Agricultural Plant Residues as Potential Co-Substrates for Biogas Production

Abstract

1. Introduction

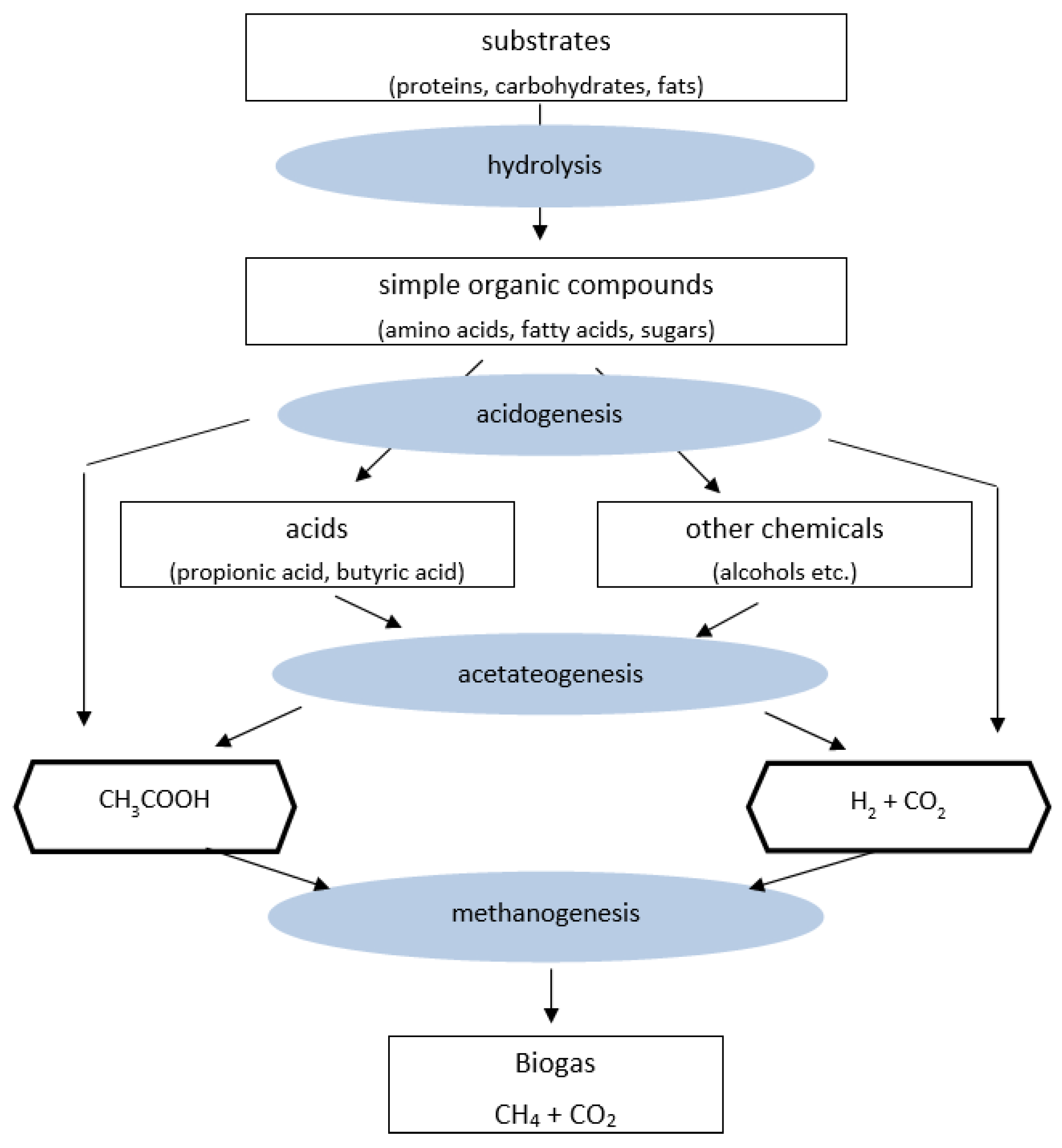

2. Agricultural Plant Residues

3. Biogas Production

4. Biogas Efficiency of Plant Agricultural Waste

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xue, L.; Zhang, P.; Shu, H.; Wang, R.; Zhang, S. Agricultural waste. Water Environ. Res. 2016, 88, 1334–1369. [Google Scholar] [CrossRef] [PubMed]

- Glithero, N.J.; Wilson, P.; Ramsden, S.J. Straw use and availability for second generation biofuels in England. Biomass Bioenergy 2013, 55, 311–321. [Google Scholar] [CrossRef] [PubMed]

- Sommer, S.G.; Hamelin, L.; Olesen, J.E.; Montes, F.; Jia, W.; Chen, Q.; Triolo, J.M. Agricultural waste biomass. In Supply Chain Management for Sustainable Food Networks; Wiley: New York, NY, USA, 2015; pp. 67–106. [Google Scholar] [CrossRef]

- Masnadi, M.S.; Grace, J.R.; Bi, X.T.; Lim, C.J.; Ellis, N. From fossil fuels towards renewables: Inhibitory and catalytic effects on carbon thermochemical conversion during co-gasification of biomass with fossil fuels. Appl. Energy 2015, 140, 196–209. [Google Scholar] [CrossRef]

- López-Bellido, L.; Wery, J.; López-Bellido, R.J. Energy crops: Prospects in the context of sustainable agriculture. Eur. J. Agron. 2014, 60, 1–12. [Google Scholar] [CrossRef]

- Garrett-Peltier, H. Green versus brown: Comparing the employment impacts of energy efficiency, renewable energy, and fossil fuels using an input-output model. Econ. Model. 2017, 61, 439–447. [Google Scholar] [CrossRef]

- Brockway, P.E.; Owen, A.; Brand-Correa, L.I.; Hardt, L. Estimation of global final-stage energy-return-on-investment for fossil fuels with comparison to renewable energy sources. Nat. Energy 2019, 4, 612–621. [Google Scholar] [CrossRef]

- Ramos, J.L.; Valdivia, M.; García-Lorente, F.; Segura, A. Benefits and perspectives on the use of biofuels. Microb. Biotechnol. 2016, 9, 436–440. [Google Scholar] [CrossRef]

- Jain, S. The current and future perspectives of biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy; Woodhead Publishing: Cambridge, UK, 2019; Part I; pp. 495–517. [Google Scholar] [CrossRef]

- Petrus, L.; Noordermeer, M.A. Biomass to biofuels, a chemical perspective. Green Chem. 2006, 8, 861–867. [Google Scholar] [CrossRef]

- Shahid, M.K.; Batool, A.; Kashif, A.; Nawaz, M.H.; Aslam, M.; Iqbal, N.; Choi, Y. Biofuels and biorefineries: Development, application and future perspectives emphasizing the environmental and economic aspects. J. Environ. Manag. 2021, 297, 113268. [Google Scholar] [CrossRef]

- European Commission. In-Depth Analysis in Support of the Commission Communication COM(2018) 773 “A Clean Planet for All. A European Long-Term Strategic Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy”; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Dwarshala, S.K.R.; Rajakumar, S.S.; Kummitha, O.R.; Venkatesan, E.P.; Veza, I.; Samuel, O.D. A Review on Recent Developments of RCCI Engines Operated with Alternative Fuels. Energies 2023, 16, 3192. [Google Scholar] [CrossRef]

- Tengerdy, R.P.; Szakacs, G. Bioconversion of lignocellulose in solid substrate fermentation. Biochem. Eng. J. 2003, 13, 169–179. [Google Scholar] [CrossRef]

- Basso, D.; Patuzzi, F.; Castello, D.; Baratieri, M.; Rada, E.C.; Weiss-Hortala, E.; Fiori, L. Agro-industrial waste to solid biofuel through hydrothermal carbonization. Waste Manag. 2016, 47, 114–121. [Google Scholar] [CrossRef]

- Chilakamarry, C.R.; Sakinah, A.M.; Zularisam, A.W.; Sirohi, R.; Khilji, I.A.; Ahmad, N.; Pandey, A. Advances in solid-state fermentation for bioconversion of agricultural wastes to value-added products: Opportunities and challenges. Bioresour. Technol. 2022, 343, 126065. [Google Scholar] [CrossRef] [PubMed]

- Zentková, I.; Cvengrošová, E. The utilization of rapeseed for biofuels production in the EU. Visegr. J. Bioecon. Sustain. Dev. 2013, 2, 11–14. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Ioannidou, O.; Skoulou, V. Rapeseed residues utilization for energy and 2nd generation biofuels. Fuel 2008, 87, 1492–1502. [Google Scholar] [CrossRef]

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Ali, S.; Yan, Q.; Razzaq, A.; Khan, I.; Irfan, M. Modeling factors of biogas technology adoption: A roadmap towards environmental sustainability and green revolution. Environ. Sci. Pollut. Res. 2023, 30, 11838–11860. [Google Scholar] [CrossRef] [PubMed]

- Abbas, Y.; Yun, S.; Mehmood, A.; Shah, F.A.; Wang, K.; Eldin, E.T.; Al-Qahtani, W.H.; Ali, S.; Bocchetta, P. Co-digestion of cow manure and food waste for biogas enhancement and nutrients revival in bio-circular economy. Chemosphere 2023, 311, 137018. [Google Scholar] [CrossRef]

- Strehler, A.; Stutzle, W. Biomass residues. In Biomass: Regenerable Energy; Wiley: New York, NY, USA, 1987; pp. 75–102. [Google Scholar]

- Werther, J.; Saenger, M.; Hartge, E.U.; Ogada, T.; Siagi, Z. Combustion of agricultural residues. Prog. Energy Combust. Sci. 2000, 26, 1–27. [Google Scholar] [CrossRef]

- Sarkar, S.; Skalicky, M.; Hossain, A.; Brestic, M.; Saha, S.; Garai, S.; Ray, K.; Brahmachari, K. Management of crop residues for improving input use efficiency and agricultural sustainability. Sustainability 2020, 12, 9808. [Google Scholar] [CrossRef]

- Dach, J.; Jędruś, A.; Kowalik, I. Biofermentor do badań procesów rozkładu płynnych odpadów organicznych. J. Res. Appl. Agric. Eng. 2004, 49, 10–13. [Google Scholar]

- Dach, J.; Koszela, K.; Boniecki, P.; Zaborowicz, M.; Lewicki, A.; Czekała, W.; Skwarcz, J.; Qiao, W.; Piekarska-Boniecka, H.; Białobrzewski, I. The use of neural modelling to estimate the methane production from slurry fermentation processes. Renew. Sustain. Energy Rev. 2016, 56, 603–610. [Google Scholar] [CrossRef]

- Mursec, B.; Vindis, P.; Janzekovic, M.; Brus, M.; Cus, F. Analysis of different substrates for processing into biogas. J. Achiev. Mater. Manuf. Eng. 2009, 37, 652–659. [Google Scholar]

- Rasi, S.; Läntelä, J.; Rintala, J. Trace compounds affecting biogas energy utilisation—A review. Energy Convers. Manag. 2011, 52, 3369–3375. [Google Scholar] [CrossRef]

- Schnürer, A. Biogas production: Microbiology and technology. Anaerobes Biotechnol. 2016, 156, 195–234. [Google Scholar]

- Goswami, R.; Chattopadhyay, P.; Shome, A.; Banerjee, S.N.; Chakraborty, A.K.; Mathew, A.K.; Chaudhury, S. An overview of physico-chemical mechanisms of biogas production by microbial communities: A step towards sustainable waste management. 3 Biotech 2016, 6, 72. [Google Scholar] [CrossRef] [PubMed]

- Christy, P.M.; Gopinath, L.R.; Divya, D. A review on anaerobic decomposition and enhancement of biogas production through enzymes and microorganisms. Renew. Sustain. Energy Rev. 2014, 34, 167–173. [Google Scholar] [CrossRef]

- Schattauer, A.; Weiland, P. Podstawy w zakresie wiedzy o fermentacji beztlenowej. In Biogaz. Produkcja i Wykorzystanie; Institut für Energetik und Umwelt, GmbH: Lipsk, Poland, 2005; pp. 5–20. [Google Scholar]

- Im, S.; Petersen, S.O.; Lee, D.; Kim, D.H. Effects of storage temperature on CH4 emissions from cattle manure and subsequent biogas production potential. Waste Manag. 2020, 101, 35–43. [Google Scholar] [CrossRef]

- Feng, L.; Yu, Q.; Zhen, X.F.; Dong, H.Y.; Zheng, J.; Wang, Y. Comparison of methanogenesis between sunflower and corn stalks mixed with pig manure at different temperatures. Appl. Ecol. Environ. Res. 2020, 18, 747–756. [Google Scholar] [CrossRef]

- Dobre, P.; Nicolae, F.; Matei, F. Main factors affecting biogas production-an overview. Rom. Biotechnol. Lett. 2014, 19, 9283–9296. [Google Scholar]

- Franqueto, R.; da Silva, J.D.; Konig, M. Effect of temperature variation on codigestion of animal waste and agricultural residue for biogas production. BioEnergy Res. 2020, 13, 630–642. [Google Scholar] [CrossRef]

- Stolze, Y.; Bremges, A.; Rumming, M.; Henke, C.; Maus, I.; Pühler, A.; Sczyrba, A.; Schlüter, A. Identification and genome reconstruction of abundant distinct taxa in microbiomes from one thermophilic and three mesophilic production-scale biogas plants. Biotechnol. Biofuels 2016, 9, 156. [Google Scholar] [CrossRef]

- Zhang, L.; Loh, K.C.; Sarvanantharajah, S.; Tong, Y.W.; Wang, C.H.; Dai, Y. Mesophilic and thermophilic anaerobic digestion of soybean curd residue for methane production: Characterizing bacterial and methanogen communities and their correlations with organic loading rate and operating temperature. Bioresour. Technol. 2019, 288, 121597. [Google Scholar] [CrossRef] [PubMed]

- Induchoodan, T.G.; Haq, I.; Kalamdhad, A.S. Factors affecting anaerobic digestion for biogas production: A review. In Advanced Organic Waste Management; Elsevier: Amsterdam, The Netherlands, 2022; pp. 223–233. [Google Scholar] [CrossRef]

- Fernández-Rodríguez, J.; Di Berardino, M.; Di Berardino, S. Promoting the Circular Economy on an Island: Anaerobic Co-Digestion of Local Organic Substrates as a Possible Renewable Energy Source. Microorganisms 2023, 11, 285. [Google Scholar] [CrossRef] [PubMed]

- Singh, D.; Tembhare, M.; Machhirake, N.; Kumar, S. Biogas generation potential of discarded food waste residue from ultra-processing activities at food manufacturing and packaging industry. Energy 2023, 263, 126138. [Google Scholar] [CrossRef]

- Pilarski, K.; Pilarska, A.A.; Boniecki, P.; Niedbała, G.; Durczak, K.; Witaszek, K.; Mioduszewska, N.; Kowalik, I. The efficiency of industrial and laboratory anaerobic digesters of organic substrates: The use of the biochemical methane potential correction coefficient. Energies 2020, 13, 1280. [Google Scholar] [CrossRef]

- Abdurashid, A. Efficient Method Of Biogas Production. Eurasian J. Eng. Technol. 2023, 17, 28–34. [Google Scholar]

- Silwadi, M.; Mousa, H.; Al-Hajji, B.Y.; Al-Wahaibi, S.S.; Al-Harrasi, Z.Z. Enhancing biogas production by anaerobic digestion of animal manure. Int. J. Green Energy 2023, 20, 257–264. [Google Scholar] [CrossRef]

- Jasińska, A.; Grosser, A.; Meers, E. Possibilities and Limitations of Anaerobic Co-Digestion of Animal Manure—A Critical Review. Energies 2023, 16, 3885. [Google Scholar] [CrossRef]

- Czekała, W.; Pulka, J.; Jasiński, T.; Szewczyk, P.; Bojarski, W.; Jasiński, J. Waste as substrates for agricultural biogas plants: A case study from Poland. J. Water Land Dev. 2023, 56, 45–50. [Google Scholar]

- Kodba, A.; Pukšec, T.; Duić, N. Analysis of Specific Greenhouse Gas Emissions Savings from Biogas Production Based on Agricultural Residues and Industrial By-Products. Energies 2023, 16, 3721. [Google Scholar] [CrossRef]

- Yang, S.; Luo, F.; Yan, J.; Zhang, T.; Xian, Z.; Huang, W.; Zhang, H.; Cao, Y.; Huang, L. Biogas production of food waste with in-situ sulfide control under high organic loading in two-stage anaerobic digestion process: Strategy and response of microbial community. Bioresour. Technol. 2023, 373, 128712. [Google Scholar] [CrossRef] [PubMed]

- Karrabi, M.; Ranjbar, F.M.; Shahnavaz, B.; Seyedi, S. A comprehensive review on biogas production from lignocellulosic wastes through anaerobic digestion: An insight into performance improvement strategies. Fuel 2023, 340, 127239. [Google Scholar] [CrossRef]

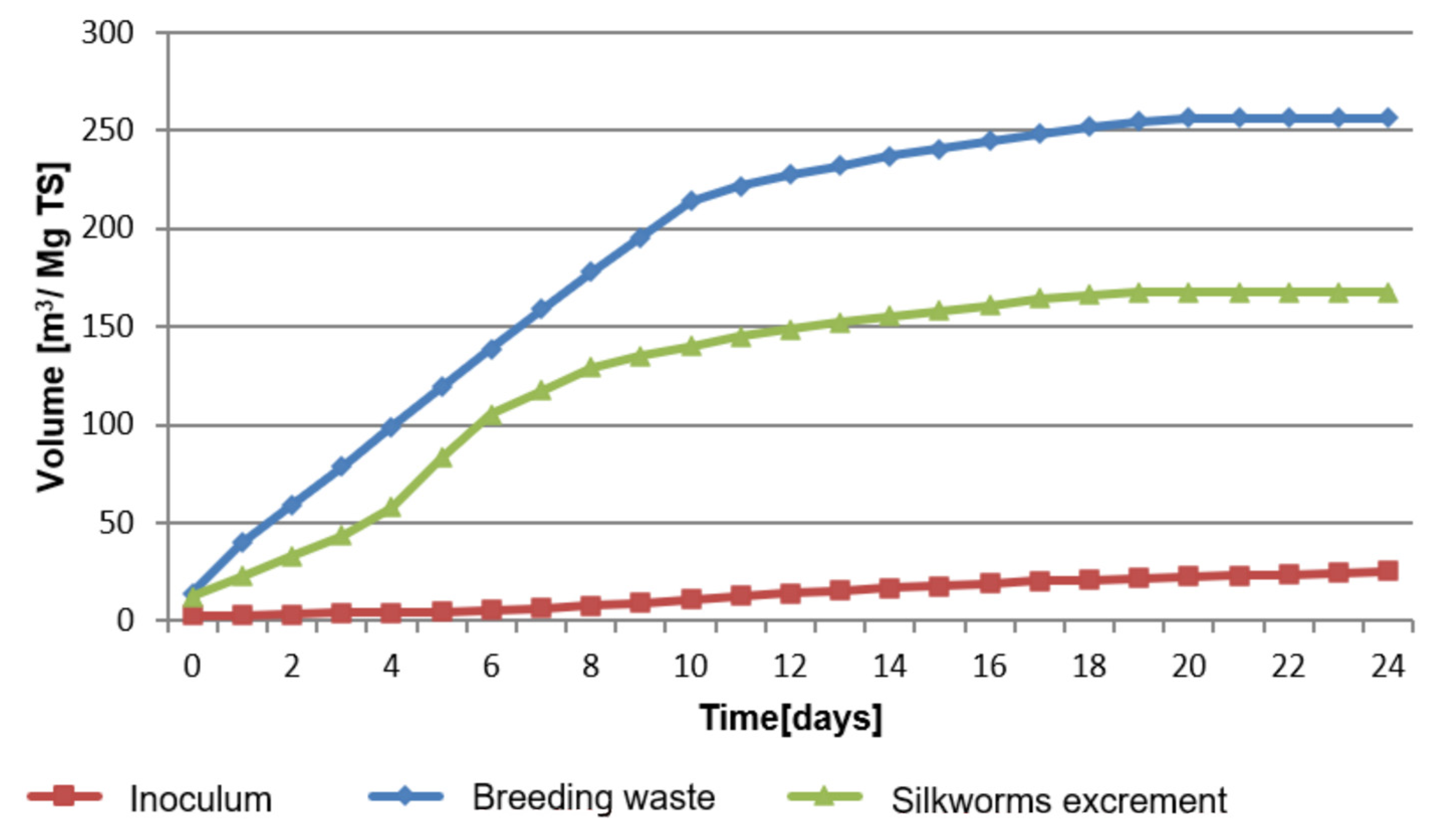

- Łochyńska, M.; Frankowski, J. The biogas production potential from silkworm waste. Waste Manag. 2018, 79, 564–570. [Google Scholar] [CrossRef]

- Dach, J.; Boniecki, P.; Przybył, J.; Janczak, D.; Lewicki, A.; Czekała, W.; Witaszek, K.; Carmona, P.C.R.; Cieślik, M. Energetic efficiency analysis of the agricultural biogas plant in 250 kWe experimental installation. Energy 2014, 69, 34–38. [Google Scholar] [CrossRef]

- Lewicki, A.; Dach, J.; Czekała, W.; Janczak, D.; Cieślik, M.; Witaszek, K.; Carmona, P.C.R. Testing the biogas substrate efficiency from the Experimental Farms’s of Poznan University of Life Sciences in Przybroda biogas plant. Arch. Waste Manag. Environ. Prot. 2014, 16, 27–30. [Google Scholar]

- Cieślik, M.; Dach, J.; Lewicki, A.; Smurzyńska, A.; Janczak, D.; Pawlicka-Kaczorowska, J.; Boniecki, P.; Cyplik, P.; Czekała, W.; Jóźwiakowski, K. Methane fermentation of the maize straw silage under meso-and thermophilic conditions. Energy 2016, 115, 1495–1502. [Google Scholar] [CrossRef]

- Amaducci, S.; Colauzzi, M.; Battini, F.; Fracasso, A.; Perego, A. Effect of irrigation and nitrogen fertilization on the production of biogas from maize and sorghum in a water limited environment. Eur. J. Agron. 2016, 76, 54–65. [Google Scholar] [CrossRef]

- Wannasek, L.; Ortner, M.; Amon, B.; Amon, T. Sorghum, a sustainable feedstock for biogas production? Impact of climate, variety and harvesting time on maturity and biomass yield. Biomass Bioenergy 2017, 106, 137–145. [Google Scholar] [CrossRef]

- Ostovareh, S.; Karimi, K.; Zamani, A. Efficient conversion of sweet sorghum stalks to biogas and ethanol using organosolv pretreatment. Ind. Crops Prod. 2015, 66, 170–177. [Google Scholar] [CrossRef]

- Lewicki, A.; Dach, J.; Kozlowski, K.; Marks, S.; Jezowska, A.; Kupryaniuk, K. Potential of biogas production from palm oil Empty Fruit Bunch (EFB) in South-East Asia. In Proceedings of the 2018 2nd International Conference on Green Energy and Applications (ICGEA), Singapore, 24–26 March 2018; pp. 1–4. [Google Scholar]

- Burczyk, H.; Oleszak, G. Oilseed hemp (Cannabis sativa L. var. oleifera) grown for seeds, oil and biogas. Probl. Inz. Rol. 2016, 24, 109–116. [Google Scholar]

- Frankowski, J.; Zaborowicz, M.; Dach, J.; Czekała, W.; Przybył, J. Biological waste management in the case of a pandemic emergency and other natural disasters. Determination of bioenergy production from floricultural waste and modeling of methane production using deep neural modeling methods. Energies 2020, 13, 3014. [Google Scholar] [CrossRef]

- Braeutigam, P.; Franke, M.; Ondruschka, B. Effect of ultrasound amplitude and reaction time on the anaerobic fermentation of chicken manure for biogas production. Biomass. Bioenerg. 2014, 63, 109–113. [Google Scholar] [CrossRef]

- Lewicki, A.; Kozłowski, K.; Pietrowski, M.; Zbytek, Z. Methane fermentation of chicken droppings. J. Res. Appl. Agric. Eng. 2016, 61, 28–30. [Google Scholar]

- Kafle, G.K.; Kim, S.H.; Sung, K.I. Ensiling of fish industry waste for biogas production: A lab scale evaluation of biochemical methane potential (BMP) and kinetics. Bioresour. Technol. 2013, 127, 326–336. [Google Scholar] [CrossRef] [PubMed]

- Smurzynska, A.; Czekala, W.; Lewicki, A.; Cieslik, M.; Kozlowski, K.; Janczak, D. Wydajność biogazowa utylizowanych nadwyżek warzyw powstałych na polskim rynku wskutek wprowadzonego embarga rosyjskigo. Tech. Rol. Ogrod. Leśna 2016, 6, 24–27. [Google Scholar]

- Bartnikowska, S.; Czekala, W.; Lewicki, A.; Olszewska, A.; Smurzynska, A.; Brzoski, M. Ziemniaki jako potencjalny substrat dla biogazowni rolniczych. Rocz. Nauk. Ekon. Rol. I Rozw. Obsz. Wiej. 2017, 104, 66–74. [Google Scholar] [CrossRef]

- Romaniuk, W.; Domasiewicz, T. Substraty dla biogazowni rolniczych. Agrotechnika. Porad. Rolnika 2014, 11, 74–75. [Google Scholar]

- Myczko, A.; Myczko, R.; Kołodziejczyk, T.; Golimowska, R.; Lenarczyk, J.; Janas, Z.; Kliber, A.; Karłowski, J.; Dolska, M. Budowa i Eksploatacja Biogazowni Rolniczych. Poradnik dla Inwestorów Zainteresowanych Budową Biogazowni Rolniczych; Wydawnictwo ITP: Warszawa-Poznań, Poland, 2011; p. 140. [Google Scholar]

- Marks, S.; Dach, J.; Fernandez Morales, F.J.; Mazurkiewicz, J.; Pochwatka, P.; Gierz, Ł. New trends in substrates and biogas systems in Poland. J. Ecol. Eng. 2020, 21, 19–25. [Google Scholar] [CrossRef]

- Lask, J.; Martinez Guajardo, A.; Weik, J.; von Cossel, M.; Lewandowski, I.; Wagner, M. Comparative environmental and economic life cycle assessment of biogas production from perennial wild plant mixtures and maize (Zea mays L.) in southwest Germany. GCB Bioenergy 2020, 12, 571–585. [Google Scholar] [CrossRef]

- Kowalczyk-Juśko, A.; Pochwatka, P.; Zaborowicz, M.; Czekała, W.; Mazurkiewicz, J.; Mazur, A.; Janczak, D.; Marczuk, A.; Dach, J. Energy value estimation of silages for substrate in biogas plants using an artificial neural network. Energy 2020, 202, 117729. [Google Scholar] [CrossRef]

- Pilarski, K.; Boniecki, P.; Dach, J.; Koszela, K.; Lewicki, A.; Zbytek, Z. Neural estimation of methane emission level from typical agricultural substrates. J. Res. Appl. Agric. Eng. 2012, 57, 115–119. [Google Scholar]

- Sławiński, K.; Piskier, T.; Bujaczek, R. Ocena przydatności kalkulatorów biogazowni przy planowaniu budowy biogazowni rolniczej. Inżynieria Rol. 2012, 16, 369–375. [Google Scholar]

- Abdellatief, T.M.; Ershov, M.A.; Kapustin, V.M.; Abdelkareem, M.A.; Kamil, M.; Olabi, A.G. Recent trends for introducing promising fuel components to enhance the anti-knock quality of gasoline: A systematic review. Fuel 2021, 291, 120112. [Google Scholar] [CrossRef]

- Ershov, M.A.; Potanin, D.A.; Tarazanov, S.V.; Abdellatief, T.M.; Kapustin, V.M. Blending characteristics of isooctene, MTBE, and TAME as gasoline components. Energy Fuels 2020, 34, 2816–2823. [Google Scholar] [CrossRef]

- Ershov, M.A.; Klimov, N.A.; Burov, N.O.; Abdellatief, T.M.; Kapustin, V.M. Creation a novel promising technique for producing an unleaded aviation gasoline 100UL. Fuel 2021, 284, 118928. [Google Scholar] [CrossRef]

| Substrate | Advantages | Disadvantages |

|---|---|---|

| Grain straw | Common Easily accessible | Seasonal product Price fluctuation depending on periodic availability Expensive Used for fodder purposes as bedding |

| Fiber plant straw | Cheaper than cereal straw, because it is not suitable as feed | Infrequent, periodic availability Difficult to fragmentize and decompose |

| Seed husks, chaff | Cheap | Light Low energy efficiency per volume unit |

| Bagasse | High-energy waste from sugar cane processing | Local availability |

| Wood chips, sawdust, bark | Carbon supplementation for animal waste with high nitrogen content | Light High lignocellulosic content |

| Sericulture waste | Homogeneous composition Free waste | Infrequent Local availability |

| Floriculture waste | Free waste or additional income for picking up | Infrequent Local availability Heterogeneous composition |

| Vegetable waste | Available all year round (from both field crops and greenhouses) Cheap or free waste | Heterogeneous composition High content of fertilizers with possible presence of pathogens |

| Substrate | Biogas Efficiency | Methane Efficiency | References |

|---|---|---|---|

| Maize silage | 218.4 m3/Mg FM | 130.88 m3/Mg FM | [51,52] |

| 204.06 m3/Mg FM | 105.28 m3/Mg FM | [53] | |

| Sorghum biomass | Unresearched | 16,505–21,700 MJ/ha | [54] |

| 6500 m3/ha | [55] | ||

| Sweet sorghum bagasse | Unresearched | 278 mL CH4/g VS | [56] |

| Palm oil empty fruit bunch | Unresearched | 74.33 m3/Mg FM | [57] |

| Hemp straw | 208.8 m3/Mg FM | unresearched | [58] |

| Sericulture waste | 125.59 m3/Mg FM | 65.81 m3/Mg FM | [50] |

| Tulip chaff | 52.04 m3/Mg FM | 28.30 m3/Mg FM | [59] |

| Tulip macerate | 52.72 m3/Mg FM | 27.98 m3/Mg FM | [59] |

| Roses | 122.76 m3/Mg FM | 61.28 m3/Mg FM | [59] |

| Sunflowers | 108.22 m3/Mg FM | 53.31 m3/Mg FM | [59] |

| Chrysanthemums | 124.08 m3/Mg FM | 59.05 m3/Mg FM | [59] |

| Eggplants | 39.91 m3/Mg FM | 19.96 m3/Mg FM | [60] |

| Pumpkins | 75.63 m3/Mg FM | 42.77 m3/Mg FM | [60] |

| Cauliflowers | 57.39 m3/Mg FM | 30.07 m3/Mg FM | [60] |

| Cabbage | 56.36 m3/Mg FM | 28.10 m3/Mg FM | [60] |

| Sweet peppers | 35.71 m3/Mg FM | 18.97 m3/Mg FM | [60] |

| Tomatoes | 32.41 m3/Mg FM | 16.78 m3/Mg FM | [60] |

| Cucumbers | 27.91 m3/Mg FM | 14.94 m3/Mg FM | [60] |

| Raw potatoes | 171.45 m3/Mg FM | 81.83 m3/Mg FM | [61] |

| Steamed potatoes | 92.46 m3/Mg FM | 39.40 m3/Mg FM | [61] |

| Raw potato peel | 139.40 m3/Mg FM | 67.50 m3/Mg FM | [61] |

| Steamed potato peel | 165.62 m3/Mg FM | 76.18 m3/Mg FM | [61] |

| Breeding Waste | ||

|---|---|---|

| Day of Fermentation | Biogas Production [%] | Cumulative CH4 Production [%] |

| 1 | 8.92 | 5.61 |

| 2 | 16.65 | 15.85 |

| 3 | 11.03 | 23.42 |

| 4 | 8.92 | 31.26 |

| 5 | 7.73 | 39.31 |

| 6 | 6.87 | 47.42 |

| 7 | 6.08 | 55.07 |

| 8 | 6.28 | 63.26 |

| 9 | 5.60 | 70.74 |

| 10 | 5.14 | 77.71 |

| 11 | 5.76 | 84.95 |

| 12 | 2.31 | 88.08 |

| 13 | 1.68 | 90.35 |

| 14 | 1.37 | 92.24 |

| 15 | 1.33 | 94.05 |

| 16 | 1.05 | 95.51 |

| 17 | 1.25 | 97.22 |

| 18 | 1.06 | 98.69 |

| 19 | 0.96 | 100.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frankowski, J.; Czekała, W. Agricultural Plant Residues as Potential Co-Substrates for Biogas Production. Energies 2023, 16, 4396. https://doi.org/10.3390/en16114396

Frankowski J, Czekała W. Agricultural Plant Residues as Potential Co-Substrates for Biogas Production. Energies. 2023; 16(11):4396. https://doi.org/10.3390/en16114396

Chicago/Turabian StyleFrankowski, Jakub, and Wojciech Czekała. 2023. "Agricultural Plant Residues as Potential Co-Substrates for Biogas Production" Energies 16, no. 11: 4396. https://doi.org/10.3390/en16114396

APA StyleFrankowski, J., & Czekała, W. (2023). Agricultural Plant Residues as Potential Co-Substrates for Biogas Production. Energies, 16(11), 4396. https://doi.org/10.3390/en16114396