Experimental Investigation of a Self-Sustained Liquid Fuel Burner Using Inert Porous Media

Abstract

1. Introduction

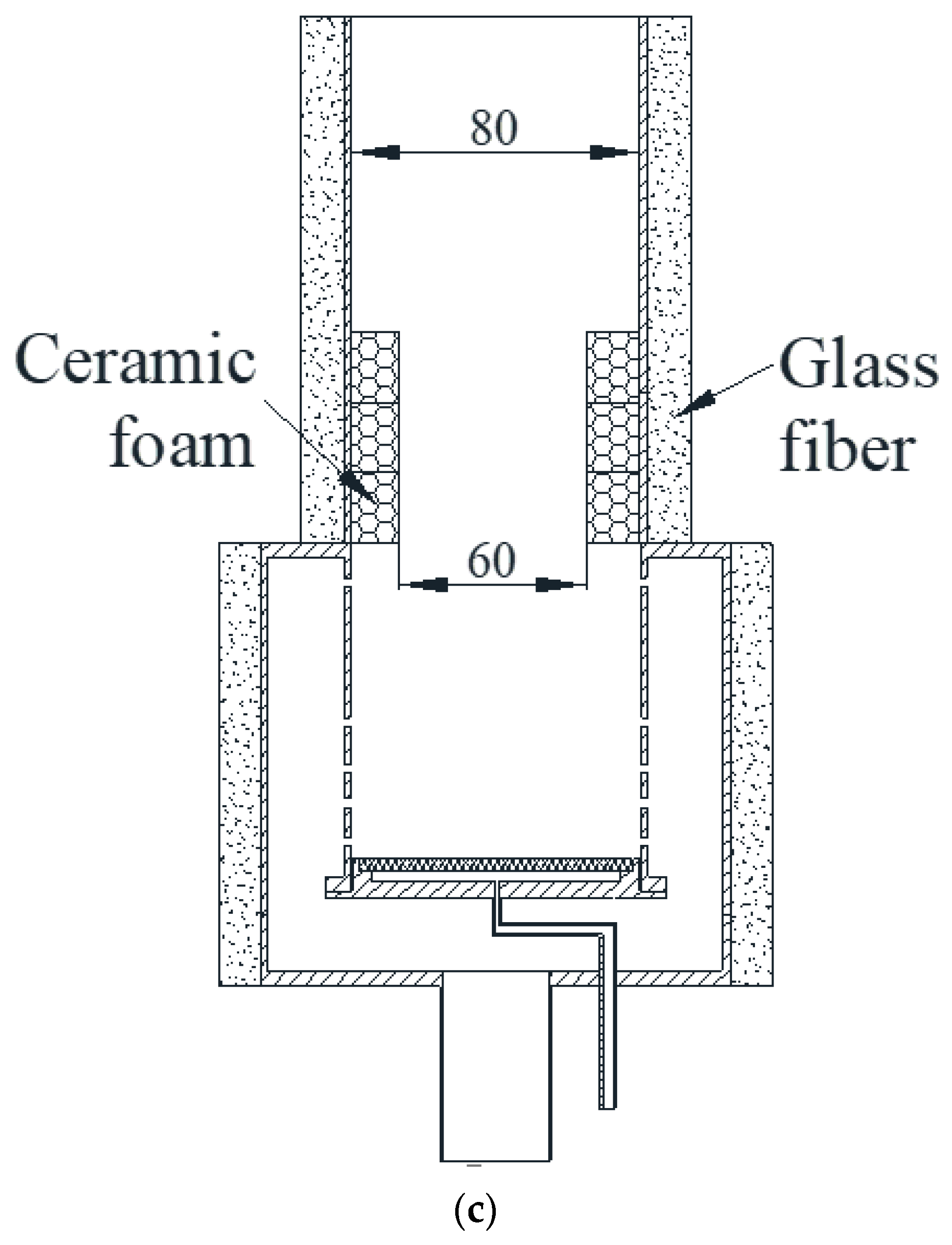

2. Experimental Setup

3. Results and Discussion

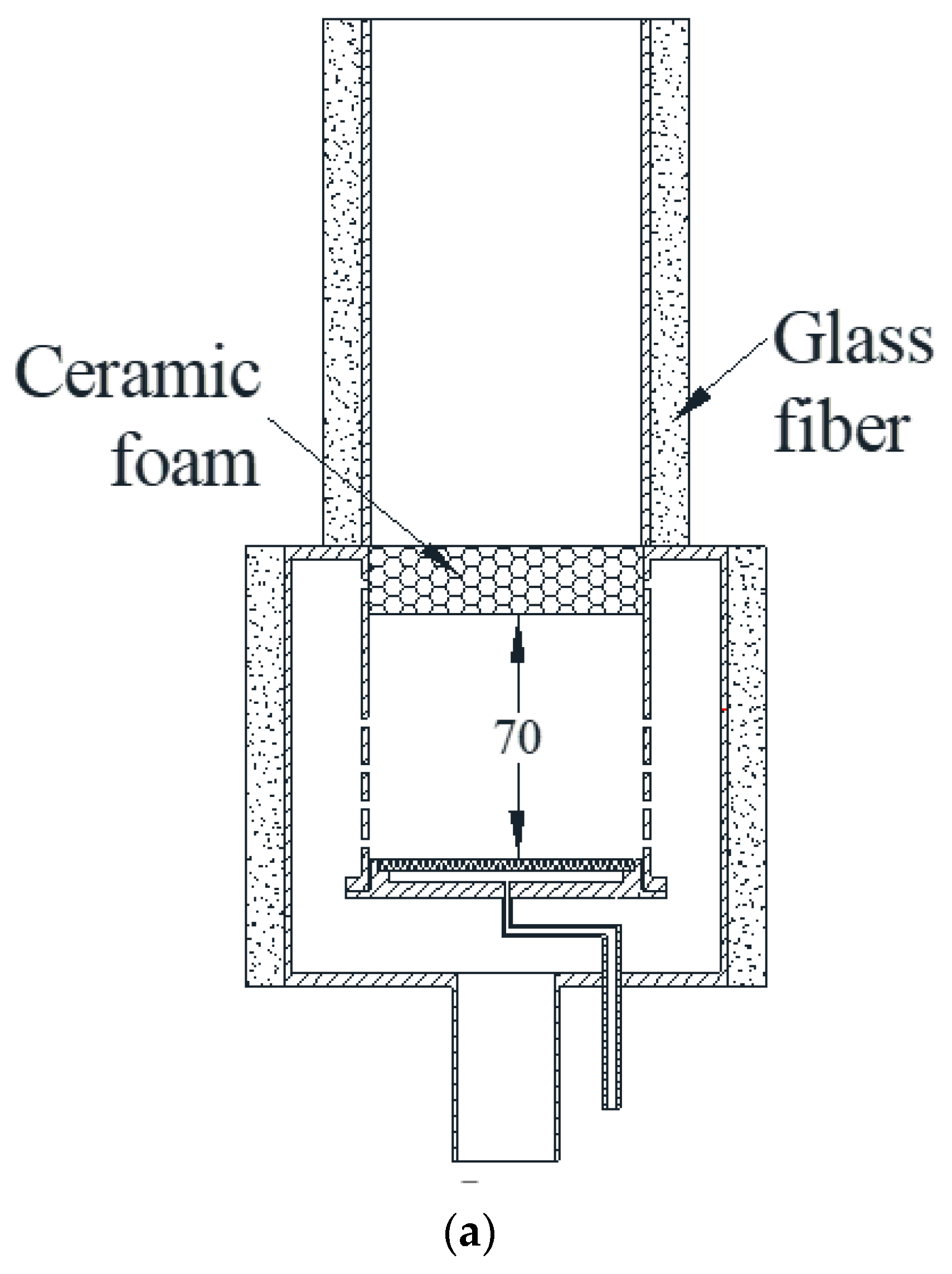

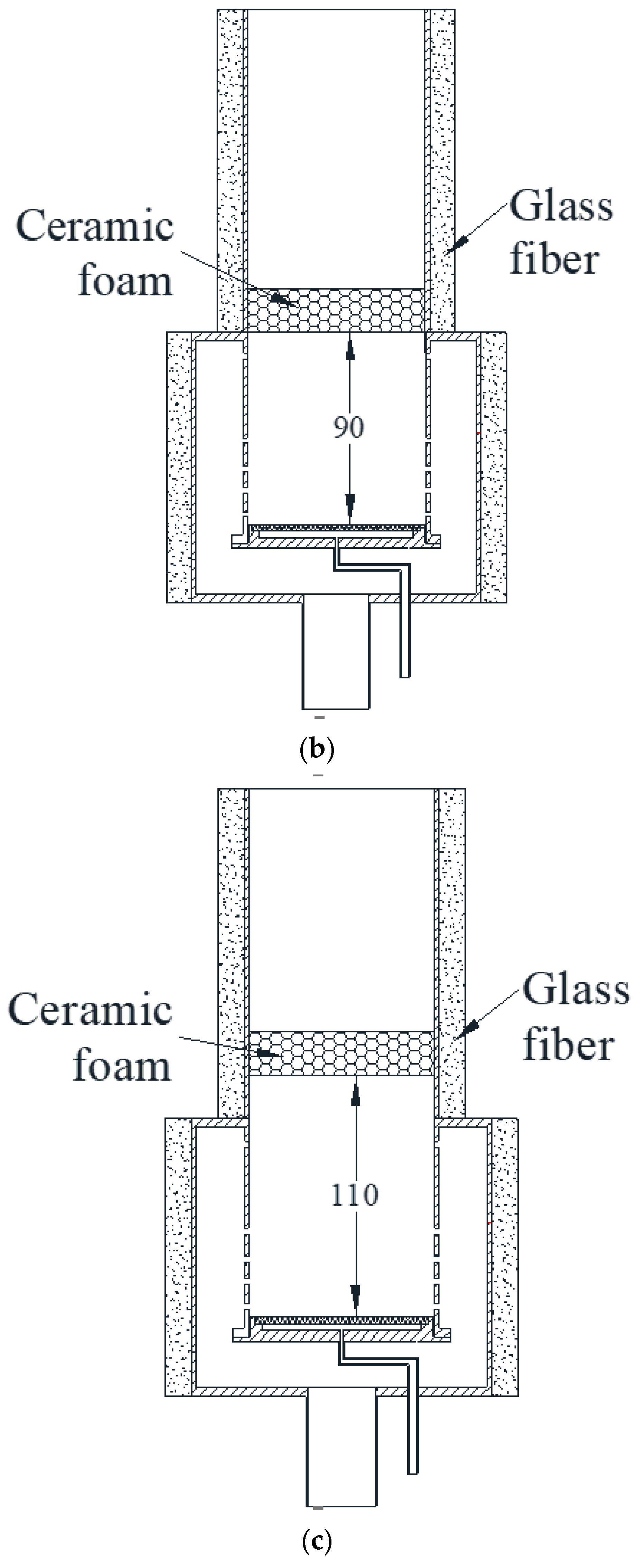

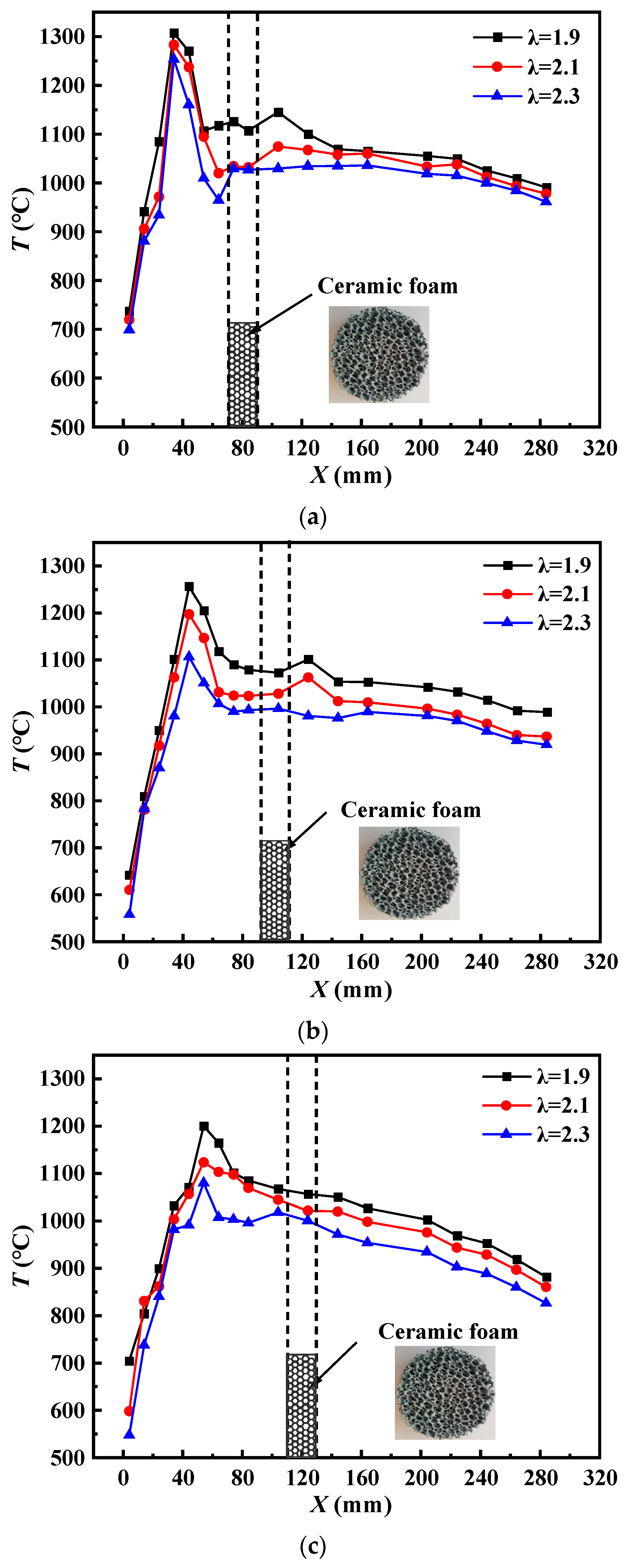

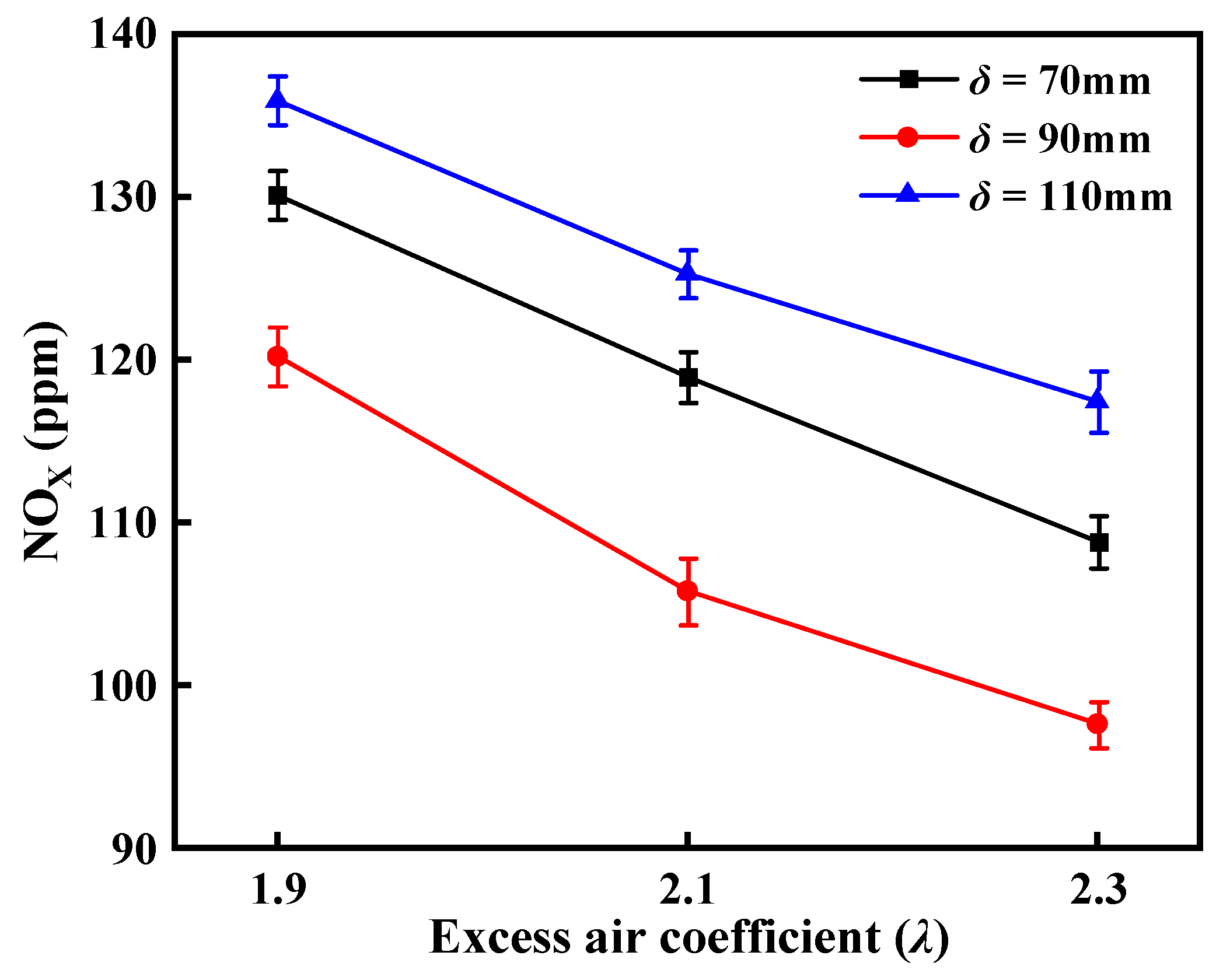

3.1. Effect of the Distance between Foam and Metal Fiber Felt

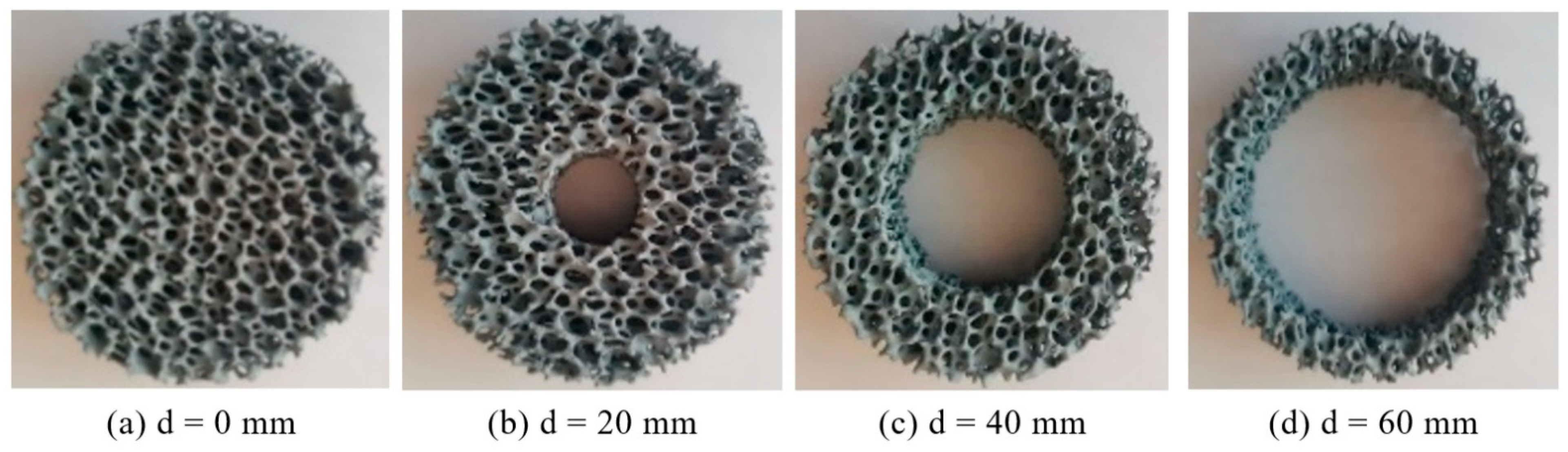

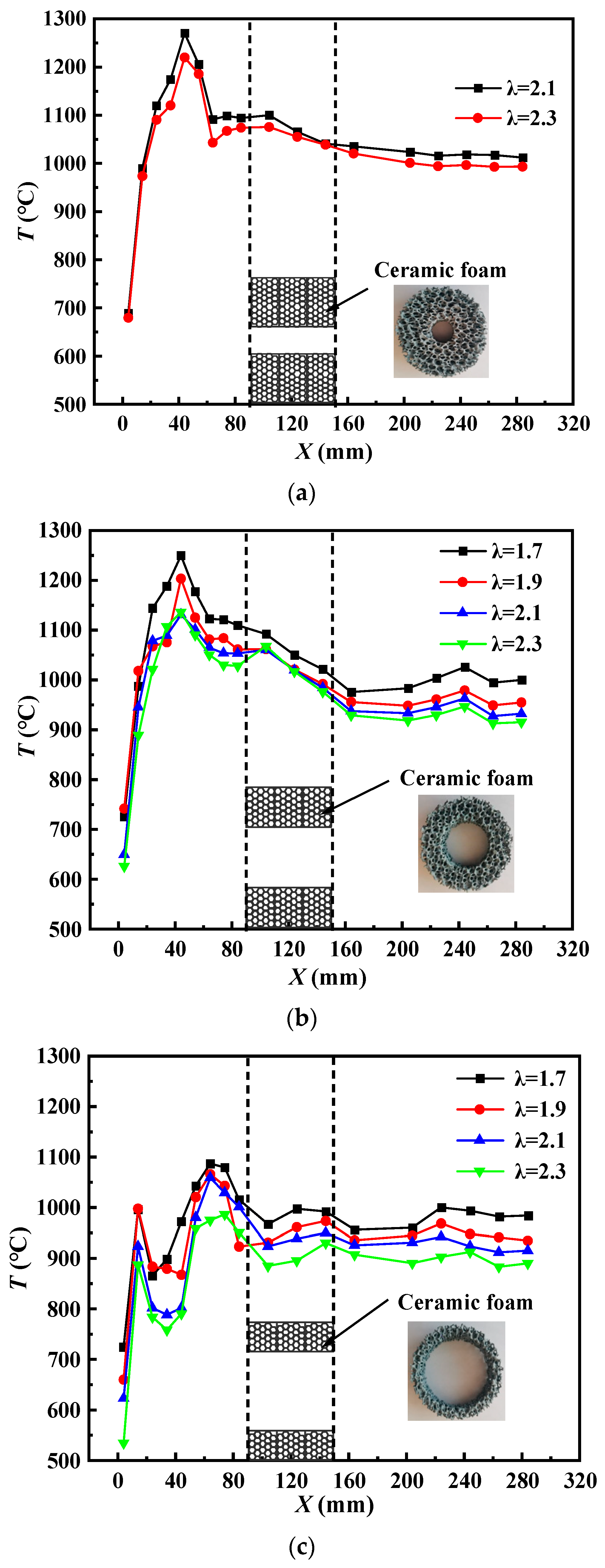

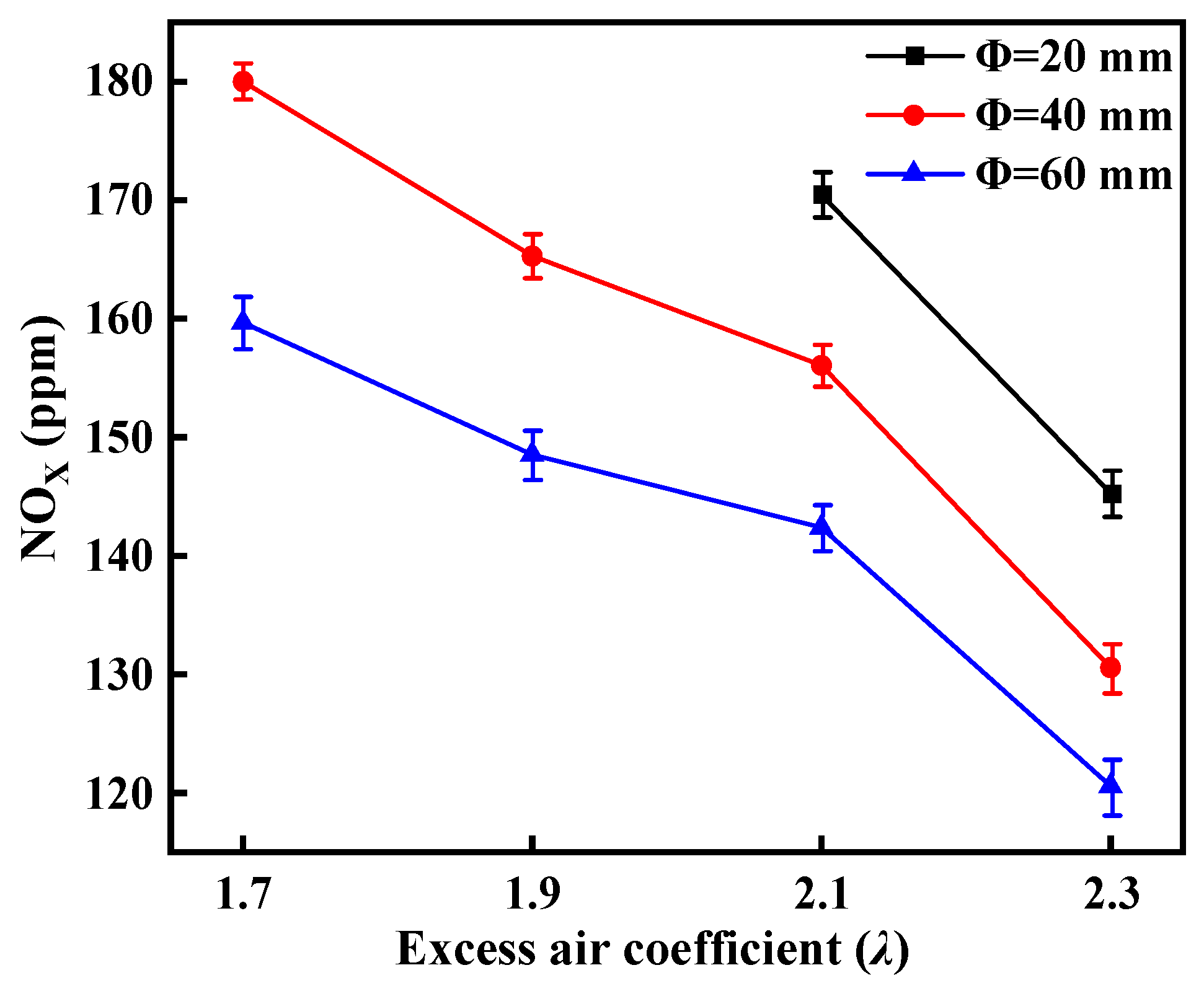

3.2. Effect of the Central Hole Diameter

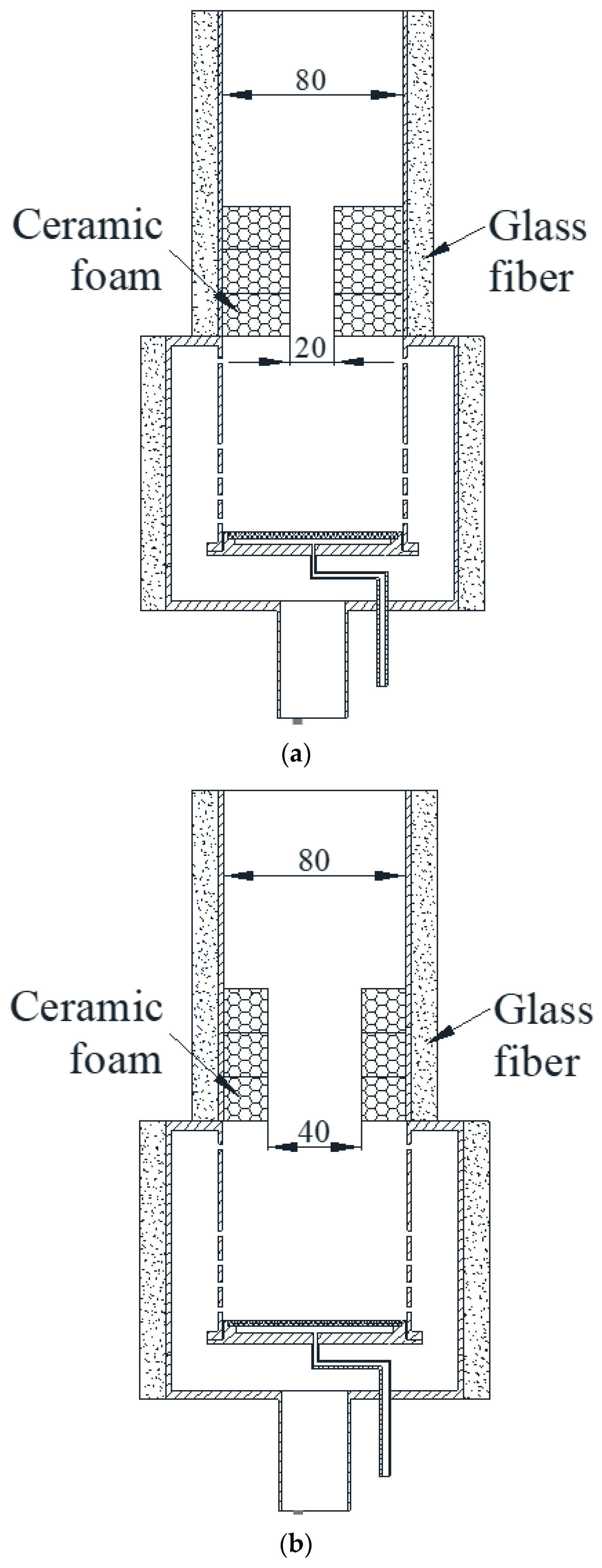

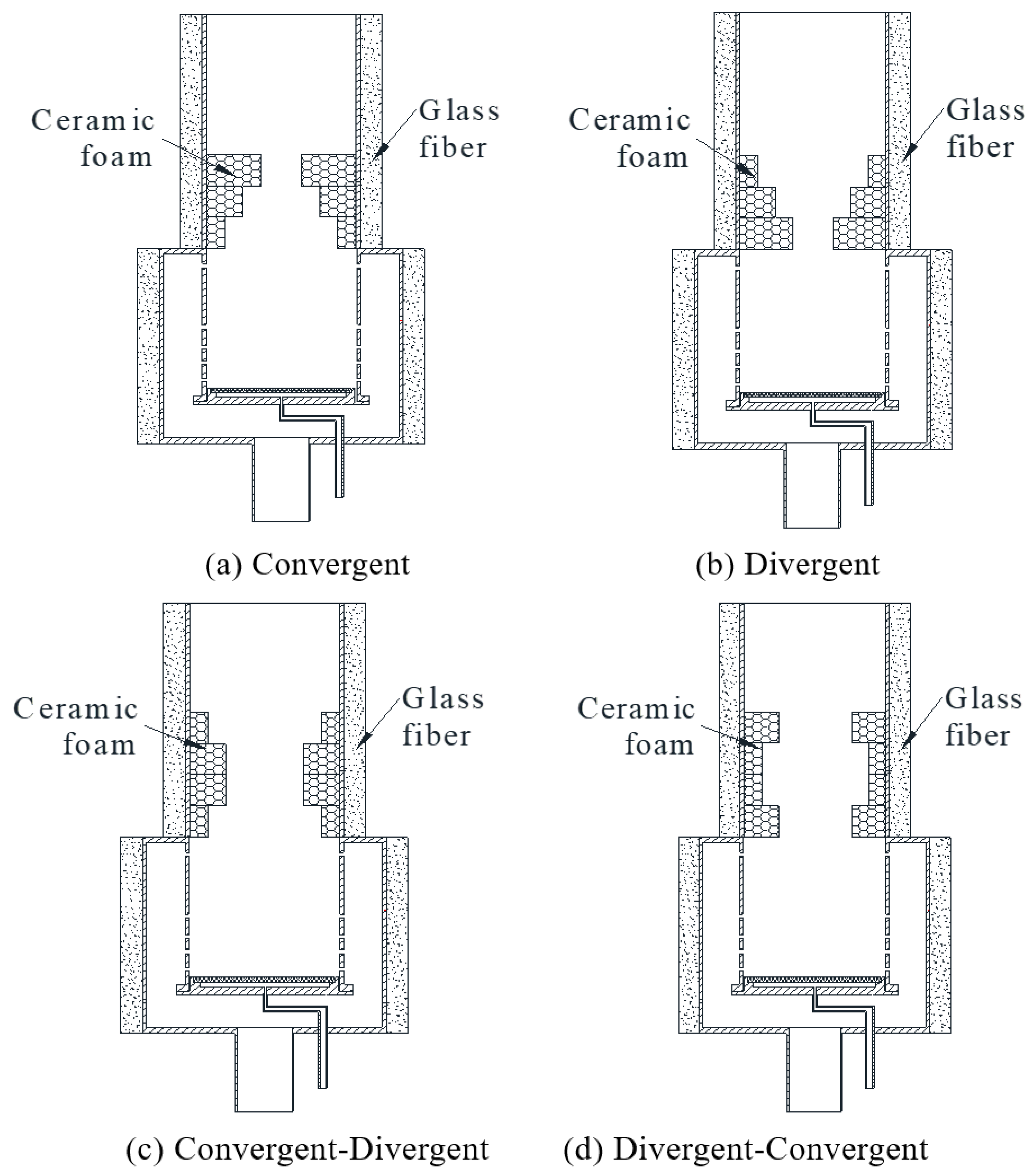

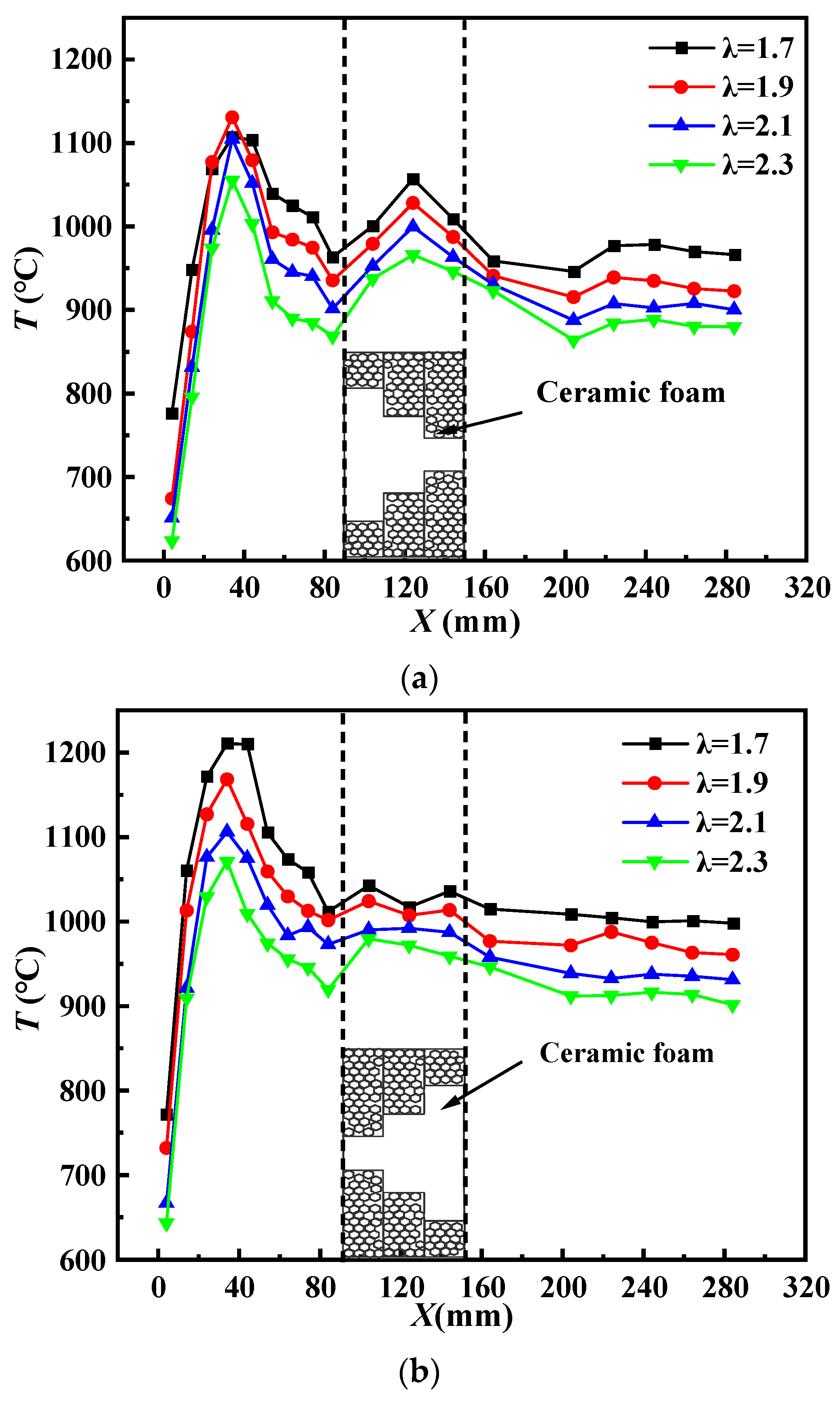

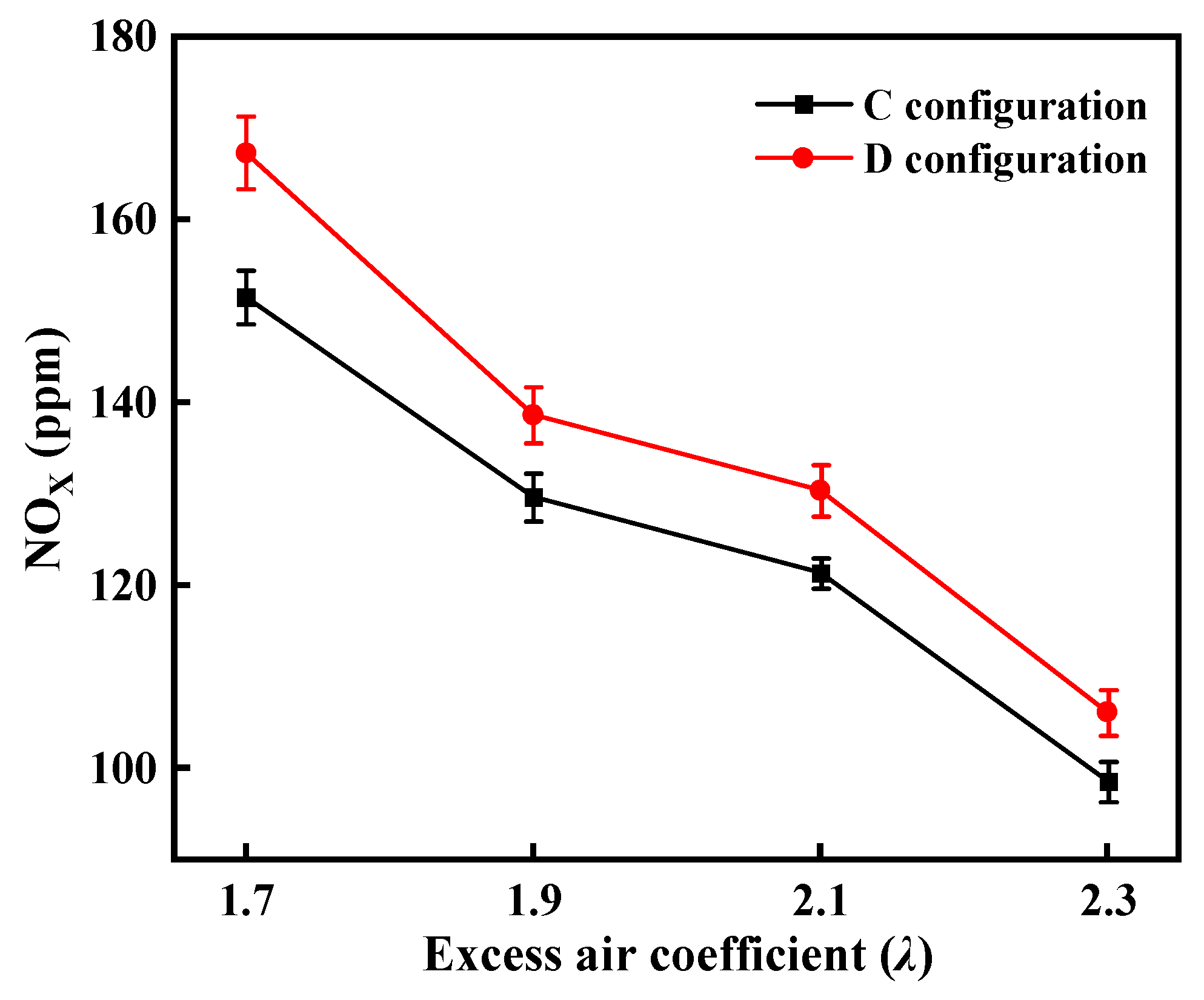

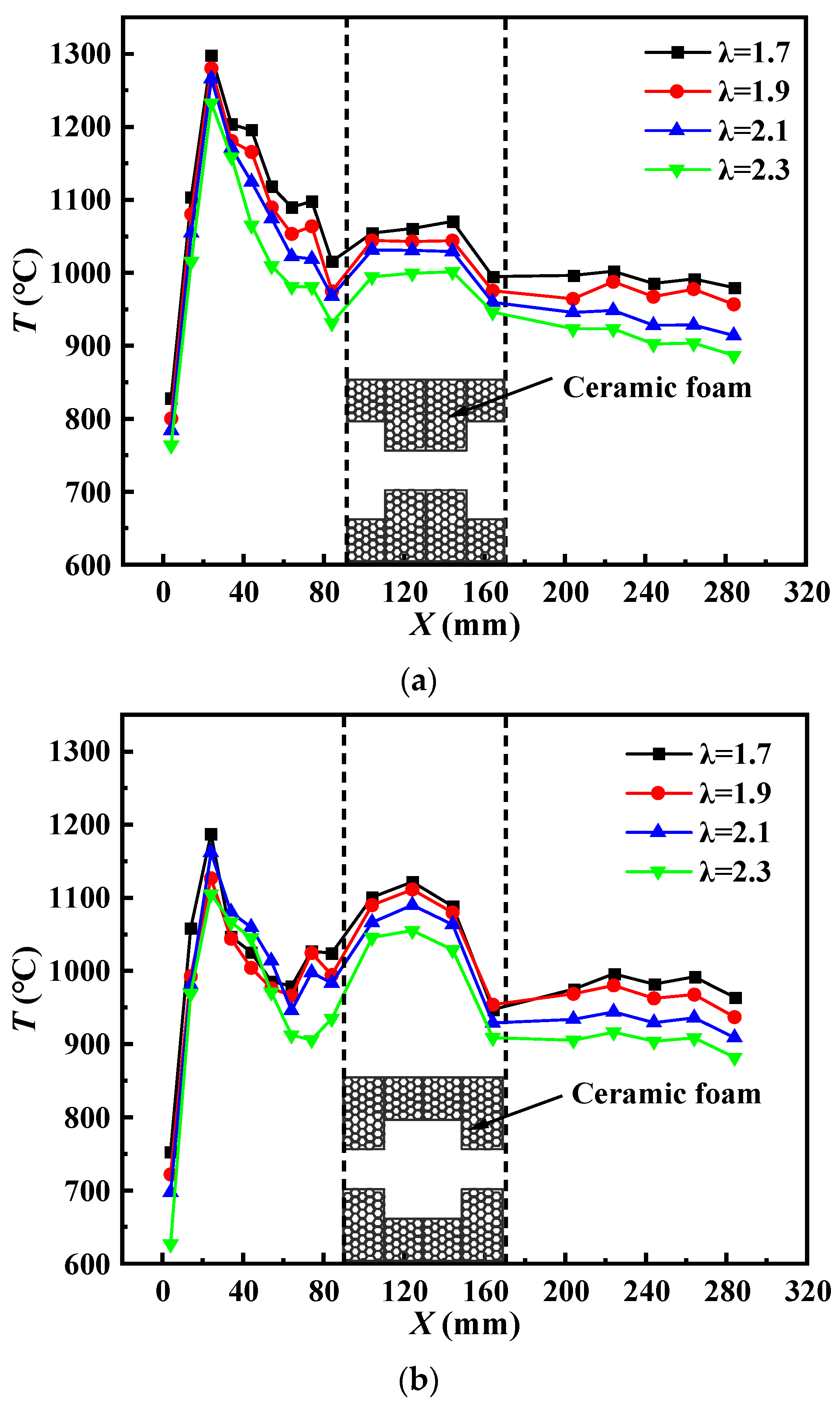

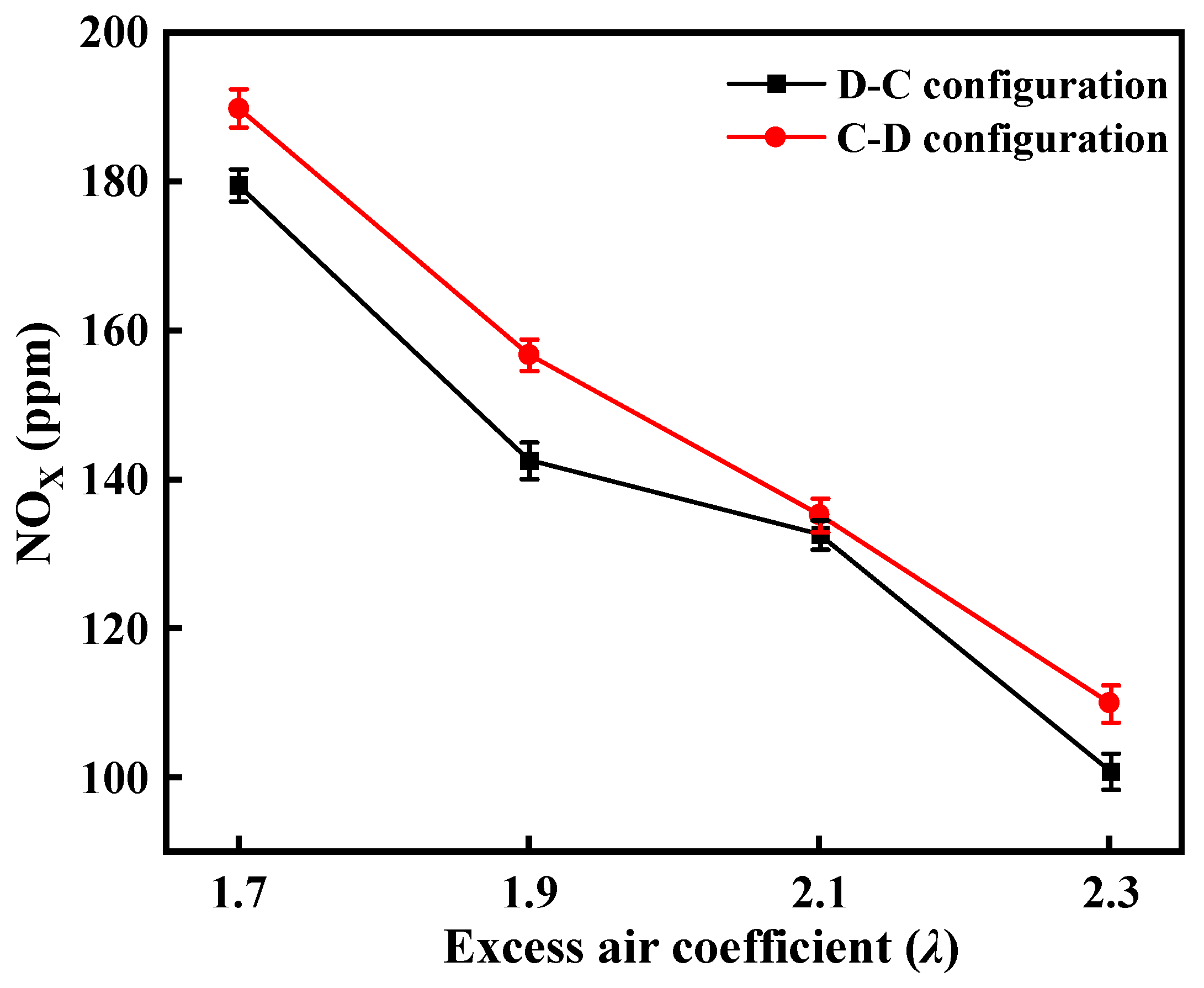

3.3. Effect of Porous Media Configuration

4. Conclusions

- (1)

- The position of the flame moves downstream, and the flame temperature simultaneously decreases when the distance between the metal fiber felt and foams increases. The NOx emission firstly reduces and then increases with the increasing distance between the foam and the metal fiber felt. The lowest NOx concentration is obtained when the distance between the foam and the metal fiber felt is 90 mm. The results show that distance has a great influence on the temperature and emission inside the burner, and excessive distance is not conducive to the combustion of liquid fuel and the performance of the burner.

- (2)

- The overall distribution along the axial direction and NOx emission declines with the increasing diameter of the central hole of porous media. Furthermore, the position of the flame moves towards the burner outlet with the increasing diameter of the central hole. This shows that the increasing diameter of the central hole weakens the thermal storage capacity of ceramic foam and leads to the decreasing internal temperature of the burner, which is not conducive to the evaporation of liquid fuel. On the whole, when the central hole diameter is 40 mm and the excess air coefficient is 2.3, the comprehensive temperature and emission performance can be considered an ideal situation.

- (3)

- Compared with the D configuration and C–D configuration, the axial temperature distribution of the C configuration and D–C configuration is more uniform and NOx emission is less. At the same time, the axial temperature distribution in the combustion chamber can be balanced by properly arranging the ceramic foam with the different diameters of the central hole, so that the thermal radiation is more uniform.

- (4)

- The presence of inert porous media in the burner has a notable impact on heat radiation and heat transfer. Experimental findings indicate that ceramic foam can increase the heat storage capacity within the burner to some extent, thereby facilitating the evaporation and self-sustaining combustion of liquid fuel. The objective of the upcoming research will be to simultaneously reduce emissions and enhance heat transfer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Howell, J.; Hall, M.; Ellzey, J. Combustion of hydrocarbon fuels within porous inert media. Prog. Energy Combust. Sci. 1996, 22, 121–145. [Google Scholar] [CrossRef]

- Oliveira, A.; Kaviany, M. Nonequilibrium in the transport of heat and reactants in combustion in porous media. Prog. Energy Combust. Sci. 2001, 27, 523–545. [Google Scholar] [CrossRef]

- Bubnovich, V.; Toledo, M.; Henríquez, L.; Rosas, C.; Romero, J. Flame stabilization between two beds of alumina balls in a porous burner. Appl. Therm. Eng. 2010, 30, 92–95. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Abdullah, M.Z.; Mohamad, A.; Bakar, M.A. Trends in modeling of porous media combustion. Prog. Energy Combust. Sci. 2010, 36, 627–650. [Google Scholar] [CrossRef]

- Mujeebu, M.A.; Abdullah, M.Z.; Bakar, M.Z.A.; Mohamad, A.A.; Abdullah, M.K. Applications of porous media combustion technology—A review. Appl. Energy 2009, 86, 1365–1375. [Google Scholar] [CrossRef]

- Aboujafari, M.; Valipour, M.S.; Hajialimohammadi, A.; Honnery, D. Porous Medium Applications in Internal Combustion Engines: A Review. Transp. Porous Media 2022, 141, 799–824. [Google Scholar] [CrossRef]

- Yang, W.M.; Chou, S.K.; Chua, K.J.; Li, J.; Zhao, X. Research on modular micro combustor-radiator with and without porous media. Chem. Eng. J. 2011, 168, 799–802. [Google Scholar] [CrossRef]

- Pan, J.F.; Wu, D.; Liu, Y.X.; Zhang, H.F.; Tang, A.K.; Xue, H. Hydrogen/oxygen premixed combustion characteristics in micro porous media combustor. Appl. Energy 2015, 160, 802–807. [Google Scholar] [CrossRef]

- Vahidhosseini, S.M.; Esfahani, J.A.; Kim, K.C. Experimental study on the radiative heat transfer in a multi-hole porous radiant burner with internal combustion regime. Appl. Therm. Eng. 2022, 201, 117732. [Google Scholar] [CrossRef]

- Djordjevic, N.; Habisreuther, P.; Zarzalis, N. Flame stabilization and emissions of a natural gas/air ceramic porous burner. Adv. Mat. Res. 2008, 47, 105–108. [Google Scholar] [CrossRef]

- Xie, M.Z.; Shi, J.R.; Deng, Y.B.; Liu, H.; Zhou, L.; Xu, Y.N. Experimental and numerical investigation on performance of a porous medium burner with reciprocating flow. Fuel 2009, 88, 206–213. [Google Scholar]

- Gao, H.; Qu, Z.; Feng, X.; Tao, W. Methane/air premixed combustion in a two-layer porous burner with different foam materials. Fuel 2014, 115, 154–161. [Google Scholar] [CrossRef]

- Peng, Q.; Xie, B.; Yang, W.; Tang, S.; Li, Z.; Zhou, P.; Luo, N. Effects of porosity and multilayers of porous medium on the hydrogen-fueled combustion and micro-thermophotovoltaic. Renew. Energy 2021, 174, 391–402. [Google Scholar] [CrossRef]

- Kaplan, M.; Hall, M.J. The combustion of liquid fuels within a porous media radiant burner. Exp. Therm. Fluid Sci. 1995, 11, 13–20. [Google Scholar] [CrossRef]

- Tseng, C.-J.; Howell, J.R. Combustion of liquid fuels in a porous radiant burner. Combust. Sci. Technol. 1996, 112, 141–161. [Google Scholar] [CrossRef]

- Vijaykant, S.; Agrawal, A.K. Liquid fuel combustion within silicon-carbide coated carbon foam. Exp. Therm. Fluid Sci. 2007, 32, 117–125. [Google Scholar] [CrossRef]

- Periasamy, C.; Sankara Chinthamony, S.K.; Gollahalli, S. A Computational Study of the Evaporation Characteristics of an Air-Blast Atomized, Kerosene Spray in Porous Media. In Proceedings of the ASME Power Conference, Baltimore, MD, USA, 30 March–1 April 2004; pp. 433–440. [Google Scholar]

- Weclas, M. Potential of porous-media combustion technology as applied to internal combustion engines. J. Thermodyn. 2010, 2010, 789262. [Google Scholar] [CrossRef]

- Liu, L.; Liu, H.; Liu, X.; Ma, J.; Xie, M. Numerical Simulation of n-Heptane Spray Combustion in a Porous Medium Burner. Combust. Sci. Technol. 2023, 195, 313–334. [Google Scholar] [CrossRef]

- Dent Jr, T.J.; Marbach, T.L.; Agrawal, A.K. Computational study of a mesoscale combustor with annular heat recirculation and porous inert media. Numer. Heat Trans. A Appl. 2012, 61, 873–890. [Google Scholar]

- Makmool, U.; Pontree, K.; Jugjai, S. Design and development of a novel self aspirating liquid fuel annular porous medium burner (SLAPMB). Fuel 2017, 192, 83–92. [Google Scholar] [CrossRef]

- Sharma, M.; Mishra, S.C.; Mahanta, P. Effect of burner configuration and operating parameters on the performance of kerosene pressure stove with submerged porous medium combustion. Appl. Therm. Eng. 2016, 107, 516–523. [Google Scholar] [CrossRef]

- Takami, H.; Suzuki, T.; Itaya, Y.; Hasatani, M. Performance of flammability of kerosene and NOx emission in the porous burner. Fuel 1998, 77, 165–171. [Google Scholar] [CrossRef]

- Fuse, T.; Araki, Y.; Kobayashi, N.; Hasatani, M. Combustion characteristics in oil-vaporizing sustained by radiant heat reflux enhanced with higher porous ceramics. Fuel 2003, 82, 1411–1417. [Google Scholar] [CrossRef]

- Jugjai, S.; Wongpanit, N.; Laoketkan, T.; Nokkaew, S. The combustion of liquid fuels using a porous medium. Exp. Therm. Fluid Sci. 2002, 26, 15–23. [Google Scholar]

- Jugjai, S.; Polmart, N. Enhancement of evaporation and combustion of liquid fuels through porous media. Exp. Therm. Fluid Sci. 2003, 27, 901–909. [Google Scholar] [CrossRef]

- Jugjai, S.; Phothiya, C. Liquid fuels-fired porous combustor-heater. Fuel 2007, 86, 1062–1068. [Google Scholar] [CrossRef]

- Wongwatcharaphon, K.; Tongtem, P.; Jugjai, S. Numerical and experimental study of a nonsprayed porous burner for liquid kerosene. J. Porous Media 2013, 16, 227–239. [Google Scholar]

- Moffat, R.J. Describing the uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–17. [Google Scholar] [CrossRef]

| Element Name | Symbol | Mass Fraction of Each Element (%) |

|---|---|---|

| Carbon | C | 85.55 |

| Hydrogen | H | 13.49 |

| Oxygen | O | 0.66 |

| Sulfur | S | 0.25 |

| Nitrogen | N | 0.04 |

| Other elements | - | 0.01 |

| Excess Air Coefficient (λ) | Actual Air Volume (L) |

|---|---|

| 1.7 | 20.4425 |

| 1.9 | 22.8475 |

| 2.1 | 25.2525 |

| 2.3 | 27.6575 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, H.; Wang, Y.; Zong, S.; Ma, Y.; Zhang, C. Experimental Investigation of a Self-Sustained Liquid Fuel Burner Using Inert Porous Media. Energies 2023, 16, 5564. https://doi.org/10.3390/en16145564

Gao H, Wang Y, Zong S, Ma Y, Zhang C. Experimental Investigation of a Self-Sustained Liquid Fuel Burner Using Inert Porous Media. Energies. 2023; 16(14):5564. https://doi.org/10.3390/en16145564

Chicago/Turabian StyleGao, Huaibin, Yongyong Wang, Shouchao Zong, Yu Ma, and Chuanwei Zhang. 2023. "Experimental Investigation of a Self-Sustained Liquid Fuel Burner Using Inert Porous Media" Energies 16, no. 14: 5564. https://doi.org/10.3390/en16145564

APA StyleGao, H., Wang, Y., Zong, S., Ma, Y., & Zhang, C. (2023). Experimental Investigation of a Self-Sustained Liquid Fuel Burner Using Inert Porous Media. Energies, 16(14), 5564. https://doi.org/10.3390/en16145564