1. Introduction

Small nuclear reactors have received widespread attention from the international nuclear industry due to their short construction period, strong adaptability, low siting cost, high safety, and ability to realize mobile deployment by vehicle or shipboard [

1]. For megawatt-class small nuclear reactor power sources, the technological approach of using gas-cooled fast reactors with Brayton cycles has been widely accepted worldwide [

2,

3,

4,

5]. In terms of working fluid, the helium-xenon gas mixture can improve the performance of the Brayton cycle as well as operate as a direct reactor coolant [

6]. Currently, conceptual design work for Small Innovative helium-xenon cooled MObile Nuclear power Systems (SIMONS) has been carried out in China [

7].

Probabilistic Safety Assessment (PSA) is an important reactor safety analysis method that provides guidance for the design and safe operation of reactors. It applies probability risk theory to evaluate the safety of the reactor system, believing that a reactor accident is a random event with many potential factors causing it. The safety of the reactor should be represented by the mathematical expected value (i.e., risk) of all potential accidents [

8]. Compared with deterministic safety assessment approaches based on design basis accidents, the PSA method not only studies the physical phenomena, processes, and consequences that occur after an event happens, but also evaluates the risk quantitatively on this basis. Furthermore, the PSA method employs more realistic assumptions to represent the actual state of the reactor, and its evaluation results are closer to reality. In the application of probabilistic safety assessment, it can be divided into three levels, as shown in

Table 1.

The basic process of the PSA-I method is shown in

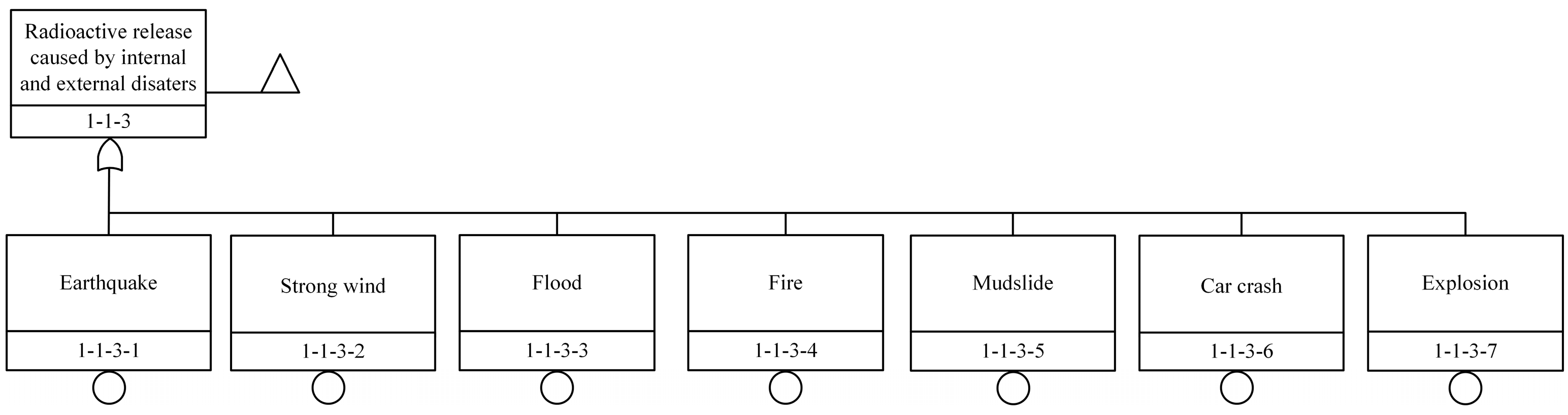

Figure 1. The first step in implementing PSA is to generate a list of initiating events to be analyzed. An initiating event is defined as an event that causes a disturbance in a nuclear power plant and has the potential to result in radioactive release consequences (core damage) [

9], and it is divided into two categories: internal events induced by equipment failure, personnel error, etc., and disasters caused by earthquakes, floods, fires, and projectile impacts. The purpose of initiating event analysis is to identify all possible initiating events as completely as possible for the following phase of accident sequence analysis [

10]. Correctly identifying the initiating event is of great significance for improving the credibility of reactor PSA analysis.

Currently, research on the initiating events of Pressurized Water Reactors (PWR, cooled by light water) [

11], Boiling Water Reactors (BWR, cooled by light water) [

12], Molten Salt Reactors (MSR, cooled by molten salt) [

9,

10], Hight Temperature Gas-cooled Reactors (HTGR, cooled by helium, carbon dioxide, etc.) [

8,

13], and other reactors has been conducted worldwide. However, there is little research on the initiation events of small modular HTGR cooled by Helium-xenon. This study primarily investigates and analyses the initiating events of SIMONS (cooled by Helium-Xenon).

The remaining sections of this study are organized as follows:

Section 2 discusses the methodology for identifying initiating events.

Section 3 presents the conceptual design of SIMONS.

Section 4 contains the results of this study. The concluding remarks of this study are given in

Section 5.

2. Methodology

There are four primary approaches for identifying initiating events, which are [

14]:

Engineering Evaluation: Systematically analyzing the reactor system and major equipment to identify failure modes that, either directly or in combination with other failures, could lead to a release of radioactivity. This method relies on the completeness of the design information, and it is difficult to obtain truly valid information for engineering analysis in the early stages of innovative design when design information is insufficient.

Reference List: Referring to the initiating events of other nuclear power plants, especially similar nuclear power plants, to identify initiating events that are applicable to the research object.

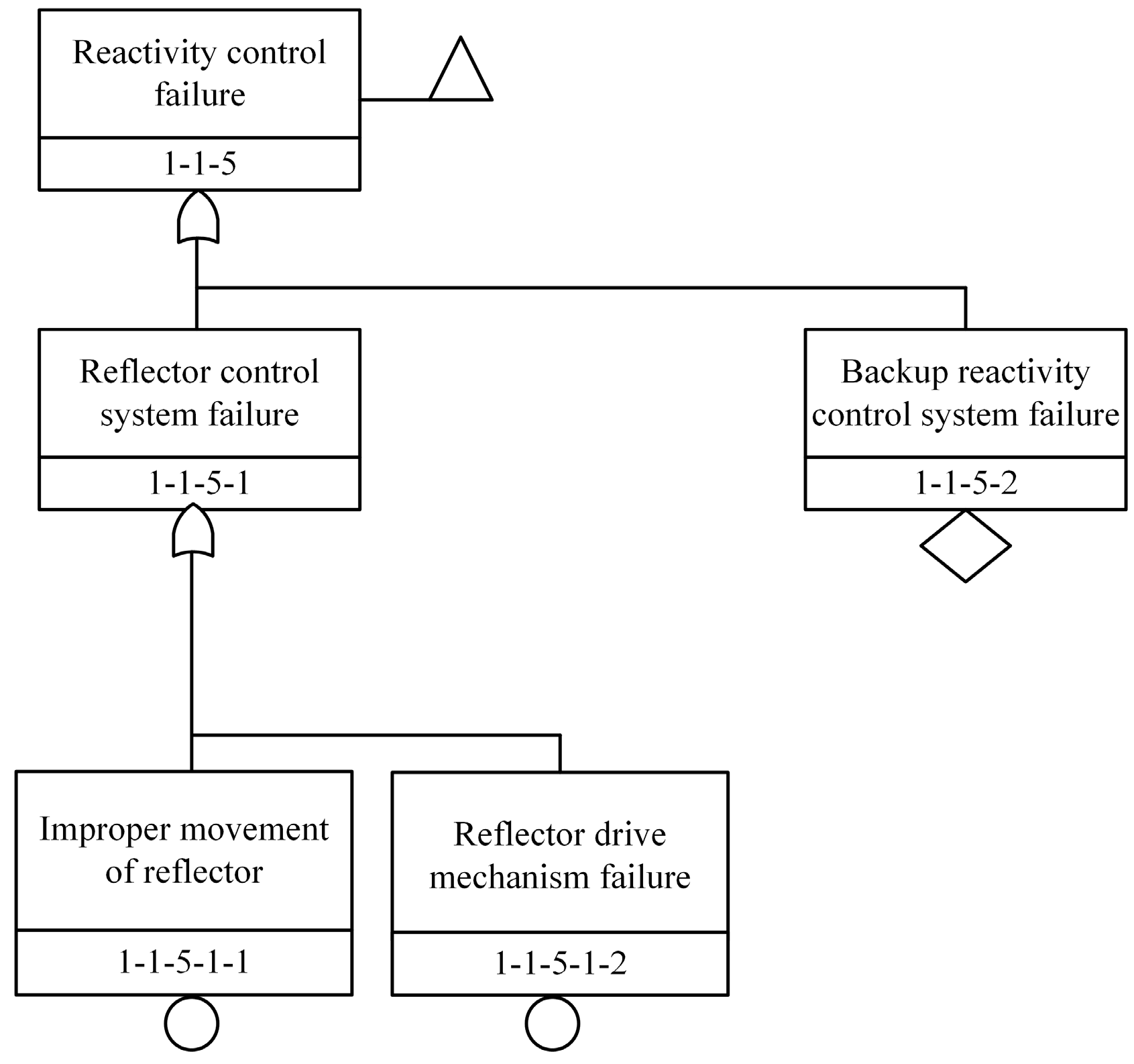

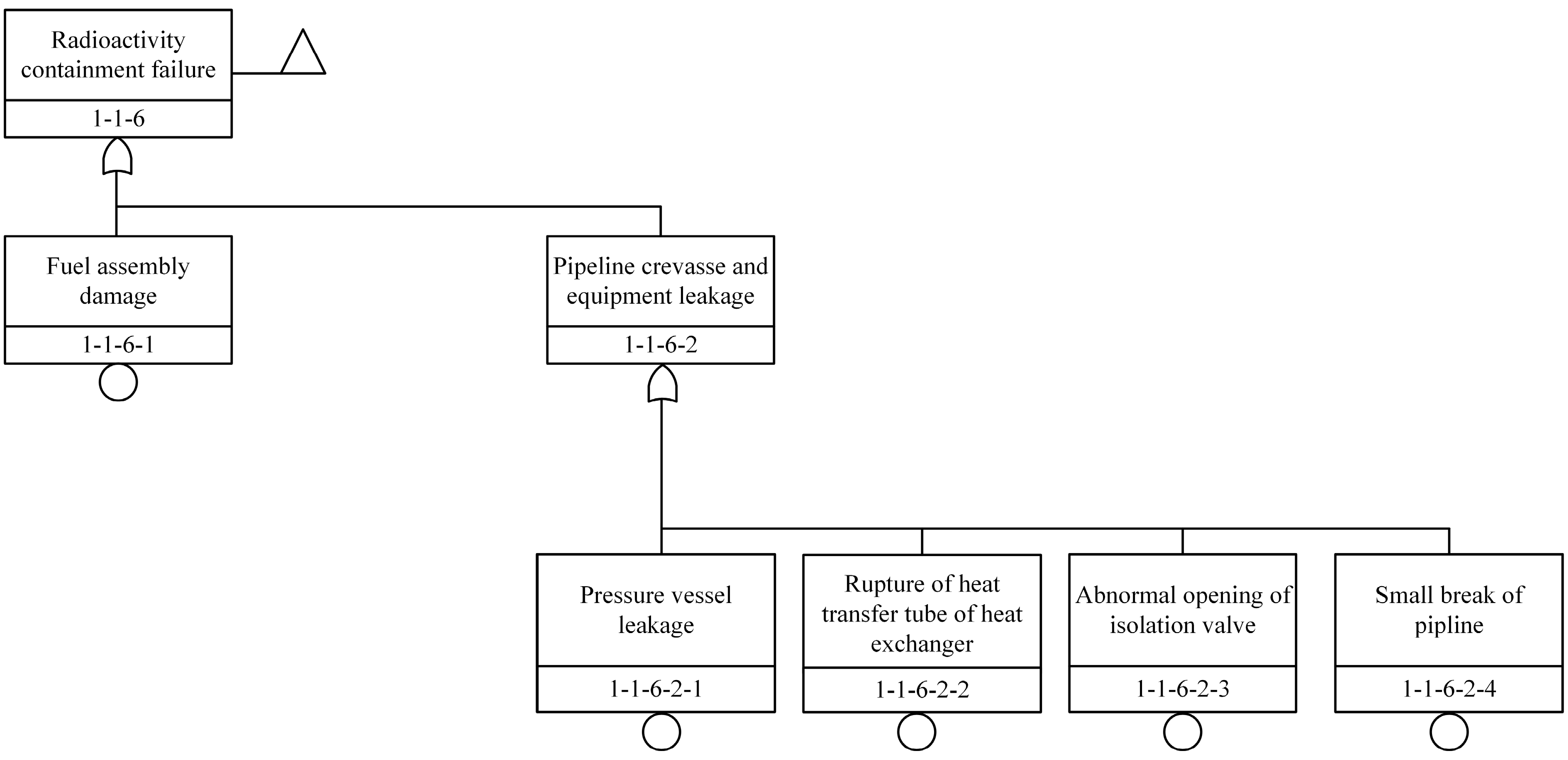

Deductive Analysis: Using a method similar to Fault Tree (such as Master Logic Diagram, MLD), the top event (such as a large release of radioactivity) is gradually decomposed into different categories of events that may lead to the occurrence of this consequence, and the initiating events can be selected from each event at the bottom level.

Operational Experience: Analyzing the feedback from the operational history of the plant under investigation and similar nuclear plants to identify initiating events that should be added. Consultation of nuclear plant operators, maintenance employees, engineers, and safety analysts can be also made to check whether some important initiating events were overlooked. Compared with Reference List, which aims to form a preliminary list of initiating events with a focus on evaluating the applicability of previous initiating events to new research subjects, the Operational Experience method aims to form a relative complete list of initiating events, with a focus on whether the initiating events to be considered are missing.

As the mature type of nuclear reactor, current commercial water-cooled nuclear reactors, including Pressurized Water Reactor (PWR) and Boiling Water Reactor (BWR), have been extensively studied in the aspects of initiating event identification using the methods of engineering evaluation and operational experience [

15]. A series of related publications can be found and among them, WASH-1400 is considered to be an epochal technical report, published by the U.S. Department of Energy (DOE) in 1975, which is also the first and complete technical report for PSA analysis [

12], evoking research activities on PSA analysis worldwide. This report concluded that the risks to the individual posed by nuclear power stations were acceptably small, compared with other tolerable risks. Specifically, this report concluded that the probability of a complete core meltdown is about 1 in 20,000 per reactor per year by using the methods, resources, and knowledge at the time. For the advanced nuclear reactors, such as the liquid metal-cooled reactor, Molten Salt Reactor (MSR), Gas Cooled Reactor (GCR), etc., methods for initiating event identification need to be determined based on the characteristics of the specific reactor because of the diversity of reactor types, advanced design, and lack of engineering construction and practical operation experience.

Table 2 shows the identification of initiating events for different types of reactors. In the European Union (EU), 34 initiating events in six categories were identified for the Advanced Lead-cooled Fast Reactor European Demonstrator (ALFRED) using the MLD method [

16]. In Japan, 77 internal initiating events in 15 categories were identified for the prototype sodium-cooled fast reactor MONJU via a combination of MLD and Engineering Evaluation methods [

17]. Shanghai Institute of Applied Physics (SINAP) of China screened 37 initiating events in six categories of Thorium-based Molten Salt Reactor with Solid Fuel (TMSR-SF1) by MLD and the Reference List method [

9]. The Nuclear Research Institute of Tsinghua University in China obtained 40 initiating events in six categories for the High-Temperature Gas-cooled reactor (HTR-10) using all four methods mentioned above [

8].

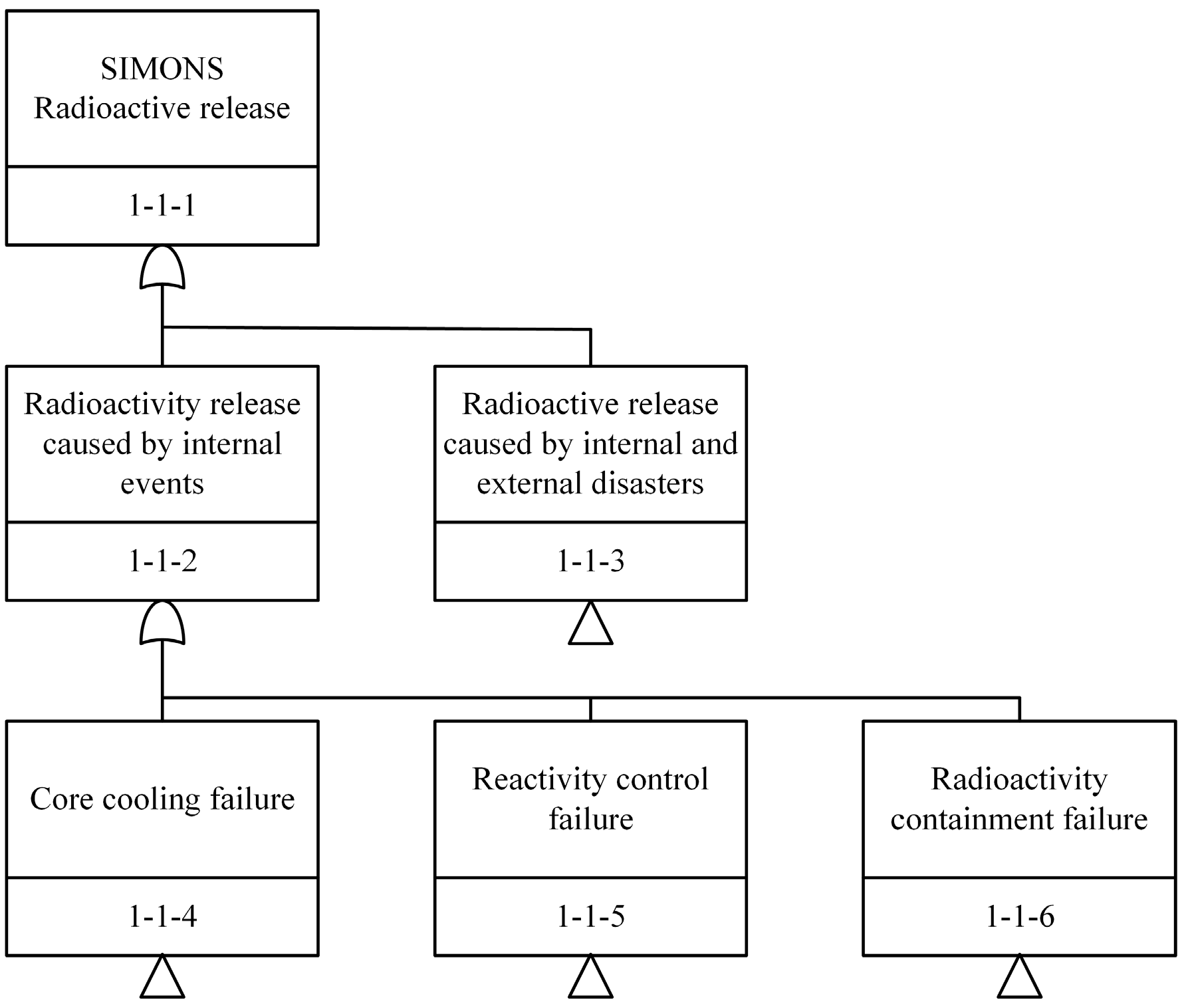

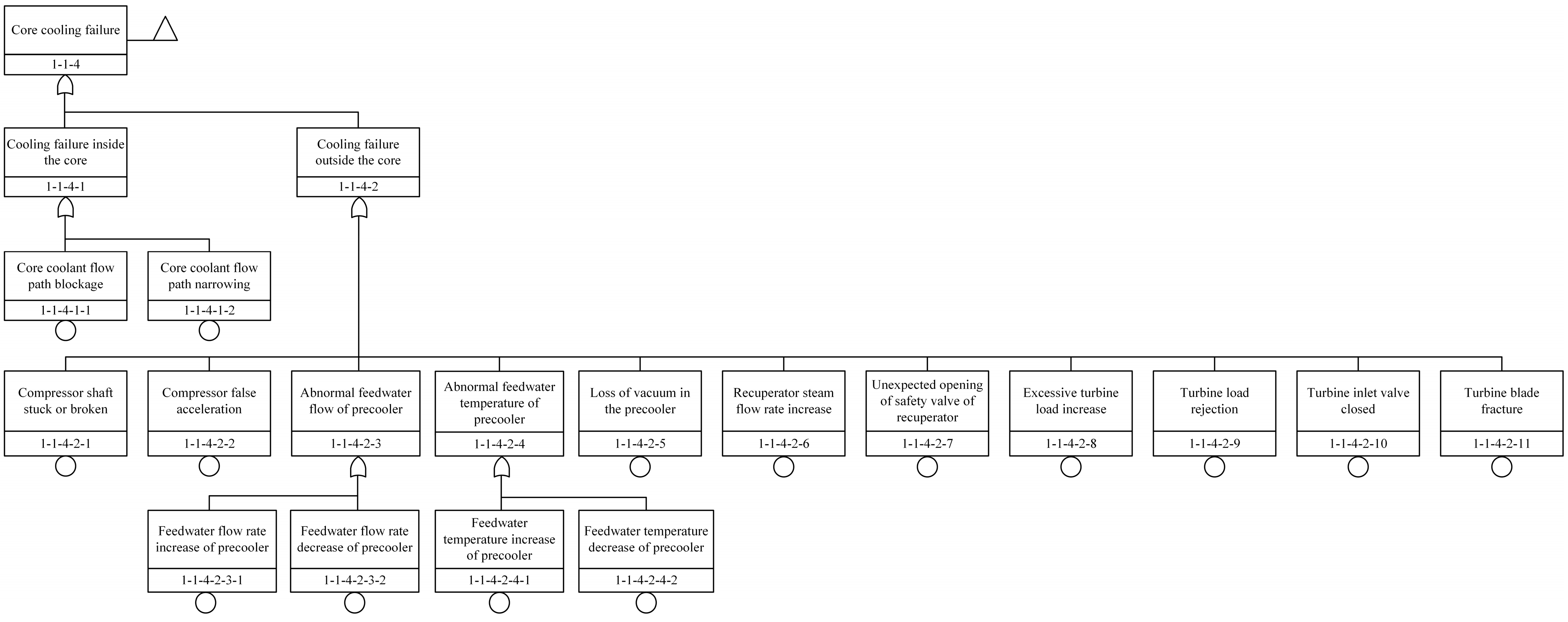

The identification of initiating events for new reactors does not have strict guidelines to follow, and it is generally a combination of multiple methods. The MLD method is a deductive analysis method widely used in identifying initiating events. It starts with the nature of the event cause and the conventional reactor event categories, then uses causal logic to reason and list the events layer by layer until obtaining the bottom-level events grouped by category as the list of reactors initiating events [

9].

Considering that SIMONS is still in the conceptual design stage, several relevant system designs and information are still unknown, and there is no historical operation experience reference. As a result, this research mainly uses the MLD method and also refers to the list of initiating events of other reactors (especially helium-cooled reactors [

18,

19] and carbon-dioxide cooled reactors [

13]) to derive the initiating events for SIMONS.

3. SIMONS

The electrical power of SIMONS is 8 MW with a thermal power of 20 MW. SIMONS uses Helium-Xenon as coolant. Compared with other gaseous coolants such as air and nitrogen, helium (as an inert gas) has excellent heat transfer performance and avoids the aforementioned problems. Moreover, adding a certain amount of xenon gas to helium can solve the problem of difficulty in compressing when using a single helium gas [

6].

In order to fulfill the design criteria of reactor mobility, the whole system is separated into three parts: core, energy conversion system, and shielding system.

3.1. Core

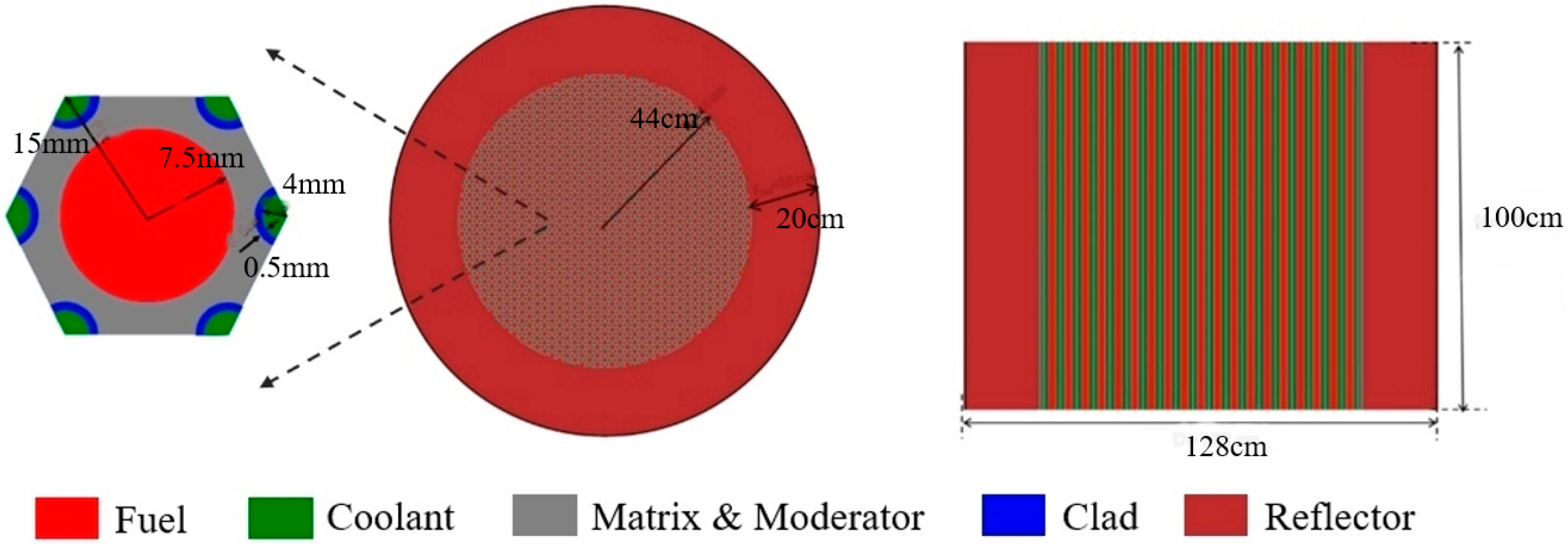

The core structure of SIMONS is shown in

Figure 2. SIMONS uses uranium carbide with U-235 enrichment achieving 19.75% as the fuel, helium-xenon gas as the coolant, and graphite as the moderator. The entire core is in a cylindrical shape with a radius of 44 cm and a height of 100 cm, and it is formed by graphite hexagons (1.5 cm pitch) with each one pierced by a channel (0.75 cm radius) for fuel circulation. Six coolant channels are symmetrically placed around the fuel rod, and each coolant channel (0.4 mm radius) is wrapped in a layer of Mo-TZM shell with a thickness of 0.05 cm. Around the core, a beryllium oxide reflector with a thickness of 20 cm is set to minimize the neutron leakage. The detailed core design parameters of SIMONS are shown in

Table 3.

Unlike conventional reactors, which rely on control rods to regulate reactivity, SIMONS mainly controls the reactivity of the core during the whole life cycle by pulling the reflector outside the core [

20]. The pull-out reflector includes multiple pull-out reflective blocks, which are axially arranged on the outer side of the core. During core operation, at least one pull-out reflective block can axially move to adjust the core reactivity.

Figure 3 shows two operational states for a core design equipped with two axial pull-out reflective blocks. In

Figure 3a, two axial pull-out reflective blocks completely close, which corresponds to the fully closed state of the reflector and minimizes the neutron leakage. In

Figure 3b, the upper pull-out reflective block (labeled 113) axially moved up over a certain distance, forming a neutron leakage channel between the two reflective blocks, thereby changing the neutron reflection effect of the pull-out reflector.

Meanwhile, to ensure sufficient safety, SIMONS will be equipped with an auxiliary reactivity control system, which, however, has not been determined yet in terms of the design.

3.2. Energy Conversion System

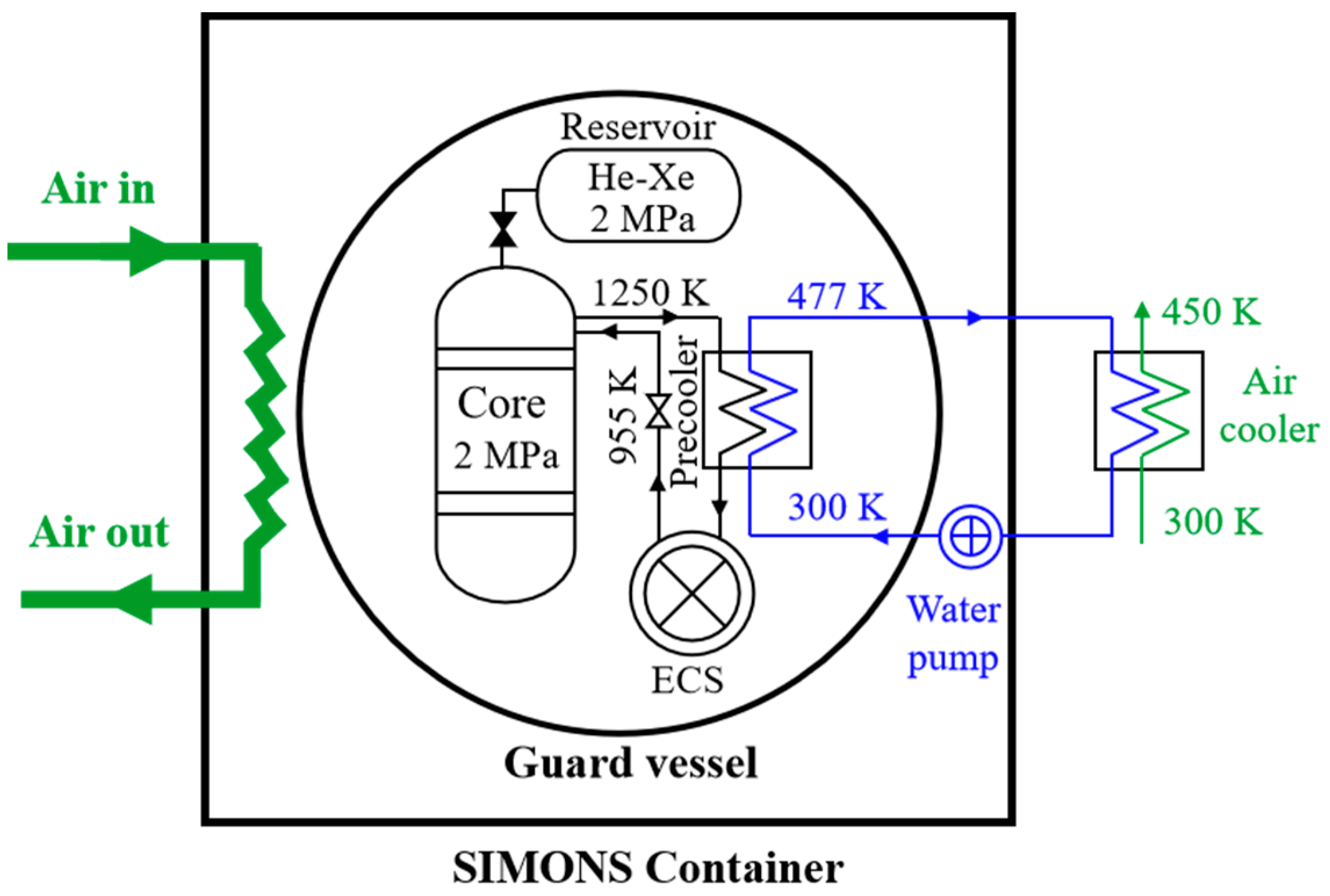

SIMONS employs a highly efficient closed Brayton cycle with helium-xenon gas as the working fluid. The energy conversion system (PCS) is composed of a compressor, a recuperator, a precooler, and a turbine.

Figure 4 depicts a schematic diagram of the energy conversion structure based on the Brayton cycle. The helium-xenon working fluid in low-temperature and low-pressure is pressurized by the compressor, and then exchanges heat with the exhaust gas from the turbine in the recuperator. After preheating to a certain temperature, it is further heated by SIMONS, and then enters the turbine to drive the generator to generate electricity. The exhausted gas flows to the recuperator, in which the exhausted gas is cooled, and then enters the precooler for further cooling, and finally enters the compressor for compression to complete the entire cycle. In order to make the whole system compact, SIMONS adopts a single stage compression and single stage expansion method, which only includes one compressor and one turbine in the whole system. Moreover, the arrangement of the rotating shaft shared by the compressor, turbine, and generator is used to reduce the loss of system efficiency and improve the compactness of the system.

Figure 5 shows the layout of the SIMONS safety system. Under normal operating conditions, the front cooler is connected to the external air cooler through a light water working medium to remove the waste heat of the Brayton cycle system. While under accident conditions, the residual heat from the reactor core is carried out by direct air cooling. The heat exchange equipment uses printed circuit heat exchangers (PCHE) that are resistant to high temperature and pressure, high strength, and high heat transfer efficiency.

3.3. Shielding System

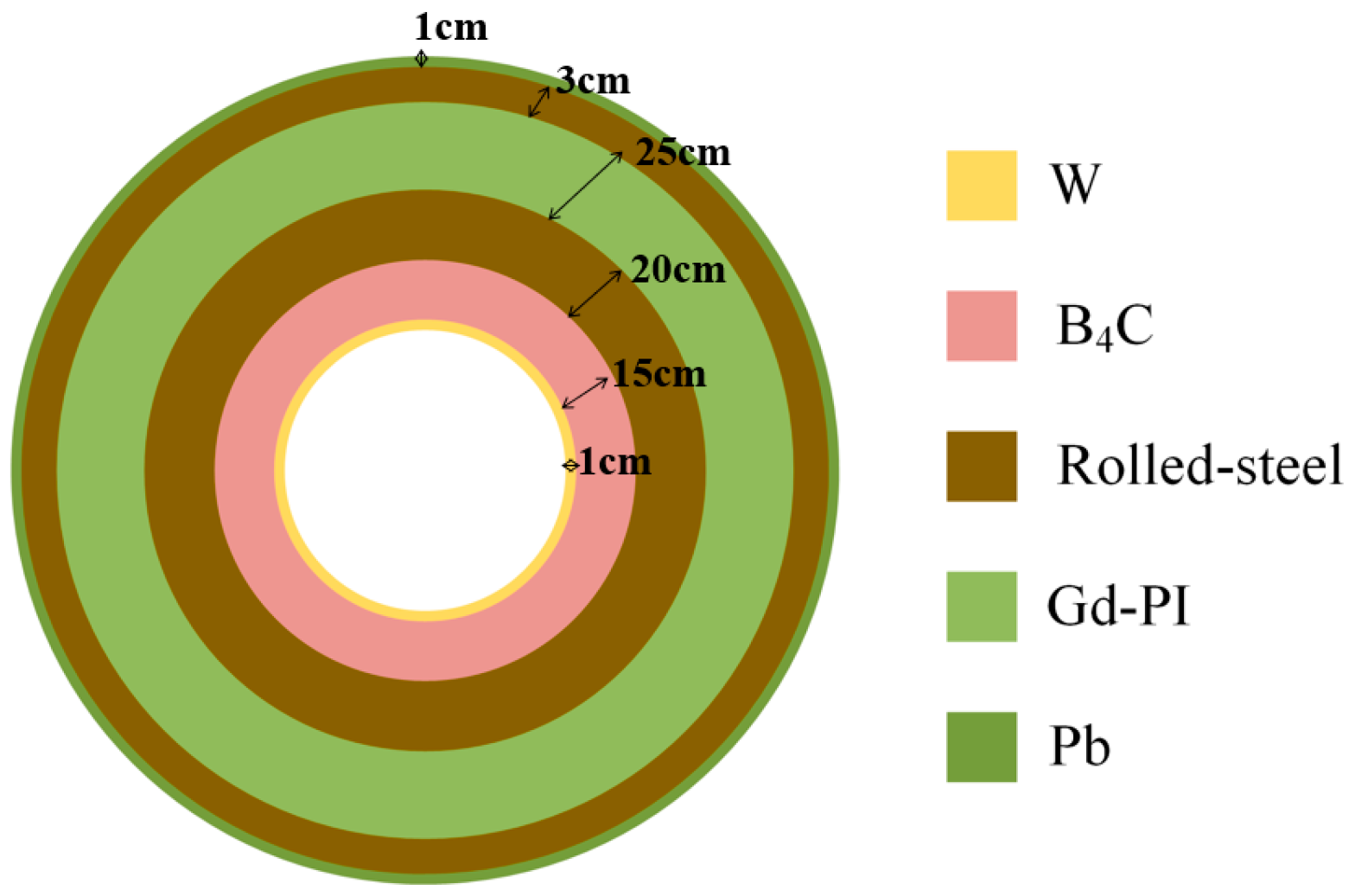

The overall design strategy of the SIMONS shielding system is a combination of fixed shielding inside the module and detachable shielding outside the module, with γ-rays and neutrons jointly shielded to ensure that the radiation dose rate in the reactor personnel operation area and equipment area is less than 2 × 10

−3 Sv/h. Highly efficient lightweight shielding materials (such as rolled steel, polyimide Gd PI, etc.) are used to ensure the shielding effect and at the same time reduce the weight of the whole reactor power system.

Figure 6 shows the layout diagram of the internal axial shielding of the SIMONS module, which is from the inside to the outside: 1 cm tungsten, 15 cm boron carbide, 20 cm rolled steel, 25 cm polyimide, 3 cm rolled steel, and 1 cm lead.

In terms of safety, the design of SIMONS mainly has the following characteristics [

21]: (1) Compact integrated design, no large circuit pipelines, eliminating the possibility of hypothetical large break accidents; (2) Helium-xenon gas is a noble gas and will generally not react with other materials, greatly reducing the corrosion of materials; (3) Mainly relying on moving the reflective layer to achieve reactivity control, reducing the occurrence of accidents such as rod bouncing and sticking; (4) Passive safety design, relying solely on the passive decay heat removal system can also ensure that the fuel temperature is below the core melting limit after shutdown, avoiding the occurrence of “core meltdown” phenomenon.

5. Conclusions

Based on the latest conceptual design of SIMONS, a small helium-xenon cooled reactor, this paper conducted a preliminary exploratory study of the initiating events of SIMONS using a combination of MLD and referring to other reactors (especially helium-cooled reactors and carbon-dioxide cooled reactors) initiating lists and initiating event selection experience, which lays an important foundation for further in-depth and detailed PSA analysis. The main conclusions are as follows:

Taking the generalized “radioactive release” as the top event, the internal initiating events of the power operation phase of SIMONS were derived, and together with the disasters (internal and external), 31 initiating events of SIMONS were identified;

According to the classification of failure types, SIMONS initiating events are classified into six groups: core heat removal increase, core heat removal decrease, abnormal reactivity and power distribution, pipeline crevasse and equipment leakage, anticipated transients without scram, and disasters (internal and external).

At present, SIMONS is still in the conceptual design stage, and the design of some systems is not yet complete. Subsequently, with the progress and improvement of SIMONS design in the future, based on the current work and combined with different application scenarios of SIMONS, further in-depth exploration will be conducted on the analysis of the initiating events of SIMONS, and the completeness and applicability of the initiating events of SIMONS will be fully demonstrated.