Investigation of Stress Sensitivity of Shale Nanopores via a Nuclear Magnetic Resonance Method

Abstract

1. Introduction

2. Experimental Materials and Methods

2.1. Samples Description

2.2. Experimental Methods

- The shale core samples were dried in a vacuum oven at 60 °C for 24 h, and the basic physical parameters of the cores, including length, diameter, weight and porosity, were measured;

- The cores were put into 8% KCl solution under a liquid solution pressure of 15 MPa for 12 h and were then taken out. It should be noted that the value of 15 MPa was determined based on the in situ formation pressure of the shale gas reservoir;

- The saturated cores were wrapped with plastic wrap and were then put into the core holder. Under constant temperature and humidity conditions, confining pressure values of 0 MPa, 6 MPa, 17 MPa and 35 MPa were applied to the core by a confining pressure pump. It should be noted that the loading time of each effective stress was 12 h and the confining pressure was equal to the effective stress in the experiment;

- After the effective stress loading experiment, the core was removed. After gently wiping the surface water off the core sample, NMR measurements under different effective stress conditions were carried out quickly;

- The NMR experimental results were processed to obtain the relaxation time (T2) maps under different effective stress conditions.

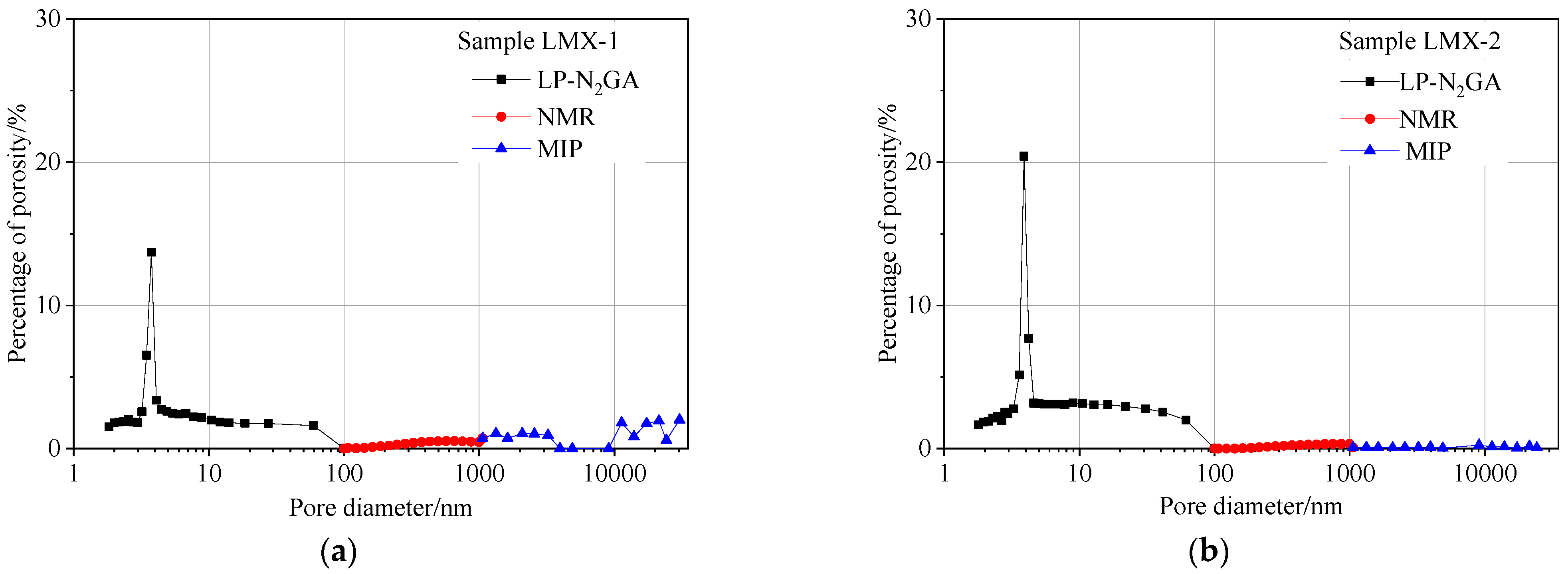

3. Results

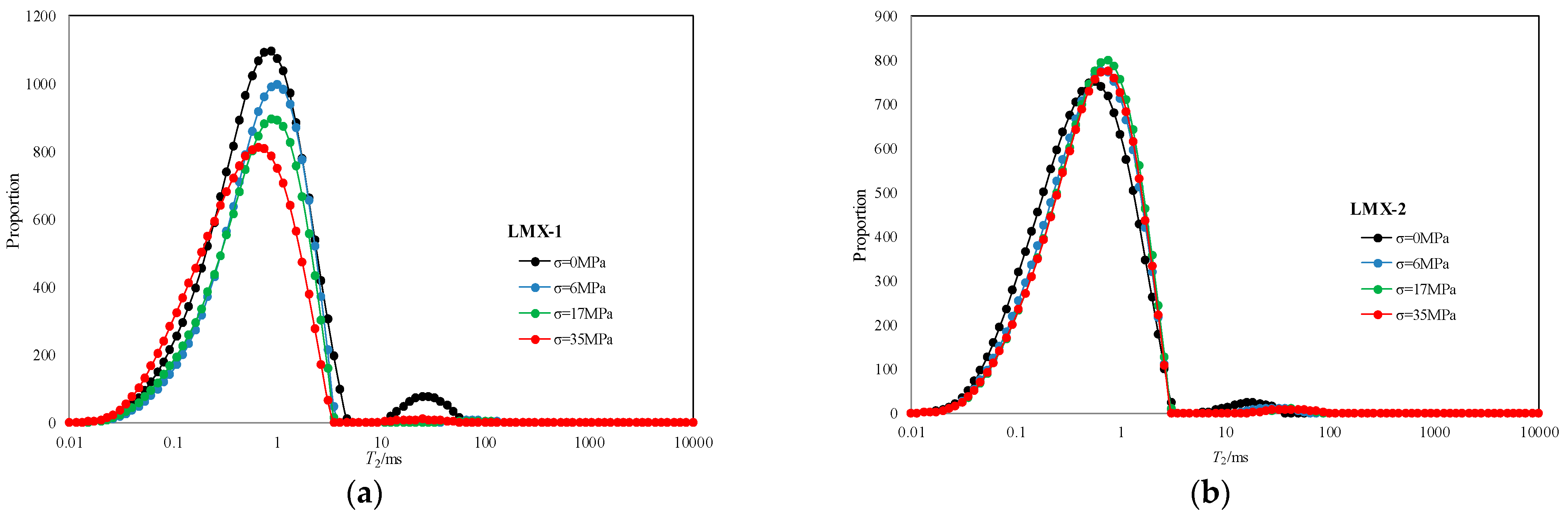

3.1. NMR Relaxation Time of Shale Samples under Different Effective Stresses

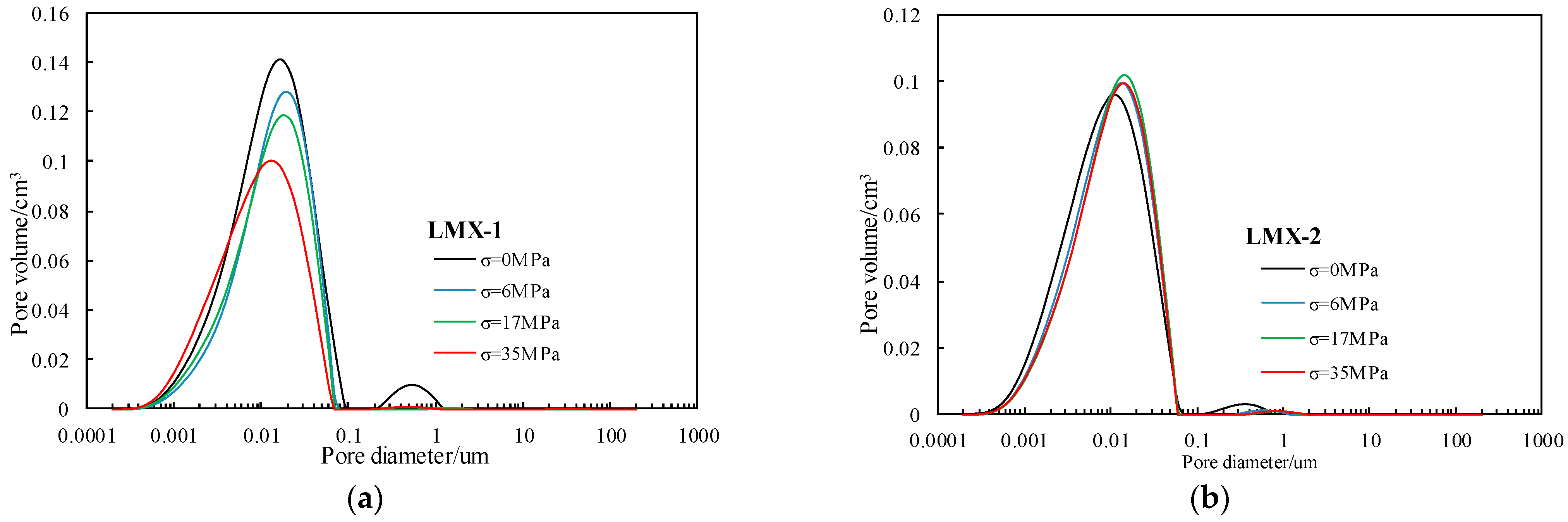

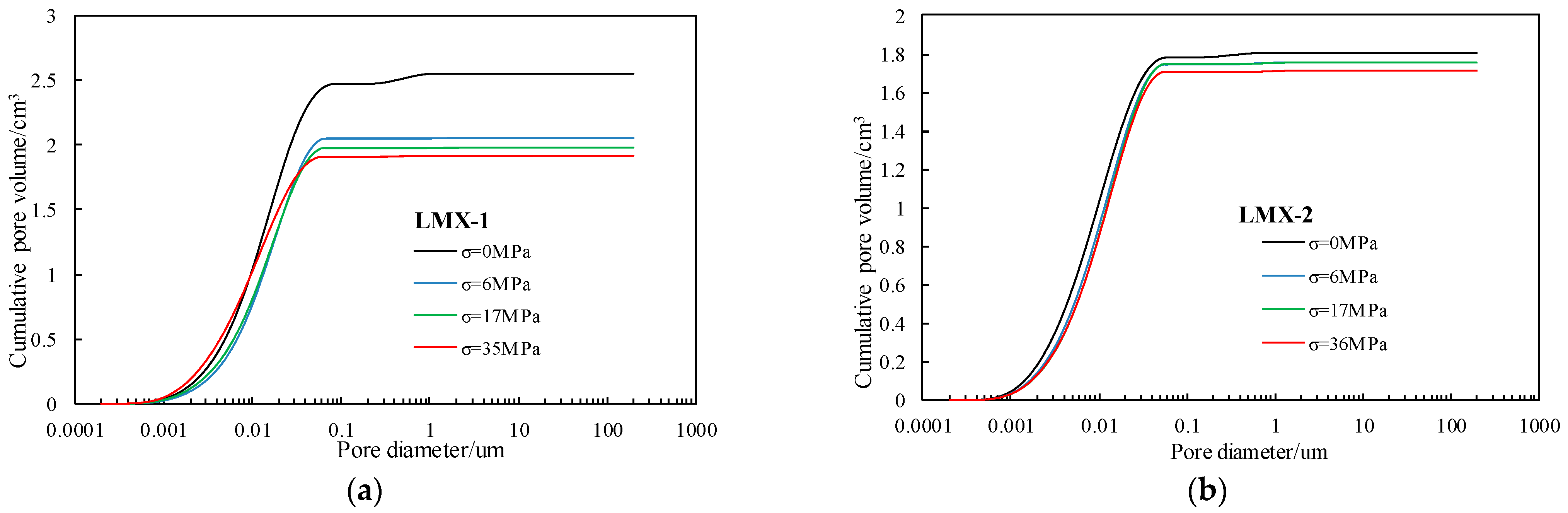

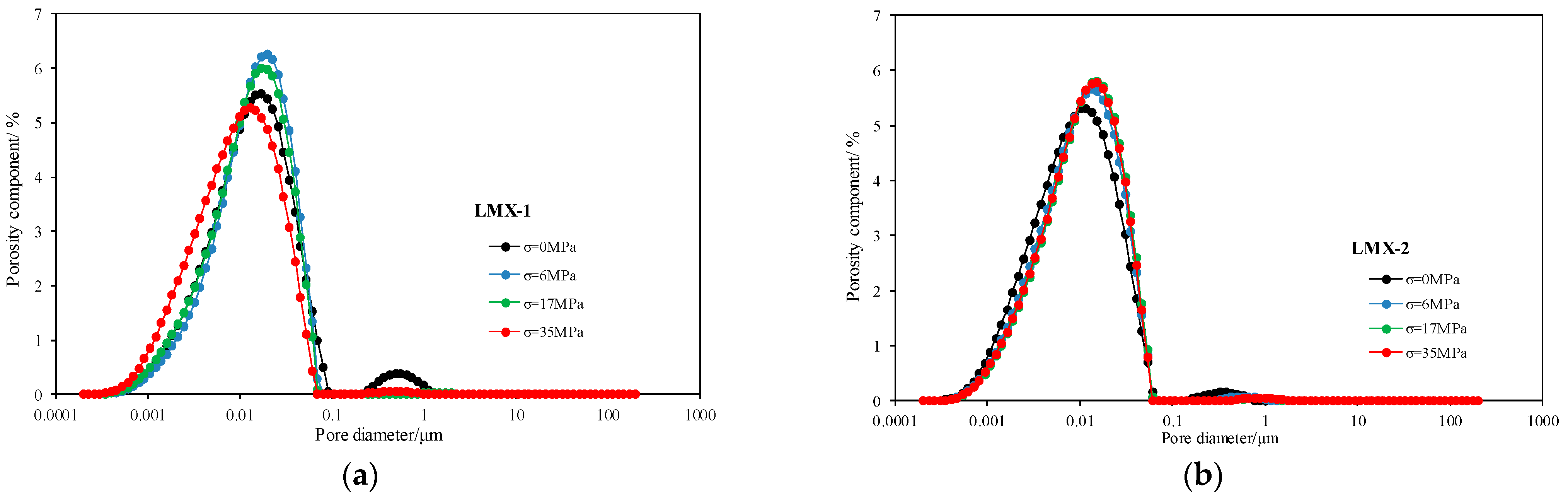

3.2. Nanoscale Shale Pore Size and Pore Volume Distribution under Different Effective Stresses

3.3. Change in Nanopore Volume in Different Pore Scale

4. Discussion

4.1. Stress Sensitivity of Multi-Scale Nanopores in Shale

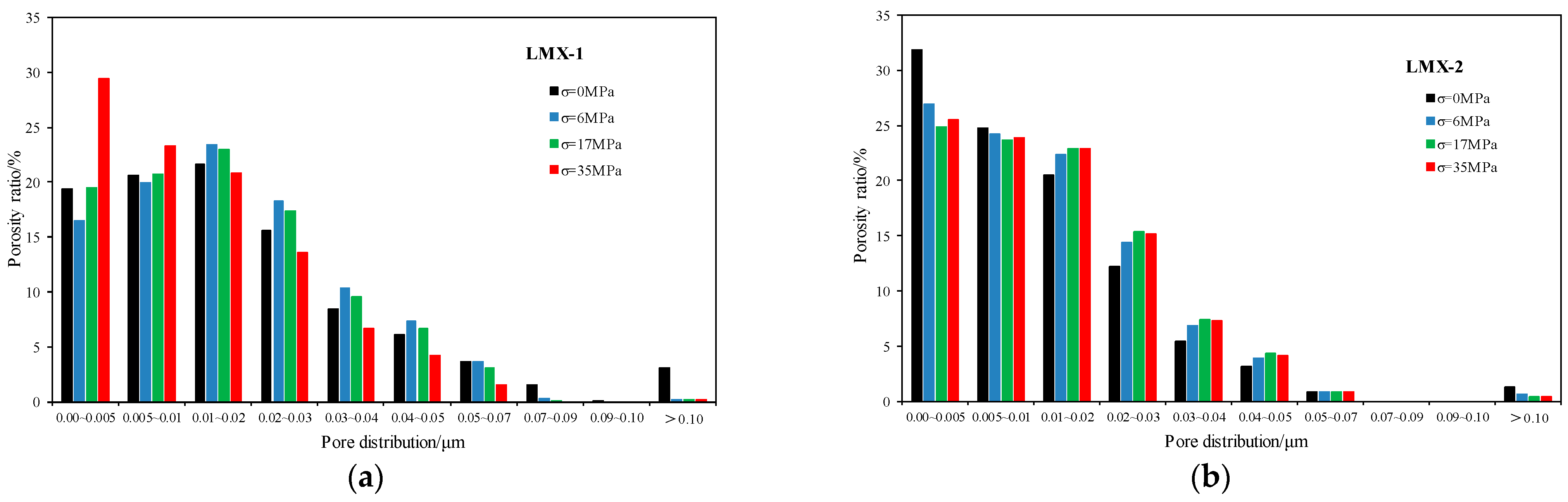

4.2. A Nanopore Division Method Based on the Variation in Porosity Proportion with Various Effective Stress

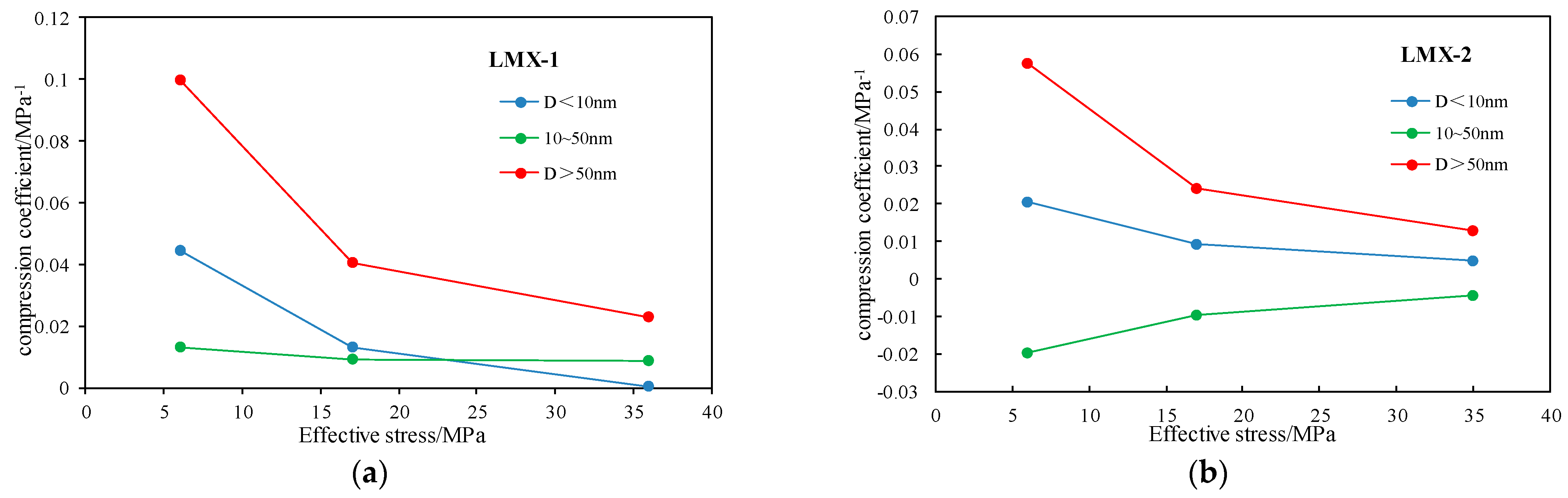

4.3. Variation Characteristics of the Compression Coefficient for Multi-Scale Nanopores under Different Effective Stresses

5. Conclusions

- (1)

- With the increase in the effective stress, the cumulative pore volume of shale decreases by 5.52–25.10%, and the pore space is continuously compressed. In terms of pore volume, during the effective stress loading process, the pore volume of shale decreases significantly in pores with diameters between 100 and 1000 nm. In the pores with diameters smaller than 100 nm, the pore volume of shale samples with natural fractures decreases with the increase in effective stress, while the pore volume of shale matrix samples increases.

- (2)

- When the effective stress is small, the pores with diameters between 10 and 50 nm can maintain the pore morphology better than those at other scales. With the continuous increase in the effective stress, the deformation of nanoscale pores tends to be stable. In terms of the pore-scale transformation, when the effective stress is small, the pores with diameters larger than 50 nm are mainly transformed to 10–50 nm diameter pores. When the effective stress increases to a certain extent, the pores with diameters between 10 and 50 nm are mainly transformed to those with diameters smaller than 10 nm.

- (3)

- The compression coefficients of nanopores of different scales under different effective stresses were calculated by NMR T2 maps. Shale with larger nanopores has a larger compression coefficient and a stronger stress sensitivity. With the increase in effective stress, the stress sensitivity of shale gradually lowers. Compared with other sized pores, the change in the compression coefficient of pores with diameters between 10 and 50 nm is relatively slow during effective stress loading, which can help maintain pore morphology.

- (4)

- Based on the variation characteristics of the porosity ratio with effective stresses for each pore distribution, a new method for dividing nanopores is proposed. According to the variation in porosity ratio with effective stress, the nanopores in shale can be divided into those with diameters smaller than 10 nm, those with diameters of 10–50 nm, and those with diameters larger than 50 nm.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zou, C.N.; Yang, Z.; Zhu, R.K.; Zhang, G.S.; Hou, L.H.; Wu, S.T.; Tao, S.Z.; Yuan, X.J.; Dong, D.Z.; Wang, Y.M.; et al. Progress in China's Unconventional Oil & Gas Exploration and Development and Theoretical Technologies. Acta Geol. Sin. 2015, 89, 979–1007. [Google Scholar]

- Duan, X.G.; Hu, Z.M.; Gao, S.S.; Shen, R.; Liu, H.X.; Chang, J.; Wang, L. Shale high pressure isothermal adsorption curve and the production dynamic experiments of gas well. Pet. Explor. Dev. 2018, 45, 119–127. [Google Scholar] [CrossRef]

- Tang, L.; Song, Y.; Jiang, Z.X.; Tang, X.L.; Li, Z.; Li, Q.W.; Chang, J.Q.; Sun, Y. Diffusion process and capacity of Longmaxi shale gas in the basin-margin transition zone of SE Chongqing and their controlling factors. Nat. Gas Ind. 2018, 38, 37–47. [Google Scholar]

- Su, Y.L.; Sheng, G.L.; Wang, W.D.; Zhan, S.Y.; Zhang, Q.; Lu, M.J.; Li, Y.J. Characterization methods for mass transfer of multiple media in shale gas reservoirs. Sci. Sin. (Technol.) 2018, 48, 510–523. [Google Scholar] [CrossRef][Green Version]

- Chen, M.J.; Kang, Y.L.; Zhang, T.S.; Chen, Z.X.; Wu, K.L. Characteristics of multiscale mass transport and coordination mechanisms for shale gas. Sci. Sin. (Technol.) 2018, 48, 473–487. [Google Scholar] [CrossRef]

- Chen, M.J.; Kang, Y.L.; Zhang, T.S.; Li, X.C.; Wu, K.L.; Chen, Z.X. Methane adsorption behavior on shale matrix at in-situ pressure and temperature conditions: Measurement and modeling. Fuel 2018, 228, 39–49. [Google Scholar] [CrossRef]

- Jiang, R.Z.; He, J.X.; Jiang, Y.; Fan, H.J.; Harold, V. Establishment and application of Blasingame production decline analysis method for fractured horizontal well in shale gas reservoirs. Acta Pet. Sin. 2019, 40, 1503–1510. [Google Scholar]

- Wang, X.Z.; Dong, F.; Li, X.F.; Yan, Y.K.; Guo, X.D.; Qiao, X.Y.; Xue, B.; Ma, C.; Wang, Q.B.; Lei, K.Y.; et al. Productivity evaluation of tight gas well with time-dependent mechanism: A case study of Yan'an gas field. Acta Pet. Sin. 2019, 40, 1358–1367. [Google Scholar]

- Chen, M.J.; Kang, Y.L.; Zhang, T.S.; You, L.J.; Li, X.C.; Chen, Z.X.; Wu, K.L.; Yang, B. Methane diffusion in shales with multiple pore sizes at supercritical conditions. Chem. Eng. J. 2018, 334, 1455–1465. [Google Scholar] [CrossRef]

- Wu, K.L.; Chen, Z.X.; Li, X.F.; Dong, X.H. Methane storage in nanoporous material at supercritical temperature over a wide range of pressures. Sci. Rep. 2016, 6, 33461. [Google Scholar] [CrossRef]

- Wu, K.L.; Li, X.F.; Guo, C.H.; Wang, C.C.; Chen, Z.X. A unified model for gas transfer in nanopores of shale-gas reservoirs: Coupling pore diffusion and surface diffusion. SPE J. 2016, 21, 1583–1611. [Google Scholar] [CrossRef]

- Tian, W.; Deng, R.J.; Zhu, W.Y.; Guo, D.B.; Li, Z.C.; Long, Y.Q.; Guo, Z.F. Stress sensitivity of shale reservoir fracture network and its effect on productivity. Reserv. Eval. Dev. 2017, 7, 71–77. [Google Scholar]

- Zhu, W.Y.; Ma, D.X. Effective stress characteristics in shale and its effect on productivity. Nat. Gas Geosci. 2018, 29, 845–852. [Google Scholar]

- Wang, F.P.; Reed, R.M. Pore networks and fluid flow in gas shales. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 4–7 October 2009. [Google Scholar]

- Zhang, R.; Ning, Z.F.; Yang, F.; Zhao, H.W. Shale stress sensitivity experiment and mechanism. Acta Pet. Sin. 2015, 36, 224–231. [Google Scholar]

- Zhang, R.; Ning, Z.F.; Yang, F.; Zhao, H.W.; Du, L.H.; Zhou, X. Experimental study of stress sensitivity of shale reservoirs. Chin. J. Rock Mech. Eng. 2015, 34, 2617–2622. [Google Scholar]

- Zhang, X.; Liu, C.; Zhu, Y.; Chen, S.; Wang, Y.; Fu, C. The characterization of a marine shale gas reservoir in the lower Silurian Longmaxi Formation of the northeastern Yunnan Province, China. J. Nat. Gas Sci. Eng. 2015, 21, 321–335. [Google Scholar] [CrossRef]

- Li, X.L.; Chen, S.J.; Wang, S.; Zhao, M.; Liu, H. Study on in situ stress distribution law of the deep mine taking Linyi Mining area as an example. Adv. Mater. Sci. Eng. 2021, 9, 5594181. [Google Scholar] [CrossRef]

- Dong, J.J.; Hsu, J.Y.; Wu, W.J.; Shimamoto, T.; Hung, J.H.; Yeh, E.C.; Wu, Y.H.; Sone, H. Stress-dependence of the permeability and porosity of sandstone and shale from TCDP Hole-A. Int. J. Rock Mech. Min. Sci. 2010, 47, 1141–1157. [Google Scholar] [CrossRef]

- Cui, X.J.; Bustin, R.M.; Brezovski, R.; Nassichuk, B.; Glover, K.; Pathi, V. A new method to simultaneously measure in-situ permeability and porosity under reservoir conditions: Implications for characterization of unconventional gas reservoirs. In Proceedings of the Canadian Unconventional Resources and International Petroleum Conference, Calgary, AL, Canada, 19–21 October 2010. [Google Scholar]

- Kassis, S.M.; Sondergeld, C.H. Fracture permeability of gas shale: Effects of roughness, proppant, fracture offset, and confining pressure. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 8–10 June 2010. [Google Scholar]

- Shao, J.X.; You, L.J.; Jia, N.; Kang, Y.L.; Chen, M.J.; Lei, X.W. Salt Crystal: Natural proppant for enhancing shale reservoir production. Energy 2023, 262, 125569. [Google Scholar] [CrossRef]

- Ambrose, R.J.; Hartman, R.C.; Diaz, C.M.; Akkutlu, I.Y.; Sondergeld, C.H. New pore-scale considerations for shale gas in place calculations. In Proceedings of the SPE Unconventional Gas Conference, Pittsburgh, PA, USA, 23–25 February 2010. [Google Scholar]

- Kang, Y.L.; Li, P.S.; Chen, M.J.; Fang, S.D.; Dai, C.; Liu, H.; You, L.J.; Liu, J. Enhancing porosity and permeability of shale matrix through supercritical water treatment. J. Nat. Gas Sci. Eng. 2022, 101, 104530. [Google Scholar] [CrossRef]

- Wang, H.J.; Ma, F.; Tong, X.G.; Liu, Z.D.; Zhang, X.S.; Wu, Z.Z.; Li, D.H.; Wang, B.; Xie, Y.F.; Yang, L.Y. Assessment of global unconventional oil and gas resources. Pet. Explor. Dev. 2016, 43, 850–862. [Google Scholar] [CrossRef]

- Wang, S.G.; Elsworth, D.; Liu, J.S. A mechanistic model for permeability evolution in fractured sorbing media. J. Geophys. Res. 2012, 117, B06205. [Google Scholar] [CrossRef]

- Liu, S.M.; Li, X.L.; Wang, D.K.; Zhang, D.M. Investigations on the mechanism of the microstructural evolution of different coal ranks under liquid nitrogen cold soaking. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–17. [Google Scholar] [CrossRef]

- Wang, X.M.; Liu, L.F.; Wang, Y.; Sheng, Y.; Zheng, S.S.; Wu, W.W.; Luo, Z.H. Comparison of the pore structures of Lower Silurian Longmaxi Formation shales with different lithofacies in the southern Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2020, 81, 103419. [Google Scholar] [CrossRef]

- He, S.; Qin, Q.; Li, H.; Zhao, S.X. Geological Characteristics of Deep Shale Gas in the Silurian Longmaxi Formation in the Southern Sichuan Basin, China. Front. Earth Sci. 2022, 9, 818155. [Google Scholar] [CrossRef]

- Xiong, J.; Li, Y.; Zhou, S.; Liu, X.; Han, H.; Liang, L.; Zhao, Z. Insights into the pore structure characteristics of the Lower Silurian Longmaxi Formation shale in the Jiaoshiba area, Southern Sichuan Basin, China. J. Petrol. Explor. Prod. Technol. 2022, 12, 2857–2868. [Google Scholar] [CrossRef]

- Sondergeld, C.; Tinni, A.; Rai, C.; Besv, A. NMR considerations in shale evaluation. In Proceedings of the SPWLA 57th Annual Logging Symposium, Reykjavik, Iceland, 25–29 June 2016. [Google Scholar]

- Zolfaghari, A.; Dehghanpour, H.; Xu, M. Water sorption behaviour of gas shales: II. Pore size distribution. Int. J. Coal Geol. 2017, 179, 187–195. [Google Scholar] [CrossRef]

- Sun, X.; Yao, Y.; Liu, D.; Zhou, Y. Investigations of CO2-water wettability of coal: NMR relaxation method. Int. J. Coal Geol. 2018, 188, 38–50. [Google Scholar] [CrossRef]

- Yang, Z.M.; Jiang, H.Q.; Zhou, R.X.; Zhu, G.Y.; Liu, X.W. Measurement research on irreducible water saturation in low-permeability water-cut gas reservoirs using NMR techniques. Oil Drill. Prod. Technol. 2008, 30, 56–59. [Google Scholar]

- Keelan, D.K.; Koepf, E.H. The role of cores and core analysis in evaluation of formation damage. J. Pet. Technol. 1977, 29, 482–490. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, Y.; Liu, D.; Zheng, S.; Sun, G.; Chang, Y. Shale pore size classification: An NMR fluid typing method. Mar. Pet. Geol. 2018, 96, 591–601. [Google Scholar] [CrossRef]

- Gu, Z.B.; Liu, W. The inversion of two-dimensional NMR map. Chin. J. Magn. Reson. 2007, 24, 311–319. [Google Scholar]

- Zhou, H.W.; Liu, Z.L.; Sun, X.T.; Ren, W.G.; Zhong, J.C.; Zhao, J.W.; Xue, D.J. Evolution characteristics of seepage channel during water infusion in deep coal samples. J. China Coal Soc. 2021, 46, 867–875. [Google Scholar]

- Ge, X.M.; Myers, M.T.; Liu, J.Y.; Fan, Y.R.; Zahid, M.A.; Zhao, J.E.; Hathon, L. Determining the transverse surface relaxivity of reservoir rocks: A critical review and perspective. Mar. Pet. Geol. 2021, 126, 104934. [Google Scholar] [CrossRef]

- Saidian, M.; Prasad, M. Effect of mineralogy on nuclear magnetic resonance surface relaxivity: A case study of Middle Bakken and Three Forks formations. Fuel 2015, 161, 197–206. [Google Scholar] [CrossRef]

- IUPAC (International Union of Pure and Applied Chemistry); Physical Chemistry Division Commission on Colloid and Surface Chemistry; Subcommittee on Characterization of Porous Solids. Recommendations for the characterization of porous solids (Technical Report). Pure Appl. Chem. 1994, 66, 1739–1758. [Google Scholar] [CrossRef]

| Number | Length/mm | Diameter/mm | TOC/wt% | Clay Mineral Content/% | Porosity/% | Permeability/mD |

|---|---|---|---|---|---|---|

| LMX-1 | 38.46 | 25.24 | 2.79 | 36.1 | 4.53 | 0.300 |

| LMX-2 | 38.12 | 25.20 | 2.66 | 38.0 | 3.94 | 0.080 |

| Effective Stress /MPa | Left Peak | Right Peak | ||||||

|---|---|---|---|---|---|---|---|---|

| Start Time/ms | Peak Time /ms | End Time /ms | Peak Ratio /% | Start Time/ms | Peak Time /ms | End Time /ms | Peak Ratio /% | |

| 0 | 0.01 | 0.76 | 4.64 | 96.88 | 10.72 | 28.48 | 57.22 | 3.12 |

| 6 | 0.01 | 1.00 | 3.51 | 99.80 | 32.75 | 75.65 | 132.19 | 0.20 |

| 17 | 0.01 | 0.87 | 3.51 | 99.79 | 28.48 | 65.79 | 132.19 | 0.20 |

| 35 | 0.01 | 0.67 | 3.05 | 99.51 | 9.32 | 24.77 | 57.22 | 0.49 |

| Effective Stress /MPa | Left Peak | Right Peak | ||||||

|---|---|---|---|---|---|---|---|---|

| Start Time/ms | Peak Time /ms | End Time /ms | Peak Ratio /% | Start Time/ms | Peak Time /ms | End Time /ms | Peak Ratio /% | |

| 0 | 0.01 | 0.57 | 3.05 | 98.73 | 6.14 | 18.78 | 37.65 | 1.27 |

| 6 | 0.01 | 0.66 | 3.05 | 99.41 | 12.33 | 28.48 | 57.22 | 0.59 |

| 17 | 0.01 | 0.75 | 3.05 | 99.57 | 18.74 | 43.28 | 75.65 | 0.43 |

| 35 | 0.01 | 0.75 | 2.66 | 99.52 | 18.74 | 43.28 | 86.97 | 0.48 |

| Pore Diameter | LMX-1 Pore Volume (cm3) | LMX-2 Pore Volume (cm3) | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 MPa | 6 MPa | 17 MPa | 36 MPa | 0 MPa | 6 MPa | 17 MPa | 36 MPa | |

| 0~2 nm | 0.1253 | 0.0831 | 0.1026 | 0.1311 | 0.1648 | 0.1275 | 0.1184 | 0.1169 |

| 2~50 nm | 2.2121 | 1.8784 | 1.8090 | 1.8042 | 1.6008 | 1.5994 | 1.5811 | 1.5757 |

| >50 nm | 0.2118 | 0.0850 | 0.0669 | 0.0357 | 0.0387 | 0.0253 | 0.0227 | 0.0207 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, M.; Lai, Z.; Kang, Y.; Fang, S.; Liu, H.; Wang, W.; Shen, J.; Chen, Z. Investigation of Stress Sensitivity of Shale Nanopores via a Nuclear Magnetic Resonance Method. Energies 2023, 16, 138. https://doi.org/10.3390/en16010138

Chen M, Lai Z, Kang Y, Fang S, Liu H, Wang W, Shen J, Chen Z. Investigation of Stress Sensitivity of Shale Nanopores via a Nuclear Magnetic Resonance Method. Energies. 2023; 16(1):138. https://doi.org/10.3390/en16010138

Chicago/Turabian StyleChen, Mingjun, Zhehan Lai, Yili Kang, Sidong Fang, Hua Liu, Weihong Wang, Jikun Shen, and Zhiqiang Chen. 2023. "Investigation of Stress Sensitivity of Shale Nanopores via a Nuclear Magnetic Resonance Method" Energies 16, no. 1: 138. https://doi.org/10.3390/en16010138

APA StyleChen, M., Lai, Z., Kang, Y., Fang, S., Liu, H., Wang, W., Shen, J., & Chen, Z. (2023). Investigation of Stress Sensitivity of Shale Nanopores via a Nuclear Magnetic Resonance Method. Energies, 16(1), 138. https://doi.org/10.3390/en16010138