Initial-Productivity Prediction Method of Oil Wells for Low-Permeability Reservoirs Based on PSO-ELM Algorithm

Abstract

1. Introduction

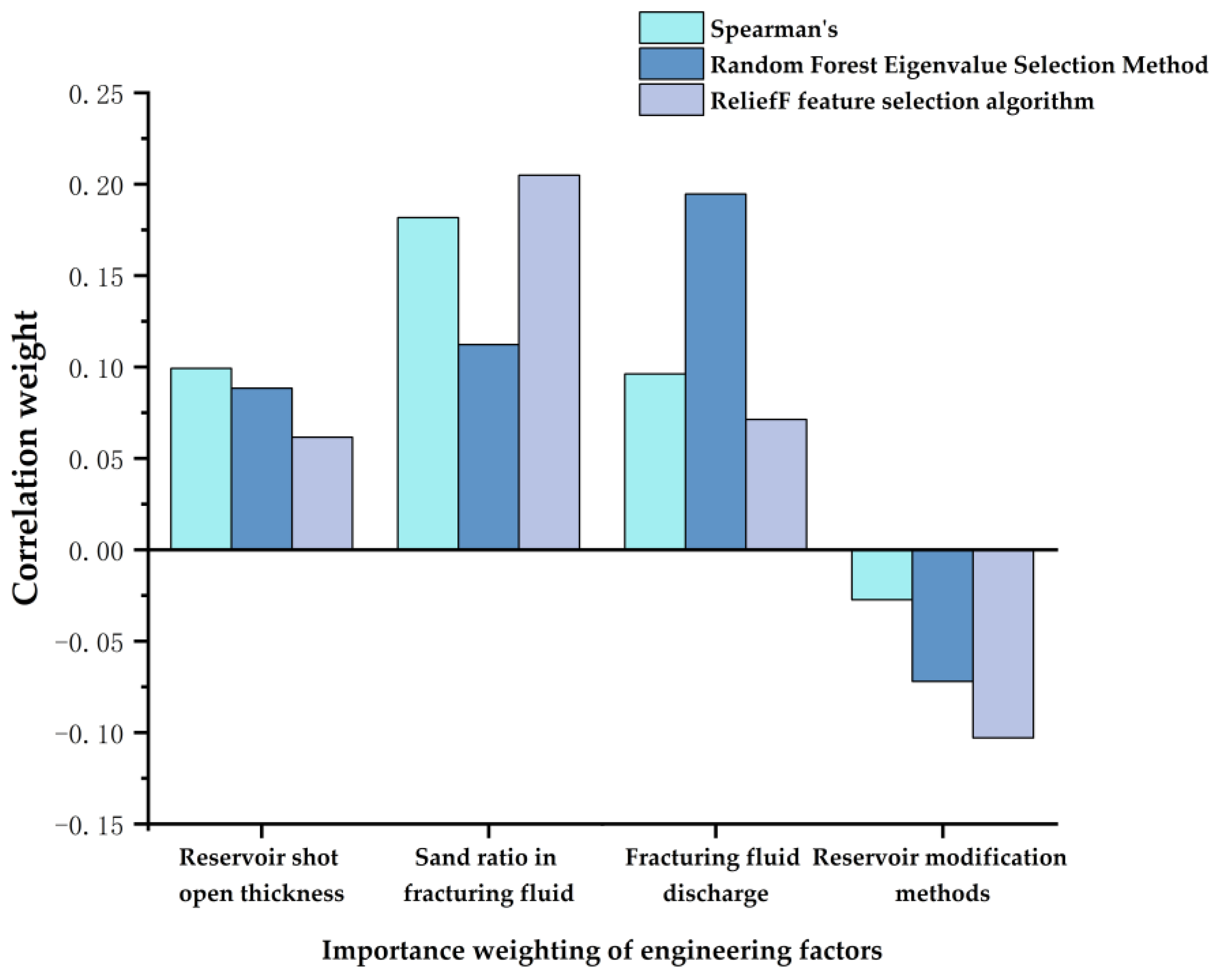

2. Selection of Characteristic Factors

3. Selection and Analysis of Main Control Factors

3.1. Spearman’s Correlation Coefficient Method

3.2. ReliefF Feature Selection Algorithm

3.3. Random Forest Selection Algorithm

3.4. Analysis and Determination of the Main Control Factors

4. Initial-Productivity Forecasting Model

4.1. Fundamentals of the Extreme Learning Machine Algorithm

4.1.1. Overview of the Algorithm

4.1.2. Mathematical Models

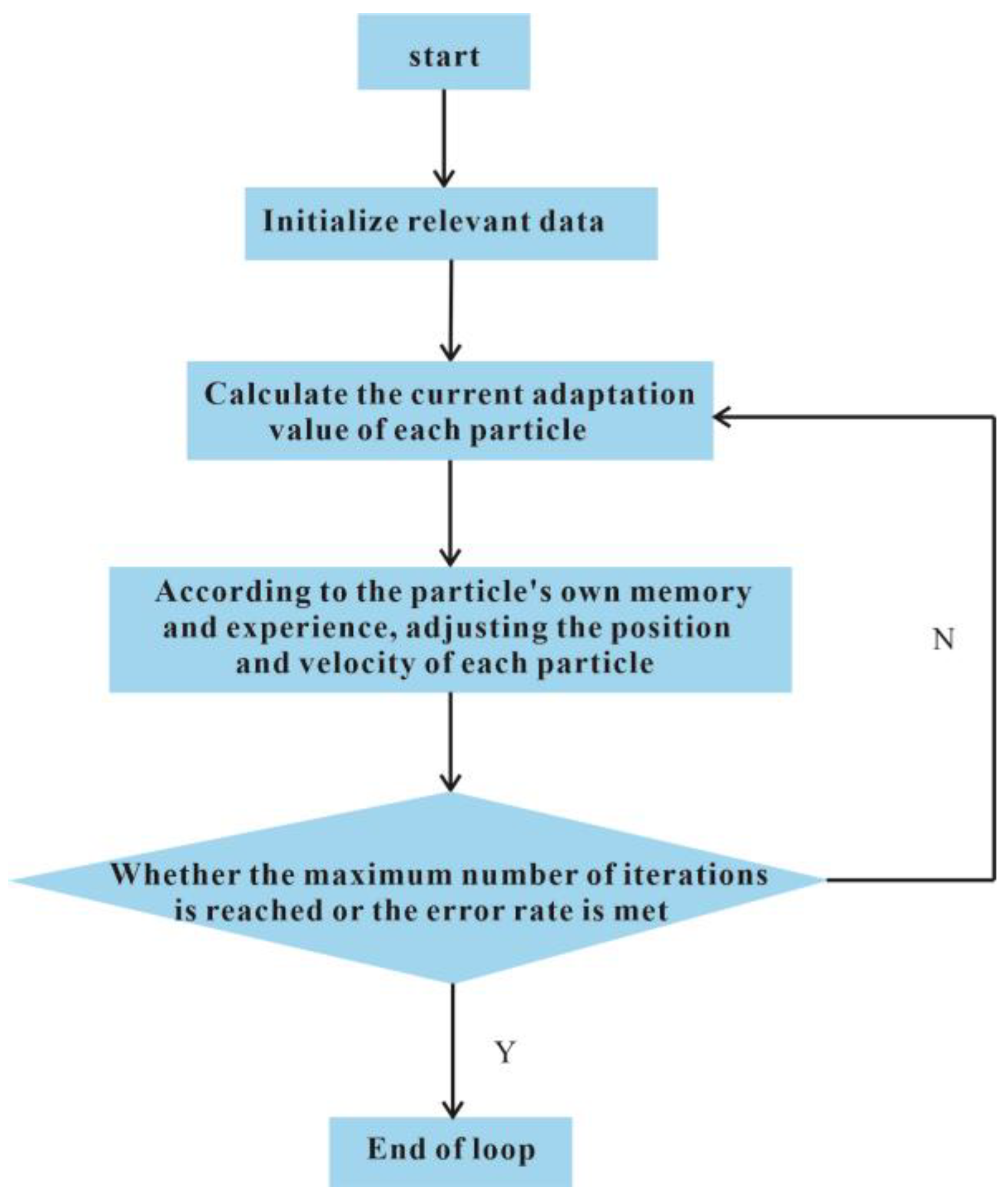

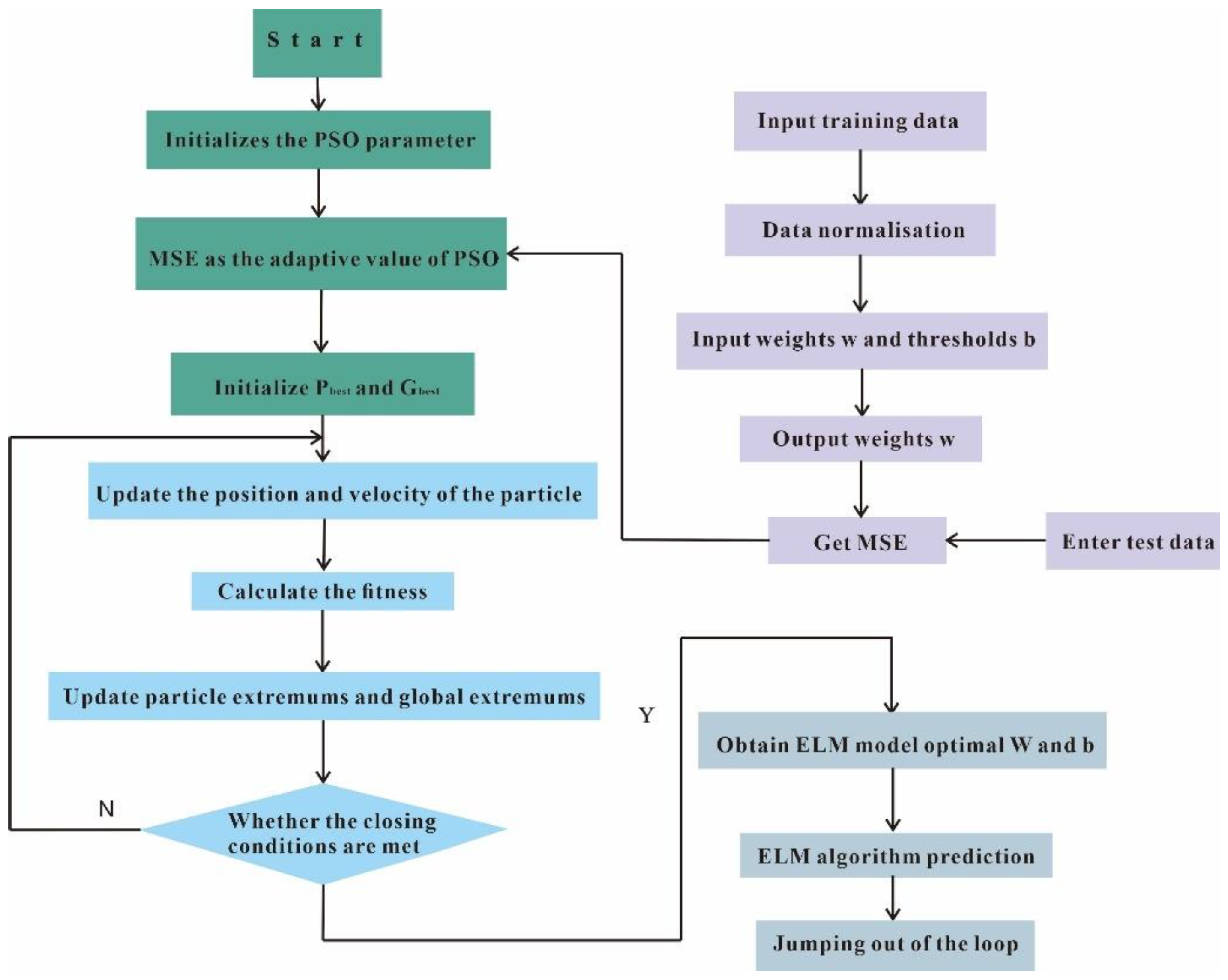

4.2. Fundamentals of the Particle Swarm Optimization–Extreme Learning Machine Algorithm

4.2.1. Overview of the Algorithm

4.2.2. Mathematical Models for Particle Swarm Optimization Algorithms

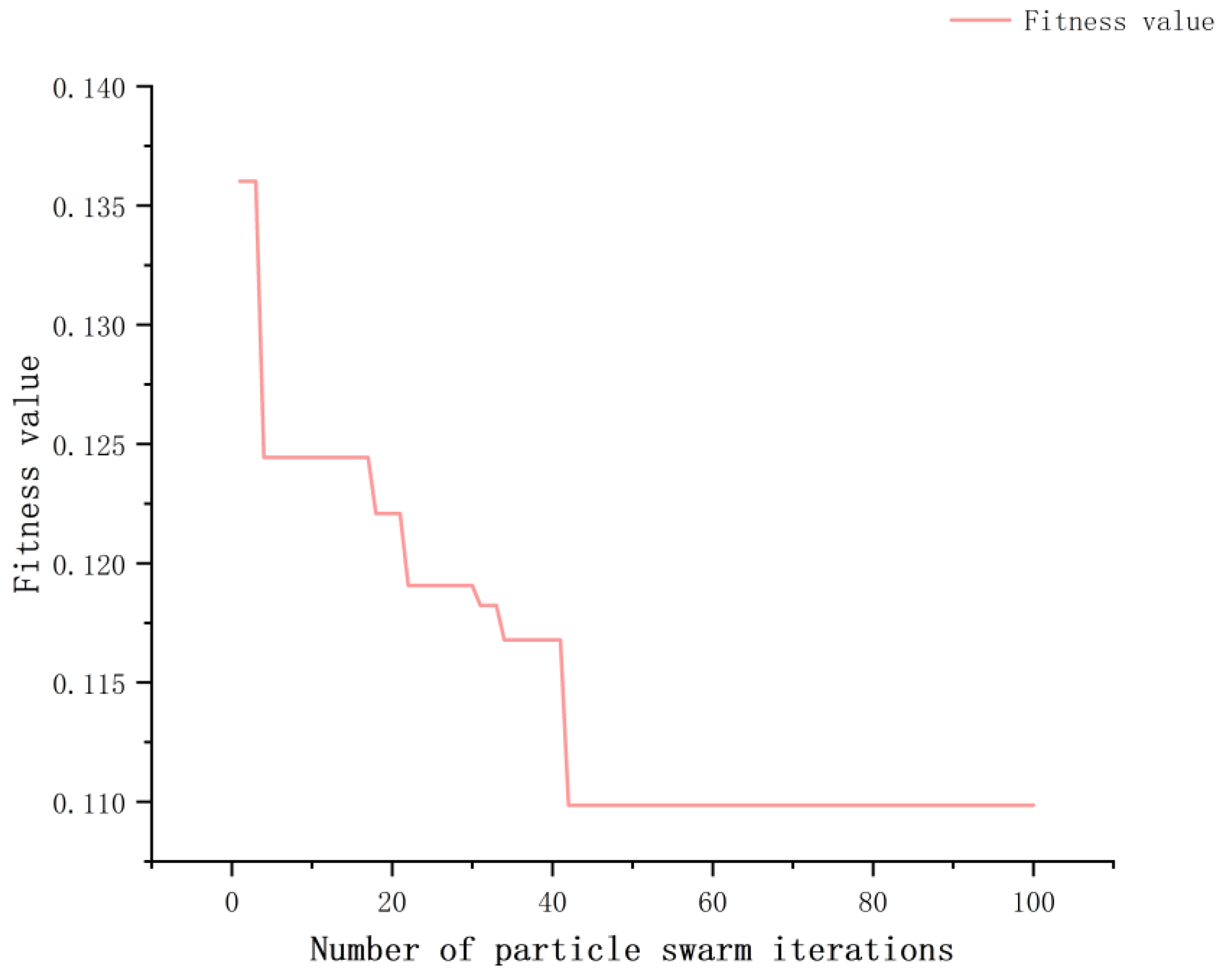

4.3. Particle Swarm Optimization–Extreme Learning Machine Algorithm

5. Example Applications

5.1. Research Area

5.2. Construction of the Initial-Productivity Model and Evaluation Analysis

5.3. Comparison of Different Forecasting Models

6. Discussion

7. Conclusions

- (1)

- This paper proposes a combination feature selection algorithm that utilizes the correlation between characteristic factors and initial productivity to provide a reasonable importance rank. The resulting main controlling factors are better suited for engineering applications in the research area.

- (2)

- Combination feature selection algorithms select seven main controlling factors. Moreover, the seven main controlling factors are porosity, permeability of the oil formation, the stratigraphic permeability grade difference, sand ratio in fracturing fluid, fracturing fluid discharge, production differential pressure, and pump depth.

- (3)

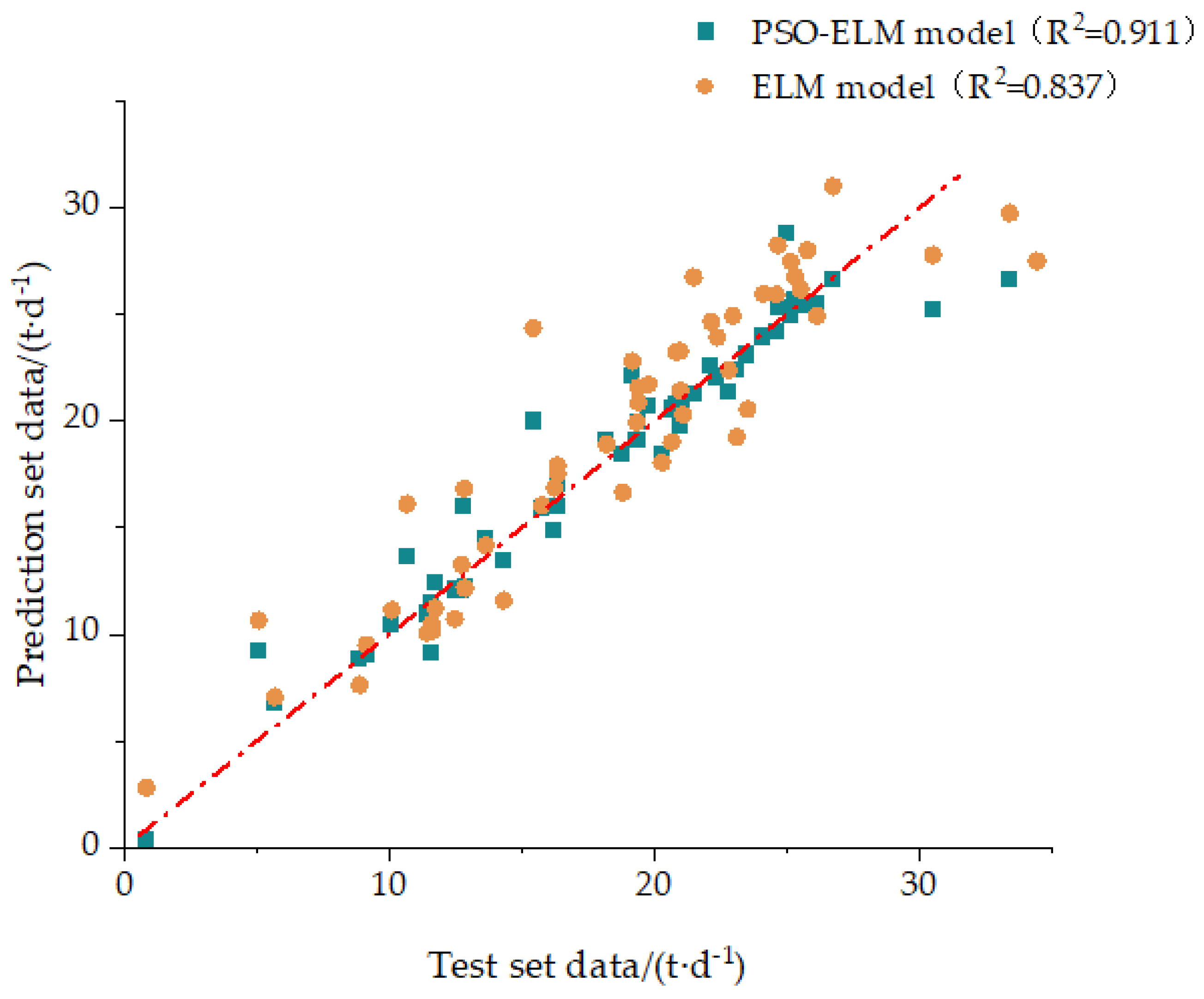

- The PSO-ELM model achieves a higher accuracy and faster speed to predict the productivity of oil wells. The model’s error evaluation indicates promising results, with an RMSE of 0.0345, MAE of 1.008, and an R2 value of 0.905. This evaluation index is better than other models.

- (4)

- This data-driven prediction model can also be applied to the other reservoirs with similar physical properties and geological characteristics. It can be very helpful for the initial-production capacity study of other oil fields.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ji, J.H.; Xi, J.H.; Zeng, F.H. Unsteady productivity model of segmented multi -cluster fractured horizontal wells in tight oil reservoir. Lithol. Reserv. 2019, 31, 157–164. [Google Scholar]

- Huang, S.; Kang, B.; Cheng, L.; Zhou, W.; Chang, S. Quantitative characterization of interlayer interference and productivity prediction of directional wells in the multilayer commingled production of ordinary offshore heavy oil reservoirs. Pet. Explor. Dev. 2015, 42, 488–495. [Google Scholar] [CrossRef]

- Ma, L. Productivity prediction model for fractured horizontal well in heterogeneous tight oil reservoirs. Pet. Geol. Oilfield Dev. Daqing 2022, 41, 168–174. [Google Scholar]

- Al-Rbeawi, S.; Artun, E. Fishbone type horizontal wellbore completion: A study for pressure behavior, flow regimes, and productivity index. J. Pet. Sci. Eng. 2019, 176, 172–202. [Google Scholar] [CrossRef]

- Cheng, Y.F.; Fu, L.Y. Nonlinear seismic inversion by physics-informed Caianiello convolutional neural networks for overpressure prediction of source rocks in the offshore Xihu depression, East China. J. Pet. Sci. Eng. 2022, 215, 110654. [Google Scholar] [CrossRef]

- Li, Z.; Li, Q.; Yang, G.; Zhang, F.; Ma, T. The Synthesis and Application of a New Plugging Inhibitor PAS-5 in Water-Based Drilling Fluid. In Proceedings of the SPE Middle East Oil and Gas Show and Conference, Manama, Bahrain, 18–21 March 2019; p. D022S052R001. [Google Scholar] [CrossRef]

- Dong, Y.; Qiu, L.; Lu, C.; Song, L.; Ding, Z.; Yu, Y.; Chen, G. A data-driven model for predicting initial productivity of offshore directional well based on the physical constrained eXtreme gradient boosting (XGBoost) trees. J. Pet. Sci. Eng. 2022, 211, 110176. [Google Scholar] [CrossRef]

- Li, Q.; Berraud-Pache, R.; Yang, Y.; Souprayen, C.; Jaber, M. Biocomposites based on bentonite and lecithin: An experimental approach supported by molecular dynamics. Appl. Clay Sci. 2023, 231, 106751. [Google Scholar] [CrossRef]

- Gao, P.; Jiang, C.; Huang, Q.; Cai, H.; Luo, Z.; Liu, M. Fluvial facies reservoir productivity prediction method based on principal component analysis and artificial neural network. Petroleum 2016, 2, 49–53. [Google Scholar] [CrossRef]

- Attanasi, E.D.; Freeman, P.A.; Coburn, T.C. Well predictive performance of play-wide and Subarea Random Forest models for Bakken productivity. J. Pet. Sci. Eng. 2020, 191, 107150. [Google Scholar] [CrossRef]

- Khormali, A.; Koochi, M.R.; Varfolomeev, M.A.; Ahmadi, S. Experimental study of the low salinity water injection process in the presence of scale inhibitor and various nanoparticles. J. Pet. Explor. Prod. Technol. 2022, 13, 903–916. [Google Scholar] [CrossRef]

- Ma, W.; Li, Z.; Gao, C.; Sun, Y.; Zhang, j.; Deng, S. “pearson-MIC” analysis method for the initial production key controlling factors of shale gas wells. China Sci. Pap. 2018, 13, 1765–1771. [Google Scholar]

- Chen, H.; Zhang, C.; Wang, Z.; Li, F.; Xu, C.; Zhang, S. Support vector machine-based initial productivity prediction for SRV of horizontal wells in tight oil reservoirs. China Offshore Oil Gas. 2022, 34, 102–109. [Google Scholar]

- Rastogi, A.; Sharma, A. Quantifying the Impact of Fracturing Chemicals on Production Performance Using Machine Learning. In Proceedings of the SPE Liquids-Rich Basins Conference-North America, Odessa, TX, USA, 7–8 November 2019. [Google Scholar]

- Wang, Z.; Tang, H.M.; Cai, H.; Hou, Y.W.; Shi, H.F.; Li, J.L.; Yang, T.; Feng, Y.T. Production prediction and main controlling factors in a highly heterogeneous sandstone reservoir: Analysis on the basis of machine learning. Energy Sci. Eng. 2022, 10, 4674–4693. [Google Scholar] [CrossRef]

- Wu, H.; Xiong, L.; Ge, Z.; Shi, H.; Wang, T.; Fan, L. Fine characterization and target window optimization of high-quality shale gas reservoirs in the Weiyuan area, Sichuan Basin. Nat. Gas Ind. 2019, 39, 11–20. [Google Scholar] [CrossRef]

- Huang, R.J.; Wei, C.J.; Yang, J.; Xu, X.; Li, B.Z.; Wu, S.W.; Xiong, L.H. Quantitative Analysis of the Main Controlling Factors of Oil Saturation Variation. Geofluids 2021, 2021, 6515846. [Google Scholar] [CrossRef]

- Chen, H.; Zhang, C.; Jia, N.H.; Duncan, I.; Yang, S.L.; Yang, Y.Z. A machine learning model for predicting the minimum miscibility pressure of CO2 and crude oil system based on a support vector machine algorithm approach. Fuel 2021, 290, 120048. [Google Scholar] [CrossRef]

- Yang, Z.; Xiong, J.; Liu, J.; Min, C.; Li, X.; Yang, C. Identification of main controlling factors on performance of CBM well fracturing based on Apriori association analysis. Reserv. Eval. Dev. 2020, 10, 63–69. [Google Scholar]

- Dong, Y.; Song, L.; Zhang, Y.; Qiu, L.; Yu, Y.; Lu, C. Initial productivity prediction method for offshore oil wells based on data mining algorithm with physical constraints. Pet. Geol. Recovery Effic. 2022, 29, 137–144. [Google Scholar]

- Tian, Y.; Ju, B. A model for predicting shale gas production decline based on the BP neural network improved by the genetic algorithm. China Sci. Pap. 2016, 11, 1710–1715. [Google Scholar]

- Hu, X.; Tu, Z.; Luo, Y.; Z hou, F. Shale gas well productivity prediction model with fitted function-neural network cooperation. Pet. Sci. Bull. 2022, 7, 394–405. [Google Scholar]

- Liu, H.-H.; Zhang, J.; Liang, F.; Temizel, C.; Basri, M.A.; Mesdour, R. Incorporation of Physics into Machine Learning for Production Prediction from Unconventional Reservoirs: A Brief Review of the Gray-Box Approach. SPE Reserv. Eval. Eng. 2021, 24, 847–858. [Google Scholar] [CrossRef]

- Song, X.; Liu, Y.; Ma, J.; Wang, J.; Kong, X.; Ren, X. Productivity forecast based on support vector machine optimized by grey wolf optimizer. Lithol. Reserv. 2020, 32, 134–140. [Google Scholar]

- Wang, H.; Chen, S. Insights into the Application of Machine Learning in Reservoir Engineering: Current Developments and Future Trends. Energies 2023, 16, 1392. [Google Scholar] [CrossRef]

- Kong, X.; Liu, Y.; Xue, L.; Li, G.; Zhu, D. A Hybrid Oil Production Prediction Model Based on Artificial Intelligence Technology. Energies 2023, 16, 1027. [Google Scholar] [CrossRef]

- Hui, G.; Gu, F.; Gan, J.; Saber, E.; Liu, L. An Integrated Approach to Reservoir Characterization for Evaluating Shale Productivity of Duvernary Shale: Insights from Multiple Linear Regression. Energies 2023, 16, 1639. [Google Scholar] [CrossRef]

- Bishara, A.J.; Hittner, J.B. Testing the Significance of a Correlation With Nonnormal Data: Comparison of Pearson, Spearman, Transformation, and Resampling Approaches. Psychol. Methods 2012, 17, 399–417. [Google Scholar] [CrossRef]

- Dhargupta, S.; Ghosh, M.; Mirjalili, S.; Sarkar, R. Selective Opposition based Grey Wolf Optimization. Expert Syst. Appl. 2020, 151, 113389. [Google Scholar] [CrossRef]

- Kou, G.; Lu, Y.; Peng, Y.; Shi, Y. Evaluation of Classification Algorithms Using MCDM and Rank Correlation. Int. J. Inf. Technol. Decis. Mak. 2012, 11, 197–225. [Google Scholar] [CrossRef]

- Ali, S.A.; Parvin, F.; Vojtekova, J.; Costache, R.; Linh, N.T.T.; Pham, Q.B.; Vojtek, M.; Gigovic, L.; Ahmad, A.; Ghorbani, M.A. GIS-based landslide susceptibility modeling: A comparison between fuzzy multi-criteria and machine learning algorithms. Geosci. Front. 2021, 12, 857–876. [Google Scholar] [CrossRef]

- Urbanowicz, R.J.; Meeker, M.; La Cava, W.; Olson, R.S.; Moore, J.H. Relief-based feature selection: Introduction and review. J. Biomed. Inform. 2018, 85, 189–203. [Google Scholar] [CrossRef]

- Wu, W.; Parmar, C.; Grossmann, P.; Quackenbush, J.; Lambin, P.; Bussink, J.; Mak, R.; Aerts, H.J.W.L. Exploratory Study to Identify Radiomics Classifiers for Lung Cancer Histology. Front. Oncol. 2016, 6, 71. [Google Scholar] [CrossRef]

- Yu, B.; Qiu, W.; Chen, C.; Ma, A.; Jiang, J.; Zhou, H.; Ma, Q. SubMito-XGBoost: Predicting protein submitochondrial localization by fusing multiple feature information and extreme gradient boosting. Bioinformatics 2020, 36, 1074–1081. [Google Scholar] [CrossRef] [PubMed]

- Degenhardt, F.; Seifert, S.; Szymczak, S. Evaluation of variable selection methods for random forests and omics data sets. Brief. Bioinform. 2019, 20, 492–503. [Google Scholar] [CrossRef] [PubMed]

- Efron, B. Prediction, Estimation, and Attribution. J. Am. Stat. Assoc. 2020, 115, 636–655. [Google Scholar] [CrossRef]

- Gregorutti, B.; Michel, B.; Saint-Pierre, P. Correlation and variable importance in random forests. Stat. Comput. 2017, 27, 659–678. [Google Scholar] [CrossRef]

- Zhu, J.-M.; Geng, Y.-G.; Li, W.-B.; Li, X.; He, Q.-Z. Fuzzy Decision-Making Analysis of Quantitative Stock Selection in VR Industry Based on Random Forest Model. J. Funct. Spaces 2022, 2022, 7556229. [Google Scholar] [CrossRef]

- Ding, S.F.; Zhao, H.; Zhang, Y.N.; Xu, X.Z.; Nie, R. Extreme learning machine: Algorithm, theory and applications. Artif. Intell. Rev. 2015, 44, 103–115. [Google Scholar] [CrossRef]

- Shariati, M.; Nguyen Thoi, T.; Wakil, K.; Mehrabi, P.; Safa, M.; Khorami, M. Moment-rotation estimation of steel rack connection using extreme learning machine. Steel Compos. Struct. 2019, 31, 427–435. [Google Scholar] [CrossRef]

- Tang, Z.; Wang, S.; Chai, X.; Cao, S.; Ouyang, T.; Li, Y. Auto-encoder-extreme learning machine model for boiler NOx emission concentration prediction. Energy 2022, 256. [Google Scholar] [CrossRef]

- Lee, K.C.; Jhang, J.Y. Application of particle swarm algorithm to the optimization of unequally spaced antenna arrays. J. Electromagn. Waves Appl. 2006, 20, 2001–2012. [Google Scholar] [CrossRef]

- Zong, W.; Huang, G.-B.; Chen, Y. Weighted extreme learning machine for imbalance learning. Neurocomputing 2013, 101, 229–242. [Google Scholar] [CrossRef]

- Tang, J.; Liu, G.; Pan, Q. A Review on Representative Swarm Intelligence Algorithms for Solving Optimization Problems: Applications and Trends. IEEE-CAA J. Autom. Sin. 2021, 8, 1627–1643. [Google Scholar] [CrossRef]

- Zeng, N.; Wang, Z.; Liu, W.; Zhang, H.; Hone, K.; Liu, X. A Dynamic Neighborhood-Based Switching Particle Swarm Optimization Algorithm. IEEE Trans. Cybern. 2022, 52, 9290–9301. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Tang, H.; Huang, J.; Wen, T.; Ma, J.; Zhang, J. A comparative study of different machine learning methods for reservoir landslide displacement prediction. Eng. Geol. 2022, 298. [Google Scholar] [CrossRef]

- Niu, W.T.; Lu, J.L.; Sun, Y.P. An improved empirical model for rapid and accurate production prediction of shale gas wells. J. Pet. Sci. Eng. 2022, 208, 109800. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Asadulagi, M.-A.M. Development of a Distributed Control System for the Hydrodynamic Processes of Aquifers, Taking into Account Stochastic Disturbing Factors. Water 2023, 15, 770. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Mir-Amal, A.M.; Chernyshev, A.B. Assessment of a Hydrogeological Object’s Distributed Control System Stability. In Proceedings of the 2022 Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), Saint Petersburg, Russia, 25–28 January 2022; pp. 768–771. [Google Scholar] [CrossRef]

- Chai, Z.; Yan, Y.; Simayi, Z.; Yang, S.; Abulimiti, M.; Wang, Y. Carbon emissions index decomposition and carbon emissions prediction in Xinjiang from the perspective of population-related factors, based on the combination of STIRPAT model and neural network. Environ. Sci. Pollut. Res. 2022, 29, 31781–31796. [Google Scholar]

- Sun, W.; Huang, C. Predictions of carbon emission intensity based on factor analysis and an improved extreme learning machine from the perspective of carbon emission efficiency. J. Clean. Prod. 2022, 338, 130414. [Google Scholar] [CrossRef]

- Ding, S.; Hipel, K.W.; Dang, Y.-G. Forecasting China’s electricity consumption using a new grey prediction model. Energy 2018, 149, 314–328. [Google Scholar] [CrossRef]

- Lin, L.; Chen, C.; Wei, B.; Li, H.; Shi, J.; Zhang, J.; Huang, N. Residential Electricity Load Scenario Prediction Based on Transferable Flow Generation Model. J. Electr. Eng. Technol. 2023, 18, 99–109. [Google Scholar] [CrossRef]

| Characteristic Factors | Numerical Range | Characteristic Factors | Numerical Range |

|---|---|---|---|

| Initial productivity (t/d) | 3.3~33.4 | Fracturing fluid sand content ratio (%) | 3~58.5 |

| Porosity (%) | 8~25 | Fracturing fluid displacement (m3/min) | 0.8~6 |

| Permeability of the oil formation (mD) | 0.01~20 | Pump depth (m) | 900~2500 |

| Initial oil content saturation | 1~40 | Depth of dynamic fluid level (m) | 750~2450 |

| Coefficient of variation of stratigraphic permeability | 0.02~3.85 | Moisture content (%) | 0~27.5 |

| Extremely poor stratigraphic permeability | 20~2600 | Production differential pressure (Mpa) | 2.17~11.81 |

| Reservoir shot open thickness (m) | 2~10 | Reservoir modification approach | Acid fracturing/directional injection/mixed water volume fracturing |

| Main Controlling Factors | |||

|---|---|---|---|

| Geological factors | Porosity | Permeability of the oil formation | Stratigraphic permeability grade difference |

| Engineering factors | Sand ratio in fracturing fluid | Fracturing fluid discharge | |

| Dynamic development factors | Production differential pressure | Pump depth | |

| PSO-ELM Algorithm (PSO-ELM) | Random Forest Algorithm (RF) | Recurrent Neural Network Algorithm (RNN) | Back Propagation Neural Network Algorithm (BP) | |

|---|---|---|---|---|

| Running time (t/s) | 13.064 | 13.690 | 15.182 | 20.105 |

| R2 | 0.905 | 0.762 | 0.860 | 0.886 |

| MAE | 1.008 | 2.270 | 1.626 | 1.408 |

| RMSE | 0.035 | 0.056 | 0.042 | 0.039 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Ju, B.; Wang, C. Initial-Productivity Prediction Method of Oil Wells for Low-Permeability Reservoirs Based on PSO-ELM Algorithm. Energies 2023, 16, 4489. https://doi.org/10.3390/en16114489

Zhao B, Ju B, Wang C. Initial-Productivity Prediction Method of Oil Wells for Low-Permeability Reservoirs Based on PSO-ELM Algorithm. Energies. 2023; 16(11):4489. https://doi.org/10.3390/en16114489

Chicago/Turabian StyleZhao, Beichen, Binshan Ju, and Chaoxiang Wang. 2023. "Initial-Productivity Prediction Method of Oil Wells for Low-Permeability Reservoirs Based on PSO-ELM Algorithm" Energies 16, no. 11: 4489. https://doi.org/10.3390/en16114489

APA StyleZhao, B., Ju, B., & Wang, C. (2023). Initial-Productivity Prediction Method of Oil Wells for Low-Permeability Reservoirs Based on PSO-ELM Algorithm. Energies, 16(11), 4489. https://doi.org/10.3390/en16114489