Yield and Bioenergy Quality of Maralfalfa Biomass Obtained at Different Plant Strata and Cutting Dates

Abstract

1. Introduction

2. Materials and Methods

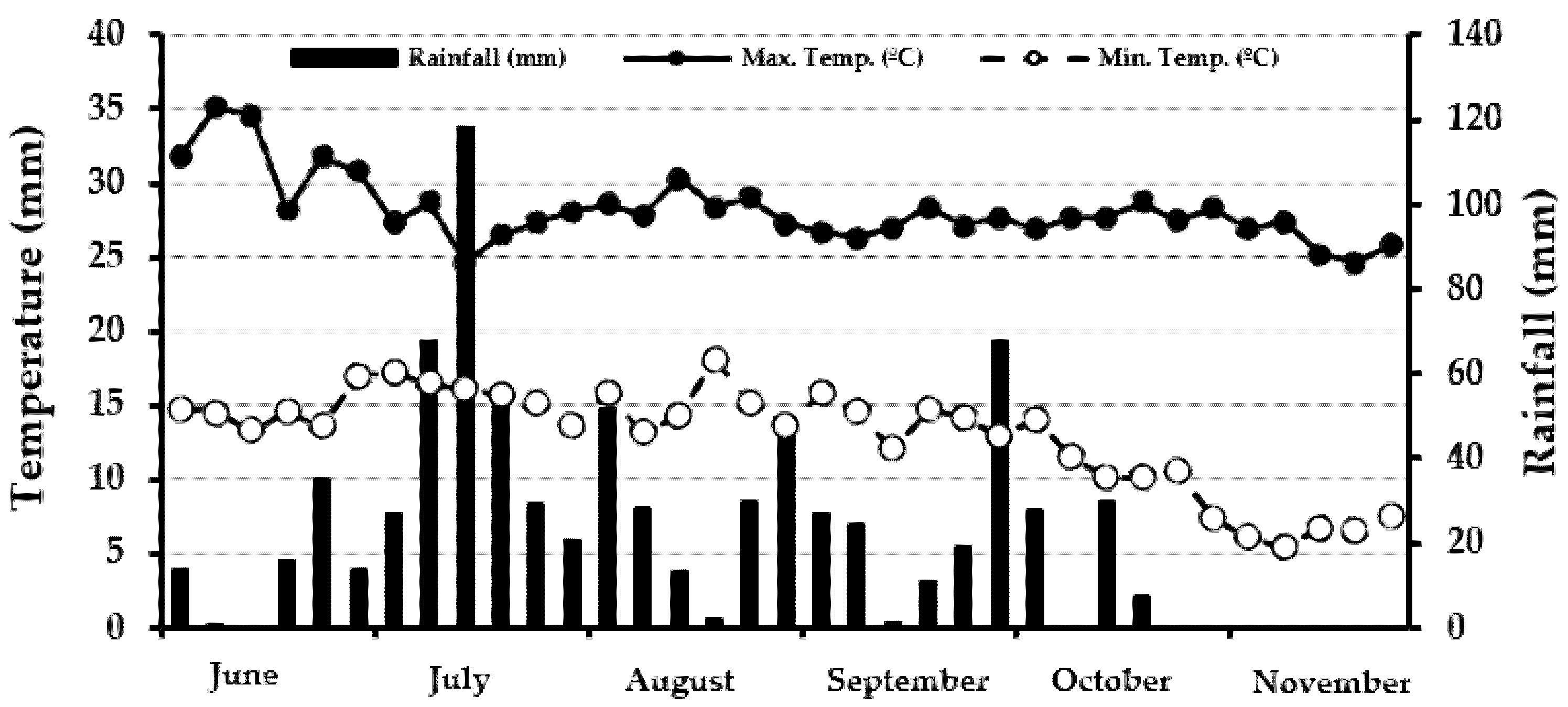

2.1. Characterization of the Study Area

2.2. Agronomic Management

2.3. Variables Evaluated in the Field

2.4. Sampling Method

2.5. Proximate Analysis and Energy Characterization

2.6. Statistical Analysis

3. Results and Discussion

3.1. Plant Height

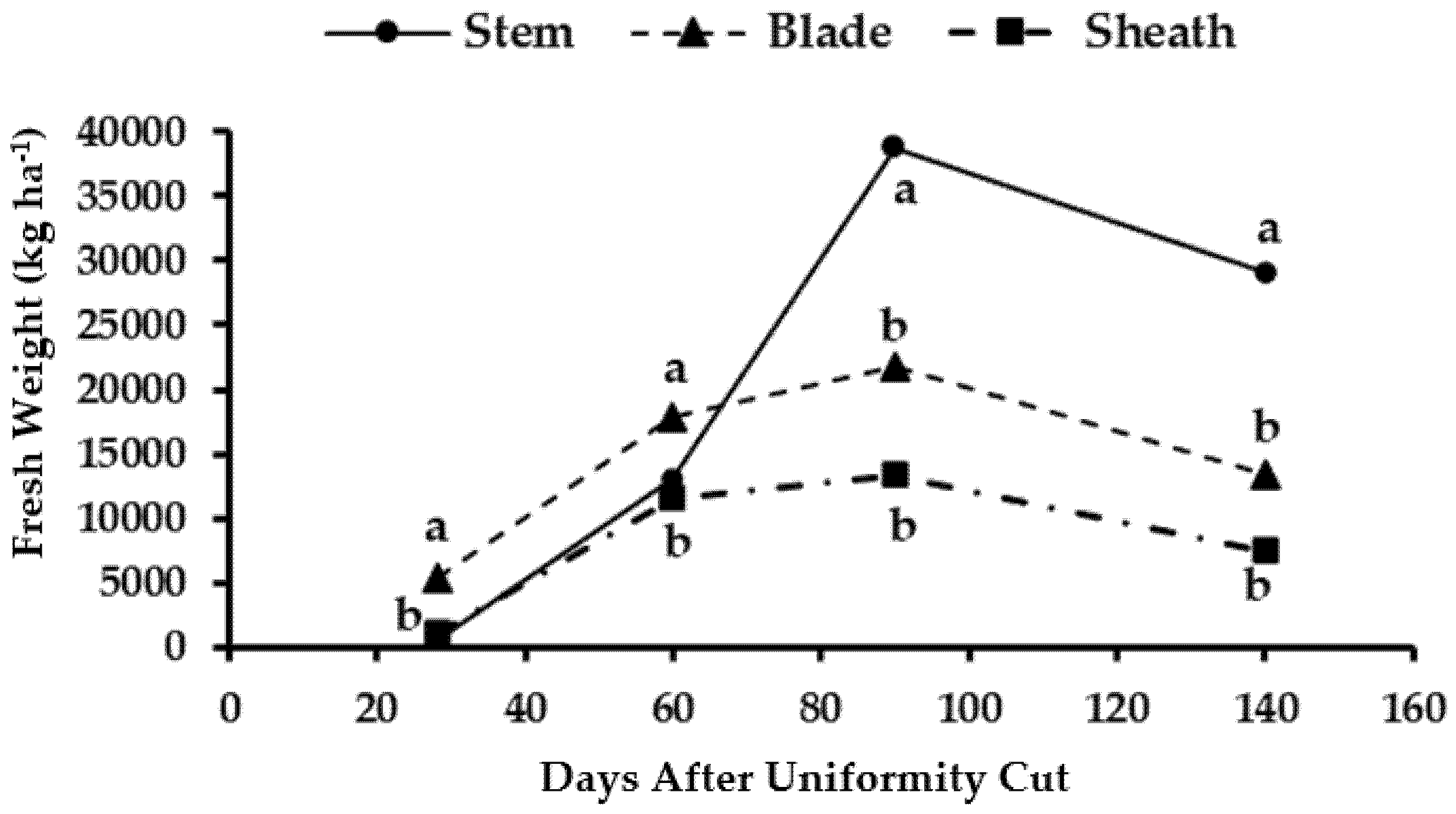

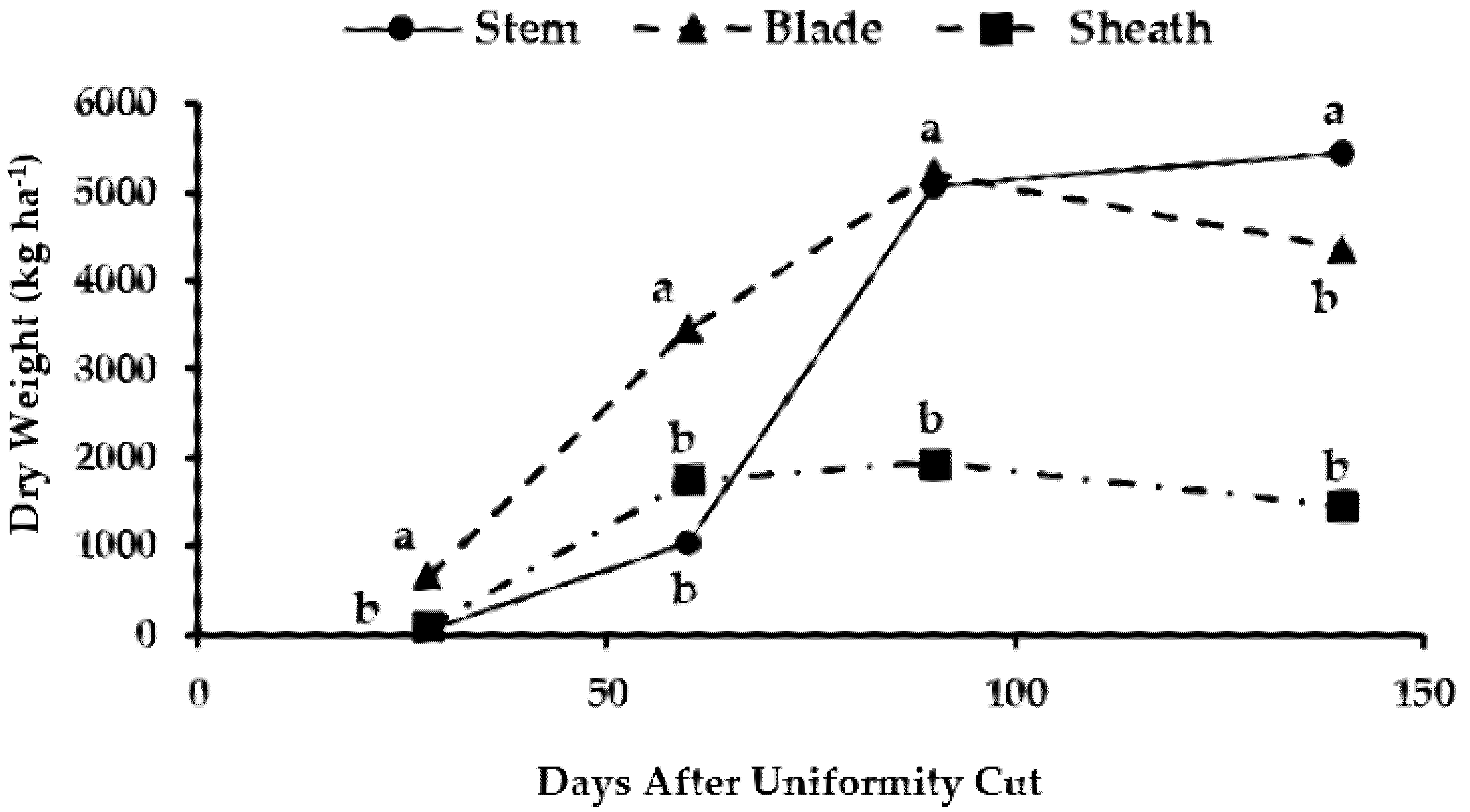

3.2. Biomass in Apical Stratum

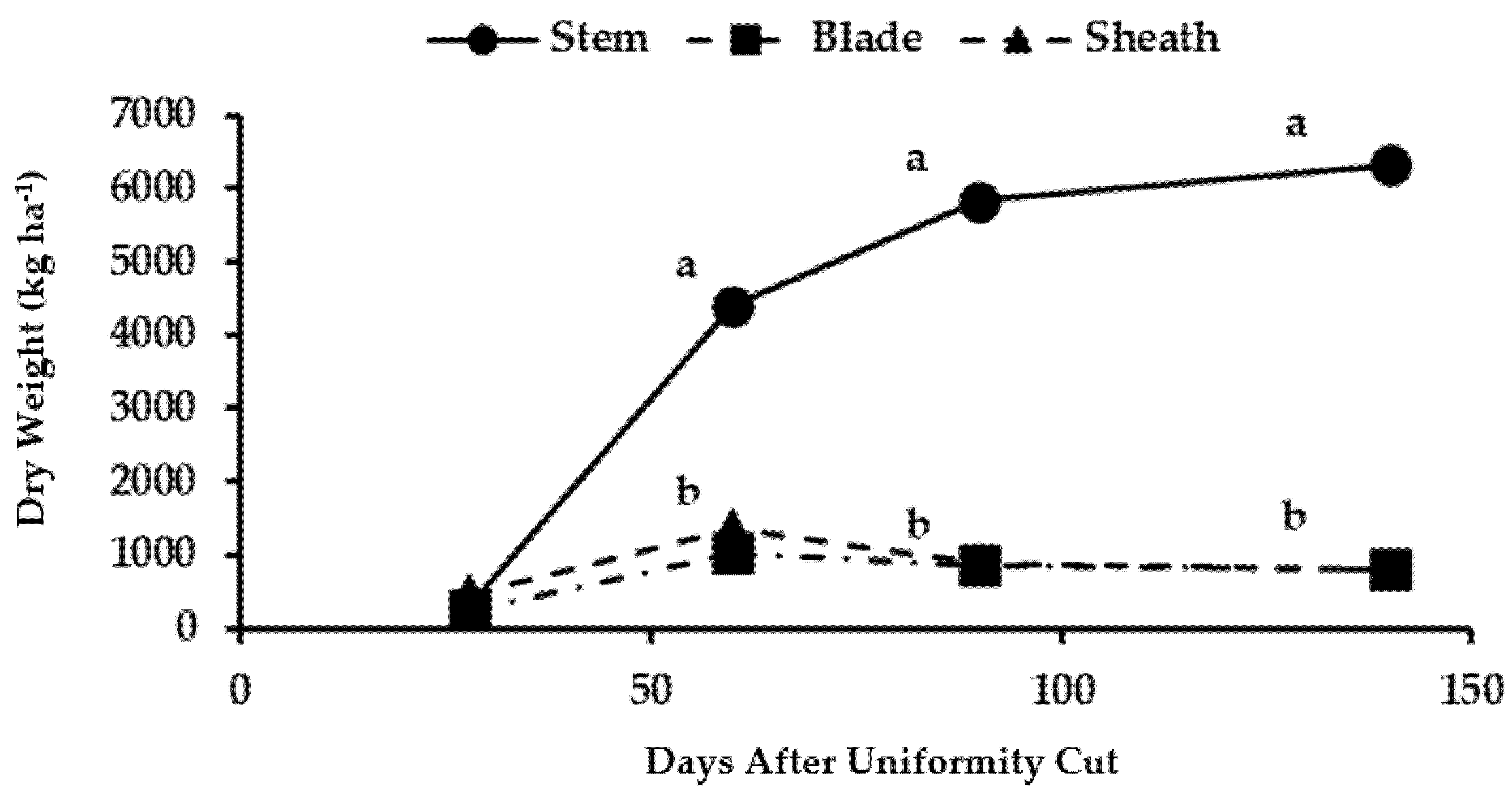

3.3. Biomass in the Basal Stratum

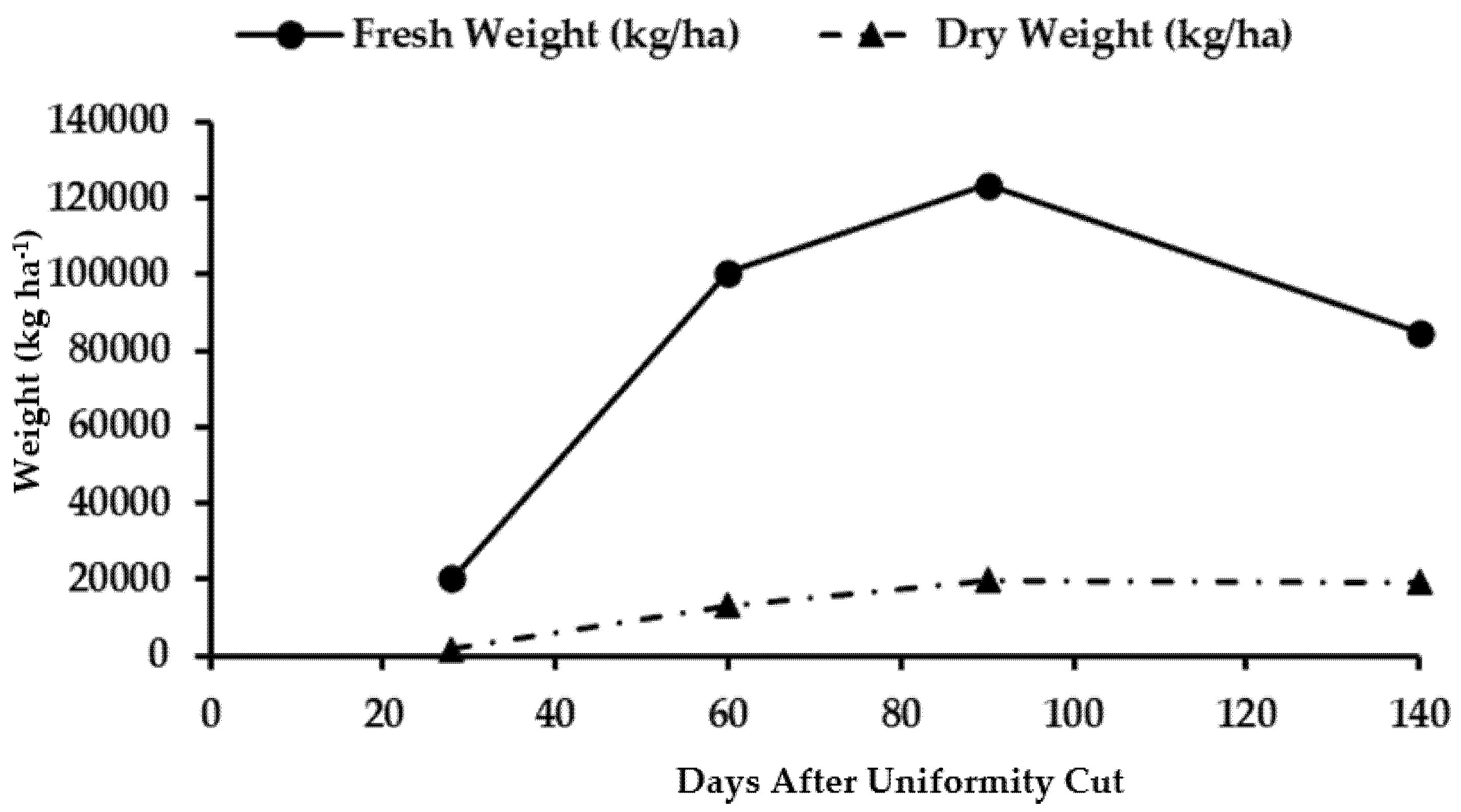

3.4. Total Biomass

3.5. Proximate Analysis

3.5.1. Volatile Material

3.5.2. Ash

3.5.3. Fixed Carbon

3.5.4. Higher Heating Value

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ohimain, E.I.; Kendabie, P.; Nwachukwu, R.E.S. Bioenergy potentials of elephant grass, Pennisetum purpureum Schumach. Annu. Res. Rev. Biol. 2014, 4, 2215–2227. [Google Scholar] [CrossRef]

- Danquah, J.A.; Roberts, C.; Appiah, M. Elephant Grass (Pennisetum purpureum): A Potential Source of Biomass for Power Generation in Ghana. Curr. J. Appl. Sci. Technol. 2018, 30, 1–12. [Google Scholar] [CrossRef]

- Montero-Lagunes, M.; Vinay-Vadillo, J.C.; Enríquez-Quiroz, J.F.; Jiménez-Montero, A.; Juárez-Lagunes, F.I.; Bolaños-Aguilar, E.D. Lignocellulosic biomass production in six cultivars of Cenchrus purpureus (Schumach.) Morrone in the tropics. Agro Product. 2022, 15. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.; Rout, P.K.; Dalai, A. Production of first and second generation biofuels: A comprehensive review. Renew. Sust. Energ. Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Kongkeitkajorn, M.B.; Sae-Kuay, C.; Reungsang, A. Evaluation of Napier Grass for Bioethanol Production through a Fermentation Process. Processes 2020, 8, 567. [Google Scholar] [CrossRef]

- Ventura-Ríos, J.; Honorato-Salazar, J.A.; Apolinar-Hidalgo, F.; Barrera-Martinez, I.; Aburto-Anell, J.; Huerta, H.V. Agronomic characterization of Taiwan grass [Cenchrus purpureus (Schumach.) Morrone] and evaluation of its potential to produce bioethanol in the warm sub-humid climate of Mexico. Trop. Grassl.-Forrajes Trop. 2022, 10, 22–31. [Google Scholar] [CrossRef]

- Reyes-Castro, S.; Enríquez-Quiroz, J.F.; Hernandez-Garay, A.C.; Esqueda-Esquivel, V.A.; Gutiérrez-Arenas, D.A. Rendimiento de seis cultivares de C. purpureus (Schumach.) Morrone con potencial para producción de bioetanol. Agro Product. 2018, 11, 56–62. [Google Scholar]

- Viana-Otero, M.V.; Siri-Prieto, G. Producción de biomasa de cultivos lignocelulósicos según el número de cortes. Agrociencia (Uruguay) 2018, 22, 13–23. [Google Scholar] [CrossRef]

- Capetillo-Burela, Á.; Zetina-Lezama, R.; Reynolds-Chávez, M.A.; Cadena-Zapata, M.; López-López, J.A.; Matilde-Hernández, C.; del Carmen, A.E. Elaboración de papel con seis variedades de Pennisetum purpureum Schumach en Veracruz, México. Rev. Iberoam. Bioecon. Cambio Clim. 2021, 7, 1644–1665. [Google Scholar] [CrossRef]

- Nava-Berumen, C.A.; Carrete-Carreón, F.O.; Rosales-Serna, R.; Reyes-Estrada, O.; Domínguez-Martínez, P.; Herrera-Torres, E. Rendimiento y calidad de forraje obtenido con el pasto maralfalfa cosechado a diferentes edades de rebrote en Durango, México. Investig. Cienc. Univ. Autónoma Aguascalientes 2021, 29, e3070. [Google Scholar] [CrossRef]

- Calzada-Marín, J.M.; Enríquez-Quiroz, J.F.; Hernández-Garay, A.; Ortega-Jiménez, E.; Mendoza-Pedroza, S.I. Análisis de crecimiento del pasto maralfalfa (Pennisetum sp.) en clima cálido subhúmedo. Rev. Mex. Cienc. Pecu. 2014, 5, 247–260. Available online: http://www.scielo.org.mx/scielo.php?script=sci_arttext&pid=S2007-242014000200009&lng=es&tlng=es (accessed on 16 December 2022). [CrossRef]

- Favare, H.G.; Abreu, J.; Barros, L.; Silva, F.G.; Ferreira, L.M.; Barelli, M.A.; da Neto, I.M.; Cabral, C.E.; Peixoto, W.; da Campos, F.I.; et al. Effect of Elephant Grass Genotypes to Bioenergy Production. J. Exp. Agric. Int. 2019, 38, 1–11. [Google Scholar] [CrossRef]

- Wijitphan, S.; Lowilai, P. Effects of cutting interval on yields and nutritive values of King Napier grass (Pennisetum purpureum cv. King grass) under Irrigation Supply. KKU Res. J. 2011, 16, 215–224. [Google Scholar]

- Lajili, M.; Guizani, C.; Escudero-Sanz, F.J.; Jeguirim, M. Fast pyrolysis and steam gasification of pellets prepared from olive oil mill residues. Energy 2018, 150, 61–68. [Google Scholar] [CrossRef]

- Reid, W.V.; Ali, M.K.; Field, C.B. The future of bioenergy. Glob. Chang. Biol. 2020, 26, 274–286. [Google Scholar] [CrossRef]

- Bueno, A.M.; de Andrade, A.F.; Viçosi, K.A.; Flores, R.A.; Sette, C.R., Jr.; da Cunha, T.Q.G.; Santos, G.G. Does Nitrogen Application Improve Elephant Grass Yield and Energetic Characteristics of Biofuels? Bioenerg. Res. 2021, 14, 774–784. [Google Scholar] [CrossRef]

- Ríos-Saucedo, J.C.; Rosales-Serna, R.; Jiménez-Ocampo, R.; Domínguez-Martínez, P.A.; Carrillo-Parra, A.; Valenzuela-Nuñez, L.M. Calidad de pélets a partir de biomasa de ocho especies dendroenergéticas de crecimiento rápido. Agrociencia 2021, 55, 557–568. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Long, S.P.; Zhu, X.G.; Naidu, S.L.; Ort, D.R. Can improvement in photosynthesis increase crop yields? Plant Cell Environ. 2006, 29, 315–330. [Google Scholar] [CrossRef]

- Jaradat, A.A. Genetic resources of energy crops: Biological systems to combat climate change. Aust. J. Crop. Sci. 2010, 4, 309–323. [Google Scholar]

- Carrillo-Parra, A.; Ngangyo-Heya, M.; Colín-Urieta, S.; Foroughbakhch-Pournavab, R.; Rutiaga-Quiñones, J.G.; Correa-Méndez, F. Physical, mechanical and energy characterization of wood pellets obtained from three common tropical species. PeerJ 2018, 6, e5504. [Google Scholar] [CrossRef]

- Wibowo, S.; Laia, D.P.O.; Khotib, M.; Pari, G. Characterization of carbon pellets made from elephant grass (Pennisetum purpureum Scumach) mixed with Nyamplung Shell (Calophyllum inophyllum Linn.). J. Penelit. Hasil Hutan 2017, 35, 73–82. [Google Scholar] [CrossRef]

- Garcia, D.; Caraschi, J.; Ventorim, G.; Vieira, F.; Protásio, T. Comparative energy properties of torrefied pellets in relation to pine and elephant grass pellets. BioResources 2018, 13, 2898–2906. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Barnthaler, G. Chemical properties of solid biofuels–significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Paciulo, D.S.C.; Gomide, J.A.; Ribeiro, K.G. Nitrogen fertilization of elephant grass cv. Mott. 1. Forage yield and morphophysiological characteristics when reaching 80 and 120 cm in height. Braz. J. Anim. Sci. 1998, 27, 1069–1075. [Google Scholar]

- García, M.E. Modificaciones al Sistema de Clasificación Climática de Köppen (Para Adaptarlo a las Condiciones de la República Mexicana), 4th ed.; Enriqueta García de Miranda: Mexico City, Mexico, 1987; 217p. [Google Scholar]

- Medina, G.G.; Díaz, P.G.; López, H.J.; Ruíz CJ, A.; Marín, S.M. Estadísticas Climatológicas Básicas del Estado de Durango (Periodo 1961–2003). Libro Técnico Núm. 1. SAGARPA-INIFAP-CIRNOC-Campo Experimental Valle del Guadiana; SAGARPA-INIFAP-CIRNOC-Campo Esperimental Valle del Guadiana: Durango, Mexico, 2005; 224p. [Google Scholar]

- CONAGUA (Comisión Nacional del Agua); Dirección local Durango. Observaciones Meteorológicas 2020; INIFAP-CIRNOC-Campo Experimental Valle del Guadiana: Durango, Mexico, 2021; 3p. [Google Scholar]

- INIFAP (Instituto Nacional de Investigaciones Forestales, Agrícolas y Pecuarias); Estación local Durango (CEVAG). Datos Consultados Localmente 15/11/2021; INIFAP-CIRPAC-CE Centro Altos de Jalisco: Durango, Mexico, 2021; 5p. [Google Scholar]

- Ruiz, C.J.A.; Medina, G.G.; González, I.J.A.; Flores, H.E.L.; Ramírez, G.O.; Ortiz, C.T.; Byerly, K.F.M.; Martínez, R.A.P. Requerimientos Agroecológicos de los Cultivos. Libro Técnico Núm. 3. INIFAP-CIRPAC-CE Centro Altos de Jalisco; Tepatitlán de Morelos: Jalisco, Mexico, 2013; 564p. [Google Scholar]

- UNE-EN 14774-3; Determinación del Contenido de Humedad. Método de Secado en Estufa. Parte 3. Humedad de la Muestra para Análisis General. Asociación Española de Normalización (UNE): Madrid, Spain, 2010. Available online: http://www.aenor.es/aenor/normas/normas/fichanorma.asp?tipo=N&codigo=N0045728#.WH_EN7GZNsM (accessed on 1 February 2022).

- SAS Institute Inc. SAS/STAT® 12.3 User’s Guide; SAS Institute Inc.: Cary, NC, USA, 2013; Available online: https://support.sas.com/documentation/cdl/en/statug/66103/HTML/default/viewer.htm#titlepage.htm (accessed on 16 October 2022).

- Valašinaitė, S.; Šimkūnas, A.; Denisov, V. Leaf size regularities in Festuca pratensis from the systemic viewpoint. Plant Biosyst. 2013, 147, 629–637. [Google Scholar] [CrossRef]

- Emonet, A.; Hay, A. Development and diversity of lignin patterns. Plant Phys. 2022, 190, 31–43. [Google Scholar] [CrossRef]

- Ibarra, B.J.C.; Rueda, Y.J.O. Biomasa Para el Aprovechamiento Energético. In Una Revisión de la Caracterización y los Modelos por Descomposición Termoquímica; Research Group on Energy and Environment GIEMA: Bucaramanga, Colombia, 2017; 18p. [Google Scholar]

- Baray, G.M.R.; Porras DA, F.; Hoffmann HE, E.; Manjarrez, C.B.D. Tratamiento de la biomasa lignocelulósica mediante la pirólisis lenta y a baja temperatura para la producción de biocombustibles. Rev. Energías Renov. 2019, 3, 1–9. [Google Scholar]

- EB (Energía Biomasa). Energías Renovables; Secretaría de Energía: Buenos Aires, Argentina, 2008; 16p. [Google Scholar]

- Ventura, R.J.; Honorato Salazar, J.A.; Hernández Garay, A.; Aburto Anell, J.A.; Vaquera Huerta, H.; Enríquez Quiroz, J.F. Composición química y rendimiento de maralfalfa para producción de bioetanol de segunda generación. Rev. Mex. Cien. Agríc. 2017, 8, 215–221. [Google Scholar]

- Carvalho, D.D.; Irving, L.J.; Carnevalli, R.A.; Hodgson, J.; Matthew, C. Distribution of current photosynthate in two Guinea grass (Panicum maximum Jacq.) cultivars. J. Exp. Bot. 2006, 57, 2015–2024. [Google Scholar] [CrossRef]

- Oitate, H.; Noguchi, K.; Terashima, I.; Suzuki, A.A. Patterns of photoassimilate translocation to reproductive shoots from adjacent shoots in Camellia sasanqua by manipulation of sink-source balance between the shoots. J. Plant Res. 2011, 124, 131–136. [Google Scholar] [CrossRef] [PubMed]

- Reza, M.S.; Islam, S.N.; Afroze, S.; Bakar, M.S.A.; Sukri, R.S.; Rahman, S.; Azad, A.K. Evaluation of the bioenergy potential of invasive Pennisetum purpureum through pyrolysis and thermogravimetric analysis. Energy Ecol. Environ. 2020, 5, 118–133. [Google Scholar] [CrossRef]

- Ferro, D.T.; Soler, P.B.; Zanzi, R. Torrefacción de biomasa densificada. Tecnol. Química 2009, 29, 180–186. [Google Scholar]

- Portilla, L.J.P.; Figueiredo, R.; dos Santos, M.B.; Kiyota, E.; Sampaio, J.L.M.; Araujo, P.; Schimpl, F.C.; Dama, M.; Pauly, M.; Mazzafera, P. Deposition of lignin in four species of Saccharum. Sci. Rep. 2019, 9, 5877. [Google Scholar]

| Source of Variation | Degree of Freedom | Volatile Material (%) | Ash (%) | Fixed Carbon (%) | Higher Heating Value (MJ kg−1) |

|---|---|---|---|---|---|

| 28 days AUC 1 | |||||

| Stratum (S) | 1 | 0.8 N.S. | 0.1 N.S. | 0.1 N.S. | 0.1 N.S. |

| Organs (O) | 2 | 27.0 ** | 0.6 N.S. | 61.0 ** | 1.2 N.S. |

| S × O | 2 | 2.5 N.S. | 0.6 N.S. | 4.2 N.S. | 0.5 N.S. |

| Error | 12 | 2.1 | 0.3 | 3.4 | 0.5 |

| CV (%) | 2.3 | 6.5 | 9.7 | 4.8 | |

| 60 days AUC | |||||

| Stratum (S) | 1 | 5.8 * | 0.1 N.S. | 8.7 * | 0.5 ** |

| Organs (O) | 2 | 32.0 ** | 2.3 * | 42.2 ** | 0.9 ** |

| S × O | 2 | 10.8 ** | 0.1 N.S. | 5.8* | 1.2 ** |

| Error | 12 | 1.3 | 0.4 | 1.3 | 0.1 |

| CV (%) | 1.7 | 7.3 | 6.0 | 1.4 | |

| 90 days AUC | |||||

| Stratum (S) | 1 | 32.5 * | 0.1 N.S. | 25.0 ** | 0.6 N.S. |

| Organs (O) | 2 | 27.0 * | 0.8 N.S. | 33.9 * | 16.3 ** |

| S × O | 2 | 4.8 N.S. | 1.2 N.S. | 8.0 N.S. | 1.0 * |

| Error | 12 | 6.1 | 0.3 | 5.8 | 0.3 |

| CV (%) | 3.8 | 6.9 | 12.1 | 3.6 | |

| 140 days AUC | |||||

| Stratum (S) | 1 | 20.9 * | 0.6 * | 8.3 N.S. | 2.2 ** |

| Organs (O) | 2 | 110.7 ** | 2.5 ** | 155.6 ** | 11.9 ** |

| S × O | 2 | 0.2 N.S. | 0.4 N.S. | 0.5 N.S. | 2.1 ** |

| Error | 12 | 3.7 | 0.2 | 4.0 | 0.1 |

| CV (%) | 2.9 | 5.2 | 10.5 | 2.4 | |

| Stratum | Structure | Volatile Material (%) | Ash (%) | Fixed Carbon (%) | Higher Heating Value (MJ kg−1) |

|---|---|---|---|---|---|

| 28 days AUC * | |||||

| Apical | Stem | 66.0 a | 8.0 | 16.4 b | 15.5 |

| Leaf | 64.1 b | 7.9 | 20.6 a | 15.4 | |

| Sheath | 63.1 b | 7.8 | 20.4 a | 14.8 | |

| basal | Stem | 66.9 a | 8.3 | 14.4 b | 15.1 |

| Leaf | 63.6 b | 7.2 | 20.9 a | 16.2 | |

| Sheath | 61.4 b | 8.3 | 21.7 a | 14.9 | |

| 60 days AUC | |||||

| Apical | Stem | 67.5 a | 8.7 a | 16.6 b B | 15.7 a A |

| Structure (ST) | Leaf | 66.9 b | 8.3 a b | 18.5 a | 16.6 a |

| S × ST | Sheath | 64.5 b | 7.5 b | 20.6 a | 15.5 b |

| basal | Stem | 69.1 a | 8.9 a | 16.0 b A | 16.3 a B |

| Leaf | 63.2 b | 8.2 a b | 21.8 a | 15.4 b | |

| CV (%) | Sheath | 63.2 b | 7.6 b | 22.1 a | 15.1 b |

| 90 days AUC | |||||

| Apical | Stem | 68.1 a A | 8.3 | 17.3 b | 16.2 a |

| Structure (ST) | Leaf | 66.0 b | 8.4 | 19.1 a | 13.8 c |

| S × ST | Sheath | 66.0 b | 7.8 | 20.0 a | 15.8 b |

| basal | Stem | 67.5 a B | 8.9 | 17.1 b | 16.8 a |

| Error | Leaf | 62.2 b | 7.4 | 23.5 a | 12.8 c |

| CV (%) | Sheath | 62.4 b | 8.2 | 22.7 a | 15.1 b |

| 140 days AUC | |||||

| Apical | Stem | 72.7 a A | 8.9 a | 13.2 c | 16.4 a A |

| Structure (ST) | Leaf | 64.4 b | 7.7 b | 22.8 a | 14.7 c |

| Sheath | 67.2 b | 7.9 b | 19.3 b | 16.1 b | |

| basal | Stem | 70.8 a B | 9.1 a | 13.9 c | 17.1 a B |

| Error | Leaf | 62.4 b | 7.7 b | 24.4 a | 13.2 c |

| CV (%) | Sheath | 64.7 b | 8.9 a | 21.0 a | 14.7 b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosales-Serna, R.; Ríos-Saucedo, J.C.; Martínez-Galindo, J.A.; Carrillo-Parra, A.; Santana-Espinoza, S.; Jiménez-Ocampo, R.; Domínguez-Martínez, P.A. Yield and Bioenergy Quality of Maralfalfa Biomass Obtained at Different Plant Strata and Cutting Dates. Energies 2023, 16, 448. https://doi.org/10.3390/en16010448

Rosales-Serna R, Ríos-Saucedo JC, Martínez-Galindo JA, Carrillo-Parra A, Santana-Espinoza S, Jiménez-Ocampo R, Domínguez-Martínez PA. Yield and Bioenergy Quality of Maralfalfa Biomass Obtained at Different Plant Strata and Cutting Dates. Energies. 2023; 16(1):448. https://doi.org/10.3390/en16010448

Chicago/Turabian StyleRosales-Serna, Rigoberto, Julio César Ríos-Saucedo, Jhessica Abigail Martínez-Galindo, Artemio Carrillo-Parra, Saúl Santana-Espinoza, Rafael Jiménez-Ocampo, and Pablo Alfredo Domínguez-Martínez. 2023. "Yield and Bioenergy Quality of Maralfalfa Biomass Obtained at Different Plant Strata and Cutting Dates" Energies 16, no. 1: 448. https://doi.org/10.3390/en16010448

APA StyleRosales-Serna, R., Ríos-Saucedo, J. C., Martínez-Galindo, J. A., Carrillo-Parra, A., Santana-Espinoza, S., Jiménez-Ocampo, R., & Domínguez-Martínez, P. A. (2023). Yield and Bioenergy Quality of Maralfalfa Biomass Obtained at Different Plant Strata and Cutting Dates. Energies, 16(1), 448. https://doi.org/10.3390/en16010448