Abstract

Biodiesel is widely known as the alternative fuel for the diesel engine, but it comes with its fair share of challenges. To minimize the pertinent drawbacks, fuel additives become an essential tool and help improve renewable fuel’s properties. In this current research, biodiesel is obtained from rice bran oil and cotton seed oil, with diethyl ether as an additive. Diethyl ether is known for good oxygen content, high cetane number, and low viscosity. Experiments were performed on a variable compression ratio engine at a compression ratio of 18:1, and the injection pressure (170 bar, 180 bar, 190 bar and 200 bar) and the injection timing (20, 21, 22 and 23°bTDC) with four different dual biodiesel blends (5%, 10%, 15% and 20% by volume). Different ratios of 1%, 2.5% and 5% of diethyl ether with biodiesel combination were examined in a single-cylinder, four-stroke diesel engine. The engine emission and performance features were discussed at different loads and constant engine speeds. It was observed that using 5% of diethyl ether with biodiesel blends improved brake thermal efficiency, brake-specific fuel consumption and decreased carbon dioxide and oxides of nitrogen emissions. The reduction of oxides of nitrogen emission contributes to biodiesel’s acceptability for the environment’s benefit. This investigation found that diethyl ether, along with dual biodiesel blends, has a better viability in diesel engines.

1. Introduction

The world’s population and industrialization drive energy demand, causing oil-based fuel stocks to deplete quickly [1]. The world is experiencing serious problems because of the rising demand for fossil fuels, the steadily rising cost of crude oil, and the characteristics of fossil fuel that cause it to emit hazardous gases, which lead to severe air pollution. Using alternative fuels, particularly fuel produced from biodiesel, would aid in lowering greenhouse gas emissions. One potential substitute for diesel fuel that has gained popularity is biodiesel [2,3,4]. Additionally, embracing renewable fuels can allow several countries to reduce their reliance on imported oil [5].

One of the most promising substitute fuels for diesel engines is biodiesel, which does not require engine modification [6]. Biodiesel can increase combustion effectiveness and reduce engine emissions as an oxygenated fuel. Due to their lower calorific values, higher density, and viscosity, most studies found that using biodiesel as a diesel fuel substitute in internal combustion engines without significant modifications can impact engine performance degradation and a substantial reduction in engine performance and thermal efficiency [7]. To make the fuel blend’s qualities more similar to diesel fuel, biodiesel is typically blended with diesel in various ratios. Furthermore, fuel additives can also be used to improve the properties of biodiesel to make them more comparable in performance to those of diesel.

Biodiesel has a higher viscosity than diesel. The combustion efficiency will be decreased due to improper atomization of high viscous fuel injection. Alcohol has a low viscosity. Alcohols are thus added to diesel–biodiesel blends to reduce the viscosity of the fuel to that of diesel. Alcohols are oxygenated fuels that are renewable and can be produced from biomass. Alcohol such as butanol, diethyl ether, methanol, and ethanol are also utilized as fuel additives. Diethyl ether can be the best fuel additive for CI engines due to its greater CN and thermal efficiency than that of ethanol and butanol. Diesel and biodiesel are also miscible with diethyl ether [8].

1.1. Literature Review on Compression Ratio

Sharma Dugala et al. [9] investigated the properties of a dual biodiesel blend, mahua, and jatropha in equal quantities with diesel in a diesel engine with CRs of 13.5:1, 14.5:1, 15.5:1, and 16.5:1. At CR 16.5:1, the brake power of the blends improves by 1.58% when compared to diesel. The blended CO and HC emissions were reduced by 33% and 62%, respectively. Blend B20 was the most effective of all the mixes tested. Areef Ahamed Shaik et al. [10] investigated the effect of CRs of 18:1, 20:1, and 22:1 on the EGR rates of a diesel engine running on a B20 blend of mango seed methyl ester. At CR 22:1, brake thermal efficiency increased by 7.4%, lower CO and HC emissions by 33.3% and 40%, respectively. The amount of NOx emitted rose significantly. NOx emissions were reduced by 40.5% when the engine was run at CR 22:1 with 5% EGR. Jatinder Kataria et al. [11] experimented with the performance of diesel engines using waste-cooking biodiesel blends, such as B20, B40, B60, B80, and B100, at various compression ratios. A CI engine that runs at a constant 1500 rpm, 200 bar of injection pressure, 15:1 to 17.5 compression ratios, and varying engine loads has been put through tests. BTE is directly related to CR. Hence an increase in CRs resulted in a rise in brake thermal efficiency. The biodiesel blends B40, which has a CR17.5 and is higher than base diesel and has the highest BTE at full load. BSFC decreased with increasing load at compression ratios of 15:1 and 17.5:1 for all tested fuels.

Antony Miraculas et al. [12] carried out the tests utilizing various Tamanu biodiesel blends. According to their findings, a higher CR raises the cylinder’s high temperature, which enhances performance. They found that higher biofuel blends and CR result in lower CO and HC emissions, but higher levels of CR also result in higher NO emissions. They have concluded that the empirical model, which is experimentally evaluated and proved to be in close accord with diesel, predicted Tamanu biodiesel in a B30 blend at CR19. Mohammed EL Kassaby et al. [13] conducted testing with a range of waste oil blends, including B10, B20, B30, and B50, and the CR was between 14 and 18. Their investigation showed that an increase in CR resulted in improvements in brake thermal efficiency for B10, B20, B30, and B50 of 18.39%, 27.48%, 18.5%, and 19.82%, respectively. The CR was increased from 14 to 18, which resulted in a 52% and 37.5% decrease in HC and CO emissions but a 36.84% rise in NO emissions. They observed that increased CR causes a reduction in the ignition delay time of 13.95%. According to their investigation, adding more biodiesel to the CR improved the engine’s efficiency and cylinder pressure compared to diesel fuel. Biswajit De et al. [14] investigated the power and emissions of a single cylinder, four-stroke variable compression ratio (16, 17, and 18), and various Jatropha oil blending ratios (10%, 30%, 50%, 80%, and 100%) in comparison to diesel. Their research showed that at a CR of 18, the BTE, exhaust gas temperature, and emission parameters, including NOx and CO, are equivalent to diesel fuel for blends comprising up to 30% (by volume) Jatropha oil. The temperature of the exhaust gases and the emission parameters like NOx and CO rise when the concentration of jatropha oil in the mixes rises, which lowers the engine’s thermal efficiency. Table 1 shows a summary of the literature review on the compression ratio.

Table 1.

Summary of the literature review on compression ratio.

1.2. Literature Review on Injection Pressure

Jindal et al. [15] examined the impact of CR and IP on a DI diesel engine operating on jatropha methyl ester. The experiments were conducted with three different loads, CRs (16, 17, and 18), and IPs (150, 200, and 250 bar). JME’s BSFC and BTE at IP of 250 bar and CR of 18 were found to be 10% and 8.9% better than those at normal CR and IP, respectively. They concluded that using neat jatropha methyl ester with CR and IP resulted in lower levels of HC, smoke output, and exhaust temperature. Mutyalu et al. [16] investigated the use of shea olein methyl ester blends to examine the engine performance and the emission characteristics at various injection pressures. The tests were carried out with varying injection pressures under constant load (190, 200, 210, 220, and 230 bars). According to reports, the BTE increased with a lower biodiesel blend when 210 bar injection pressure was used, which is greater than the other injection pressures. With the biodiesel combinations, the CO and HC emissions were reduced, while at 210 bar injection pressure, the NOx emissions increased. It has been determined that for all biodiesel blends, the 210-bar injection pressure improves performance as well as emission characteristics. Shehata et al. [17] have analyzed the impact of IP on the performance of a diesel engine using biodiesel blends of corn and soybeans. Experiments were conducted utilizing 20% biodiesel blends, such as C20 and S20, with IPs of 180, 190, and 200 bar at varied engine speeds and loads. They have observed that for all tested fuels, a rise in IP at 200 bar results in better performance when compared to that of the original IP. According to their research, S20 and C20 obtained the highest BTE and the lowest BSFC at an IP of 200 bar. They concluded that the peak pressure was greater than that of C20 and S20 blended fuels at an IP of 200 bar. Additionally, they concluded that a rise in IP demonstrated a reduction in combustion time, an increase in peak pressure, and an increase in heat release rate.

Cenk Sayin et al. [18] investigated the effect of IP on the combustion and performance parameters of a DI diesel engine fueled with canola oil–methyl esters (COME)–diesel combinations. Four different IP such as 18, 20, 22, and 24 MPa, were examined at various engine loads while maintaining a constant engine rpm. They have stated that the highest pressure in the cylinder and maximum rate of pressure increase was lower for COME than that of diesel at high IP, and also maximum heat release rate was lower. They observed that the Canola Oil Methyl Esters, performed better on BSFC, BSEC, and BTE at an IP of 24 MPa. Pankaj Shrivastava et al. [19] investigated the impact of B20, B40, and B100 Roselle biodiesel blends on compression ignition engines examined by varying the fuel injection pressure (180, 200, 220, 240, and 260 bars), loading (25, 50, 75, and 100%), and comparing the results to diesel fuel. According to the findings, increasing the injection pressure increased brake-specific fuel consumption, exhaust gas temperature, cylinder pressure, maximum rate of pressure rise, carbon dioxide, and oxide of nitrogen emissions while decreasing the ignition delay period, smoke emission, thermal efficiency, and indicated efficiency. Additionally, at 220 bar injection pressure, smoke and nitrogen oxide emissions for RB20 blend reduced by 3.18 and 2.20 percent, respectively, while carbon dioxide emissions increased by 1.6%. Table 2 shows a summary of the literature review on injection pressure.

Table 2.

Summary of the literature review on injection pressure.

1.3. Literature Review on Injection Timing

Akash Deep et al. [20] examined the effects of changing fuel injection time and pressure on the combustion, performance, and emission of a C.I. engine running on a 20% castor biodiesel blend of diesel. Their analysis indicates that for all fuel injection pressures, BTE was reduced by advancing and retarding fuel injection timing. According to the findings, the original engine setup, 23°bTDC at 200 bars, produced the least CO and HC emissions. While the NOx emissions were reduced at a retarded IT of 21°bTDC at IP 300 bar, the smoke capacity was lowered at an advanced IT of 25°bTDC for a 20% blend of castor biodiesel at the expense of a sizable loss in BTE.

Arun Kumar Wamankar et al. [21] studied IT’s impact on the performance and emissions of a DI diesel engine running on a synthetic fuel blend (carbon black derived from the pyrolysis of waste automobile tires). Experiments were conducted with advanced IT 26°bTDC and 24.5°bTDC, as well as retarded IT 21.5°bTDC and 20°bTDC, utilizing a synthetic fuel blend consisting of 10% C.B. and 90% diesel on a volume basis. The BTE for CB10 was greater by 6.4%, and the BSFC was lower by 11.9% than that of the original IT, according to the 26°bTDC’s advanced IT, which they have observed. They concluded that the 26°bTDC advanced IT had a 13.5% reduced smoke emission and a NO emission that was 23% greater than the original IT

Niraj Kumar et al. [22] performed experiments using Jatropha biodiesel (40% B.D. + 60% diesel) with three IP of 180, 210, and 240 bar, three CR of 16, 17, and 18, and three IT of 20°, 23°, 26°bTDC. They observed that compared to the original CR in the instance of B40, an increase in CR increases BTE and BSFC and decreases tailpipe emissions. They discovered that compared to other ITs, boosting IT enhances BTE and reduces emissions in the case of B40. They concluded that the combination of CR18:1, IP 240 bar, and IT 26°bTDC considerably increased BTE, BSFC, and decreased exhaust pollutants when compared to a diesel with conventional values for CR, IP, and IT

Arunprasad et al. [23] examined the impact of injection time and pressure on the performance and emission characteristics of diesel engines using a blend of biodiesel produced by a combination of thevetia peruviana, jatropha, pongamia, and azadirachta indica. The IT is adjusted from 23 to 29°bTDC at an increment of 2°bTDC and 10 bar, respectively, while the IP is increased from 200 to 230 bar. It was noted that the BTE increased by 1.5% with an increase in IT at maximum load and 2.4% with an increase in IP at maximum load. By increasing the IP and IT, it is possible to observe the decrease in HC, CO, and smoke emissions and the increase in NOx and CO2 emissions at the maximum load.

Cenk Sayin et al. [24] conducted experiments at five different IT, including 21°, 24°, 27°, 30°, and 33°bTDC using a 5% ethanol biodiesel mixture and two distinct loads of 15 and 30 Nm. They observed that while NOx emissions from ethanol-blend diesel fuel increased by 5–15%, CO, and HC emissions decreased by 10–70% and 10–45%, respectively. They have also noted that as compared to the original IT (27°bTDC), the retarded IT (21° and 24°bTDC) produces more NO and CO2 emissions while emitting less HC. and CO. They concluded that IT that was both advanced and retarded, had detrimental effects on BTE and BSFC at all loads and speeds. Table 3 shows a summary of the literature review on injection pressure.

Table 3.

Summary of the literature review on injection timing.

1.4. Literature Review on Diethyl Ether

Tudu et al. [25] investigated the impact of DEE as an additive (up to 4%) on a combination of 60% diesel and 40% of tire-derived fuel. The results indicated that the NOx emission decreased by 25% and the BSFC by 6% compared to diesel operation at maximum load. Sivalaksmi et al. [26] carried out the study with 5% DEE added to the neem-biodiesel mixture and concluded that DEE, BTE, and BSFC were better and observed a decrease in CO and smoke emissions. Based on the experiments’ results, it was determined that adding up to 5% DEE to diesel fuel would have a significant effect without requiring structural modifications to the engine. This was made possible by advancements in spray atomization and fuel–air mixing. Because of improved spray atomization and fuel–air mixing, the rich region in the cylinder was reduced, lowering CO emissions. Qi et al. [27] examined the impacts of adding ethanol and DEE to the mixture of biodiesel and diesel on engine performance. Adding 5% DEE, BSFC, and CO emissions decreased, and NOx and HC emissions increased compared to a biodiesel B30 blend. The primary factor may be the higher volatility of diethyl ether, which increases the combining of the air/fuel mixture, improves combustion and increases combustion efficiency.

Barik et al. [28] investigated a biogas-Karanja methyl ester-fueled dual-fuel engine. With the aid of an electronic injector, they injected 2%, 4%, and 6% DEE while running the engine on Karanja methyl ester, biogas, and DEE. This resulted in a 2.3% increase in BTE and a 5.8% decrease in BSFC compared to BDFM24.5 at full engine load. However, NOx levels with the blend were approximately 12.7% higher at full load than with BDFM24.5. Venu et al. [29] examined the influence of diethyl ether (DEE) in addition to methanol and ethanol biodiesel blends in a diesel engine. They observed that adding 10% of DEE decreased NOx, HC, and BSFC. Devaraj et al. [30] analyzed the performance of a single-cylinder diesel engine by adding waste plastic pyrolysis oil blended with diethyl ether (5% and 10%). The study found that combining DEE up to 10% with plastic waste oil increased BTE from 28% to 29% while lowering pollutants like NOx and CO. Murat et al. [31] investigated the performance and exhaust emission attribute of a compression ignition engine powered with cottonseed oil biodiesel /DEE and diesel blends. The experimental results exhibited that BTE, HC, CO2, and NOx emissions decreased, and BSFC increased by adding 10% of DEE in the combinations compared to diesel. Paul et al. [32] investigated the effects of adding DEE and ethanol to diesel fuel on emission and performance using a single-cylinder diesel engine. There were six different biodiesel fuel blends utilized. With a 5% DEE blend, the engine’s thermal efficiency, whereas with a 10% DEE blend. However, engine efficiency increased in both cases when ethanol was added to the mixture. Ethanol and DEE significantly reduced CO, NOx, hydrocarbon, and particulate matter emissions.

Kaimal et al. [33] examined the diesel engine’s emission properties using 5% to 15% of DEE added to waste plastic blends and concluded that higher DEE resulted in high thermal efficiency and reduced NOx emission. Rajan et al. [34] studied the engine’s performance under various loading circumstances using Karanja biodiesel with 10% and 15% using DEE as an additive. They found a decrease in NOx and smoke emission for Karanja biodiesel utilizing a DEE combination of a 15% decrease in peak pressure. The lower NOx emissions from DEE may be due to the high latent heat of vaporization of DEE, which resulted in cooling the charge at maximum load when compared to biodiesel. Pragyan et al. [35] evaluated the performance, combustion, and emission parameters of a CI engine with a 15% DEE combination. It was also revealed that, when compared to diesel, DEE additives reduced CO, HC, and smoke while increasing NOx. Ramadhas et al. [36] examined the performance of a biodiesel-fueled engine with crude rubber seed oil and diethyl ether as an additive. DEE was combined with biodiesel in a 5% to 20% concentration. Comparing DEE blends with diesel, it was found that 5% DEE blends resulted in higher BTE and lower CO and NOx emissions.

Patil et al. [37] investigated the effects of DEE combinations with kerosene and diesel on a diesel engine’s performance, emissions, and combustion characteristics. DEE was blended with diesel ranging from 2%, 5%, 8%, 10%, 15%, 20%, and 25% by volume. The test outcome revealed that the DEE combination had high brake-specific fuel consumption, low brake thermal efficiency, and reduced NOx. As DEE was added, the blends’ oxygen content and cetane number increased, whereas their density and calorific value decreased. Rakopoulos et al. [38] conducted a study to assess the performance and exhaust emission properties of diesel fuel blends with diethyl ether at various ratios, 8%, 16%, and 24% in single-cylinder, four-stroke diesel engines. For the test, the engine was operated in diesel with three loads, fuel consumption, and smoke emissions such as NOx, Carbon monoxide, and HC. It has been observed that DEE improved the BSFC, increased the HC emission and decreased the smoke emission, NOx, and CO. Lee et al. [39] examined that combining the DEE to diesel in various proportions of 10%, 25% and 50% NOx increased, HC and CO decreased. DEE with a higher cetane number performs as an ignition enhancer, reducing the combustion duration and implying a greater combustion rate, resulting in lower CO emissions. Due to DEE’s low boiling point, combustion can start earlier, increasing the temperature of the combustion gas and allowing it to reach the activation temperature of carbon combustion rapidly. It thus enhanced hydrogen fuel oxidation, resulting in better combustion and reduced HC emissions. Table 4 summarizes the literature review of diethyl ether with biodiesel blends.

Table 4.

Summary of the literature review of diethyl ether with biodiesel blends.

1.5. Research Gap and Motivation of the Research

The depletion of fossil fuels and serious environmental issues force us to use alternative fuels in automobiles. It has been observed that biodiesel is a viable and possible solution for diesel fuel. Some researchers have attempted to use neat biodiesel, despite its disadvantages of decreased performance and increased NOx emission. Because of their high viscosity, low volatility, and high molecular weight, direct vegetable oils cannot be used in CI engines. The transesterification process would therefore improve the performance and emissions of biodiesel.

Many researchers have investigated vegetable oils for fuel production, such as karanja, jatropha, mahua, neem, and rubber. Except for jatropha and karanja, very few studies have been conducted on the use of vegetable oils for biodiesel production. Agriculture is the Indian economy’s backbone; plants for biodiesel can be easily cultivated on barren land and in dry regions.

India is the second-largest producer of rice and cotton, and the availability of cottonseed oil and rice bran oil biodiesel feedstocks helps with the production of biodiesel, which would be able to replace the fossil fuel and helps to meet future energy needs [40].

Based on an extensive review of the literature, it has been found that minimal attention has been paid to the use of biodiesel in VCR engines, and more specifically, on the use of a combination of methyl ester cotton seed oil and methyl ester rice bran oil as biodiesel in VCR engines. In the current study, cotton seed and rice bran biodiesel have been used in a conventional VCR diesel engine with a focus on assessing the dependence of different loading conditions on engine performance parameters and emission characteristics. In addition, the effect of using DEE as an additive has also been investigated.

2. Experimental Methodology

2.1. Experimental Setup

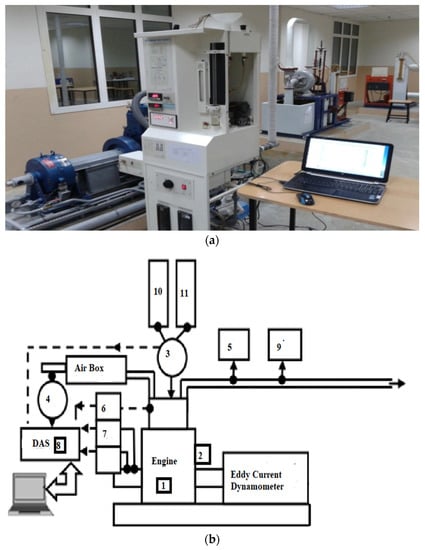

The tests were conducted on a single-cylinder, four-stroke, 3.5 kW diesel engine to analyze the VCR diesel engine’s performance and emissions when using dual biodiesel and DEE. The experimental setup is represented in Figure 1a, and schematic diagram of the experimental setup are shown in Figure 1b. An AVL DIGAS analyzer was connected to the engine exhaust, and the pollutants were measured using the exhaust gas analyzer. The engine started at zero load and ran for some time to achieve steady-state operation. Stopwatch and fuel measuring unit were used to determine the fuel consumption by measuring the time taken for the fuel consumption of 20cc fuel. Engine performance analysis software package, Enginesoft, was used for online performance assessments. The performance of the engine, BSFC, and BTE were calculated. The exhaust emission from the engine, such as HC, CO, CO2, and NOx, were analyzed using an AVL DIGAS analyzer. Table 5 shows the technical specification of the test engine.

Figure 1.

(a) Experimental Setup; (b) Schematic diagram of the experimental setup.

In the current research work, clean and filtered water was used to avoid any suspended particles that may clog the piping. We circulated the engine cooling water through the dynamometer for 5 to 10 min after shutting down the engine. VCR engine was initially permitted to run with diesel fuel and at no-load for the first 20 min to ensure that the exhaust gas and outlet cooling water temperatures remained consistent to attain the steady-state condition. This signified that the combustion process within the cylinder had achieved a stable condition and that the engine was set to collect data. The engine was then gradually restored to a full load condition and ran for 5 min. The exhaust gas analyzer was also turned on slightly early to stabilize the system before commencing the experiment to measure emissions. The analysis started with recording the engine’s baseline results while fueled with diesel at various loads (0 kg, 3 kg, 6 kg, 9 kg, and 12 kg). Following the diesel tests, biodiesel blends were tested. For each change of load, the engine was allowed to run for 5 min to become stabilized at the new load and then all other readings were taken. Finally, three different readings were taken for each parameter and recorded.

The important components of the experimental setup are:

- Diesel Engine

- Measurement of Speed and Load

- Fuel Flow Measurement

- Air Flow Measurement

- Measurement of Temperature

- Pressure Measurement

- Charge Amplifier

- Data Acquisition System (DAS)

- Emission Measurement

- Diesel Tank

- Biodiesel Tank

Table 5.

Technical Specification of Test Engine.

Table 5.

Technical Specification of Test Engine.

| Description | Engine Specification |

|---|---|

| Make and Model | Kirloskar Oil Engine, TV1 |

| Type | Single-cylinder, Four-stroke Diesel engine |

| Dynamometer | Eddy Current, Water Cooled, with the Loading Unit |

| Power | 3.5 kW |

| Bore | 87.5 mm |

| Stroke | 110 mm |

| Compression Ratio | CR 12 to 18 |

| Rated Speed | 1500 rpm |

| Fuel Injection Timing | 23°bTDC |

| Engine Setup Dimensions | W 2000 × L 2500 × H 1500 mm |

2.2. Procedure for Preparation of Methyl Ester Cotton Seed Oil and Methyl Ester Rice Bran Oil

Numerous researchers have made significant efforts to develop the processes for producing biodiesel, and they are still looking into ways to increase product yields, improve fuel quality, and lower production costs. Many researchers have investigated biodiesel production procedures and found that the transesterification method is the most effective. One of the most practical processes for producing biodiesel is transesterification, which entails the reaction of any triacylglycerol, such as vegetable oil, with alcohol in the presence of a catalyst to produce both biodiesel and glycerol [41,42,43]. The procedure for preparing Methyl Ester Cotton seed Oil and Methyl Ester Rice Bran Oil has been represented in Table 6. Homogenizers were used at the speed of 1000–1500 rpm for mixing MECSO, MERBO, and DEE with diesel for 15 min. The biodiesel properties, DEE combination with diesel, are represented in Table 7 and Table 8. DEE fuel properties are shown in Table 9. Stirring and handling of biodiesel solutions can often produce a fine mist of liquid droplets. If this mist is inhaled, severe irritation of the respiratory tract and breathlessness can occur. Masks were used for the preparation of biodiesel.

Table 6.

MECSO and MERBO production process.

Table 7.

Properties of Diesel, Dual (MECSO and MERBO) Biodiesel Blends [44,45].

Table 8.

Diesel DEE with biodiesel and B20 properties [44,45,46].

Table 9.

DEE properties [47,48].

This study compared the engine performance and emission characteristics of various fuel blends, as shown in Table 10 and Table 11. In the current research work, 1%, 2.5% and 5% of diethyl ether were added to the biodiesel and diesel. The effects of the fuel’s attributes on emission characteristics and performance were investigated.

Table 10.

Nomenclature of Dual Fuel (MECSO and MERBO).

Table 11.

Nomenclature of fuel.

2.3. Selection of Operating Parameters

According to several researchers, there is a need for research in the field of operating parameters to accommodate. Studies show that diesel engines effectively utilize operational factors, including compression ratio, injection duration, and injection pressure to enhance performance and lower emissions.

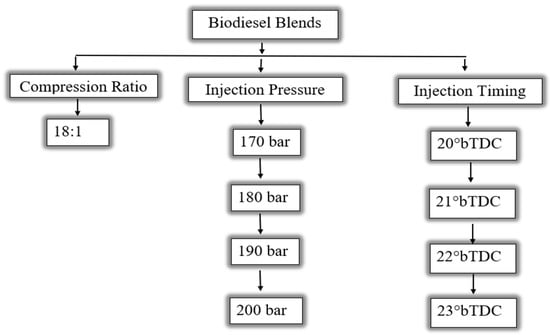

From the literature review, the CR of most CI engines that run on biodiesel ranges from 16 to 22. In the current experiment, the compression ratio of 18:1 was selected to investigate the performance of the CI engine due its supreme performance based on the previous research of the authors [44,46]. The IP of most biodiesel-powered CI engines ranges from 150 to 260 bar. In this investigation, the IP varied from 170 to 200 bars. Most researchers pointed out that 20° to 35°bTDC IT is most suitable for advancing IT. Therefore, in the current study, 20°bTDC, 21°bTDC, 22°bTDC, and 23°bTDC were selected to investigate the performance and emission characteristics of the CI engine using MECSO and MERBO biodiesel. Figure 2 shows the selection of operating parameters.

Figure 2.

Selection of operating parameters.

3. Results and Discussion

An alternative fuel used in engines is constantly assessed based on how well it performs in engines and how it affects the environment. As a result, this part will describe and analyze many parameters that define the diesel engines’ efficiency and emissions assessed experimentally in this work.

The result and discussion section discusses the engine test results and the data analysis. Dual biodiesel is used as a fuel and is blended with diesel in various amounts, such as 5%, 10%, 15%, and 20%. Section 3.1 and Section 3.2 examine the performance and emission characteristics with varied injection pressure and timing. The engine’s performance is improved by adjusting the operating parameters. The use of biodiesel causes increased NOx emissions. Based on the necessity, diethyl has been chosen to mix with biodiesel blends to reduce NOx emissions in Section 3.3.

The performance of diesel engines powered by dual biodiesel was improved, and gas emissions were decreased using the following techniques:

- Experiment of injection pressure optimization;

- Experiment of injection timing optimization;

- Experiment of the effect of diethyl ether with dual biodiesel blends.

The findings of experiments performed using the aforementioned approaches are described in this section. A VCR diesel engine’s performance and emission characteristics fueled by dual biodiesel blends are then compared.

3.1. Experiment of Injection Pressure Optimization

These experiments were conducted at various loads 0, 3, 6, 9 and 12 kg at Injection pressures of 170 bar, 180 bar, 190 bar, and 200 bar used in the tests, a compression ratio of 18, 23°bTDC IT, and at the constant speed of 1500 rpm in the VCR diesel engine. Dual biodiesel blends (MECSO and MERBO) and diesel are used in the experiment. B20 and diesel blends were chosen for the experiment. Here are the various performance characteristic curves developed based on the findings of the experiments. For proper comprehension of various curves, 0 kg is not considered.

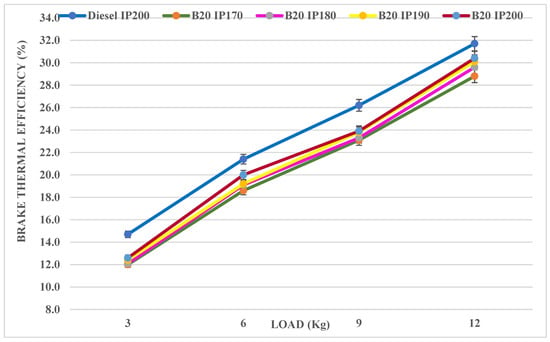

3.1.1. Brake Thermal Efficiency

Figure 3 shows the variation of BTE with load for the B20 blend at different injection pressure. The graph demonstrates that the BTE increases as the load rises. The BTE at IP 200 bar is 30.4%, and for IP 170 bar, it is 28.8% at full load. Due to better atomization and the creation of fine spray under higher injection pressure, which results in complete combustion, BTE has increased. Higher IP increases the pressure inside the combustion chamber to rise, which shortens the ignition delay and raises BTE. Lower IP causes lower internal pressure and a longer ignition delay, leading to poor combustion and a decline in BTE. BTE of IP 200 is higher by 5.26% compared to IP 170.

Figure 3.

Variation of BTE with Load for Different IPs with Diesel and B20 Blend.

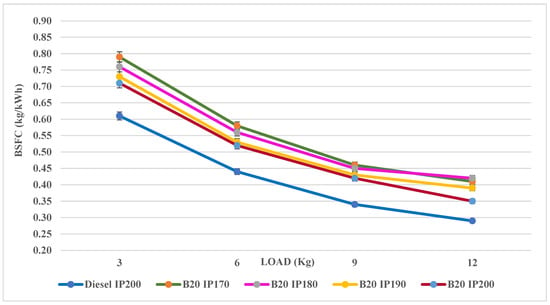

3.1.2. Brake-Specific Fuel Consumption

Figure 4 displays the variation of BSFC with load for the B20 blend at different injection pressure. From Figure 4, the BSFC decreases as the load increases. The BSFC at IP 200 bar is 0.35 kg/kWh, and for 170 bar, it is 0.41 kg/kWh at full load. The reduction in BSFC is due to enhanced mixing and atomization in the combustion chamber. When the IP is high, the fuel enters the combustion chamber quickly as a fine spray, improving good combustion through improved atomization. Low IP will result in a bigger fuel spray size and poor atomization and combustion. Additionally, more fuel is needed to solve the abovementioned issue, raising the BSFC at low IP. The BSFC of IP 200 is 14.63% lower than the BSFC of IP 170.

Figure 4.

Variation of BSFC with Load for Different IPs with Diesel and B20 Blend.

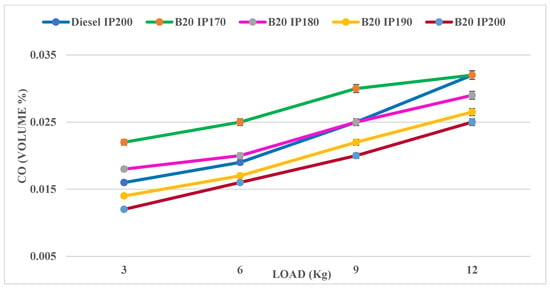

3.1.3. Carbon Monoxide

Figure 5 shows the variation of CO emission with load for the B20 blend at different injection pressure. In general, the CO increases as the load increases. According to the graph, CO is lower in IP at 200 bar than in other IPs. The CO for IP 200 bar is decreased by 21.87% compared to IP 170 bar at full load. At a high IP, the fuel is well atomized and mixed entirely with air, producing complete combustion and reducing CO emissions. This is also due to better air-fuel mixing and complete combustion of the smaller droplets at higher IP. At low IP, the droplet size of the fuel is larger and causes poor atomization. At high IP, better mixing of air-fuel and rapid evaporation of fuel sprays leads to complete combustion, which decreases CO emissions.

Figure 5.

Variation of CO with Load for Different IPs with Diesel and B20 Blends.

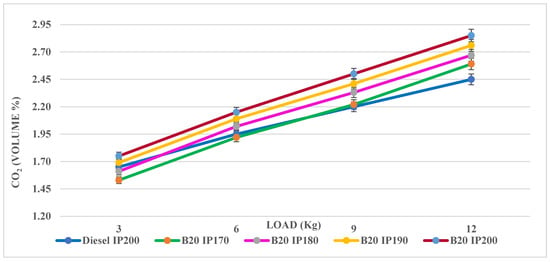

3.1.4. Carbon Dioxide

The variation of CO2 emission with load for the B20 blend at various injection pressures is shown in Figure 6. In general, as loads increase, CO2 levels rise as well. According to the graph, IP at 200 bars has a higher CO2 than other IPs. The CO2 for IP 200 bar is increased by 9.12% compared to that of IP 170 bar at full load. A high IP encourages the fuel to be completely atomized and thoroughly mixed with the air, which results in complete combustion and increases CO2 emissions.

Figure 6.

Variation of CO2 with Load for Different IPs with Diesel and B20 Blends.

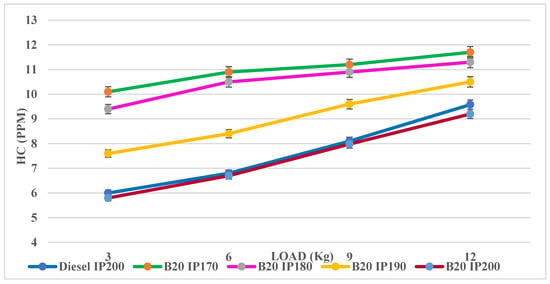

3.1.5. Unburnt Hydrocarbon

Figure 7 shows the variation of HC emission with load for the B20 blend at various injection pressure. From Figure 7, the HC rises as the load increases. The HC for IP 200 bar is decreased by 21.36% compared to IP 170 bar at full load. The fuel enters at high pressure, leaves with smaller droplets, mixes with the compressed air, and reduces the HC emission when the IP is high. In low IP, due to inadequate atomization and the larger fuel droplet size, complete combustion is not achievable, more fuel is needed for burning, and as it impacts the combustion chamber wall, more HC is released.

Figure 7.

Variation of HC with Load for Different IPs with Diesel and B20 Blends.

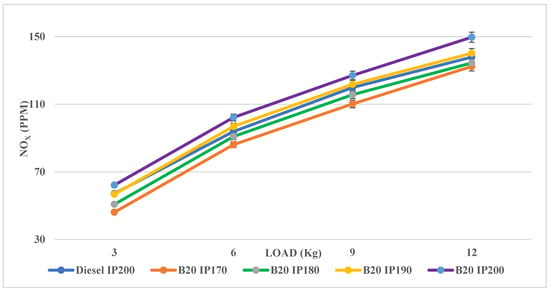

3.1.6. Oxides of Nitrogen

Figure 8 illustrates how the nitrogen oxides with load for the B20 dual biodiesel blend at various injection pressures. In general, it has been shown that as loads increase, NOx emissions rise as well. It can be seen from the graph that IP 200 bar emits more NOx than other IPs. The intense heat in the combustion is the cause of the higher IP, which results in more NOx emissions. The fuel starts to burn partially during the premixed phase of combustion, which raises the combustion chamber’s temperature. The fuel droplet size is smaller with higher IP, which prevents fuel spray from penetrating deeply into the combustion chamber. This is the other factor contributing to the increase in NOx emission. This causes combustion to occur more quickly and at a higher temperature, which raises NOx emissions. Low IP causes incomplete combustion and larger fuel droplet sizes, which lowers combustion chamber temperature and reduces NOx emission. The HC for IP 200 bar is increased by 11.55% compared to IP 170 bar at full load.

Figure 8.

Variation of NOx with Load for Different IPs with Diesel and B20 Blends.

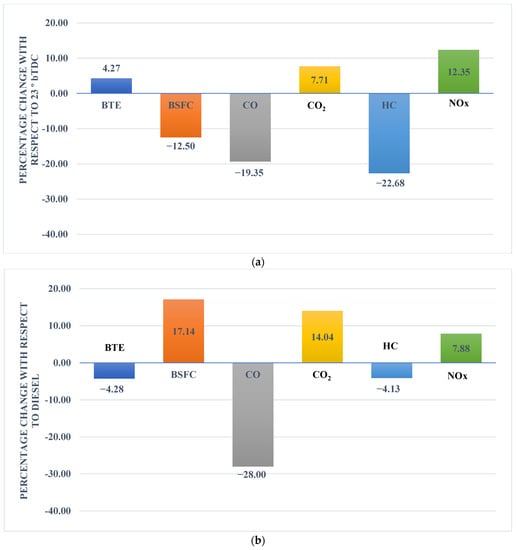

3.1.7. Summary

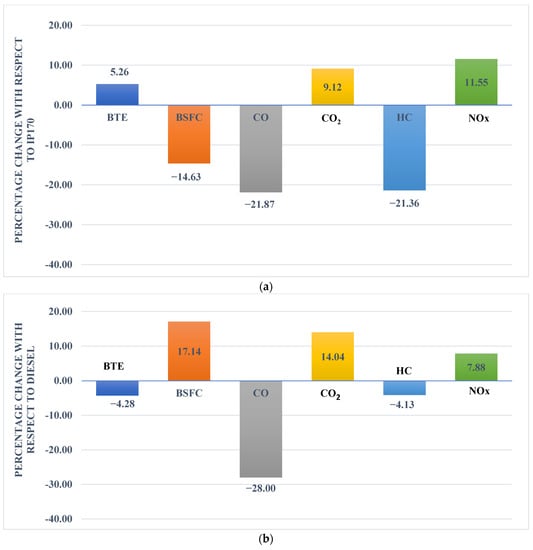

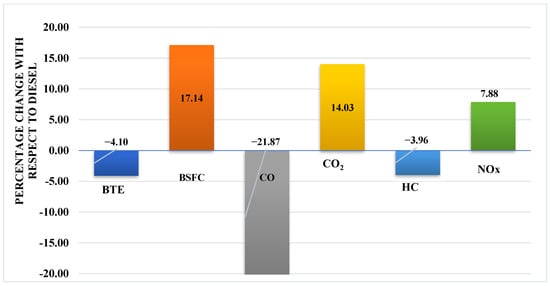

From the experimental research, it has been discovered that IP 200, when compared to IP 170, IP 180, and IP 190, is the best injection pressure to utilize. Except for NOx emissions, all emissions have significantly decreased and enhanced performance at IP 200. The detailed summary is shown in Figure 9a,b and shows the comparative performance of diesel and dual biodiesel blend B20 at IP 200.

Figure 9.

(a) The effect of IP 200 compared with IP170 for dual biodiesel B20; (b) comparative Performance of diesel and dual biodiesel blend B20 at IP 200.

3.2. Experiment of Injection Timing Optimization

An analysis is done on the results of the experiments for the performance, combustion, and emission analyses. The engine is run completely on diesel to ensure it is ready to be evaluated before the experiments begin. The tests, conducted using an engine with specifications of 200 IP, CR18, are run at various loads ranging from 0 kg to 12 kg in stages of 3 kg. Injection timing of 20°, 21°, 22°, and 23°bTDC are employed. The experiment makes use of dual biodiesel mixes (MECSO and MERBO) as well as diesel. The mixtures of B20 and diesel were selected for the experiment. The various performance characteristic curves that were found based on the experimental results are depicted below. When interpreting different curves, 0 kg is not considered.

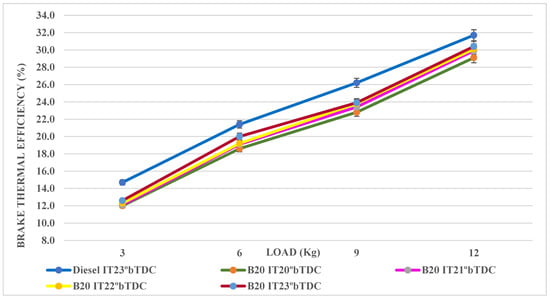

3.2.1. Brake Thermal Efficiency

Figure 10 depicts the fluctuation of BTE with load for a B20 blend at varying IT. It can also be seen that the BTE rises as the load increases. At advanced, IT of 23°bTDC has a greater BTE than other IT. At full load, the BTE for IT of 23°bTDC is 30.4%, while that for IT of 20°bTDC is 29.4%. Due to the piston being at TDC and the elevated temperature and pressure during advanced IT, the ignition latency will be reduced, enhancing the BTE. Another element influencing improved BTE is the rapid heat release in a premixed phase. Early fuel injection causes the air to enter the combustion chamber at a lower initial temperature and pressure, which prolongs the ignition delay and reduces BTE at delayed IT.

Figure 10.

Variation of BTE with Load for Different ITs with Diesel and B20 Blend.

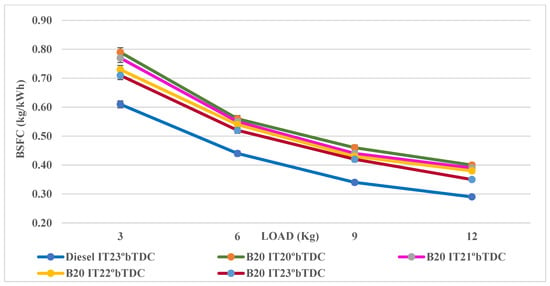

3.2.2. Brake-Specific Fuel Consumption

Figure 11 depicts the variation of BSFC with load for a B20 blend at varying IT. According to Figure 11, as loads increase, the BSFC decreases. The graph shows that compared to other IT, 23°bTDC advanced IT exhibited a lower BSFC. Compared to IT 20°bTDC, the BSFC is 12.5% lower in IT 23°bTDC. This could be because the improved IT reduced back force, shortened the ignition delay, and brought the piston close to TDC. Furthermore, the BSFC is decreased by this. The BSFC rises when the IT is slowed down and more fuel is injected.

Figure 11.

Variation of BSFC with Load for Different ITs with Diesel and B20 Blend.

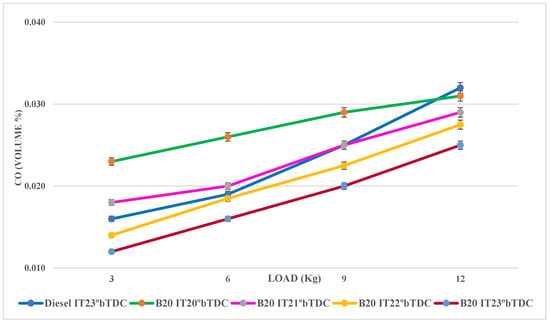

3.2.3. Carbon Monoxide

Figure 12 shows the difference in CO emission with load for the B20 blend at varied IT. It has been discovered that CO increases as the load increases. The graph depicts that at all loads, IT of 23°bTDC contains less CO than other IT. This is due to a higher temperature inside the cylinder, allowing for complete combustion and converting all carbon and oxygen molecules to carbon dioxide. More air will be compressed with more modern IT because the temperature of compressed air is higher than that temperature of self-ignition, resulting in improved combustion and less CO emission. When the IT is delayed, less time is required to compress the air, resulting in inefficient combustion and increased CO emissions. Compared to 20°bTDC, the CO for 23°bTDC is reduced by 19.37%.

Figure 12.

Variation of CO with Load for Different ITs with Diesel and B20 Blends.

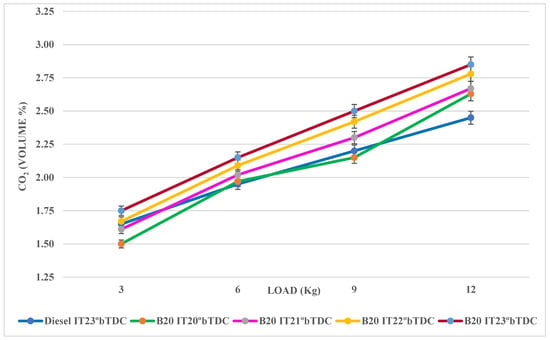

3.2.4. Carbon Dioxide

Figure 13 displays the variability in CO2 emission for the B20 blend at different IT. It has been determined that CO2 increases as loads increase. The graph can be used to determine that IT of 23°bTDC emits more CO2 than other IT under all loads. When the IT is high, the fuel burns completely, converting all the carbon and oxygen molecules into carbon dioxide, increasing the CO2 emission. Compared to diesel, the combustion gases produced when utilizing biodiesel enable a higher relative concentration of oxygen to predominate, which increases the conversion of CO to CO2. Compared to 20°bTDC, the CO2 for 23°bTDC has an increase of 7.71%.

Figure 13.

Variation of CO2 with Load for Different ITs with Diesel and B20 Blends.

3.2.5. Unburnt Hydrocarbon

Figure 14 illustrates the variation in HC emission for B20 blends at varying IT. Figure 14 shows that when the loads increase, the HC also increases. Compared to IT of 20°bTDC A at maximum load, the HC for IT of 23°bTDC is reduced by 22.68%. This is because IT will take less time to heat the charge and raise the temperature over the fuel’s auto-ignition point as IT advances. This will improve ignition, resulting in complete combustion and less HC emissions. The retarded IT enables earlier combustion to start, compressing the cylinder charge as the piston approaches TDC, leading to incomplete combustion and increased HC emission.

Figure 14.

Variation of HC with Load for Different ITs with Diesel and B20 Blends.

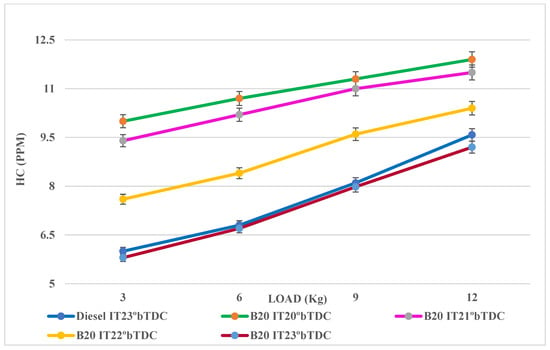

3.2.6. Oxides of Nitrogen

The fluctuation in nitrogen oxides with load for the B20 dual biodiesel blend at different IT is shown in Figure 15. Figure 15 shows that the NOx emission also increases when the load and IT increase. Compared to IT of 20°bTDC, the NOx for IT of 23°bTDC has an increase of 11.75%. IT is advanced, the NOx emission increases as a result of higher combustion temperature due to improved combustion in the premixed combustion phase. At retarded IT, as the fuel injection is delayed, lesser fuel gets accumulated in the combustion chamber before burning takes place and this reduces the intensity of premixed combustion, the lesser heat release rate leads to a lesser in cylinder temperature which contributes to reduced NOx emissions.

Figure 15.

Variation of NOX with Load for Different ITs with Diesel and B20 Blends.

3.2.7. Summary

Experimental investigations have demonstrated that, compared to the other IT, the IT at 23°bTDC performed better and dramatically decreased all pollutants except NOx. It has been found that the optimum IT for B20 biodiesel is 23°bTDC. The detailed summary is shown in Figure 16a, and the comparative performance of dual biodiesel blend B20 at 23°bTDC with diesel is shown in Figure 16b.

Figure 16.

(a) The effect of 23°bTDC compared with 20°bTDC for dual biodiesel B20; (b) comparative Performance of dual biodiesel blend B20 at 23°bTDC.

3.3. Experiment of the Effect of Diethyl Ether with Dual Biodiesel Blends

These experiments were conducted at various loads 0, 3, 6, 9 and 12 kg at a compression ratio of 18 and at the constant speed of 1500 rpm in the VCR diesel engine. In the first phase, diesel is used as a fuel, and in the second phase, a B20 biodiesel blend is used for determining the performance parameters and emissions. In the third phase, biodiesel blends B19DEE1, B17.5DEE2.5, and B15DEE5 are utilized as fuel, then evaluated for B20 and diesel.

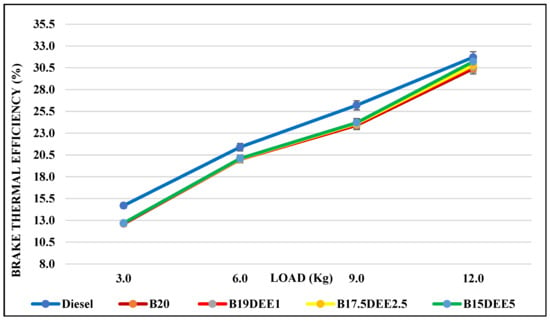

3.3.1. Brake Thermal Efficiency

The brake thermal efficiency measures the proportion of brake power applied at the engine crankshaft to power produced by fuel combustion. It measures how quickly the heat energy in the fuel is converted into effective energy capacity. At all loading conditions, the BTE of this VCR diesel engine tends to increase as the DEE content of the dual blend increases. At all loads, the BTE was lower for all biodiesel blends than diesel, which may be related to the lower calorific values of the dual combination, as depicted in Figure 17.

Figure 17.

Variation of BTE vs. load at CR18 for various blends.

Overall, it was determined that the B15 + DEE5 blend has the highest thermal efficiency when operating the engines at a higher load. The BTE increases for all the fuel blends as the load increases. The BTE at full load for diesel, B15 + DEE5, B17.5 + DEE2.5, B19 + DEE1, and B20 blends were 31.7%, 31.20%, 30.78%, 30.62%, and 30.4%, respectively. At maximum load conditions, the B15 + DEE5 combination has greater brake thermal efficiency than the B20 blend. The following are the key reasons for the increased BTE relative to the B20 blend: (1) DEE enhanced fuel atomization performance, and its lower viscosity and density increased combustion efficiency despite having a calorific value less than that of diesel and biodiesel; and (2) There is enough oxygen present to completely burn the fuel, which raises combustion efficiency [49,50,51]. The BTE of the biodiesel blend B15 + DEE5 is greater by 2.56% than that of B20 and decreases by 1.58% than that of diesel at maximum load (12 kg) and CR18.

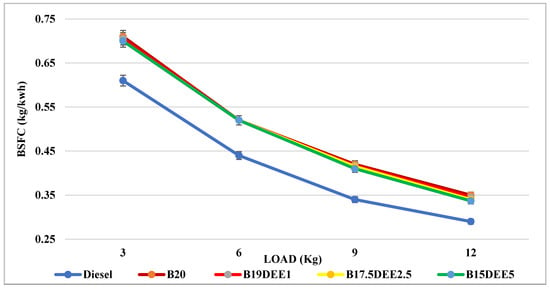

3.3.2. Brake-Specific Fuel Consumption

Figure 18 illustrates the fluctuations in the BSFC with load for the B20 biodiesel blend and various biodiesel mixtures with DEE and diesel. BSFC measures fuel efficiency by evaluating how effectively fuel is consumed to generate unit power; it is the proportion of fuel consumption rate to brake power. At full load (12 kg) at CR18, BSFC shows the B15 + DEE5 blends when compared to B20. The biodiesel blend of B15 + DEE5 has a BSFC that is lower than B20 by 3.71% and higher than diesel by 13.95% [44,51,52]. This effect emphasizes the benefits of DEE as an ignition improver for DEE–biodiesel blends over dual biodiesel blends (B20).

Figure 18.

Variation of BSFC vs. load at CR18 for various blends.

The reasons for the reduced BSFC of the B15 + DEE5 blend are (1) The ability of biodiesel and DEE to reduce viscosity resulted in an improvement in spray properties, which decreased BSFC for the DEE blend. Adding DEE to biodiesel reduced its calorific value but improved other aspects, like viscosity and cetane index, which decreased the BSFC.

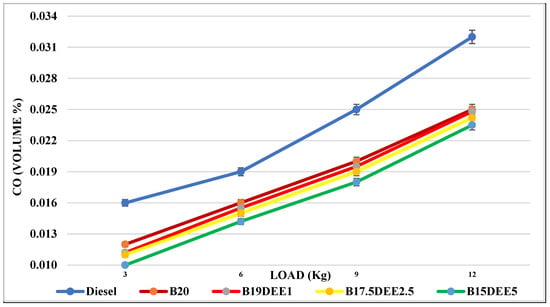

3.3.3. Carbon Monoxide

Figure 19 illustrates the variations in CO with load for the B20 biodiesel blend and other biodiesel mixtures containing DEE and diesel. The CO of B15 + DEE5 is lower at higher loads than that of diesel and B20. CO emission of the biodiesel blend B15 + DEE5 is lower by 6.0% compared to B20 and 25.56% related to diesel at maximum load (12 kg) and CR18. Diesel emits the most CO under all loading situations, but dual blends emit CO at a lower rate than diesel. B15 + DEE5 also emits the least CO under all loading conditions.

Figure 19.

Variation of CO vs. load at CR18 for various blends.

The key reasons for the decreased CO compared to the diesel and B20 blend are as follows: (1) The higher oxygen content of the B15 + DEE5 blend increases the oxygen concentration in the combustion chamber, which helps to decrease CO emissions. (2) CO emissions decreased initially until they increased at peak loads when the load was increased. This could be because the fuel–air ratio increased at average to high-level loading conditions. Further reductions in CO emissions may be possible due to the engine’s greater performance under heavier loading conditions. At greater loads, the CO of B15 + DEE5 is lesser than that of diesel and B20.

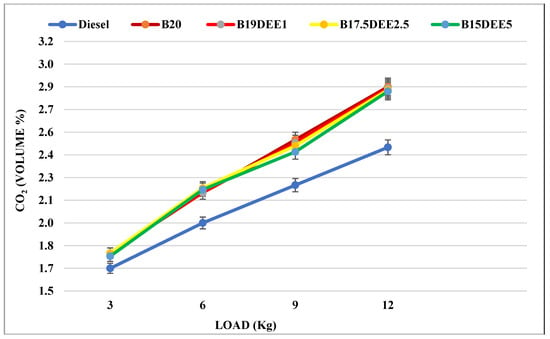

3.3.4. Carbon Dioxide

CO2 is widely recognized as a complete combustion by-product of the combustion chamber and is referred to as a greenhouse gas. Therefore, monitoring the CO2 emissions from diesel engines operating on biodiesel is essential. The fluctuations in CO2 with load for B20 biodiesel blend, various biodiesel blends with diethyl ether, and diesel is depicted in Figure 20. At lower loads, CO2 emissions are lower. As the load increases, the air–fuel ratio becomes richer, which could lead to increased CO2 emissions. Due to the more oxygen content in the biodiesel blend, proper combustion increases CO2 emissions. The CO2 emission of the biodiesel blend B15 + DEE5 is 13.12% more than diesel and a 1.05% decrease than B20. Diethyl ether is added to biodiesel to enhance its combustion properties. As seen in Figure 20, diesel fuel produces less CO2 emissions when it is blended with one of the different biodiesel combinations tested at all loads.

Figure 20.

Variation of CO2 vs. load at CR18 for various blends.

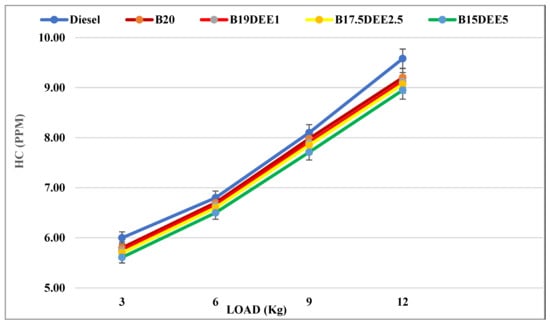

3.3.5. Unburnt Hydrocarbons

The efficiency of fuel combustion and the combustion process affect engine emissions of unburned hydrocarbons. The incomplete combustion of the fuel within the cylinder produces HC emissions. The fluctuations in the HC with load for diesel, B20, and various DEE proportions with biodiesel blends are shown in Figure 21. Compared to B20 and diesel, B15 + DEE5 was shown to have lower hydrocarbon emissions by 2.72% and 6.58%, respectively. The key factors contributing to the lower HC than diesel is (1) The greater oxygen content in the biodiesel blends aided in combusting the unburned fuel in the combustion chamber during the diffusion flame phase. (2) DEE–biodiesel blends decrease HC emissions due to better fuel spray characteristics inside the combustion chamber. The biodiesel–DEE blends’ higher cetane number promotes early combustion, which leads to better HC emission.

Figure 21.

Variation of HC vs. load at CR18 for various blends.

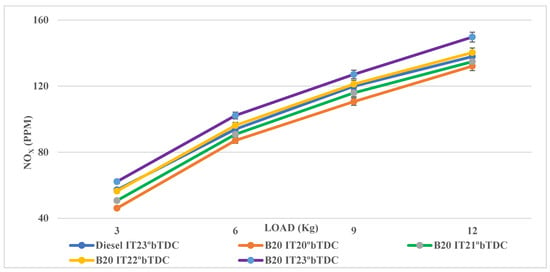

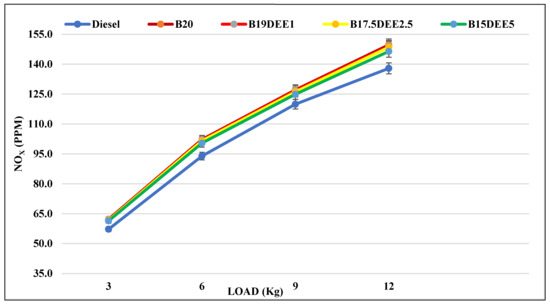

3.3.6. Oxides of Nitrogen

NOx formation is impacted by the flame temperature, the time that nitrogen spends at that temperature, and the local oxygen levels in the combustion chamber. Figure 22 depicts the differences in NOx with load for the B20 combination, various biodiesel mixtures with DEE, and diesel. At maximum load, NOx for B15 + DEE5 is 146.4 ppm, 149.7 ppm for B20, and 137.9 ppm for diesel. Compared to B20, B15 + DEE’s NOx decreased by 2.2%, whereas diesel at full load exhibits a 5.8% increase. The low engine load produced the lowest NOx emissions because of reduced chamber temperature due to the high air-fuel ratio, which resulted in less NOx emissions. The amount of NOx increases steadily as engine load increases. More fuel was injected and burned at higher loads, resulting in higher cylinder temperatures and NOx emissions. Biodiesel blends produce more NOx emissions, which are decreased by adding DEE. In biodiesel blend B15DEE5, it was noticed that the NOx was reduced.

Figure 22.

NOx vs. load at CR18 for various blends.

Dual biodiesel blends increase NOx emissions for the following reasons. (1) Higher oxygen concentrations in biodiesel blends influence the combustion temperature and NOx emissions to increase, and (2) biodiesel’s increased viscosity also inhibits it from atomizing and evaporating. As a result, the cylinder has more oil-rich regions, which boosts the temperature and promotes NOx generation.

DEE–dual biodiesel blends reduce NOx emissions for the reasons listed below: (1) The amount of diesel injected and burned in the cylinder increased as the engine load increased, which increased the gas temperature and increased NOx generation. Therefore, NOx emission increased with engine load. It can also be noted that NOx emissions were marginally lower with DEE blends than with B20 blends; due to the low calorific value and high latent heat of vaporization of DEE, the combustion temperature was low, which reduced the flame temperature and reduced NOx emissions. (2) The decrease aided the reduction in NOx emissions in peak combustion temperature brought on by the addition of DEE, which decreased the blend’s calorific value. Due to DEE’s more significant cetane number, the ignition delay time was lowered, and the combustion time was shortened, which contributed to lessened NOx emissions.

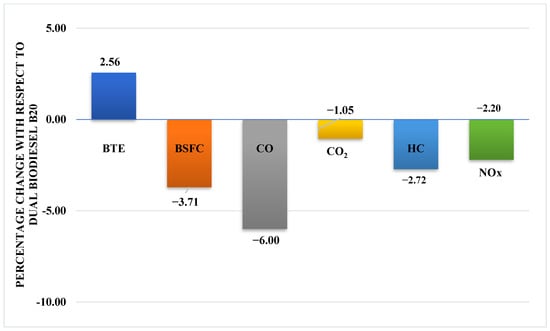

3.3.7. Summary

Comparative performance of dual biodiesel B20 and B15DEE5 at CR18 shows that the increased percentage of diethyl ether in the blends has led to a slight increase in brake thermal efficiency. The CO, CO2, and HC emissions decreased as the diethyl ether blend increased. When compared to a dual biodiesel blend, the use of diethyl ether decreased the NOx emissions.

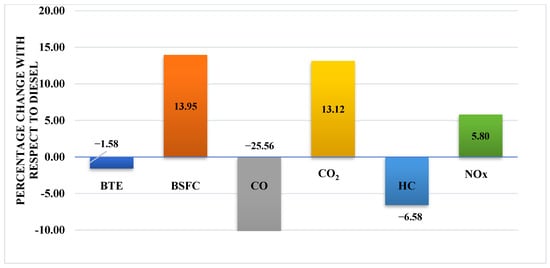

The comparison of diesel and B15DEE5 performance at CR18 revealed that increasing the percentage of diethyl ether in the blends resulted in a slight decrease in brake thermal efficiency, carbon monoxide, and unburned hydrocarbon and an increase in brake-specific fuel consumption, carbon dioxide, and oxides of nitrogen. Diethyl reduces all emissions while improving engine performance, as seen in Figure 23, Figure 24 and Figure 25.

Figure 23.

Comparative Performance of Dual Biodiesel B20 and B15DEE5 at CR18.

Figure 24.

Comparative Performance of Diesel and B15DEE5 at CR18.

Figure 25.

The effect of dual biodiesel B20 compared with Diesel at CR18.

4. Conclusions

Various fuels were examined in the engine to assess the performance and emission characteristics of a VCR diesel engine under varied loads and at a constant speed of 1500 rpm. Diesel, biodiesel–diesel combination, and dual biodiesel–diesel–DEE mixtures with DEE concentrations of 1%, 2.5%, and 5% by volume were used. The engine’s efficiency and emission characteristics were assessed in the current study, and the outcomes were contrasted with those of diesel and a dual biodiesel blend (B20). The following outcomes were discovered:

Performance significantly improved using B20 and different operational parameters, including CR, IP, and IT. High IP and IT results in a significant reduction of HC and CO. The NOx emission is drastically increased by raising the various IP and IT operating parameters. Operating parameters of CR18:1, IP 200 bar, and IT 23°bTDC result in the highest performance and emission reduction.

When a diesel–biodiesel blend was used as a potential substitute for diesel, there was some engine performance deterioration due to the higher viscosity and lower calorific value of biodiesel compared to diesel. The minimum BSFC increased by 17.14%, and the thermal efficiency dropped by 4.1%.

At high loads, the maximum BTE measured was 31.20% for the B15 + DEE5 blend, the highest of all the tested fuels. It was about 2.56% higher than the dual biodiesel blend (B20) fuel. Compared to the same combination, a minimal amount of BSFC was identified, about 3.71% less than neat diesel, which indicates better combustion.

CO and HC emissions for the B15 + DEE5 blend decreased by 6.0% and 2.72%, respectively, compared to the B20 blend, and there was a decrease of 25.56% and 6.58% compared to diesel as a result of the DEE’s better physicochemical qualities.

NOx emissions increased while using B20 blends under all loading situations, possibly due to the oxygen in the dual biodiesel blend’s quick combustion rate. Moreover, the level of NOx decreased by 2.20% when using B15 + DEE5 blends, which may be attributable to the cooling impact of the DEE additive.

The BSFC declined, and thermal efficiency enhanced at most engine loads when the diesel–biodiesel combination was blended with 5% DEE compared to a dual biodiesel blend. According to these results, dual biodiesel with DEE can be employed as a feasible fuel in a standard diesel engine.

5. Future Scope

The research on injection timing and injection pressure evaluation may be considered as future efforts to adopt such an innovative diethyl ether with biodiesel fuels, as there is still more work to be done to control NOx emissions.

The engine ran smoothly during the trial with the twin biodiesels and the additive with diesel. However, the long-term impact of the fuel on engine suitability can be determined by conducting experiments continuously for a longer period and assessing engine wear and tear.

Author Contributions

Conceptualization, S.K.P., U.R. and S.K.; Methodology, S.K.P.; Software, S.K.P.; Validation, S.K.P.; Formal analysis, S.K.P., U.R. and S.K.; Investigation, S.K.P., U.R. and S.K.; Resources, S.K.P.; Data curation, S.K.P.; Writing—original draft, S.K.P.; Writing—review & editing, S.K.P., U.R. and S.K.; Visualization, S.K.; Supervision, U.R. and S.K.; Project administration, U.R. and S.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

No potential conflict of interest were reported by the authors.

Nomenclature

| % | Percentage |

| ASTM | American Standard Test Method |

| BP | Brake power |

| BDFM | Biodiesel Biogas Dual Fuel Mode |

| BSEC | Brake Specific Energy Consumption |

| BSFC | Brake-Specific Fuel Consumption |

| BTE | Brake Thermal Efficiency |

| C | Carbon |

| CN | Cetane Number |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| CI | Compression Ignition |

| CSO | Cotton Seed Oil |

| CR | Compression Ratio |

| CV | Calorific Value |

| DEE | Diethyl Ether |

| DI | Direct Injection |

| K | Gas constant |

| kJ | Kilo joules |

| kg | Kilogram |

| KOH | Potassium Hydroxide |

| MECSO | Methyl Ester Cotton Seed Oil |

| MERBO | Methyl Ester Rice Bran Oil |

| Ppm | Parts Per Million |

| RBO | Rice Bran Oil |

| VCR | Variable Compression Ratio |

| Vol | Volume |

References

- Thakur, A.K.; Kaviti, A.K.; Mehra, R.; Mer, K.K.S. Progress in performance analysis of ethanol-gasoline blends on SI engine. Renew. Sustain. Energy Rev. 2017, 69, 324–340. [Google Scholar]

- Oyetola, O.; Noor, A. Overview of Biodiesel Combustion in Mitigating the Adverse Impacts of Engine Emissions on the Sustainable Human–Environment Scenario. Sustainability 2021, 13, 5465. [Google Scholar]

- Feroskhan, M.; Ismail, S.; Reddy, M.G.; Teja, A.S. Effects of charge preheating on the performance of a biogas-diesel dual fuel CI engine. Eng. Sci. Technol. Int. J. 2018, 21, 330–337. [Google Scholar] [CrossRef]

- Damanik, N.; Ong, H.C.; Chong, W.T.; Silitonga, A.S. Biodiesel production from Calophyllum inophyllumpalm mixed oil. Energy Source Part A 2017, 39, 1283–1289. [Google Scholar] [CrossRef]

- Ibrahim, A. Investigating the effect of using diethyl ether as a fuel additive on diesel engine performance and combustion. Appl. Therm. Eng. 2016, 107, 853–862. [Google Scholar] [CrossRef]

- El-Adawy, M.; Ibrahim, A.; El-Kassaby, M.M. An experimental evaluation of using waste cooking oil biodiesel in a diesel engine. Energy Technol. 2013, 1, 726–734. [Google Scholar] [CrossRef]

- Mahmudul, H.M.; Hagos, F.Y.; Mamat, R.; Abdul Adam, A.; Ishak, W.F.M.; Alenezi, R. Production, characterization, and performance of biodiesel as an alternative fuel in diesel engines—A review. Renew. Sustain. Energy Rev. 2017, 72, 497–503. [Google Scholar] [CrossRef]

- Krzysztof, G.; Marcin, P. Evaluation of the influence of diethyl ether (DEE) addition on selected physicochemical properties of diesel oil and ignition delay period. Energy Fuels 2014, 28, 2608–2616. [Google Scholar]

- Dugala, N.S.; Goindi, G.S.; Sharma, A. Experimental investigations on the performance and emissions characteristics of dual biodiesel blends on a varying compression ratio diesel engine. SN Appl. Sci. 2021, 3, 622. [Google Scholar] [CrossRef]

- Shaik, A.A.; Reddy, S.R.; Raju, V.D.; Govindarajan, M. Combined influence of compression ratio and EGR on diverse characteristics of a research diesel engine fueled with waste mango seed biodiesel blend. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 1–24. [Google Scholar] [CrossRef]

- Jatinder, K.; Mohapatra, S.K.; Kundu, K. Biodiesel production from waste cooking oil using heterogeneous catalysts and its operational characteristics on variable compression ratio CI engine. J. Energy Inst. 2019, 92, 275–287. [Google Scholar]

- Antony, M.; Bose, G.; Edwin, R. Optimization of biofuel blends and compression ratio of a diesel engine fueled with calophyllum inophyllumoil methyl ester. Arab. J. Sci. Eng. 2015, 41, 1723–1733. [Google Scholar]

- Mohammed, E.K.; Medhat, A.N. Studying the effect of compression ratio on an engine fueled with waste oil produced biodiesel/diesel fuel. Alex. Eng. J. 2013, 52, 1–11. [Google Scholar]

- Biswajit, D.; Panua, R.S. Performance and emission characteristics of diesel and vegetable oil blends in a direct-injection VCR engine. J. Braz. Soci. Mech. Sci. Eng. 2016, 38, 633–641. [Google Scholar]

- Jindal, S.; Nandwana, B.P.; Rathore, N.S.; Vashistha, V. Experimental investigation of the effect of compression ratio and injection pressure in a direct injection diesel engine running on jatropha methyl ester. Appl. Ther. Eng. 2010, 30, 442–448. [Google Scholar] [CrossRef]

- Mutyalu, K.B.; Das, V.C.; Srinivasa Rao, K. Effect of Fuel Injection Pressure on Performance and Emission Characteristics of DI- CI Engine with Shea Olein Biodiesel. Mater. Today Proc. 2018, 5, 494–500. [Google Scholar] [CrossRef]

- Shehata, M.S.; Attia, A.M.A.; Abdel Razek, S.M. Corn and soybean biodiesel blends as alternative fuels for diesel engine at different injection pressures. Fuel 2015, 161, 49–58. [Google Scholar] [CrossRef]

- Cenk, S.; Metin, G.; Mustafa, C. Effect of fuel injection pressure on the injection, combustion and performance characteristics of a DI diesel engine fueled with canola oil methyl esters-diesel fuel blends. Biomass Bioenergy 2012, 46, 435–446. [Google Scholar]

- Pankaj, S.; Tikendra, N.V. Effect of fuel injection pressure on the characteristics of CI engine fuelled with biodiesel from Roselle oil. Fuel 2020, 265, 117005. [Google Scholar]

- Akash, D.; Sarbjot, S.S.; Subhash, C. Experimental investigations on the influence of fuel injection timing and pressure on single cylinder C.I. engine fueled with 20% blend of castor biodiesel in diesel. Fuel 2017, 210, 15–22. [Google Scholar]

- Arun Kumar, W.; Murugan, S. Effect of injection timing on a DI diesel engine fuelled with a synthetic fuel blend. J. Energy Inst. 2015, 88, 406–413. [Google Scholar]

- Niraj, K.; Varun, G.; Sant Ram, C. Evaluation of the effects of engine parameters on performance and emissions of diesel engine operating with biodiesel blend. Int. J. Ambient Energy 2014, 37, 121–135. [Google Scholar]

- Arunprasad, S.; Balusamy, T. Experimental investigation on the performance and emission characteristics of a diesel engine by varying the injection pressure and injection timing using mixed biodiesel. Int. J. Green Energy 2018, 15, 376–384. [Google Scholar] [CrossRef]

- Cenk, S.; Mustafa, C. Effects of injection timing on the engine performance and exhaust emissions of a dual-fuel diesel engine. Energy Conver. Manag. 2009, 50, 203–213. [Google Scholar]

- Tudu, K.; Murugan, S.; Patel, S.K. Effect of diethyl ether in a DI diesel engine run on a tyre derived fuel-diesel blend. J. Energy Inst. 2016, 89, 525–535. [Google Scholar] [CrossRef]

- Sivalakshmi, S.; Balusamy, T. Effect of biodiesel and its blends with diethyl ether on the combustion, performance and emissions from a diesel engine. Fuel 2013, 106, 106–110. [Google Scholar] [CrossRef]

- Qi, D.H.; Chen, H.; Geng, L.M.; Bian, Y.Z. Effect of diethyl ether and ethanol additives on the combustion and emission characteristics of biodiesel-diesel blended fuel engine. Renew. Energy 2011, 36, 1252–1258. [Google Scholar] [CrossRef]

- Barik, D.; Murugan, S. Effects of diethyl ether (DEE) injection on combustion performance and emission characteristics of Karanja methyl ester (KME)– biogas fueled dual fuel diesel engine. Fuel 2016, 164, 286–296. [Google Scholar] [CrossRef]

- Venu, H.; Madhavan, V. Influence of diethyl ether (DEE) addition in ethanol biodiesel-diesel (EBD) and methanol-biodiesel-diesel (MBD) blends in a diesel engine. Fuel 2017, 189, 377–390. [Google Scholar] [CrossRef]

- Devaraj, J.; Robinson, Y.; Ganapathi, P. Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy 2015, 85, 304–309. [Google Scholar] [CrossRef]

- Murat Kadir, Y.; Mustafa, A. Experimental investigation on the performance, combustion and exhaust emission characteristics of a compression ignition engine fueled with cottonseed oil biodiesel/diethyl ether/diesel fuel blends. Energy Convers. Manag. 2020, 205, 112355. [Google Scholar]

- Paul, P.; Kumar, P.; Panua, R.; Debroy, D. Study of performance and emission characteristics of a single cylinder CI engine using diethyl ether and ethanol blends. J. Energy Inst. 2015, 88, 1–10. [Google Scholar] [CrossRef]

- Kaimal, V.K.; Vijayabalan, P. An investigation on the effects of using DEE additive in a DI diesel engine fuelled with waste plastic oil. Fuel 2016, 180, 90–96. [Google Scholar] [CrossRef]

- Rajan, K.; Prabhahar, M.; Senthilkumar, K.R. Experimental studies on the performance, emission and combustion characteristics of a biodiesel-fueled (Pongamia methyl ester) diesel engine with diethyl ether as an oxygenated fuel additive. Int. J. Ambient Energy 2016, 37, 439–445. [Google Scholar] [CrossRef]

- Patnaik, P.P.; Jena, S.P.; Acharya, S.K.; Das, H.C. Effect of FeCl3 and diethyl ether as additives on compression ignition engine emissions. Sustain. Environ. Res. 2017, 27, 154–161. [Google Scholar] [CrossRef]

- Ramadhas, A.S.; Jayaraj, S.; Muraleedharan, C. Experimental investigations on diethyl ether as fuel additive in biodiesel engine. Int. J. Glob. Energy Issues 2008, 29, 329–336. [Google Scholar] [CrossRef]

- Patil, K.R.; Thipse, S.S. Experimental investigation of CI engine combustion, performance and emissions in DEE–kerosene–diesel blends of high DEE concentration. Energy Convers. Manag. 2015, 89, 396–408. [Google Scholar] [CrossRef]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G.; Dimaratos, A.M. Characteristics of performance and emissions in high-speed direct injection diesel engine fueled with diethyl ether/diesel fuel blends. Energy 2012, 43, 214–224. [Google Scholar] [CrossRef]

- Lee, S.; Kim, T.Y. Performance and emission characteristics of a DI diesel engine operated with diesel/DEE blended fuel. Appl. Therm. Eng. 2017, 121, 454–461. [Google Scholar] [CrossRef]

- Sundar, K.; Udayakumar, R.; Periasamy, R.; Khurana, S. Cotton Seed Oil and Rice Bran Oil as a Source of Biodiesel in India, International Conference on Recent Advances in Fluid and Thermal Sciences. IOP Conf. Ser. J. Phys. Conf. Ser. 2019, 1276, 012086. [Google Scholar] [CrossRef]

- Vijayaraj, K.; Sathiyagnanam, A.P. Comparative study on properties of methyl ester cotton seed oil and methyl ester mango seed oil with diesel. Glob. J. Res. Eng. 2014, 14, 14–22. [Google Scholar]

- Mohanthy, S.K. A production of biodiesel from rice bran oil and experimenting on small capacity diesel engine. Int. J. Mod. Eng. Res. 2013, 3, 920–923. [Google Scholar]

- Chhabra, M.; Sharma, A.; Dwivedi, G. Performance evaluation of diesel engine using rice bran biodiesel. Egypt. J. Pet. 2017, 26, 511–518. [Google Scholar] [CrossRef]

- Sundar, K.; Udayakumar, R.; Periasamy, R. Experimental investigation on performance characteristics of a variable compression ratio engine operated on dual fuel mode using diesel and biodiesel (obtained from cotton seed oil and rice bran oil). J. Mech. Eng. Res. Dev. 2018, 41, 106–113. [Google Scholar]

- Sundar, K.; Udayakumar, R. Performance and emissions characteristics of a variable compression ratio engine operated on dual fuel mode using diesel and biodiesel with additives. J. Phys. Conf. Ser. 2019, 1276, 012084. [Google Scholar] [CrossRef]

- Sundar, K.; Udayakumar, R.; Khurana, S. Experimental investigation on emission characteristics of a variable compression ratio engine operated on dual fuel mode using diesel and biodiesel (obtained from cotton seed oil and rice bran oil). J. Mech. Eng. Res. Dev. 2018, 41, 59–66. [Google Scholar]

- Babu, P.R.; Rao, K.P.; Rao, B.V.A.; Srivastava, S.; Beohar, H.; Gupta, B. The role of oxygenated fuel additive (DEE) along with mahuva methyl ester to estimate performance and emission analysis of DI-diesel engine. Int. J. Therm. Technol. 2012, 2, 119–123. [Google Scholar]

- Sandip, S.J.; Bhagat, M.; Moghe, S.M.; Pakhale, V.A. Diethyl Ether as Additive and its Effect on Diesel Engine Performance A Review. Glob. Res. Dev. J. Eng. 2016, 1, 27–31. [Google Scholar]

- Rashed, M.M.; Kalam, M.A.; Masjuki, H.H.; Mofijur, M.; Rasul, M.G.; Zulkifli, N.W.M. Performance and emission characteristics of a diesel engine fuelled with palm, jatropha, and moringa oil methyl ester. Ind. Crop. Prod. 2016, 79, 70–76. [Google Scholar] [CrossRef]

- Nalgundwar, A.; Paul, B.; Sharma, S.K. Comparison of performance and emissions characteristics of di CI engine fuelled with dual biodiesel blends of palm and jatropha. Fuel 2016, 173, 172–179. [Google Scholar] [CrossRef]

- Chauhan, B.S.; Kumar, N.; Cho, H. A study on the performance and emission of a diesel engine fuelled with Jatropha biodiesel oil and its blends. Energy 2012, 37, 616–622. [Google Scholar] [CrossRef]

- Cheung, C.S.; Zhu, L.; Huang, Z. Regulated and unregulated emissions from a diesel engine fuelled with biodiesel and biodiesel blended with methanol. Atmos. Environ. 2009, 43, 4865–4872. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).