Computed Tomography Observation and Image-Based Simulation of Fracture Propagation in Compressed Coal

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Sample Preparation

2.2. Testing and Monitoring Methods

3. Experimental Results

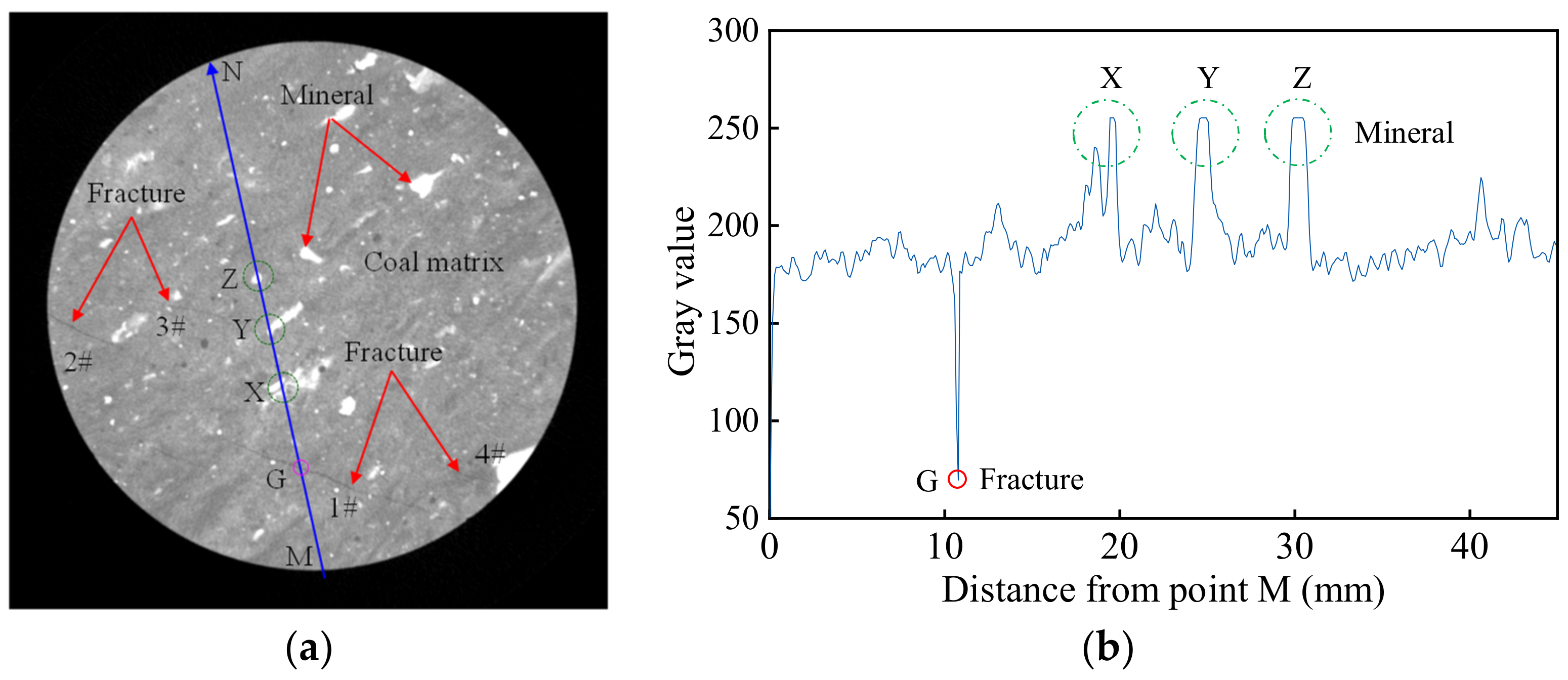

3.1. Spatial Distribution of the Original Fractures

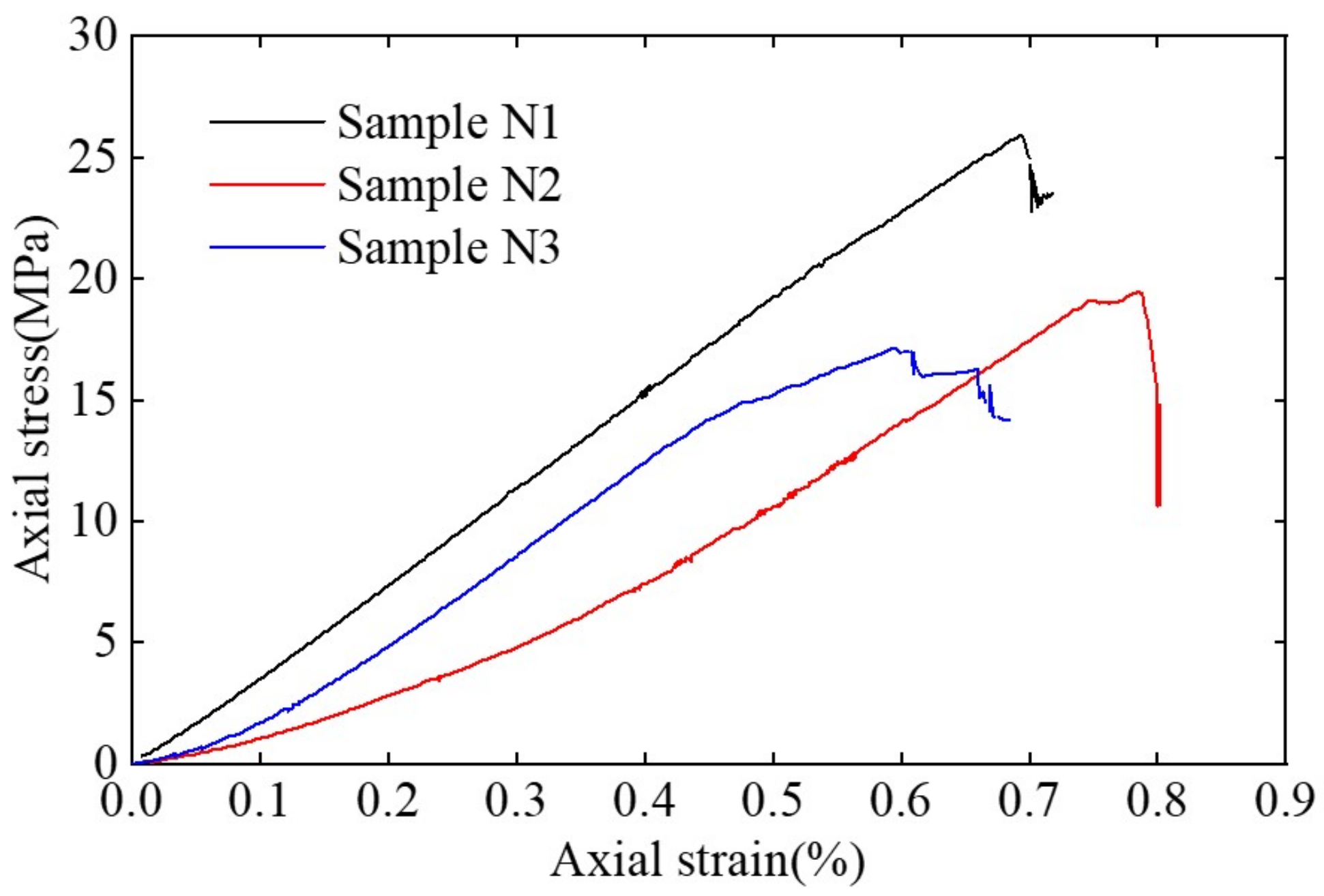

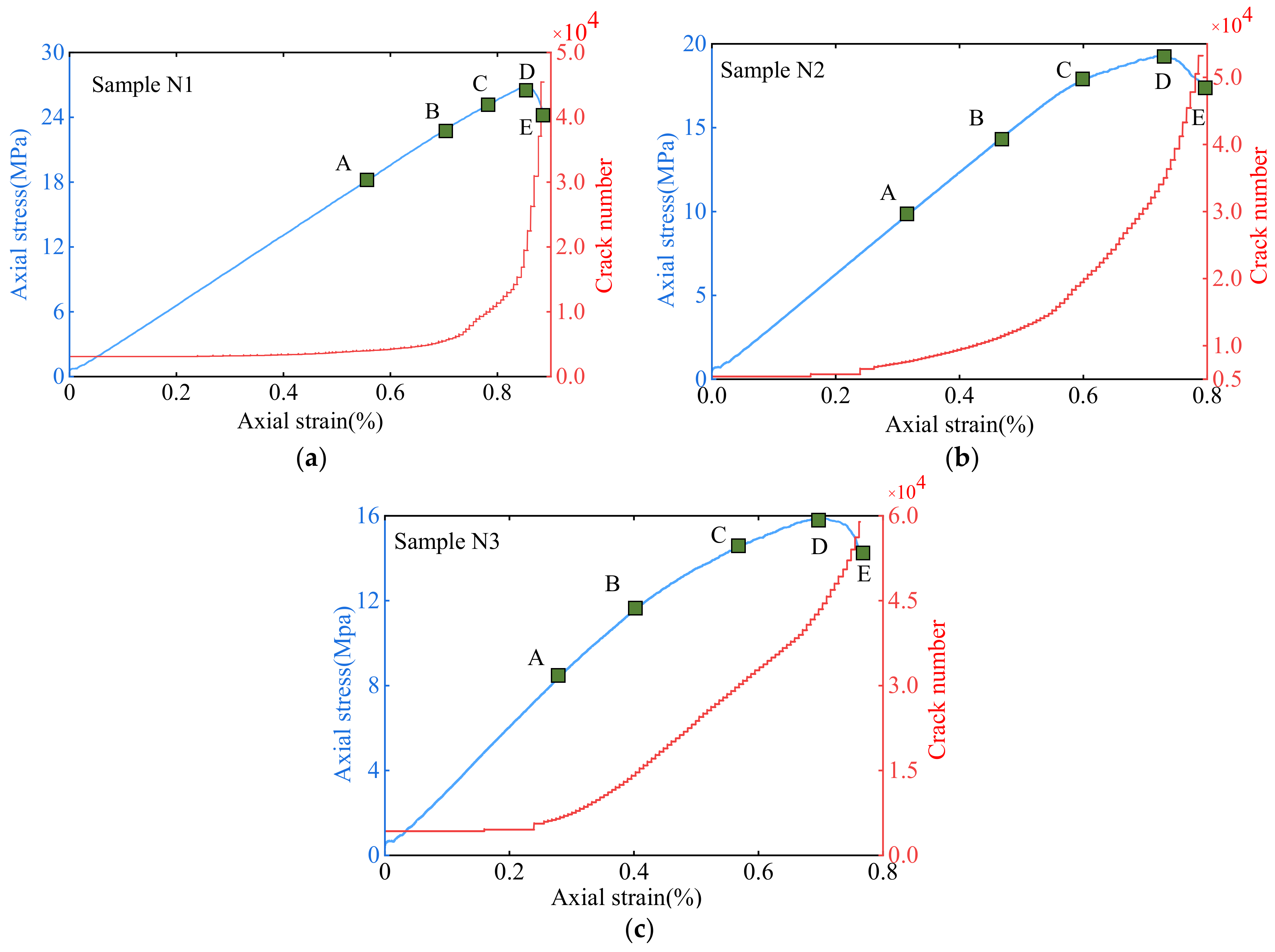

3.2. Stress–Strain Responses of Fractured Coal Sample

3.3. Fracture Propagation in 2D CT Images

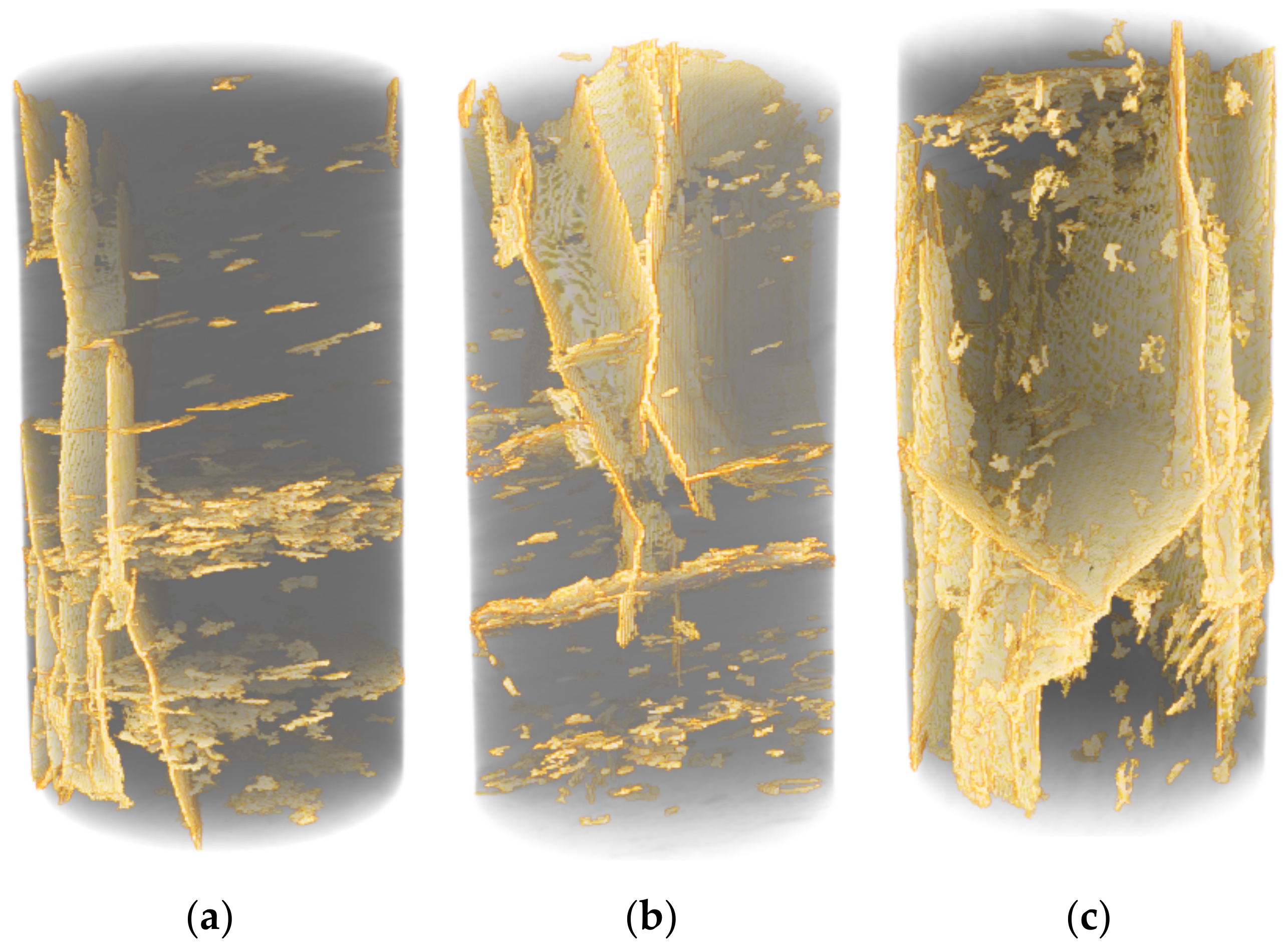

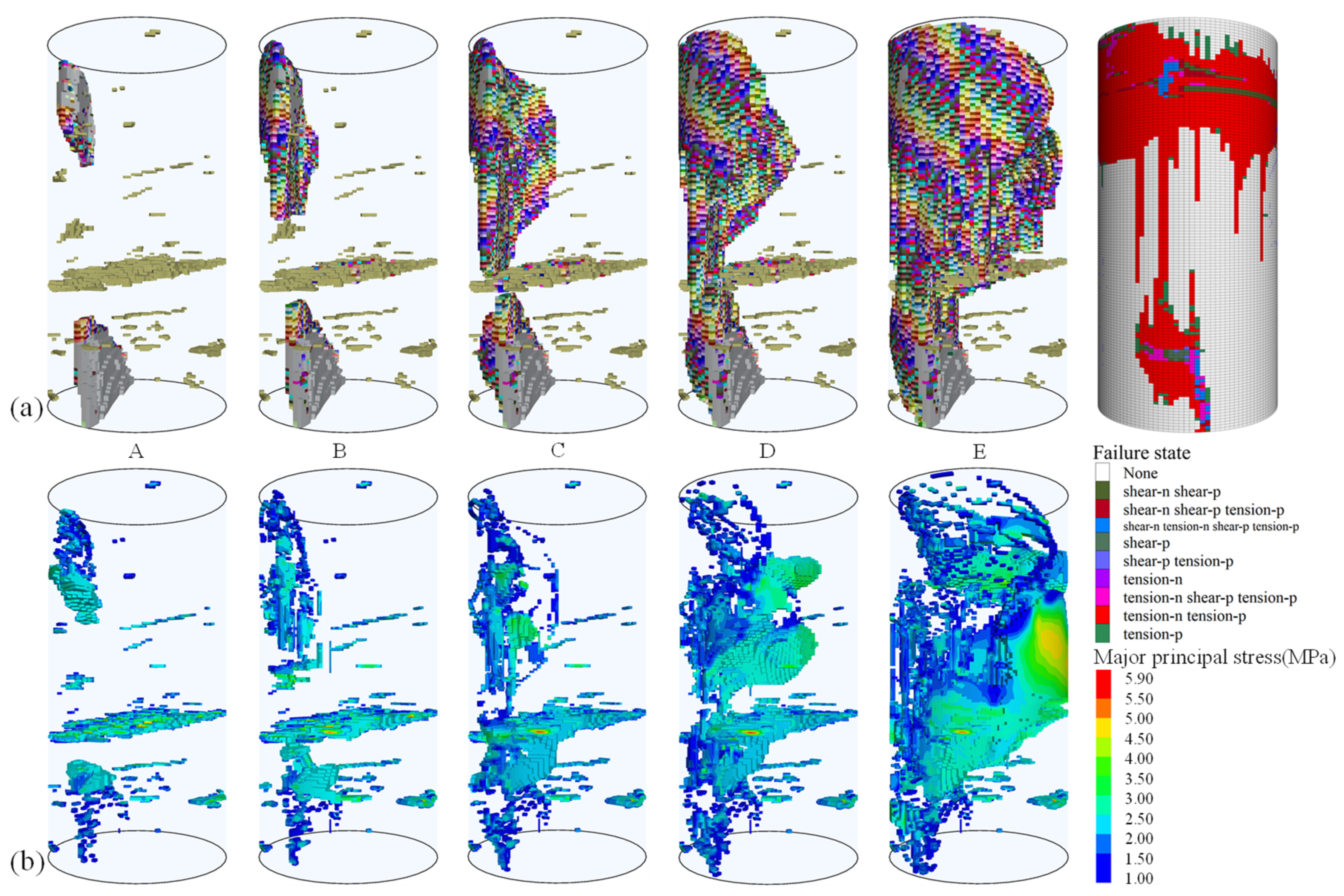

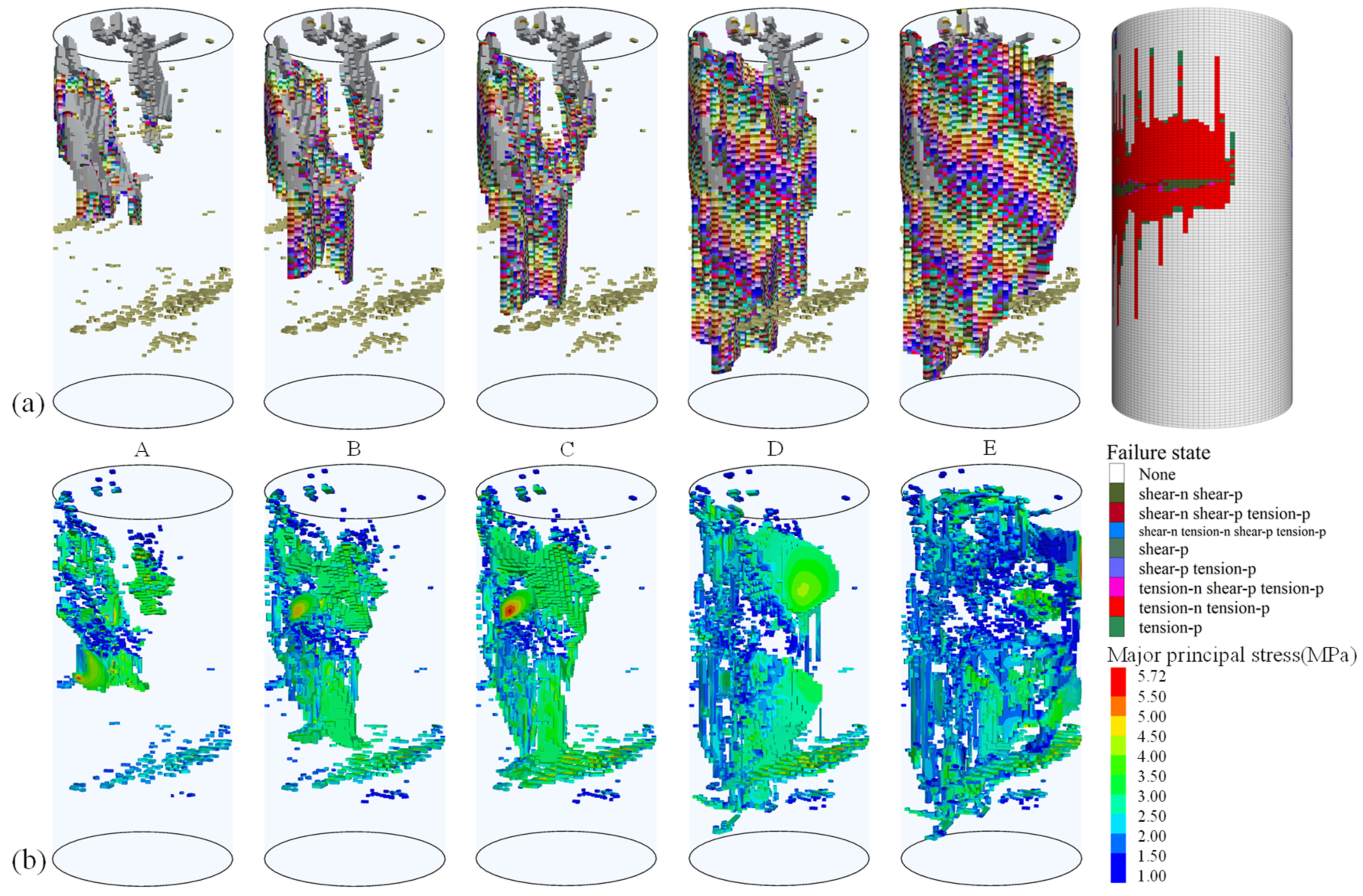

3.4. Spatial Distribution of 3D Failure Fractures

4. Numerical Modeling

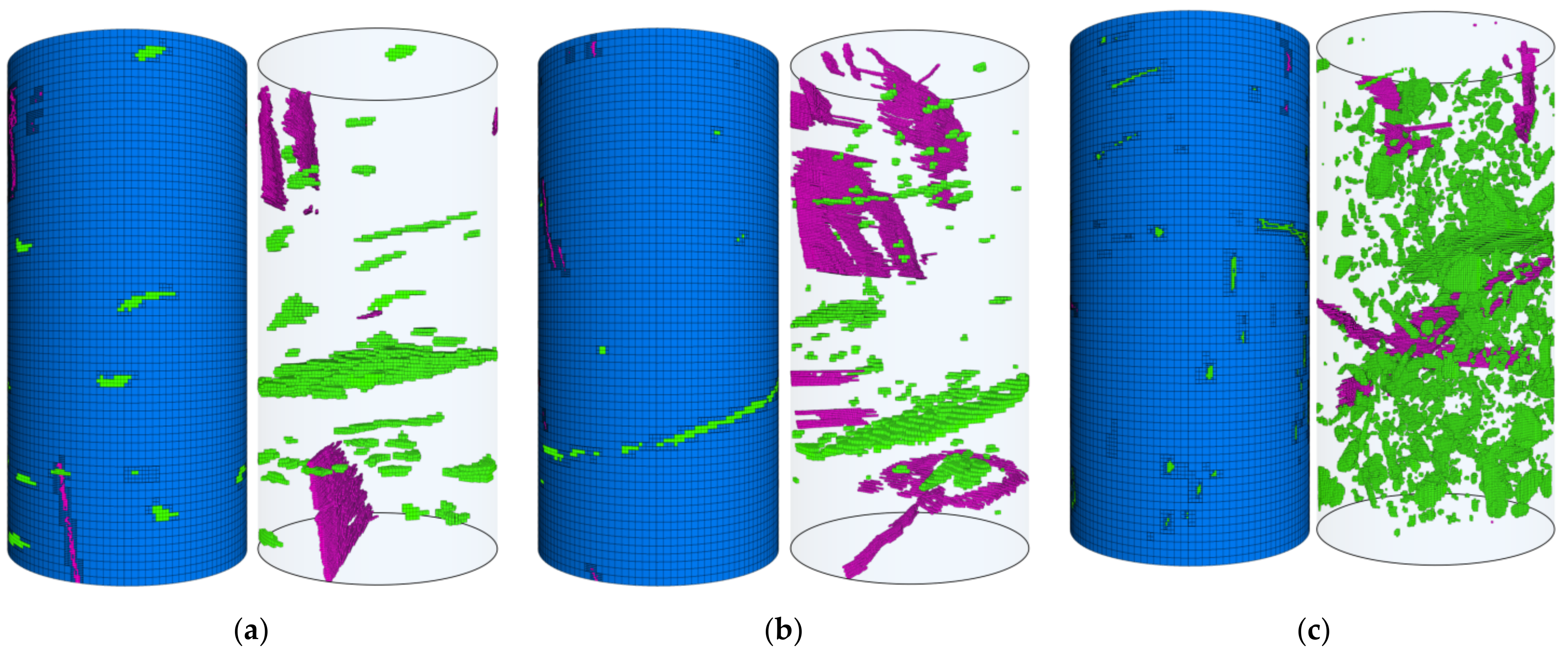

4.1. Image-Based Modeling Method

- (1)

- Spatial distribution of original fractures and mineral inclusions in the tested coal sample is first determined by reconstructing 2D CT scanning images, as shown in Figure 4. The coordinate information of involved fractures and mineral inclusions is then extracted and exported from the reconstructed model. The obtained coordinate data include the position of the point, edge, polygon, and polyhedron, which are composed of the reconstructed fractures and minerals.

- (2)

- Original fractures and mineral inclusions are imported into FLAC3D with the help of the determined coordinate data. Such data are used to generate geometry object, which can interact with mechanical model but has no influence on mechanical calculation in FLAC3D. The original fractures and mineral inclusions are represented by polygonal and polyhedral geometry sets, respectively. In addition, geometry sets can also be distinguished by assigning different names.

- (3)

- A numerical model is then developed for subsequent simulation, which has the same shape and size with the tested coal sample. In this study, the numerical model is discretized into zones. The generated geometry sets are then moved to the same position with the numerical model and thus, the overlaying between them is realized in FLAC3D.

- (4)

- The zones representing the fractures and mineral inclusions of the coal sample are identified based on the type of the geometry set. The zones intersecting with polyhedral geometry set are identified as the mineral inclusions and these intersecting with a polygonal geometry set are identified as pre-existing fractures. The left zones are defined as a coal matrix. In this way, the main components of the tested coal sample, namely, coal matrix, original fractures, and mineral inclusions, are precisely separated in the numerical model.

- (5)

- In the modeling process, failure behavior of coal is mainly controlled by the zones representing pre-existing defects. They are further subdivided into smaller zones. Such densification and refinement of local zone discretization ensures that fracture propagation can be realistically reproduced by the image-based model, which takes spatial distribution and structural morphology of original fractures into account.

4.2. Mechanical Properties

4.3. Modeling Results

5. Conclusions

- (1)

- Based on CT observation, both original fractures and mineral inclusions in coal samples are identified and reconstructed. Original fractures with small dip angle and large opening result in more obvious fracture closure and strain-hardening behaviors of coal while failure mode tends to be dominated by those with large dip angle. Spatial distribution and structural morphology of original fractures provide significant influence on the final failure fracture network, which mainly originates from the propagation of the original fractures. The fractures with a large dip angle result in splitting dominated failure fracture network. Fracture interaction is enhanced between original fractures with small dip angle, leading to a mixed splitting and shearing dominated failure fracture network.

- (2)

- An image-based modeling method is proposed by importing original fractures of coal into numerical model. The location and geometry of pre-existing fractures and mineral inclusions are obtained from CT image reconstruction. The coordination data are utilized to generate geometry sets in FLAC3D, which is, moreover, used for model refinement. Original fractures and mineral inclusions are accurately represented by polygonal and polyhedral geometry objects, respectively. The zones intersecting with the geometry objects are distinguished from coal matrix and defined as original defects. That means both spatial distribution and structural morphology of original defects are properly characterized in the image-based model, which strengthens its modeling capability.

- (3)

- The predicted complexity in a failure fracture network is consistent with that observed in the experiment. Both fracture interaction and mineral influence are accurately captured by the proposed model. In the loading process, tensile stress distribution presents a similar evolution trend with failure fracture network, implying that the propagation of original fractures is mainly dominated by tensile stress. Under a compressive condition, tensile stress mainly appears around the fracture and in the vicinity of mineral layer. In the pre-peak stage, propagation speed of the fractures with small dip angle is faster than that with large dip angle. In the post-peak stage, propagation speed of the fractures with large dip angle is greatly stimulated. Shear cracks mainly occur after the large tensile fracture running through the coal sample has been formed.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.H.; Wang, J.C.; Yang, Y.; Tang, Y.S.; Wang, L. Mechanical relation between support stiffness and longwall face stability within fully-mechanized mining faces. J. China Univ. Min. Technol. 2019, 48, 258–267. [Google Scholar]

- Zhang, G.C.; Wen, Z.J.; Liang, S.J.; Tan, Y.L.; Tian, L.; Zhao, Y.Q.; Zhao, D.S. Ground response of a gob-side entry in a longwall panel extracting 17 m-thick coal seam: A case study. Rock Mech. Rock Eng. 2020, 53, 497–516. [Google Scholar] [CrossRef]

- Li, H.Q.; Wong, L.N.Y. Influence of flaw inclination angle and loading condition on crack initiation and propagation. Int. J. Solids Struct. 2012, 49, 2482–2499. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.H.; Wang, J.C.; Yang, S.L. An ultrasonic-based method for longwall top-coal cavability assessment. Int. J. Rock Mech. Min. Sci. 2018, 112, 209–225. [Google Scholar] [CrossRef]

- Wang, Z.H.; Wang, J.C.; Yang, S.L.; Li, L.H.; Li, M. Failure behaviour and acoustic emission characteristics of different rocks under uniaxial compression. J. Geophys. Eng. 2020, 17, 76–88. [Google Scholar] [CrossRef]

- Jaeger, J.C. Shear failure of anisotropic rocks. Geol. Mag. 1960, 97, 65–72. [Google Scholar] [CrossRef]

- Hoek, E.; Bieniawski, Z.T. Brittle fracture propagation in rock under compression. Int. J. Fract. Mech. 1965, 1, 137–155. [Google Scholar] [CrossRef]

- Wawersik, W.R.; Fairhurst, C. A study of brittle rock fracture in laboratory compression experiments. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1970, 7, 561–575. [Google Scholar] [CrossRef]

- Hudson, J.A.; Brown, E.T.; Fairhurst, C. Optimizing the control of rock failure in servo-controlled laboratory tests. Rock Mech. 1971, 3, 217–224. [Google Scholar] [CrossRef]

- Jaeger, J.C.; Cook, N.G.W.; Zimmerman, R.W. Fundamentals of Rock Mechanics; Methuen: London, UK, 1969. [Google Scholar]

- Jaeger, J.C. Friction of rocks and the stability of rock slopes. Geotechnique 1971, 21, 97–134. [Google Scholar] [CrossRef]

- Peng, S.; Johnson, A.M. Crack growth and faulting in cylindrical specimens of chelmsford granite. Int. J. Rock Mech. Min. Sci. 1972, 9, 37–86. [Google Scholar] [CrossRef]

- ISRM Testing Commission. Suggested methods for the quantitative description of discontinuities in rock masses. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1978, 15, 319–368. [Google Scholar]

- ISRM Testing Commission. Suggested method for determining mode I fracture toughness using cracked chevron Brazilian (CCNBD) specimens. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 57–64. [Google Scholar] [CrossRef]

- Nemat-Nasser, S.; Horii, H. Compression-induced nonplanar crack extension with application to splitting, exfoliation, and rockburst. J. Geophys. Res. Solid Earth 1982, 87, 6805–6821. [Google Scholar] [CrossRef]

- Horii, H.; Nemat, N.S. Compression-induced microcrack growth in brittle solids: Axial splitting and shear failure. J. Geophys. Res. 1985, 90, 3105. [Google Scholar] [CrossRef]

- Yang, Z.Y.; Huang, T.H. Effect of joint sets on the aniso-tropic strength of rock masses. In Proceedings of the 8th ISRM, Tokyo, Japan, 25–29 September 1995. [Google Scholar]

- Yang, Z.Y.; Chen, J.M.; Huang, T.H. Effect of joint sets on the strength and deformation of rock mass models. Int. J. Rock Mech. Min. Sci. 1998, 35, 75–84. [Google Scholar] [CrossRef]

- Gong, Q.M.; Zhao, J.; Jiao, Y.Y. Numerical modeling of the effects of joint orientation on rock fragmentation by TBM cutters. Tunn. Undergr. Space Technol. 2005, 20, 183–191. [Google Scholar] [CrossRef]

- Gong, Q.M.; Jiao, Y.Y.; Zhao, J. Numerical modelling of the effects of joint spacing on rock fragmentation by TBM cutters. Tunn. Undergr. Space Technol. 2006, 21, 46–55. [Google Scholar] [CrossRef]

- Klawitter, M.; Esterle, J.; Collins, S. A study of hardness and fracture propagation in coal. Int. J. Rock Mech. Min. Sci. 2015, 76, 237–242. [Google Scholar] [CrossRef]

- Mishra, B.; Nie, D. Experimental investigation of the effect of change in control modes on the post-failure behavior of coal and coal measures rock. Int. J. Rock Mech. Min. Sci. 2013, 60, 363–369. [Google Scholar] [CrossRef]

- Gao, F.Q.; Kang, H.P. Experimental study on the residual strength of coal under low confinement. Rock Mech. Rock Eng. 2016, 50, 285–296. [Google Scholar] [CrossRef]

- Alejano, L.R.; Arzúa, J.; Bozorgzadeh, N.; Harrison, J.P. Triaxial strength and deformability of intact and increasingly jointed granite samples. Int. J. Rock Mech. Min. Sci. 2017, 95, 87–103. [Google Scholar] [CrossRef]

- Bruning, T.; Karakus, M.; Nguyen, G.D.; Goodchild, D. Experimental study on the damage evolution of brittle rock under triaxial confinement with full circumferential strain control. Rock Mech. Rock Eng. 2018, 51, 3321–3341. [Google Scholar] [CrossRef]

- Xiong, L.; Wu, S.; Zhang, S. Mechanical behavior of a granite from Wuyi mountain: Insights from strain-based approaches. Rock Mech. Rock Eng. 2019, 52, 719–736. [Google Scholar] [CrossRef]

- Liu, M.; Liu, E. Dynamic mechanical properties of artificial jointed rock samples subjected to cyclic triaxial loading. Int. J. Rock Mech. Min. Sci. 2017, 98, 54–66. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, B.; Tanabashi, Y. Estimating the relation between surface roughness and mechanical properties of rock joints. Int J. Rock Mech. Min. Sci. 2006, 43, 837–846. [Google Scholar] [CrossRef]

- Li, B.; Jiang, Y.; Mizokami, T.; Ikusada, K.; Mitani, Y. Anisotropic shear behavior of closely jointed rock masses. Int. J. Rock Mech. Min. Sci. 2014, 71, 258–271. [Google Scholar] [CrossRef] [Green Version]

- Serhii, S.; Oleksandr, K.; Tatiana, P.; Liliia, P. On the methodology for considering scale effect of rock strength. Min. Miner. Depos. 2020, 14, 24–30. [Google Scholar]

- Zuo, J.P.; Wei, X.; Shi, Y.; Liu, C.; Li, M.; Wong, R.H.C. Experimental study of the ultrasonic and mechanical properties of a naturally fractured limestone. Int. J. Rock Mech. Min. Sci. 2020, 125, 104162. [Google Scholar] [CrossRef]

- Li, D.; Wang, E.; Kong, X.; Ali, M.; Wang, D. Mechanical behaviors and acoustic emission fractal characteristics of coal specimens with a pre-existing flaw of various inclinations under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2019, 116, 38–51. [Google Scholar] [CrossRef]

- Zhu, Q.; Li, D.; Han, Z.; Li, X.; Zhou, Z. Mechanical properties and fracture evolution of sandstone specimens containing different inclusions under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2019, 115, 33–47. [Google Scholar] [CrossRef]

- Arstanbek, A.; Rakhat, M.; Aziz, A.; Sher, A. Studying a correlation between characteristics of rock and their conditions. Min. Miner. Depos. 2020, 14, 87–100. [Google Scholar]

- Munoz, H.; Taheri, A.; Chanda, E.K. Pre-peak and post-peak rock strain characteristics during uniaxial compression by 3D digital image correlation. Rock Mech. Rock Eng. 2016, 49, 2541–2554. [Google Scholar] [CrossRef]

- Munoz, H.; Taheri, A.; Chanda, E.K. Fracture energy-based brittleness index development and brittleness quantification by pre-peak strength parameters in rock uniaxial compression. Rock Mech. Rock Eng. 2016, 49, 4587–4606. [Google Scholar] [CrossRef]

- Sharafisafa, M.; Shen, L.; Xu, Q. Characterisation of mechanical behaviour of 3D printed rock-like material with digital image correlation. Int. J. Rock Mech. Min. Sci. 2018, 112, 122–138. [Google Scholar] [CrossRef]

- Tran, T.P.H.; Bouissou, S.; Chemenda, A.; Ambre, J.; Vacher, P.; Michel, P. Initiation and evolution of a network of deformation bands in a rock analogue material at brittle–ductile transition. Rock Mech. Rock Eng. 2019, 52, 737–752. [Google Scholar] [CrossRef]

- Zhou, H.W.; Zhong, J.C.; Ren, W.G.; Wang, X.Y.; Yi, H.Y. Characterization of pore-fracture networks and their evolution at various measurement scales in coal samples using X-ray μCT and a fractal method. Int. J. Coal Geol. 2018, 189, 35–49. [Google Scholar] [CrossRef]

- Ju, Y.; Xi, C.; Zhang, Y.; Mao, L.; Gao, F.; Xie, H. Laboratory in situ CT observation of the evolution of 3D fracture networks in coal subjected to confining pressures and axial compressive Loads: A novel approach. Rock Mech. Rock Eng. 2018, 51, 3361–3375. [Google Scholar] [CrossRef]

- Zhao, Y.; Song, H.; Liu, S.; Zhang, C.; Dou, L.; Cao, A. Mechanical anisotropy of coal with considerations of realistic microstructures and external loading directions. Int. J. Rock Mech. Min. Sci. 2019, 116, 111–121. [Google Scholar] [CrossRef]

- Zhou, S.; Liu, D.; Cai, Y.; Yao, Y.; Li, Z. 3D characterization and quantitative evaluation of pore-fracture networks of two Chinese coals using FIB-SEM tomography. Int. J. Coal Geol. 2017, 174, 41–54. [Google Scholar] [CrossRef]

- Akhondzadeh, H.; Keshavarz, A.; Al-Yaseri, A.Z.; Ali, M.; Awan, F.U.R.; Wang, X.; Yang, Y.; Iglauer, S.; Lebedev, M. Pore-scale analysis of coal cleat network evolution through liquid nitrogen treatment: A Micro-Computed Tomography investigation. Int. J. Coal Geol. 2020, 219, 103370. [Google Scholar]

- Keishanu, B.; Jyotirmoy, M. An optimum solution for coal permeability estimation from mesoscopicscale calibrated stochastic and deterministic discrete fracturenetwork models. Fuel 2023, 331, 125620. [Google Scholar]

- Mohammad, E.; Denis, O.; Vladislav, A.; Alexander, B.; Vladislav, K.; Dmitry, K. Lift the veil of secrecy in sub-resolved pores by Xe-enhanced computed tomography. Fuel 2022, 328, 125274. [Google Scholar]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar]

- Zhao, Y.; Huang, J.; Wang, R. Real-time SEM observations of the microfracturing process in rock during a compression test. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1993, 30, 643–652. [Google Scholar] [CrossRef]

- Zhao, Y. Crack pattern evolution and a fractal damage constitutive model for rock. Int. J. Rock Mech. Min. Sci. 1998, 35, 349–366. [Google Scholar] [CrossRef]

- Paliwal, B.; Ramesh, K.T. An interacting micro-crack damage model for failure of brittle materials under compression. J. Mech. Phys. Solids 2008, 56, 896–923. [Google Scholar] [CrossRef]

- Tang, C.A.; Liu, H.; Lee, P.K.; Tsui, Y.; Tham, L. Numerical studies of the influence of microstructure on rock failure in uniaxial compression—Part I: Effect of heterogeneity. Int. J. Rock Mech. Min. Sci. 2000, 37, 555–569. [Google Scholar] [CrossRef]

- Tang, C.A.; Lin, P.; Wong, R.H.C.; Chau, K.T. Analysis of crack coalescence in rock-like materials containing three flaws—Part II: Numerical approach. Int. J. Rock Mech. Min. Sci. 2001, 38, 925–939. [Google Scholar] [CrossRef]

- Chen, W.; Konietzky, H. Simulation of heterogeneity, creep, damage and lifetime for loaded brittle rocks. Tectonophysics 2014, 633, 164–175. [Google Scholar] [CrossRef]

- Wang, J.C.; Wang, Z.H.; Yang, S.L. A coupled macro- and meso-mechanical model for heterogeneous coal. Int. J. Rock Mech. Min. Sci. 2017, 94, 64–81. [Google Scholar] [CrossRef]

- De Bellis, M.L.; Pandolf, A. Applications of a micro-structured brittle damage model to laboratory tests on rocks. Int. J. Fract. 2022, 238, 57–69. [Google Scholar] [CrossRef]

- Kishan, R.K.; Hadi, H. Multiscale simulation of inelastic creep deformation for geological rocks. J. Comput. Phys. 2021, 440, 110439. [Google Scholar]

- Konietzky, H.; Heftenberger, A.; Feige, M. Life-time prediction for rocks under static compressive and tensile loads: A new simulation approach. Acta Geotech. 2009, 4, 73–78. [Google Scholar] [CrossRef]

- Li, X.; Huai, Z.; Konietzky, H.; Li, X.; Wang, Y. A numerical study of brittle failure in rocks with distinct microcrack characteristics. Int. J. Rock Mech. Min. Sci. 2018, 106, 289–299. [Google Scholar] [CrossRef]

- Shi, F.; Liu, J.S. A fully coupled hydromechanical XFEM model for the simulation of 3D non-planar fluid-driven fracture propagation. Comput. Geotech. 2021, 132, 103971. [Google Scholar] [CrossRef]

- Lan, H.X.; Martin, C.D.; Hu, B. Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J. Geophys. Res. Solid Earth 2010, 115, B01202. [Google Scholar] [CrossRef]

- Potyondy, D.O. A grain-based model for rock: Approaching the true microstructure. In Proceedings of the Rock Mechanics in the Nordic Countries, Kongsberg, Norway, 9–12 June 2010. [Google Scholar]

- Gao, F.Q.; Stead, D.; Coggan, J. Evaluation of coal longwall caving characteristics using an innovative UDEC Trigon approach. Comput. Geotech. 2014, 55, 448–460. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.H.; Yang, S.L.; Tang, Y.S. Mechanical behavior of different sedimentary rocks in the Brazilian test. Bull. Eng. Geol. Environ. 2020, 79, 5415–5432. [Google Scholar] [CrossRef]

- Ivars, D.M.; Pierce, M.T.; Darcel, C.; Reyes-Montes, J.; Potyondy, D.O.; Young, R.P.; Cundall, P.A. The synthetic rock mass approach for jointed rock mass modelling. Int. J. Rock Mech. Min. Sci. 2011, 48, 219–244. [Google Scholar] [CrossRef]

- Marilyn, S.; Mohammad, A.; Antoine, N.; Fabrice, E.; Christian, G.; Annette, E.F. DEM modeling of biocemented sand: Influence of the cohesive contact surface area distribution and the percentage of cohesive contacts. Comp. Geotech. 2022, 149, 104860. [Google Scholar]

- Nazanin, M.M.; Ardakani, A.M.; Noorzad, A. Experimental and numerical studies of a three-dimensional bonded contact model of cemented granular soils. Comp. Part. Mech. 2022. [Google Scholar] [CrossRef]

- Mostafa, A.; Saeed, K.; Javad, K.; Taghi, S.; Sanaz, V.; Hossaini, M.F. Mechanical behavior of single-flawed cylindrical specimens subjected to axial loading: A numerical investigation. Bull. Eng. Geol. Environ. 2022, 81, 442. [Google Scholar]

- Turichshev, A.; Hadjigeorgiou, J. Experimental and numerical investigations into the strength of intact veined rock. Rock Mech. Rock Eng. 2015, 48, 1897–1912. [Google Scholar] [CrossRef]

- Turichshev, A.; Hadjigeorgiou, J. Triaxial compression experiments on intact veined andesite. Int. J. Rock Mech. Min. Sci. 2016, 86, 179–193. [Google Scholar] [CrossRef]

- Yang, S.Q.; Tian, W.L.; Huang, Y.H.; Ranjith, P.G.; Ju, Y. An experimental and numerical study on cracking behavior of brittle sandstone containing two non-coplanar fissures under uniaxial compression. Rock Mech. Rock Eng. 2015, 49, 1497–1515. [Google Scholar] [CrossRef]

- Yang, S.Q.; Huang, Y.H.; Tian, W.L.; Yin, P.F.; Jing, H.W. Effect of high temperature on deformation failure behavior of granite specimen containing a single fissure under uniaxial compression. Rock Mech. Rock Eng. 2019, 18, 1725. [Google Scholar]

- Gomar, M.; Goodarznia, I.; Shadizadeh, S.R. Fully coupled analysis of interaction between the borehole and pre-existing fractures. Int. J. Rock Mech. Min. Sci. 2016, 89, 151–164. [Google Scholar] [CrossRef]

- Fu, J.W.; Chen, K.; Zhu, W.; Zhang, X.; Li, X. Progressive failure of new modelling material with a single internal crack under biaxial compression and the 3-D numerical simulation. Eng. Fract. Mech. 2016, 165, 140–152. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, L.; Elsworth, D. Uniaxial strength and failure in sandstone containing a pre-existing 3-D surface flaw. Int. J. Fract. 2015, 194, 59–79. [Google Scholar] [CrossRef]

- Gao, F.Q.; Kang, H.P. Effects of pre-existing discontinuities on the residual strength of rock mass–Insight from a discrete element method simulation. J. Struct. Geol. 2016, 85, 40–50. [Google Scholar] [CrossRef]

- Wang, J.C.; Wang, Z.H.; Yang, J.; Tang, Y.S.; Li, B.B.; Meng, Q.B. Mining-induced stress rotation and its application in longwall face with large length in kilometer deep coal mine. J. China Coal Soc. 2020, 45, 876–888. [Google Scholar]

- Liu, X.S.; Tan, Y.L.; Ning, J.G.; Lu, Y.W.; Gu, Q.H. Mechanical properties and damage constitutive model of coal in coal-rock combined body. Int. J. Rock Mech. Min. Sci. 2018, 110, 140–150. [Google Scholar] [CrossRef]

- Mohammadi, H.; Pietruszczak, S. Description of damage process in fractured rocks. Int. J. Rock Mech. Min. Sci. 2019, 113, 295–302. [Google Scholar] [CrossRef]

| Sample Number | Tangent Modulus (GPa) | Secant Modulus (GPa) | Initial Yield Stress (MPa) | UCS (MPa) |

|---|---|---|---|---|

| N1 | 3.9 | 3.7 | 25.0 | 26.2 |

| N2 | 3.4 | 2.4 | 18.0 | 19.5 |

| N3 | 3.7 | 2.8 | 14.6 | 16.1 |

| Material Properties | Elastic Modulus (GPa) | Poisson’s Ratio | Internal Cohesion (MPa) | Friction Angel (°) | Tensile Strength (MPa) | Softening Model Parameters | ||

|---|---|---|---|---|---|---|---|---|

| m | k | n | ||||||

| Coal | 3.2 | 0.30 | 12 | 36 | 6.0 | 0.00025 | 0.1 | 500 |

| Mineral | 5.0 | 0.28 | 15 | 42 | 7.5 | 0.00016 | 0.3 | 800 |

| Fracture | 0.8 | 0.32 | 0 | 28 | 0 | -- | -- | -- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Sun, W.; Shui, Y.; Liu, P. Computed Tomography Observation and Image-Based Simulation of Fracture Propagation in Compressed Coal. Energies 2023, 16, 260. https://doi.org/10.3390/en16010260

Wang Z, Sun W, Shui Y, Liu P. Computed Tomography Observation and Image-Based Simulation of Fracture Propagation in Compressed Coal. Energies. 2023; 16(1):260. https://doi.org/10.3390/en16010260

Chicago/Turabian StyleWang, Zhaohui, Wenchao Sun, Yanting Shui, and Pengju Liu. 2023. "Computed Tomography Observation and Image-Based Simulation of Fracture Propagation in Compressed Coal" Energies 16, no. 1: 260. https://doi.org/10.3390/en16010260

APA StyleWang, Z., Sun, W., Shui, Y., & Liu, P. (2023). Computed Tomography Observation and Image-Based Simulation of Fracture Propagation in Compressed Coal. Energies, 16(1), 260. https://doi.org/10.3390/en16010260