Economic and Ecological Impacts on the Integration of Biomass-Based SNG and FT Diesel in the Austrian Energy System

Abstract

:1. Introduction

- Potential analysis of biogenic feedstock suitable for DFB gasification in Austria;

- Modelling of commercial scale concepts for the production of biomass-based SNG and FT diesel;

- Techno-economic and ecological assessment of both routes;

- Development of integration scenarios for biomass-based SNG and FT diesel in the Austrian energy system.

2. Materials and Methods

2.1. Potential Analysis of Biogenic Feedstock

2.2. Commercial Scale SNG and FT Production Concepts

2.3. Techno-Economic and Ecological Assessment

2.4. Scenarios for Integrating Biomass-Based SNG and FT Diesel in the Austrian Energy System

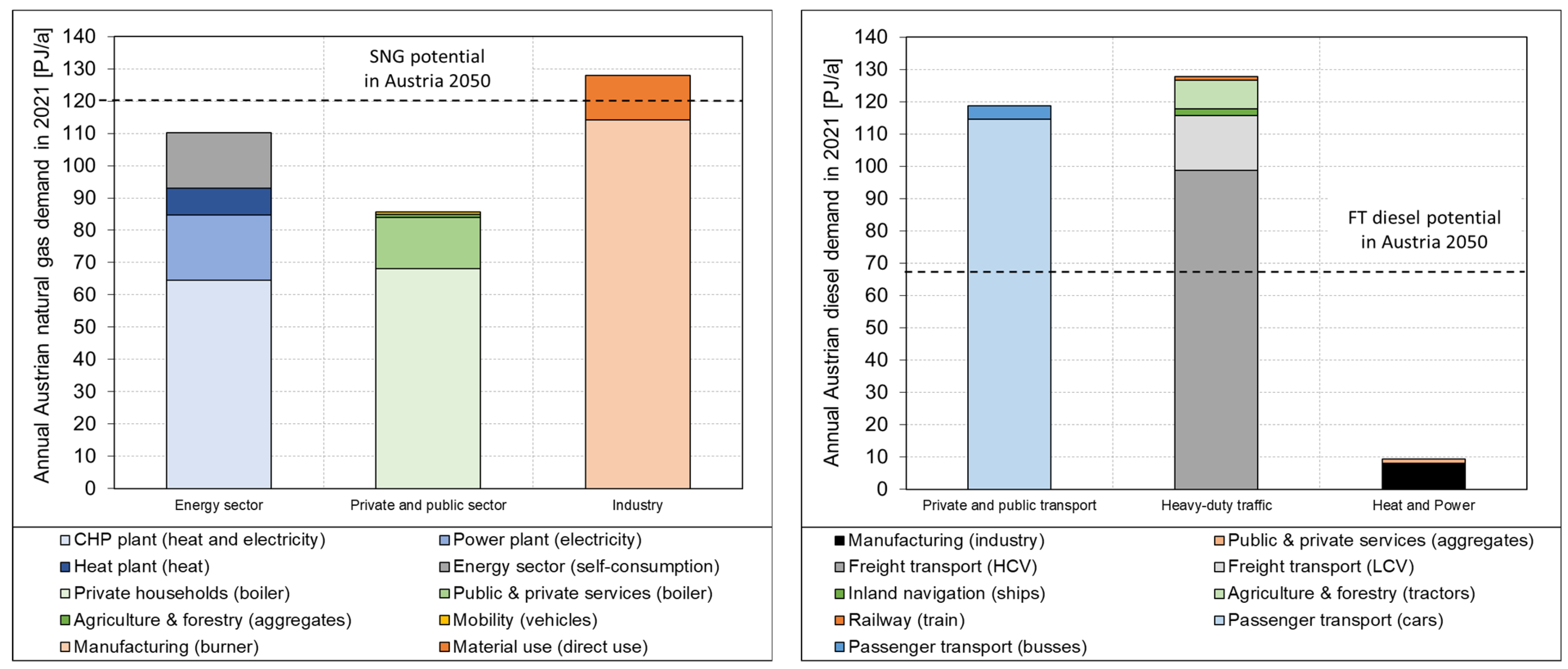

- (a)

- SNG use in the energy sector

- (b)

- SNG use in the private and public sector (without mobility)

- (c)

- SNG use in the industry

- (d)

- FT diesel in private and public transport

- (e)

- FT diesel in heavy-duty traffic

- (f)

- FT diesel in heat and power

3. Results and Discussion

3.1. Input- and Output Streams of Commercial SNG and FT Production Plants

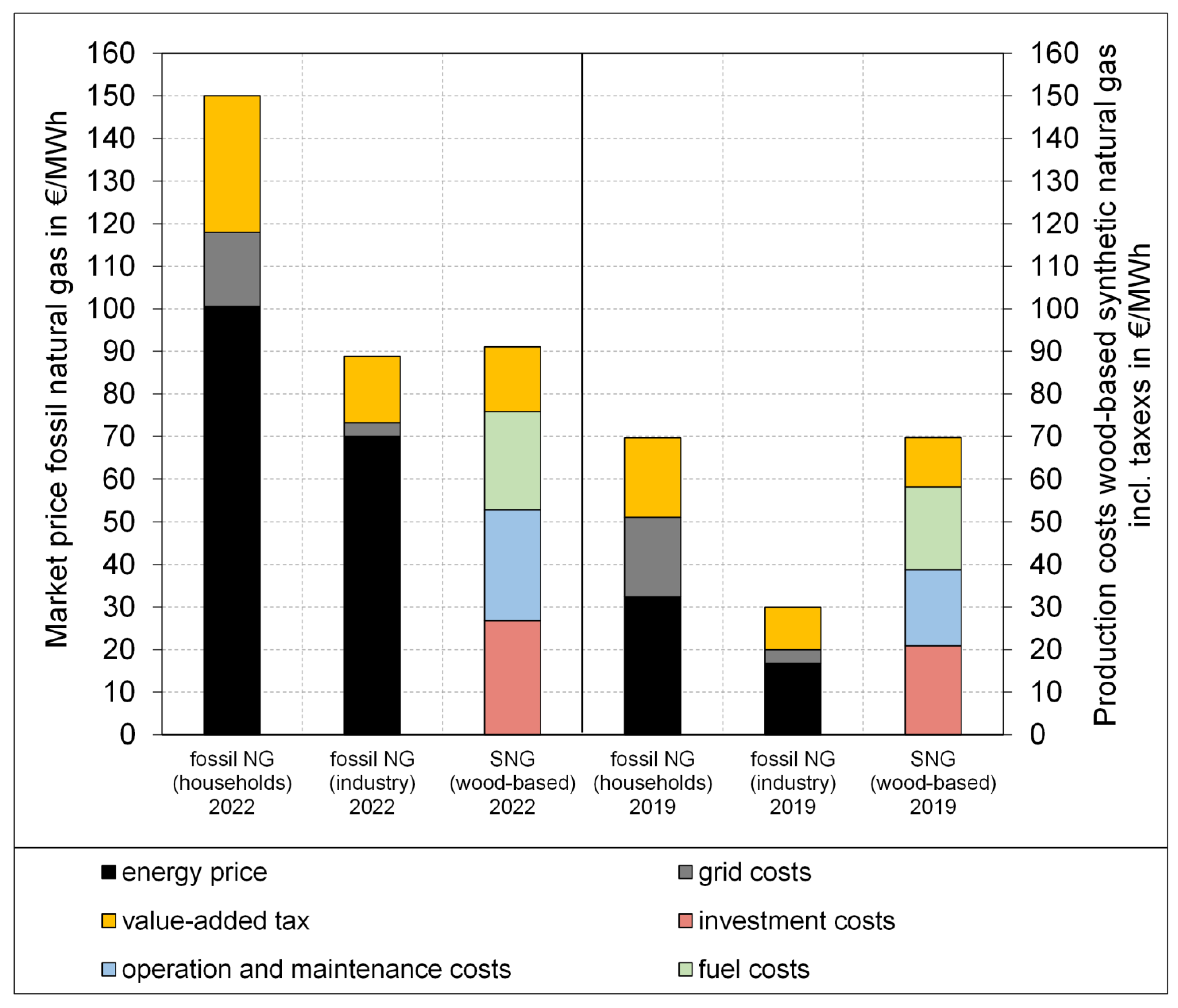

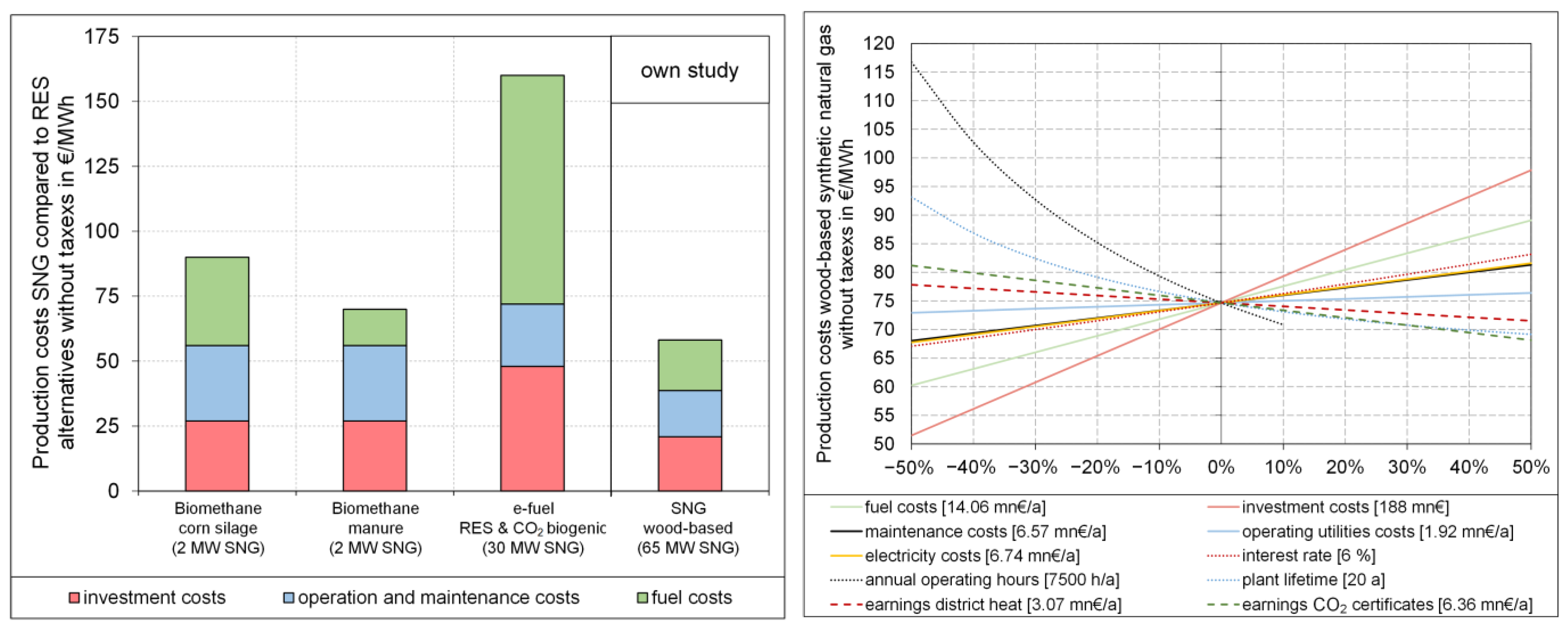

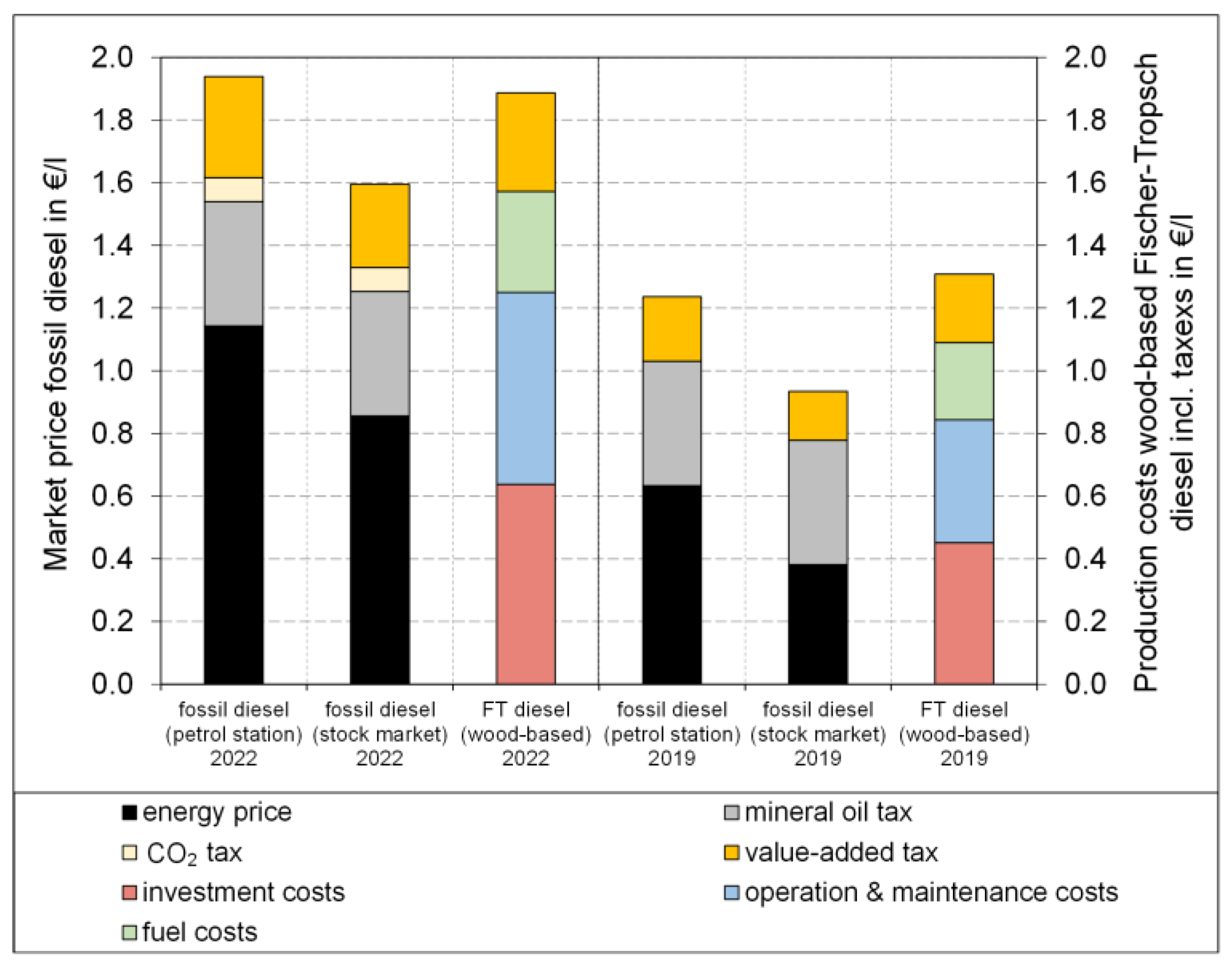

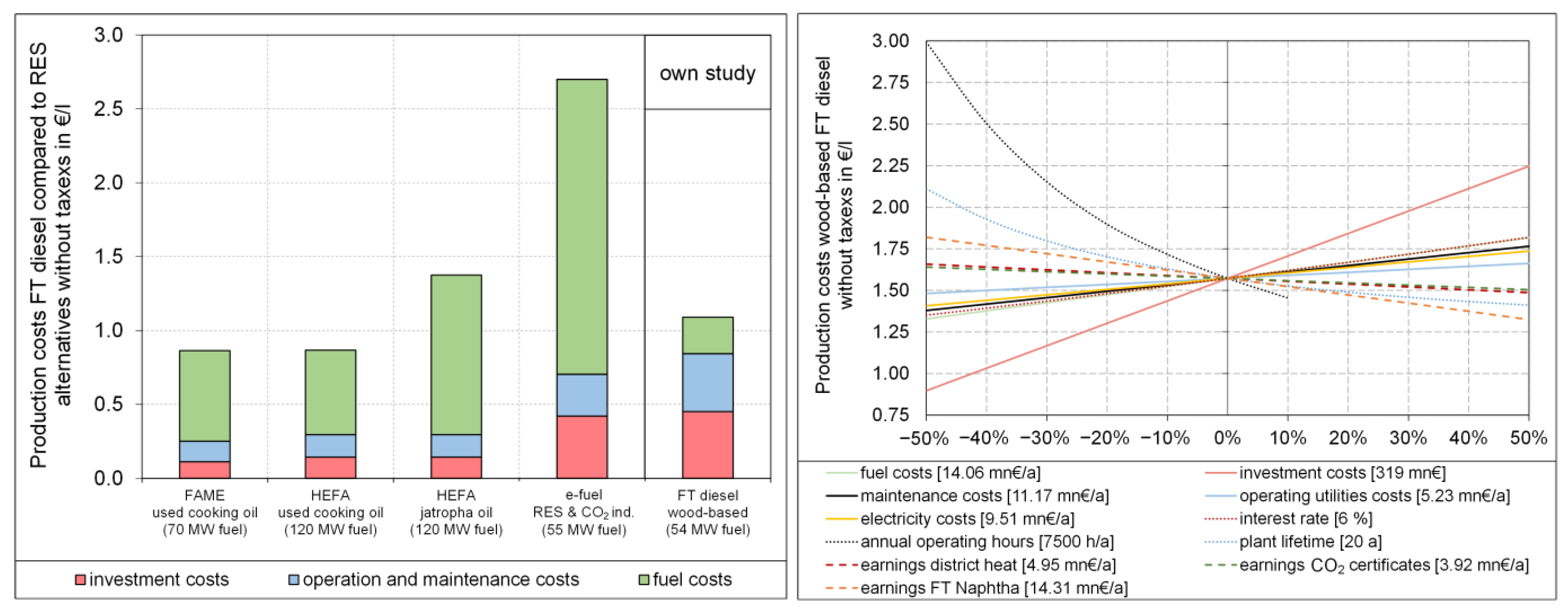

3.2. Techno-Economic Results of Commercial SNG and FT Production Plants

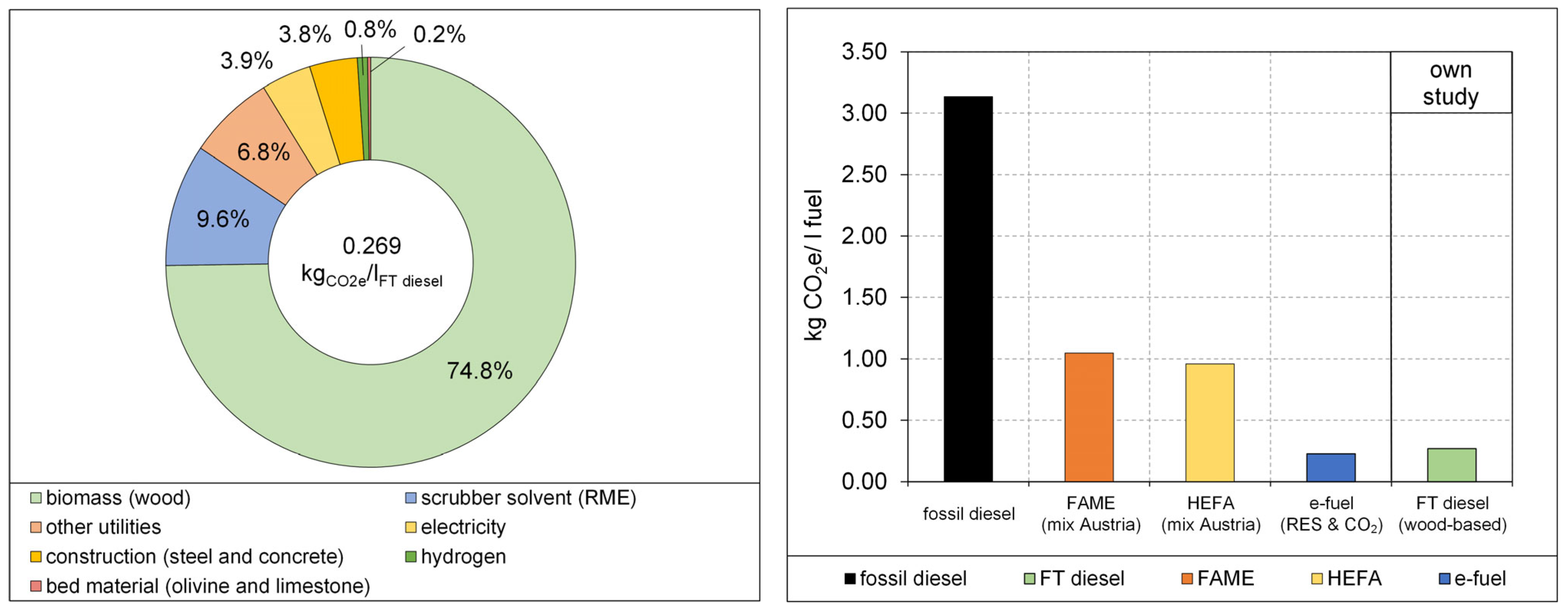

3.3. Ecological Results of Commercial SNG and FT Production Plants

3.4. Integration of Biomass-Based SNG and FT Diesel in the Austrian Energy System

4. Conclusions and Outlook

- SNG use for covering electricity peak loads in the energy sector 🡺 helps to prevent blackouts and to decouple the domestic electricity market from the gas market;

- SNG use in the industry sector for the provision of high-temperature heat 🡺 economically feasible and a good option, when no waste heat or heat pumps can be used;

- FT diesel in heavy-duty traffic 🡺 economically feasible and an excellent option to facilitate the defossilization of inland navigation, railway, freight transport, agriculture, and forestry.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AC | activated carbon |

| AT | Austria |

| C1–C3 | gaseous short-chain hydrocarbons recycled in Fischer–Tropsch tailgas |

| C4–C9 | naphtha fraction (raw product for producing gasoline) |

| C10–C19 | middle distillate fraction (after upgrading equivalent to diesel) |

| C10+ | middle distillate fraction and long-chain waxes |

| C20+ | long-chain waxes |

| CH4 | methane |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CO2e | carbon dioxide equivalent |

| DE | Germany |

| DFB | dual fluidized bed |

| EC | economic competitiveness |

| FAME | fatty acid methyl ester |

| FT | Fischer–Tropsch |

| GEMIS | software tool with database for life cycle analysis |

| GVA | gross value added |

| H2 | hydrogen |

| H2O | water |

| H2S | hydrogen sulfide |

| HCV | heavy commercial vehicles |

| HEFA | hydroprocessed ester and fatty acid |

| IEA | International Energy Agency |

| IPSEpro 8.0 | software tool for process simulation from company SimTech GmbH |

| JP | Japan |

| LCOP | levelized costs of products |

| LCV | light commercial vehicles |

| MP | market prices |

| NH3 | ammonia |

| O&M | operation and maintenance |

| PFD | process flow diagram |

| PG | product gas |

| PV | photovoltaic |

| raw-SNG | synthetic natural gas after methanation unit and before upgrading |

| RES | renewable energy sources |

| RME | rapeseed methyl ester |

| SE | Sweden |

| SNG | synthetic natural gas |

| TH | Thailand |

| TSA | temperature swing adsorption |

| ZnO | zinc oxide |

| Symbols: | |

| % | percent |

| cumulative discount factor | |

| Chemical Engineering Plant Cost Index based on 2019 or 2022 | |

| Chemical Engineering Plant Cost Index based on base year of literature | |

| equipment costs based on base year and base scale of literature | |

| overall costs for installed equipment based on 2019 or 2022 | |

| carbon dioxide reduction potential in sector i | |

| total carbon dioxide equivalent in sector i | |

| annual expenditures | |

| economic competitiveness in sector i based on 2019 or 2022 | |

| substituted annual fossil gas or diesel demand in sector i | |

| carbon dioxide equivalent footprint of fossil natural gas or diesel | |

| carbon dioxide equivalent footprint of biomass-based SNG or FT diesel | |

| total gross value added in sector i based on 2019 or 2022 | |

| interest rate | |

| total capital investment costs of plant | |

| liter | |

| levelized costs of products | |

| levelized costs of products for SNG or FT diesel based on 2019 or 2022 | |

| liters of diesel | |

| market prices of fossil natural gas or diesel in 2019 or 2022 | |

| annual quantity of the produced main product | |

| megawatt | |

| megawatt hours | |

| megawatt hours of thermal fuel power | |

| megawatt hours of synthetic natural gas | |

| plant lifetime | |

| petajoule per year | |

| scaling factor | |

| annual revenues of secondary products | |

| base scale | |

| desired scale | |

| overall installation factor | |

References

- European Union. The European Green Deal. 2019. Available online: https://commission.europa.eu/system/files/2019-12/european-green-deal-communication_de.pdf (accessed on 2 July 2023).

- Anderl, M.; Bartel, A.; Frei, E.; Gugele, B.; Gössl, M.; Mayer, S.; Heinfellner, H.; Heller, C.; Heuber, A.; Köther, T.; et al. Klimaschutzbericht 2022; Federal Environmental Agency: Vienna, Austria, 2022. Available online: https://www.umweltbundesamt.at/fileadmin/site/publikationen/rep0816.pdf (accessed on 2 July 2023).

- Kaltschmitt, M.; Hartmann, H.; Hofbauer, H. Energie aus Biomasse: Grundlagen, Techniken und Verfahren, 3rd ed.; Springer Vieweg: Berlin/Heidelberg, Germany, 2016. [Google Scholar] [CrossRef]

- Schmid, J.C.; Benedikt, F.; Fuchs, J.; Mauerhofer, A.M.; Müller, S.; Hofbauer, H. Syngas for biorefineries from thermochemical gasification of lignocellulosic fuels and residues—5 years’ experience with an advanced dual fluidized bed gasifier design. Biomass Convers. Biorefinery 2021, 11, 2405–2442. [Google Scholar] [CrossRef]

- Benedikt, F.; Schmid, J.C.; Fuchs, J.; Mauerhofer, A.M.; Müller, S.; Hofbauer, H. Fuel flexible gasification with an advanced 100 kW dual fluidized bed steam gasification pilot plant. Energy 2018, 164, 329–343. [Google Scholar] [CrossRef]

- Bartik, A.; Benedikt, F.; Fuchs, J.; Hofbauer, H.; Müller, S. Experimental investigation of hydrogen-intensified synthetic natural gas production via biomass gasification: A technical comparison of different production pathways. Biomass Convers. Biorefinery 2023. [Google Scholar] [CrossRef]

- Thunman, H.; Seemann, M.; Berdugo Vilches, T.; Maric, J.; Pallares, D.; Ström, H.; Berndes, G.; Knutsson, P.; Larsson, A.; Breitholtz, C.; et al. Advanced biofuel production via gasification—Lessons learned from 200 man-years of research activity with Chalmers’ research gasifier and the GoBiGas demonstration plant. Energy Sci. Eng. 2018, 6, 6–34. [Google Scholar] [CrossRef]

- Cleantech Cluster. Erstes Produkt der Fischer-Tropsch-Pilotanlage in Wien-Simmering kommt in Flottentest zum Einsatz. 2023. Available online: https://www.cleantech-cluster.at/partnerunternehmen-im-ctc/ctc-partnernews-umwelt/detail/news/erstes-produkt-der-fischer-tropsch-pilotanlage-in-wien-simmering-kommt-in-flottentest-zum-einsatz (accessed on 28 May 2023).

- Kadlez, D.; Benedikt, F.; Bartik, A.; Müller, S.; Hofbauer, H.; Karel, T.; Binder, M.; Huber, M.; Egger, A.; Hochstöger, D.; et al. First results of mass and energy balances of a 1 MW advanced dual fluidized bed steam gasification demonstration plant. In Proceedings of the Central European Biomass Conference, Graz, Austria, 18–20 January 2023. [Google Scholar]

- Kuba, M.; Karel, T.; Fürsatz, K.; Binder, M.; Hannl, T.; Huber, M.; Hochstöger, D.; Egger, A.; Weber, G.; Haslinger, W.; et al. Second generation biomass gasification: The Syngas Platform Vienna—Current status and outlook. In Proceedings of the Central European Biomass Conference, Graz, Austria, 18–20 January 2023. [Google Scholar]

- Hofbauer, H.; Mauerhofer, A.M.; Benedikt, F.; Hammerschmid, M.; Bartik, A.; Veress, M.; Haas, R.; Siebenhofer, M.; Resch, G. Reallabor zur Herstellung von Holzdiesel und Holzgas aus Biomasse und Biogenen Reststoffen für die Land- und Forstwirtschaft; TU Wien: Vienna, Austria, 2020; Available online: https://dafne.at/projekte/ftsng-reallabor (accessed on 2 July 2023).

- Fuchs, J.; Schmid, J.C.; Müller, S.; Hofbauer, H. Dual fluidized bed gasification of biomass with selective carbon dioxide removal and limestone as bed material: A review. Renew. Sustain. Energy Rev. 2019, 107, 212–231. [Google Scholar] [CrossRef]

- Schmid, M.; Beirow, M.; Schweitzer, D.; Waizmann, G.; Spörl, R.; Scheffknecht, G. Product gas composition for steam-oxygen fluidized bed gasification of dried sewage sludge, straw pellets and wood pellets and the influence of limestone as bed material. Biomass Bioenergy 2018, 117, 71–77. [Google Scholar] [CrossRef]

- Schmid, M.; Hafner, S.; Scheffknecht, G. Experimental Parameter Study on Synthesis Gas Production by Steam-Oxygen Fluidized Bed Gasification of Sewage Sludge. Appl. Sci. 2021, 11, 579. [Google Scholar] [CrossRef]

- Schweitzer, D.; Beirow, M.; Gredinger, A.; Armbrust, N.; Waizmann, G.; Dieter, H.; Scheffknecht, G. Pilot-Scale Demonstration of Oxy-SER steam Gasification: Production of Syngas with Pre-Combustion CO2 Capture. Energy Procedia 2016, 86, 56–68. [Google Scholar] [CrossRef]

- Karl, J.; Pröll, T. Steam gasification of biomass in dual fluidized bed gasifiers: A review. Renew. Sustain. Energy Rev. 2018, 98, 64–78. [Google Scholar] [CrossRef]

- Kuba, M.; Benedikt, F.; Fürsatz, K.; Fuchs, J.; Demuth, M.; Aichernig, C.; Arpa, L.; Hofbauer, H. Integration of dual fluidized bed steam gasification into the pulp and paper industry. Biomass Convers. Biorefinery 2021. [Google Scholar] [CrossRef]

- Loipersböck, J.; Weber, G.; Rauch, R.; Hofbauer, H. Developing an adsorption-based gas cleaning system for a dual fluidized bed gasification process. In Proceedings of the International Conference on Polygeneration Strategies, Vienna, Austria, 18–20 November 2019; Hofbauer, H., Müller, S., Eds.; TU Wien: Vienna, Austria, 2019. [Google Scholar] [CrossRef]

- Bardolf, R. Optimierung eines Produktgaswäschers bei der Biomassedampfvergasung im Zweibettwirbelschichtverfahren. Ph.D. Thesis, TU Wien, Vienna, Austria, 2017. [Google Scholar]

- Rehling, B. Development of the 1MW Bio-SNG Plant, Evaluation on Technological and Economical Aspects and Upscaling Considerations. Ph.D. Thesis, TU Wien, Vienna, Austria, 2012. [Google Scholar]

- Schildhauer, T.J.; Biollaz, S.M.A. Reactors for Catalytic Methanation in the Conversion of Biomass to Synthetic Natural Gas (SNG). Chimia 2015, 69, 603–607. [Google Scholar] [CrossRef] [PubMed]

- Seemann, M.C.; Schildhauer, T.J.; Biollaz, S.M.A. Fluidized Bed Methanation of Wood-Derived Producer Gas for the Production of Synthetic Natural Gas. Ind. Eng. Chem. Res. 2010, 49, 7034–7038. [Google Scholar] [CrossRef]

- Gruber, H. Synthesis and Refining of Biomass- Derived Fischer-Tropsch Paraffin Waxes. Ph.D. Thesis, TU Wien, Vienna, Austria, 2020. [Google Scholar]

- Sauciuc, A.; Abosteif, Z.; Weber, G.; Potetz, A.; Rauch, R.; Hofbauer, H.; Schaub, G.; Dumitrescu, L. Influence of operating conditions on the performance of biomass-based Fischer–Tropsch synthesis. Biomass Convers. Biorefinery 2012, 2, 253–263. [Google Scholar] [CrossRef]

- Guilera, J.; Díaz-López, J.A.; Berenguer, A.; Biset-Peiró, M.; Andreu, T. Fischer-Tropsch synthesis: Towards a highly-selective catalyst by lanthanide promotion under relevant CO2 syngas mixtures. Appl. Catal. A Gen. 2022, 629, 118423. [Google Scholar] [CrossRef]

- Müller, S.; Groß, P.; Rauch, R.; Zweiler, R.; Aichernig, C.; Fuchs, M.; Hofbauer, H. Production of diesel from biomass and wind power—Energy storage by the use of the Fischer-Tropsch process. Biomass Convers. Biorefinery 2018, 8, 275–282. [Google Scholar] [CrossRef]

- Rauch, R.; Hrbek, J.; Hofbauer, H. Biomass gasification for synthesis gas production and applications of the syngas. WIREs Energy Environ. 2014, 3, 343–362. [Google Scholar] [CrossRef]

- Thunman, H.; Gustavsson, C.; Larsson, A.; Gunnarsson, I.; Tengberg, F. Economic assessment of advanced biofuel production via gasification using cost data from the GoBiGas plant. Energy Sci. Eng. 2019, 7, 217–229. [Google Scholar] [CrossRef]

- Neuling, U.; Kaltschmitt, M. Techno-economic and environmental analysis of aviation biofuels. Fuel Process. Technol. 2018, 171, 54–69. [Google Scholar] [CrossRef]

- Jungmeier, G.; Canella, L.; Pucker-Singer, J.; Beermann, M. Geschätzte Treibhausgasemissionen und Primärenergieverbrauch in der Lebenszyklusanalyse von Pkw-basierten Verkehrssystemen; Joanneum Research Forschungsgesellschaft: Graz, Austria, 2019. [Google Scholar]

- Österreichische Vereinigung für das Gas- und Wasserfach. Richtlinie G B210—Gasbeschaffenheit: Gas Quality; Österreichische Vereinigung für das Gas- und Wasserfach: Vienna, Austria, 2021; Available online: https://shop.austrian-standards.at/action/de/public/details/697809/OEVGW_G_B210_2021_06 (accessed on 2 July 2023).

- DIN EN 15940; Kraftstoffe—Paraffinischer Dieselkraftstoff aus Synthese oder Hydrierungsverfahren—Anforderungen und Prüfverfahren. Beuth Verlag: Berlin, Germany, 2019. Available online: https://www.beuth.de/de/norm/din-en-15940/309170058 (accessed on 2 July 2023).

- Österreichischer Biomasseverband. Basidaten 2019 Bioenergie; Österreichischer Biomasseverband: Vienna, Austria, 2019; Available online: https://www.biomasseverband.at/wp-content/uploads/Basisdaten_Bioenergie_2019.pdf (accessed on 2 July 2023).

- Dißauer, C.; Rehling, B.; Strasser, C. Machbarkeitsuntersuchung Methan aus Biomasse; Bioenergy 2020+: Wieselburg, Austria, 2019; Available online: https://www.gruenes-gas.at/assets/Uploads/BioEenergy2020+_Machbarkeitsuntersuchung_Methan_aus_Biomasse.pdf (accessed on 2 July 2023).

- Hammerschmid, M.; Konrad, J.; Werner, A.; Popov, T.; Müller, S. ENECO2Calc—A Modeling Tool for the Investigation of Energy Transition Paths toward Climate Neutrality within Municipalities. Energies 2022, 15, 7162. [Google Scholar] [CrossRef]

- Kranzl, L. Bioenergy—A Key Option within all Energy Sectors. VO Economic Perspectives of Renewable Energy Systems; Energy Economics Group (EEG), TU Wien: Vienna, Austria, 2020. [Google Scholar]

- Kranzl, L.; Haas, R.; Kalt, G.; Diesenreiter, F.; Eltrop, L.; König, A.; Makkonen, P. Strategien zur Optimalen Erschließung der Biomassepotenziale in Österreich bis zum Jahr 2050 mit dem Ziel einer Maximalen Reduktion an Treibhausgasemissionen; Energy Economics Group (EEG), TU Wien: Vienna, Austria, 2008. [Google Scholar]

- Alamia, A.; Gardarsdòttir, Ò.S.; Larsson, A.; Normann, F.; Thunman, H. Efficiency Comparison of Large-Scale Standalone, Centralized, and Distributed Thermochemical Biorefineries. Energy Technol. 2017, 5, 1435–1448. [Google Scholar] [CrossRef]

- Förtsch, D.; Pabst, K.; Groß-Hardt, E. The product distribution in Fischer–Tropsch synthesis: An extension of the ASF model to describe common deviations. Chem. Eng. Sci. 2015, 138, 333–346. [Google Scholar] [CrossRef]

- Pratschner, S.; Hammerschmid, M.; Müller, F.J.; Müller, S.; Winter, F. Simulation of a Pilot Scale Power-to-Liquid Plant Producing Synthetic Fuel and Wax by Combining Fischer–Tropsch Synthesis and SOEC. Energies 2022, 15, 4134. [Google Scholar] [CrossRef]

- Hammerschmid, M.; Rosenfeld, D.C.; Bartik, A.; Benedikt, F.; Fuchs, J.; Müller, S. Methodology for the Development of Virtual Representations within the Process Development Framework of Energy Plants: From Digital Model to Digital Predictive Twin—A Review. Energies 2023, 16, 2641. [Google Scholar] [CrossRef]

- Konstantin, P. Praxisbuch Energiewirtschaft: Energieumwandlung, -Transport und -Beschaffung, Übertragungsnetzausbau und Kernenergieausstieg, 4th ed.; VDI-Buch; Springer Vieweg: Berlin/Heidelberg, Germany, 2017; ISBN 978-3-662-49823-1. [Google Scholar]

- Resch, G.; Kranzl, L.; Faninger, G.; Geipel, J. Block 1: Introduction: Energy & climate challenge and basics of economic assessment. In VO Economic Perspectives of Renewable Energy Systems; Energy Economics Group (EEG), TU Wien: Vienna, Austria, 2020. [Google Scholar]

- Kost, C.; Shammugam, S.; Jülch, V.; Nguyen, H.-T.; Schlegl, T. Stromgestehungskosten Erneuerbare Energien; Fraunhofer-Institut für solare Energiesysteme (ISE): Freiburg, Germany, 2018. [Google Scholar]

- Veress, M. Optimization of a Process Concept for the Industrial Production of Bio-SNG from Low-Grade Fuels. Master’s Thesis, TU Wien, Vienna, Austria, 2020. [Google Scholar]

- Peters, M.S.; Timmerhaus, K.D. Plant Design and Economics for Chemical Engineers, 4th ed.; McGraw-Hill Chemical Engineering Series; McGraw-Hill: New York, NY, USA, 1991; ISBN 0-07-049613-7. [Google Scholar]

- Wulf, C.; Kaltschmitt, M. Hydrogen Supply Chains for Mobility—Environmental and Economic Assessment. Sustainability 2018, 10, 1699. [Google Scholar] [CrossRef]

- Lichtblau, G.; Pölz, W.; Stix, S.; Winter, R. Ökobilanzen Ausgewählter Biotreibstoffe: Projekt proVISION; Umweltbundesamt Österreich: Vienna, Austria, 2012; Available online: https://www.umweltbundesamt.at/fileadmin/site/publikationen/rep0360.pdf (accessed on 2 July 2023).

- Federal Environmental Agency Austria. Berechnung von Treibhausgas (THG)-Emissionen verschiedener Energieträger; FEA: Vienna, Austria, 2022. Available online: https://secure.umweltbundesamt.at/co2mon/co2mon.html (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Prozessorientierte Basisdaten für Umweltmanagementsysteme; FEA Germany: Dessau-Roßlau, Germany, 2015. Available online: https://www.probas.umweltbundesamt.de/php/index.php (accessed on 2 July 2023).

- INAS GmbH, Version 4.94. Globales Emissions-Modell Integrierter Systeme (GEMIS). Internationales Institut für Nachhaltigkeitsanalysen und -Strategien: Freiburg, Germany, 2018.

- Gollner, M. Gesamtenergiebilanz Österreich 1970 bis 2021; Statistik Austria: Vienna, Austria, 2022; Available online: https://www.statistik.at/web_de/statistiken/energie_umwelt_innovation_mobilitaet/energie_und_umwelt/energie/energiebilanzen/index.html (accessed on 2 July 2023).

- Resch, G.; Burgholzer, B.; Totschnig, G.; Lettner, G.; Auer, H.; Geipel, J.; Haas, R. Stromzukunft Österreich 2030: Analyse der Erfordernisse und Konsequenzen eines Ambitionierten Ausbaus von Erneuerbaren Energien; Energy Economics Group (EEG), TU Wien: Vienna, Austria, 2017; Available online: https://www.igwindkraft.at/mmedia/download/2017.07.10/1499698755049626.pdf (accessed on 2 July 2023).

- Kranzl, L.; Müller, A.; Büchele, R. Wärmezukunft 2050: Anforderungen an die Gebäudesanierung: Endbericht; Energy Economics Group (EEG), TU Wien: Vienna, Austria, 2018; Available online: https://www.igwindkraft.at/mmedia/download/2018.02.05/1517825327514183.pdf (accessed on 2 July 2023).

- Baumann, M.; Fazeni-Fraisl, K.; Kienberger, T.; Nagovnak, P.; Pauritsch, G.; Rosenfeld, D.; Sejkora, C.; Tichler, R. Erneuerbares Gas in Österreich 2040: Quantitative Abschätzung von Nachfrage und Angebot; Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Vienna, Austria, 2021. Available online: https://www.bmk.gv.at/themen/energie/publikationen/erneuerbares-gas-2040.html (accessed on 2 July 2023).

- Terlouw, W.; Peters, D.; van Tilburg, J.; Schimmel, M.; Berg, T.; Cihlar, J.; Ur Rehman Mir, G.; Spöttle, M.; Staats, M.; Lejaretta, A.V.; et al. Gas for Climate: The Optimal Role for Gas in a Net-Zero Emissions Energy System; Navigant: Utrecht, The Netherlands, 2019; Available online: https://gasforclimate2050.eu/wp-content/uploads/2020/03/Navigant-Gas-for-Climate-The-optimal-role-for-gas-in-a-net-zero-emissions-energy-system-March-2019.pdf (accessed on 2 July 2023).

- Götz, M.; Lefebvre, J.; Mörs, F.; Koch, A.M.; Graf, F.; Bajohr, S.; Reimert, R.; Kolb, T. Renewable Power-to-Gas: A technological and economic review. Renew. Energy 2016, 85, 1371–1390. [Google Scholar] [CrossRef]

- Maniatis, K.; Landälv, I.; Waldheim, L.; van den Heuvel, E.; Kalligeros, S. Final Report—Building up the Future: Sub Group on Advanced Biofeuls—Sustainable Transport Forum; European Comission: Luxembourg, 2017; ISBN 978-92-79-69010-5. [Google Scholar]

- Pratschner, S.; Hammerschmid, M.; Müller, S.; Winter, F. Converting CO2 and H2O into Fischer-Tropsch Products—A Techno-economic assessment. In Proceedings of the 27th International Symposium for Chemical Reaction Engineering—ISCRE 27, Quebec City, QC, Canada, 11–14 June 2023. [Google Scholar]

- Jungmeier, G. Umweltbilanz von E-Fuels—Vergleich mit anderen Treibstoffen im Lebenszyklus. In Proceedings of the ÖGEW/DGMK Onlinekonferenz „Innovative Energieversorgung“, Graz, Austria, 13 November 2020; Available online: https://www.wko.at/site/oegew/veranstaltungen/umweltbilanz-von-e-fuels.pdf (accessed on 2 July 2023).

- Aichmayer, S.; Mitterhuemer, R.; Winter, R. Biokraftstoffe im Verkehrssektor 2021; Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Vienna, Austria, 2021; Available online: https://www.biokraft-austria.at/media/18119/biokraftstoffbericht_2021.pdf (accessed on 2 July 2023).

- Pratschner, S.; Hammerschmid, M.; Müller, S.; Winter, F. CO2 Footprint of Fischer-Tropsch Products produced by a Power-to-Liquid Plant. In Proceedings of the 15th Mediterranean Congress of Chemical Engineering—MECCE 2023, Barcelona, Spain, 30 May–2 June 2023. [Google Scholar]

- European Union. Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources, RED II. Off. J. Eur. Union 2018, L 328/82. Available online: https://eur-lex.europa.eu/legal-content/DE/TXT/?qid=1575559881403&uri=CELEX:32018L2001 (accessed on 12 May 2021).

- Bundesrepublik Österreich. Erneuerbaren-Ausbau-Gesetz, EAG. 2021. Available online: https://www.parlament.gv.at/PAKT/VHG/XXVII/I/I_00733/index.shtml (accessed on 12 August 2021).

- Ringhofer, T. Evaluierung des Biomassetrockners der Kraft-Wärme-Kopplungsanlage Oberwart. Bachelor’s Thesis, TU Wien, Vienna, Austria, 2011. [Google Scholar]

- Müller, S. Hydrogen from Biomass for Industry—Industrial Application of Hydrogen Production Based on Dual Fluid Gasification. Ph.D. Thesis, TU Wien, Vienna, Austria, 2013. [Google Scholar]

- Benedikt, F.; Fuchs, J.; Schmid, J.C.; Müller, S.; Hofbauer, H. Advanced dual fluidized bed steam gasification of wood and lignite with calcite as bed material. Korean J. Chem. Eng. 2017, 34, 2548–2558. [Google Scholar] [CrossRef]

- Benedikt, F.; Müller, S.; Hofbauer, H. 1 MW scale-up of the advanced fuel flexible dual fluidized bed steam gasification process by process simulation. In Proceedings of the ICPS19—International Conference on Polygeneration Strategies, Vienna, Austria, 18–20 November 2019; ISBN 978-3-9503671-1-9. [Google Scholar]

- Wolfesberger, U. Profiling Tar Behavior in Dual Fluidized Bed Biomass Steam Gasification. Ph.D. Thesis, TU Wien, Vienna, Austria, 2013. [Google Scholar]

- Hofbauer, H.; Rauch, R.; Bosch, K.; Koch, R.; Aichernig, C. Biomass CHP plant Güssing—A success story. In Proceedings of the Pyrolysis and Gasification of Biomass and Waste—Expert Meeting, Strasbourg, France, 30 September–1 October 2002. [Google Scholar]

- Pröll, T.; Siefert, I.G.; Friedl, A.; Hofbauer, H. Removal of NH3 from Biomass Gasification Producer Gas by Water Condensing in an Organic Solvent Scrubber. Ind. Eng. Chem. Res. 2005, 44, 1576–1584. [Google Scholar] [CrossRef]

- Stidl, M. Prozesssimulation von spezifischen Anwendungsfällen der Zweibett-Wirbelschicht-Dampfvergasungs-Technologie für die Papier- und Zellstoffindustrie. Ph.D. Thesis, TU Wien, Vienna, Austria, 2012. [Google Scholar]

- Sadegh, A.M.; Worek, W.M. Marks’ Standard Handbook for Mechanical Engineers, 12th ed.; McGraw-Hill Education: New York, NY, USA, 2018; ISBN 9781259588518. [Google Scholar]

- Broer, K.M.; Woolcock, P.J.; Johnston, P.A.; Brown, R.C. Steam/oxygen gasification system for the production of clean syngas from switchgrass. Fuel 2015, 140, 282–292. [Google Scholar] [CrossRef]

- Bartik, A.; Fuchs, J.; Pacholik, G.; Föttinger, K.; Hofbauer, H.; Müller, S.; Benedikt, F. Experimental investiga-tion on the methanation of hydrogen-rich syngas in a bubbling fluidized bed reactor utilizing an optimized catalyst. Fuel Process. Technol. 2022, 237, 107402. [Google Scholar] [CrossRef]

- Li, K.; Leigh, W.; Feron, P.; Yu, H.; Tade, M. Systematic study of aqueous monoethanolamine (MEA)-based CO2 capture process: Techno-economic assessment of the MEA process and its improvements. Appl. Energy 2016, 165, 648–659. [Google Scholar] [CrossRef]

- Günther, L. Biomethanreinigung mit der Drucklosen Wäsche zur Herstellung von Biomethan und Kohlendioxid. Fachtagung “Innogas”; DGE GmbH Presentation: Wittenberg, Germany, 2007; Available online: https://www.dge-wittenberg.de/vortraege/DGE%20Fachtagung%20WB%202006.pdf (accessed on 2 July 2023).

- Neagu, M.; Cursaru, D.L. Technical and economic evaluations of the triethylene glycol regeneration processes in natural gas dehydration plants. J. Nat. Gas Sci. Eng. 2017, 37, 327–340. [Google Scholar] [CrossRef]

- Kidnay, A.J.; Parrish, W.R.; McCartney, D.G. Fundamentals of Natural Gas Processing; CRC Press: Boca Raton, FL, USA, 2019; ISBN 9780429464942. [Google Scholar]

- Gruber, H.; Groß, P.; Rauch, R.; Reichhold, A.; Zweiler, R.; Aichernig, C.; Müller, S.; Ataimisch, N.; Hofbauer, H. Fischer-Tropsch products from biomass-derived syngas and renewable hydrogen. Biomass Convers. Biorefinery 2019, 48, 22. [Google Scholar] [CrossRef]

- De Klerk, A. Fischer-Tropsch Refining; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; ISBN 9783527635603. [Google Scholar]

- Schädel, B.T.; Duisberg, M.; Deutschmann, O. Steam reforming of methane, ethane, propane, butane, and natural gas over a rhodium-based catalyst. Catal. Today 2009, 142, 42–51. [Google Scholar] [CrossRef]

- Ali, S.; Sørensen, K.; Nielsen, M.P. Modeling a novel combined solid oxide electrolysis cell (SOEC)—Biomass gasification renewable methanol production system. Renew. Energy 2020, 154, 1025–1034. [Google Scholar] [CrossRef]

- Clariant International Ltd. Catalysts and Adsorbents for Syngas; Clariant International Ltd.: Muttenz, Switzerland, 2017; Available online: https://de.scribd.com/document/477562978/Clariant-Brochure-Catalysts-And-Adsorbents-For-Syngas-2017-EN-1 (accessed on 2 July 2023).

- Petersen, A.M.; Chireshe, F.; Okoro, O.; Gorgens, J.; van Dyk, J. Evaluating refinery configurations for deriving sustainable aviation fuel from ethanol or syncrude. Fuel Process. Technol. 2021, 219, 106879. [Google Scholar] [CrossRef]

- Fahim, M.A. Fundamentals of Petroleum Refining; Elsevier Science & Technology: Oxford, UK, 2010; ISBN 978-0-444-52785-1. [Google Scholar]

- De Klerk, A. Can Fischer–Tropsch Syncrude Be Refined to On-Specification Diesel Fuel? Energy Fuels 2009, 23, 4593–4604. [Google Scholar] [CrossRef]

- Kang, J.; Ma, W.; Keogh, R.A.; Shafer, W.D.; Jacobs, G.; Davis, B.H. Hydrocracking and Hydroisomerization of n-Hexadecane, n-Octacosane and Fischer–Tropsch Wax Over a Pt/SiO2–Al2O3 Catalyst. Catal. Lett. 2012, 142, 1295–1305. [Google Scholar] [CrossRef]

- Murali, C.; Voolapalli, R.K.; Ravichander, N.; Gokak, D.T.; Choudary, N.V. Trickle bed reactor model to simulate the performance of commercial diesel hydrotreating unit. Fuel 2007, 86, 1176–1184. [Google Scholar] [CrossRef]

- Busca, G. Heterogeneous Catalytic Materials; Elsevier: Amsterdam, The Netherlands, 2014; ISBN 978-0-444-59524-9. [Google Scholar]

- Mauerhofer, A.M.; Schmid, J.C.; Benedikt, F.; Fuchs, J.; Müller, S.; Hofbauer, H. Dual fluidized bed steam gasification: Change of product gas quality along the reactor height. Energy 2019, 173, 1256–1272. [Google Scholar] [CrossRef]

- Schmid, J.C. Technoökonomische Fallstudien als Entscheidungsunterstützung für das Strategische Management. Master’s Thesis, Fachhochschule Burgenland, Eisenstadt, Austria, 2016. [Google Scholar]

- E-Control. Gaspreisentwicklung; E-Control: Vienna, Austria, 2022; Available online: https://www.e-control.at/statistik/gas/marktstatistik/preisentwicklung (accessed on 10 August 2022).

- E-Control. Strom- und Gaspreise in Österreich; E-Control: Vienna, Austria, 2022; Available online: https://www.e-control.at/preismonitor (accessed on 10 August 2022).

- Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie. Treibstoffpreise aktuell. Bundesministerium für Klimaschutz, Umwelt, Energie, Mobilität, Innovation und Technologie: Vienna, Austria, 2022. Available online: https://www.bmk.gv.at/themen/energie/preise/aktuelle_preise.html (accessed on 15 October 2022).

- Deutsche Börse; Diesel: Frankfurt, Germany, 2022; Available online: https://www.boerse.de/charts/Dieselpreis/XC0009677813 (accessed on 15 October 2022).

- Statistik Austria. Erzeugerpreisindex Produzierender Bereich—Österreich. Vienna, Austria; 2022. Available online: https://www.statistik.at/statistiken/volkswirtschaft-und-oeffentliche-finanzen/preise-und-preisindizes/erzeugerpreisindex-produzierender-bereich (accessed on 10 August 2022).

- Meehan, J. Europe Monoethanolamine Prices Move Down on Import Pressure. 2013. Available online: https://www.icis.com/explore/resources/news/2013/06/19/9680122/europe-monoethanolamine-prices-move-down-on-import-pressure/ (accessed on 13 December 2019).

- Billig, E. DBFZ Report Nr. 26. Ph.D. Thesis, Universität Leipzig, Helmholtz-Zentrum für Umweltforschung, Leipzig, Germany, 2016. [Google Scholar]

- Thrän, D.; Pfeiffer, D. Methodenhandbuch: Stoffstromorientierte Bilanzierung der Klimagaseffekte. Energetische Biomassenutzung 2013, 2013, 4. [Google Scholar]

- European Energy Exchange AG (EEX). EEX EUA Spot Market—CO2 Emission Allowances; EEX: Leipzig, Germany, 2022; Available online: https://www.eex.com/de/marktdaten/umweltprodukte/spot (accessed on 15 October 2022).

- E-Control. Strompreisentwicklung; E-Control: Vienna, Austria, 2022; Available online: https://www.e-control.at/statistik/strom/marktstatistik/preisentwicklung (accessed on 10 August 2022).

- Godula-Jopek, A.; Stolten, D. Hydrogen Production: By Electrolysis, 1st ed.; Wiley-VCH: Weinheim, Germany, 2015; ISBN 9783527676507. [Google Scholar]

- Goritschnig, M.; Kreuter, K.; Novakovits, P.; Pomper, M.; Zweiler, R. Winddiesel_klienIF: Untersuchung des Lastwechselverhaltens eines Slurryreaktors zur Einkopplung von H2 und Produktion von FT-Diesel. Güssing Energy Technologies. 2017. Available online: https://www.winddiesel.at/images/Downloads/13003-BB008a_Winddiesel_kurzfassung.pdf (accessed on 15 October 2022).

- Perry, R.H.; Green, D.W.; Maloney, J.O. Perry’s Chemical Engineers’ Handbook, 7th ed.; McGraw-Hill: New York, NY, USA, 1997; ISBN 0070498415. [Google Scholar]

- Batidzirai, B.; Shotman, G.S.; van der Spek, M.W.; Junginger, M.; Faaij, A.P.C. Techno-economic performance of sustainable international bio-SNG production and supply chains on short and longer term. Biofuels Bioprod. Biorefining 2019, 13, 325–357. [Google Scholar] [CrossRef]

- Brasington, R.D.; Haslbeck, J.L.; Kuehn, N.J.; Lewis, E.G.; Pinkerton, L.L.; Turner, M.; Varghese, E.; Woods, M. Cost and Performance Baseline for Fossil Energy Plants: Volume 2, Coal to Synthetic Natural Gas and Ammonia; DOE/NETL-2010/1402; Report for the U.S. Department of Energy; National Energy Technology Laboratory by the Research and Development Solutions, LLC (RDS): Morgantown, WV, USA, 2011.

- Heyne, S.; Harvey, S. Impact of choice of CO2 separation technology on thermo-economic performance of Bio-SNG production processes. Int. J. Energy Res. 2014, 38, 299–318. [Google Scholar] [CrossRef]

- Arvidsson, M.; Morandin, M.; Harvey, S. Biomass gasification-based syngas production for a conventional oxo synthesis plant—Greenhouse gas emission balances and economic evaluation. J. Clean. Prod. 2015, 99, 192–205. [Google Scholar] [CrossRef]

- Holmgren, K.M. Investment Cost Estimates for Gasification- Based Biofuel Production Systems; IVL Swedish Environmental Research Institute: Stockholm, Sweden, 2015; Available online: https://www.ivl.se/download/18.694ca0617a1de98f472a45/1628413810159/FULLTEXT01.pdf (accessed on 2 July 2023).

- Federal Environmental Agency Germany. ProBas—Xtra-AbbauQuarzsand-DE-2030; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7b843DA94D-BDA7-442E-A9A3-B80D8B40E66F%7d (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—LKW oder Lastzug; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2010. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7b539F70D8-E544-FE35-BBCA-700578003269%7d (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—BioRaff-IIRME-DE-2020/brutto; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2011. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={35FD7B45-BBDF-4D1B-BEE6-7EEAA29BFDAE} (accessed on 20 March 2023).

- Jekel, M.; Baur, N.; Böckelmann, U.; Dünnbier, U.; Eckhardt, A.; Gnirß, R.; Grummt, T.; Hummelt, D.; Lucke, T.; Meinel, F.; et al. Anthropogene Spurenstoffe und Krankheitserreger im Urbanen Wasserkreislauf; Universitätsverlag der TU Berlin: Berlin, Germany, 2016; ISBN 978-3-7983-2815-0. [Google Scholar]

- Federal Environmental Agency Germany. ProBas—Zink; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7b50476E3A-C90A-4AE4-A1FB-3BC08579E219%7d (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—MetallNickel-DE-2020; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7b65C51F09-9F88-4D3C-8858-CFBCACF98D53%7d (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—AufbereitungTonerde-DE-2020; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2010. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={9DFA17E4-264F-459F-90D0-8EDF677F1BC0} (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Kobalt; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={81A717DC-DA5B-4EDC-A754-03331A829E4F} (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—EdelmetallPt-primär-mix-Welt; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={0E0B2A95-9043-11D3-B2C8-0080C8941B49} (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Quarz, Quarzite; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={9E9C7D4E-6240-4BF8-823A-D80C0F0C257B} (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Trimethylamin; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7bCC66D615-2F74-4C6C-8EDA-74119209C218%7d (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Chem-OrgPEG+DPM (Hochrein); Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2011. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id=%7b150EFBAB-DBA6-4752-BF86-FB34F95A1B3C%7d (accessed on 20 March 2023).

- NREL. H2A: Hydrogen Analysis Production Models: Case Studies 2018; National Renewable Energy Laboratory: Denver, CO, USA, 2018. Available online: https://www.nrel.gov/hydrogen/h2a-production-models.html (accessed on 28 June 2021).

- Federal Environmental Agency Germany. ProBas—MetallStahl-Profile-85%Recycling-Welt-2005; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2012. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={E0B82461-4166-4CFB-9F80-3EDFBF6B858C} (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Stahl; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2008. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={19E7D6CB-2337-4ED1-A096-3DF3961DDA87} (accessed on 20 March 2023).

- Federal Environmental Agency Germany. ProBas—Beton; Federal Environmental Agency Germany: Dessau-Roßlau, Germany, 2012. Available online: https://www.probas.umweltbundesamt.de/php/prozessdetails.php?id={707E23CA-304F-485C-83A6-90C0A0F1BAA6} (accessed on 20 March 2023).

- Wirtschaftskammer Österreich. Statistisches Jahrbuch 2023; Wirtschaftskammer Österreich: Vienna, Austria, 2023; Available online: https://www.wko.at/service/zahlen-daten-fakten/statistisches-jahrbuch.html (accessed on 2 July 2023).

- Gollner, M. Nutzenergieanalyse 1993–2021; Statistik Austria: Vienna, Austria, 2022; Available online: https://www.statistik.at/statistiken/energie-und-umwelt/energie/nutzenergieanalyse (accessed on 2 July 2023).

- Turner, J.; Winkler, G.; Swoboda, G. Statistiken Sonderheft: Einkommen, Konsum und Vermögen der Haushalte—Sektorale Volkswirtschaftliche Gesamtrechnungen in den Letzten 20 Jahren; Oesterreichische Nationalbank: Vienna, Austria, 2022. Available online: https://www.oenb.at/Publikationen/Statistik/Statistiken-Sonderhefte/2022/sektorale-vgr.html (accessed on 2 July 2023).

- Fichtinger, M.; Grohall, G.; Helmenstein, C.; Schitnig, H.; Sengschmid, E.; Zalesak, M. Die volkswirtschaftliche Bedeutung des österreichischen Logistiksektors: Studie im Auftrag der Wirtschaftskammer Österreich—Sparte Transport und Verkehr, der Vereinigung der Österreichischen Industrie und des Zentralverbandes Spedition & Logistik; Economica GmbH: Vienna, Austria, 2022; Available online: https://news.wko.at/news/oesterreich/221115-Logistik-Studienbericht-EconomicaG.pdf (accessed on 2 July 2023).

| Property Classes and Components | Additional Technical Biomass Potential 2050 (Study Dißauer et al. [34]) | Additional Technical Biomass Potential 2050 (Study Biomass Association [33]) | Additional Technical Biomass Potential 2050 Scenario “High” and “Biomasse Max” (Study Kranzl et al. [37]) | Additional Reduced Technical Biomass Potential 2050 (Present Study) |

|---|---|---|---|---|

| Woody biomass | 126 PJ/a | 50 PJ/a | 110 PJ/a | 75 PJ/a |

| Agricultural raw materials and residues | 126 PJ/a | 200 PJ/a | 100 PJ/a | 80 PJ/a |

| Other biogenic residues and waste | 67 PJ/a | 50 PJ/a | 10 PJ/a | 30 PJ/a |

| Plant Input | Plant Output | ||||

|---|---|---|---|---|---|

| Input Stream | Unit | Value | Output Stream | Unit | Value |

| Biomass (wood) | kg/h | 33,250 | Synthetic natural gas | Nm3/h | 6840 |

| kWbefore drying | 94,360 | kW | 64,960 | ||

| kWafter drying | 100,000 | District heat | kW | 14,170 | |

| Fresh bed material (80% olivine and 20% limestone) | kg/h | 150 | Captured CO2 for storage or utilization | Nm3/h | 6150 |

| Fresh scrubber solvent (rapeseed methyl ester) | kg/h | 110 | Ash and dust | kg/h | 350 |

| Fresh amine (monoethanolamine) | kg/h | 18.4 | Waste water | kg/h | 320 |

| Fresh glycol | kg/h | 0.1 | |||

| Electricity | kW | 4340 | |||

| Plant Input | Plant Output | ||||

|---|---|---|---|---|---|

| Input Stream | Unit | Value | Output Stream | Unit | Value |

| Biomass (wood) | kg/h | 33,250 | FT diesel | L/h | 3850 |

| kWbefore drying | 94,360 | kW | 36,563 | ||

| kWafter drying | 100,000 | FT naphtha | L/h | 2000 | |

| Fresh bed material (80% olivine and 20% limestone) | kg/h | 150 | kW | 17,561 | |

| Fresh scrubber solvent (rapeseed methyl ester) | kg/h | 110 | District heat | kW | 22,823 |

| Fresh amine (monoethanolamine) | kg/h | 11.5 | Captured CO2 for storage or utilization | Nm3/h | 3790 |

| Hydrogen (for hydrocracking and hydrotreating) | kg/h | 26.3 | Ash and dust | kg/h | 350 |

| Electricity | kW | 6120 | Waste water | kg/h | 2635 |

| Implementation Scenarios | Natural Gas or Diesel Demand in 2050 | Substituted Natural Gas or Diesel Demand in 2050 | Additionally Produced by-Products | Sectoral CO2 Reduction Potential | Economic Competitiveness (Change of Sectoral GVA) | Possible Renewable Alternatives | |

|---|---|---|---|---|---|---|---|

| 2019 | 2022 | ||||||

| SNG use in energy sector | 110 PJ/a 1 | 110 PJ/a | 24 PJ/a district heat | 89.1% | −12.4% | −0.5% | Peak-load power coverage

|

| SNG use in private and public sector (without mobility) | 85 PJ/a 1 | 85 PJ/a | 18.5 PJ/a district heat | 70.6% | 0% | 8.6% | Provision of decentral heat

|

| SNG use in industry | 128 PJ/a 1 | 120 PJ/a | 26.2 PJ/a district heat | 30.3% | −2.0% | −0.1% |

|

| FT diesel in private and public transport | 61.5 PJ/a 2 | 61.5 PJ/a | 38.4 PJ/a district heatand 29.6 PJ/a FT naphtha | 40.2% | −0.2% | 0.2% | Alternative mobility options

|

| FT diesel in heavy-duty traffic | 119 PJ/a 2 | 67.5 PJ/a | 42.2 PJ/a district heatand 32.5 PJ/a FT naphtha | 58.5% | −1.8% | −0.8% | Alternative mobility options

|

| FT diesel in heat and power | 9 PJ/a 3 | 9 PJ/a | 5.5 PJ/a district heat and4.2 PJ/a FT naphtha | 2.6% | −0.1% | −0.1% | Provision of high-temperature heat

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hammerschmid, M.; Bartik, A.; Benedikt, F.; Veress, M.; Pratschner, S.; Müller, S.; Hofbauer, H. Economic and Ecological Impacts on the Integration of Biomass-Based SNG and FT Diesel in the Austrian Energy System. Energies 2023, 16, 6097. https://doi.org/10.3390/en16166097

Hammerschmid M, Bartik A, Benedikt F, Veress M, Pratschner S, Müller S, Hofbauer H. Economic and Ecological Impacts on the Integration of Biomass-Based SNG and FT Diesel in the Austrian Energy System. Energies. 2023; 16(16):6097. https://doi.org/10.3390/en16166097

Chicago/Turabian StyleHammerschmid, Martin, Alexander Bartik, Florian Benedikt, Marton Veress, Simon Pratschner, Stefan Müller, and Hermann Hofbauer. 2023. "Economic and Ecological Impacts on the Integration of Biomass-Based SNG and FT Diesel in the Austrian Energy System" Energies 16, no. 16: 6097. https://doi.org/10.3390/en16166097

APA StyleHammerschmid, M., Bartik, A., Benedikt, F., Veress, M., Pratschner, S., Müller, S., & Hofbauer, H. (2023). Economic and Ecological Impacts on the Integration of Biomass-Based SNG and FT Diesel in the Austrian Energy System. Energies, 16(16), 6097. https://doi.org/10.3390/en16166097