Influence of the Use of EtG Synthetic Fuel in Spark-Ignition Engines on Vehicle Fuel Consumption and Pollutant Emissions

Abstract

:1. Introduction

- −

- use of special engines, e.g., self-ignition engines, adapted to be powered by E95 bioethanol fuel (other designation: ED95) and flexi-fuel spark-ignition engines powered by E85 fuel;

- −

- the use of fuels of biological origin as biocomponents for the conventional fuels in concentrations compliant with applicable regulations and engine specifications.

2. Tests Methodology

- engine rotational speed;

- engine load, which is usually measured by torque or mean useful pressure (the measurement of load can also be useful power, which is a linear function of torque, and engine control; engine control is understood as a physical quantity describing the operator’s activities with the internal combustion engine, e.g., in the case of a vehicle engine the angle of depressing the accelerator pedal);

- thermal state of the internal combustion engine.

- dynamic properties—due to the useful power or the ability to accelerate the vehicle;

- economic properties—due to the overall efficiency of the engine or fuel consumption;

- ecological properties—mainly due to emission of pollutants or noise emission;

- durability, reliability, and serviceability.

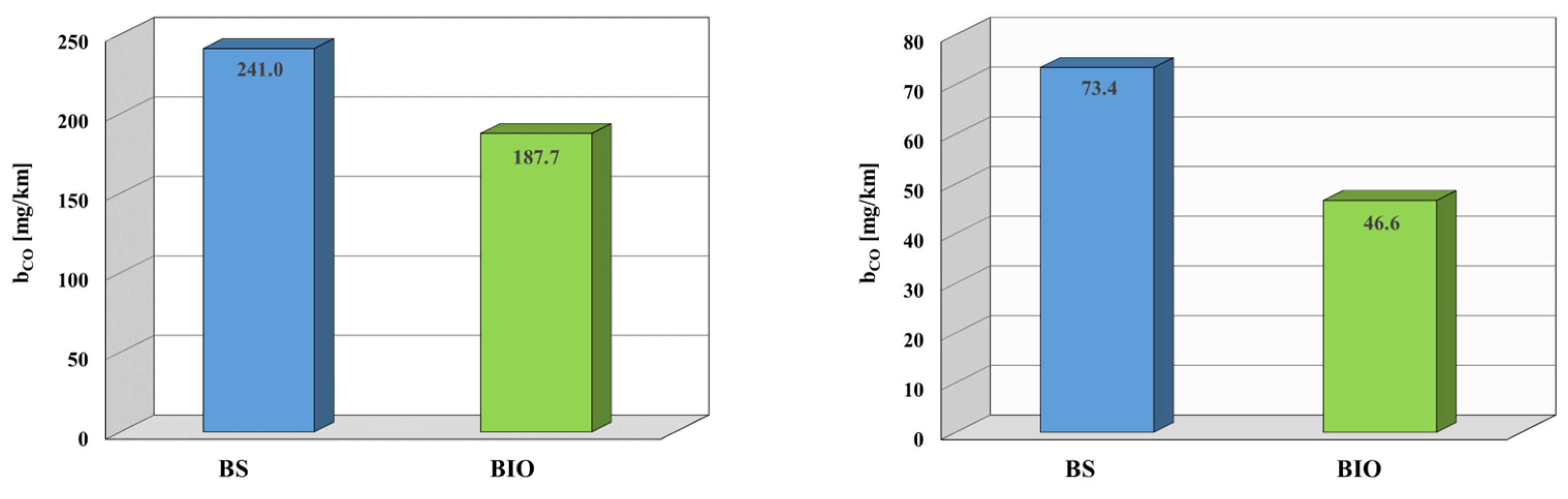

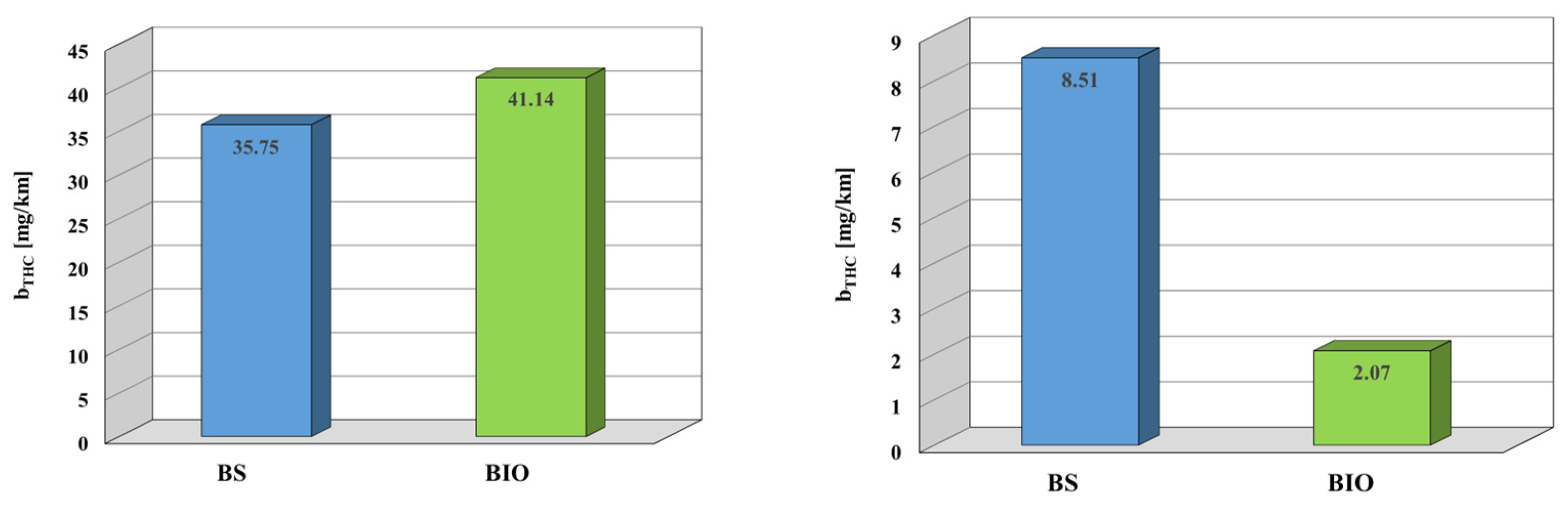

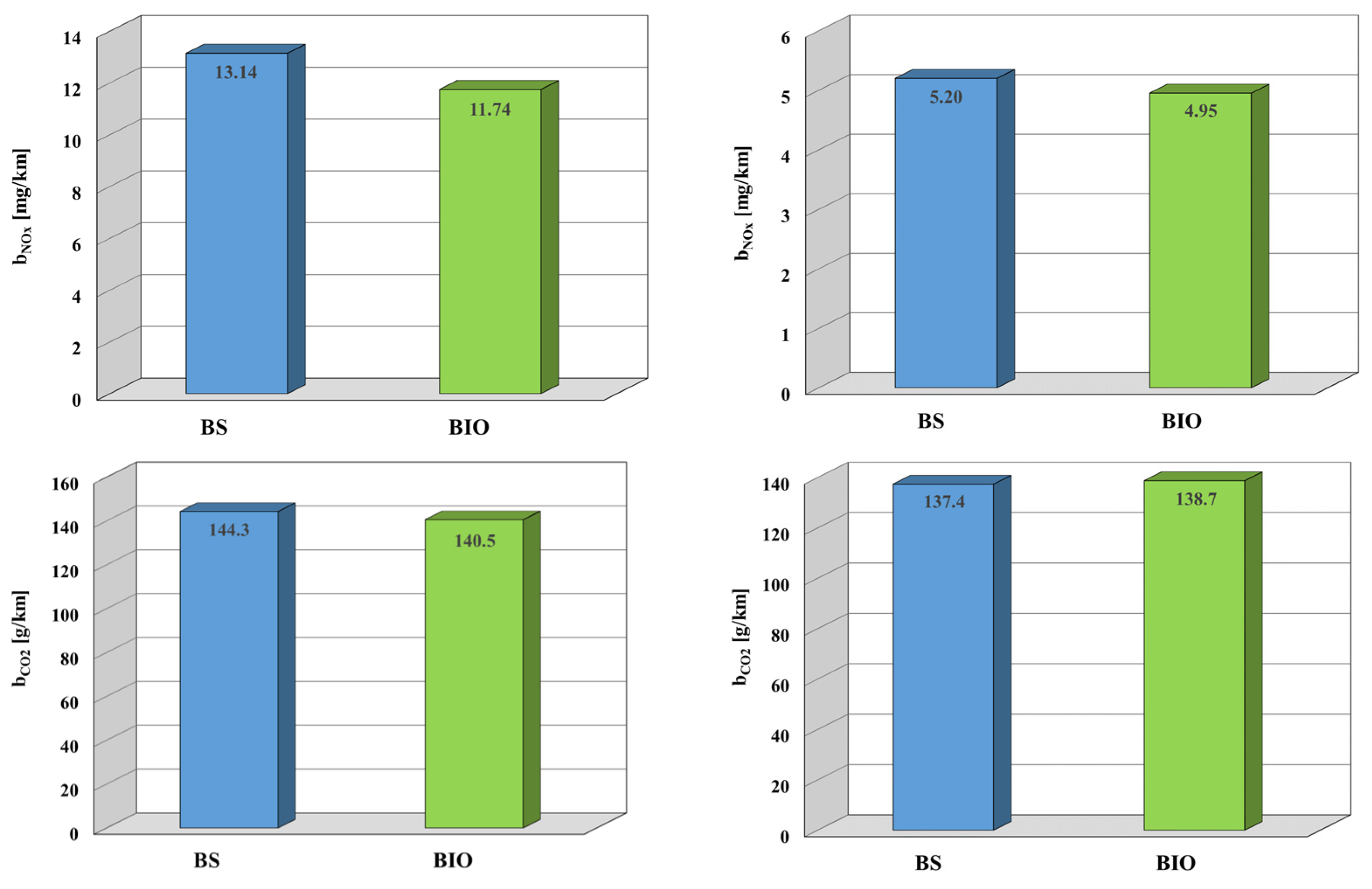

- average specific distance emission of substances harmful to the health of living organisms: carbon monoxide, total hydrocarbons, non-methane hydrocarbons, and nitrogen oxides in the WLTC (Worldwide Harmonized Light Vehicles Test Cycle) test,

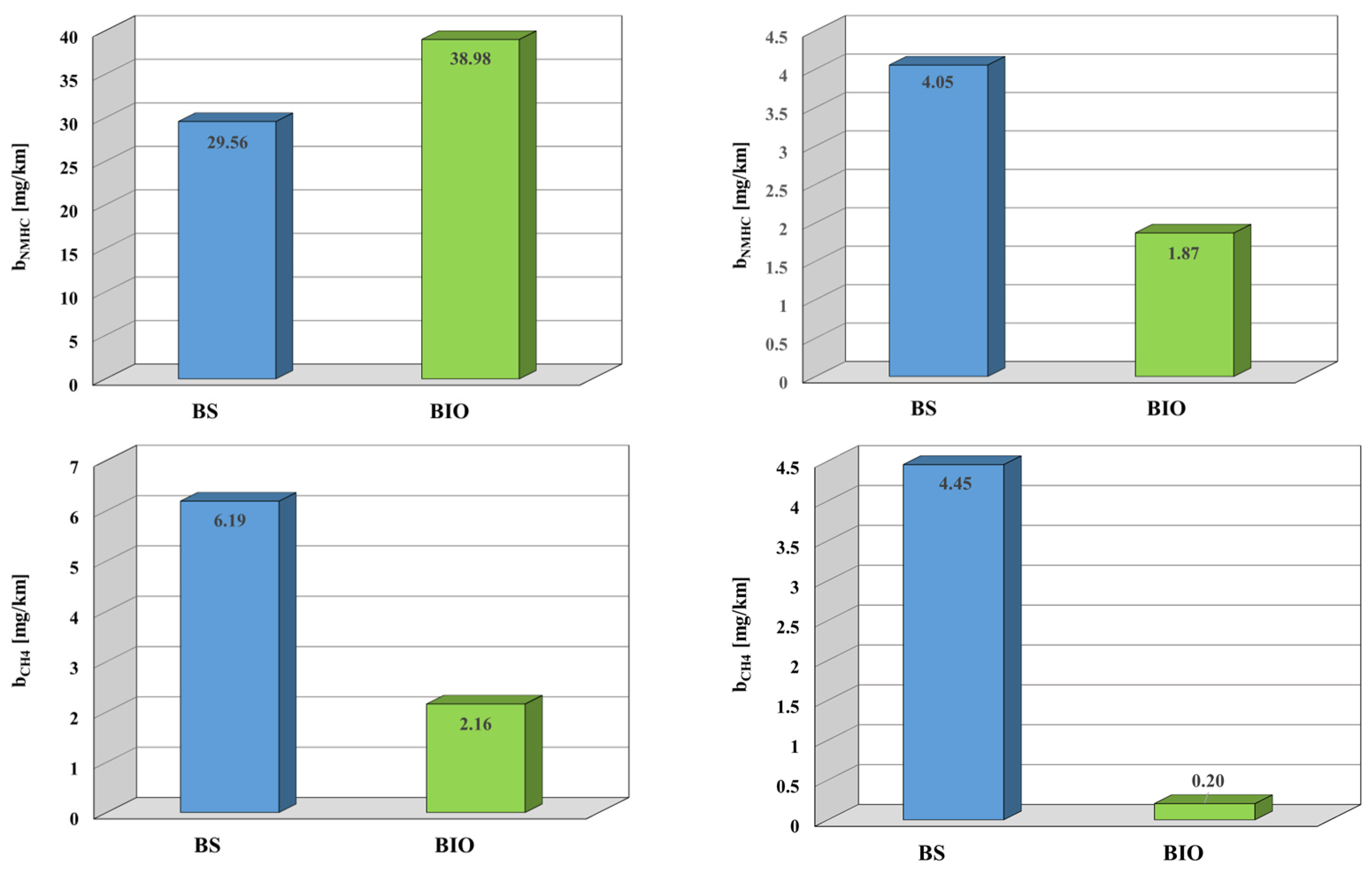

- average specific distance emission of methane and carbon dioxide in the WLTC test as substances conducive to the intensification of the greenhouse effect in the atmosphere,

- operational fuel consumption in the WLTC test.

- −

- a system for measuring pollutant emissions produced by AVL; during the tests, the configuration “13 Diluted Bag Particles Gasoline” containing the following measuring devices was used:

- exhaust gas collection system CFV-CVS type CVS i60 LD S2 by AVL;

- PSS i60 particulate emission measurement system by AVL;

- AVL489 APC ADVANCED particulate matter counter by AVL;

- a set of AMA i60 D1-CD LE analysers by AVL equipped with two-band analysers enabling the measurement of concentrations of the following gases: carbon dioxide—CO2, nitrogen oxides—NOx, carbon monoxide—CO, total hydrocarbons—THC, and methane—CH4;

- VAISALA PTU303 weather station for measuring air temperature, pressure and humidity in the chassis dynamometer room;

- −

- one-roller chassis dynamometer with adjustable resistance curve by AVL-Zoellner;

- −

- MT5 microbalance by Mettler Toledo;

- −

- OBD system AVL DIOBD 880 error code reader;

- −

- LAB-EL thermo-hygrometer type LB-701, version M with a reading panel LB-702B

3. Results of Empirical Tests

4. Conclusions

- Specific distance emission of carbon monoxide is much lower for EtG fuel, especially when starting a hot engine.

- Specific distance emission of nitrogen oxides is slightly lower for EtG fuel, the difference is particularly small when starting a warm engine.

- Specific distance emission of organic compounds, i.e., both total hydrocarbons and non-methane hydrocarbons, at the start of a cold engine is higher for EtG fuel, while at the start of a hot engine it is much lower for EtG fuel.

- Specific distance emission of methane is much lower for EtG fuel, and when starting a hot engine it is almost negligible.

- Specific distance emission of carbon dioxide for both fuels is very similar.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| (m/m) | mass share |

| (v/v) | volume fraction |

| b | specific distance pollutant emission |

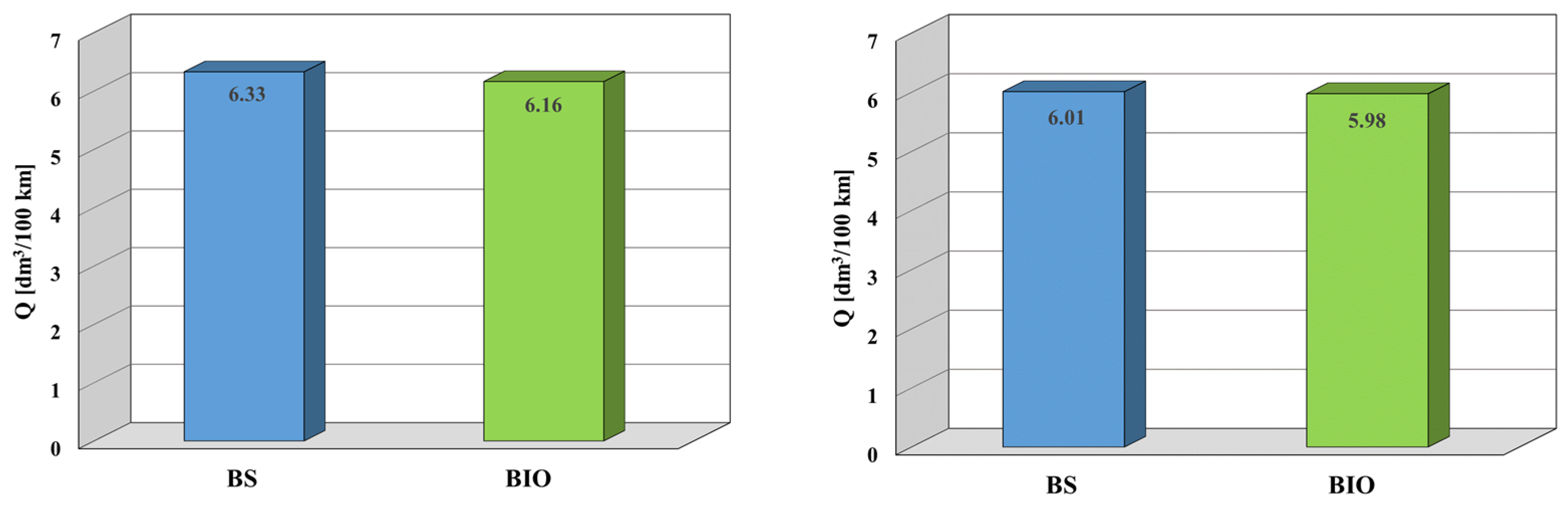

| BIO | synthetic gasoline EtG |

| BS | gasoline |

| CFV | Carbon Footprint Verification Constant Volume Sampler |

| CVS | Constant Volume Sampler |

| CH4 | methane |

| CO | carbon oxide |

| CO2 | carbon dioxide |

| E85 | bioethanol fuel for flexi-fuel spark ignition engines |

| E95 (ED95) | bioethanol fuel for diesel engines |

| EEV | Enhanced Environmentally Friendly Vehicle |

| EtG | ethanol to gasoline |

| NCR | National Reduction Target |

| NCW | National Indicator Target |

| NMHC | non-methane hydrocarbons |

| NOx | nitrogen oxides |

| OBD | On-Board Diagnostics |

| Q | operational fuel consumption |

| RDE | Real Emissions Driving |

| SORT | Standardised On-Road Test Cycles |

| THC | total hydrocarbons |

| TtW | Tank to Wheel |

| UE | European Union |

| UITP | Union Internationale des Transports Publics |

| UN | United Nations |

| WLTC | Worldwide Harmonized Light Vehicles Test Cycle |

| WLTP | Worldwide Harmonized Light Vehicles Test Procedure |

| WtW | Well to Wheel |

References

- Annevelink, B.; Chavez, L.G.; van Ree, R.; Gursel, I.V. Global Biorefinery Status Report 2022, Global Biorefinery Status Report 2022. In IEA Bioenergy: Task 42 Biorefining in a Circular Economy; IEA Bioenergy; ISBN 979-12-80907-14-1. Available online: https://www.ieabioenergy.com/wp-content/uploads/2022/09/IEA-Bioenergy-Task-42-Global-biorefinery-status-report-2022-220712.pdf (accessed on 24 August 2023).

- Chłopek, Z. Ekologiczne i ekonomiczne aspekty eksploatacji silników o zapłonie samoczynnym na biopaliwo bioetanolowe, (Ecological and economic aspects of operation of self-ignition engines using bioethanol biofuel). Veh. Transp. 2008, 2, 37–50. [Google Scholar]

- Anekwe, I.M.S.; Isa, Y.M.; Oboirien, B. Bioethanol as a potential eco-friendlier feedstock for catalytic production of Fuels and petrochemicals. J. Chem. Technol. Biotechnol. 2023, 98, 2077–2094. [Google Scholar] [CrossRef]

- Xiang, H.; Xin, R.; Prasongthum, N.; Natewong, P.; Sooknoi, T.; Wang, J.; Reubroycharoen, P.; Fan, X. Catalytic conversion of bioethanol to value-added chemicals and fuels: A review. Resour. Chem. Mater. 2022, 1, 47–68. [Google Scholar] [CrossRef]

- Dąbrowski, W.; Bednarski, W. Ekologiczne aspekty produkcji oraz stosowania biodiesla (Ecological aspects of biodiesel production and use). Eng. Sci. Technol. 2013, 3, 18–34. [Google Scholar]

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources (Recast) (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/PL/TXT/PDF/?uri=CELEX:32018L2001 (accessed on 24 August 2023).

- European Technology and Innovation Platform, Sustainable Feedstocks for Advanced Biofuels and Intermediate Bioenergy Carriers Production in Europe. Available online: http://www.etipbioenergy.eu/everyone/biofuel-feedstocks (accessed on 10 October 2022).

- European Technology and Innovation Platform, Current Status of Advanced Biofuels Demonstrations in Europe, ETIP Bioenergy Working Group 2–Conversion Process and ETIP-B-SABS2 project team, Final version 09.03.2020. 2020.

- UN Regulation No. 83, Uniform Provisions Concerning the Approval of Vehicles with Regard to the Emission of Pollutants according to Engine Fuel Requirements.

- Worldwide Fuel Charter, 6th ed.; Gasoline and Diesel Fuel. 28 October 2019; Available online: https://www.acea.auto/uploads/publications/WWFC_19_gasoline_diesel.pdf (accessed on 12 January 2023).

- Shell TechXplorer Digest 2022 Volume 2, Pathways to decarbonization. December 2022. Available online: https://www.shell.com/energy-and-innovation/shell-techxplorer-digest-pathways-to-decarbonisation/_jcr_content/root/main/section/simple/call_to_action/links/item0.stream/1675673568192/0bb646eb5038f98c5dc25d7fcb8f2914635d75c2/complete.pdf (accessed on 24 August 2023).

- IRENA. Advanced Biofuels. What Holds Them Back? International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Biernat, K.; Grzelak, P.L. Biorefinery Systems as an Element of Sustainable Development. Biofuels–Status Perspect. 2015, 30, 427–444. [Google Scholar] [CrossRef]

- Jungmeier, G.; Hingsamer, M.; van Ree, R. Biofuel-driven Biorefineries. A selection of the most promising biorefinery concepts to produce large volumes of road transportation biofuels by 2025. Rep. IEA Bioenergy Task 2013, 42. [Google Scholar]

- Kalnes, T.N.; Marker, T.; Shonnard, D.R.; Koers, K.P. Green diesel production by hydrorefining renewable feedstocks. Biofuels Technol. 2008, 7–11. Available online: https://www.academia.edu/32915572/Green_diesel_production_by_hydrorefining_renewable_feedstocks (accessed on 10 October 2022).

- Ragauskas, A.J.; Williams, C.K.; Davison, B.H.; Britovsek, G.; Cairney, J.; Eckert, C.A.; Frederick, W.J., Jr.; Hallett, J.P.; Leak, D.J.; Liotta, C.L.; et al. The Path Forward for Biofuels and Biomaterials. Science 2006, 311, 484–489. [Google Scholar] [CrossRef] [PubMed]

- Rosentrater, K.A. Production and Use of Evolving Corn-Based Fuel Ethanol Coproducts in the U.S. Biofuels-Status Perspect. 2015, 81–98. [Google Scholar] [CrossRef]

- Speight, J.G. Synthetic Fuels Handbook–Properties, Processes and Performances; McGraw-Hill: New York, NY, USA, 2008; Volume 422. [Google Scholar]

- Van Dyk, S.; Su, J.; McMillan, J.D.; Saddles, J.N. Drop-in BIOFUELS: The Key Role That Co-Processing Will Play in Its Production; IEA Bioenergy, Task 39, January 2019. Available online: https://www.ieabioenergy.com/wp-content/uploads/2019/09/Task-39-Drop-in-Biofuels-Full-Report-January-2019.pdf (accessed on 15 December 2022).

- Van Ree, R.; Annevelink, E. Status Report Biorefinery 2007. November 2007. Available online: www.biorefinery.nl (accessed on 31 October 2022).

- Chłopek, Z.; Lasocki, J. Problemy kompleksowej oceny emisji zanieczyszczeń z silników spalinowych i pojazdów samochodowych (Problems of comprehensive assessment of pollutant emissions from internal combustion engines and motor vehicles). Sci. J. Inst. Veh. Wars. Univ. Technol. 2012, 1, 165–173. [Google Scholar]

- Lasocki, J.; Chłopek, Z. Kompleksowa ocena zagrożenia środowiska przez eksploatację pojazdów samochodowych (Comprehensive assessment of environmental hazards caused by the operation of motor vehicles). Combust. Engines 2012, 148, 82–87. [Google Scholar]

- Macha, D. Biowęglowodory ciekłe–biokomponent przyszłości. Potencjał rynkowy i technologiczny (Liquid biohydrocarbons-a biocomponent of the future. Market and technological potential), XV Forum Dyskusyjne Sekcji PETROL-GAZ Klubu POLLAB (XV Discussion Forum of the PETROL-GAZ Section of the POLLAB Club), Sandomierz 7–9 czerwca 2016.

- Raport Polski Rynek Paliw Płynnych 2022 (Report Polish Market of Liquid Fuels 2022), Polska Izba Paliw Płynnych (Polish Chamber of Liquid Fuels), Warszawa, Lipiec 2023 (Warsaw, June 2023). 20 June.

- Orsia, F.; Muratoria, M.; Roccob, M.; Colombob, E.; Rizzoni, G. A multi-dimensional well-to-wheels analysis of passenger vehiclesin different regions: Primary energy consumption, CO2 emissions, and economic cost. Appl. Energy 2016, 169, 197–209. [Google Scholar] [CrossRef]

- Pielecha, J.; Magdziak, A.; Markowski, J.; Jasiński, R. Ekologiczna ocena eksploatacyjna autobusów miejskich z zastosowaniem wybranych stabilizatorów do paliw (Ecological operational assessment of city buses with the use of selected fuel stabilizers). Buses 2016, 12, 1289–1296. [Google Scholar]

- Jakóbiec, J.; Mazanek, A. Czynniki kształtujące ocenę ekologiczną pracy silników samochodowych (Factors shaping the ecological evaluation of vehicle engines operation). Logistics 2014, 6, 4716–4730. [Google Scholar]

- Grzelak, P.L.; Żółtowski, A. Environmental assessment of the exploitation of diesel engines powered by biofuels. Combust. Engines 2020, 180, 31–35. [Google Scholar] [CrossRef]

- Kowalek, S. Wpływ fizycznych parametrów biopaliw na eksploatację silnika z zapłonem samoczynnym (Influence of physical parameters of biofuels on the operation of a self-ignition engine). Buses 2014, 6, 166–168. [Google Scholar]

- Grzelak, P.L. DMF jako biopaliwo drugiej generacji (DMF as a second generation biofuel). Tech. Rev. 2019, 9–10, 24–28. [Google Scholar]

- Commission Regulation (EU) 2017/1151 of 1 June 2017 Supplementing Regulation (EC) No. 715/2007 of the European Parliament and of the Council on Type-approval of Motor Vehicles with Respect to Emissions from Light Passenger and Commercial Vehicles (Euro 5 and Euro 6) and on Access to Vehicle Repair and Maintenance Information, Amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) No. 1230/2012 and Repealing Commission Regulation (EC) No. 692/2008 (Text with EEA relevance) (OJ L 175, 7.7.2017, p. 1); The European Parliament: Brussels, Belgium. 2017. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32017R1151 (accessed on 16 December 2022).

- Commission Regulation (EU) 2018/1832 of 5 November 2018 amending Directive 2007/46/EC of the European Parliament and of the Council, Commission Regulation (EC) No 692/2008 and Commission Regulation (EU) 2017/1151 for the Purpose of Improving the Emission Type Approval Tests and Procedures for Light Passenger and Commercial Vehicles, Including Those for In-Service Conformity and Real-Driving Emissions and Introducing Devices for Monitoring the Consumption of Fuel and Electric Energy, European Parliament: Brussels, Belgium. 2018. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018R1832 (accessed on 25 November 2022).

- Regulation No. 101 ONZ “Uniform Provisions Concerning the Approval of Passenger Cars Powered by an Internal Combustion Engine Only, or Powered by a Hybrid Electric Power Train with Regard to the Measurement of the Emission of Carbon Dioxide and Fuel Consumption and/or the Measurement of Electric Energy Consumption and Electric Range, and of Categories M1 and N1 Vehicles Powered by an Electric Power Train only with Regard to the Measurement of Electric Energy Consumption and Electric Range”, Revision 3, Supplement 1 to the 01 Series of Amendments to the Regulation—Date of Entry Into Force: 27 January 2013: E/ECE/324/Rev.2/Add.100/Rev.3-E/ECE/TRANS/505/Rev.2/Add.100/Rev.3; Geneva, Switzerland. 2013. Available online: https://unece.org/transport/vehicle-regulations-wp29/standards/addenda-1958-agreement-regulations-101-120 (accessed on 25 November 2022).

- Regulation No. 115 ONZ “Uniform Provisions Concerning the Approval of: I. Specific LPG (Liquefied Petroleum Gases) Retrofit Systems to be Installed in Motor Vehicles for the Use of LPG in Their Propulsion System, II. Specific CNG (Compressed Natural Gas) Retrofit Systems to be Installed in Motor Vehicles for the Use of CNG in Their Propulsion System”, Revision 1, Supplement 5 to the Original Version of the Regulation—Date of Entry into Force: 15 July 2013: E/ECE/324/Rev.2/Add.114/Rev.1-E/ECE/TRANS/505/Rev.2/Add.114/Rev.1; Economic Commission for Europe of the United Nations: Geneva, Switzerland, 2013; Available online: https://unece.org/fileadmin/DAM/trans/main/wp29/wp29regs/2013/R115r1e.pdf (accessed on 25 November 2022).

| Measured Parameter | Measuring Equipment | Accuracy |

|---|---|---|

| Flow | Exhaust dilution system | ±0.5% |

| Speed | Chassis dynamometer | ±0.025% |

| Distance | Chassis dynamometer | ±0.1% |

| Concentration | Analyzers | ±2% |

| Make and Model | Hyundai i30 |

|---|---|

| VIN Number | TMAH281CAMJ085654 |

| Engine type | G4LG |

| Engine displacement | 1498 cm3 |

| Rated power | 80.9 kW |

| Number of cylinders | 4 |

| Vehicle category | M1 |

| Emission level when running on Euro 6AP petrol | Euro 6AP |

| Odometer reading | 8624 km |

| Parameter | Unit | Result |

|---|---|---|

| Research Octane Number (RON) | - | 91 |

| Kinematic viscosity | mm2/s (at 40 °C) | <1 |

| Autoignition temperature | °C | 480 |

| Density at the temperature 15 °C | kg/m3 | 761.1 |

| Appearance | - | bright and transparent |

| Vapour pressure (dry vapour pressure equivalent) | kPa | 57.0 |

| Fraction composition, distillation start temperature | °C | 30.3 |

| distills up to 70% | % (v/v) | 23.8 |

| distills up to 100% | % (v/v) | 40.8 |

| distills up to 150% | % (v/v) | 69.1 |

| Fraction composition, distillation end temperature | °C | 206.7 |

| Residue after distillation | % (v/v) | 1.1 |

| N-paraffins | % (v/v) | 11.44 |

| I-paraffins | % (v/v) | 32.59 |

| Olefins | % (v/v) | 1.95 |

| Naphthenes | % (v/v) | 7.60 |

| Aromatic hydrocarbons | % (v/v) | 41.84 |

| Polycyclic hydrocarbons | % (v/v) | 0.31 |

| Not specified | % (v/v) | 4.27 |

| Oxygen derivatives | % (v/v) | 0.00 |

| Oxygen | % (m/m) | 0.00 |

| Benzene | % (v/v) | 0.30 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biernat, K.; Chłopek, Z.; Grzelak, P.L. Influence of the Use of EtG Synthetic Fuel in Spark-Ignition Engines on Vehicle Fuel Consumption and Pollutant Emissions. Energies 2023, 16, 6273. https://doi.org/10.3390/en16176273

Biernat K, Chłopek Z, Grzelak PL. Influence of the Use of EtG Synthetic Fuel in Spark-Ignition Engines on Vehicle Fuel Consumption and Pollutant Emissions. Energies. 2023; 16(17):6273. https://doi.org/10.3390/en16176273

Chicago/Turabian StyleBiernat, Krzysztof, Zdzisław Chłopek, and Paulina Luiza Grzelak. 2023. "Influence of the Use of EtG Synthetic Fuel in Spark-Ignition Engines on Vehicle Fuel Consumption and Pollutant Emissions" Energies 16, no. 17: 6273. https://doi.org/10.3390/en16176273

APA StyleBiernat, K., Chłopek, Z., & Grzelak, P. L. (2023). Influence of the Use of EtG Synthetic Fuel in Spark-Ignition Engines on Vehicle Fuel Consumption and Pollutant Emissions. Energies, 16(17), 6273. https://doi.org/10.3390/en16176273