1. Introduction

The need to reduce the environmental impact of anthropic activities has become, in the last few years, one of the major drivers in R&D activities in most of the fields of engineering. In the area of fluid power, the energy management of hydraulic systems is a crucial topic, both in mobile and in industrial sectors [

1]. This paper is focused on the application of compact hydraulic power packs. Despite each single unit being typically sized in the range of just a few kW of power [

2], hundreds of thousands of units are produced per year. Thus, taking the overall installed power into account, even moderate improvements in their efficiency provides a significant energy impact.

Recent advances and improvements in compact power packs are fostering the radical review and innovation of the engineering practices and technologies [

3]. A first aspect of innovation is the progressive migration from fossil-based hydraulic oils to eco-friendly biodegradable formulates. A further element is the ever-broader use of pump-controlled systems. The external gear hydraulic pump is traditionally driven at fixed speeds; today, cost-effective electric drives allow the controlled-speed pump management to achieve flow control, pressure control, and load sensing control with fixed displacement units, such as external gear pumps. A third element is related to the opportunity of integrating sensors in hydraulic manifolds and benefiting new programmable logic controllers’ (PLCs) computational power. Hence, sophisticated control logics, once reserved for high-end hydraulic applications, are now available for small hydraulic power packs.

In light of this perspective, the enhancement of pump efficiency is required to efficiently transform mechanical power into hydraulic power. For the electric drive-pump matching and, more generally, in the design of pump-controlled systems, it is also fundamental to assess the pump energy performance in its whole operating range, in terms of overall, volumetric, and torque efficiency. Hence, the development of compact power packs can be oriented to achieving the best compromise between investment and operational costs.

The literature reports that the efficiency of hydraulic pumps depends on complex interactions among several factors. Reference [

4] is an interesting review of the ISO standard 4409:2007 [

5], which defines the methods of testing and presenting the basic steady-state performance of positive displacement pumps. The overall efficiency is typically analyzed and modelled through the product of volumetric and torque losses [

6], although alternative approaches, such as reference [

7], have recently been proposed. Regardless of the specific assumptions in the loss modeling, a fundamental point is to rely on robust yet simple models to understand the experimental results and to make virtual predictive models available. The Lumped Parameter (LP) approach has proven to be very effective in modeling the pump efficiency, since the first studies in the field [

8]. Many specific research activities are devoted to increasing pump efficiency [

9,

10], and other efforts are aimed at improving pump technology [

11], exploring alternative designs [

12], and refining modeling tools [

13,

14]. Beside the pump technology level, the hydraulic fluid is the other fundamental factor affecting the hydraulic system efficiency [

15]. Viscosity, bulk modulus, and density (that depend on pressure and temperature) influence the effective pump performance [

4]. Regarding the new eco-friendly fluids, there is still quite limited literature, with very few contributions supported by laboratory tests or simulations rather than experiments in the field [

16]. The assessment of a new eco-friendly fluid through an accelerated durability test under laboratory conditions is reported in reference [

17], relating to the operational properties of the fluid and to the wear of the pump during the tests. Flow efficiency and physic-chemical properties, such as viscosity, additive depletion, and contamination, were monitored. Furthermore, reference [

17] assesses the system performance considering the volumetric efficiency, neglecting, however, the toque efficiency. In reference [

18], a detailed CFD modeling of an external gear pump highlights that the use of aged eco-friendly fluids does not degrade the pump volumetric efficiency, encouraging further research on the topic; also, here the torque efficiency is not considered. High pressure piston pumps operating with blends of alternative renewable fluids are investigated in reference [

19]. Reference [

20] reports a contribution to experimentally evaluating the influence of a biodegradable fluid, globally, on the dig cycle efficiency of a crawler excavator. The process of the aging of the fluid [

21], and the development of fluid degradation sensors [

22,

23], are further emerging topics in the literature.

The current article is devoted to experimentally investigating the efficiency of the gear pumps typically used in small hydraulic power packs. Unlike the literature presented, the authors aim to investigate the change in performance not only from the volumetric loss perspective but by taking overall efficiency and torque efficiency into account, which will be proven to be an essential contribution to the performance degradation of aged fluids.

The research considers two different pumps, belonging to the most used units covering the major power packs configurations, and two different eco-friendly hydraulic fluids available on the market. Their impact on pump performance is investigated and related to what is obtained with a standard mineral oil. Since eco-friendly fluids are biodegradable, their resistance to aging plays a fundamental role. The main question concerns the durability of the fluid performance. In many applications, and particularly in the field of small hydraulic packs, the use of thermal conditioning systems is not common, and the fluid can easily reach relatively high temperatures. Based on these concerns, the performance of the pumps is also tested with the same two eco-friendly fluids after a mechanical–thermal aging process, highlighting the influence of eco-fluids’ aging on pump performance. The results section reports all the trends of efficiencies related to the pump operating conditions and to the new and aged eco-friendly fluids, unveiling how the aged fluids influence the pump performance. Based on a lumped parameter approach, the results are then summarized in a practical form by means of loss coefficients and loss terms.

2. Materials and Methods

2.1. Pump Efficiency

The hydromechanical (or torque) and volumetric efficiency were standardized by ISO 4409:2019 [

5]. According to the standard, the actual displacement of the pump was obtained by measuring pump speed and pump flow rate under unloaded condition, to virtually eliminate the volumetric losses due to compressibility and leakage. The pump displacement was calculated according to Equation (1), where

is the measured flow rate and

is the shaft speed.

According to references [

6,

8], the overall efficiency of the pump,

, is expressed as (2):

where

is the hydraulic power and

is the mechanical power at pump shaft. The equation can be rewritten as product of

, flow delivered by the pump, and

pressure difference between delivery and inlet over the product of

, the torque at pump shaft;

is the pump speed. Finally, introducing the pump displacement

, Equation (2) is expressed as the product of two factors, volumetric and torque efficiency, under the hypothesis of negligible pressure on suction line.

2.2. Hydromechanical Efficiency

The torque efficiency or hydromechanical efficiency of the pump was calculated using Equation (3):

where

is the theoretical torque at pump shaft. The theoretical torque is written as product of pump displacement

and

, the pressure difference between delivery and inlet. Once

was set in delivery ambient, torque

was measured at pump shaft. The actual pump displacement was obtained using Equation (1) and the torque efficiency

was calculated.

2.3. Volumetric Efficiency

The volumetric efficiency is expressed as Equation (4), where

is the experimentally measured flow rate and

is the theoretical flow rate.

The theoretical flow rate is evaluated as pump displacement times pump speed. The actual flow rate differs from the theoretical one due to volumetric losses. The volumetric losses are due to the pump leakages, to the fluid compressibility, and to the filling efficiency.

2.4. Pump Loss Modeling

To explain and systematize the results it is important to recall some basic yet fundamental definitions and mathematical extrapolations, which were firstly formulated by Wilson [

8]. Even if quite basic, these formulations can be a useful operative tool for finding and analyzing the relevant trends within results. According to Wilson’s approach, volumetric efficiency is affected by leakages and by fluid compressibility. The theoretical volumetric flow rate is reduced by the fluid compressibility. Referring to the fluid bulk modulus

,

gives the compressibility term (or compressibility flow rate), whose extent depends on pump load level (

.

Leakages are due to unideal sealing between delivery and admission sides of the pump, and they are modeled according to the laminar flow in a rectangular meatus. Thus, , the leakage term, is proportional to the group of laminar flows. Since can be conveniently referred to the pump displacement , Equation (5) is rewritten with the help of the parameter , which is the empirical coefficient representing the pump leakage behavior.

According to Wilson’s approach, torque efficiency is affected by friction, which comprises two physical terms (contact and viscous friction). Equation (3) is thus rewritten as Equation (6), where

is the torque loss due to viscous friction and

is the torque loss due to contact friction. Wilson also introduced the empirical loss term

that is not explicitly affected by speed and load of the pump.

The actual torque

is thus expressed as the sum of theoretical torque and all the loss terms, as a function of pump speed

, pump load

, fluid viscosity

, and pump capacity

, through the empirical coefficients

and

[

8]. Dividing each term by

, the actual torque

is then expressed in the dimensionless form

, as in Equation (7):

that is rewritten as Equation (8):

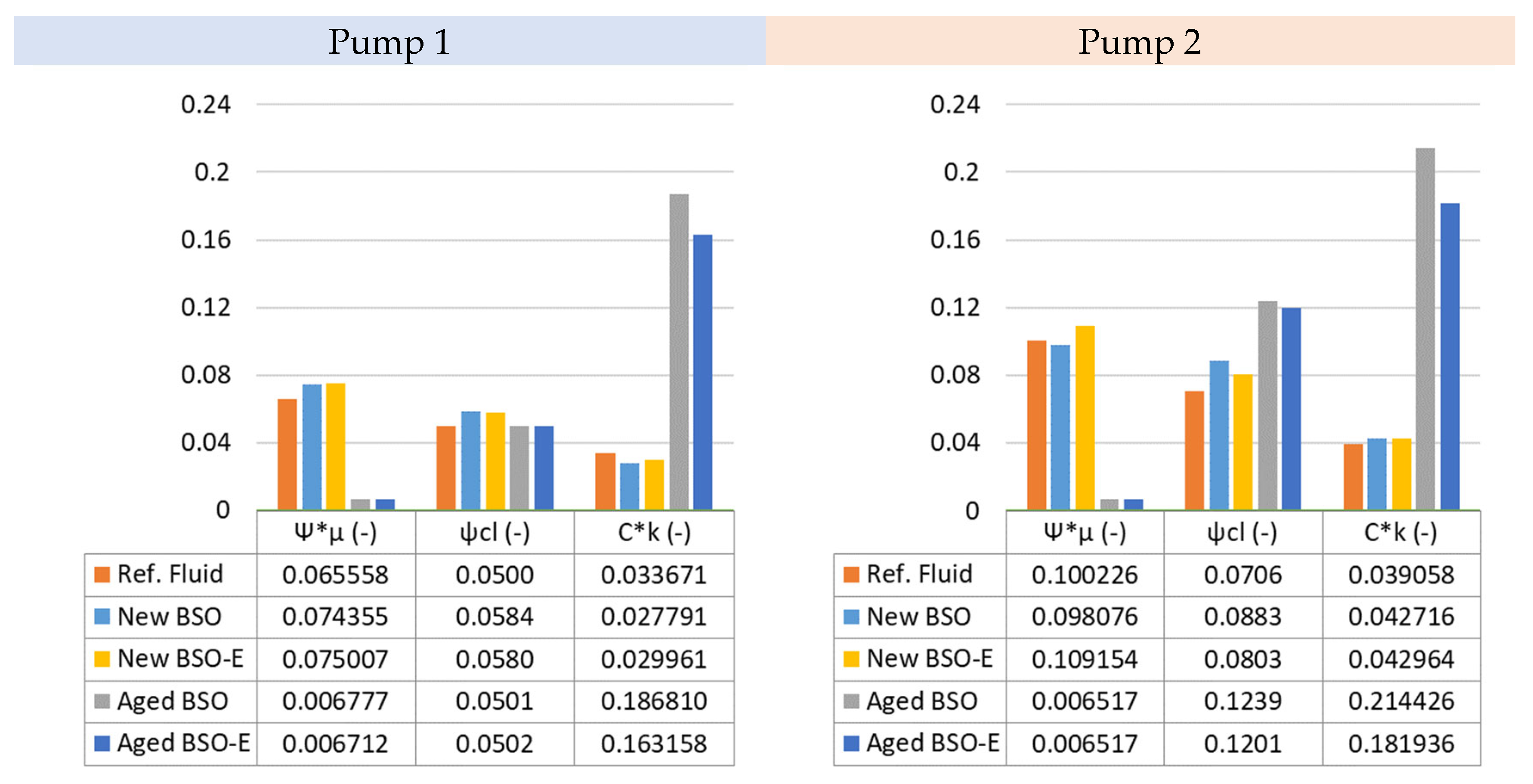

where:

| | ; |

| ; | ; |

2.5. Experimental Set-Up

As described above, the measurement of torque and volumetric efficiency was based on the measurement of the pump flow rate, delivery pressure, torque, and pump shaft speed.

A specific experimental set-up was built to replicate the typical operating conditions of the pump in the hydraulic power packs, where the hydraulic manifold body is the key structural element to support pump, electric motor, and tank; valves and other components were integrated in the manifold to realize the most part of the hydraulic circuit.

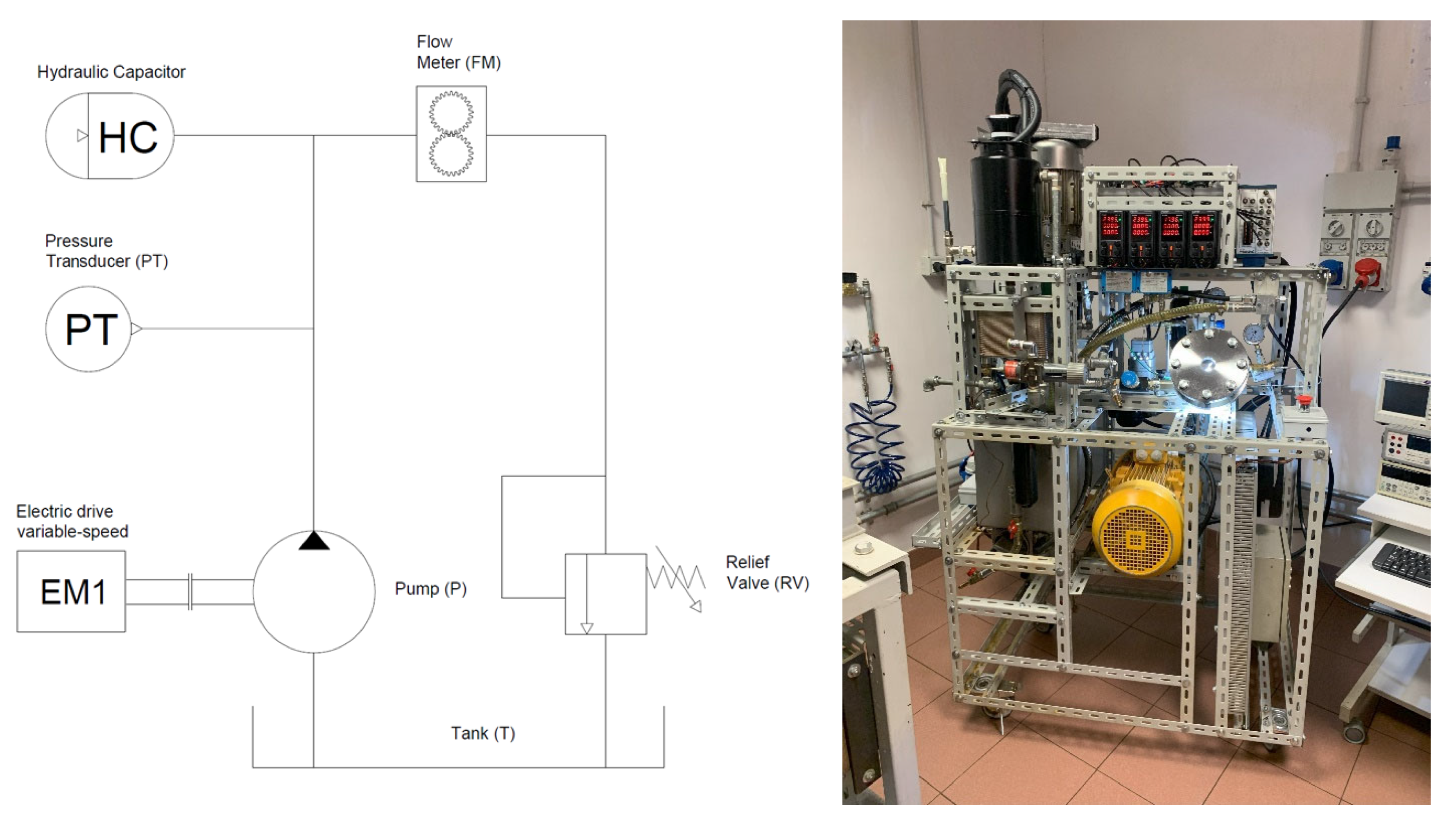

The scheme of the experimental set-up is shown in

Figure 1; the pump under test (P) was driven by a variable frequency electric drive (EM1). The pressure measurement in the delivery line was carried out via a pressure transducer (PT). A hydraulic capacitor (HC) limited the pressure fluctuations induced by the gear pump at a negligible level. Flow rate was measured through a volumetric flow meter (FM) on the high-pressure side. The pressure level at the pump head was set through a spring-loaded relief valve (RV).

Figure 2 shows the set-up to measure torque and speed at pump shaft. Usually, the electric motor is coupled to the pump passing the shaft through the hydraulic manifold; here, two hydraulic manifolds were used to build a frame that housed a torque meter (TM), still preserving the standard mount for the electric motor (EM1) and the pump (P).

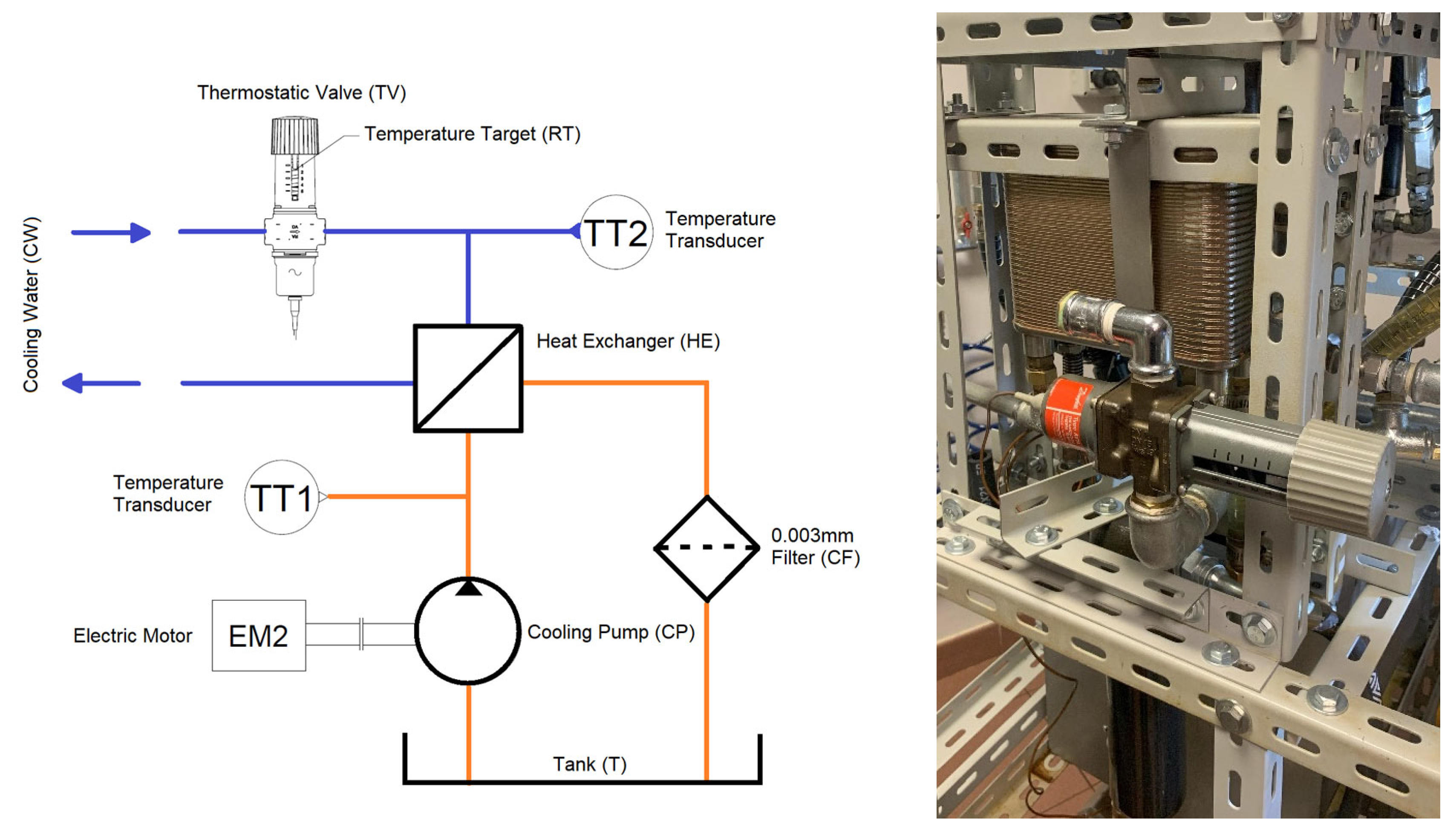

The offline fluid conditioning circuit is shown in

Figure 3 and was used to guarantee proper fluid cleanliness and temperature during the tests. The cooling pump (CP) fed the heat exchanger (HE) and the filter (CF). Inlet and return ducts were set to ensure the correct circulation within the tank (T). The thermostatic valve (TV) operated on the cooling water line according to the target temperature, under a closed control loop. The tank temperature was measured (TT1) and continuously monitored during the tests.

Table 1 reports the main features of the adopted instrumentation.

2.6. Pumps under Test

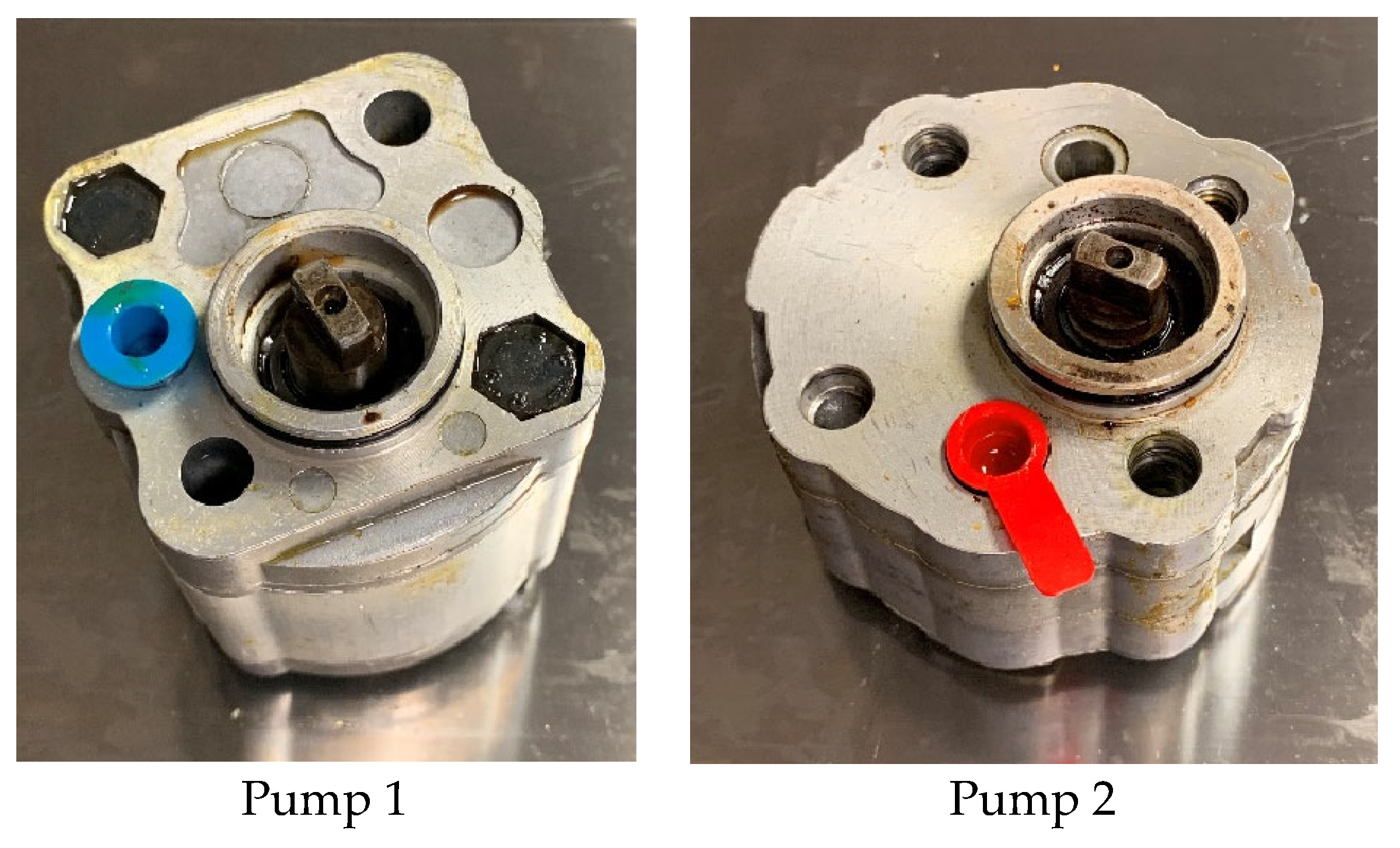

The investigation was carried out on two external gear pumps, belonging to the same dimensional class (01-Group). The pumps had similar displacement, and they were representative of the two mostly used layouts (or families) in the field of hydraulic power packs. The body of Pump 1 (0.8 cc/rev) was made of three parts. The body of Pump 2 (1.2 cc/rev) was simply made of two parts, so that the housing of the gears was blind machined on the main body (

Figure 4). An important difference is that Pump 1 included two moving bushes while Pump 2 had just one bushing, then the gears were coupled on one side with the bushing and on the other side directly with the pump body.

2.7. Experimental Test Bench for Aging the Fluids

A specific experimental test bench was developed to perform the study described in [

23], with the aim of aging the hydraulic fluids fast and continuously, under controlled conditions and excluding contamination by external agents. The aging was caused by stressing and heating the fluid, simply running the pump with the regulating relief valve. The pressure was set at 70 bar and the fluid temperature was kept at about 90 °C through an electronic control operating on an oil cooler; these settings reproduced the heavy-duty fluid working conditions of the real fluid power system of mobile machines. The typical recommendations on hydraulic fluid replacement refer to a fluid lifetime in the range of 1500–2500 h.

In

Figure 5a,b, the schematic layout, in accordance with the Standard ISO 1219, and the picture of the developed test bench are shown, respectively. The main components are an external gear pump (P) driven by an electric motor (EM), a throttle valve (TR), an oil cooler with an electric fan drive (C), a 30 L reservoir (T), a fluid level sensor (LS), a pressure and a temperature sensor (PT and ST), and an electronic control unit. The volume of each eco-friendly fluid treated with the test bench is about 18 L.

2.8. Tested Fluids

To carry out the present study, i.e., to investigate the efficiency of the pumps, some fluids were produced by different companies. As a first step in such a research field, the investigations were limited to three fluids available on the market, in the widely used ISO VG 46 class.

The first one was a standard mineral fluid typically used in hydraulic systems, referred to here as Reference Fluid (named “RF”). The other two were eco-friendly fluids, based on synthetic esters; they met EU Ecolabel performance (HEES, ISO 15380) and are named BSO and BSO-E throughout the text. These fluids are biodegradable substitutes of the mineral RF, belonging to the same viscosity class. They can be generally used as an eco-friendly alternative in the same wide range of applications.

In the case of eco-friendly fluids, they were used to test the pump efficiency as received (New) and after (Aged) a 2000 h degradation process. In order to give a frame of reference on the fluid lifetime, several typical recommendations on hydraulic fluid replacement refer to a fluid lifetime in the range of 1500–2500 h. The main properties of the considered fluids were measured (cinematic viscosity ν, density ρ, resistance to oxidation, and total acid number—T.A.N.) or calculated (dynamic viscosity μ) and are summarized in

Table 2.

It must be noted that viscosity changed for both eco-friendly fluids after the aging process, but only for the BSO one does it exceed the ISO VG 46 range. In the case of T.A.N., the eco-friendly fluids showed an increase of almost an order of magnitude after aging. This property is a clear indication of fluid degradation but cannot be uniquely related to other properties by any bijective correspondence mathematic formulation. Finally, the resistance to the oxidation of the fresh eco-friendly fluids, determined by the Rotating Pressure Vessel Oxidation Test (RPVOT) according to ASTM D2272, was nearly twice for BSO-E when compared to BSO, despite the similar properties and compositions reported in their datasheets. This result suggests a faster degradation process in BSO fluid, in agreement with the viscosity measurements.

2.9. Test Cases

For each considered hydraulic fluid, the test points (Ti,j) swept the typical operating range of the pumps. Pump speed ranged from 750 RPM to 3000 RPM, whereas delivery pressure level ranged from 60 to 180 bar, as reported in

Table 3.

4. Conclusions

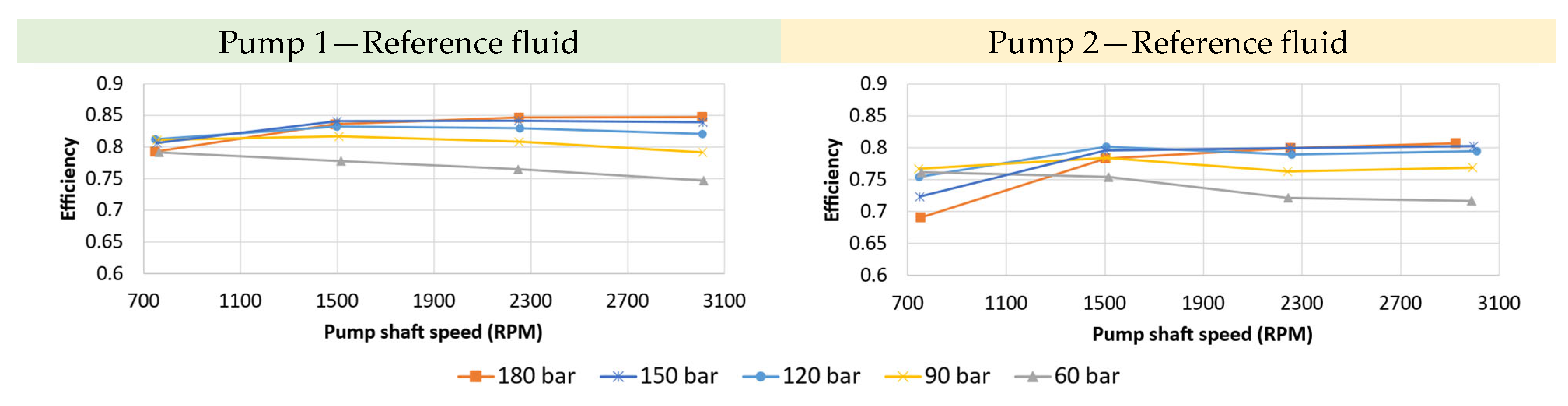

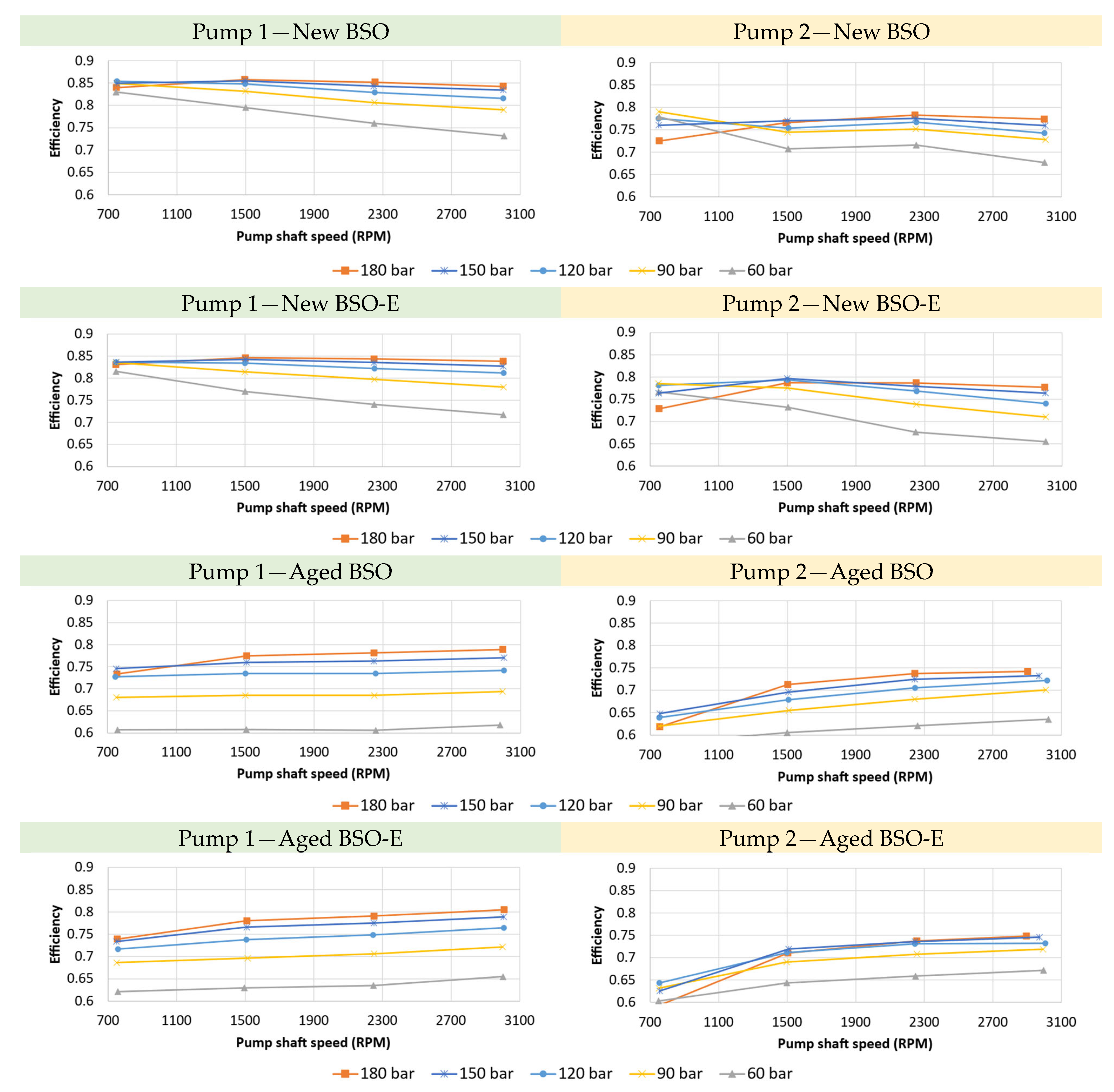

The investigations highlight the influence of eco-friendly fluids on the energy performance of the two most used types of gear pumps for compact hydraulic power packs.

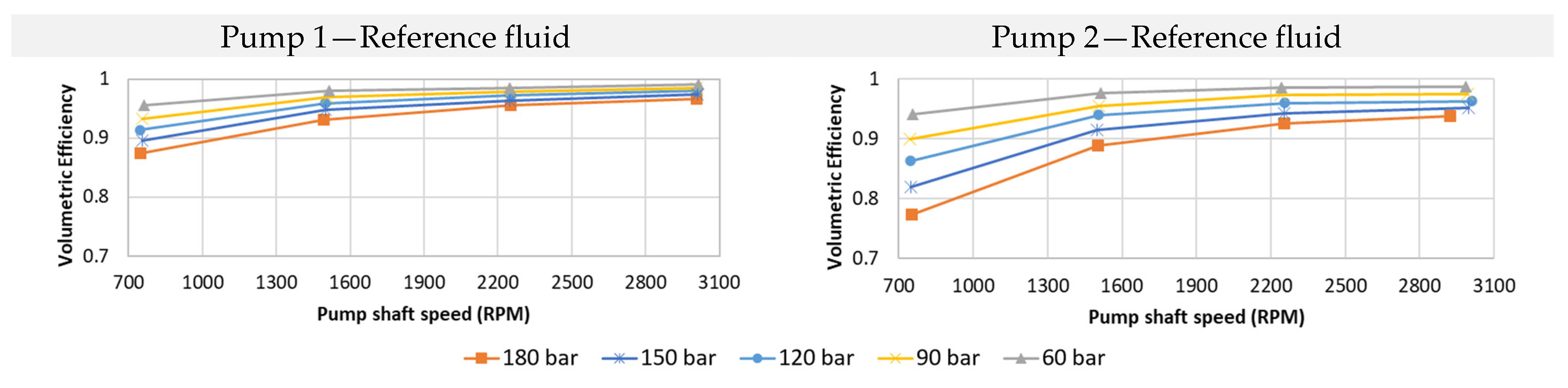

The two eco-friendly hydraulic fluids exert significant effects on the overall efficiency of the pumps. The efficiency increases, marking an up to 5% improvement depending on the cases. These improvements are recorded in both pump types, and they are due to the relevant rise (up to over 10%) of volumetric efficiency in the whole working range of the pumps, that is soundly marked in the most severe conditions (low speed and high pressure). The energy profile of the two pumps improves significantly, but it is worth pointing out that the eco-friendly fluids do not level their performance profile, which still reflects their different characteristics and performance targets.

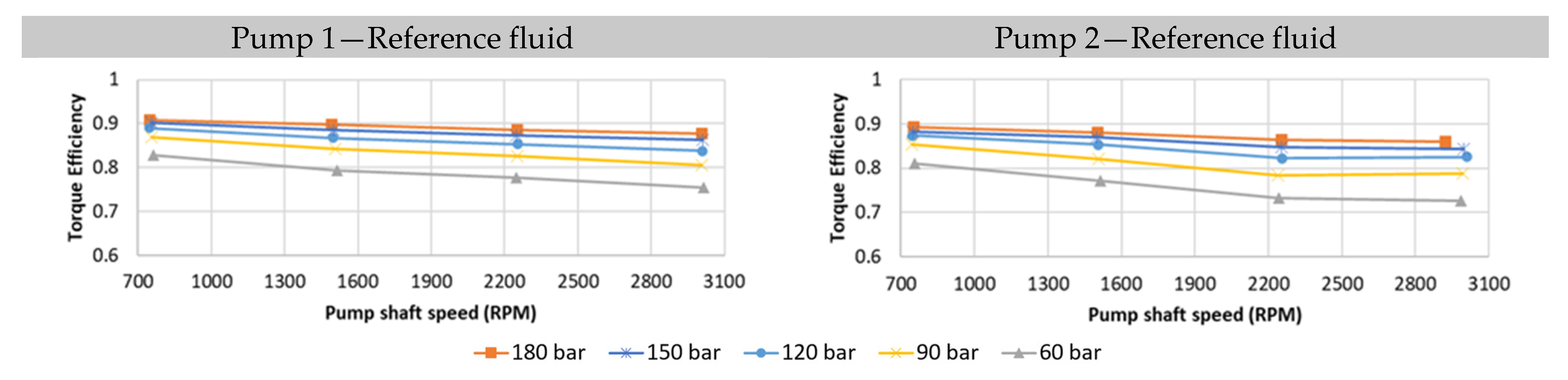

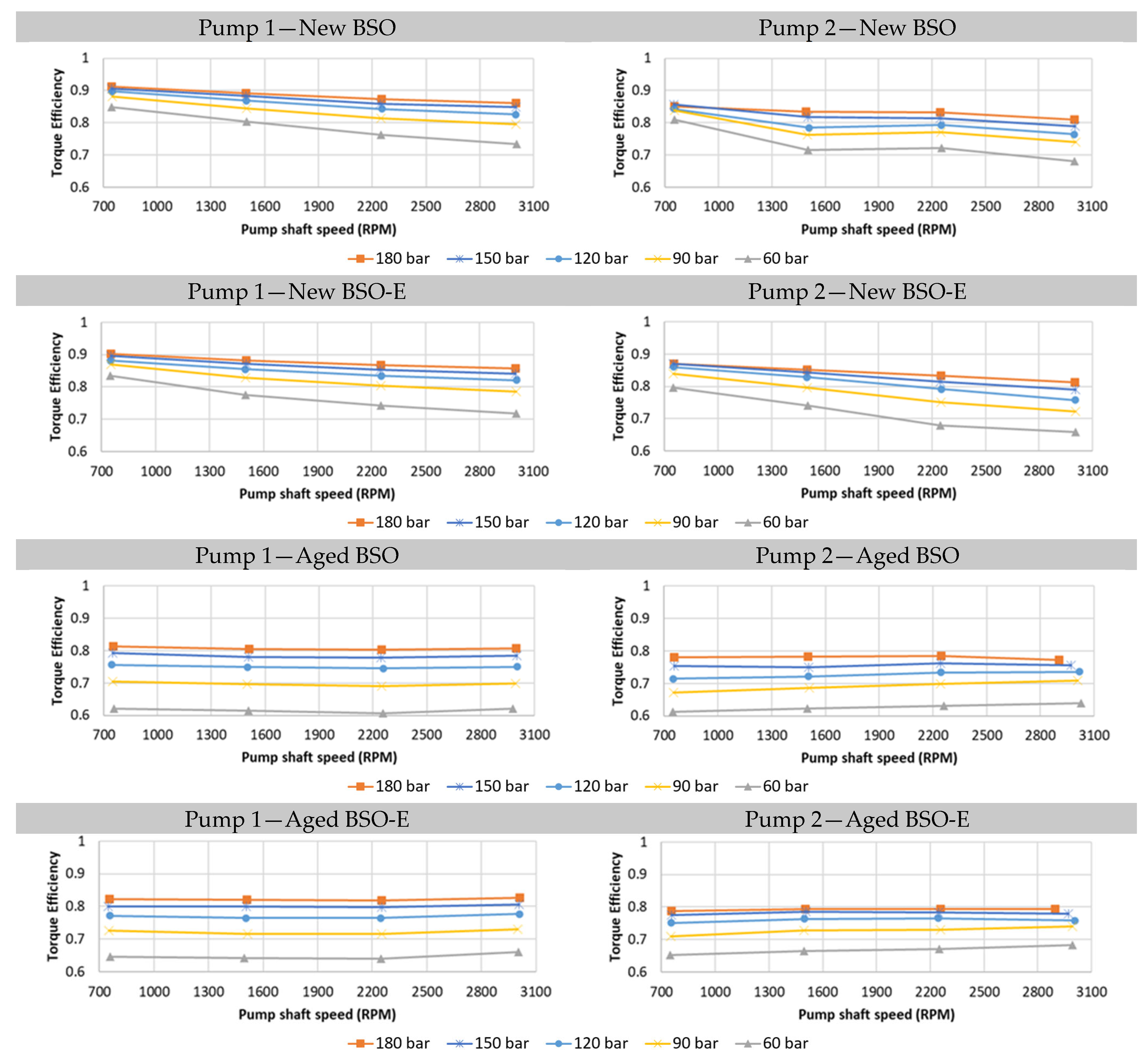

Biodegradable fluids also affect the torque efficiency, which undergoes a slight decrease. This performance loss is more than compensated by the increase in volumetric efficiency.

After a heavy-duty aging process, based on 2000 h thermal-mechanical stress, the two eco-friendly fluids significantly affect the performance of the pumps. The worsening in overall pump performance is mainly due to the lowering of torque efficiency. The volumetric efficiency slightly decreases, but it never drops below what is obtained with reference mineral fluid. The pump type that achieves the highest performance with new eco-friendly fluids undergoes the largest alteration of torque efficiency and the smallest reduction in volumetric efficiency, highlighting that the link between volumetric and torque efficiencies influences the energy profile of each pump.

The major interest lies in the torque efficiency data, due to their strong dependence on fluid aging. According to the canonical model of torque loss, the torque efficiency points are lumped through torque loss terms and coefficients. In such a form, they provide reference information for the set-up of variable speed motor-pump units and for building advanced control tools that take the energy performance of the pumps into account; indeed, the higher the pump efficiency, the higher the hydraulic power level available in the hydraulic system. Going into more detail, using the Wilson formulation, an original contribution was made, finding that the pressure-dependent losses coefficients had a slight variation, while the constant term had a huge increase, representing the major contribution to efficiency loss; conversely, the speed terms became practically irrelevant.

At least as a first approximation, these results can be generalized and applied to all the pumps belonging to the same dimensional group. Furthermore, additional efforts can be carried out in the future in order to map the progressive decrease at different aging stages and to compare the different types of hydraulic machines and fluids.