Abstract

Increasingly, the exploitation of buildings involves the need for comprehensive management of all systems operating within it, their continuous monitoring, both for the safety of users and to mainly optimize the operating parameters of systems that are largely dependent on each other, interact with each other. This is mainly associated with the need for the most energy-efficient management of energy consumption, which has the largest share of operating costs. The main cost for the facilities is the cooling aspect, which is significant, and for this reason, it is necessary to analyze the possibility of its minimization. One of the possible systems to consider in order to reduce the consumption of cooling energy in the facility is the application of free-cooling technology, which is based on the use of the natural cooling capacity of the outside air for cooling rooms with high heat gains. The application of the free cooling system for facilities with a relatively stable cooling load, with significant heat gains from equipment is justified due to the possibility of maintaining low room temperatures, below the comfort value for people, for a long period of time. The problem arises when a large proportion of the heat gains are from people. In such a situation, cooling of rooms is possible but requires a large amount of ventilation air, which is already a serious limitation on the one hand because of the existing air conditioning equipment, lack of possibility to increase the ventilation air stream; on the other hand, the low heat capacity of the air itself, compared to, e.g., water systems used for cooling of the facility or multisplit systems. These limitations put a question mark over the possibility of adapting the technology of free cooling for the existing facilities, where the majority of heat gains come from people. It is not possible in such objects to lower the room temperature below the limit values for the sake of thermal comfort, which in itself limits the possibilities of using air as a natural cooling agent in such objects. Based on the measurement data obtained from the object, it was decided to check the possibilities of applying free-cooling technology in a large shopping facility and obtaining an answer as to what extent it is possible to reduce the power of cooling units with the application of free-cooling exchangers.

1. Introduction

The free-cooling system is used mainly where heat gains in a given facility are significant throughout the year. Such facilities include, among others: server rooms, shopping centers, cinemas, mines, and industrial plants [1,2]. It should be noted that currently, there are many facilities of this type, in which, during the period of low outside temperature, there are large heat gains inside the facility, mainly sports and recreation facilities, sports and entertainment centers, and conference centers. The use of this system is also associated with a significant increase in investment expenses incurred for the purchase of chillers equipped with a free-cooling system, mainly due to the need to equip the system with additional free-cooling coolers or a chiller bypass system [3,4,5,6,7]. The applicability of free cooling is strongly dependent on the amount of heat gains in the room and on the temperature of the outside air. Because the system works in the period when the outside air temperature is low enough to cool the cooling water or air in the room, therefore, in the room the appropriate heat gains that are necessary to remove despite the relatively low temperature outside air must be generated. This is a situation that significantly limits the possibility of using this type of system for a month-two maximum, assuming the operation of the air conditioning system several hours a day [1,8,9,10,11,12]. Due to the relatively high costs of cold production by compressor chillers, the use of a system that allows the use of outdoor air cooling capacity allows for a very quick return on the costs of additional investments, which, depending on the intensity of use of the facility, may vary from 6 months in the center’s hotel and conference type, and mines up to several years in smaller facilities such as cinemas, sports, and entertainment facilities. This largely contributes to the popularization of this type of solution, especially in existing facilities and, in principle, for all newly designed facilities, mainly due to the much smaller carbon footprint of this type of solution and much lower operating costs of expensive refrigeration installations. A shopping mall is not an object in which one could, with a high degree of certainty, expect to obtain significant results associated with the application of a free-cooling system (except for rooms such as cinemas, training rooms, generally with a large number of people—large heat gains, without external windows). The analyzed case was to illuminate the possibility of adopting the solution also on a larger scale in this type of object.

The authors took up the subject of analyzing this type of object because of its nature, indicating small possibilities in free-cooling. In addition, a considerable amount of data was available from the facilities to conduct such an analysis. The thesis of the research is the possibility of adaptation of the free-cooling system for commercial facilities with significant variability of the heat load resulting from the presence of persons (large-area commercial facilities). While the application of this system in objects with high internal heat gains such as cinemas, server rooms, and mines is not questioned, in objects with a varied heat load schedule, it is always a matter requiring deeper analysis. In this paper, it was pointed out that such solutions can be successfully applied in such objects with significant economic benefits, which were analyzed in the paper. It was shown that the energy benefits make it possible to reduce the cooling capacity to a lesser extent than is assumed for free-cooling systems, e.g., by equipment manufacturers, but it is possible even in such non-obvious cases as the one analyzed.

2. Principles of Free-Cooling Systems

One of the simplest systems using the phenomenon of natural use of the cooling capacity of outdoor air is the direct free-cooling system. This system consists of using outside air directly to cool air-conditioned rooms. This solution is used in modular air handling units or monoblock air conditioning units that prepare primary air in systems with two-stage air treatment. In control panels consisting of individual modules, the free cooling function is realized through a mixing chamber in which the proportion of outside air up to 100% in the supply air is increased by appropriate control of the fresh and recirculating air dampers (to maximize cold in the external air) [13,14,15]. The increased amount of fresh outside air is maintained at the maximum level only for a certain time when conditions are induced to occur that are conducive to the implementation of the free-cooling process. After reaching the required cooling of the room with the use of outdoor air (during this period, the cooling production system from chilled water chillers is turned off), the room ventilation system gradually returns to the default settings until the minimum outdoor airflow, necessary for hygienic or technological purposes, is achieved. The period of time during which the free-cooling process is possible depends mainly on internal heat gains. Objects with the highest possible heat gains are desirable, or objects where internal heat gains are relatively high, constant over time and independent of the outside air temperature. These can be buildings or rooms without windows, well-insulated thermally, with a large number of people or other sources of internal heat. In the remaining time, the dampers are set to the minimum fresh air. The microprocessor controller is responsible for the proportions determined by individual air flows in the supply air, which, based on ambient temperature sensors and a special control algorithm (economizer), makes the optimal setting of the angle of throttles on the outside air duct and the exhaust ventilation duct.

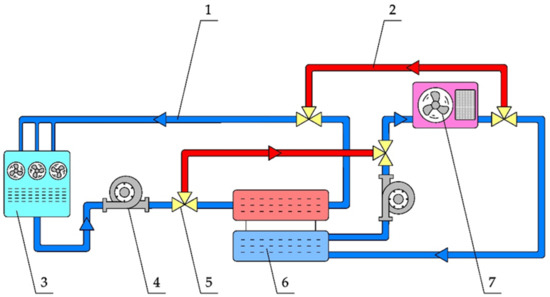

In monoblock air conditioning units preparing primary air, due to operation with 100% fresh air, the free-cooling function is performed by deactivating the compressor refrigeration system at low outside air temperatures, allowing one to obtain the desired supply air temperature behind the central unit without system operation refrigerant. The second possible type of use of cold contained in the outside air is so-called “indirect free-cooling”, which enables the cooling of the internal air by means of an intermediate medium that allows the exchange of heat between the occupation zone of a relatively large amount of heat gains and ambient air at low temperature. The intermediate liquid, most often in the form of an aqueous glycol solution 1, receives heat from the air on the free-cooling exchangers or on a cooling tower (depending on the size, power of the system, and the technological solution used) 3, then the liquid is transported by pumps 4 through the bypass of the cooling aggregate 2 to the system of coolers 7, where the heat from the object is collected; thus, the outside air indirectly cools the air in the room (Figure 1). It is one of the most interesting solutions, enabling easy adaptation of intimate chilled water systems based on compressor and absorption chilled water production systems with water-cooled condensers in a closed system on both dry and evaporative cooling towers. This mainly applies to systems with higher powers from 500 kW upwards, where the existing technical infrastructure and installation equipment allow for a slight interference in the system (in this case, the installation of a bypass on a chiller). In systems based on air-cooled condensers, greater interference in the system will be required due to the need to ensure the cooling of process water from air coolers in air conditioning on specially dedicated free-cooling exchangers. From the existing solutions, it can be seen that both solutions are economically very profitable, taking into account the above-mentioned facilities. With increasing standards in terms of thermal comfort in buildings, where the customer has the ability to set the internal temperature at any level throughout the year, and such situations are already commonplace in winter, when rooms heated by the central heating system are simultaneously air-conditioned at the same time by an independent air conditioning system, to which the user has the possibility of greater intervention compared to the centralized heating system. Hence, the need to cool the facility may occur practically throughout the year, due to very individual preferences regarding the level of comfort inside rooms for various purposes located within one facility (hotel rooms, conference rooms, swimming pools, sports halls, gyms, etc.). Therefore, the question of the profitability of using a free-cooling solution in both adapted and new air conditioning systems is beyond question.

Figure 1.

Schema of the ice water production unit with free cooling system: 1, ice-water circulation; 2, free-cooling circulation; 3, cooling tower; 4, pump; 5, three-way valve; 6, chiller; 7, air conditioning unit.

Figure 2 shows the air cooling water transformations in the free-cooling process. The pressure drops in the pipes are negligible in comparison with the other transformations. In principle, according to Figure 1, the free-cooling exchanger (7) with a water circuit in a closed system cooled by external air Tz is able to dissipate all the heat gained at the water cooler (3) and a small amount of heat supplied by the circulation pumps. If it is necessary to run the chiller (6) according to Figure 1, Section 1 and Section 2 will be divided according to the proportion of the extracted cooling from free-cooling (transformation 1-x in Figure 2) and the transformation occurring at the chiller (transformation x-2 in Figure 2).

Figure 2.

Transformation of cooling water during the free-cooling process according to Figure 1.

Air conditioning systems that require the preparation of refrigerated water at a certain temperature usually use compressor chillers to cool it down. The use of low-temperature outdoor air to cool the intermediate liquid without interfering with the compressor refrigeration system brings tangible financial benefits associated with lower operating costs and also increases the value of the facility due to the higher efficiency of the systems operating in it. The intermediate liquid may be the water supplying the cold receivers, such as fan coil units, chilled beams, etc. Another medium may be a refrigerant (carrier solution). Due to the fact that the free cooling process is carried out only at the temperature of the outside air lower than the return temperature from the installation, free cooling is often carried out with the participation of compressor chillers. Mechanically, the free-cooling solution is to some extent related to the operation of the unit; for this reason, we can distinguish the following variants of free-cooling to medium-sized:

- Solution in the form of an additional free-cooling exchanger with a three-way control valve, as optional equipment for a monoblock chiller;

- Solution in the form of an indirect exchanger, glycol pump, and an additional free-cooling exchanger (cooperating with a compressor cold water unit);

- Solution without an additional free-cooling exchanger, using the typical refrigeration system of the refrigeration unit and the refrigerant pump working during the compressor’s standstill and in favorable conditions for the process of cooling the liquid by means of low-temperature air (solution used by the carrier);

- Other solutions, for example, using a “free-cooler”, or dry-cooler, whose task is to cool the liquid in the system through cold air.

The dry cooler that realizes the free cooling process can be used in solutions where monoblock refrigeration units with a liquid-cooled condenser are used, as well as in monoblock aggregates with an air-cooled condenser. In the case of aggregates with a liquid-cooled condenser in periods of high outside air temperatures, the dry-cooler dissipates heat from the condensers during the production of cooling power, while during low outside air temperatures, the dry cooler performs the function of a free cooler, that is, devices that, at the expense of power consumption of only fan motors, allow the liquid to cool to the desired temperature [6,7,16]. In the case of monoblock chillers with an air-cooled condenser, the dry cooler can be used as a precooling device to the desired temperature, while further cooling can be carried out on the evaporator of the chiller [7,17].

3. Analysis of System Operation Using Free Cooling

The demand for cooling energy was calculated for the adopted object, which is the building of the type of shopping center. Due to the properties of the rooms used, it is a facility that meets the requirements for facilities where it is possible to use free-cooling-based cooling. In such a facility, there are numerous rooms with a small window area and, therefore, with small session fluctuations in terms of internal heat gains. In addition, there is a large group of recreational rooms such as sports halls, fitness, gym, aerobics, and also multi-cinema rooms. It is a facility that is characterized by a large number of people and large gains of internal heat, well thermally insulated, which results in the need to discharge heat gains also in periods with a relatively low temperature of the outside air. Indoor and outdoor air parameters were adopted in accordance with applicable standards in this regard. The internal temperature in the summer period was set at 21 °C, while the outside temperature is assumed to be variable, depending on the period of the year under consideration, based on statistical data representing the Podkarpacie region from the Rzeszów-Jasionka meteorological station. 14:00 in July was assumed as the calculation hour. This is the time when the internal and external heat gains in the facility reach their maximum value. Based on the maximum heat gains, the amount of ventilation air was determined at 1,076,630 m3/h, which corresponds to a cooling capacity of 3473 kW. In the analyzed case, the air-conditioning units include heat recovery systems used in the summer to recover cold from the exhaust air with an efficiency of approximately 55%. Despite the cold recovery used to cool the air from an outside temperature of 29.5 °C (45% relative humidity) to 26.5 °C (at 7/12 °C temperature of cooling water), the cooling capacity has reached 3473 kW. For such assumptions, the demand for cooling energy was determined for each month, assuming that it depends on the enthalpy difference between indoor air enthalpy hp and outdoor air hz, which allows for obtaining satisfactory calculation results. Therefore, for the remaining months, this value depends approximately on the air parameters, according to the dependence:

where:

Qchmonth—demand for cold for a given month, kW

QchJuly—demand for cold for July, kW

ΔhJuly—enthalpy difference for cooling for the month of July read from the humid air graph, −15 kJ/kg

Δhmonth—difference in enthalpy for the radiator for a given month, kJ/kg, calculated as:

where:

hzmonth—average air enthalpy value for each month according to the meteorological station, kJ/kg

hch—enthalpy of the air after cooling, kJ/kg.

Cooling only occurs when the required air enthalpy in the room is less than the outdoor air enthalpy, hp < hz. On the basis of the average hourly demand for cold in particular months, the amount of seasonal monthly demand for cooling energy was determined.

where:

t—operating time of the cooling device (ventilation) in a month in hours, h.

For a statistical month, it was assumed on average that the refrigeration system operates daily for 12 h on weekdays and 10 h on Sunday, which in total defines the number of hours per month at the level of t = 26 × 12 + 4 × 10 = 352 h. The results of the calculations are presented in Table 1. The results presented in Table 1 show that the demand for energy for cooling occurs only in the summer months from May to September inclusive. In order to define the time frame in which it will be possible to use a free-cooling system, it is first necessary to determine the limits of use of the cooling system and the need to use cooling in the facility. It turns out that most of the cooling energy should be provided in August and July. During these months, the average air temperature outside the Tz average is lower than the temperature required in the building of 21 °C, therefore, it should be assumed that it is possible to use free-cooling systems to cool the rooms during the months that require cooling.

Table 1.

Cooling power for each month.

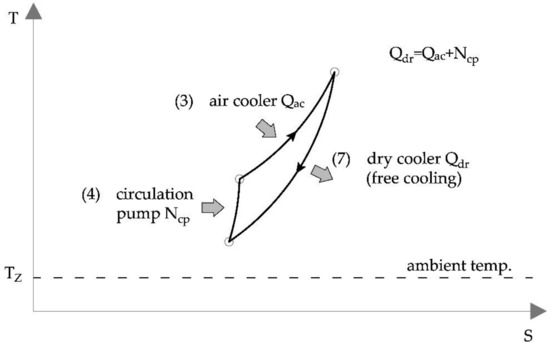

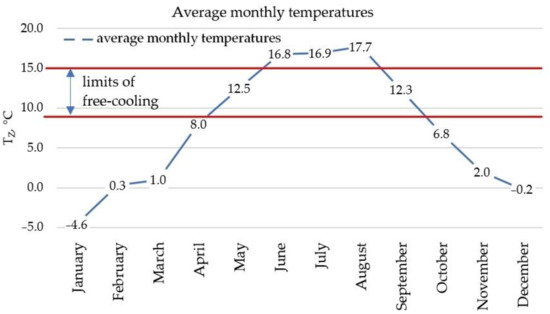

The cooling of the object is required if the supply air temperature is equal to the temperature after heat recovery in the counter-flow heat exchanger and stays until the supply air temperature equals the outdoor air temperature. Figure 3 shows the change of the characteristic air parameters in the facility on the operational diagram, which allows determining the values of characteristic temperatures in the air-conditioning system depending on the outside air temperature Tz.

Figure 3.

Diagram Tz-Tp for the analyzed circumstance of the building cooling load (Tch-end of cooling period temperature).

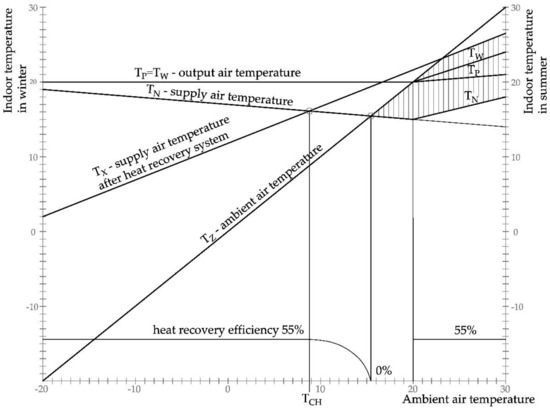

It was assumed that in summer, the chilled water would be cooled from 12 to 7 °C, while in the transition period, it would be from 15 to 9 °C. Therefore, the starting point for the free-cooling system is the equalization of the outdoor air temperature with the return temperature of the cooling water system during the transition period Tz < 15 °C. Additionally, during the winter period, the cooperation of the air conditioning system with the central heating installation was assumed by accepting the difference in temperature between the air in the room and the supply air at the temperature of ΔTwinter = 1 K. The possibility of obtaining cold from the outside air for the purpose of preparing cooling water for air in the air conditioning central unit during the transition period occurs only in the months of April, May, and September (Figure 4).

Figure 4.

Diagram of the temperature change due to months (Tz- ambient temperature).

The amount of seasonal power that is possible to obtain from the Qfc free-cooling system determines the dependence:

where:

Qchseason—seasonal consumption of cooling energy for months at an average temperature of 9 to 15 °C, kWh

ηfc—efficiency of the free-cooling system, %.

On this basis, the power values of the cooling system from the free-cooling system were determined. These amounts are summarized in Table 2. These values result from the hourly demand for energy for cooling, and thus from the temperature level in individual hours in the analyzed months, and not from the average temperature in the temperature itself, which exceeds the threshold related to the free-charge limit. Cooling, in this case, was set to 15 °C. The number of hours in individual months for which the outside temperature is below 15 °C is presented in Table 2. During these hours, it is possible to use the free-cooling system, while in the remaining hours, it will be necessary to turn on the cooling unit. The share of hours with a temperature below 15 °C to the total number of hours (taking into account the adopted schedule of 10 h of operation of the air-conditioning system during the day from 8 to 20) will also constitute the possibility of producing cold in the analyzed months. By convention, this relationship was defined as the share of ηfc free-cooling; its values are presented in Table 2.

Table 2.

Demand for free cooling power for the month.

Analyzing the data in Table 2, it can be seen that in the period with the highest demand for cooling energy for air conditioning, the free-cooling system can obtain small amounts, ranging from 12.9% in July, slightly more in August, to 25.0% in June. Over 60% can be obtained in the cooler months, i.e., May and September. During the cooling season, it is possible to obtain approx. 1.23 MWh of cooling energy from the free-cooling system, which constitutes a significant share of the total demand, reaching 26.6%. This is a very significant figure in the overall cooling energy demand. The efficiency of the free-cooling system (Equation (5)) determines the share of time during which it is possible to run the free-cooling process tfc in the period of individual months compared to the total time of operation of the system twork, assuming that during a day the system operates only for 10 h during the day, i.e., from 8 a.m. to 8 p.m.

ηfc = tfc/twork

Markings in the text above. For example, for the month of May, consisting of 31 days, the number of hours of operation of the system will be 31 days × 10 h of operation per day = 310 (twork) h of operation of the system in that month. On the basis of the data from the meteorological station Rzeszów-Jasionka [18], the time of operation of the free-cooling system has been determined, assuming that it will be possible only in a situation when it will be possible to sweeten the water cooling the room (the average temperature of rooms in summer is 21 °C) at least to a temperature lower by 7 K (such a difference is assumed to result from the possibility of carrying out effective cooling on the air-water exchanger during cooling). In this particular case, it means that only the hours from 8 a.m. to 8 p.m. when the air temperature is lower than 15 °C, tfc = 198 h.

4. Conclusions

Free-cooling systems should be used primarily in buildings with high internal heat gains, especially in the transition period, when the outside air temperature is lower than the required indoor temperature, but the heat gains generated in the facility cause a significant increase in the internal air temperature. According to the presented simplified analysis of the possibility of obtaining cold with the use of a free-cooling system for the analyzed object, the amount of cooling energy in the entire refrigeration season reaches a significant share, which is an interesting investment point of view. Taking into account only the period of months in which the system can operate, it covers about 26.6% of the total cooling demand in the consideration period, which may already be a certain alternative when it comes to the source of cold source, especially interesting due to its very low operating cost compared to traditional compressor refrigeration systems. The decision to use a free-cooling system should be additionally justified by using at least a preliminary analysis showing the impact of this type of system on reducing CO2 emissions and the costs that the user is able to save over the period of individual years, depending on the investment costs. The assumptions adopted for the calculations are presented below:

- 0.20 (Euro/kWh) average cost of electricity in industry;

- 344 (gCO2/kWh) average CO2 emissions from electricity production;

- Works 10 h per day, 365 days a year;

- SEER (seasonal energetic efficiency ratio) = 3.5 to 4.1 (the results will be discussed in this range);

- Seasonal cooling energy demand 4,624,194 kWh;

- cooling energy obtained from free cooling 1,229,524 kWh.

Thus, the seasonal demand for electricity for a system in which the cooling energy is fully covered by the cooling system with the assumed seasonal energy efficiency factor SEER will be from 1321 to 1128 MWh with the minimum assumed factor SEER. The variability between these values is 14.6%, therefore, the results for the SEER amounting to 3.5 (the weakest variant due to the highest electricity consumption) are presented in the further part of the analysis. It was also assumed that the system with a cooling unit consumes about 5% more energy due to the necessary operation of circulating pumps with chilled water, water cooling the condensers, and cooling towers. In the case of a free-cooling system, the electricity demand was assumed to be at the same level as that necessary to power the auxiliary Eadd devices with the chiller turned on. The results are summarized in Table 3.

Table 3.

Electricity consumption E, electricity costs K, and CO2 emission M for the analyzed free-cooling system for SEER = 3.5 for the total cooling season.

The use of a free-cooling system for a facility such as a shopping center with not too high gains of internal heat and assuming a very low SEER rate allows for real savings. As a result of the operation of the free-cooling system, it is possible to reduce the production of cold on chillers by 26.6%, and this, in turn, is associated with the possibility of reducing the costs associated with the use of electricity in the entire system by approx. 25.3% in costs expressed in money. Certainly, the indicator that should realistically make the investor aware of the actual impact of the installation with free-cooling will be the percentage value of reduced CO2 emissions into the atmosphere, which in the weakest variant reaches 25%. This solution allows to reduce the impact by nearly ¼, and with SEER at the level of 4.1 (this is the average value of this indicator for compression refrigeration systems) by 26.6%. These savings will be higher if we take into account buildings with more favorable parameters, such as sports and conference centers, server rooms, and mines. From this brief analysis, it can be seen that in a facility with a high proportion of human heat gain, it is justified to use a free cooling system. It should be noted that the achieved values of benefits related to the reduction of demand for cooling energy are not at the levels specified by manufacturers of cooling devices at the level of up to 40%, but much lower, which translates into noticeable savings in operating costs. Therefore, the application of free-cooling technology for already existing facilities of the type analyzed or of a similar purpose is justified from the economic point of view.

The above-presented short discussion of the possibility of using systems with free-cooling allows you to get a perspective on the further sustainable development of technologies based on the recovery of cold from the outside air and the financial and social benefits that are associated with it.

Author Contributions

Conceptualization, S.R. and K.N.; methodology, S.R. and K.N.; formal analysis, S.R. and K.N. resources, S.R. and K.N.; writing—original draft preparation, S.R. and K.N.; writing—review and editing, S.R. and K.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, H.; Shao, S.; Xu, H.; Zou, H.; Tian, C. Free cooling of data centers: A review. Renew. Sustain. Energy Rev. 2014, 35, 171–182. [Google Scholar] [CrossRef]

- Ding, J.; Zhang, H.; Leng, D.; Xu, H.; Tian, C.; Zhai, Z. Experimental investigation and application analysis on an integrated system of free cooling and heat recovery for data centers. Int. J. Refrig. 2022, 136, 142–151. [Google Scholar] [CrossRef]

- Wu, D.; Jiang, J.; Hu, B.; Wang, R.Z. Experimental Investigation on the Performance of a Very High Temperature Heat Pump with Water Refrigerant. Energy 2019, 190, 116427. [Google Scholar] [CrossRef]

- Madsbøll, H. New Multistage Axial Compressor and Chiller Development for Water as Refrigerant. In Proceedings of the 7th International Conference on Compressors and Their Systems 2011; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 39–49, ISBN 978-0-85709-208-3. [Google Scholar]

- Amado, E.A.; Schneider, P.S.; Bresolin, C.S. Free cooling potential for Brazilian data centers based on approach point methodology. Int. J. Refrig. 2020, 122, 171–180. [Google Scholar] [CrossRef]

- Rabczak, S. Free-Cooling in Seasonal Cold Accumulator. Int. J. New Technol. Res. 2015, 1, 49–52. [Google Scholar]

- Rabczak, S.; Proszak-Miąsik, D.; Nowak, K. Free cooling system application in air conditioning. J. Civ. Eng. Environ. Arch. 2014, 31, 433–442. [Google Scholar] [CrossRef]

- Chen, Y.-T.; Lee, D.-S. Experimental investigation on the improved cooling seasonal performance factor by recycling air flow energy from AC outdoor fans. Case Stud. Therm. Eng. 2021, 28, 101364. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, B.; Zhou, Q. Air Conditioning System Design using Free Cooling Technology and Running Mode of a Data Center in Jinan. Procedia Eng. 2017, 205, 3545–3549. [Google Scholar] [CrossRef]

- Chu, J.; Huang, X. Research status and development trends of evaporative cooling air-conditioning technology in data centers. Energy Built Environ. 2021. [Google Scholar] [CrossRef]

- Ni, J.; Bai, X. A review of air conditioning energy performance in data centers. Renew. Sustain. Energy Rev. 2017, 67, 625–640. [Google Scholar] [CrossRef]

- Tozer, R.; Flucker, S. Data Center Energy-Efficiency Improvement Case Study. ASHRAE Trans. 2015, 121, 298–304. [Google Scholar]

- Ma, Y.; Ma, G.; Zhang, S.; Zhou, F. Cooling performance of a pump-driven two phase cooling system for free cooling in data centers. Appl. Therm. Eng. 2016, 95, 143–149. [Google Scholar] [CrossRef]

- Kamali, S. Review of free cooling system using phase change material for building. Energy Build. 2014, 80, 131–136. [Google Scholar] [CrossRef]

- Arkar, C.; Medved, S. Free cooling of a building using PCM heat storage integrated into the ventilation system. Sol. Energy 2007, 81, 1078–1087. [Google Scholar] [CrossRef]

- Muñoz, J.; Martínez-Val, J.M.; Abbas, R.; Abánades, A. Dry cooling with night cool storage to enhance solar power plants performance in extreme conditions areas. Appl. Energy 2012, 92, 429–436. [Google Scholar] [CrossRef] [Green Version]

- Hart, R.; Boldt, J.; Rosenberg, M. Pre-Cooling Chilled Water Return—Replacing Yesterday’s Strainer Cycle. ASHRAE Trans. 2014, 120, 1. [Google Scholar]

- Climate Statistics Hourly Averages over a Decade for the Rzeszów-Jasionka Weather Station. Available online: https://www.gov.pl/documents/33377/436740/wmo125800iso.txt (accessed on 24 March 2022).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).