Assessing the Environmental Sustainability of Deep Geothermal Heat Plants

Abstract

:1. Introduction

2. Research Gaps in Current LCA Practices for Geothermal Systems

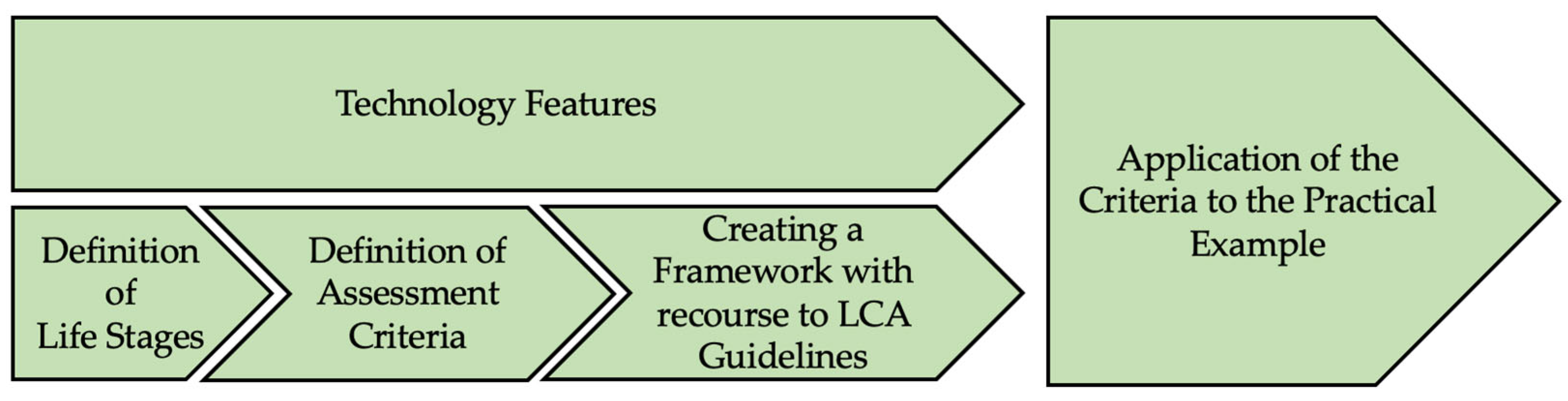

3. Systematic Approach to Assessing the Environmental Sustainability of Geothermal Heat Plants

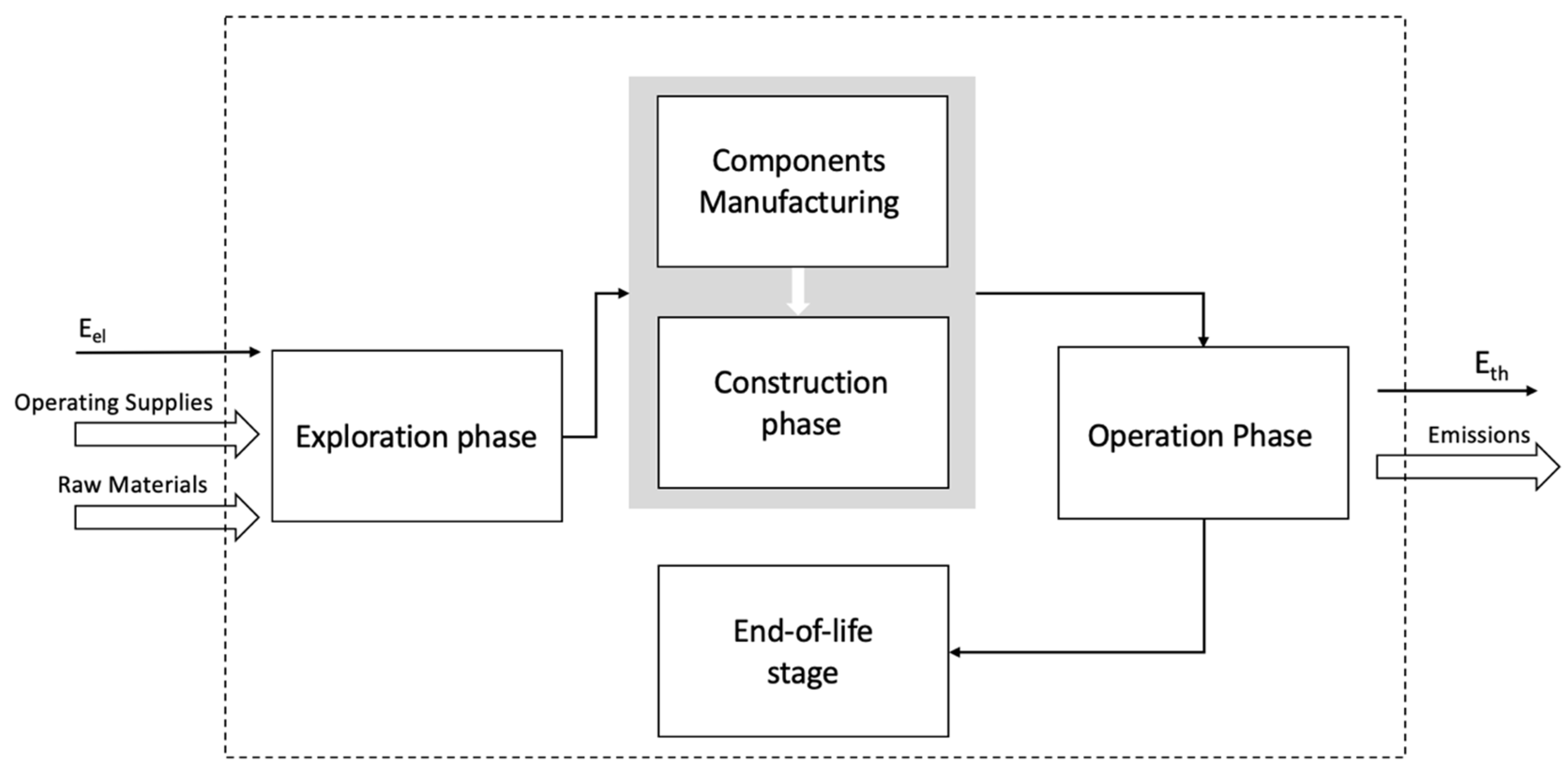

3.1. Definition of Life Stages

- “Exploration phase”: When planning the construction of a deep geothermal heat plant, the exploration of an area with geothermal potential takes place before the construction of the site.

- “Construction phase”: More important is, however, the construction phase, as this is where most of the climate-impacting process steps occur.

- “Operation phase”: Even though the operation of a geothermal power or heat plant is emission-free, the operation phase can be taken into consideration as well—for instance, by looking at the auxiliary energy used during operation.

- “End-of-life stage”: Finally, aspects of the dismantling of a geothermal plant can be included in a sustainability assessment in the end-of-life stage [11].

3.2. Definition of Assessment Criteria

- The “space requirement” of the plant, including the area needed during both the construction phase and the operation phase.

- The “energy consumption” over the life cycle of the plant, which can ultimately be related to the “energy returned on energy invested” (EROI) over its lifetime.

- The “material consumption”, e.g., steel, cement, bentonite, and silica sand, used over the life cycle of a plant; this includes aspects of the deep well drilling and manufacturing of the components.

- Resulting “CO2 emissions”, mainly considering the upstream chain, i.e., the production of materials and electricity.

- The “water consumption” over the life cycle of the plant, mainly referring to the upstream chain of the manufacturing of the components.

3.3. Creation of a Framework Based on LCA Guidelines

3.3.1. Definition of the Goal, System Boundaries, and Limitations of this Study

3.3.2. Identification and Quantification of Implications of Relevant Energy and Material Flows

Exploration Phase

Construction Phase

Operation Phase

End-of-Life Stage

4. Application of the Approach to a Practical Example and Interpretation of the Results Obtained

4.1. Specific Space Requirement of the Plant

4.2. EROI and Energy Payback Time

4.3. CO2 Emission Factor

4.4. Water Consumption

4.5. Discussion

5. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Category | Input Data | Reference |

|---|---|---|

| Diesel consumption of a vibration truck while driving | 1 L/km | Expert interview with the truck producer |

| Diesel consumption of a vibration truck while vibrating | 50 L/h | Expert interview with the truck producer |

| Route of vibration trucks | 250 km | Seismic survey study provided by a service provider |

| Category | Input Data | Reference |

|---|---|---|

| Surface of the drilling site | 5000 m2 | Expert interview with a civil engineer |

| thereof surface of concrete | 2200 m2 | |

| thereof surface of asphalt | 2800 m2 | |

| Thickness of concrete | 0.5 m | |

| Thickness of asphalt | 0.04 m | |

| Diesel consumption of a 40-ton truck | 25 L/100 km | Expert interview with a civil engineer |

| Diesel consumption of a concrete mixer (drilling site) | 15 L/h | Expert interview with a civil engineer |

| Diesel consumption of a compactor roll (drilling site) | 14 L/h | |

| Diesel consumption of a wheel loader (trench for district heating grid) | 9.5 L/h | Expert interview with a civil engineer |

| Diesel consumption of a compactor (trench for district heating grid) | 5.5 L/h | |

| Depth of each deep well | 3500 m | Authors’ own estimate based on local geophysical data and comparable projects in the Upper Rhine Valley |

| Electricity consumption (drilling of the two deep wells) | 1.2 GWh | Expert interview with a drilling service provider |

| Volume of drilling fluid | 7300 m3 | [26] |

| Material consumption of casing | [11] | |

| thereof steel | 565 t | |

| thereof cement | 539 t | |

| thereof silica sand | 217 t | |

| thereof bentonite | 33.6 t | |

| Floor area of aboveground heat plant | 240 m2 | Expert interview with a plant operator |

| Power of an LSP | 550 kW | [30] |

| Material consumption of an LSP | Expert interview with a pump manufacturer | |

| thereof steel | 40 t | |

| thereof aluminum | 450 kg | |

| thereof tin | 180 kg | |

| Material consumption of the electric motor of an LSP | Ref. [11]; Expert interview with a pump manufacturer | |

| thereof steel | 1.25 t | |

| thereof copper | 1.25 t | |

| Material consumption of an injection pump thereof steel | 1.2 t | Expert interview with a pump manufacturer |

| Material consumption of a heat exchangerthereof steel | 9 t | Expert interview with a heat exchanger manufacturer |

| Material consumption of a district heating pipeline | Expert interview with a pump manufacturer | |

| thereof steel | 44 t/km | |

| thereof polyethylene | 6.7 t/km | |

| thereof polyurethane | 4 t/km | |

| Material consumption of four district heating network pumps + motors (power of motor: 110 kW) | Service datasheet of a pump manufacturer | |

| thereof steel | 5.67 t | |

| thereof copper | 2.19 t | |

| Distance between the heat plant and district heating network | 1.5 km | Authors’ own estimate based on local geographic conditions |

| Category | Input Data | Reference |

|---|---|---|

| Lifetime of the LSP | 7 years | Authors’ own estimate based on comparable projects; [30] |

| Material consumption for the replacement of the LSP | Authors’ own calculations | |

| thereof steel | 22 t | |

| thereof aluminum | 1800 kg | |

| thereof copper | 1080 kg | |

| thereof tin | 720 kg |

| Category | Input Data | Reference |

|---|---|---|

| Material consumption for the backfilling of the deep wells | [41] | |

| thereof cement | 33.5 t | |

| thereof bentonite | 1.5 t | |

| thereof silica sand | 15.8 t |

References

- Risquez, M.A.; Grassi, G.; Solazzo, E.; Jacome, F.O.D.; Guizzardi, D.; Rossi, S.; San-Miguel-Ayanz, J.; Pagani, F.; Crippa, M.; Olivier, J.; et al. Emissions Database for Global Atmospheric Research; Version v7.0_FT_2021; European Commission, Joint Research Centre (JRC): Brussels, Belgium, 2022; Available online: http://data.europa.eu/89h/e0344cc3-e553-4dd4-ac4c-f569c8859e19 (accessed on 5 February 2023).

- IRENA. Renewable Capacity Statistics 2022; IRENA: Abu Dhabi, United Arab Emirates, 2022; Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2022/Apr/IRENA_RE_Capacity_Statistics_2022.pdf (accessed on 29 August 2022).

- Lauf, T.; Memmler, M.; Schneider, S. Emissionsbilanz Erneuerbarer Energieträger 2020—Bestimmung der Vermiedenen Emissionen Im Jahr 2020; Umweltbundesamt: Dessau-Roßlau, Germany, 2021; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2021-12-13_climate-change_71-2021_emissionsbilanz_erneuerbarer_energien_2020_bf_korr-01-2022.pdf (accessed on 6 February 2023).

- Agemar, T.; Suchi, E.; Moeck, I. Die Rolle der Tiefen Geothermie Bei der Wärmewende—Wie Deutschland 60% Erneuerbare Wärme bis 2050 Schaffen Könnte; Positionspapier; Leibniz-Institut für Angewandte Geophysik: Hannover, Germany, 2018; Available online: https://www.leibniz-liag.de/fileadmin/user_upload/s4/downloads/positionspapier_waermewende.pdf (accessed on 15 October 2022).

- Ortner, S.; Mellwig, P.; Blömer, S.; Rettenmaier, N.; Pehnt, M.; Möhring, P.; Sandrock, M.; Akram, P. Berichtspflicht Gemäß der Richtlinie (EU) 2018/2001 Zum Potenzial der Nutzung von Energie Aus Erneuerbaren Quellen. Bewertung des Potenzials im Bereich der Energie Aus Erneuerbaren Quellen und Der Nutzung von Abwärme und -kälte im Wärme- und Kältesektor in der Bundesrepublik Deutschland; Ifeu—Institut für Energie- und Umweltforschung Heidelberg gGmbH: Heidelberg, Germany; Hamburg Institut Research gGmbH: Hamburg, Germany, 2020; Available online: https://ec.europa.eu/energy/sites/default/files/de_ca_2020_de_a01_art_157_red_ii_report_germany.pdf (accessed on 14 June 2022).

- Parisi, M.L.; Basosi, R. Geothermal Energy Production in Italy: An LCA Approach for Environmental Performance Optimization. In Life Cycle Assessment of Energy Systems and Sustainable Energy Technologies: The Italian Experience; Basosi, R., Cellura, M., Longo, S., Parisi, M.L., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 31–44. [Google Scholar]

- Marchand, M.; Blanc, I.; Marquand, A.; Beylot, A.; Bezelgues-Courtade, S.; Traineau, H. Life Cycle Assessment of High Temperature Geothermal Energy Systems; O.I.E.—Centre for Observation, Impacts, Energy: Melbourne, Australia, 2015; Available online: https://hal-mines-paristech.archives-ouvertes.fr/hal-01146355/document (accessed on 29 January 2023).

- Douziech, M.; Ravier, G.; Ferrara, N.; Damen, L.; Sigurjonsson, H.A.; Pérez-López, P.; Tosti, L.; Gudjonsdottir, S.; Harcouet-Menou, V.; Parisi, M.; et al. Simplified Parameterized Models for a Multi-Criteria Environmental Impact Assessment of Four Types of Geothermal Installations. In Proceedings of the World Geothermal Congress 2020 + 1, Reykjavik, Iceland, 24–27 October 2021; Available online: https://hal-mines-paristech.archives-ouvertes.fr/hal-03616551/document (accessed on 15 June 2023).

- Colucci, V.; Manfrida, G.; Mendecka, B.; Talluri, L.; Zuffi, C. LCA and Exergo-Environmental Evaluation of a Combined Heat and Power Double-Flash Geothermal Power Plant. Sustainability 2021, 13, 1935. [Google Scholar] [CrossRef]

- GEOENVI. About the Project; GEOENVI: Florianópolis, Brasil, 2019; Available online: https://www.geoenvi.eu/about-us/ (accessed on 29 July 2022).

- Tosti, L.; Ferrara, N.; Blanc, I.; Douziech, M.; Fiaschi, D.; Manfrida, G.; Mendecka, B.; Parisi, M.L.; Pérez-López, P.; Ravier, G. Environmental Assessment of GEOENVI Case Studies: A Selection of GEOENVI Case Studies Following the Harmonized LCA Guidelines: GEOENVI, n.p. 2020. Available online: https://www.geoenvi.eu/wp-content/uploads/2020/11/D3.3-Environmental-assessment-of-GEOENVI-case-studies.pdf (accessed on 5 July 2022).

- DIN EN ISO 14040:2006 + A1:2020; Umweltmanagement—Ökobilanz—Grundsätze und Rahmenbedingungen. International Organization for Standardization: Geneva, Switzerland, 2021.

- ProBas. ProBas—Willkommen bei ProBas! 2022. Available online: https://www.probas.umweltbundesamt.de/php/index.php (accessed on 6 February 2023).

- DIN EN ISO 14044:2006 + A1:2018 + A2:2020; Umweltmanagement—Ökobilanz—Anforderungen und Anleitungen. International Organization for Standardization: Geneva, Switzerland, 2021.

- Frick, S.; Kaltschmitt, M.; Schröder, G. Life cycle assessment of geothermal binary power plants using enhanced low-temperature reservoirs. Energy 2010, 35, 2281–2294. [Google Scholar] [CrossRef]

- Stober, I.; Bucher, K. Geothermal Energy; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Kuchling, H. Taschenbuch der Physik: Mit Tabellen; Hanser: München, Germany, 2011. [Google Scholar]

- Amtsblatt der Europäischen Kommission. DURCHFÜHRUNGSVERORDNUNG (EU) 2022/996 DER KOMMISSION vom 14. Juni 2022 über Vorschriften für die Überprüfung in Bezug auf die Nachhaltigkeitskriterien und die Kriterien für Treibhausgaseinsparungen Sowie die Kriterien für ein Geringes Risiko Indirekter Landnutzungsänderungen. 2022. Available online: https://eur-lex.europa.eu/legal-content/DE/TXT/PDF/?uri=CELEX:32022R0996&from=EN (accessed on 15 July 2022).

- ProBas. ProBas—Prozessdetails: RaffinerieÖl-Produkte-EU-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7bCD742530-52AB-4F73-8291-978FA3233904%7d (accessed on 5 January 2023).

- Umweltbundesamt. CO2-Emissionsfaktoren Für Fossile Brennstoffe; Umweltbundesamt: Dessau-Roßlau, Germany, 2022; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/479/publikationen/cc_28-2022_emissionsfaktoren-brennstoffe_bf.pdf (accessed on 8 July 2022).

- Watson, A. Geothermal Engineering; Springer: New York, NY, USA, 2013. [Google Scholar]

- ProBas. ProBas—Prozessdetails: Steine-ErdenBeton-DE-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={4E639AF4-5C74-4E19-92DB-2C2362779C93} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: Asphalt. 2000. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={3928FE68-D230-4711-9F6D-EFD800E73A4C} (accessed on 5 January 2023).

- NatürLich Insheim GmbH. Unser Projektvorhaben Natür3Lich Insheim. 2022. Available online: https://natuerlich-insheim.eu/ (accessed on 27 November 2022).

- Icha, P.; Lauf, T. Entwicklung der Spezifischen Treibhausgas-Emissionen des Deutschen Strommix in den Jahren 1990–2021; Umweltbundesamt, Dessau-Roßlau Herausgeber: Dessau-Roßlau, Germany, 2022; Available online: https://www.umweltbundesamt.de/sites/default/files/medien/1410/publikationen/2022-04-13_cc_15-2022_strommix_2022_fin_bf.pdf (accessed on 2 April 2023).

- Pratiwi, A.; Ravier, G.; Genter, A. Life-Cycle Climate-Change Impact Assessment of Enhanced Geothermal System Plants in the Upper Rhine Valley. Geothermics 2018, 75, 26–39. [Google Scholar] [CrossRef]

- ProBas. ProBas—Prozessdetails: Steine-ErdenZement-DE-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={25EB12F5-7A9B-425D-AC38-AAFE68C10831} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: Bentonit. 1999. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={8134CC95-DA9F-4670-BB70-BB2A0A04C6E4} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: Quarzsand. 2000. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={DE74DB83-30E7-4846-B6AE-8321A4273634} (accessed on 5 January 2023).

- Hettkamp, T.; Baumgärtner, J.; Paredes, R.; Ravier, G.; Seibel, O. Industrial Experiences with Downhole Geothermal Line-Shaft Production Pumps in Hostile Environment in the Upper Rhine Valley. In Proceedings of the World Geothermal Congress 2020, Reykjavik, Iceland, 26 April–2 May 2020; Available online: https://docplayer.net/181155892-Industrial-experiences-with-downhole-geothermal-line-shaft-production-pumps-in-hostile-environment-in-the-upper-rhine-valley.html (accessed on 4 September 2022).

- Gec-co Global Engineering & Consulting-Company GmbH. Vorbereitung und Begleitung Bei der Erstellung Eines Erfahrungsberichts Gemäß § 97 Erneuerbare-Energien-Gesetz—Teilvorhaben II b; Final Scientific Report; Geothermie: Augsburg, Germany, 2019; Available online: https://www.erneuerbare-energien.de/EE/Redaktion/DE/Downloads/bmwi_de/gec-co-vorbereitung-begleitung-eeg.pdf?__blob=publicationFile&v=7 (accessed on 27 January 2023).

- Konstantin, P.; Konstantin, M. Praxisbuch der Fernwärme- und Fernkälteversorgung; Systeme, Netzaufbauvarianten, Kraft-Wärme- und Kraft-Wärme-Kälte-Kopplung, Kostenstrukturen und Preisbildung; Springer: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- ProBas. ProBas—Prozessdetails: MetallStahl-mix-DE-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={00D85136-E496-4DE0-929B-10CB6A19DA02} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: MetallKupfer-DE-sekundär-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={10BA69B7-53A2-4384-B5E3-BA9053623CE4} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: MetallAluminium-DE-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={DD29CB08-8E9B-4E7A-A5F8-B74E631F2290} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: Zinn. 2000. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={6657A539-8BED-48E2-BE3A-FC2B46127395} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: Chem-OrgLDPE-DE-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={48CFC911-59BE-4B9A-B1B0-41FE2AA152A8} (accessed on 5 January 2023).

- ProBas. ProBas—Prozessdetails: KunststoffPUR-Hartschaum-DE-2020. 2020. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={7D803D25-E3D0-406C-8A4E-C883F6FEB851} (accessed on 5 January 2023).

- Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit (BMU). Klimaschutz in Zahlen—Fakten, Trends und Impulse Deutscher Klimapolitik, Ausgabe. 2021. Available online: https://www.bmuv.de/fileadmin/Daten_BMU/Pools/Broschueren/klimaschutz_zahlen_2021_bf.pdf (accessed on 15 July 2022).

- Clausthal-Zellerfeld, O. Richtlinie des Oberbergamtes in Clausthal-Zellerfeld über das Verfüllen auflässiger Bohrungen. 1998. Available online: https://bergpass.lbeg.de/media/204 (accessed on 16 July 2022).

- Parisi, M.L.; Douziech, M.; Tosti, L.; Pérez-López, P.; Mendecka, B.; Ulgiati, S.; Fiaschi, D.; Manfrida, G.; Blanc, I. Definition of LCA Guidelines in the Geothermal Sector to Enhance Result Comparability. Energies 2020, 13, 3534. [Google Scholar] [CrossRef]

- Joos, F. Nachhaltige Energieversorgung: Hemmnisse, Möglichkeiten und Einschränkungen; Eine Interdisziplinäre Statusbetrachtung: Wiesbaden, Germany, 2019. [Google Scholar]

- Atlason, R.S.; Unnthorsson, R. Hot Water Production Improves the Energy Return on Investment of Geothermal Power Plants. Energy 2013, 51, 273–280. [Google Scholar] [CrossRef]

- Technische Universität Dresden. Zertifikat. 2020. Available online: https://www.mvv-netze.de/fileadmin/user_upload_mvv-netze/Dokumente/partner/installateure/Zertifikate_PEF_CO2_2020.pdf (accessed on 6 February 2023).

| Criterion/Life Stage | Exploration Phase | Construction Phase | Operation Phase | End-of-Life Stage |

|---|---|---|---|---|

| Space requirement | X | X | ||

| Energy consumption | X | X | X | X |

| Material consumption | X | X | X | |

| CO2 emissions | X | X | X | X |

| Water consumption | X | X | X | X |

| Material | CO2 Emission Factor | Specific Water Consumption |

|---|---|---|

| Diesel fuel (driving) | 3.166 t CO2/t | - |

| Diesel fuel (production) | 7.624 t CO2/TJ | 4607 kg water/TJ |

| Concrete | 0.161 kg CO2/kg | 0.267 kg water/kg |

| Asphalt | 186.1 kg CO2/kg | 1.413 kg water/kg |

| Cement | 0.91 kg CO2/kg | 1.13 kg water/kg |

| Bentonite | 0.0247 kg CO2/kg | 0.0698 kg water/kg |

| Silica sand | 0.0193 kg CO2/kg | 1.466 kg water/kg |

| Steel | 1.36 kg CO2/kg | 11.7 kg water/kg |

| Copper | 1.64 kg CO2/kg | 4.01 kg water/kg |

| Aluminum | 9.42 kg CO2/kg | 39.9 kg water/kg |

| Tin | 15.803 kg CO2/kg | 1046.482 kg water/kg |

| Polyethylene | 2.42 kg CO2/kg | 6.2 kg water/kg |

| Polyurethane | 4.2 kg CO2/kg | 4.2 kg water/kg |

| Criterion/Life Stage | Exploration Phase | Construction Phase | Operation Phase | End-of-Life Stage |

|---|---|---|---|---|

| Space requirement | 15,000 m2 | 5000 m2 | ||

| Energy consumption | 497 MWh | 1858 MWh | 157,223 MWh | 388 MWh |

| Material consumption | concrete: 3365 t asphalt: 1240 t bentonite: 2134 t steel: 685 t silica sand: 217 t aluminum: 0.45 t copper: 16 t tin: 0.18 t stainless steel: 6.8 t polyethylene: 10 t polyurethane: 6 t | steel: 27 t aluminum: 1.8 t copper: 11.9 t tin: 0.7 t | concrete: 34 t bentonite: 1.5 t sand: 16 t | |

| CO2 emissions | 151.8 t | 2807 t 1 or 2343 t 2 | 27,759 t 3 or 90 t 4 | 149 t |

| Water consumption | 8.24 m3 | 14,424 m3 | 1133 m3 | 63 m3 |

| Criterion | Value |

|---|---|

| Energy consumption | 159,965 MWh |

| Max. CO2 emissions | 30,867 t |

| Water consumption | 15,628 m3 |

| Sustainability Indicator | Value |

|---|---|

| Energy returned on energy invested (EROI) Energy payback time | ~34 ~315 days |

| CO2 emission factor | ~5.56 g/kWhth resp. ~0.05 g/kWhth |

| Water consumption | ~0.0028 L/kWhth (≙2.8 L/MWhth) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maar, L.; Seifermann, S. Assessing the Environmental Sustainability of Deep Geothermal Heat Plants. Energies 2023, 16, 6774. https://doi.org/10.3390/en16196774

Maar L, Seifermann S. Assessing the Environmental Sustainability of Deep Geothermal Heat Plants. Energies. 2023; 16(19):6774. https://doi.org/10.3390/en16196774

Chicago/Turabian StyleMaar, Lilli, and Stefan Seifermann. 2023. "Assessing the Environmental Sustainability of Deep Geothermal Heat Plants" Energies 16, no. 19: 6774. https://doi.org/10.3390/en16196774

APA StyleMaar, L., & Seifermann, S. (2023). Assessing the Environmental Sustainability of Deep Geothermal Heat Plants. Energies, 16(19), 6774. https://doi.org/10.3390/en16196774