1. Introduction

The insufficient availability of energy is a significant constraint for economic growth in developing nations with middle- and low-income economies [

1]. Nonrenewable energy resources, specifically fossil fuels, are susceptible to being inadequate in fulfilling the needs related to increasing industrialization and population growth [

2]. Moreover, the continuous combustion of fossil fuels leads to the emission of multiple greenhouse gases, contributing to the depletion of the ozone layer and global warming, which in turn pollutes the atmosphere [

3]. In such scenarios, the necessity to diminish reliance on fossil fuels, along with the escalating global energy demand and the prevailing urge to mitigate atmospheric greenhouse gas emissions, has encouraged exploration into substitute fuels that enable the utilization of conveniently accessible renewable resources with minimal or zero adverse effects [

4]. Renewable energy sources offer tremendous potential for reducing carbon emissions in energy generation. These sources can serve as valuable alternatives to fossil fuel-based inputs across a wide range of applications [

5,

6,

7]. Biomass stands out as the most pressing and hopeful substitute for fossil fuels, being the fourth largest provider of energy globally and offering a sustainable and environmentally friendly source for fueling energy production [

8,

9]. Biomass encompasses a broad spectrum of materials, serving as a flexible and abundant input for producing transport fuels, biochemicals, and heat and power. However, in its raw form, several inherent characteristics of biomass, such as dispersed distribution, irregular shape, high moisture content, low bulk density, low heating value, and poor flowability, pose transportation, storage, and energy conversion challenges that can be costly [

10,

11,

12]. Hence, it is essential to convert raw biomass into a denser energy carrier through appropriate treatments.

Advanced biomass processing methods, such as pelletizing, briquetting, torrefaction, hydrothermal carbonization, and pyrolysis, transform biomass into high-energy products with enhanced characteristics that facilitate easier transportation, storage, conversion, and utilization [

13]. Among these technologies, densification, including palletization, briquetting, and extrusion, is a relatively simple way that offers several direct advantages through lower costs of handling, transportation, and storage, and higher overall efficiency of biomass utilization [

14]. Densification is the compacting process of material under specified conditions with the primary aim defined as “the agglomeration of small particles into larger particles by means of a mechanical process in combination with moisture, heat, and pressure” [

15]. Pelletization is regarded as one of the most important processing methods for converting raw biomass into efficient solid fuel. The conversion of fuel into pellets represents a form of solid waste management that not only generates energy but also lowers the expenses and environmental consequences associated with waste disposal [

16]. The improved uniformity and flowability of biomass pellets make them highly suitable for transportation using elevators, hoppers, and conveyor belts. Furthermore, pelletization can significantly increase the energy density of raw biomass from 186 kJ/mol to 260 kJ/mol, as well as its volume density from 40–250 kg/m³ to 600–750 kg/m³ [

17,

18]. In addition to agricultural residues, wood resources or wood waste are typically the primary raw materials utilized in the production of biomass pellets. In recent decades, woody biomass (industrial byproducts such as sawdust, shavings along with wood chips) is the main material for producing pellets, as it has a higher bulk density after pelletization than that of crop residues [

19]. The present-day environmental and social constraints have restricted the global wood harvest volumes, which could lead to a shortage of economical woody waste biomass for pellet producers in the future. An effective remedy to this situation would be to increase the value of plant residues, particularly those arising from agricultural activities [

20]. Nonwoody lignocellulosic biomass, such as crop straw left over after harvest, has been a significant source of biomass for several decades in countries like China where wood shortages prevail [

21]. Furthermore, the significance of pellet production from nonwoody biomass is on the rise.

Being a large, agricultural country, China annually produces a large quantity of various agricultural waste products, including corn straw, wheat straw, rice straw, cotton straw, bagasse waste, etc., which can be utilized as a potential renewable energy source [

22]. Corn stalk, mainly comprising rind, pith, and leaves, is an abundant byproduct in agriculture with an annual production rate of about three billion tons, which probably accounts for the production of one-third of the total agricultural residues in China [

23]. To date, the most widely adopted method of handling corn stalks has been either through their incineration or abandonment to facilitate the preparation of fields for subsequent planting seasons. Nevertheless, this traditional approach results in the squandering of potential renewable resources, as well as the degradation of both local and global air quality, coupled with the destruction of soil health [

24]. Corn stalk is rich in cellulose, hemicellulose, and lignin, which could act as natural binders during the pelletization process [

25]. Therefore, the preparation of pellets using corn stalks is one of the most promising approaches to make full use of this abundant bioresource.

The primary characteristics that determine the quality of pellets are their strength and durability. Additional measures of pellet quality include resistance to compression, abrasion, impacts, as well as water absorption [

26]. The factors that exert a significant influence on the quality of pellets can be broadly classified into two categories. The first category encompasses material properties, which include variables such as chemical composition, moisture content, and particle size. The second category pertains to various processing parameters [

27]. Prior studies have yielded several conclusions regarding the physical characteristics of pellets derived from corn residues. However, the examination of corn stalk rinds as favorable feedstock for producing solid biofuel pellets is a topic that has received little attention in scholarly research thus far. Therefore, the aim of this study was to analyze how different processing factors, including the size of particles and amount of moisture in the raw materials, temperature of the die, and pressure during molding, impact the mechanical and physical properties of pellets. Furthermore, the optimal values of the abovementioned parameters were also explored using the Box–Behnken design (BBD).

2. Materials and Methods

2.1. Preparation of Biomass Materials

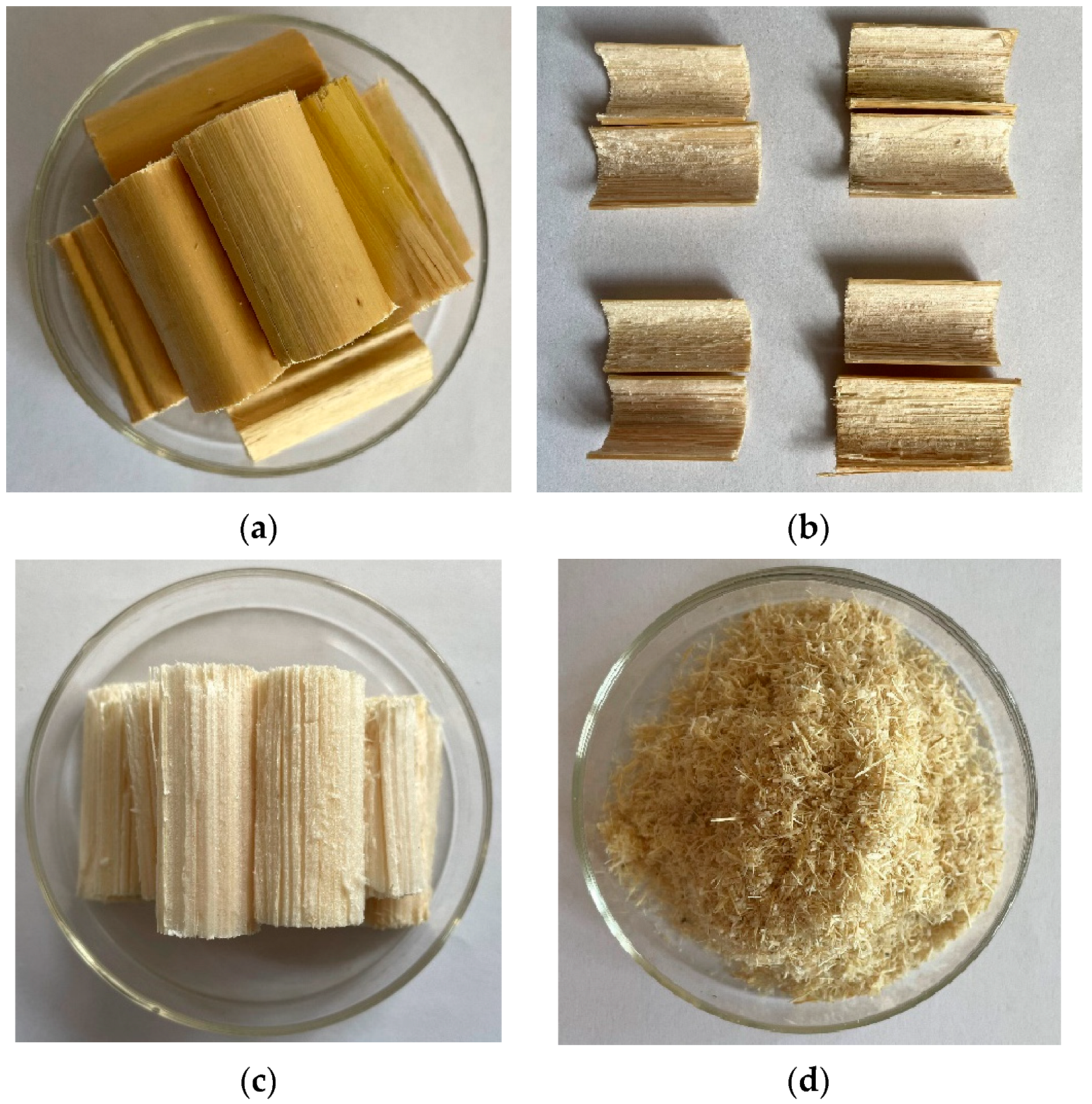

Corn stalks were collected from the test field located at Heilongjiang Bayi Agricultural University in Daqing City, Heilongjiang Province, China, as shown in

Figure 1a. Initially, the corn stalks were left to dry naturally at room temperature for a period of 1–2 months until their moisture content reached equilibrium. Next, corn stalks were cut and separated into corn stalk rinds and corn stalk piths, as shown in

Figure 1b,c. Later, corn stalk rinds were crushed and sieved to obtain the desired particle sizes, as shown in

Figure 1d. After that, the ground rinds were subjected to drying in a convection oven at 40 °C until the sample weight stabilized. Thereafter, a predetermined amount of deionized water was added to the ground rinds to adjust the moisture content of the feedstock to the designed level. Finally, to achieve moisture content equilibration, feedstock materials were transferred into a plastic container that was hermetically sealed and placed in a refrigerator set to maintain a temperature of 4 ± 0.5 °C. The feedstock materials remained stored under these conditions for a duration of 2 days.

2.2. Pelletizing Apparatus and Procedures

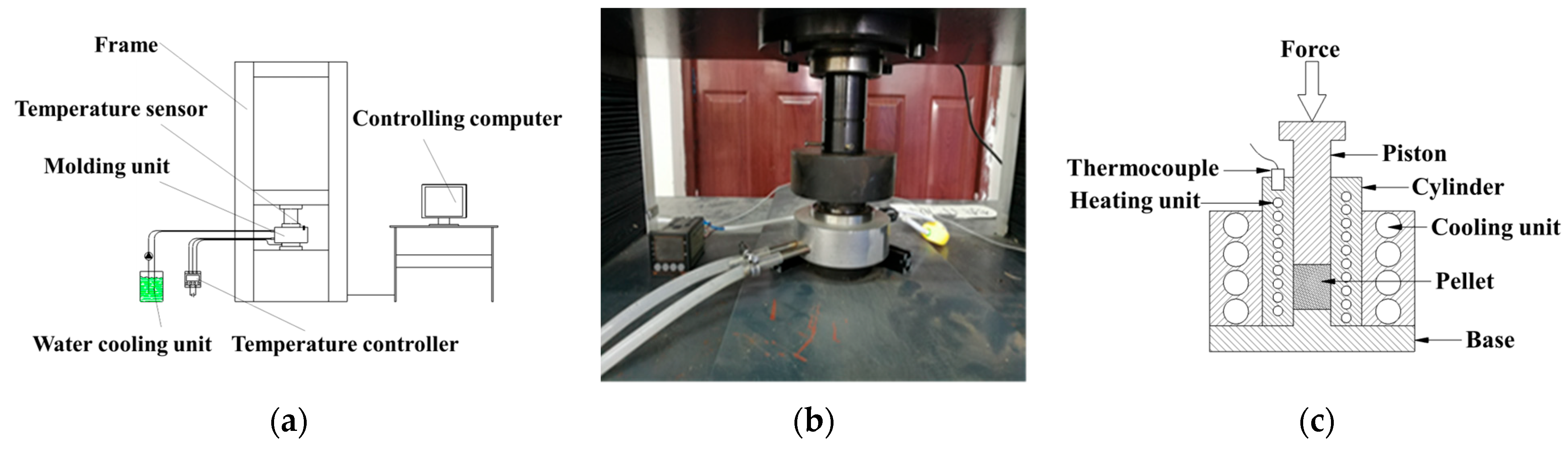

A computer-controlled pelleting press (WDW-200E, Jinan Time Shijin Testing Machine Co., Ltd., Jinan, China) was employed for the fabrication of single pellets (

Figure 2). The equipment known as the single pellet press comprises a cylindrical die that is designed to maintain insulation through an electromagnetic heating unit. Additionally, this component also includes a spiral water-cooling mechanism to further regulate temperatures during operation. The cylinder’s length and inner diameter were 100 and 15 mm, respectively. Pradhan et al. successfully generated pellets from garden waste, wherein the average diameter of the pellets typically fell within the range of 12 to 15 mm [

28]. Necessary steps were implemented to ensure that the temperature was brought up to the intended level, and a thermocouple was positioned inside the cylinder. The computer system had the capability to detect and manage the die temperature within a range of 0 to 400 °C.

Details of the pellet fabrication procedures utilized in this study can be found in our prior investigation [

29]. Biomass pellets were generated employing various processing parameters, including particle size (0.5–1.1 mm), moisture content (9–15%, dry basis), temperature (100–160 °C), and pressure (100–160 MPa). The effects of process parameters on quality attributes (e.g., relaxed density, mechanical durability, and compressive strength) were investigated. The generated pellets were cooled to ambient temperature and subsequently preserved within a hermetically sealed container for subsequent analysis.

2.3. Measurement of the Physical Properties of Pellets

2.3.1. Relaxed Density

Regarding densified pellets, the relaxed density is widely noted as a crucial parameter that is closely linked to the effective management and transportation of pellets, during which the density of raw materials is sharply elevated because of compression. After removal from the die, the pellet density gradually decreases over time under the action of elastic deformation and stress relaxation. The pellet density typically stabilizes after being left to sit under natural ventilation at room temperature for a few days (often ranging from 3 to 7 days). The corresponding density measurement obtained at this stage is referred to as the relaxed density of the pellet.

In this test, the relaxed density of each individual pellet was determined by measuring the mass, length, and diameter of the pellets following a storage period of 7 days. For the purpose of this investigation, the precise measurements of the length and diameter of individual pellets were obtained using an electronic caliper with an accuracy level of 0.01 mm. Additionally, each pellet was individually weighed on an electrical balance that had a precision of 0.001 g. The determination of relaxed density was accomplished through the utilization of Equations (1) and (2) [

30].

where RD refers to the relaxed density (kg/m

3),

Mp refers to the mass of the pellet (kg),

Vp refers to the volume of the pellet (m

3),

D refers to the diameter of the pellet (mm), and

L refers to the length of the pellet (mm), respectively.

2.3.2. Mechanical Durability

The parameter of durability holds significant importance, as it is an indicator of the ability of densified biofuel pellets to withstand and endure various types of destructive forces, which are encountered during transportation and handling operations [

31]. Several devices, including rotating drums, tumbling cans, vibrating beds, friabilators, and Holmen and Ligno testers, can be used to test the durability of pellets. By employing a rotating drum, it is possible to simulate the mechanical handling of pellets and anticipate any potential fines that may be generated as a result of the collisions between pellets or between the pellets and the chamber walls of a defined rotating enclosure. In the current investigation, the durability of pellets was defined using a self-developed rotating drum of 150 mm in diameter and 200 mm in length. Two baffles of 50 × 198 mm were installed perpendicular to the drum’s inner wall and opposite to each other. To conduct the experiment, a predetermined quantity of 10 pellets generated under varying conditions was loaded into the rotating drum. The rotation speed was held constant at 50 ± 2 rpm, and the revolutions were carried out over a period of 10 min. Subsequent to the test period, the contents of the drum were passed through a sieve with a screen size of 3.15 mm [

32]. Finally, the durability was computed using Equation (3).

where DU refers to the durability of the densified pellets (%),

Ma refers to the initial mass of the tested pellets before the test (g), and

Mb refers to the mass of the tested pellets after the test (g), respectively.

2.3.3. Compressive Strength

Compressive strength is defined as the resistance of the material to permanent deformation or failure. A universal testing machine was applied to measure the compressive strength of the pellets based on the procedure used in a previous study [

33]. Firstly, each pellet was vertically placed between two steel plates. After that, the compressing plunger compressed the pellet with a constant loading rate of 5 mm/min. Compression continued until the failure of the pellet, and the maximum force was recorded during the process. Then, compression strength was calculated using Equation (4).

where σ is the compression strength (MPa),

D is the diameter of the pellet (mm),

L is the length of the pellet (mm), and F is the maximum breaking force (N), respectively.

2.4. Experimental Design

Quality attributes, including density, durability, compressive strength, etc., which may largely depend on the process parameters and feedstock variables, are vital concerns associated with the production of biomass pellets. For instance, the durability of densified biomass can be improved through the presence of a high concentration of natural binders. Moreover, it is essential to recognize that the presence of unbound moisture trapped in the nonfunctional walls of the pellets has the potential to significantly reduce the heating efficiency of the final product. This phenomenon can mainly result in the growth and proliferation of microbial organisms and the significant loss of dry mass during prolonged storage and transportation [

30]. Therefore, it is essential to undertake a rigorous and exhaustive investigation into how an array of diverse operating parameters can potentially affect the overall quality attributes and inherent properties of biomass pellets. Taking into account the aforementioned parameters and their significance, a judicious decision was made to adopt response surface methodology (RSM) in tandem with BBD, which is a robust mathematical modeling technique, as the preferred experimental design strategy. Meanwhile, the statistical software of Design Expert 8.0.5b was applied for the statistical analysis and optimization of process variables for the production of biomass pellets. BBD is a design that encompasses three factors and three levels, comprising a center point replicated multiple times and a group of points situated at the midpoint of every edge of the multidimensional cube, which outlines the region of interest. The use of BBD was preferred because previous research has demonstrated that this particular design offers relatively higher efficiency than both central composite design and three-level full factorial design, respectively [

34].

As part of the current investigation, four independent variables were identified and subsequently designated as X

1, X

2, X

3, and X

4 after being subjected to a coding process, involving but not limited to the size of particles, level of moisture present, the temperature of the die, as well as pressure during the molding process; meanwhile, the relaxed density, the mechanical durability, and the compressive strength with the codes of Y

1, Y

2, and Y

3, respectively, were designed as the responses. Each variable in the BBD was prescribed into different three levels assigned as −1, 0, and +1 in the coded factors, corresponding to the lower level, center level, and upper level, respectively. These three levels of each factor were obtained from the results of the preliminary experiment. The levels and ranges of these factors are presented in

Table 1.

The calculation of the optimal number of runs for BBD can be facilitated through the use of a specific equation, namely Equation (5) [

35].

Within the context of this investigation, it was established that the value assigned to c0, which serves as an indicator of the number of center points, was equal to 5. As a reminder, it should be emphasized that N is representative of the overall count of variables that have been incorporated within the analytical framework, and k is the number of independent variables employed in the work.

Thus, utilizing the BBD methodology, a total of 29 experimental runs were conducted in a randomized manner. The primary objective of this approach was to minimize the impact of unexplained sources of variability on the observed response variable. A polynomial quadratic equation was fitted to establish the correlation between the independent variables and the corresponding response values. The equation used for this purpose is presented below.

In the equation utilized to determine the relationship between the independent variables and their respective responses, several coefficients are employed to represent different factors. Specifically, Yi denotes the measured response for a given combination of factor levels, while β0 represents the model intercept coefficient. Additional coefficients include βi, βii, and βij, which correspond to the linear, quadratic, and interaction terms, respectively. Finally, Xi and Xj denote the coded values assigned to the independent factors under investigation.

The utilization of the software tool Design Expert facilitated the application of statistical methodologies, namely analysis of variance (ANOVA) and regression analysis. The investigation of statistical significance pertaining to the regression coefficients involved an evaluation of either the F-value or

p-value, at a confidence level of 95%. The level of significance pertaining to a coefficient is directly proportional to the magnitude of its corresponding F-value and inversely proportional to the

p-value (Prob > F) associated with it. Therefore, when the F-value is large, and the

p-value is small, it indicates a greater degree of statistical significance for that particular coefficient. The significance of model terms can be determined by examining the

p-value, with a value equal to or less than 0.05 indicating strong statistical significance and close alignment with experimental outcomes. Conversely, higher

p-values may suggest that noise or other extraneous factors are present in the data, potentially leading to less precise modeling results [

36].

The evaluation of the quadratic models involved the consideration of multiple parameters, such as the coefficient of determination (R

2), the adjusted coefficient of determination (Adj-R

2), and the lack-of-fit test. To gauge the accuracy of the experimental data, R

2 values were employed, while Adj-R

2 values were utilized to evaluate the deviations between the predicted and actual data. Discrepancies arising from significant differences between R

2 and Adj-R

2 values indicate the presence of nonsignificant model terms, which can have a detrimental impact on the overall effectiveness of the model [

37].

To perform the lack-of-fit test, the variability of the actual model residuals was investigated, and the obtained values were compared with our observations when the factors were replicated. A model was deemed statistically significant at a 95% confidence level if the p-value resulting from the lack-of-fit test was less than or equal to 0.05. The use of quadratic models was instrumental in constructing three-dimensional (3D) plots and analyzing the interactive impact generated by each individual factor. The contribution of the most significant factor was examined via Pareto analysis.

2.5. Statistical Analysis

To analyze and visualize the data obtained from the experiment, a two-pronged approach was chosen. Firstly, Origin 8.5 software was employed for graph-based analysis that allowed for a detailed examination of the results. Secondly, Design Expert 8.0.5b was utilized to perform ANOVA and construct a 3D response surface. In order to rigorously assess the significance of the experimental results, a multifaceted approach was used. Firstly, the statistical method of Duncan’s multiple range test was employed to identify the least significant difference (at a confidence level of p < 0.05) between the various factors that were being studied. Additionally, all experiments were repeated three times to ensure that the results were consistent and reproducible.

3. Results

3.1. Statistical Analysis and Model Fitting

To systematically evaluate the effects of multiple independent variables on a set of predetermined physical properties associated with biomass pellets, a comprehensive experimental design was constructed utilizing the Box–Behnken methodology, resulting in the execution of a total of 29 carefully orchestrated runs. The complete design matrix with predicted and experimental values is presented in

Table 2.

To ensure a robust analysis, numerous polynomial mathematical models were employed to fit the data individually, encompassing linear, second-order interaction (2FI), quadratic, and cubic models. The findings derived from this rigorous methodology are comprehensively detailed in

Table 3. The quadratic model was found to be the recommended model for the three responses because of its maximum value of adjusted R

2 and predicted R

2.

Furthermore, through the meticulous application of multiple regression analysis, a comprehensive assessment was conducted to scrutinize the intricate interrelationships between various independent variables and their corresponding impacts on all responses under investigation. Subsequently, a highly sophisticated second-order polynomial quadratic model was formulated to accurately represent these complex interactions in terms of coded factors:

The regression equations’ coefficients play a crucial role in determining the outcome variables, and those with positive signs demonstrate a favorable impact, while negative values indicate an unfavorable effect. One specific application of the analytical approach used in this study is in Equation (7), where several types of variables and their corresponding terms are incorporated. These include linear terms associated with X4, interaction terms involving X23 and X34, as well as quadratic terms related to X12 and X42, which all contributed positively to the relaxed density’s increase. Conversely, it was observed that the remaining terms in the equation, which were characterized by negative coefficients, had a detrimental effect on the response variable being studied.

Mathematical equations developed after fitting the experimental data to the quadratic models may lead to inaccurate results. Thus, to assess the accuracy and significance of the model, ANOVA was employed to examine the main effects and interactions that impact the responses related to relaxed density, mechanical durability, and compressive strength. Subsequently, the findings of this analysis were compiled for tabulation and further examination, which are shown in

Table 4.

As illustrated in

Table 4, in the analysis of the regression models, all the

p-values obtained from the F tests were found to be below the critical significance level of 0.05, thus demonstrating the high statistical significance of the quadratic regression models. Moreover, the suitability of BBD was demonstrated by the high R

2 values of 0.9467, 0.8669, and 0.9196 for the three responses, respectively. The study’s results indicate that the variables played a vital role in explaining the observed variation in the three responses, namely the relaxed density, mechanical durability, and compressive strength, with percentages exceeding 94.67%, 86.69%, and 91.96%, respectively. These findings suggest that the proposed models have satisfactory accuracy and possess a notable capacity to account for the complexity of the responses. Due to the presence of additional terms in the quadratic models, which arise from the three-level independent variables, the use of Adj-R

2 is more effective in assessing the level of fit. This is because the Adj-R

2 is less susceptible to the effects of degrees of freedom and can provide a more accurate measure of the model’s fitness compared with other metrics [

38]. In the current research, the Adj-R

2 values obtained for the three responses were 0.8935, 0.7338, and 0.8392, respectively, indicating that the models accurately captured the observed data, which corresponded well with the response variables. These results provide further evidence of the reliability and validity of the proposed models. The lack-of-fit test is frequently used to assess the adequacy and reliability of regression models. The obtained

p-values for the lack-of-fit test of the proposed mathematical models were 0.3504, 0.1132, and 0.4349 for the relaxed density, mechanical durability, and compressive strength responses, respectively. No significant evidence was found to suggest any inadequacies or deficiencies in the models’ ability to predict the experimental data accurately. The reproducibility of the developed models was assessed using the coefficient of variation (CV), which yielded values of 6.70, 3.75, and 8.40, respectively, indicating a higher level of reproducibility. Additionally, the adequacy of precision (Adeq Precision) was initially utilized to evaluate the signal-to-noise ratio (SNR), where an SNR value greater than 4 was deemed desirable. To determine the SNR in the three responses, the adequacy of precision (Adeq Precision) was utilized as a metric, and the obtained values were 17.989, 10.909, and 13.701, respectively. These results indicate that there is an adequate level of signal present in the experimental data, further supporting the reliability and validity of the developed models. Hence, it is feasible to employ the quadratic model for exploring and navigating the design space, given its capacity to accurately predict responses of interest.

In general, terms that exhibit a p-value greater than 0.05 are deemed significant and noteworthy factors. It was clear that all factors had positive effects on the relaxed density. Out of the four variables considered, particle size was determined to be the most impactful factor due to its F-value of 80.99, which was the highest. Molding pressure came next in influence, followed by die temperature and moisture content. Based on the results, it was determined that the molding pressure had the greatest impact on mechanical durability, and this was demonstrated by the fact that it had the highest F-value and the lowest p-value compared with the other variables being studied. Following this factor, particle size, molding temperature, and moisture content were observed to have a lower, while still significant, influence on the outcome. In the case of compressive strength, the most influential factor was molding pressure, with an F-value of 52.04, followed by particle size, die temperature, and moisture content, in order of decreasing importance. However, for quadratic and interaction terms, apart from X22 and X32, all other terms were statistically insignificant for the three responses.

3.2. Pareto Analysis

In the context of evaluating mechanical durability, Pareto analysis was employed to identify the key operating parameters that contributed to the observed outcomes. By plotting a Pareto graph, we were able to determine the percentage effects of each parameter on all responses using the equation below:

The estimation of significant operating parameters was represented as bi in this study. The response equations were formulated using the coded factors and are provided in Equations (7)–(9).

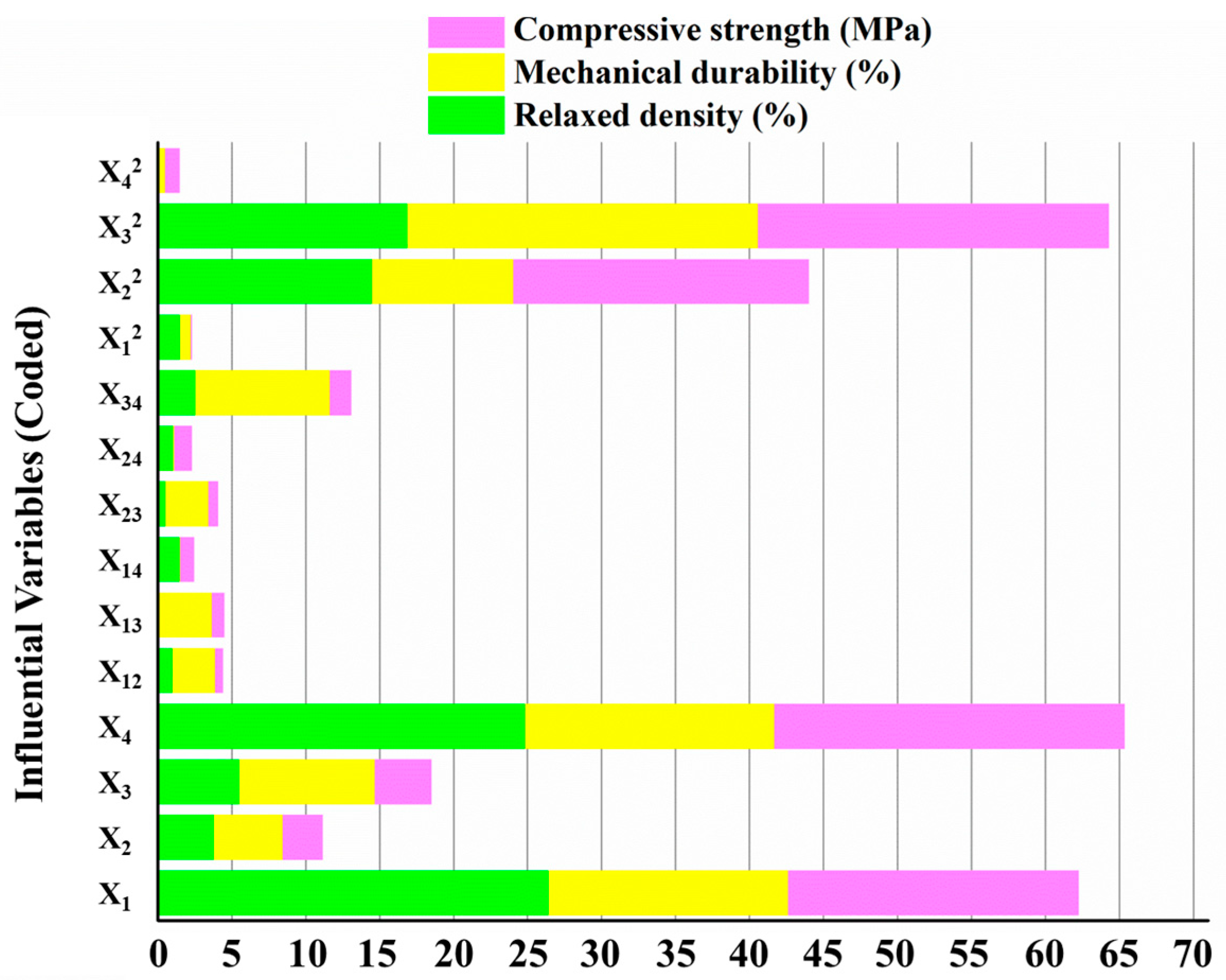

Contributions of operating parameters (e.g., X

1, X

2, X

3, and X

4) on the responses are presented in

Figure 3.

It was observed that particle size had the greatest influence on the relaxed density, accounting for 26.41% of the variation observed in the response variable. Molding pressure was the next most significant factor, contributing 24.82%, while the die temperature and moisture content accounted for 5.54% and 3.79% of the variability, respectively. Molding pressure showed the most significant contribution to mechanical durability and compressive strength by 16.83% and 23.69%, respectively, compared with other parameters. Similarly, the contributions of interaction effects were also investigated using the Pareto curve as X3X4 contributed to all responses by 2.55%, 9.08%, and 1.43%, respectively. Additionally, X32 was the major contributor to the relaxed density (16.87%), mechanical durability (23.69%), and compressive strength (23.69%). By contrast, X2 showed the lowest contribution in the three responses.

3.3. Effects of Operating Parameters on the Pelletization Process

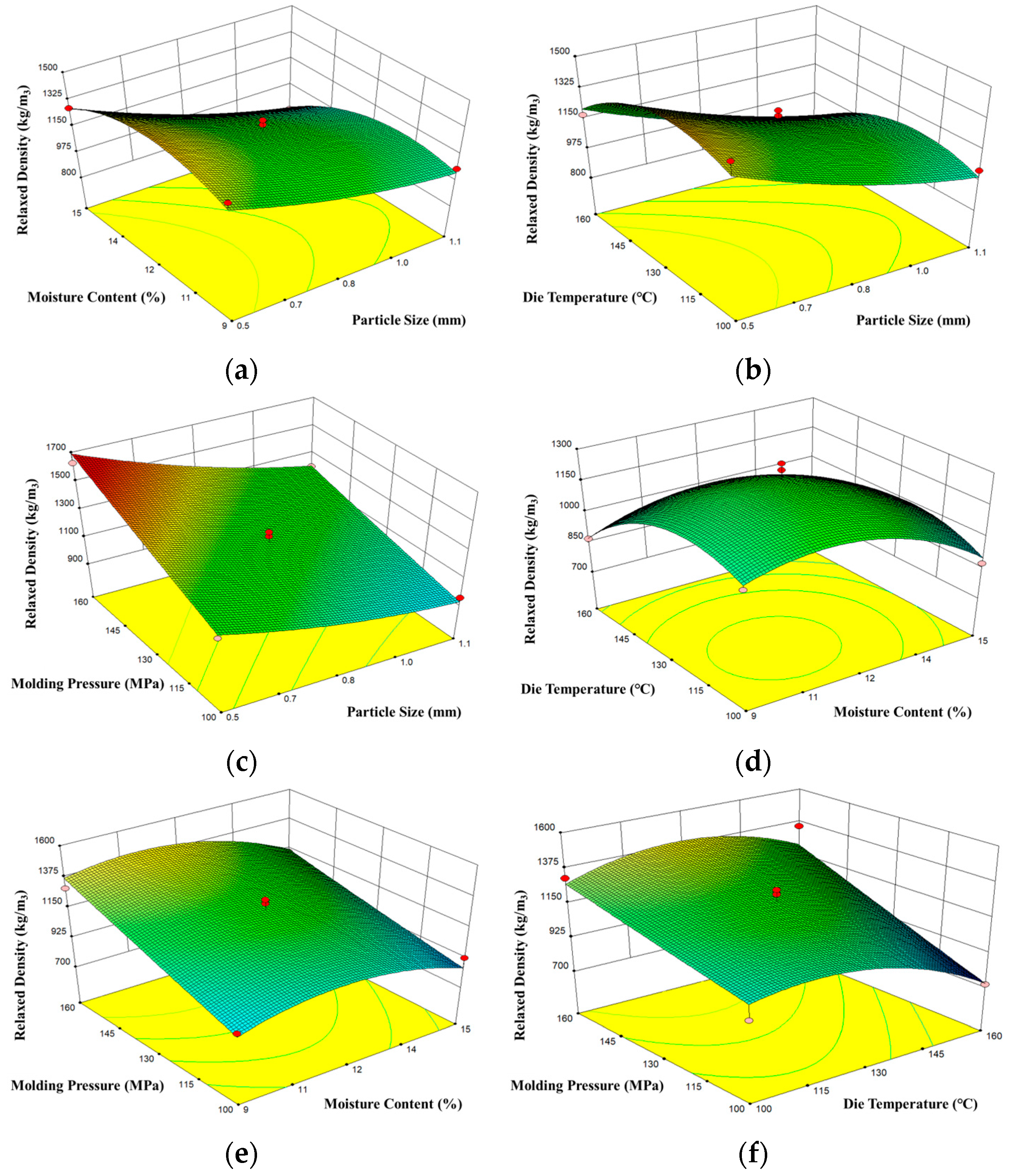

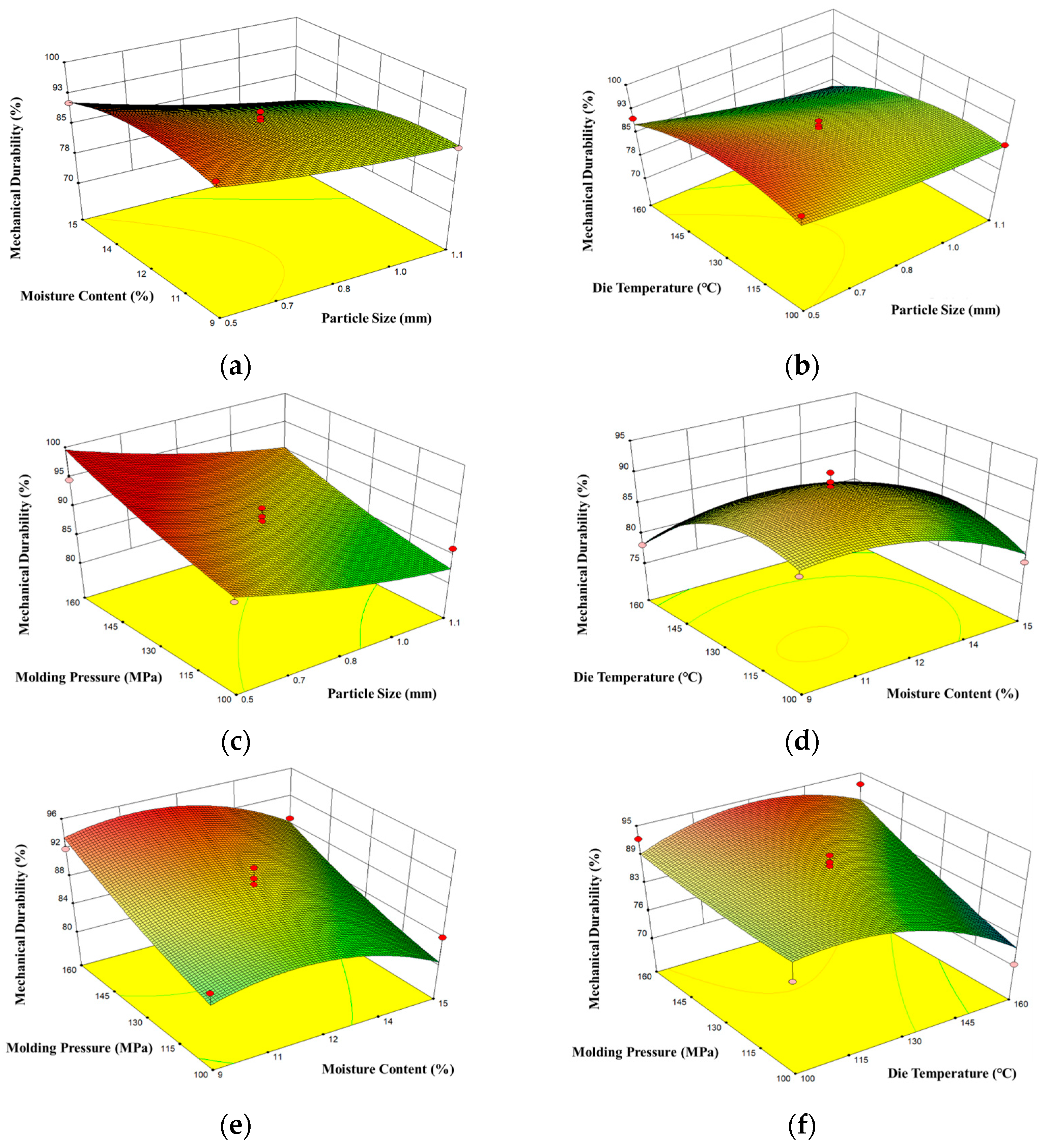

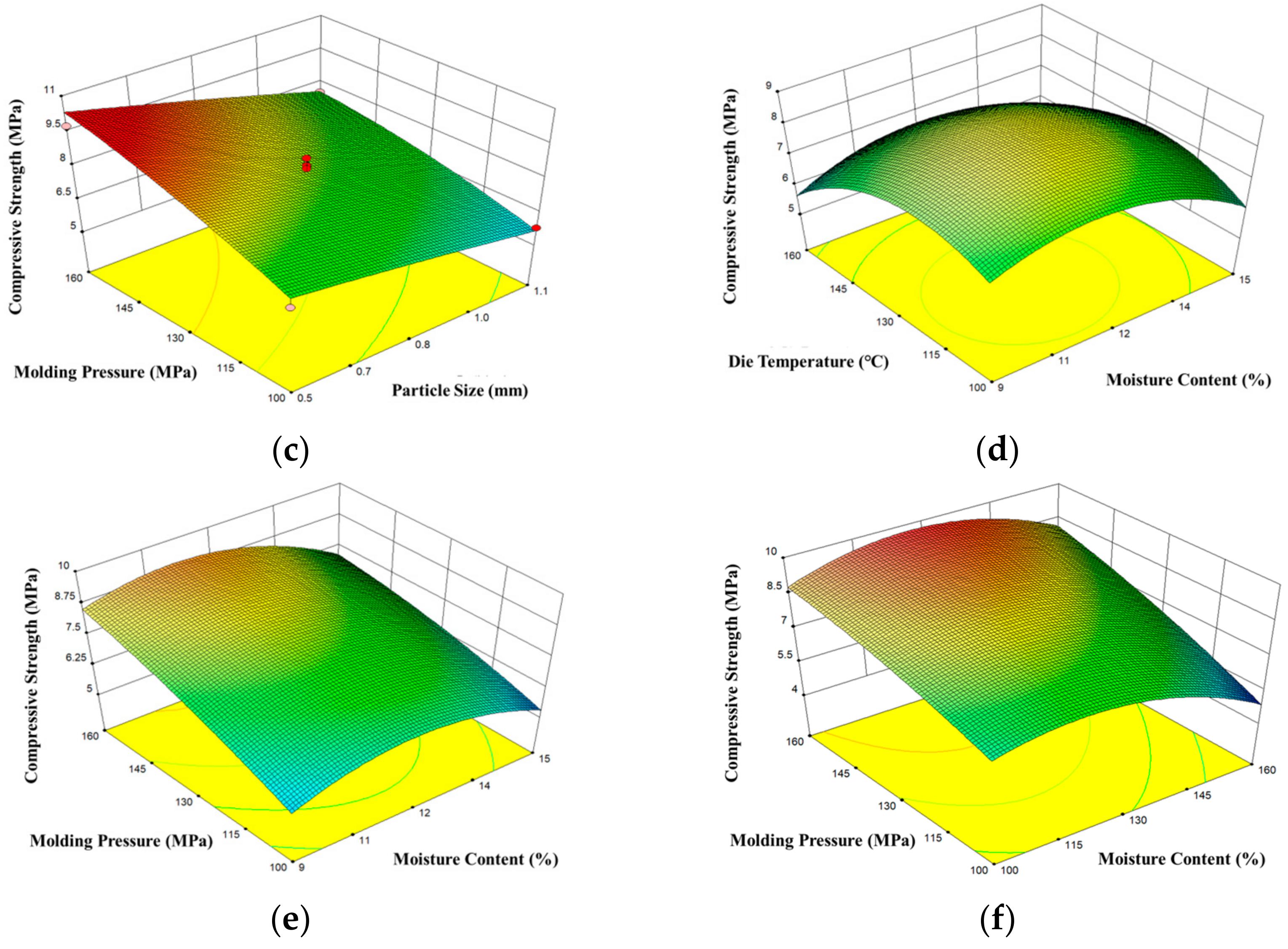

After validating the suitability of the model, three-dimensional (3D) surface plots were used to present the predicted regression equations and intuitively investigate the influences of the independent variables on the responses. The 3D plots could show the interaction influence of two factors on the response, while the other two factors were kept at the medium level. Three-dimensional plots in

Figure 4,

Figure 5 and

Figure 6 illustrate the impact of varying levels of particle size (X

1), moisture content (X

2), die temperature (X

3), and molding pressure (X

4) on the relaxed density (Y

1), mechanical durability (Y

2), and compressive strength (Y

3).

3.3.1. Effect on Relaxed Density

Designing storage containers and transportation systems for biomass pellets requires careful consideration of various quality parameters, among which the relaxed density holds particular importance. Regarding densified pellets, the relaxed density is widely noted as a crucial parameter that is closely linked to the effective management and transportation of pellets, during which the density of raw materials is sharply elevated because of the compression. After removal from the die, the pellet density gradually decreases over time under the action of elastic deformation and stress relaxation. The pellet density typically stabilizes after being left to sit under natural ventilation at room temperature for a few days (often ranging from 3 to 7 days). Pellets with lower relaxed density are deemed less desirable in the market because they occupy a larger volume of storage space and reduce the transportation capacity and efficiency of trucks, trains, and ships. As a result, ensuring that pellets meet the required relaxed density standards is crucial for maintaining their marketability and optimizing logistical operations. In order to better understand how the relaxed density is influenced by different levels of particle size, moisture content, die temperature, and molding pressure, response surface plots were generated, as shown in

Figure 4. This figure provides a graphical representation of the complex interplay between these independent variables and the dependent variable of interest, allowing for a visual assessment of the impact of each variable on the relaxed density. It was revealed that particle size had the most significant influence on the relaxed density based on its F-values and

p-values (

Table 4). The strong effect of particle size on the relaxed density has already been documented in previous studies [

39,

40].

Figure 4a demonstrates the interaction of X

1 and X

2 and their reciprocal action on the relaxed density, while X

3 and X

4 were fixed at the zero level. The results revealed that the increase in particle size from 0.5 mm to 1.1 mm led to a decrease in the relaxed density from 1346 to 1035 kg/m

3. This trend was consistent with that reported by Shaw et al. [

41] and Carone et al. [

39]. The observed effect of reducing particle size on increased relaxed density can be attributed to the improved ability of smaller particles to fill void spaces more effectively, due to their greater mobility and increased contact points with neighboring particles under applied pressure. As the size of the particles decreases, the spaces between them are reduced, promoting a denser packing arrangement that in turn leads to an increase in the relaxed density. Mani et al. [

42] and Yılmaz et al. [

43] also concluded that smaller particles could improve the density of briquettes during the briquetting. In a prior study, it was suggested that pellets exhibiting favorable quality can be obtained by utilizing particles within the range of 0.5 to 0.8 mm in size [

26]. In addition, the initial rise in moisture content from 9% to 12% resulted in an increase in the relaxed density of pellets, followed by a subsequent decrease. The peak value of the relaxed density (1450 kg/m

3) appeared at the moisture content of 12%. Therefore, in the current research, the appropriate moisture content for producing pellets with corn stalk rinds was 11–13%. The aforementioned finding is in line with the earlier conclusion according to which a density peak was observed for compacted pellets at an optimal moisture content range of 10% to 15% [

40]. In the pelleting process, moisture is one of the most useful agents and can act as both a binder and a lubricant. Increasing the moisture content within a reasonable range is beneficial for the smaller particles to flow into the voids between larger particles under pressure, thereby contributing to the high level of relaxed density in the densified products.

Figure 4b illustrates the effects of X

3 and X

4 and their reciprocal action on the relaxed density, while X

1 and X

2 were kept at medium values. It was found that the relaxed density of the pellets made of corn stalk rinds initially increased when the die temperature increased in the range of 100–130 °C and then decreased with a further increase in the die temperature. Moreover, in the current research, the maximum relaxed density was obtained as a die temperature and molding pressure of 130 °C and 160 MPa, respectively. Die temperature is regarded as an important factor for pellet quality. The correlation between the temperature of the die and the density of the pellets is attributable to the composition of the raw materials, with natural binders such as lignin, cellulose, and hemicellulose playing a significant role in biomass species. Elevated temperatures enable lignin to reach the glass transition temperature (typically ranging from 100 to 140 °C). When the die temperature increases to a certain threshold, the raw material components start melting and seeping into the empty spaces between biomass layers during pelletization. This results in the formation of a natural binding agent that promotes bonding and reduces density. Additionally, molding pressure plays an important role in determining the relaxed density of the pellets. Initially, increasing the pressure leads to a rapid rise in particle density, which eventually levels off. At low molding pressure, particles tend to rearrange themselves while retaining their original physical properties, thus causing a slight reduction in raw material volume. Upon applying increasing levels of molding pressure to the particles, a concomitant occurrence of both elastic and plastic deformation was observed. This led to a phenomenon whereby smaller particles were able to enter the interstitial spaces between larger particles due to the high degree of particle mobility induced by deformation. As a result of this flow behavior, inter-particle bonding occurred, which subsequently contributed to an increase in the relaxed density of the material. With further increments in molding pressure, there was a corresponding enhancement in pellet quality due to the aforementioned mechanisms. Other plots in

Figure 4 also present the interactions of X

1X

3, X

1X

4, X

2X

3, and X

2X

4 in terms of the relaxed density of the biomass pellets.

3.3.2. Effect on Mechanical Durability

In the context of pellet production and utilization, the mechanical durability of these materials is widely regarded as a paramount parameter that demands meticulous attention. The presence of an excessive quantity of fines can give rise to an array of deleterious effects such as substantial losses during transportation, heightened risk of explosions during storage and handling, as well as the emergence of bridging phenomena within storage facilities. This culminates in issues such as material flow hindrance and operational impediments [

20]. Apart from these, low mechanical durability may also contribute to high dust emissions and stocking problems in boilers. The effects of independent variables on the mechanical durability of the biomass pellets are illustrated in

Figure 5.

Figure 5a shows the effects of X

1 and X

2 and their reciprocal action on the relaxed density, while X

3 and X

4 were set at the center level. The results demonstrated that particle size had an obvious effect and directly influenced the mechanical durability of the pellet. The mechanical durability could be significantly improved by decreasing the particle size of the corn stalk rinds. It is a known fact that the bonding forces between particles within pellets are primarily limited to short-range interactions, comprising hydrogen bridges, van der Waals forces, mechanical interlocking, free chemical bonds, and other similar mechanisms. The fine grinding of biomass can significantly augment the inter-particle contact area while concurrently reducing the inter-particle distance. This, in turn, facilitates the formation of solid bridges between adjacent particles at the respective points of contact. A decrease in particle size was found to have a pronounced effect on the surface area of contact between particles, with a corresponding increase in van der Waals forces that mainly act at the points of contact between adjacent particles. This phenomenon ultimately resulted in an improvement in pellet durability, which can be attributed to the development of stronger inter-particle bonding mechanisms. The durability of the biomass pellet was also largely related to the moisture content of the feedstock. Increasing moisture content from 9% to 12% caused a sharp increase in pellet mechanical durability from 91.5% to 93.85%. However, a further increase in moisture content may negatively affect the mechanical durability. Therefore, in this study, it can be concluded that moisture content in the range of 10–12% is suitable for the production of pellets from cornstalk rinds with superior mechanical properties. The reasons behind this may be that increasing the moisture content in a rational range is advantageous for accelerating the flowability of particles, resulting in the generation of strong interlocking bonds between adjacent particles due to the enhancement of the contact area between particles.

Figure 5b illustrates the effect of X

3 and X

4 and their reciprocal action on mechanical durability, while the other two factors were maintained at intermediate values. The analysis results unequivocally demonstrated that the impact of die temperature on the mechanical durability of the pellets was analogous to that of the moisture content. In contrast, molding pressure had a distinctly positive effect on the mechanical durability of the pellets. In this study, under a lower die temperature, the binding role of the natural binders contained in the feed (i.e., lignin, cellulose, hemicellulose, and protein) was limited. With an increase in temperature, there was a corresponding softening of lignin and denaturation of proteins. These changes ultimately facilitated the binding of the pellets upon the application of compression. However, when the die temperature exceeded the optimum value, an increasing temperature may lead to the plasticization of lignocellulose fibers and lower the elasticity of the particles, finally reducing the mechanical durability. Attention should be paid to the slight increase in pellet durability when molding pressure changed from 100 to 160 MPa. Undoubtedly, in the pelletization industry, molding pressure represents a crucial factor in the pellet compression process. Nevertheless, as per the outcomes of this study, the production of pellets with superior mechanical durability was found to have a reduced dependency on molding pressure. To put it differently, it was observed that higher-quality pellets could be obtained by employing lower levels of applied pressure.

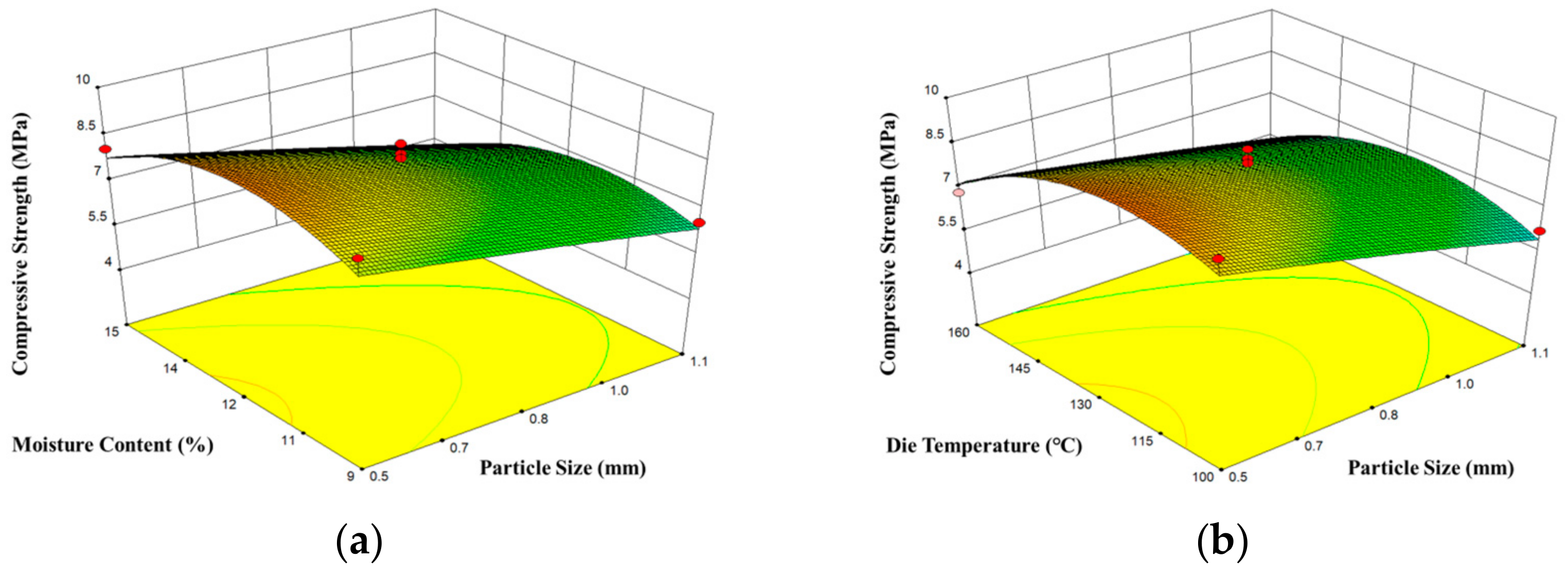

3.4. Effect on Compressive Strength

Figure 6 depicts the effects of independent variables on the compressive strength of the pellet made from corn stalk rinds.

Figure 6c shows the effects of X

1 and X

4 and their reciprocal action on compressive strength by fixing X

2 and X

3 at the zero level. It is noteworthy that particle size had an adverse impact on the compressive strength of the pellets, whereas molding pressure exerted a positive influence on this parameter. One possible explanation for the observed impact of particle size on compressive strength is that a reduction in particle size leads to an increase in surface area. This, in turn, enhances the ability of the material to absorb moisture and heat, and the activation of binding properties present in certain natural binders is a highly important step in the production of biomass pellets. Similarly, high molding pressure brings particles closer to each other, and inter-particle bonding is then initiated. This study revealed an additional aspect of the pellet formation process, specifically that of the softened natural binding components within the material. Upon the application of pressure, these components were found to be pressed out and displaced from the original location, and as a consequence of these effects, the agents were able to diffuse between adjacent particles, primarily at points where neighboring particles made contact. Meanwhile, the influences of X

2 and X

3 and their reciprocal action on compressive strength while setting X

1 and X

4 at middle values are expressed in

Figure 6d. It was observed that compressive strength initially increased and then decreased with an increase in moisture content and die temperature. The observed pellet formation process can be attributed to the combined effects of moisture and temperature, whereby lignin, cellulose, and hemicellulose present in the material underwent melting and simultaneous extrusion from the particle surface. The extruded material subsequently filled in inter-particle gaps, and this ultimately led to the formation of a robust bond between neighboring particles, promoting greater stability and structural integrity in the overall product. Upon exiting the pelletizer, the pellets were allowed to cool, which induced the hardening of lignin and reassociation of proteins, leading to an improvement in compressive strength. However, during the compression, the moisture content of the feed, which is mainly related to the composition of biomass materials, should be maintained in a rational range to enhance its role as a binder agent. In addition, when the die temperature exceeds the appropriated value, the process of drying biomass typically involves the evaporation of a large portion of its water content, which can occur simultaneously with excessive denaturation, leading to the development of brittle protein. Both of these issues have the potential to negatively impact the production of high-quality pellets, underscoring the need for strategies that can mitigate or prevent such problems from arising.

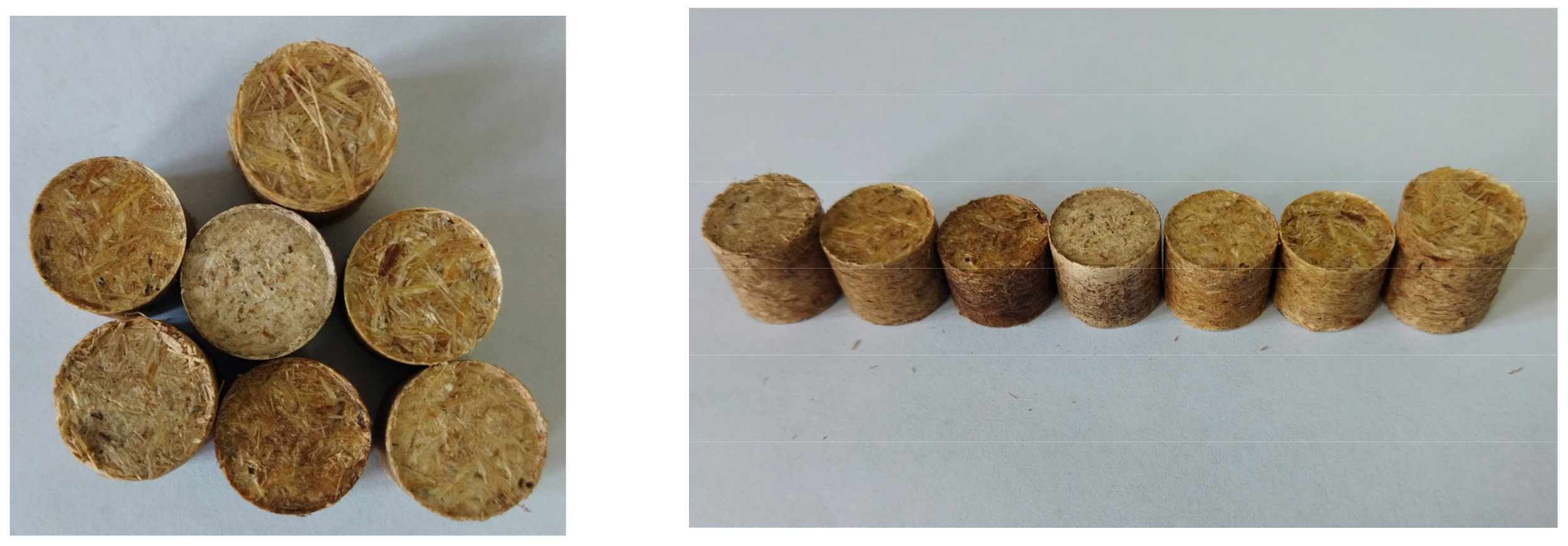

3.5. Process Optimization and Validation

Process optimization involves the condition where multiple parameters interdependently influence the responses, with the objective of obtaining a desired product or outcome [

44]. Optimizing all the responses under the same operational conditions presents a challenge, given that their respective regions of interest are distinct. As such, multiresponse optimization techniques were employed in order to identify conditions for the independent factors that would lead to optimal values for the response variables simultaneously. Design Expert employs two nodes, numerical and graphical, for process optimization. In this instance, the numerical node was selected for optimization purposes to maximize all responses while simultaneously ensuring that all independent variables are within their respective ranges. Following the optimization process, the optimal conditions for the production of high-quality pellets from corn stalk rinds were successfully determined. These conditions involved setting the particle size at 0.5 mm, maintaining a moisture content of 11.35%, utilizing a die temperature of 125.7 °C, and applying a molding pressure of 154.2 MPa. Based on these parameters, corresponding predictive values were generated for relaxed density, mechanical durability, and compressive strength, which were found to be 1639.61 kg/m

3, 97.95%, and 10.18 MPa, respectively.

To test the validity of the regression models, verification experiments were carried out at the above optimal condition, and the results are presented in

Table 5. Additionally, the produced pellets are shown in

Figure 7.

As shown in

Table 5, the values of the responses obtained from the verification test had good consistency with the predicted values, indicating that the experimental data were precisely predicted using the obtained regression models. Furthermore, the practicability and accuracy of the models were also confirmed with the desirability factor of 1.00.

4. Conclusions

In the current research, pellets were produced from corn stalk rinds at different processing conditions. A statistical technique involving multiple variables, known as BBD experimentation, was implemented in order to enhance the quality of the pellet through process optimization. In the experimental investigation, the four key process conditions that were taken into consideration as variables included particle size, moisture content, die temperature, and molding pressure. Furthermore, the response variables of relaxed density, mechanical durability, and compressive strength were also analyzed to evaluate the effectiveness of the optimization process. The study yielded regression models that demonstrated relatively high R2 values of 0.9467, 0.8669, and 0.9196, respectively, reflecting a high affinity between the proposed models and the experimental data. Using multiresponse optimization, and after conducting a thorough analysis of the data, we were able to establish the optimal conditions required for producing high-quality pellets from corn stalk rinds. Specifically, it was found that a range of factors needed to be carefully controlled, including particle size (0.5 mm), moisture content (11.35%), die temperature (125.7 °C), and molding pressure (154.2 MPa). Correspondingly, the predicted values of the responses under this condition resulted in a relaxed density of 1639.61 kg/m3, mechanical durability of 97.95%, and compressive strength of 10.18 MPa. The values obtained experimentally under the optimal condition were consistent with the predicted values with a desirability factor of 1.00, demonstrating that valuable results could be achieved for all responses.

Lastly, the co-pelletization of biomass waste with other agro-residues (e.g., soybean straw and cotton straw rich in lignin) revealed the potential to produce high-quality fuel pellets. Therefore, the potential for further exploration and utilization of biomass sources in terms of the co-pelletization of waste products is a promising avenue for future research. By investigating this approach, a more comprehensive understanding of these materials can be gained, leading to the development of more effective and efficient methods for utilizing them.