google Scholar] [CrossRef]

- Kaldellis, J.K.; Kapsali, M. Simulating the dust effect on the energy performance of photovoltaic generators based on experimental measurements. Energy 2011, 36, 5154–5161. [Google Scholar] [CrossRef]

- Zang, J.; Li, X.; Wang, J.; Qiao, L. CFD–DEM Simulation of Dust Deposition on Solar Panels for Desert Railways. Appl. Sci. 2023, 13, 4. [Google Scholar] [CrossRef]

- Kasim, N.; Al-Wattar, A.; Abbas, K. New Technique for Treatment of the dust accumulation from PV solar panels surface. Iraqi J. Phys. 2010, 8, 54–59. [Google Scholar]

- Available online: https://www.wamda.com/memakersge/2015/06/solar-piezoclean-and-dust-problem-mena (accessed on 10 December 2022).

- Chen, J.; Pan, G.; Ouyang, J.; Ma, J.; Fu, L.; Zhang, L. Study on impacts of dust accumulation and rainfall on PV power reduction in East China. Energy 2020, 194, 116915. [Google Scholar] [CrossRef]

- Elminir, H.K.; Ghitas, A.E.; Hamid, R.; El-Hussainy, F.; Beheary, M.; Abdel-Moneim, K.M. Effect of dust on the transparent cover of solar collectors. Energy Convers. Manag. 2006, 47, 3192–3203. [Google Scholar] [CrossRef]

- Dulgheru, V.; Dumitrescu, C.; Cristescu, C. Sun Orientation System of the Group of Photovoltaic Panels. Available online: https://ibn.idsi.md/sites/default/files/imag_file/72_76_Sistem%20de%20orientare%20la%20soare%20a%20grupului%20de%20panouri%20fotovoltaice.pdf (accessed on 19 December 2022).

- Govindasamy, D.; Kumar, A. Evaluation of the impact of different composite phase change materials on reduction in temperature and enhancement of solar panel efficiency. J. Energy Storage 2023, 60, 106631. [Google Scholar] [CrossRef]

- Available online: http://free-energy-monitor.com/index.php/energy/fotovoltaice (accessed on 20 December 2022).

- Mekhilef, S.; Saidur, R.; Kamalisarvestani, M. Effect of dust, humidity and air velocity on efficiency of photovoltaic cells. Renew. Sustain. Energy Rev. 2012, 16, 2920–2925. [Google Scholar] [CrossRef]

- Kempe, M.D. Modeling of rates of moisture ingress into photovoltaic modules. Sol. Energy Mater. Sol. Cells 2006, 90, 2720–2738. [Google Scholar] [CrossRef]

- Tan, C.M.; Chen, B.K.E.; Toh, K.P. Humidity study of a-Si PV cell. Microelectron. Reliab. 2010, 50, 1871–1874. [Google Scholar] [CrossRef]

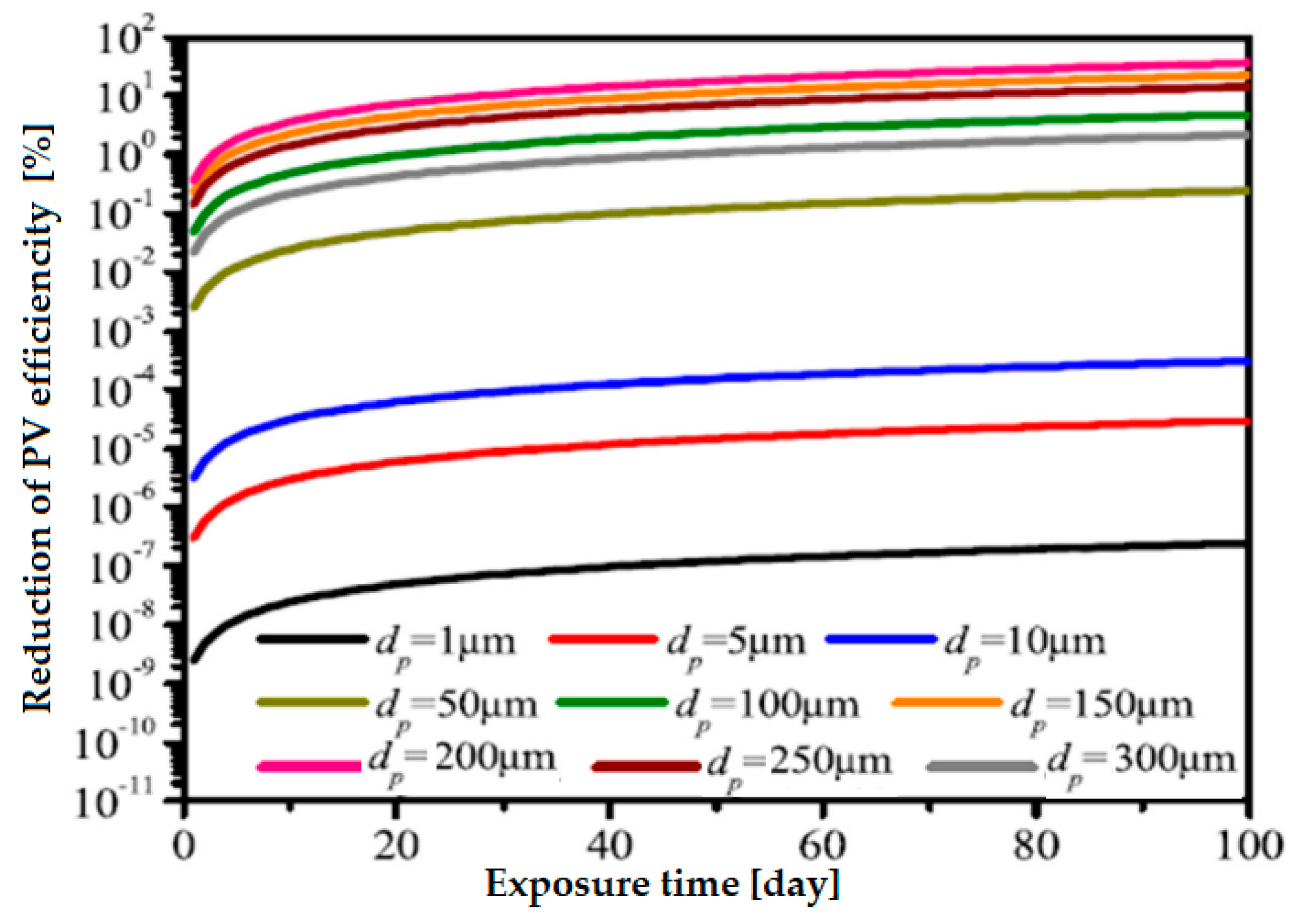

- Lu, H.; Zhao, W. Effects of particle sizes and tilt angles on dust deposition characteristics of a ground-mounted solar photovoltaic system. Appl. Energy 2018, 220, 514–526. [Google Scholar] [CrossRef]

- Meral, M.E.; Dinçer, F.A. Review of the factors affecting operation and efficiency of Photovoltaic based electricity generation systems. Renew. Sustain. Energy Rev. 2011, 15, 2176–2184. [Google Scholar] [CrossRef]

- Mackley, R.D.; Thomle, J.N.; Anderson, D.M.; Strickland, C.E. Technical and Economic Assessment of Solar Photovoltaic for Groundwater Extraction on the Hanford Site; Pacific Northwest National Lab (PNNL): Richland, WA, USA, 2015. [Google Scholar]

- Rusănescu, C.O.; Paraschiv, G.; Murad, E.; David, M.F. Monitoring solar radiation intensity in the year 2011 in the north west of Bucharest with sun-earth angle. In Proceedings of the International symposium ISB/INMA TEH 2012, Bucharest, Romania, 1–3 November 2012; pp. 159–164. [Google Scholar]

- Cano, J. Photovoltaic Modules: Effect of Tilt Angle on Soiling. Master’s Thesis, Arizona State University, Tempe, AZ, USA, 2011. [Google Scholar]

- Manolache, A.I.; Andrei, G.; Rusu, L. An Evaluation of the Efficiency of the Floating Solar Panels in the Western Black Sea and the Razim-Sinoe Lagunar System. J. Mar. Sci. Eng. 2023, 11, 203. [Google Scholar] [CrossRef]

- Kazem, H.A.; Chaichan, M.T.; Saif, S.A.; Dawood, A.A.; Salim, S.A.; Rashid, A.A.; Alwaeli, A.A. Experimental investigation of dust type effect on photovoltaic systems in north region, Oman. Int. J. Sci. Eng. Res. 2015, 6, 293–298. [Google Scholar]

- Liu, D.; Yang, X.; Gao, J.; Ran, Q.; Zhu, G.; Yuan, J.; Zheng, D.; Guo, J.; Zhao, J.; Tang, Q. Smart Solar-Panel Umbrella toward High-Efficient Hybrid Solar and Rain Energy Harvesting. Energy Tehnol. 2022, 11, 2201044. [Google Scholar] [CrossRef]

- Ghazi, S.; Sayigh, A.; Ip, K. Dust effect on flat surfaces—A review paper. Renew. Sustain. Energy Rev. 2014, 33, 742–751. [Google Scholar] [CrossRef]

- Rida, K.; Al-Waeli, A.A.; Al-Asadi, K.A. The impact of air mass on photovoltaic panel performance. Eng. Sci. Rep. 2016, 1, 1. [Google Scholar] [CrossRef]

- Chaichan, M.T.; Abass, K.I.; Kazem, H.A. Energy Yield Loss Caused by Dust and Pollutants Deposition on Concentrated Solar Power Plants in Iraq Weathers. Int. Res. J. Adv. Eng. Sci. 2018, 3, 160–169. [Google Scholar]

- Jiang, H.; Lu, L.; Sun, K. Experimental investigation of the impact of airborne dust deposition on the performance of solar photovoltaic modules. Atmos. Environ. 2011, 45, 4299–4304. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Al-Sawafta, I.; Said, Z. Impact of dust on the performance of solar photovoltaic (PV) systems under United Arab Emirates weather conditions. Renew. Energy 2019, 141, 287–297. [Google Scholar] [CrossRef]

- Aïssa, B.; Isaifan, R.J.; Madhavan, V.E.; Abdallah, A.A. Structural and physical properties of the dust particles in Qatar and their influence on the PV panel performance. Sci. Rep. 2016, 6, 1–12. [Google Scholar] [CrossRef]

- El-Shobokshy, M.S.; Hussein, F.M. Effect of dust with different physical properties on the performance of photovoltaic cells. Sol. Energy 1993, 51, 505–511. [Google Scholar] [CrossRef]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T. The effect of dust with different morphologies on the performance degradation of photovoltaic modules. Sustain. Energy Technol. Assess. 2019, 31, 347–354. [Google Scholar] [CrossRef]

- Goossens, D.; Lundholm, R.; Goverde, H.; Govaerts, J. Effect of soiling on wind-induced cooling of photovoltaic modules and consequences for electrical performance. Sustain. Energy Technol. Assess. 2019, 34, 116–125. [Google Scholar] [CrossRef]

- Sadat, S.A.; Faraji, J.; Nazififard, M.; Ketabi, A. The experimental analysis of dust deposition effect on solar photovoltaic panels in Iran’s desert environment. Sustain. Energy Technol. Assess. 2021, 47, 101542. [Google Scholar]

- Kazem Ali, A.; Chaichan, M.T.; Kazem, H.A. Dust effect on photovoltaic utilization in Iraq: Review article. Renew. Sustain. Energy Rev. 2014, 37, 734–749. [Google Scholar] [CrossRef]

- Zorrilla-Casanova, J.; Piliougine, M.; Carretero, J.; Bernaola, P.; Carpena, P.; Mora -Lopez, L.; Sidrach-de-Cardona, M. Analysis of dust losses in photovoltaic modules. In Proceedings of the World Renewable Energy Congress, Linköping, Sweden, 8–13 May 2011. [Google Scholar]

- Ndiaye, A.; Kébé, C.M.F.; Ndiaye, P.A.; Charki, A.; Kobi, A.; Sambou, V. Impact of dust on the photovoltaic (PV) modules characteristics after an exposition year in Sahelian environment: The case of Senegal. Int. J. Phys. Sci. 2013, 8, 1166–1173. [Google Scholar] [CrossRef]

- Tylim, A. The importance of a PV system washing program. Renew. Energy World 2013, 11. [Google Scholar]

- Marion, B.; Deceglie, M.G.; Silverman, T.J. Analysis of measured photovoltaic module performance for Florida, Oregon, and Colorado locations. Solar Energy 2014, 10, 736–744. [Google Scholar] [CrossRef]

- McMillon-Brown, L.; Peshek, T.J.; Pal, A.M.; McNatt, J. A study of photovoltaic degradation modes due to dust interaction on Mars. Sol. Energy Mater. Sol. Cells 2021, 221, 110880. [Google Scholar] [CrossRef]

- Kimber, A.; Mitchell, L.; Nogradi, S.; Wenger, H. Effect of soiling on large grid-connected photovoltaic systems in California and the Southwest region of the United States. In Proceedings of the Photovoltaic Energy Conversion: Record of the IEEE 4th World Conference, Waikoloa, HI, USA, 7–12 May 2006; p. 2391. [Google Scholar]

- Weiß, K.A.; Klimm, E.; Kaaya, I. Accelerated aging tests vs field performance of PV modules. Prog. Energy 2022, 4, 042009. [Google Scholar] [CrossRef]

- Hajighorbani, S.; Radzi, M.; Ab Kadir, M.; Shafie, S.; Khanaki, R.; Maghami, M. Evaluation of Fuzzy Logic Subsets Effects on Maximum Power Point Tracking for Photovoltaic System. Int. J. Photoenergy 2014, 2014, 719126. [Google Scholar] [CrossRef]

- El-Nashar, A.M. The effect of dust accumulation on the performance of evacuated tube collectors. Sol. Energy 1994, 53, 105–115. [Google Scholar] [CrossRef]

- Hasan, K.; Yousuf, S.B.; Tushar, M.S.H.K.; Das, B.K.; Das, P.; Islam, M.S. Effects of different environmental and operational factors on the PV performance: A comprehensive review. Energy Sci. Eng. 2022, 10, 656–675. [Google Scholar] [CrossRef]

- Kim, J.; Rabelo, M.; Padi, S.P.; Yousuf, H.; Cho, E.C.; Yi, J. A Review of the Degradation of Photovoltaic Modules for Life Expectancy. Energies 2021, 14, 4278. [Google Scholar] [CrossRef]

- Keller, J.; Lamprecht, R. Road dust as an indicator for air pollution transport and deposition: An application of SPOT imagery. Remote Sens. Environ. 1995, 54, 1–12. [Google Scholar] [CrossRef]

- Said, S.A.M. Effects of dust accumulation on performances of thermal and photovoltaic flat-plate collectors. Appl. Energy 1990, 37, 73–84. [Google Scholar] [CrossRef]

- Juaidi, A.; Muhammad, H.H.; Abdallah, R.; Albatayneh, A.; Kawa, F. Experimental validation of dust impact on-grid connected PV system performance in Palestine: An energy nexus perspective. Energy Nexus 2022, 6, 100082. [Google Scholar] [CrossRef]

- Asl-Soleimani, E.; Farhangi, S.; Zabihi, M.S. The effect of tilt angle, air pollution on performance of photovoltaic systems in Tehran. Renew. Energy 2001, 24, 459–468. [Google Scholar] [CrossRef]

- Sanusi, Y.K. The performance of amorphous silicon PV system under Harmattan dust conditions in a tropical area. Pac. J. Sci. Technol. 2012, 13, 168–175. [Google Scholar]

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T.; Pryor, T. The contribution of dust to performance degradation of PV modules in a temperate climate zone. Sol. Energy 2015, 120, 147–157. [Google Scholar] [CrossRef]

- O’Hara, S.L.; Clarke, M.L.; Elatrash, M.S. Field measurements of desert dust deposition in Libya. Atmos. Environ. 2006, 40, 3881–3897. [Google Scholar] [CrossRef]

- Kawamoto, H.; Shibata, T. Electrostatic cleaning system for removal of sand from solar panels. J. Electrost. 2015, 73, 65–70. [Google Scholar] [CrossRef]

- Darwish, Z.A.; Kazem, H.A.; Sopian, K.; Alghoul, M.A.; Chaichan, M.T. Impact of Some Environmental Variables with Dust on Solar Photovoltaic (PV) Performance: Review and Research Status. Int. J. Energy Environ. 2013, 7, 152–159. [Google Scholar]

- Costa, S.C.S.; Diniz, A.S.A.C.; Kazmerski, L.L. Dust and soiling issues and impacts relating to solar energy systems: Literature review update for 2012–2015. Renew. Sustain. Energy Rev. 2016, 63, 33–61. [Google Scholar] [CrossRef]

- Orioli, A.; Di Gangi, A. An improved photographic method to estimate the shading effect of obstructions. Sol. Energy 2012, 86, 3470–3488. [Google Scholar] [CrossRef]

- Benatiallah, A.; Mouly Ali, A.; Abidi, F.; Benatiallah, D.; Harrouz, A.; Mansouri, I. Experimental study of dust effect in mult-crystal PV solar module. Int. J. Multidiscip. Sci. Eng. 2012, 3, 3–6. [Google Scholar]

- Mazumder, M.; Horenstein, M.; Stark, J.; Hudelson, J.N.; Sayyah, A.; Heiling, C.; Yellowhair, J. Electrodynamic removal of dust from solar mirrors and its applications in concentrated solar power (CSP) plants. In Proceedings of the Industry Applications Society Annual Meeting, IEEE, Vancouver, BC, Canada, 5–9 October 2014; pp. 1–7. [Google Scholar] [CrossRef]

- Appels, R.; Muthirayan, B.; Beerten, A.; Paesen, R.; Driesen, J.; Poortmans, J. The effect of dust deposition on photovoltaic modules. In Proceedings of the Conference Record of the IEEE Photovoltaic Specialists Conference, Lake Buena Vista, FL, USA, 3–7 January 2012; pp. 1886–1889. [Google Scholar] [CrossRef]

- Vikrant, S.; Chandel, S.S. Performance analysis of a 190 kW p grid interactive solar photovoltaic power plant in India. Energy 2013, 55, 476–485. [Google Scholar] [CrossRef]

- Guo, B.; Javed, W.; Figgis, B.W.; Mirza, T. Effect of dust and weather conditions on photovoltaic performance in Doha, Qatar. In Proceedings of the 1st Work, Smart Grid Renew, Energy SGRE, Doha, Qatar, 22–23 March 2015. [Google Scholar] [CrossRef]

- Hassan, A.H.; Rahoma, U.A.; Elminir, H.K.; Fathy, A.M. Effect of airborne dust concentration on the performance of PV modules. J. Astron. Soc. Egypt. 2005, 13, 24–38. [Google Scholar]

- Al-Hasan, A.Y.; Ghoneim, A.A. A new correlation between photovoltaic panel’s efficiency and amount of sand dust accumulated on their surface. Int. J. Sustain. Energy 2005, 24, 187–197. [Google Scholar] [CrossRef]

- Pavan, A.M.; Mellit, A.; De Pieri, D. The effect of soiling on energy production for large-scale photovoltaic plants. Sol. Energy 2011, 85, 1128–1136. [Google Scholar] [CrossRef]

- Sreenath, S.; Sudhakar, K.; Yusop, A.F.; Solomin, E.; Kirpichnikova, I.M. Solar PV Energy System in Malaysian Airport: Glare Analysis, General Design and Performance Assessment. Energy Rep. 2020, 6, 698–712. [Google Scholar] [CrossRef]

- Shiva Kumar, B.; Sudhakar, K. Performance Evaluation of 10 MW Grid Connected Solar Photovoltaic Power Plant in India. Energy Rep. 2015, 1, 184–192. [Google Scholar] [CrossRef]

- Belmahdi, B.; Bouardi, A. El Solar Potential Assessment Using PVsyst Software in the Northern Zone of Morocco. Procedia Manuf. 2020, 46, 738–745. [Google Scholar] [CrossRef]

- Atsu, D.; Seres, I.; Farkas, I. The State of Solar PV and Performance Analysis sof Different PV Technologies Grid-Connected Installations in Hungary. Renew. Sustain. Energy Rev. 2021, 141, 110808. [Google Scholar] [CrossRef]

- Haibaoui, A.; Hartiti, B.; Elamim, A.; Karami, M.; Ridah, A. Performance Indicators for Grid-Connected PV Systems: A Case Study In Casablanca, Morocco. IOSR J. Electr. Electron. Eng. IOSR-JEEE 2017, 12, 55–65. [Google Scholar] [CrossRef]

- Kumar Saini, R.; Kumar Saini, D.; Gupta, R.; Verma, P.; Dwivedi4, R.P.; Kumar, A.; Chauhan, D.; Kumar, S. Effects of dust on the performance of solar panels—A review update from 2015–2020. Energy Environ. 2022, 34, 1–53. [Google Scholar]

- Emziane, M.; Ali, M.A. Performance assessment of rooftop PV systems in Abu Dhabi. Energy Build. 2015, 108, 101–105. [Google Scholar] [CrossRef]

- Omar, M.A.; Mahmoud, M.M. Grid connected PV- home systems in Palestine: A review on technical performance, effects and economic feasibility. Renew. Sustain. Energy Rev. 2018, 82, 2490–2497. [Google Scholar] [CrossRef]

- Anang, N.; Syd Nur Azman, S.N.A.; Muda, W.M.W.; Dagang, A.N.; Daud, M.Z. Performance analysis of a grid-connected rooftop solar PV system in Kuala Terengganu, Malaysia. Energy Build. 2021, 248, 111182. [Google Scholar] [CrossRef]

- Aslam, A.; Ahmed, N.; Qureshi, S.A.; Assadi, M.; Ahmed, N. Advances in Solar PV Systems; A Comprehensive Review of PV Performance, Influencing Factors, and Mitigation Techniques. Energies 2022, 15, 7595. [Google Scholar] [CrossRef]

- Lee, J.F.; Rahim, N.A.; Al-Turki, Y.A. Performance of Dual-Axis Solar Tracker versus Static Solar System by Segmented Clearness Index in Malaysia. Int. J. Photoenergy 2013, 2013, 820714. [Google Scholar] [CrossRef]

- Hosenuzzaman, M.; Rahim, N.A.; Selvaraj, J.; Hasanuzzaman, M.; Malek, A.B.M.A.; Nahar, A. Global prospects, progress, policies, and environmental impact of solar photovoltaic power generation. Renew. Sustain. Energy Rev. 2015, 41, 284–297. [Google Scholar] [CrossRef]

- Ghadikolaei, S.S.C. An enviroeconomic review of the solar PV cells cooling technology effect on the CO2 emission reduction. Sol. Energy 2021, 216, 468–492. [Google Scholar] [CrossRef]

- Mensah, L.D.; Yamoah, J.O.; Adaramola, M.S. Performance Evaluation of a Utility-Scale Grid-Tied Solar Photovoltaic (PV) Installation in Ghana. Energy Sustain. Dev. 2019, 48, 82–87. [Google Scholar] [CrossRef]

- Phap, V.M.; Nga, N.T. Feasibility study of rooftop photovoltaic power system for a research institute towards green building in Vietnam. EAI Endorsed Trans. Energy 2020, 7, 162825. [Google Scholar] [CrossRef][Green Version]

| Location | Major Oxides | Major Elements (Except O) | Origin | |

|---|---|---|---|---|

| [33] | Hangzhou, China | SiO2, Al2O3, CaO, Fe2O3, etc. | Si, Ca, Al, Fe, K, Mg, Na | Sand, potash feldspar, mechanical wear, straw burning |

| [33] | Doha, Qatar | Calcite (CaCO3), Dolomite (CaMg(CO3)2), Quartz (SiO2), etc. | Ca, Si, Fe, Mg, Al | Dolomite, Calcite, local soil, and buildings |

| [33] | Northern Poland | SiO2, Al2O3, MgO, etc. | Si, Al, Mg, Fe, K. Ca, P, S | Sand, the wear of frictional elements of mechanical components |

| [34] | Cairo, Egypt | Quartz (SiO2), Calcite (CaCO3), etc. | Si, Ca, Al, Fe, Mg, K, Na | Deserts, cement industry emissions, fossil fuel combustion |

| [34] | Perth, Australia | Quartz (SiO2), Calcium oxide (CaO), Orthoclase (KAlSi3O8), etc. | Si, Ca, Al, Fe, K | Dominated by acid and sandy soils that might be caused by deserts |

| Density (Mass/Area) g/m2 | Solar Radiation (W/m2) | Temperature (°C) | Wind Velocity (m/s) | Humidity (%) | Efficiency (%) |

|---|---|---|---|---|---|

| 0 | 697 | 31.8 | 2.5 | 79.9 | 11.1 |

| 11.11 | 698 | 32.0 | 5.0 | 80.6 | 10.1 |

| 22.22 | 702 | 31.9 | 2.5 | 79.8 | 9.9 |

| 33.33 | 704 | 31.9 | 5.0 | 79.9 | 9.8 |

| 44.44 | 709 | 31.9 | 5.0 | 79.4 | 9.6 |

| 55.55 | 710 | 31.9 | 2.5 | 79.8 | 9.6 |

| 66.66 | 710 | 32.0 | 2.5 | 80.3 | 9.6 |

| 77.77 | 710 | 32.0 | 5.0 | 80.8 | 9.5 |

| 88.88 | 710 | 32.0 | 2.5 | 81.5 | 9.4 |

| 100 | 713 | 31.8 | 5.0 | 81.7 | 9.3 |

| 111.11 | 713 | 31.7 | 5.0 | 82.4 | 9.1 |

| Daily Average Insolation (kWh/m2) | ||||||

|---|---|---|---|---|---|---|

| 0° | 23° | 33° | 0° | 23° | 33° | |

| Before Rain | After Rain | |||||

| Clean | 4.97 | 7.09 | 7.59 | 3.74 | 4.75 | 4.95 |

| Unclean | 4.78 | 6.94 | 7.45 | 3.69 | 4.71 | 4.90 |

| Insolation | ||||||

| Loss | 3.82% | 2.12% | 1.84% | 1.34% | 0.84% | 1.01% |

| Modules | Parameter | Initial Value | Clean Module after One Exposition Year | Dusty Module after One Exposition Year |

|---|---|---|---|---|

| Monocrystalline PV module | Pmax (W) | 145 | 144.59 | 32.17 |

| Vmax (V) | 17.9 | 17.83 | 20.79 | |

| Imax (A) | 8.1 | 8.06 | 1.57 | |

| Voc (V) | 22.7 | 22.7 | 22.7 | |

| Isc (A) | 8.5 | 8.47 | 2.09 | |

| FF (%) | 75.14 | 73.64 | 60.4 | |

| Polycrystalline PV module | Pmax (W) | 230 | 217.37 | 178.19 |

| Vmax (V) | 29.2 | 28.04 | 30.09 | |

| Imax (A) | 7.88 | 7.75 | 5.93 | |

| Voc (V) | 36.6 | 36.16 | 36.16 | |

| Isc (A) | 8.44 | 8.33 | 6.61 | |

| FF (%) | 74.48 | 72.09 | 70.64 |

| PV Type | Rated Capacity | Energy Generation (kWh/year) | Final Yield (kW h/kWp-day) | PR (%) | CF (%) | ηsyst | Tilt Angle (°) | R |

|---|---|---|---|---|---|---|---|---|

| MC | 20 MW | 26,304,000 | 4.19 | 76.8 | 15.22 | 11.54 | 15 | [99] |

| PC | 23.92 MW | 43,261,400 | 4.95 | 82.0 | 20.64 | - | 15 | [99] |

| MC | 28 kW | 45,119 | 4.4 | 71.89 | 18.58 | 10.99 | 27 | [99] |

| PC | 10 MW | 15,798,192 | 4.07 | 85 | 17.68 | 10.12 | 33.7 | [91] |

| PC | 2.5 MW | 3,547,800 | 4.49 | 70.6 | 16.2 | 11.56 | 12.5 | [103] |

| MC | 56.7 kW | 68,625 | 3.32 | 82.4 | - | 14.45 | 18 | [104] |

| PC | 9.6 kW | 8839 | 3.07 | 77.22 | - | 9.8 | 30 | [93] |

| MC | 2.04 kW | 3370.89 | 4.96 | 76.7 | 18.86 | 11.7 | 30 | [94] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rusănescu, C.O.; Rusănescu, M.; Istrate, I.A.; Constantin, G.A.; Begea, M. The Effect of Dust Deposition on the Performance of Photovoltaic Panels. Energies 2023, 16, 6794. https://doi.org/10.3390/en16196794

Rusănescu CO, Rusănescu M, Istrate IA, Constantin GA, Begea M. The Effect of Dust Deposition on the Performance of Photovoltaic Panels. Energies. 2023; 16(19):6794. https://doi.org/10.3390/en16196794

Chicago/Turabian StyleRusănescu, Carmen Otilia, Marin Rusănescu, Irina Aura Istrate, Gabriel Alexandru Constantin, and Mihaela Begea. 2023. "The Effect of Dust Deposition on the Performance of Photovoltaic Panels" Energies 16, no. 19: 6794. https://doi.org/10.3390/en16196794

APA StyleRusănescu, C. O., Rusănescu, M., Istrate, I. A., Constantin, G. A., & Begea, M. (2023). The Effect of Dust Deposition on the Performance of Photovoltaic Panels. Energies, 16(19), 6794. https://doi.org/10.3390/en16196794