Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5

Abstract

1. Introduction

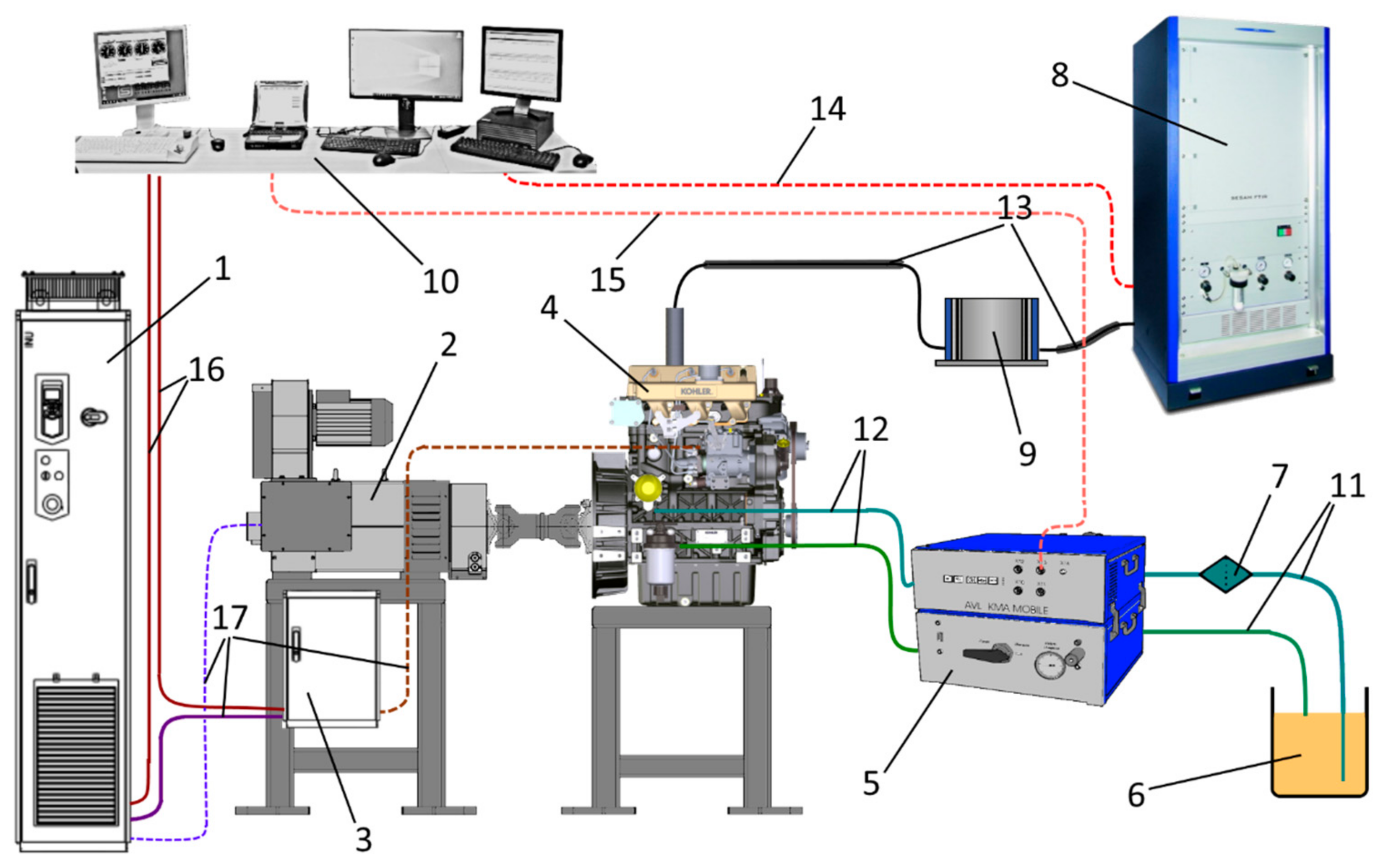

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

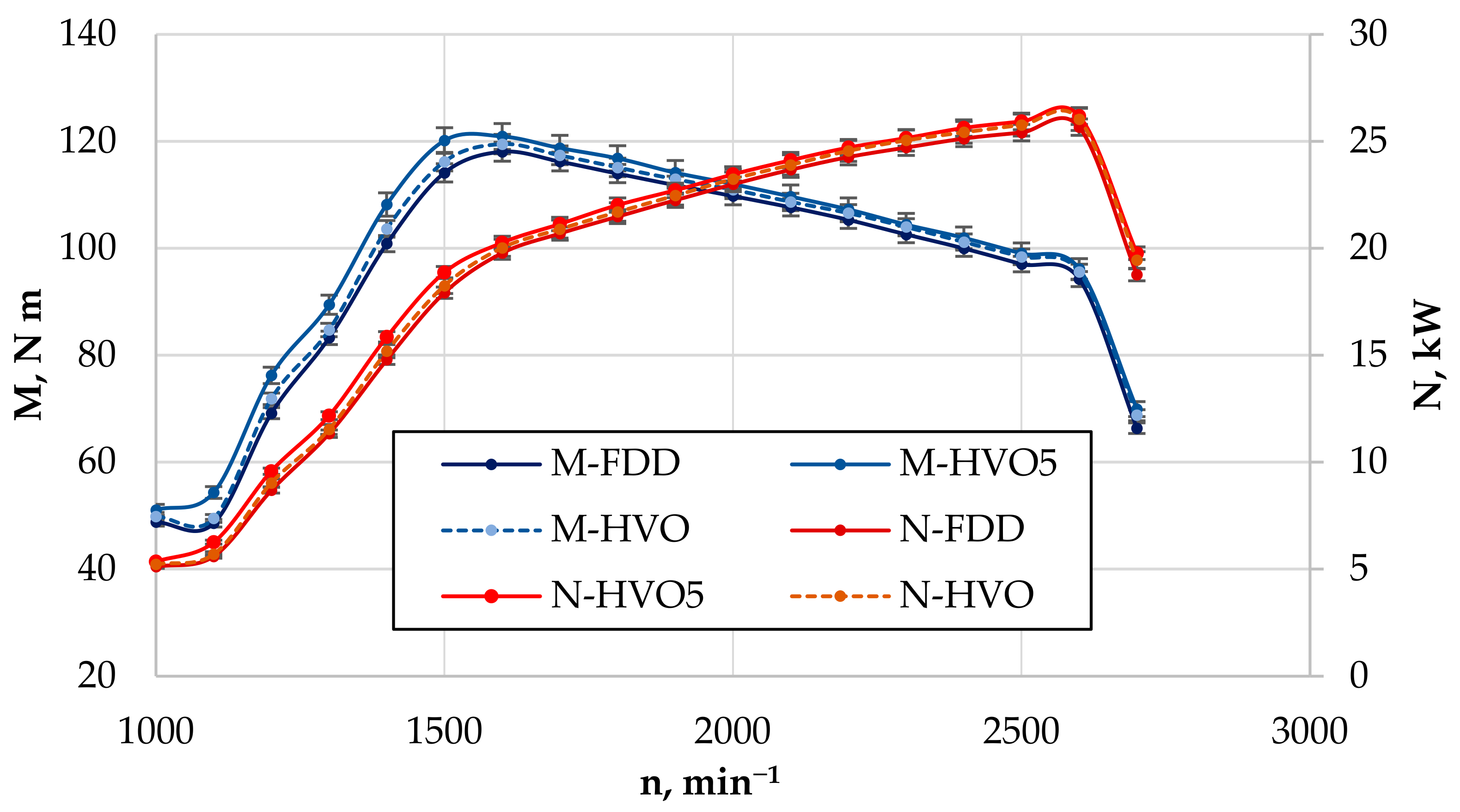

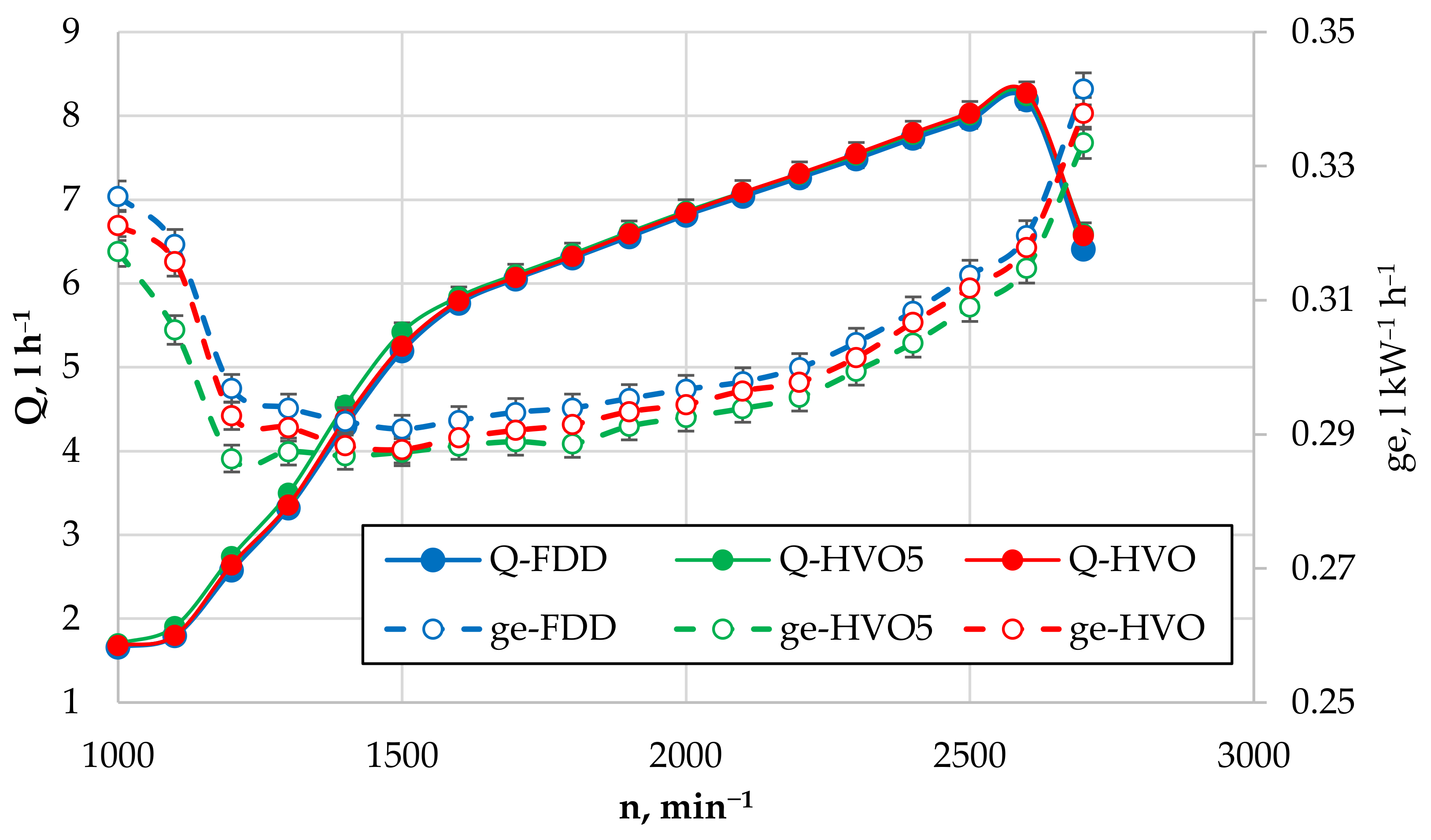

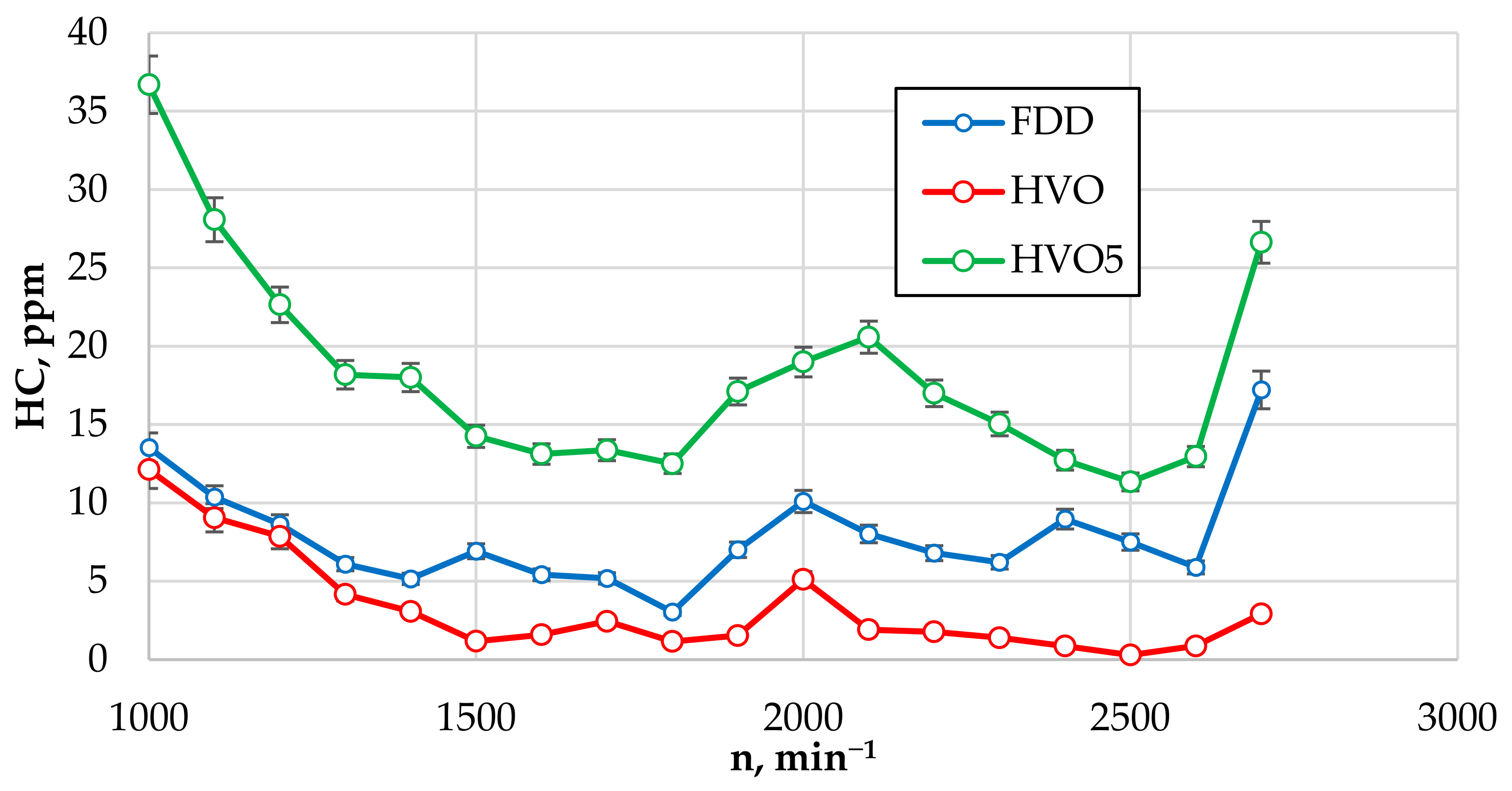

- Studies have shown that there are benefits in using HVO fuel and its admixture, namely, power increases slightly and fuel consumption and hydrocarbons in the exhaust gases decrease. At the same time, no additional effect can be observed from increasing the mixture concentration; HVO5 showed better power and torque indicators than HVO compared to FDD.

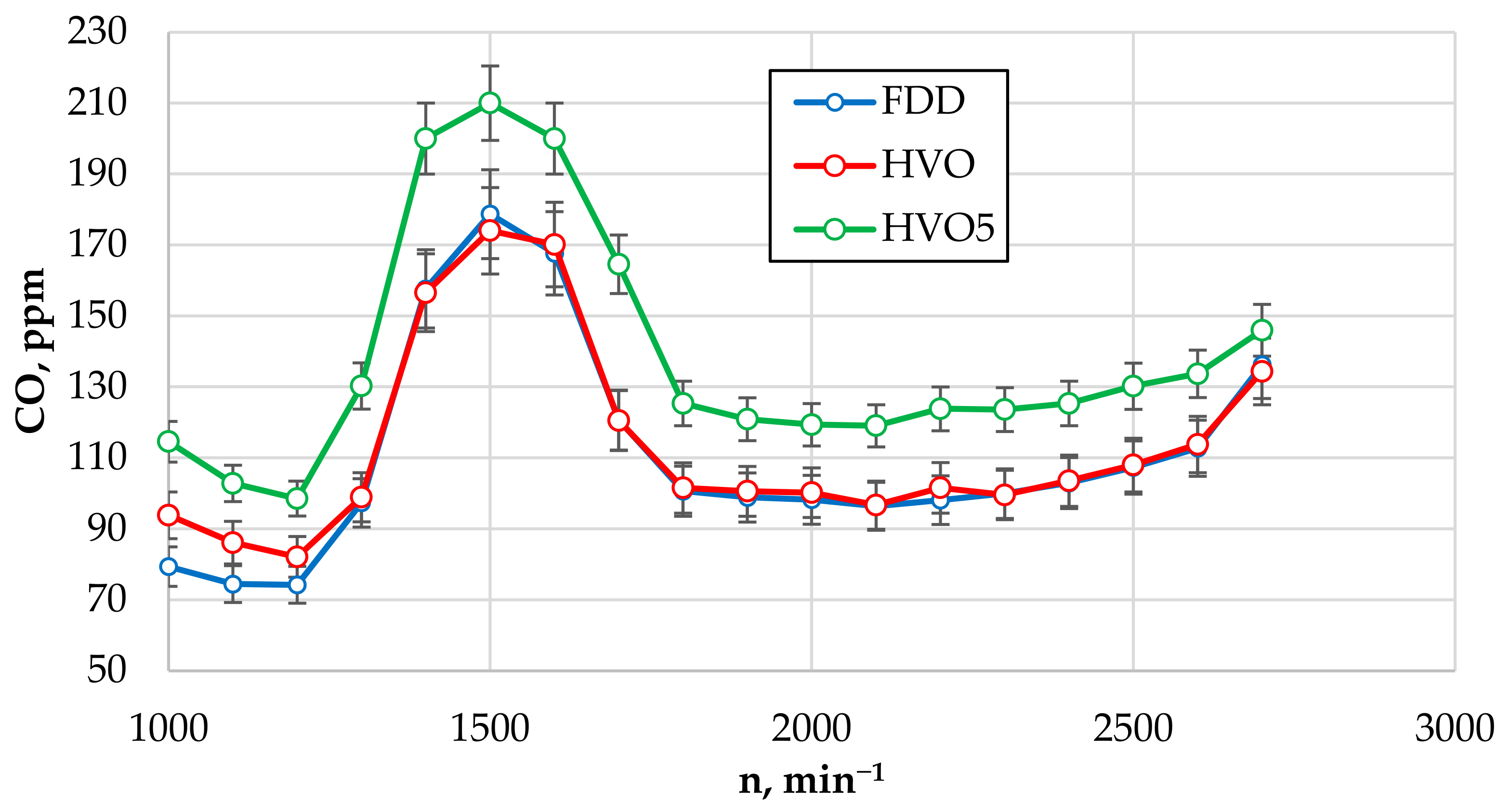

- The full desired ecological effect found by other researchers has not been achieved. The carbon monoxide content in emissions increased by an average of 3.0% using HVO and by an average of 36% using HVO5, while the NOx content in the emissions increased by an average of 3.0% using HVO and by an average of 8.8% using HVO5.

- To achieve significant improvements in results, more attention should be paid to research the impact of other different factors, such as the fuel composition, spray characteristics, air-to-fuel ratio, compression ratio, injection strategy, engine parameter adjustments, etc., which can further affect the combustion process and, accordingly, the exhaust gas composition. This means that achieving the benefits of HVO cannot be fully realized with the existing internal combustion engine adapted to work with diesel fuel, but only after optimal adaptation to work with HVO.

- Considering society’s desire for low-emission and zero-emission vehicles, the ecological effect could be the most important driver of the use of this fuel in the latest generation of diesel engines. In addition, the slight increase in power in the case of using pure HVO will not be felt by the end-user, which will therefore hinder the full evaluation of this fuel. In that case, some more extensive outdoor studies using portable emission measurement systems (PEMSs) and high-precision fuel consumption measurement systems (AVL KMA Mobile) for fuel consumption and emission detection would be recommended and probably will be realized in future research.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 24 November 2022).

- Greenhouse Gas Emissions from Transport in Europe. Available online: https://www.eea.europa.eu/ims/greenhouse-gas-emissions-from-transport (accessed on 24 November 2022).

- Report—Vehicles in Use, Europe. 2022. Available online: https://www.acea.auto/publication/report-vehicles-in-use-europe-2022/ (accessed on 24 November 2022).

- Mulholland, E.; Miller, J.; Braun, C.; Jin, L.; Rodríguez, F. Quantifying the Long-Term Air Quality and Health Benefits from Euro 7/VII Standards in Europe; International Council on Clean Transportation: Washington, DC, USA, 2021; Available online: https://theicct.org/publication/quantifying-the-long-term-air-quality-and-health-benefits-from-euro-7-vii-standards-in-europe/ (accessed on 24 November 2022).

- EEA. Air Quality in Europe 2022. Report No. 05/2022. Available online: https://www.eea.europa.eu//publications/air-quality-in-europe-2022 (accessed on 24 November 2022).

- EU Ban on the Sale of New Petrol and Diesel Cars from 2035 Explained. Available online: https://www.europarl.europa.eu/news/en/headlines/economy/20221019STO44572/eu-ban-on-sale-of-new-petrol-and-diesel-cars-from-2035-explained (accessed on 24 November 2022).

- Di Blasio, G.; Ianniello, R.; Beatrice, C. Hydrotreated vegetable oil as enabler for high-efficient and ultra-low emission vehicles in the view of 2030 targets. Fuel 2022, 310, 122206. [Google Scholar] [CrossRef]

- Andersson, Ö.; Börjesson, P. The greenhouse gas emissions of an electrified vehicle combined with renewable fuels: Life cycle assessment and policy implications. Appl. Energy 2021, 289, 116621. [Google Scholar] [CrossRef]

- Dobrzynska, E.; Szewczynska, M.; Posniak, M.; Szczotka, A.; Puchalka, B.; Woodburn, J. Exhaust emissions from diesel engines fueled by different blends with the addition of nanomodifiers and hydrotreated vegetable oil HVO. Environ. Pollut. 2020, 259, 113772. [Google Scholar] [CrossRef]

- Mikkonen, S.; Honkanen, M.; Kuronen, M. HVO, hydrotreated vegetable oil. A premium renewable biofuel for diesel engines. Germany. In Proceedings of the Conference: 9. International Colloquium Fuels: Conventional and Future Energy for Automobiles, Ostfildern, Germany, 15–17 January 2013; pp. 281–291. Available online: https://www.osti.gov/etdeweb/biblio/22114203 (accessed on 24 November 2022).

- Stumborg, M.; Wong, A.; Hogan, E. Hydroprocessed vegetable oils for diesel fuel improvement. Bioresour. Technol. 1996, 56, 13–18. [Google Scholar] [CrossRef]

- Suarez-Bertoa, R.; Kousoulidou, M.; Clairotte, M.; Giechaskiel, B.; Nuottimaki, J.; Sarjovaara, T.; Lonza, L. Impact of HVO blends on modern diesel passenger cars emissions during real world operation. Fuel 2019, 235, 1427–1435. [Google Scholar] [CrossRef]

- Bjorgen, K.O.P.; Emberson, D.R.; Lovas, T. Combustion and soot characteristics of hydrotreated vegetable oil compression-ignited spray flames. Fuel 2020, 266, 116942. [Google Scholar] [CrossRef]

- Rodriguez-Fernandez, J.; Lapuerta, M.; Sanchez-Valdepenas, J. Regeneration of diesel particulate filters: Effect of renewable fuels. Renew. Energy 2017, 104, 30–39. [Google Scholar] [CrossRef]

- Müller, M.; Šleger, V.; Čedík, J.; Pexa, M. Research on the Material Compatibility of Elastomer Sealing O-Rings. Polymers 2022, 14, 3323. [Google Scholar] [CrossRef]

- Singh, D.; Subramanian, K.A.; Garg, M.O. Comprehensive review of combustion, performance and emissions characteristics of a compression ignition engine fueled with hydroprocessed renewable diesel. Renew. Sustain. Energy Rev. 2018, 81, 2947–2954. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Natsios, I.; Dimaratos, A.; Katsaounis, D.; Samaras, Z.; Bezergianni, S.; Lehto, K. Evaluation of a Hydrotreated Vegetable Oil (HVO) and effects on emissions of a passenger car diesel engine. Front. Mech. Eng. 2018, 4, 7. [Google Scholar] [CrossRef]

- Simacek, P.; Kubicka, D.; Sebor, G.; Pospisil, M. Fuel properties of hydroprocessed rapeseed oil. Fuel 2010, 89, 611–615. [Google Scholar] [CrossRef]

- Lapuerta, M.; Villajos, M.; Agudelo, J.R.; Boehman, A.L. Key properties and blending strategies of hydrotreated vegetable oil as biofuel for diesel engines. Fuel Process. Technol. 2011, 92, 2406–2411. [Google Scholar] [CrossRef]

- Cheng, Q.; Tuomo, H.; Kaario, O.T.; Martti, L. Spray dynamics of HVO and EN590 diesel fuels. Fuel 2019, 245, 198–211. [Google Scholar] [CrossRef]

- Zhang, T.; Andersson, M.; Munch, K.; Denbratt, I. Optical Diagnostics of Spray Characteristics and Soot Volume Fractions of N-Butanol, N-Octanol, Diesel, and Hydrotreated Vegetable Oil Blends in a Constant Volume Combustion Chamber; SAE Technical Paper Series 2019-01-0019; SAE International: Warrendale, PA, USA, 2019. [Google Scholar] [CrossRef]

- Demuynck, J.; Dauphin, R.; Yugo, M.; Mendoza Villafuerte, P.; Bosteels, D. Advanced Emission Controls and Sustainable Renewable Fuels for Low Pollutant and CO2 Emissions on a Diesel Passenger Car. Sustainability 2021, 13, 12711. [Google Scholar] [CrossRef]

- Aatola, H.; Larmi, M.; Sarjovaara, T.; Mikkonen, S. Hydrotreated Vegetable Oil (HVO) as a renewable diesel fuel: Trade-off between NOx, particulate emission, and fuel consumption of a heavy duty engine. SAE Int. J. Engines 2008, 1, 1251–1262. [Google Scholar] [CrossRef]

- Kuronen, M.; Mikkonen, S.; Aakko, P.; Murtonen, T. Hydrotreated Vegetable Oil as Fuel for Heavy Duty Diesel Engines; SAE Technical Paper 2007-01-4031; SAE International: Warrendale, PA, USA, 2007. [Google Scholar] [CrossRef]

- Pirjola, L.; Ronkko, T.; Saukko, E.; Parviainen, H.; Malinen, A.; Alanen, J.; Saveljeff, H. Exhaust emissions of non-road mobile machine: Real-world and laboratory studies with diesel and HVO fuels. Fuel 2017, 202, 154–164. [Google Scholar] [CrossRef]

- Bugarski, A.D.; Hummer, J.A.; Vanderslice, S. Effects of hydrotreated vegetable oil on emissions of aerosols and gases from light-duty and medium-duty older technology engines. J. Occup. Environ. Hyg. 2016, 13, 297–306. [Google Scholar] [CrossRef]

- Serrano, L.; Santana, B.; Pires, N.; Correia, C. Performance, Emissions, and Efficiency of Biodiesel versus Hydrotreated Vegetable Oils (HVO), Considering Different Driving Cycles Sensitivity Analysis (NEDC and WLTP). Fuels 2021, 2, 448–470. [Google Scholar] [CrossRef]

- Pardhi, S.; El Baghdadi, M.; Hulsebos, O.; Hegazy, O. Optimal Powertrain Sizing of Series Hybrid Coach Running on Diesel and HVO for Lifetime Carbon Footprint and Total Cost Minimisation. Energies 2022, 15, 6974. [Google Scholar] [CrossRef]

- Sondors, K.; Birkavs, A.; Dukulis, I.; Pirs, V.; Jesko, Z. Investigation in tractor Claas Ares 557ATX operating parameters using hydrotreated vegetable oil fuel. In Proceedings of the 13th International Scientific Conference “Engineering for Rural Development”, Jelgava, Latvia, 29–30 May 2014; pp. 63–68. [Google Scholar]

- Pexa, M.; Čedík, J.; Mařík, J.; Hönig, V.; Horníčková, Š.; Kubín, K. Comparison of the operating characteristics of the internal combustion engine using rapeseed oil methyl ester and hydrogenated oil. Agron. Res. 2015, 13, 613–620. [Google Scholar]

- Singh, D.; Subramanian, K.A.; Singal, S.K. Emissions and fuel consumption characteristics of a heavy duty diesel engine fueled with Hydroprocessed Renewable Diesel and Biodiesel. Appl. Energy 2015, 155, 440–446. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Ahmed, C.M.S.; Canchola, A.; Chen, J.Y.; Li, C.; Johnson, K.C.; Durbin, T.D.; Lin, Y.-H.; Karavalakis, G. Effects of hydrogenated vegetable oil (HVO) and HVO/biodiesel blends on the physicochemical and toxicological properties of emissions from an off-road heavy-duty diesel engine. Fuel 2022, 323, 124283. [Google Scholar] [CrossRef]

- Kumar, N.; Sonthalia, A.; Tomar, M.; Koul, R. An experimental investigation on spray, performance and emission of hydrotreated waste cooking oil blends in an agricultural engine. Int. J. Engine Res. 2021, 22, 2305–2317. [Google Scholar] [CrossRef]

- Makinen, R.; Nylund, N.O.; Erkkila, K.; Saikkonen, P.; Amerla, A. Bus Fleet Operation on Renewable Paraffinic Diesel Fuel; SAE Technical Paper 2011-01-1965; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Erkkilam, K.; Nylund, N.O.; Hulkkonen, T.; Tilli, A.; Mikkonen, S.; Saikkonen, P.; Mamkinen, R.; Amberla, A. Emission Performance of Paraffinic HVO Diesel Fuel in Heavy Duty Vehicles; SAE Technical Paper 2011-01-1966; SAE International: Warrendale, PA, USA, 2011. [Google Scholar] [CrossRef]

- Happonen, M.; Heikkila, J.; Murtonen, T.; Lehto, K.; Sarjovaara, T.; Larmi, M.; Keskinen, J.; Virtanen, A. Reductions in particulate and NOx emissions by diesel engine parameter adjustments with HVO fuel. Environ. Sci. Technol. 2012, 46, 6198–6204. [Google Scholar] [CrossRef] [PubMed]

- Szeto, W.; Leung, D.Y.C. Is hydrotreated vegetable oil a superior substitute for fossil diesel? A comprehensive review on physicochemical properties, engine performance and emissions. Fuel 2022, 327, 125065. [Google Scholar] [CrossRef]

- Bohl, T.; Smallbone, A.; Tian, G.; Roskilly, A.P. Particulate number and NOx trade-off comparisons between HVO and mineral diesel in HD applications. Fuel 2018, 215, 90–101. [Google Scholar] [CrossRef]

- Kim, D.; Kim, S.; Oh, S.; No, S.Y. Engine performance and emission characteristics of hydrotreated vegetable oil in light duty diesel engines. Fuel 2014, 125, 36–43. [Google Scholar] [CrossRef]

- Preuß, J.; Munch, K.; Denbratt, I. Performance and emissions of renewable blends with OME3–5 and HVO in heavy duty and light duty compression ignition engines. Fuel 2021, 303, 121275. [Google Scholar] [CrossRef]

- Rantanen, L.R.; Linnaila, P.; Aakko, P.; Harju, T. NExBTL-Biodiesel Fuel of the Second Generation; SAE Technical Paper 2005–01-3771; SAE International: Warrendale, PA, USA, 2005. [Google Scholar] [CrossRef]

- Chau, V.T.; Chinda, C.; Preechar, K.; Sato, S.; Kosaka, H. Optical study on combustion characteristics of hydrotreated vegetable oil and blends under simulated CI engine conditions and various EGR. J. Mech. Sci. Technol. 2017, 31, 4521–4531. [Google Scholar] [CrossRef]

- Dimitriadis, A.; Seljak, T.; Vihar, R.; Baskovic, U.Z.; Dimaratos, A.; Bezergianni, S.; Samaras, Z.; Katrasnik, T. Improving PM-NOx trade-off with paraffinic fuels: A study towards diesel engine optimization with HVO. Fuel 2020, 265, 116921. [Google Scholar] [CrossRef]

- No, S.-Y. Application of hydrotreated vegetable oil from triglyceride based biomass to CI engines—A review. Fuel 2014, 115, 88–96. [Google Scholar] [CrossRef]

- Sonthalia, A.; Kumar, N. Hydroprocessed vegetable oil as a fuel for transportation sector: A review. J. Energy Inst. 2019, 92, 1–17. [Google Scholar] [CrossRef]

- Sunde, K.; Brekke, A.; Solberg, B. Environmental impacts and costs of hydrotreated vegetable oils, transesterified lipids and woody BTL—A review. Energies 2011, 4, 845–877. [Google Scholar] [CrossRef]

| Property | Method | Fuel | ||

|---|---|---|---|---|

| FDD | HVO | HVO5 | ||

| Density at 15 °C, g·m−3 | EN ISO 12185 | 816.1 | 780.8 | 807.4 |

| Viscosity at 40 °C, mm2·s−1 | IN ISO 3104 | 1.853 | 3.025 | 1.797 |

| CFPP, °C | EN 116 | −40 | −38 | −42 |

| CP, °C | EN 23015 | −28 | −34 | −33 |

| Cetane number | EN ISO 5165 | 53.8 | 74.5 | 55.0 |

| Parameter | Value |

|---|---|

| Engine capacity, cm3 | 1861 |

| Cylinder number | 3 |

| Top power, kW | 31 at 2600 min−1 |

| Maximum torque, Nm | 133 at 1500 min−1 |

| Compression ratio | 17 |

| Bore, mm | 88 |

| Stroke, mm | 102 |

| Fuel injection system | Direct injection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Smigins, R.; Sondors, K.; Pirs, V.; Dukulis, I.; Birzietis, G. Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5. Energies 2023, 16, 4785. https://doi.org/10.3390/en16124785

Smigins R, Sondors K, Pirs V, Dukulis I, Birzietis G. Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5. Energies. 2023; 16(12):4785. https://doi.org/10.3390/en16124785

Chicago/Turabian StyleSmigins, Ruslans, Kristaps Sondors, Vilnis Pirs, Ilmars Dukulis, and Gints Birzietis. 2023. "Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5" Energies 16, no. 12: 4785. https://doi.org/10.3390/en16124785

APA StyleSmigins, R., Sondors, K., Pirs, V., Dukulis, I., & Birzietis, G. (2023). Studies of Engine Performance and Emissions at Full-Load Mode Using HVO, Diesel Fuel, and HVO5. Energies, 16(12), 4785. https://doi.org/10.3390/en16124785