Hyperparameter Bayesian Optimization of Gaussian Process Regression Applied in Speed-Sensorless Predictive Torque Control of an Autonomous Wind Energy Conversion System

Abstract

1. Introduction

- Enhancement of controller reliability;

- Adaptation to variations in magnetizing inductance;

- Improved accuracy of the estimator through the implementation of HBO and the gray box approach;

- Reduction of overall system costs;

- Mitigation of harmonics through the introduction of galvanic isolation between the two stars.

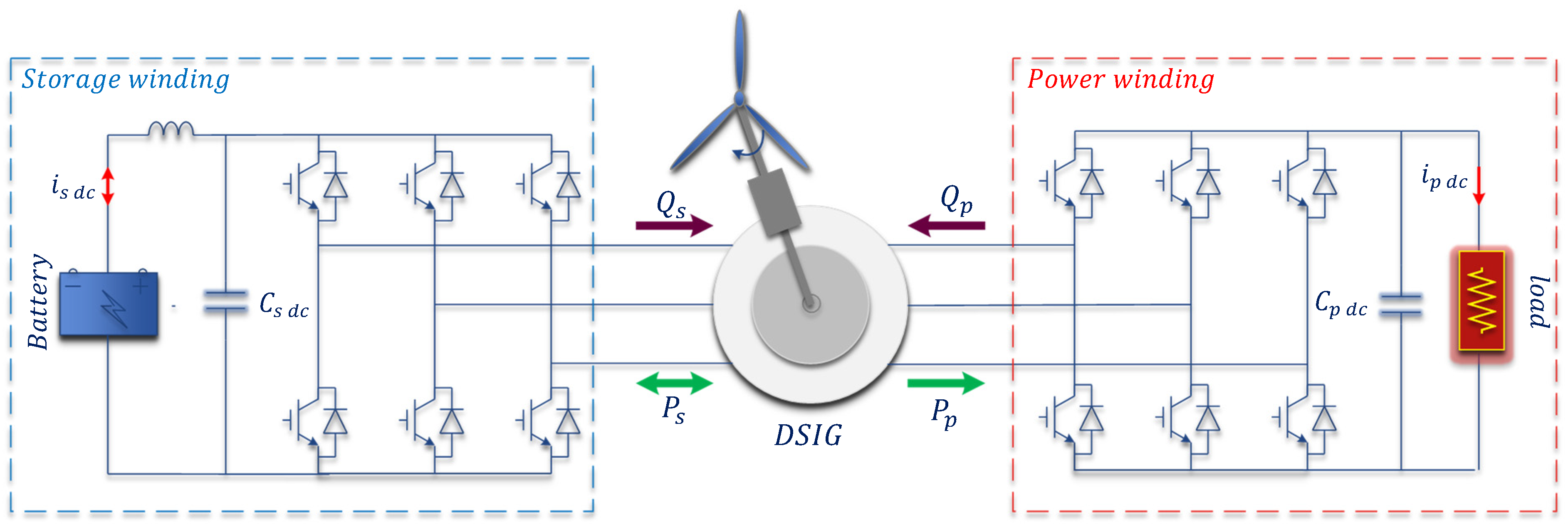

2. ADSIG Modeling

3. Gaussian Process Regression Theory

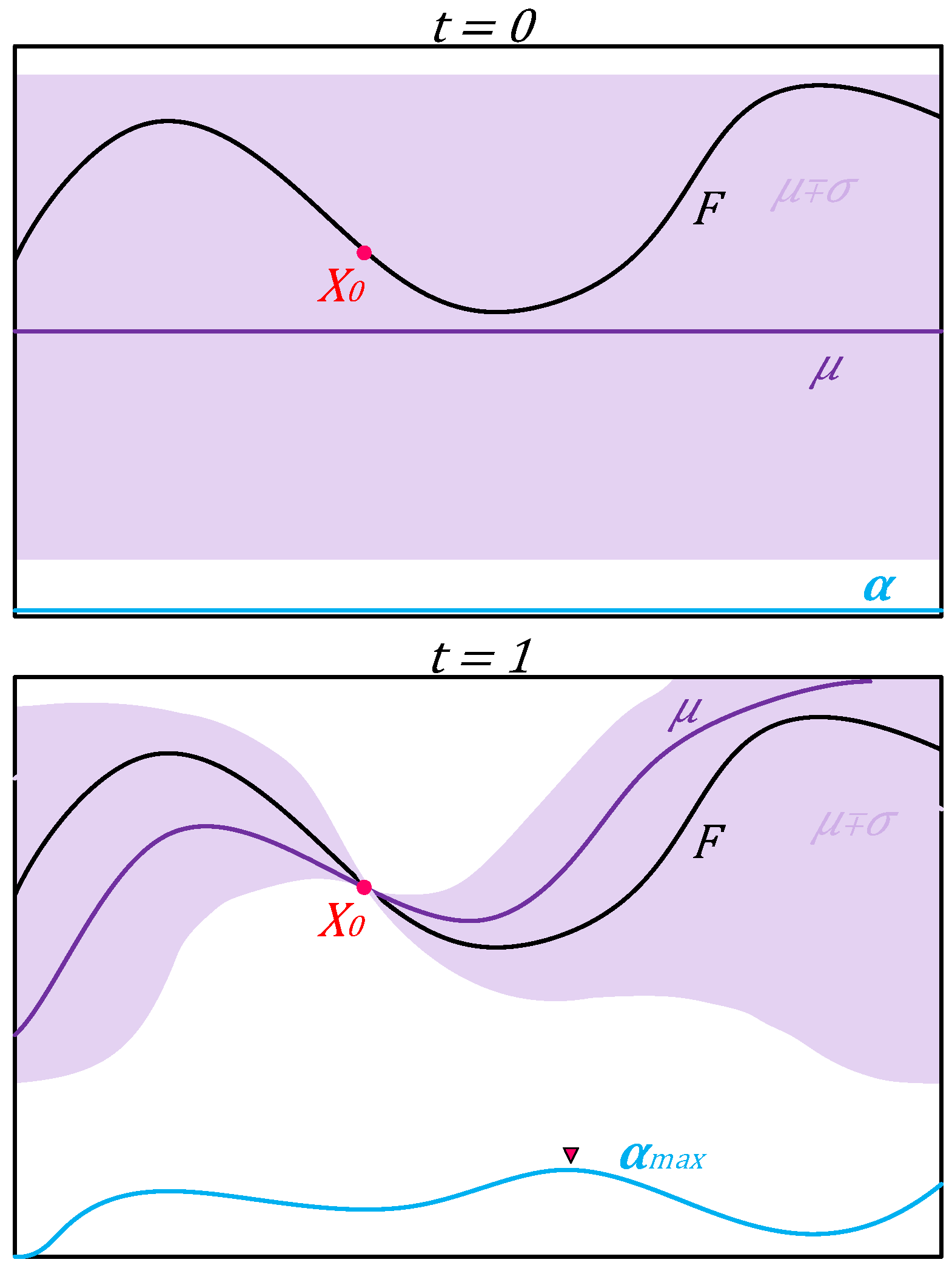

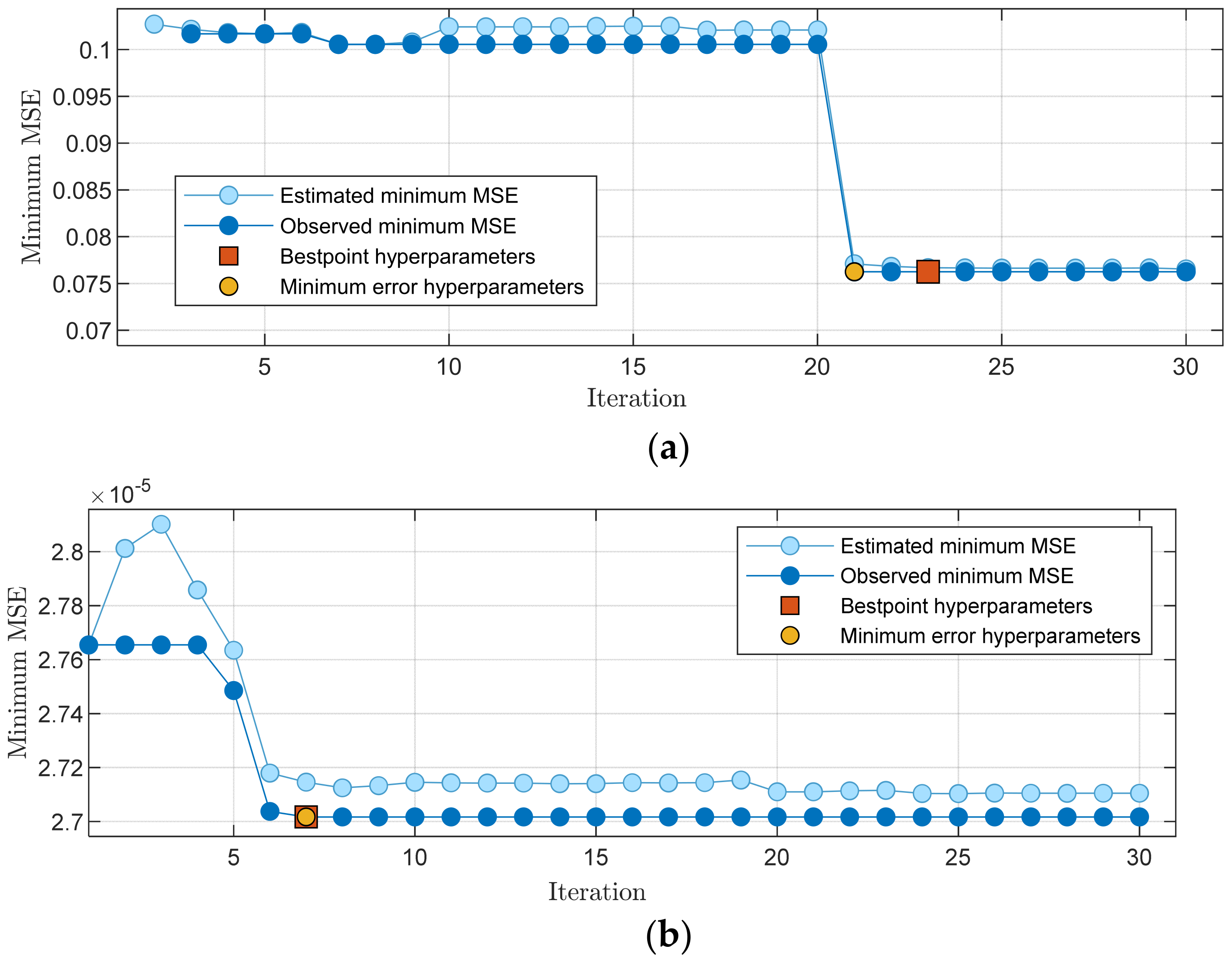

3.1. Hyperparameter Bayesian Optimization

| Algorithm 1. Pseudocode of Bayesian optimization with the GP surrogate model. |

| 1: Input data 2: Initial small set of data randomly chosen from 3: Compute a probabilistic Surrogate Function (Gaussian Process) in such a way to find 4: for iterations do 5: Select a new data set from by optimizing the Acquisition Function (expected improvement per second plus. Equation (14)): 4: Augment data set 5: Evaluate the Surrogate Function for to find 7: end for |

3.2. Gray Box Principle

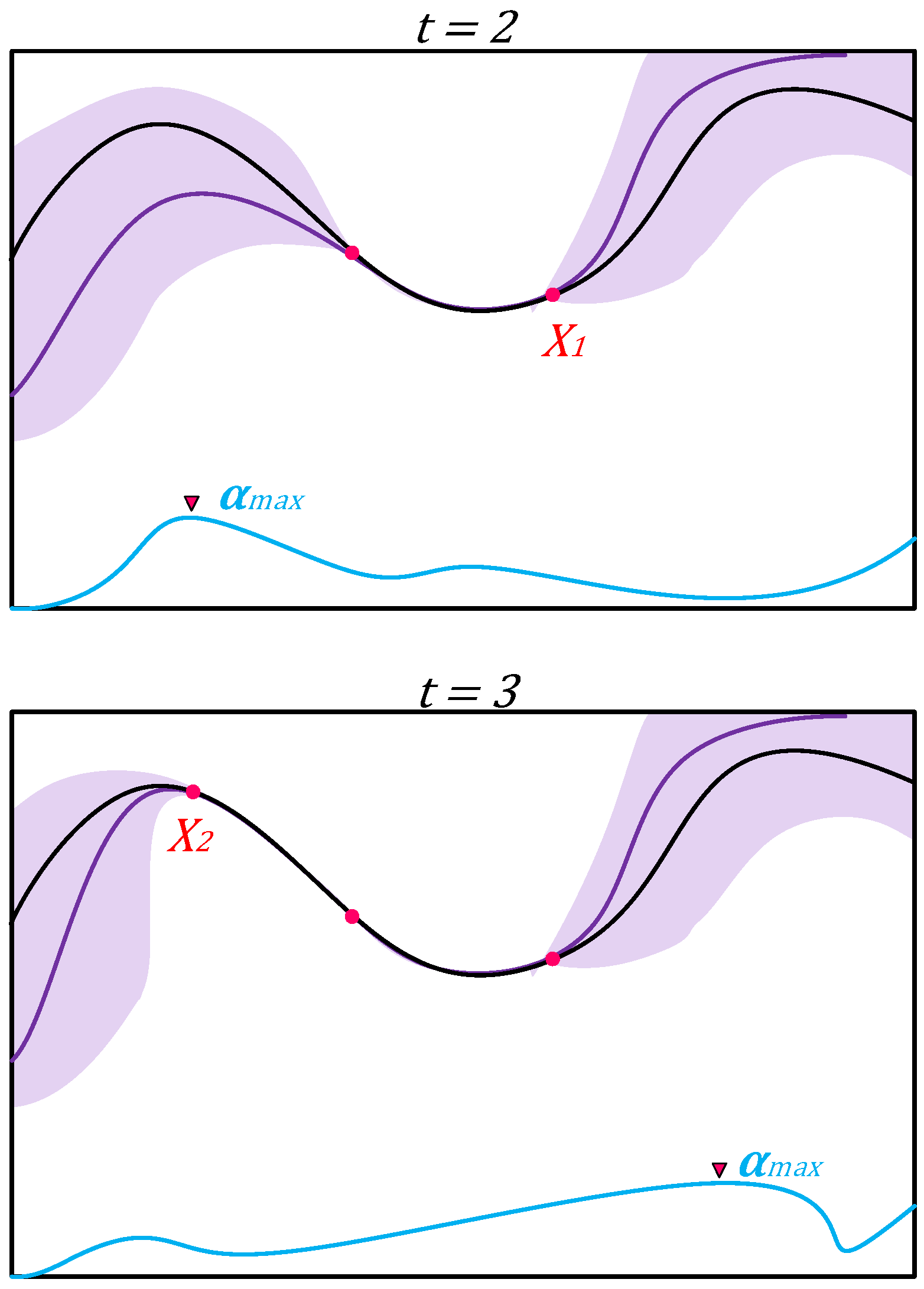

4. Model Predictive Torque Control

- -

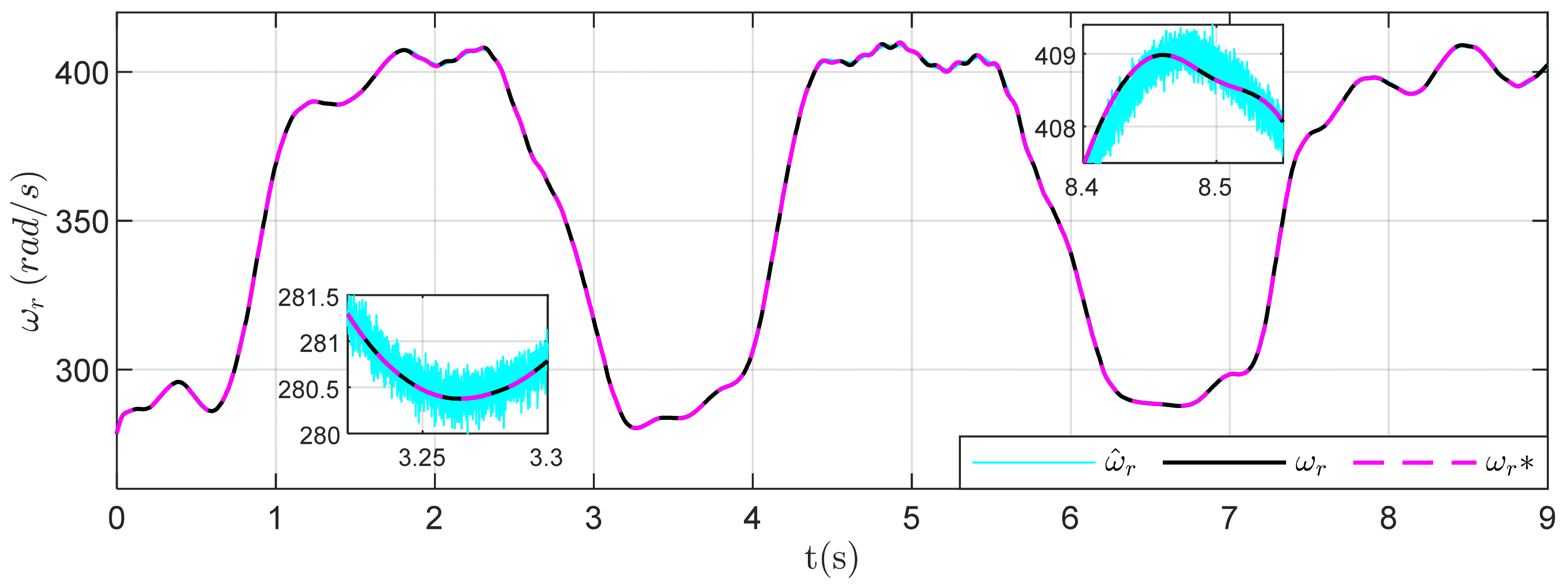

- First are the estimation of the stator and rotor flux values and the machine’s rotation speed using the GPR algorithm, as are detailed in Section 3.

- -

- The second step concerns prediction of the electromagnetic torque and the stator flux value through the stator current prediction. In this step, the prediction is made using forward Euler discretization of the ADSIG model presented in Section 2 (Equations (1), (2) and (7)), as shown in Equations (21)–(23):where: .

- -

- The last step is the choice and design of the cost function. This depicts a multi-objective online torque and flux optimization. Several cost functions have been developed in the literature, but for this work, we chose the simplest one, represented in Equation (24), where is the storage winding cost function and is the cost function of the power winding:

5. Training Results

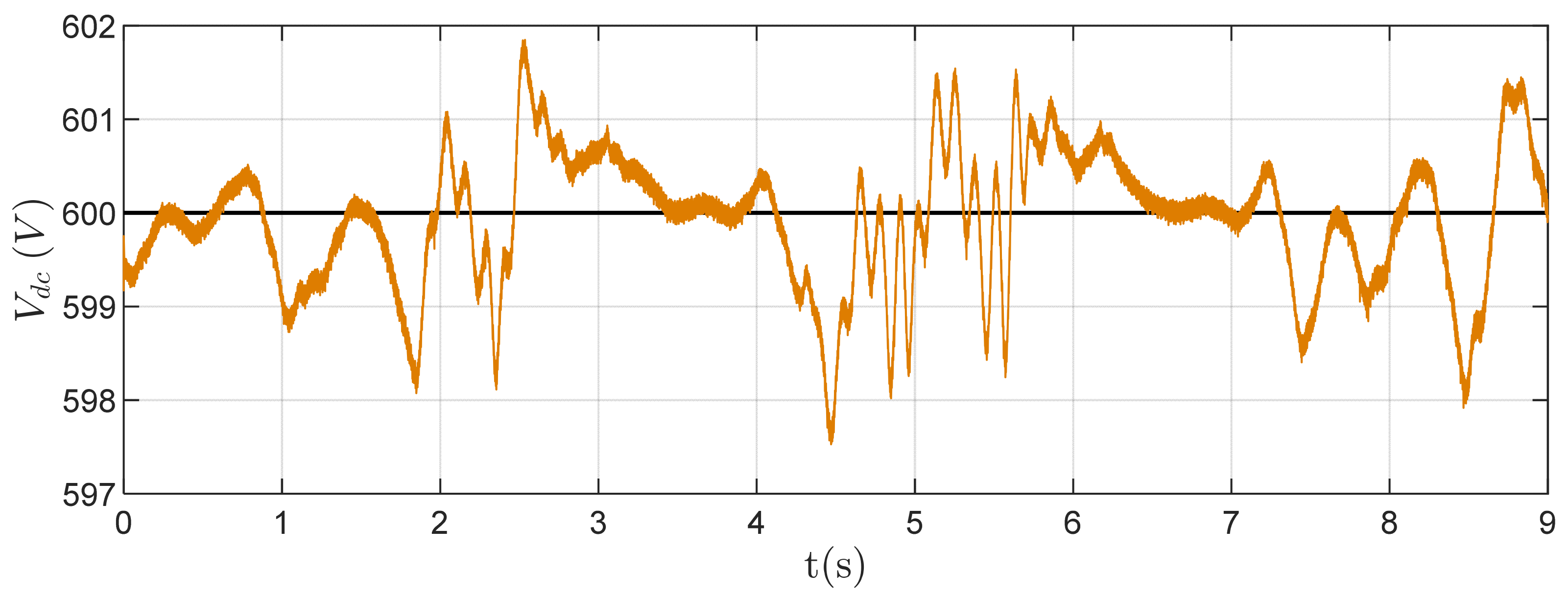

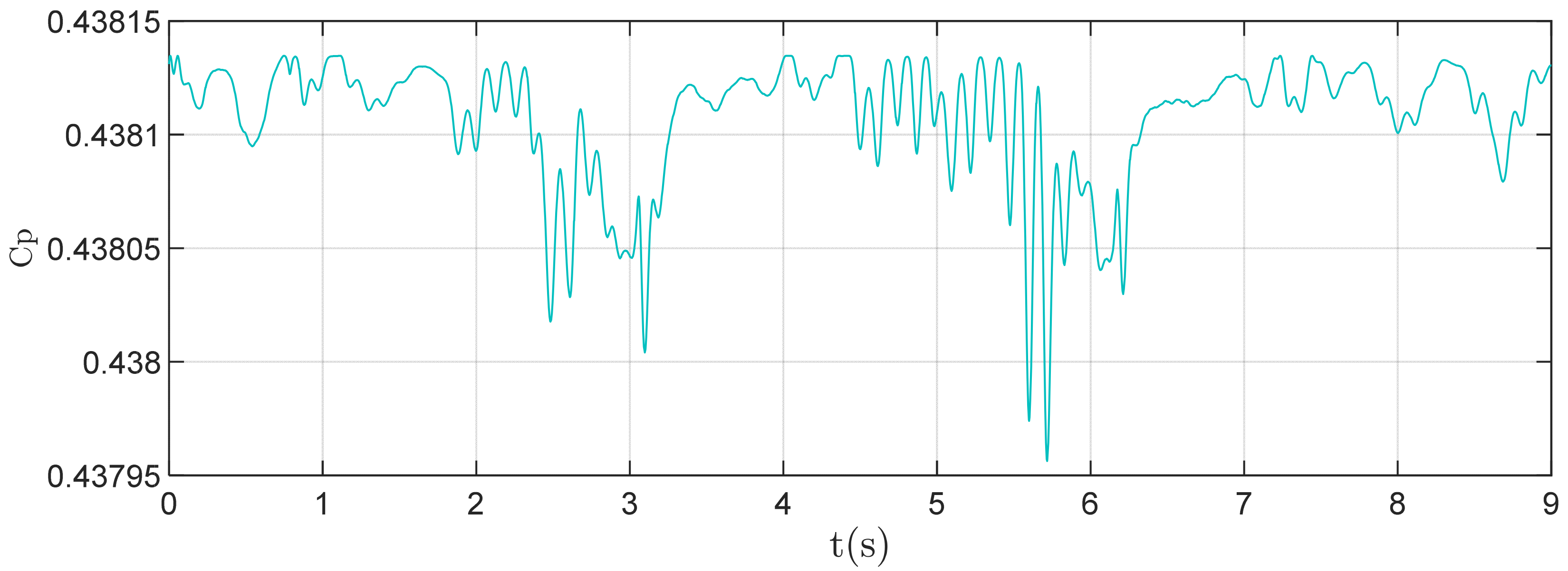

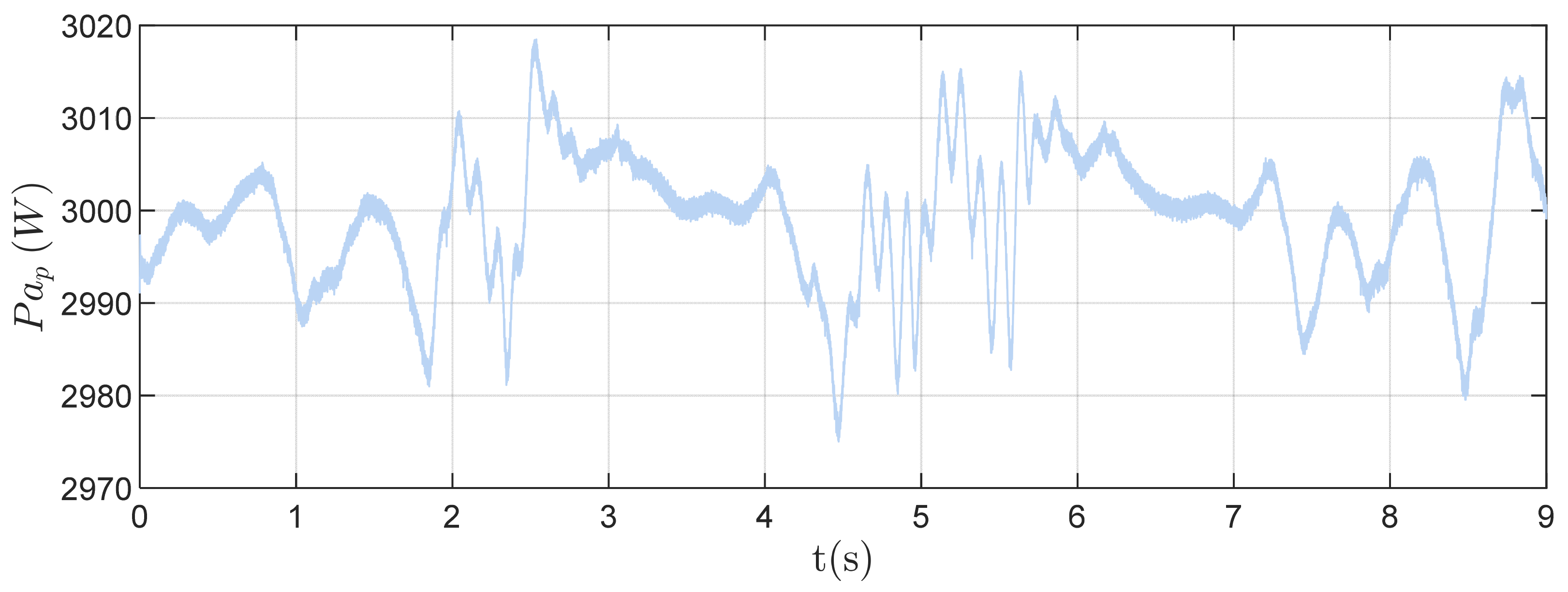

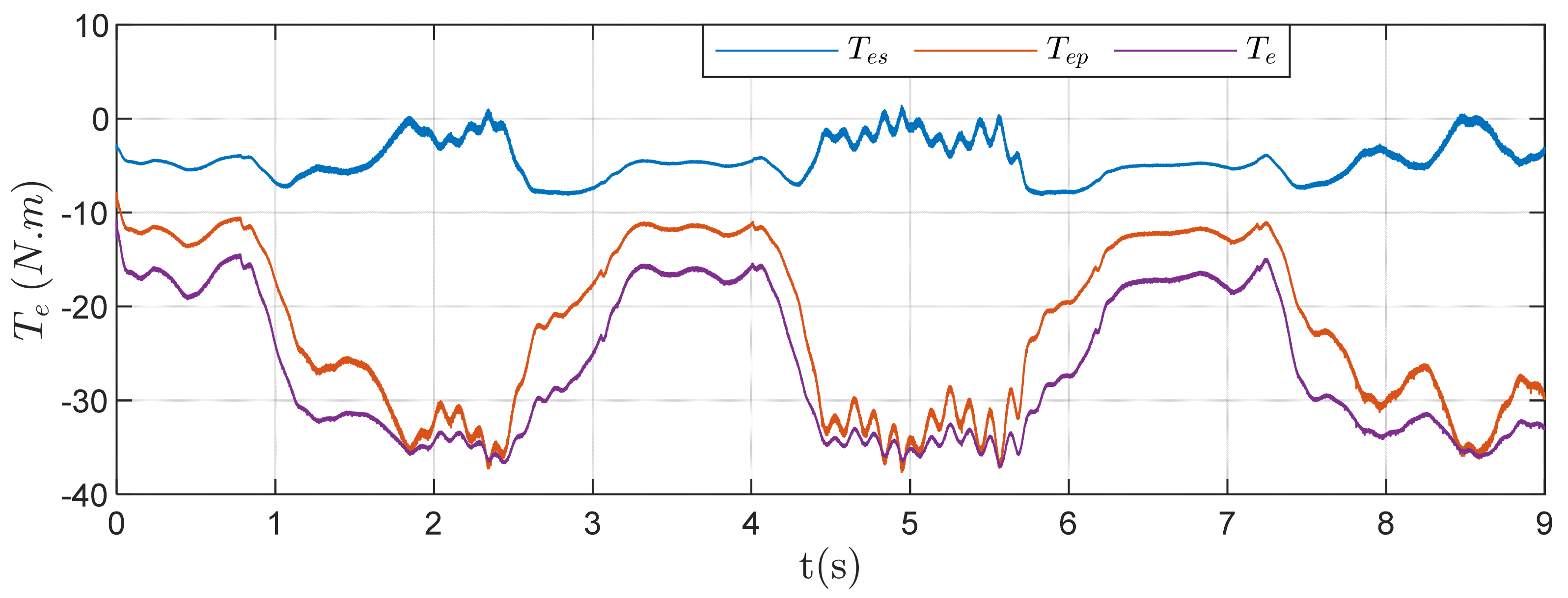

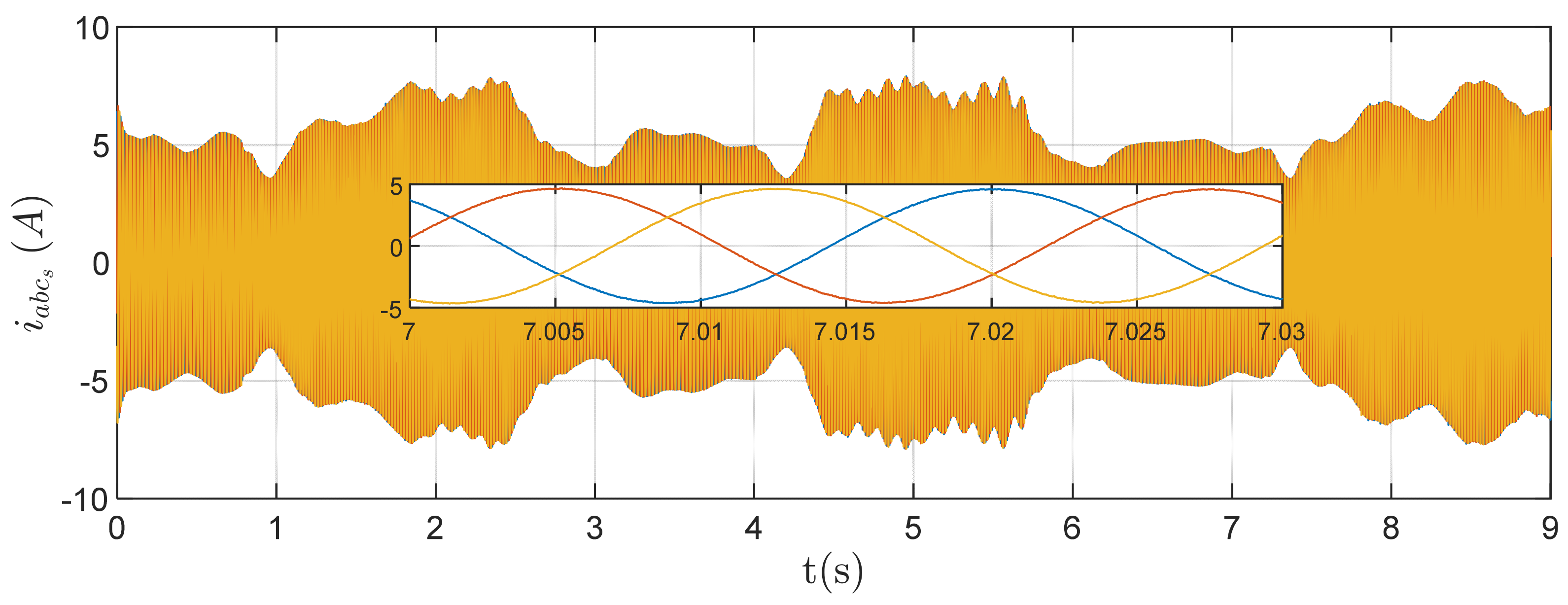

6. GPR-PTC Simulation Results

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The role of renewable energy in the global energy transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Nadeem, F.; Aftab, M.A.; Hussain, S.S.; Ali, I.; Tiwari, P.K.; Goswami, A.K.; Ustun, T.S. Virtual Power Plant Management in Smart Grids with XMPP Based IEC 61850 Communication. Energies 2019, 12, 2398. [Google Scholar] [CrossRef]

- Das, A.; Dawn, S.; Gope, S.; Ustun, T.S. A Strategy for System Risk Mitigation Using FACTS Devices in a Wind Incorporated Competitive Power System. Sustainability 2022, 14, 8069. [Google Scholar] [CrossRef]

- Singh, N.K.; Koley, C.; Gope, S.; Dawn, S.; Ustun, T.S. An Economic Risk Analysis in Wind and Pumped Hydro Energy Storage Integrated Power System Using Meta-Heuristic Algorithm. Sustainability 2021, 13, 13542. [Google Scholar] [CrossRef]

- Mousavi, S.M.G. An autonomous hybrid energy system of wind/tidal/microturbine/battery storage. Int. J. Electr. Power Energy Syst. 2012, 43, 1144–1154. [Google Scholar] [CrossRef]

- Housseini, B.; Okou, A.F.; Beguenane, R. Robust Nonlinear Controller Design for On-Grid/Off-Grid Wind Energy Battery-Storage System. IEEE Trans. Smart Grid 2017, 9, 5588–5598. [Google Scholar] [CrossRef]

- Chowdhury, M.M.; Haque, M.; Aktarujjaman, M.; Negnevitsky, M.; Gargoom, A. Grid integration impacts and energy storage systems for wind energy applications—A review. In Proceedings of the 2011 IEEE Power and Energy Society General Meeting, Detroit, MI, USA, 24–28 July 2011; pp. 1–8. [Google Scholar]

- Hamitouche, K.; Chekkal, S.; Amimeur, H.; Aouzellag, D. A New Control Strategy of Dual Stator Induction Generator with Power Regulation. J. Eur. Des. Syst. Autom. 2020, 53, 469–478. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z.; Mei, X.; Rodríguez, J.; Kennel, R. Advanced Control Strategies of Induction Machine: Field Oriented Control, Direct Torque Control and Model Predictive Control. Energies 2018, 11, 120. [Google Scholar] [CrossRef]

- Bounasla, N.; Barkat, S. Optimum Design of Fractional Order PIα Speed Controller for Predictive Direct Torque Control of a Sensorless Five-Phase Permanent Magnet Synchronous Machine (PMSM). J. Eur. Syst. Autom. 2020, 53, 437–449. [Google Scholar]

- Ayala, M.; Doval-Gandoy, J.; Rodas, J.; Gonzalez, O.; Gregor, R.; Rivera, M. A Novel Modulated Model Predictive Control Applied to Six-Phase Induction Motor Drives. IEEE Trans. Ind. Electron. 2021, 68, 3672–3682. [Google Scholar] [CrossRef]

- Basic, M.; Vukadinovic, D.; Grgic, I.; Bubalo, M. Speed-Sensorless Vector Control of an Induction Generator Including Stray Load and Iron Losses and Online Parameter Tuning. IEEE Trans. Energy Convers. 2019, 35, 724–732. [Google Scholar] [CrossRef]

- Kumar, R.; Das, S.; Syam, P.; Chattopadhyay, A.K. Review on model reference adaptive system for sensorless vector control of induction motor drives. IET Electr. Power Appl. 2015, 9, 496–511. [Google Scholar] [CrossRef]

- Benlaloui, I.; Drid, S.; Chrifi-Alaoui, L.; Ouriagli, M. Implementation of a New MRAS Speed Sensorless Vector Control of Induction Machine. IEEE Trans. Energy Convers. 2014, 30, 588–595. [Google Scholar] [CrossRef]

- Korzonek, M.; Tarchala, G.; Orlowska-Kowalska, T. A review on MRAS-type speed estimators for reliable and efficient induction motor drives. ISA Trans. 2019, 93, 1–13. [Google Scholar] [CrossRef]

- Aurora, C.; Ferrara, A. A sliding mode observer for sensorless induction motor speed regulation. Int. J. Syst. Sci. 2007, 38, 913–929. [Google Scholar] [CrossRef]

- Shtessel, Y.; Edwards, C.; Fridman, L.; Levant, A. Sliding Mode Control and Observation; Springer: New York, NY, USA, 2014. [Google Scholar]

- Di Gennaro, S.; Dominguez, J.R.; Meza, M.A. Sensorless High Order Sliding Mode Control of Induction Motors with Core Loss. IEEE Trans. Ind. Electron. 2013, 61, 2678–2689. [Google Scholar] [CrossRef]

- Amirouche, E.; Iffouzar, K.; Houari, A.; Ghedamsi, K.; Aouzellag, D. Improved control strategy of dual star permanent magnet synchronous generator based tidal turbine system using sensorless field oriented control and direct power control techniques. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–22. [Google Scholar] [CrossRef]

- Amirouche, E.; Iffouzar, K.; Houari, A.; Ghedamsi, K.; Aouzellag, D. Improved Control Strategy of DS-PMSG Based Standalone Tidal Turbine System Using Sensorless Field Oriented Control. Math. Model. Eng. Probl. 2021, 8, 293–301. [Google Scholar]

- Habibullah, M.; Lu, D.D.-C. A Speed-Sensorless FS-PTC of Induction Motors Using Extended Kalman Filters. IEEE Trans. Ind. Electron. 2015, 62, 6765–6778. [Google Scholar] [CrossRef]

- Tanvir, A.A.; Merabet, A. Artificial Neural Network and Kalman Filter for Estimation and Control in Standalone Induction Generator Wind Energy DC Microgrid. Energies 2020, 13, 1743. [Google Scholar] [CrossRef]

- Ridhatullah, A.I.; Hang Tuah Surabaya University; Joret, A.; Karyatanti, I.D.P.; Ponniran, A.; Malaysia, U.T.H.O. Three-Phase Induction Motor Speed Estimation Using Recurrent Neural Network Structure. J. Electron. Volt. Appl. 2021, 2, 23–35. [Google Scholar] [CrossRef]

- Pintelas, E.; Livieris, I.E.; Pintelas, P. A Grey-Box Ensemble Model Exploiting Black-Box Accuracy and White-Box Intrinsic Interpretability. Algorithms 2020, 13, 17. [Google Scholar] [CrossRef]

- Ufnalski, B.; Grzesiak, L.M. Selected Methods in Angular Rotor Speed Estimation for Induction Motor Drives. In Proceedings of the EUROCON 2007—The International Conference on “Computer as a Tool”, Warsaw, Poland, 9–12 September 2007; pp. 1764–1771. [Google Scholar]

- Yu, T.; Zhu, H. Hyper-Parameter Optimization: A Review of Algorithms and Applications. arXiv 2020, arXiv:2003.05689. [Google Scholar]

- Turner, R.; Eriksson, D.; McCourt, M.; Kiili, J.; Laaksonen, E.; Xu, Z.; Guyon, I. Bayesian Optimization is Superior to Random Search for Machine Learning Hyperparameter Tuning: Analysis of the Black-Box Optimization Challenge 2020. arXiv 2021, arXiv:2104.10201. [Google Scholar]

- Goguelin, S.; Dhokia, V.; Flynn, J.M. Bayesian optimisation of part orientation in additive manufacturing. Int. J. Comput. Integr. Manuf. 2021, 34, 1263–1284. [Google Scholar] [CrossRef]

- Shintani, K.; Fujimoto, T.; Okamoto, M.; Abe, A.; Yamamoto, Y. Surrogate modeling of waveform response using singular value decomposition and Bayesian optimization. J. Adv. Mech. Des. Syst. Manuf. 2021, 15, 20-00169. [Google Scholar] [CrossRef]

- Cai, D.; Liu, W.; Ji, L.; Shi, D. Bayesian optimization assisted meal bolus decision based on Gaussian processes learning and risk-sensitive control. Control Eng. Pract. 2021, 114, 104881. [Google Scholar] [CrossRef]

- Meldgaard, S.A.; Kolsbjerg, E.L.; Hammer, B. Machine learning enhanced global optimization by clustering local environments to enable bundled atomic energies. J. Chem. Phys. 2018, 149, 134104. [Google Scholar] [CrossRef]

- Brochu, E.; Brochu, T.; Freitas, N. A Bayesian interactive optimization approach to procedural animation design. In Proceedings of the SCA ‘10: Proceedings of the 2010 ACM SIGGRAPH/Eurographics Symposium on Computer Animation, Madrid, Spain, 2–4 July 2010; pp. 103–112. [Google Scholar]

- Lizotte, D.; Wang, T.; Bowling, M.; Schuurmans, D. Automatic gait optimization with Gaussian process regression. Int. Jt. Conf. Artif. Intell. 2007, 7, 944–949. [Google Scholar]

- Martinez-Cantin, R.; de Freitas, N.; Doucet, A.; Castellanos, J. Active Policy Learning for Robot Planning and Exploration under Uncertainty. In Robotics; The MIT Press: Cambridge, MA, USA, 2008; Volume 3, pp. 321–328. [Google Scholar] [CrossRef]

- Perdikaris, P.; Karniadakis, G.E. Model inversion via multi-fidelity Bayesian optimization: A new paradigm for parameter estimation in haemodynamics, and beyond. J. R. Soc. Interface 2016, 13, 20151107. [Google Scholar] [CrossRef]

- Galuzzi, B.G.; Perego, R.; Candelieri, A.; Archetti, F. Bayesian Optimization for Full Waveform Inversion. In AIRO Springer Series; Springer: Berlin/Heidelberg, Germany, 2018; Volume 1, pp. 257–264. [Google Scholar] [CrossRef]

- Marchant, R.; Ramos, F. Bayesian optimisation for Intelligent Environmental Monitoring. In Proceedings of the 2012 IEEE/RSJ International Conference on Intelligent Robots and Systems, Vilamoura-Algarve, Portugal, 7–12 October 2012; pp. 2242–2249. [Google Scholar]

- Wang, Z.; Shakibi, B.; Jin, L.; de Freitas, N. Bayesian Multi-Scale Optimistic Optimization. J. Mach. Learn. Res. 2014, 33, 1005–1014. [Google Scholar]

- Wang, Z.; Zoghiy, M.; Hutterz, F.; Matheson, D.; De Freitas, N. Bayesian optimization in high dimensions via random embeddings. Int. Jt. Conf. Artif. Intell. 2013, 1778–1784. [Google Scholar]

- Swersky, K.; Snoek, J.; Adams, R.P. Multi-task Bayesian optimization. Adv. Neural Inf. Process. Syst. 2013, 26, 1–9. [Google Scholar]

- Thornton, C.; Hutter, F.; Hoos, H.H.; Leyton-Brown, K. Auto-WEKA. In Proceedings of the 19th ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Chicago, IL, USA, 11–14 August 2013; Volume Part F1288, pp. 847–855. [Google Scholar]

- Srinivas, N.; Krause, A.; Kakade, S.; Seeger, M. Gaussian process optimization in the bandit setting: No regret and experimental design. In Proceedings of the 27th International Conference on International Conference on Machine Learning, Haifa, Israel, 21–24 June 2010; pp. 1015–1022. [Google Scholar]

- Mahendran, N.; Wang, Z.; Hamze, F.; De Freitas, N. Adaptive MCMC with Bayesian optimization. J. Mach. Learn. Res. 2012, 22, 751–760. [Google Scholar]

- Azimi, J.; Jalali, A.; Fern, X.Z. Hybrid batch bayesian optimization. In Proceedings of the 29th International Conference on Machine Learning ICML, Edinburgh, Scotland, 27 June–3 July 2012; 2, pp. 1215–1222. [Google Scholar]

- Brochu, E.; Cora, V.M.; de Freitas, N. A Tutorial on Bayesian Optimization of Expensive Cost Functions, with Application to Active User Modeling and Hierarchical Reinforcement Learning. arXiv 2010, arXiv:1012.2599. [Google Scholar]

- Benakcha, M.; Benalia, L.; Tourqui, D.E.; Benakcha, A. Backstepping control of dual stator induction generator used in wind energy conversion system. Int. J. Renew. Energy Res. 2018, 8, 384–395. [Google Scholar]

- Benakcha, M.; Benalia, L.; Ameur, F.; Tourqui, D.E. Control of dual stator induction generator integrated in wind energy conversion system. J. Energy Syst. 2017, 1, 21–31. [Google Scholar] [CrossRef]

- Amimeur, H.; Abdessemed, R.; Aouzellag, D.; Merabet, E.; Hamoudi, F. Modeling and Analysis of Dual-Stator Windings Self-Excited Induction Generator. J. Electr. Eng. 2015, 6, 1–6. [Google Scholar]

- Abdessemed, R.; Bendjeddou, Y.; Merabet, E. Improved field oriented control for stand alone dual star induction generator used in wind energy conversion. Eng. Rev. 2020, 40, 34–46. [Google Scholar] [CrossRef]

- Rasmussen, C.E.; Nickisch, H. Gaussian processes for machine learning (GPML) toolbox. J. Mach. Learn. Res. 2010, 11, 3011–3015. [Google Scholar]

- Kocijan, J.; Ažman, K.; Grancharova, A. The concept for Gaussian process model based system identification toolbox. In Proceedings of the 2007 International Conference on Computer Systems and Technologies—CompSysTech ’07, Sofia, Bulgaria, 14–15 June 2007; Volume 285, p. 1. [Google Scholar]

- Rasmussen, C.E.; Williams, C.K.I. Gaussian Processes for Machine Learning, 3rd ed.; MIT Press: Cambridge, MA, USA, 2008. [Google Scholar] [CrossRef]

- Myren, S.; Lawrence, E. A comparison of Gaussian processes and neural networks for computer model emulation and calibration. Stat. Anal. Data Min. ASA Data Sci. J. 2021, 14, 606–623. [Google Scholar] [CrossRef]

- Galuzzi, B.G.; Giordani, I.; Candelieri, A.; Perego, R.; Archetti, F. Hyperparameter optimization for recommender systems through Bayesian optimization. Comput. Manag. Sci. 2020, 17, 495–515. [Google Scholar] [CrossRef]

- Hannan, M.A.; Abdolrasol, M.G.M.; Mohamed, R.; Al-Shetwi, A.Q.; Ker, P.J.; Begum, R.A.; Muttaqi, K.M. ANN-Based Binary Backtracking Search Algorithm for VPP Optimal Scheduling and Cost-Effective Evaluation. IEEE Trans. Ind. Appl. 2021, 57, 5603–5613. [Google Scholar] [CrossRef]

- Abdolrasol, M.G.M.; Hussain, S.M.S.; Ustun, T.S.; Sarker, M.R.; Hannan, M.A.; Mohamed, R.; Ali, J.A.; Mekhilef, S.; Milad, A. Artificial Neural Networks Based Optimization Techniques: A Review. Electronics 2021, 10, 2689. [Google Scholar] [CrossRef]

- Abdolrasol, M.G.M.; Mohamed, R.; Hannan, M.A.; Al-Shetwi, A.Q.; Mansor, M.; Blaabjerg, F. Artificial Neural Network Based Particle Swarm Optimization for Microgrid Optimal Energy Scheduling. IEEE Trans. Power Electron. 2021, 36, 12151–12157. [Google Scholar] [CrossRef]

- Ustun, T.S.; Hussain, S.M.S.; Ulutas, A.; Onen, A.; Roomi, M.M.; Mashima, D. Machine Learning-Based Intrusion Detection for Achieving Cybersecurity in Smart Grids Using IEC 61850 GOOSE Messages. Symmetry 2021, 13, 826. [Google Scholar] [CrossRef]

- Ustun, T.S.; Hussain, S.M.S.; Yavuz, L.; Onen, A. Artificial Intelligence Based Intrusion Detection System for IEC 61850 Sampled Values under Symmetric and Asymmetric Faults. IEEE Access 2021, 9, 56486–56495. [Google Scholar] [CrossRef]

| Specifications | Values |

|---|---|

| Resistance of a Stator Phase | |

| Resistance of a Rotor Phase (Star 1 and 2) | |

| Self-Leakage Inductance of a Stator Phase (star 1 and 2) | |

| Self-Leakage Inductance of a Rotor Phase | |

| Mutual Leakage Inductance Between Stator and Rotor | |

| Cyclical Inter-Saturation Inductance between Stator and Rotor | |

| Nominal Speed (Synchronism) | |

| Moment of Inertia |

| Speed | ANN | SVM | EL | DT | GPR |

|---|---|---|---|---|---|

| RMSE (Validation) (Test) | 0.99045 1.3321 | 3.6243 2.786 | 3.3403 3.1116 | 3.3611 2.9657 | 0.27658 0.27412 |

| R2 (Validation) (Test) | 1.00 1.00 | 0.99 1.00 | 1.00 1.00 | 1.00 1.00 | 1.00 1.00 |

| MSE (Validation) (Test) | 0.98099 1.7745 | 13.136 7.7621 | 11.158 9.6818 | 11.297 8.7956 | 0.076498 0.07514 |

| MAE (Validation) (Test) | 0.71611 0.97354 | 2.143 1.8061 | 2.4024 2.3535 | 2.0371 1.8879 | 0.21719 0.21417 |

| Prediction Speed (~obs/s) | 160,000 | 100,000 | 47,000 | 130,000 | 3300 |

| Training Time (s) | 140.82 | 223.7 | 40.253 | 18.676 | 2427.5 |

| Flux | ANN | SVM | EL | DT | GPR |

|---|---|---|---|---|---|

| RMSE (Validation) (Test) | 0.015035 0.012887 | 0.017103 0.016238 | 0.016529 0.014499 | 0.021983 0.020285 | 0.0052222 0.0050421 |

| R2 (Validation Test) | 0.99 0.99 | 0.99 0.99 | 0.99 0.99 | 0.98 0.98 | 1.00 1.00 |

| MSE (Validation) (Test) | 0.00022604 0.00016609 | 0.00029252 0.00026366 | 0.0002732 0.00021023 | 0.00048327 0.00041149 | 2.7271 × 10−5 2.5423 × 10−5 |

| MAE (Validation) (Test) | 0.010463 0.0093419 | 0.012947 0.012361 | 0.0094641 0.0083299 | 0.010803 0.010395 | 0.0035783 0.0033773 |

| Prediction Speed (~obs/s) | 95,000 | 110,000 | 42,000 | 47,000 | 5700 |

| Training Time (s) | 338.4 | 2385.5 | 63.999 | 36.918 | 1022.6 |

| Speed | Flux | |

|---|---|---|

| Sigma | 493.9326 | 0.043146 |

| Basis Function | Constant | Linear |

| Kernel Function | Non-isotropic rational quadratic | Non-isotropic matern 5/2 |

| Standardized | False | False |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hamoudi, Y.; Amimeur, H.; Aouzellag, D.; Abdolrasol, M.G.M.; Ustun, T.S. Hyperparameter Bayesian Optimization of Gaussian Process Regression Applied in Speed-Sensorless Predictive Torque Control of an Autonomous Wind Energy Conversion System. Energies 2023, 16, 4738. https://doi.org/10.3390/en16124738

Hamoudi Y, Amimeur H, Aouzellag D, Abdolrasol MGM, Ustun TS. Hyperparameter Bayesian Optimization of Gaussian Process Regression Applied in Speed-Sensorless Predictive Torque Control of an Autonomous Wind Energy Conversion System. Energies. 2023; 16(12):4738. https://doi.org/10.3390/en16124738

Chicago/Turabian StyleHamoudi, Yanis, Hocine Amimeur, Djamal Aouzellag, Maher G. M. Abdolrasol, and Taha Selim Ustun. 2023. "Hyperparameter Bayesian Optimization of Gaussian Process Regression Applied in Speed-Sensorless Predictive Torque Control of an Autonomous Wind Energy Conversion System" Energies 16, no. 12: 4738. https://doi.org/10.3390/en16124738

APA StyleHamoudi, Y., Amimeur, H., Aouzellag, D., Abdolrasol, M. G. M., & Ustun, T. S. (2023). Hyperparameter Bayesian Optimization of Gaussian Process Regression Applied in Speed-Sensorless Predictive Torque Control of an Autonomous Wind Energy Conversion System. Energies, 16(12), 4738. https://doi.org/10.3390/en16124738