Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions

Abstract

1. Introduction

2. Component Specifications and Operation

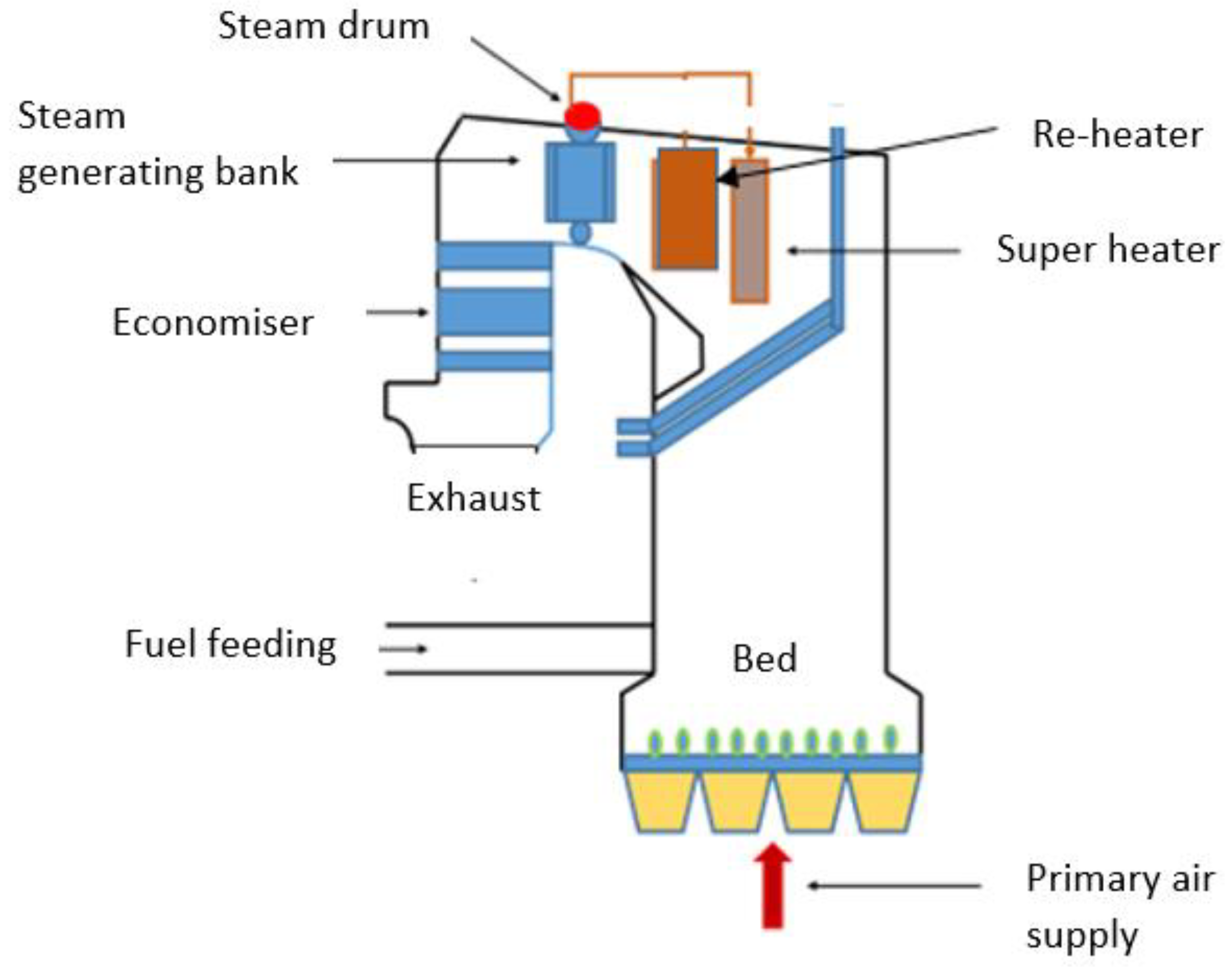

2.1. Fluidized Bed Combustion (FBC) System

2.2. VAR System

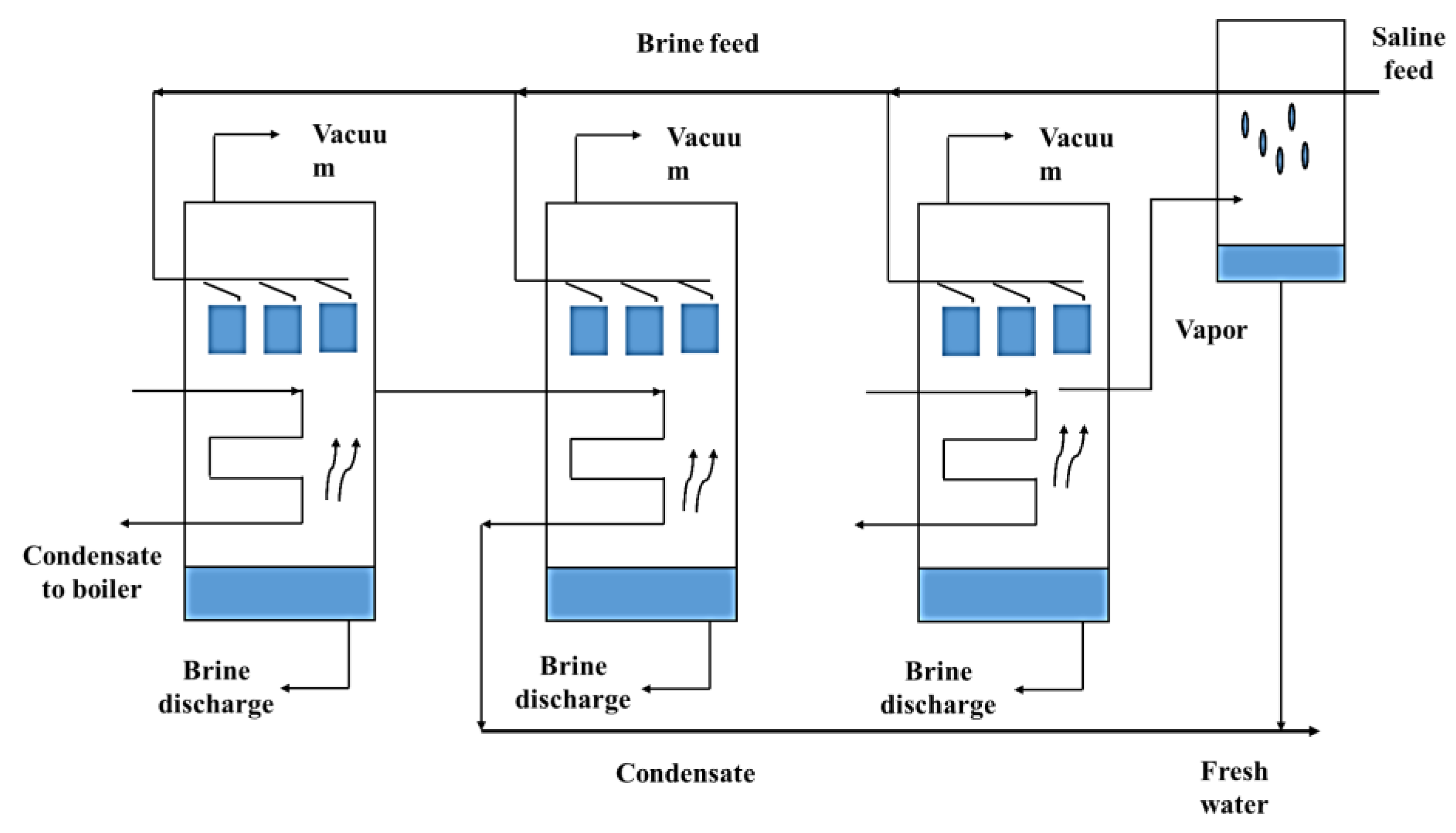

2.3. MED System

3. Methods and Criteria

3.1. Energy and Exergy Analysis

- FBC operation at different pressures

- VAR for single effect and double effect

- MED for 3 stage and 5 stage

3.2. Operation of MSW Boiler

3.3. MSW Generation Rate and Its Components

3.4. Variants within the Three Models

- Variant A: Single effect VAR+3 effect MED

- Variant B: Single effect VAR + 5 effect MED

- Variant C: Double effect VAR + 3 effect MED

- Variant D: Double effect VAR + 5 effect MED

4. Results and Discussion

Different Climate Zones-Implementation Case Study of the Models

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Khourchid, A.M.; Al-Ansari, T.A.; Al-Ghamdi, S.G. Cooling Energy and Climate Change Nexus in Arid Climate and the Role of Energy Transition. Buildings 2023, 13, 836. [Google Scholar] [CrossRef]

- Rambo, K.A.; Warsinger, D.M.; Shanbhogue, S.J.; Ghoniem, A.F. Water-energy nexus in Saudi Arabia. Energy Procedia 2017, 105, 3837–3843. [Google Scholar] [CrossRef]

- Albaik, I.; Al-Dadah, R.; Mahmoud, S.; Almesfer, M.K.; Ismail, M.A.; Elsayed, E.; Saleh, M. A comparison between the packed and coated finned tube for adsorption system using aluminium fumarate: Numerical study. Therm. Sci. Eng. Prog. 2021, 22, 100859. [Google Scholar] [CrossRef]

- Dajnak, D.; Lockwood, F. Use of thermal energy from waste for seawater desalination. Desalination 2000, 130, 137–146. [Google Scholar] [CrossRef]

- Udomsri, S.; Martin, A.R.; Martin, V. Thermally driven cooling coupled with municipal solid waste-fired power plant: Application of combined heat, cooling and power in tropical urban areas. Appl. Energy 2011, 88, 1532–1542. [Google Scholar] [CrossRef]

- Shao, Y.; Wang, J.; Preto, F.; Zhu, J.; Xu, C. Ash Deposition in Biomass Combustion or Co-Firing for Power/Heat Generation. Energies 2012, 5, 5171–5189. [Google Scholar] [CrossRef]

- Bolhàr-Nordenkampf, M.; Nummelin, T.; Luomaharju, T.; Viljanen, J. Operating Experience from the Worlds Largest Waste Fired Circulating Fluidized Bed Reactor in Västerås. Waste Manag. 2015, 5, 168–178. [Google Scholar]

- Fitzgerald, G. Pre-processing and treatment of municipal solid waste (MSW) prior to incineration. In Waste to Energy Conversion Technology; Elsevier: Amsterdam, The Netherlands, 2013; pp. 55–71. [Google Scholar]

- Available online: https://www.veoliawatertechnologies.com/en/technologies/multiple-effect-distillation-med (accessed on 10 June 2023).

- Nubi, O.; Morse, S.; Murphy, R.J. Prospective Life Cycle Costing of Electricity Generation from Municipal Solid Waste in Nigeria. Sustainability 2022, 14, 13293. [Google Scholar] [CrossRef]

- Tozlu, A.; Abusoglu, A.; Ozahi, E.; Anvari-Moghaddam, A. Municipal solid waste-based district heating and electricity production: A case study. J. Clean. Prod. 2021, 297, 126495. [Google Scholar] [CrossRef]

- Fabricius, M.; Tarp, D.; Rasmussen, T.W.; Arabkoohsar, A. Utilization of Excess Production of Waste-Fired CHP Plants for District Cooling Supply, an Effective Solution for a Serious Challenge. Energies 2020, 13, 3319. [Google Scholar] [CrossRef]

- Köppen, W.; Geiger, R. Handbuch der Klimatologie; Gebrüder Borntraeger: Berlin, Germany, 1930; Volume 1. [Google Scholar]

- Leckner, B.; Lind, F. Combustion of municipal solid waste in fluidized bed or on grate—A comparison. Waste Manag. 2020, 109, 94–108. [Google Scholar] [CrossRef] [PubMed]

- AlRwashdeh, S.S.; Ammari, H. Life cycle cost analysis of two different refrigeration systems powered by solar energy. Case Stud. Therm. Eng. 2019, 16, 100559. [Google Scholar] [CrossRef]

- Chen, H. Forward Osmosis of Water Across Ionic Membranes for Desalination; University of Delaware: Newark, DE, USA, 2020. [Google Scholar]

- Available online: https://www.epa.gov/sites/default/files/2015_07/documents/catalog_of_chp_technologies_section_4._technology_characterization_-_steam_turbines.pdf (accessed on 10 June 2023).

- Najjar, Y.S.H.; Abu-Shamleh, A. Performance evaluation of a large-scale thermal power plant based on the best industrial practices. Sci. Rep. 2020, 10, 20661. [Google Scholar] [CrossRef] [PubMed]

- Alqahtani, F.K.; Alswailem, Y.K.; Alshabragi, A.M.; Sherif, M.A. Smart Planning of Waste Management System in Saudi Arabia; Challenges and Opportunities. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2022. [Google Scholar]

- Ibikunle, R.; Titiladunayo, I.; Akinnuli, B.; Dahunsi, S.; Olayanju, T. Estimation of power generation from municipal solid wastes: A case Study of Ilorin metropolis, Nigeria. Energy Rep. 2019, 5, 126–135. [Google Scholar] [CrossRef]

- D5231-92; Standard Test Method for Determination of the Composition of Unprocessed Municipal Solid Waste. ASTM: West Conshohocken, PA, USA, 2016.

- Ouda, O.K.M. Assessment of the Environmental Values of Waste-to-Energy in the Gaza Strip. Curr. World Environ. J. 2013, 8, 355–364. [Google Scholar] [CrossRef]

- Islam, K.M.N. Municipal Solid Waste to Energy Generation in Bangladesh: Possible Scenarios to Generate Renewable Electricity in Dhaka and Chittagong City. J. Renew. Energy 2016, 2016, 1712370. [Google Scholar] [CrossRef]

- Konwar, D.; Gogoi, T. Performance of double effect H2O–LiCl absorption refrigeration systems and comparison with H2O–LiBr systems, Part 1: Energy analysis. Therm. Sci. Eng. Prog. 2018, 8, 184–203. [Google Scholar] [CrossRef]

- Ameri, M.; Mohammadi, S.S.; Hosseini, M.; Seifi, M. Effect of design parameters on multi-effect desalinationsystem specifications. Desalination 2009, 245, 266–283. [Google Scholar] [CrossRef]

- Ortega-Delgado, B.; García-Rodríguez, L.; Alarcón-Padilla, D.-C. Opportunities of improvement of the MED seawater desalination process by pretreatments allowing high-temperature operation. Desalination Water Treat. 2017, 97, 94–108. [Google Scholar] [CrossRef]

- Available online: https://www.argaam.com/en/article/articledetail/id/1611319 (accessed on 10 June 2023).

- Navarro, R.; Lizaso, J.L.S.; Sola, I. Assessment of Energy Consumption of Brine Discharge from SWRO Plants. Water 2023, 15, 786. [Google Scholar] [CrossRef]

- Available online: https://www.stats.gov.sa/sites/default/files/Electrical%20Energy%20Statistics%202020EN_0.pdf (accessed on 10 June 2023).

- Amaripadath, D.; Velickovic, M.; Attia, S. Performance Evaluation of a Nearly Zero-Energy Office Building in Temperate Oceanic Climate Based on Field Measurements. Energies 2022, 15, 6755. [Google Scholar] [CrossRef]

- Ghaffour, N.; Missimer, T.M.; Amy, G.L. Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination 2013, 309, 197–207. [Google Scholar] [CrossRef]

- Karmakar, A.; Daftari, T.; Sivagami, K.; Chandan, M.R.; Shaik, A.H.; Kiran, B.; Chakraborty, S. A comprehensive insight into Waste to Energy conversion strategies in India and its associated air pollution hazard. Environ. Technol. Innov. 2023, 29, 103017. [Google Scholar] [CrossRef]

- Aldhafeeri, Z.M.; Alhazmi, H. Sustainability Assessment of Municipal Solid Waste in Riyadh, Saudi Arabia, in the Framework of Circular Economy Transition. Sustainability 2022, 14, 5093. [Google Scholar] [CrossRef]

- Shahzad, M.W.; Burhan, M.; Ghaffour, N.; Ng, K.C. A multi evaporator desalination system operated with thermocline energy for future sustainability. Desalination 2018, 435, 268–277. [Google Scholar] [CrossRef]

| Model 1 | Model 2 | Model 3 | |

|---|---|---|---|

| Energy | |||

| Boiler | |||

| Turbine | |||

| VAR | |||

| MED | |||

| OFWH | - | ||

| Pump | + | ||

| Exergy | |||

| Boiler | |||

| Turbine | |||

| VAR | |||

| MED | |||

| OFWH | - | ||

| Pump | |||

| Components | LHV kWh/kg | % | LHV per kg | Contents of the Components |

|---|---|---|---|---|

| Paper | 3.75 | 28.5 | 1.03 | Wasted Papers, cardboard, box board, bags, magazines, tissue, newspapers, tissues |

| Plastic | 9.72 | 5.2 | 0.60 | Disposable glass, spoons, plates, wrapping films, wrapping film, plastic bottles, polythene |

| Glass | 0.00 | 4.6 | 0.00 | Bottles, glassware, bulbs, ceramics, etc. |

| Wood | 4.72 | 8 | 0.38 | Bottles, glassware, bulbs, ceramics, etc. |

| Textiles | 5.23 | 6.4 | 0.39 | Clothes, diapers, etc. |

| Organics | 1.55 | 37 | 0.56 | Food stuff, fruits and vegetable refuse, peel, etc. |

| Others | 3.36 | 10.3 | 0.35 | Leathers, rubber, fibers, rubber, yard waste, soils, tire, appliances, electronics |

| State Points | T (°C) | P (kPa) | x (%) | H (kJ/kg) | m (kg/s) | Exergy (kJ/kg) |

|---|---|---|---|---|---|---|

| (a) Model 1 | ||||||

| 1 | 250 | 1200 | 100 | 2936 | 422 | 903.7 |

| 2 | 120 | 190 | 100 | 2707 | 211 | 579.4 |

| 3 | 90 | 70.18 | 0.99 | 2659 | 211 | 434.6 |

| 4 | 118.6 | 190 | 0 | 497.9 | 211 | 51.39 |

| 5 | 90 | 70.18 | 0 | 377 | 211 | 25.95 |

| 6 | 90.01 | 190 | 0 | 377.2 | 211 | 26.07 |

| 7 | 104.3 | 190 | 0 | 437.5 | 422 | 37.83 |

| 8 | 104.5 | 1200 | 0 | 438.8 | 422 | 38.92 |

| (b) Model 2 | ||||||

| 1 | 250 | 1200 | 100 | 2936 | 422 | 903.6 |

| 2 | 120 | 198.7 | 1 | 2589 | 84.4 | 556.7 |

| 3 | 120 | 198.7 | 1 | 2589 | 337.6 | 556.7 |

| 4 | 250 | 198.7 | 100 | 2971 | 337.6 | 676.3 |

| 5 | 120 | 198 | 1 | 2970 | 337.6 | 675.5 |

| 6 | 119.9 | 198 | 0 | 503.4 | 337.6 | 52.72 |

| 7 | 120 | 198.7 | 0 | 503.8 | 84.4 | 52.83 |

| 8 | 119.9 | 198.7 | 0 | 503.4 | 337.6 | 52.72 |

| 9 | 119.9 | 198.7 | 0 | 503.5 | 422 | 52.74 |

| 10 | 120 | 1200 | 0 | 504.7 | 422 | 53.85 |

| (c) Model 3 | ||||||

| 1 | 250 | 1200 | 100 | 2936 | 422 | 903.5 |

| 2 | 120 | 198.7 | 1 | 2589 | 422 | 557.4 |

| 3 | 100 | 80 | 0.6 | 1756 | 422 | 283.4 |

| 4 | 100 | 80 | 0 | 391.7 | 422 | 28.64 |

| 5 | 100.4 | 1200 | 0 | 421.7 | 422 | 35.4 |

| Output @ P = 1200 (kPa) T = 250 °C | Units | Model 1 | Model 2 | Model 3 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | A | B | C | D | A | B | C | D | ||

| Turbine output Power (×103) | kW | 106.5 | 106.5 | 106.5 | 106.5 | 146.6 | 146.6 | 146.6 | 146.6 | 146.1 | 146.1 | 146.1 | 146.1 |

| VAR Inlet (×103) | kW | 456.1 | 456.1 | 456.6 | 456.1 | 176.0 | 176.0 | 176.0 | 176.0 | 351.9 | 351.9 | 351.9 | 351.9 |

| MED Inlet (×103) | kW | 481.6 | 481.6 | 481.8 | 481.6 | 832.9 | 832.9 | 832.9 | 832.9 | 575.6 | 575.6 | 575.6 | 575.6 |

| Cooling rate (×103) | kW | 319.3 | 319.3 | 315.0 | 314.7 | 320.3 | 320.3 | 592.0 | 592.0 | 320.3 | 320.3 | 419.8 | 419.8 |

| Distilled water output | kg/s | 357 | 639.5 | 357.2 | 639.8 | 805.8 | 1388 | 806 | 1388 | 477.2 | 839.8 | 477.2 | 839.8 |

| Name of the city | New Delhi [31] | Riyadh [32] | London [33] | |

| Climatic zone | Humid subtropical | Arid desert | Temperate oceanic | |

| MSW generation rate (million tons/year) | 4.13 | 3.4 | 7 | |

| Composition | Paper | 11% | 11.6 | 15% |

| Plastic | 13.5% | 13.0 | 15% | |

| Glass | 6% | 3.0 | 11% | |

| Wood | 6% | 6.60 | 5% | |

| Textiles | 1.5 | 2.90 | 5% | |

| Organics | 50–55% | 57.20 | 18% | |

| Others | 6.3% | 3.36 | 28% | |

| LHV (kWh/kg) | 2.06 | 2.51 | 2.77 | |

| Electrical power requirement (GWh/y) | 26,319 | 48,478 | 37,800 | |

| Cooling energy requirement, GWh/y) | 1350 | 33,934 | 0.018 | |

| Desalination energy requirement (GWh/y) | 1040 | 722 | 816,000 | |

| Availability from MSW using Model 1 (% replacement) | Electrical power, GWh/y | 3718.76 (14.3%) | 3061.45 (6.32%) | 26,319 (23.95%) |

| Cooling, GWh/y | 7963.04 (589.85%) | 6555.53 (19.32%) | 1350 (999.75%) | |

| Water, GWh/y | 378.37 (36.38%) | 311.49 (42.56%) | 1040 (61.66%) | |

| Availability from MSW using Model 2 (% replacement) | Electrical power, GWh/y | 5118.96 (19.45%) | 4214.16 (8.69%) | 26,319 (32.97%) |

| Cooling, GWh/y | 3072.78 (227.65) | 2529.65 (7.45%) | 1350 (385.79%) | |

| Water, GWh/y | 654.37 (62.92%) | 538.71 (73.60%) | 1040 (106.65%) | |

| Availability from MSW using Model 3 (% replacement) | Electrical power, GWh/y | 5101.51 (19.38%) | 4199.79 (8.66%) | 26,319 (32.85%) |

| Cooling, GWh/y | 4300.67 (318.57%) | 3540.50 (10.43%) | 1350 (539.95%) | |

| Water, GWh/y | 452.22 (43.48%) | 372.29 (50.87%) | 1040 (73.70%) | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaneesamkandi, Z.; Sayeed, A. Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions. Energies 2023, 16, 5696. https://doi.org/10.3390/en16155696

Kaneesamkandi Z, Sayeed A. Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions. Energies. 2023; 16(15):5696. https://doi.org/10.3390/en16155696

Chicago/Turabian StyleKaneesamkandi, Zakariya, and Abdul Sayeed. 2023. "Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions" Energies 16, no. 15: 5696. https://doi.org/10.3390/en16155696

APA StyleKaneesamkandi, Z., & Sayeed, A. (2023). Evaluation of Multi-Utility Models with Municipal Solid Waste Combustion as the Primary Source under Specific Geographical and Operating Conditions. Energies, 16(15), 5696. https://doi.org/10.3390/en16155696