Development of a Numerical Method for Calculating a Gas Supply System during a Period of Change in Thermal Loads

Abstract

1. Introduction

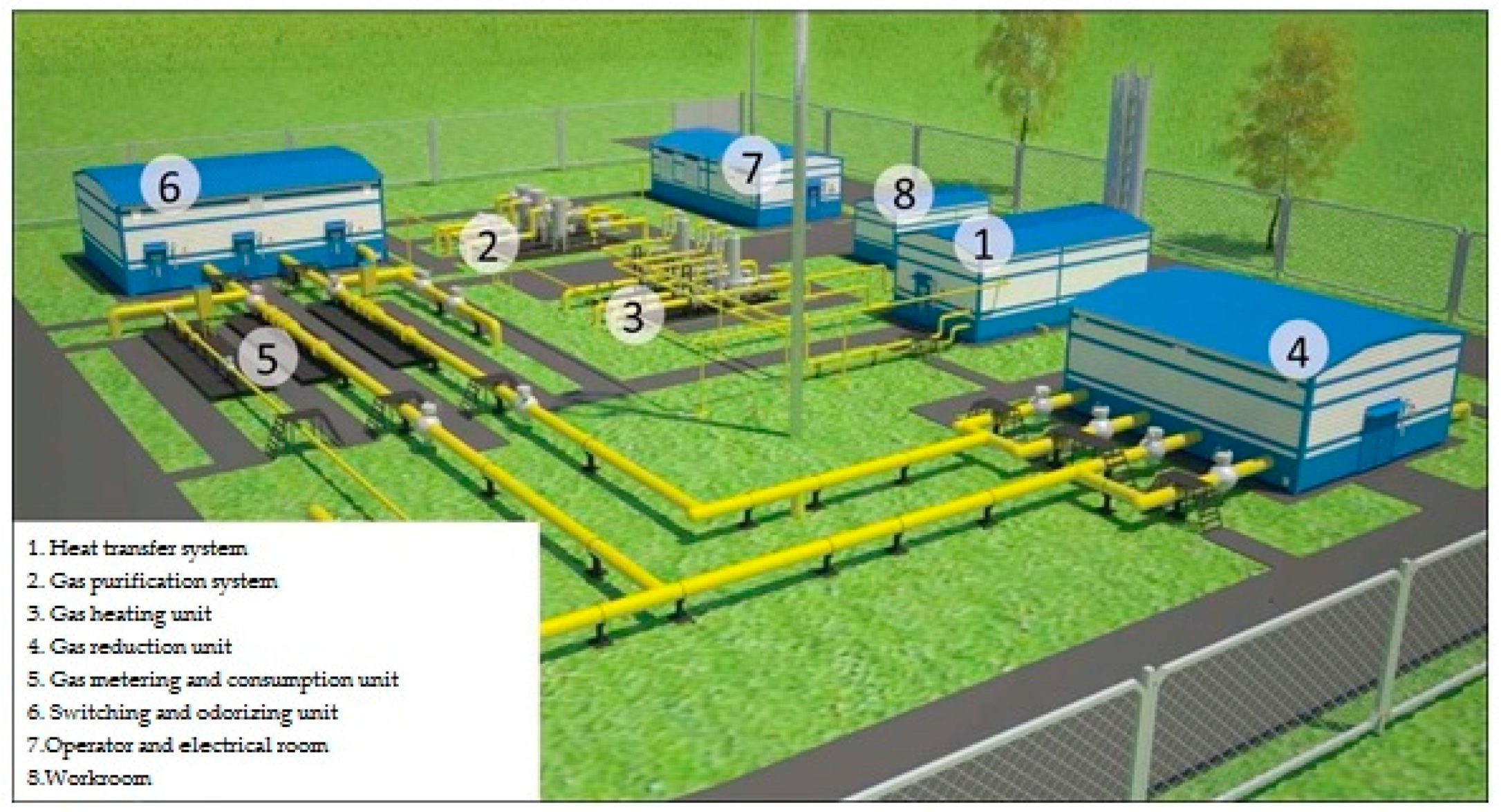

2. Case Study

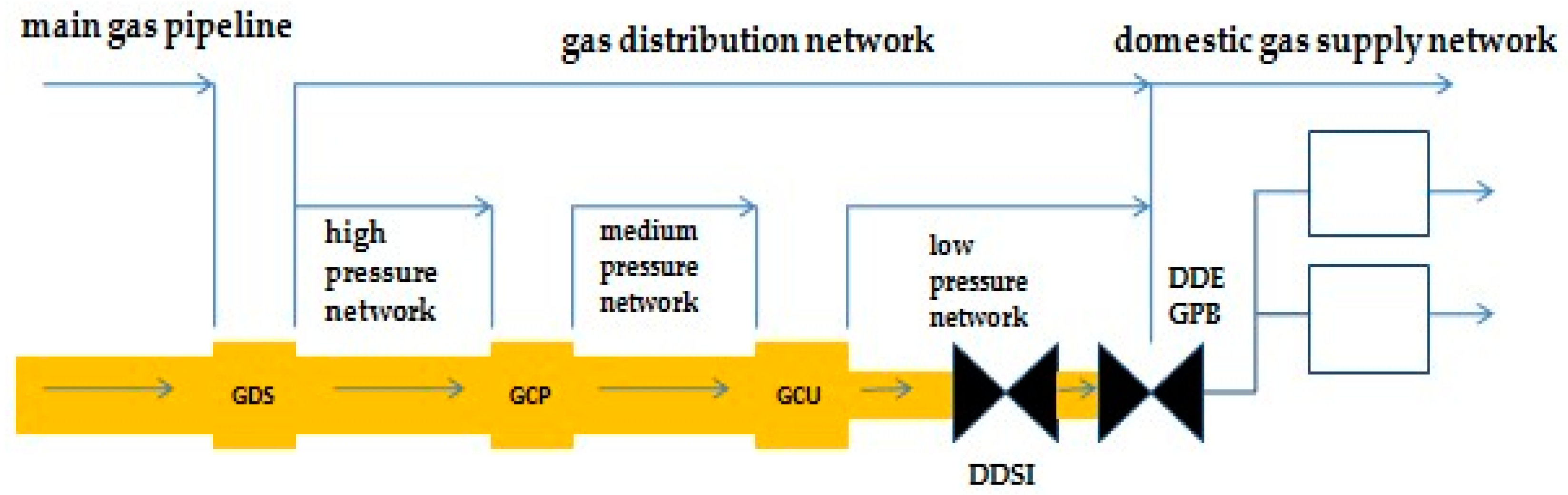

2.1. City Gas Supply Systems

2.2. The Physical Properties of the Pumped Gas

2.3. The Choice and Justification of the Gas Supply System

3. Results

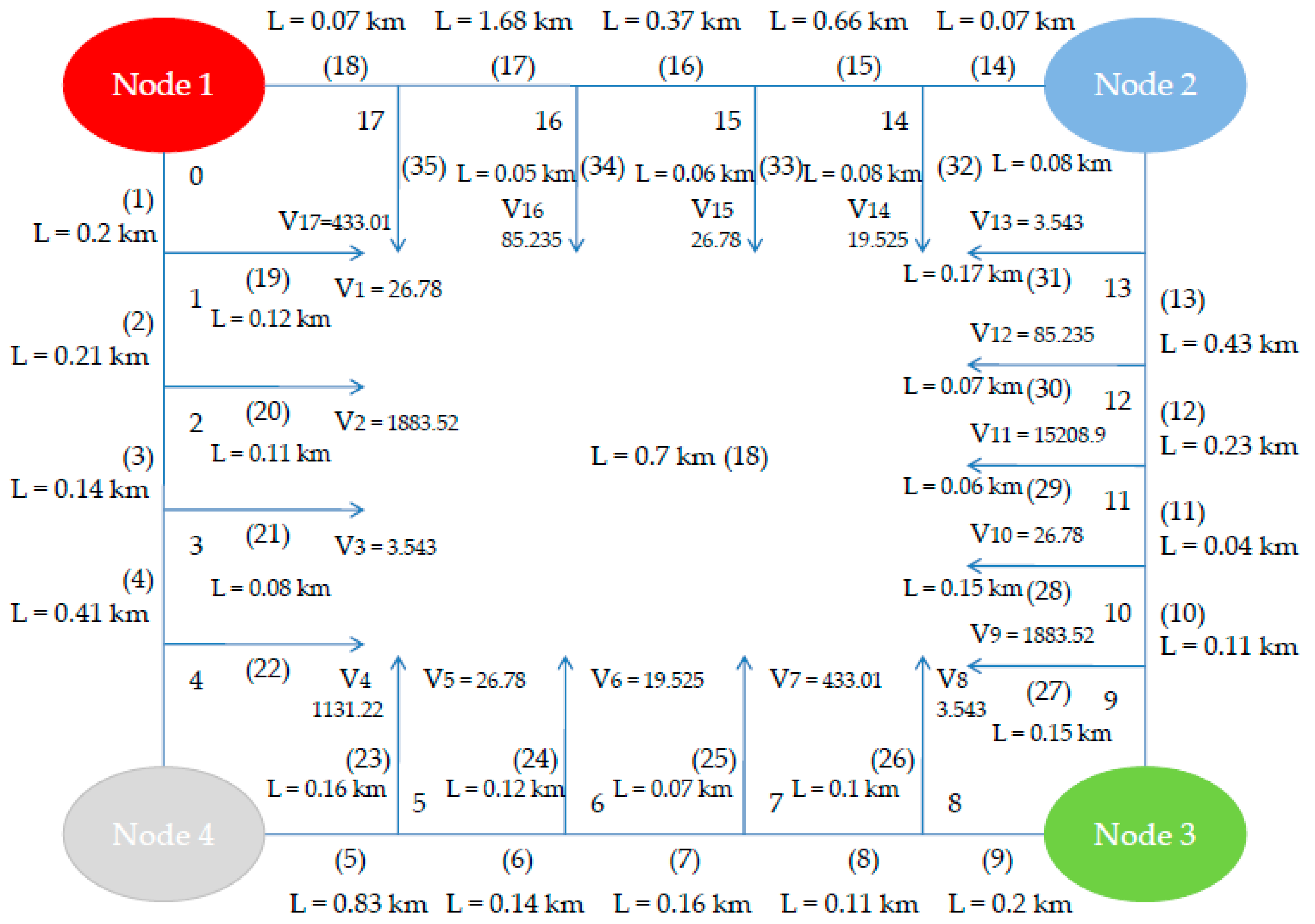

3.1. Calculation in Emergency Modes

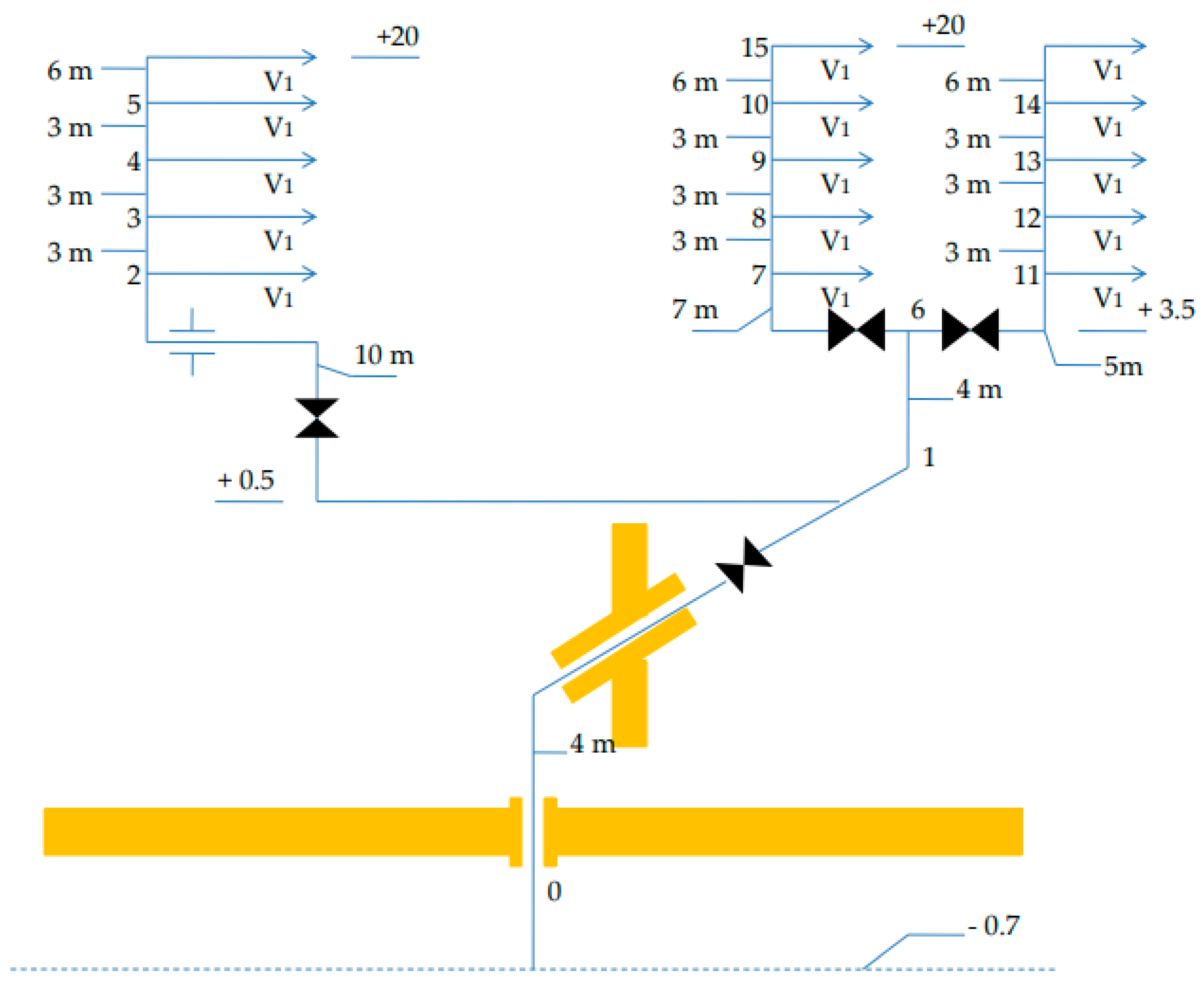

3.2. Hydraulic Calculation of Dead-End Low-Pressure Gas Pipelines

3.3. Determination of the Main Direction of Gas

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| Qc | the heat of combustion value of dry gas, kJ/m3 |

| Q1,Q2,Q3,Qk | the heat of combustion of the components that make up the gaseous fuel, kJ/m3 |

| x1,x2,x3 | the volume fractions of the components that make up the gaseous fuel, % |

| p | the density of dry gas, kg/m3 |

| p1, p2,…, pk | the densities of the components, kg/m3 |

| Vh | the maximum hourly gas consumption of the corresponding consumer, m3/h, Vh = 1.17 (m3/h) |

| Ki | the simultaneity factors |

| ∑∆Pi | the sum of pressure losses in all sections of the pipeline, Pa |

| ∆P | additional overpressure in the gas pipeline, Pa |

| ∆P∗ | loss of gas pressure in the gas-using device, Pa |

| ∆Pi∗ | given pressure drop, Pa |

| MPa | megapascal |

| GDS | gas distribution stations |

| GCP | gas control points |

| GCU | gas control units |

| DDSI | the disconnecting device on the subscriber inlet |

| DDEGPB | disconnecting device at the entrance of the gas pipeline to the building |

References

- Abeysekera, M.; Wu, J.; Jenkins, N.; Rees, M. Steady state analysis of gas networks with distributed injection of alternative gas. Appl. Energy 2016, 164, 991–1002. [Google Scholar] [CrossRef]

- Cui, G.; Jia, Q.-S.; Guan, X.; Liu, Q. Data-driven computation of natural gas pipeline network hydraulics. Results Control Optim. 2020, 1, 100004. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Rahbari, H.R. Unsteady natural gas flow within pipeline network, an analytical approach. J. Nat. Gas Sci. Eng. 2016, 28, 397–409. [Google Scholar] [CrossRef]

- Brkić, D. An improvement of Hardy Cross method applied on looped spatial natural gas distribution networks. Appl. Energy 2009, 86, 1290–1300. [Google Scholar] [CrossRef]

- Bagajewicz, M.; Valtinson, G. Computation of Natural Gas Pipeline Hydraulics. Ind. Eng. Chem. Res. 2014, 53, 10707–11072. [Google Scholar] [CrossRef]

- Brkić, D.; Praks, P. An Efficient Iterative Method for Looped Pipe Network Hydraulics Free of Flow-Corrections. Fluids 2019, 4, 73. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Reza Rahbari, H. Response of natural gas distribution pipeline networks to ambient temperature variation (unsteady simulation). J. Nat. Gas Sci. Eng. 2018, 52, 94–105. [Google Scholar] [CrossRef]

- Lustenberger, P.; Schumacher, F.; Spada, M.; Burgherr, P.; Stojadinovic, B. Assessing the Performance of the European Natural Gas Network for Selected Supply Disruption Scenarios Using Open-Source Information. Energies 2019, 12, 4685. [Google Scholar] [CrossRef]

- Zhu, M.; Xu, C.; Dong, S.; Tang, K.; Gu, C. An integrated multi-energy flow calculation method for electricity-gas-thermal integrated energy systems. Prot. Control Mod. Power Syst. 2021, 6, 5. [Google Scholar] [CrossRef]

- Herrán-González, A.; De La Cruz, J.M.; De Andrés-Toro, B.; Risco-Martín, J.L. Modeling and simulationof a gas distribution pipeline network. Appl. Math. Model. 2009, 33, 1584–1600. [Google Scholar] [CrossRef]

- Schipachev, A.; Fetisov, V.; Nazyrov, A.; Donghee, L.; Khamrakulov, A. Study of the Pipeline in Emergency Operation and Assessing the Magnitude of the Gas Leak. Energies 2022, 15, 5294. [Google Scholar] [CrossRef]

- Vasiliev, G.G.; Dzhaljabov, A.A.; Leonovich, I.A. Analysis of the causes of engineering structures deformations at gas industry facilities in the permafrost zone. J. Min. Inst. 2021, 249, 377–385. [Google Scholar] [CrossRef]

- Vasilyev, G.G.; Vasilyev, G.G.; Leonovich, I.A.; Latifov, K.A. On the methodology of risk-oriented standardization of safety parameters at the design and construction of gas and oil pipelines. Labor Saf. Ind. 2019, 2, 84–90. [Google Scholar] [CrossRef]

- Reddy, H.P.; Narasimhan, S.; Bhallamudi, S.M. Simulation and State Estimation of Transient Flow in Gas Pipeline Networks Using a Transfer Function Model. Ind. Eng. Chem. Res. 2006, 45, 3853–3863. [Google Scholar] [CrossRef]

- Li, T.; Liu, P.; Li, Z. Modelling and optimization of a natural gas supply system at a transient stage: A case study of China. BMC Energy 2019, 1, 5. [Google Scholar] [CrossRef]

- Belousov, A.E.; Ovchinnikov, E.S. Mathematical Modeling of the Operation of an Expander-Generator Pressure Regulator in Non-Stationary Conditions of Small Gas Pressure Reduction Stations. Mathematics 2022, 10, 393. [Google Scholar] [CrossRef]

- Möller, B.; Lund, H. Conversion of individual natural gas to district heating: Geographical studies of supply costs and consequences for the Danish energy system. Appl. Energy 2010, 87, 1846–1857. [Google Scholar] [CrossRef]

- Shan, X.; Wang, P.; Lu, W. The reliability and availability evaluation of repairable district heating networks under changeable external conditions. Appl. Energy 2017, 203, 686–695. [Google Scholar] [CrossRef]

- van der Linden, R.; Blokland, H.; Busking, T. Security of Supply in Gas and Hybrid Energy Networks. Energies 2021, 14, 792. [Google Scholar] [CrossRef]

- Nikolaev, A.K.; Zaripova, N.A. Substantiation of analytical dependences for hydraulic calculation of high-viscosity oil transportation. J. Min. Inst. 2021, 252, 885–895. [Google Scholar] [CrossRef]

- Faghri, A.; Zhang, Y. Generalized governing equations for multiphase systems: Averaging formulations. In Transport Phenomena in Multiphase Systems; Faghri, A., Zhang, Y., Eds.; Academic Press: Cambridge, MA, USA, 2006; pp. 238–330. [Google Scholar] [CrossRef]

- Wichterle, K.; Večeř, M. (Eds.) The steady unidirectional flow. In Transport and Surface Phenomena; Elsevier: Amsterdam, The Netherlands, 2020; pp. 127–145. [Google Scholar] [CrossRef]

- Wichterle, K.; Večeř, M. (Eds.) The basics of steady heat conduction and diffusion. In Transport and Surface Phenomena; Elsevier: Amsterdam, The Netherlands, 2020; pp. 147–157. [Google Scholar] [CrossRef]

- Su, H.; Zhang, J.; Zio, E.; Yang, N.; Li, X.; Zhang, Z. An integrated systemic method for supply reliability assessment of natural gas pipeline networks. Appl. Energy 2018, 209, 489–501. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Ilyushin, Y.V.; Afanaseva, O.V. Development of a Distributed Mathematical Model and Control System for Reducing Pollution Risk in Mineral Water Aquifer Systems. Water 2022, 14, 151. [Google Scholar] [CrossRef]

- Brkić, D. Iterative Methods for Looped Network Pipeline Calculation. Water Resour. Manag. 2011, 25, 2951–2987. [Google Scholar] [CrossRef]

- An, Y.; Wang, Y.; Yue, B.; Jin, S.; Wu, L.; Qu, Z. A novel method for natural gas pipeline safety online monitoring based on acoustic pulse compression. Process Saf. Environ. Prot. 2019, 130, 174–181. [Google Scholar] [CrossRef]

- Litvinenko, V.; Bowbrick, I.; Naumov, I.; Zaitseva, Z. Global guidelines and require-ments for professional competencies of natural resource extraction engineers: Implications for ESG principles and sustainable development goals. J. Clean. Prod. 2022, 338, 130530. [Google Scholar] [CrossRef]

- Yang, N.; Qin, T.; Wu, L.; Huang, Y.; Huang, Y.; Xing, C.; Zhang, L.; Zhu, B. A multi-agent game based joint planning approach for electricity-gas integrated energy systems considering wind power uncertainty. Electr. Power Syst. Res. 2022, 204, 107673. [Google Scholar] [CrossRef]

- Tchórzewska-Cieślak, B.; Pietrucha-Urbanik, K.; Urbanik, M.; Rak, J.R. Approaches for Safety Analysis of Gas-Pipeline Functionality in Terms of Failure Occurrence: A Case Study. Energies 2018, 11, 1589. [Google Scholar] [CrossRef]

- Ullah, Z.; Wang, X.; Chen, Y.; Zhang, T.; Ju, H.; Zhao, Y. Time-Domain Output Data Identification Model for Pipeline Flaw Detection Using Blind Source Separation Technique Complexity Pursuit. Acoustics 2019, 1, 13. [Google Scholar] [CrossRef]

- Zhu, B.; Yang, X.; Wang, J.; Shao, C.; Li, F.; Hong, B.; Song, D.; Guo, J. Third-Party Damage Model of a Natural Gas Pipeline Based on a Bayesian Network. Energies 2022, 15, 6067. [Google Scholar] [CrossRef]

- Morales, J.; Yu, W. Improving neural network’s performance using Bayesian inference. Neurocomputing 2021, 461, 319–326. [Google Scholar] [CrossRef]

- El-Shiekh, T.M. The Optimal Design of Natural Gas Transmission Pipelines. Energy Sources Part B Econ. Plan. Policy 2013, 8, 7–13. [Google Scholar] [CrossRef]

- Farzaneh-Gord, M.; Reza Rahbari, K.; Bajelan, M.; Pilehvari, L. Investigation of hydrate formation in natural gas flow through underground transmission pipeline. J. Nat. Gas Sci. Eng. 2013, 15, 27–37. [Google Scholar] [CrossRef]

- Guo, Q.; Liu, Y.; Yang, Y.; Song, T.; Wang, S. Improved Adaptive Time Step Method for Natural Gas Pipeline Transient Simulation. Energies 2022, 15, 4961. [Google Scholar] [CrossRef]

- Fan, D.; Gong, J.; Zhang, S.; Shi, G.; Kang, Q.; Xiao, Y.; Wu, C. A transient composition tracking method for natural gas pipe networks. Energy 2021, 215, 119131. [Google Scholar] [CrossRef]

- Yu, W.; Wen, K.; Li, Y.; Huang, W.; Gong, J. A Methodology to Assess the Gas Supply Capacity and Gas Supply Reliability of a Natural Gas Pipeline Network System. In Proceedings of the 2018 ASME 12th International Pipeline Conference, 2: Pipeline Safety Management Systems, Project Management, Design, Construction, and Environmental Issues, Strain Based Design, Risk and Reliability; Northern Offshore and Production Pipelines, Calgary, AL, Canada, 24–28 September 2018. [Google Scholar] [CrossRef]

- Yu, W.; Song, S.; Li, Y.; Min, Y.; Huang, R.; Wen, K.; Gong, J. Gas supply reliability assessment of natural gas transmission pipeline systems. Energy 2018, 162, 853–870. [Google Scholar] [CrossRef]

- Behrooz, H.A.; Boozarjomehry, R.B. Modeling and state estimation for gas transmission networks. J. Nat. Gas Sci. Eng. 2015, 22, 551–570. [Google Scholar] [CrossRef]

- Chaczykowski, M.; Sund, F.; Zarodkiewicz, P.; Mongstad Hope, S. Gas composition tracking in transient pipeline flow. J. Nat. Gas Sci. Eng. 2018, 55, 321–330. [Google Scholar] [CrossRef]

- Lurie, M.V.; Musailov, I.T.; Lysenko, N.O. The Effective Method of Calculating Gas Leaks through Holes in the Walls of Gas Pipelines and High-Pressure Vessels. TerritorijaNeftegas Oil and Gas Territory. 2020. Available online: https://tng.elpub.ru/jour/article/view/1136/985 (accessed on 26 October 2022).

- Wang, P.; Yu, B.; Han, D.; Sun, D.; Xiang, Y. Fast method for the hydraulic simulation of natural gas pipeline networks based on the divide-and-conquer approach. J. Nat. Gas Sci. Eng. 2018, 50, 55–63. [Google Scholar] [CrossRef]

- Oosterkamp, A.; Helgaker, J.F.; Ytrehus, T. Modelling of Natural Gas Pipe Flow with Rapid Transients-case Study of Effect of Ambient Model. Energy Procedia 2015, 64, 101–110. [Google Scholar] [CrossRef][Green Version]

- Mikolajková, M.; Haikarainen, C.; Saxén, H.; Pettersson, F. Optimization of a natural gas distribution network with potential future extensions. Energy 2017, 125, 848–859. [Google Scholar] [CrossRef]

- Schmidt, M.; Steinbach, M.C.; Willert, B.M. High detail stationary optimization models for gas networks. Optim. Eng. 2015, 16, 131–164. [Google Scholar] [CrossRef]

- Kudaisya, S.K.; Kar, S.K. A Comprehensive Review of City Gas Distribution in India. In Natural Gas Markets in India; Kar, S., Gupta, A., Eds.; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Fadeev, A.; Komendantova, N.; Cherepovitsyn, A.; Tsvetkova, A.; Paramonov, I. Methods and priorities for human resource planning in oil and gas projects in Russia and OPEC. OPEC Energy Rev. 2021, 45, 365–389. [Google Scholar] [CrossRef]

- Morenov, V.; Leusheva, E.; Lavrik, A.; Lavrik, A.; Buslaev, G. Gas-Fueled Binary Energy System with Low-Boiling Working Fluid for Enhanced Power Generation. Energies 2022, 15, 2551. [Google Scholar] [CrossRef]

- Bolobov, V.I.; Latipov, I.U.; Popov, G.G.; Buslaev, G.V.; Martynenko, Y.V. Estimation of the Influence of Compressed Hydrogen on the Mechanical Properties of Pipeline Steels. Energies 2021, 14, 6085. [Google Scholar] [CrossRef]

- Atroshchenko, V.A.; Avksentiev, S.Y.; Makharatkin, P.N.; Trufanova, I.S. Experimental hydrotransportation unit for testing material resistance of pipelines and parts of dredging pumps to hydro-abrasive wear. Obogas. Rud 2021, 2021, 39–45. [Google Scholar] [CrossRef]

- Ríos-Mercado, R.Z.; Borraz-Sánchez, C. Optimization problems in natural gas transportation systems: A state-of-the-art review. Appl. Energy 2015, 147, 536–555. [Google Scholar] [CrossRef]

- Schipachev, A.M.; Dmitrieva, A.S. Application of the resonant energy separation effect at natural gas reduction points in order to improve the energy efficiency of the gas distribution system. J. Min. Inst. 2021, 248, 253–259. [Google Scholar] [CrossRef]

| The Component of Natural Gas | CH4 | C2H6 | C3H8 | C4H10 | C5H12 | N2 | CO2 | H2S |

|---|---|---|---|---|---|---|---|---|

| Natural gas field | Shtokmanovskoye, Murmansk region | |||||||

| % content | 98.7 | 0.33 | 0.12 | 0.04 | 0.01 | 0.7 | 0.1 | - |

| Natural gas field | Medvezhye, Tyumen region | |||||||

| % content | 99 | 0.1 | 0.005 | - | - | 0.8 | 0.095 | - |

| Natural gas field | Vaneyviskoe, Arkhangelsk region | |||||||

| % content | 89.59 | 2.42 | 0.7 | 0.27 | 1.16 | 3.93 | 1.68 | 0.25 |

| Natural gas field | Zapolyarnoye, Tyumen region | |||||||

| % content | 98.5 | 0.2 | 0.05 | 0.012 | 0.001 | 0.7 | 0.5 | - |

| Natural gas field | Bovanenkovo, Yamalo-Nenets Autonomous Okrug | |||||||

| % content | 80.23 | 2.64 | 1.15 | 0.7 | 0.71 | 13.8 | 0.73 | - |

| Natural gas field | Angaro-Lenskoe, Irkutsk Region | |||||||

| % content | 93.1 | 2 | 0.4 | 0.2 | 0.3 | 4 | - | - |

| Composition of the Natural Gas | The Density, kg/m3 at a Temperature = 0 °C, P = 101.3 kPa | The Relative Density by Air |

|---|---|---|

| 1 | 2 | 3 |

| Methane CH4 | 0.7168 | 0.5545 |

| Ethane C2H6 | 1.3566 | 1.049 |

| Propane C3H8 | 2.019 | 1.562 |

| Butane C4H10 | 2.703 | 2.091 |

| i-sobutane C5H12 | 2.668 | 2.064 |

| Nitrogen N2 | 1.2505 | 0.9673 |

| Carbon dioxide CO2 | 1.9768 | 1.5291 |

| Hydrogen sulfide H2S | 1.5392 | 1.1906 |

| TheNaturalGas | The Combustion Heat | |

|---|---|---|

| Higher | Lower | |

| MJ/m3 at a Temperature = 0 °C and 101.3 kPa | ||

| 1 | 2 | 3 |

| CH4 | 39.86 | 35.84 |

| C2H6 | 70.42 | 63.73 |

| C3H8 | 101.74 | 93.37 |

| C4H10 | 133.98 | 123.77 |

| C5H12 | 131.89 | 121.84 |

| CO2 | 12.64 | 12.64 |

| H2S | 25.46 | 23.49 |

| № Area | dN (Diameter) mm | lp (Length) km | VP (Gas Flow) m3/h | (P21−P22)/lP(m) (Pressure) MPa | P21−P22, (Pressure) MPa |

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 |

| 18 | 500 | 0.077 | 10,053.831 | 0.045 | 0.003465 |

| 17 | 500 | 1.848 | 9849.4501 | 0.04 | 0.07392 |

| 16 | 500 | 0.407 | 9809.2192 | 0.04 | 0.01628 |

| 15 | 500 | 0.726 | 9796.579 | 0.04 | 0.02904 |

| 14 | 400 | 0.077 | 9787.3632 | 0.19 | 0.01463 |

| 13 | 400 | 0.473 | 9785.6909 | 0.19 | 0.08987 |

| 12 | 400 | 0.253 | 9745.46 | 0.18 | 0.04554 |

| 11 | 250 | 0.044 | 2566.8403 | 0.1 | 0.0044 |

| 10 | 250 | 0.121 | 2554.2002 | 0.1 | 0.0121 |

| 9 | 250 | 0.22 | 1665.1787 | 0.053 | 0.01166 |

| 8 | 250 | 0.121 | 1663.5064 | 0.053 | 0.006413 |

| 7 | 250 | 0.176 | 1459.1257 | 0.045 | 0.00792 |

| 6 | 250 | 0.154 | 1449.9099 | 0.045 | 0.00693 |

| 5 | 250 | 0.913 | 1437.2697 | 0.045 | 0.041085 |

| 4 | 200 | 0.451 | 903.3339 | 0.045 | 0.020295 |

| 3 | 150 | 0.154 | 901.6616 | 0.2 | 0.0308 |

| 2 | 100 | 0.363 | 12.64016 | 0.031 | 0.011253 |

| 6.578, (km) | , (MPa) | ||||

| , (Pa) | |||||

| Refusal at Area 18 | |||||

|---|---|---|---|---|---|

| № Area | dN (Diameter) mm | lp (Length) km | VP (Gas Flow) m3/h | (P21−P22)/lp(m) (Pressure) MPa | P21−P22, (Pressure) MPa |

| 1 | 2 | 3 | 4 | 5 | 6 |

| 1 | 500 | 0.22 | 10,053.831 | 0.045 | 0.0099 |

| 2 | 500 | 0.231 | 10,041.191 | 0.045 | 0.010395 |

| 3 | 500 | 0.154 | 9152.1692 | 0.038 | 0.005852 |

| 4 | 500 | 0.451 | 9150.4969 | 0.038 | 0.017138 |

| 5 | 400 | 0.913 | 8616.5611 | 0.1 | 0.0913 |

| 6 | 400 | 0.154 | 8603.9209 | 0.1 | 0.0154 |

| 7 | 400 | 0.176 | 8594.7051 | 0.1 | 0.0176 |

| 8 | 400 | 0.121 | 8390.3244 | 0.1 | 0.0121 |

| 9 | 400 | 0.22 | 8388.6521 | 0.1 | 0.022 |

| 10 | 400 | 0.121 | 7499.6307 | 0.085 | 0.010285 |

| 11 | 400 | 0.044 | 7486.9905 | 0.085 | 0.00374 |

| 12 | 125 | 0.253 | 308.37082 | 0.085 | 0.021505 |

| 13 | 125 | 0.473 | 268.1399 | 0.06 | 0.02838 |

| 14 | 125 | 0.077 | 266.4676 | 0.06 | 0.00462 |

| 15 | 125 | 0.726 | 257.2518 | 0.06 | 0.04356 |

| 16 | 125 | 0.407 | 244.61169 | 0.06 | 0.02442 |

| 17 | 125 | 1.903 | 204.38072 | 0.045 | 0.085635 |

| 6.644, (km) | , (MPa) | ||||

| (MPa) | |||||

| Point Number on the Ring | The Gas Pipeline Accident at Area 1 | The Gas Pipeline Accident at Area 19 |

|---|---|---|

| Gas Pressure, MPa | Gas Pressure, MPa | |

| 0 | 0.7 | 0.7 |

| 1 | 0.2537696 | 0.6928925 |

| 2 | 0.2750491 | 0.6853503 |

| 3 | 0.3262698 | 6810675 |

| 4 | 0.3560154 | 0.6683674 |

| 5 | 0.409673 | 0.5961669 |

| 6 | 0.418055 | 0.5831081 |

| 7 | 0.4274131 | 0.567816 |

| 8 | 0.4348505 | 0.5570592 |

| 9 | 0.4480569 | 0.5369497 |

| 10 | 0.4613621 | 0.5272855 |

| 11 | 0.4661062 | 0.523727 |

| 12 | 0.5126353 | 0.5027773 |

| 13 | 0.593856 | 0.473714 |

| 14 | 0.6060487 | 0.4688123 |

| 15 | 0.6295514 | 0.4197916 |

| 16 | 0.6423512 | 0.3896216 |

| 17 | 0.6975206 | 0.2572353 |

| Month | January 2021 | February 2021 | March 2021 | April 2021 | May 2021 | June 2021 |

|---|---|---|---|---|---|---|

| Capacity of GDS, Q2, thousand. m3/h | 15.225 | 12.132 | 10.243 | 9.897 | 8.223 | 4.867 |

| Month | July 2021 | August 2021 | September 2021 | October 2021 | November 2021 | December 2021 |

| Capacity of GDS, Q2, thousand. m3/h | 2.185 | 2.186 | 4.105 | 5.867 | 10.125 | 16.225 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fetisov, V.; Shalygin, A.V.; Modestova, S.A.; Tyan, V.K.; Shao, C. Development of a Numerical Method for Calculating a Gas Supply System during a Period of Change in Thermal Loads. Energies 2023, 16, 60. https://doi.org/10.3390/en16010060

Fetisov V, Shalygin AV, Modestova SA, Tyan VK, Shao C. Development of a Numerical Method for Calculating a Gas Supply System during a Period of Change in Thermal Loads. Energies. 2023; 16(1):60. https://doi.org/10.3390/en16010060

Chicago/Turabian StyleFetisov, Vadim, Aleksey V. Shalygin, Svetlana A. Modestova, Vladimir K. Tyan, and Changjin Shao. 2023. "Development of a Numerical Method for Calculating a Gas Supply System during a Period of Change in Thermal Loads" Energies 16, no. 1: 60. https://doi.org/10.3390/en16010060

APA StyleFetisov, V., Shalygin, A. V., Modestova, S. A., Tyan, V. K., & Shao, C. (2023). Development of a Numerical Method for Calculating a Gas Supply System during a Period of Change in Thermal Loads. Energies, 16(1), 60. https://doi.org/10.3390/en16010060