The Current Status and Lost Biogas Production Potential of Kazakhstan from Anaerobic Digestion of Livestock and Poultry Manure

Abstract

:1. Introduction

- Cultivation of crops: Collection and processing of wheat, barley, and sugar beet. Typical waste types include stems, straw, leaves, husks, cake, roots, etc.

- Livestock: Breeding of pigs, cows, horses, chickens, and other animals. Typical waste types include slurry, animal manure, animal wastewater, silage, slaughter waste, litter residues, etc.

2. Materials and Methods

2.1. Area of Study and Challenges to Overcome

- -

- One of the most successful projects for generating electricity from organic waste in Kazakhstan was implemented at a distance of 7 km from the village of Kogershin in the Zhambyl region. There is a pig-breeding complex with an area of 30 ha. The daily productivity of biogas is 5300 m3 per day;

- -

- In the Kostanay region, on the territory of the Karaman-K farm, a biogas plant has been operating since 2011. All equipment for the production of biogas and electricity was designed and supplied by “Zorg Biogas Ukraine”. The biogas plant, consisting of 2 reactors of 2400 m3 each, has been brought to full capacity, and generates 360 kW of electrical power. Annually it is expected to produce 3 million kWh of electricity from biogas. There are about 5000 cows on the farm;

- -

- In the East Kazakhstan region, in the village of Privolnoye, a biogas plant operates on the basis of the Bagration farm, which allows the processing of 10 tons of manure per day and produces 400 m3 of gas;

- -

- In the Aktobe region, in the village of Sazdy, a biogas plant operates on the Bolashak farm, and produces 2 m3 of biogas per day.

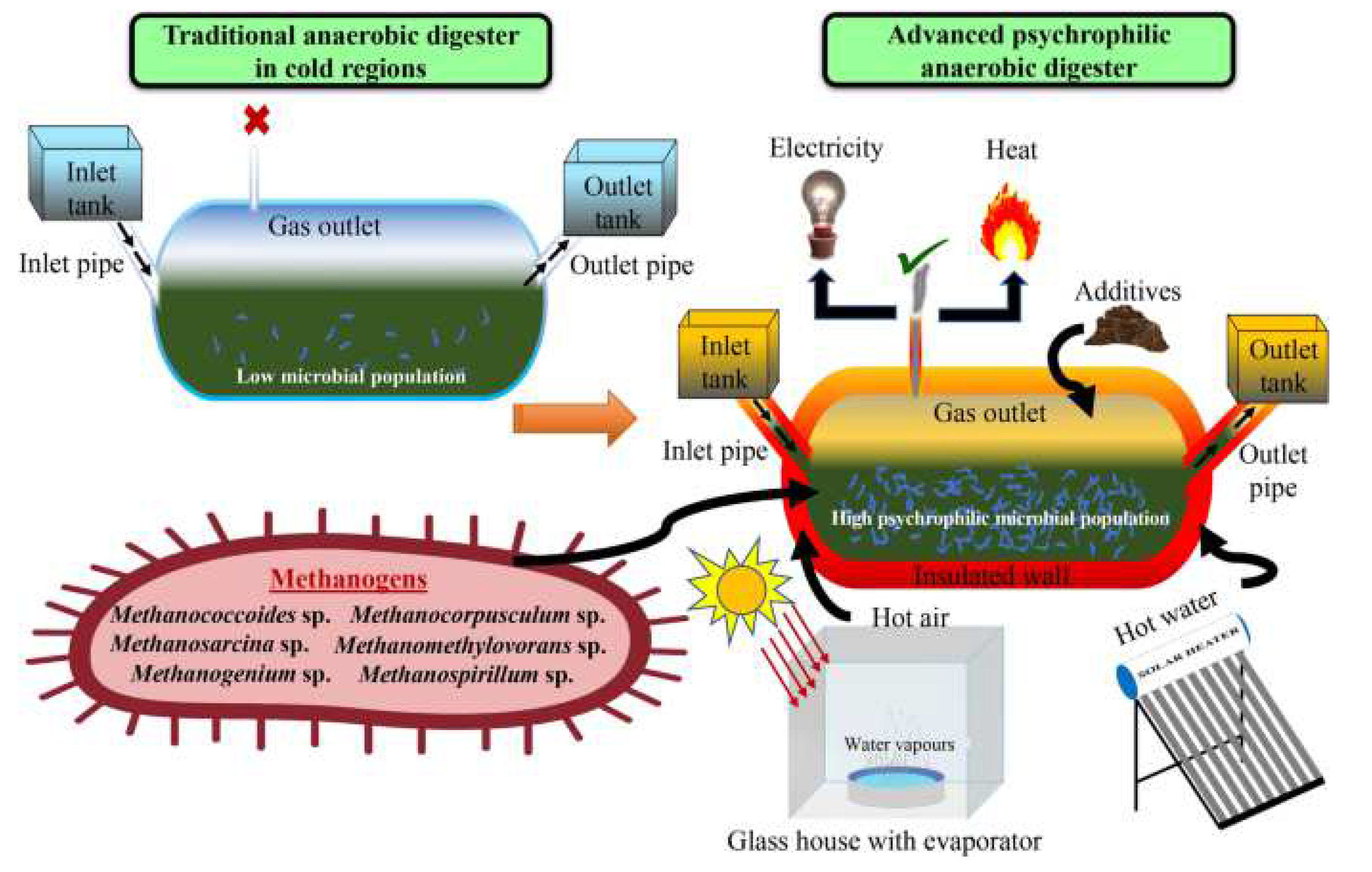

2.2. Biogas Production Features in Cold Regions

2.3. Agricultural Land Distribution

2.4. Calculation of Approximate Amounts of Produced Livestock and Poultry Manure

3. Results and Discussion

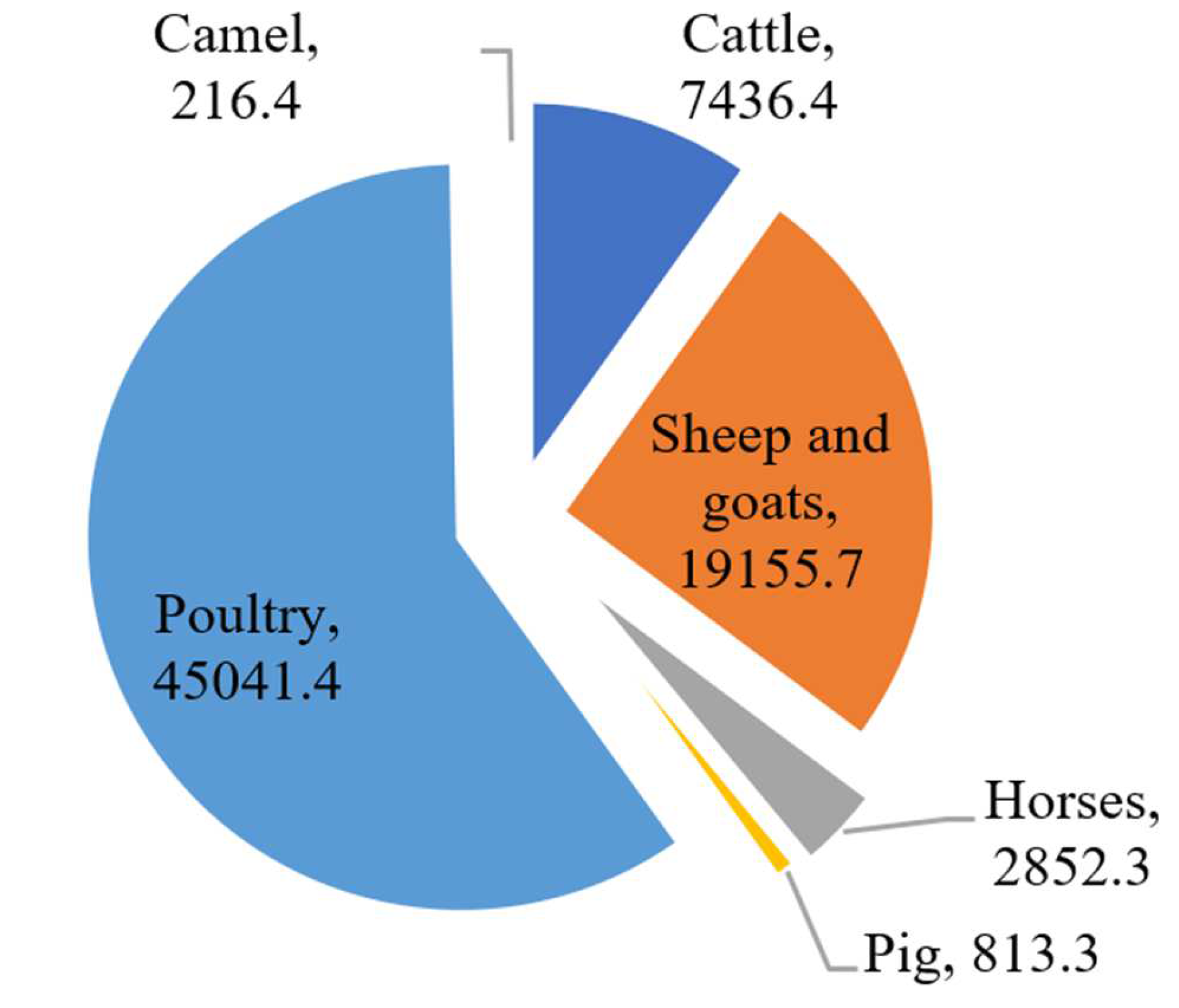

3.1. The Analysis of Livestock and Poultry Distribution in Kazakhstan

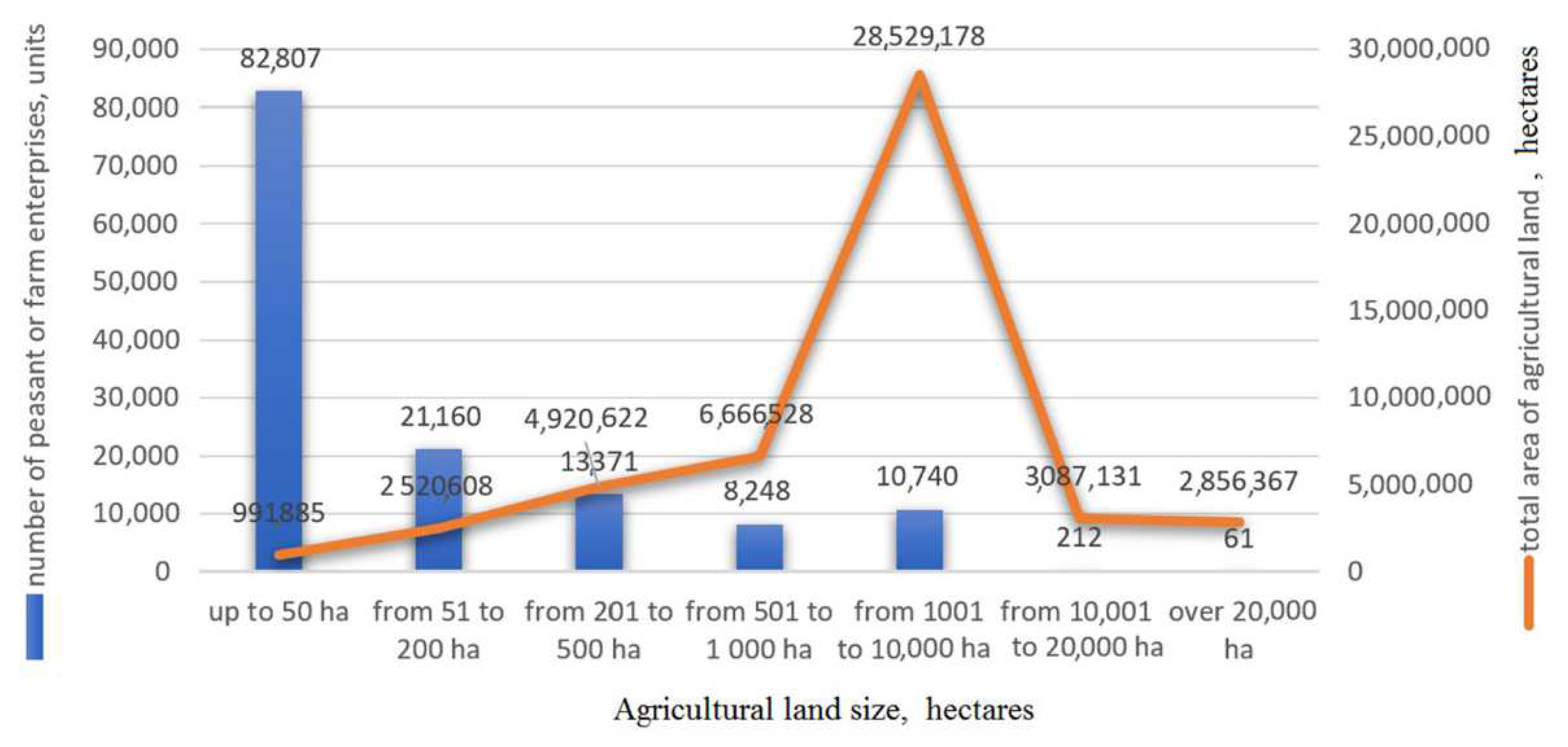

3.2. Analysis of Agricultural Land Distribution

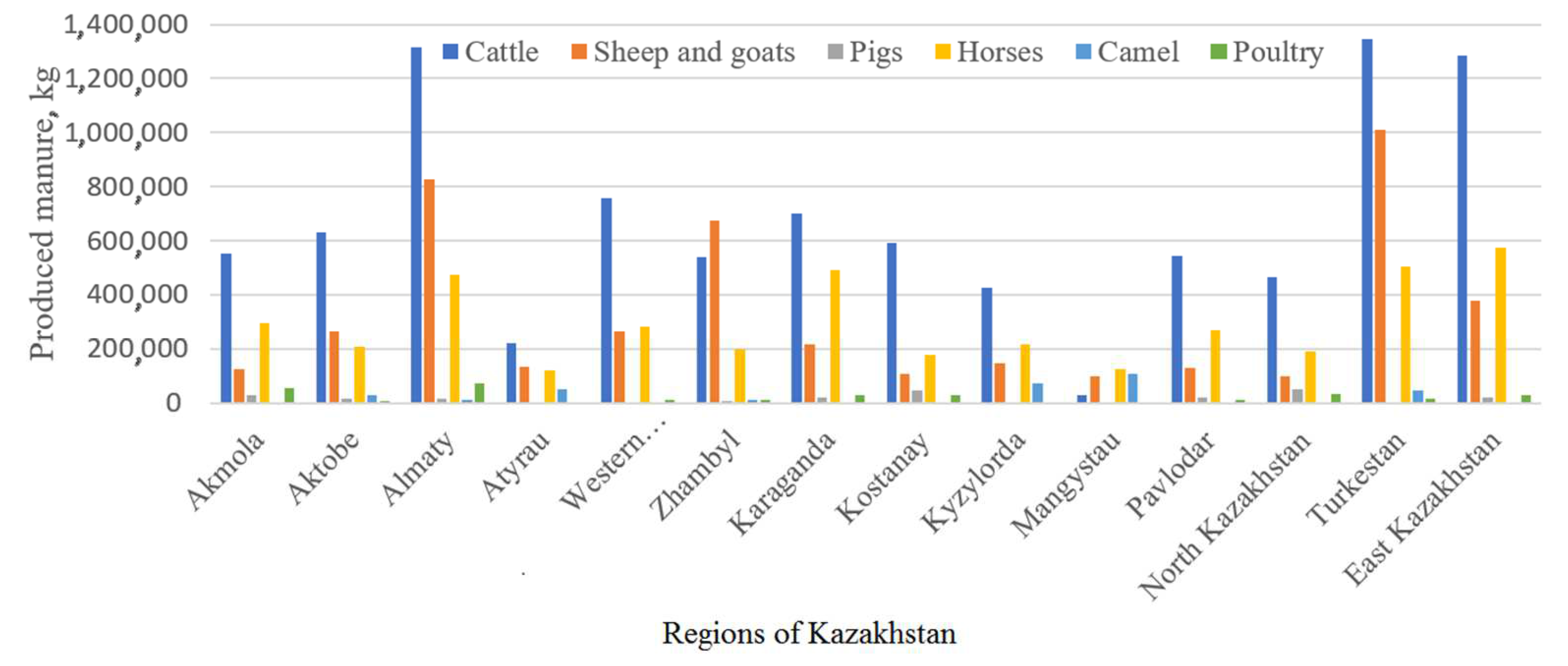

3.3. Livestock and Poultry Manure Production Results

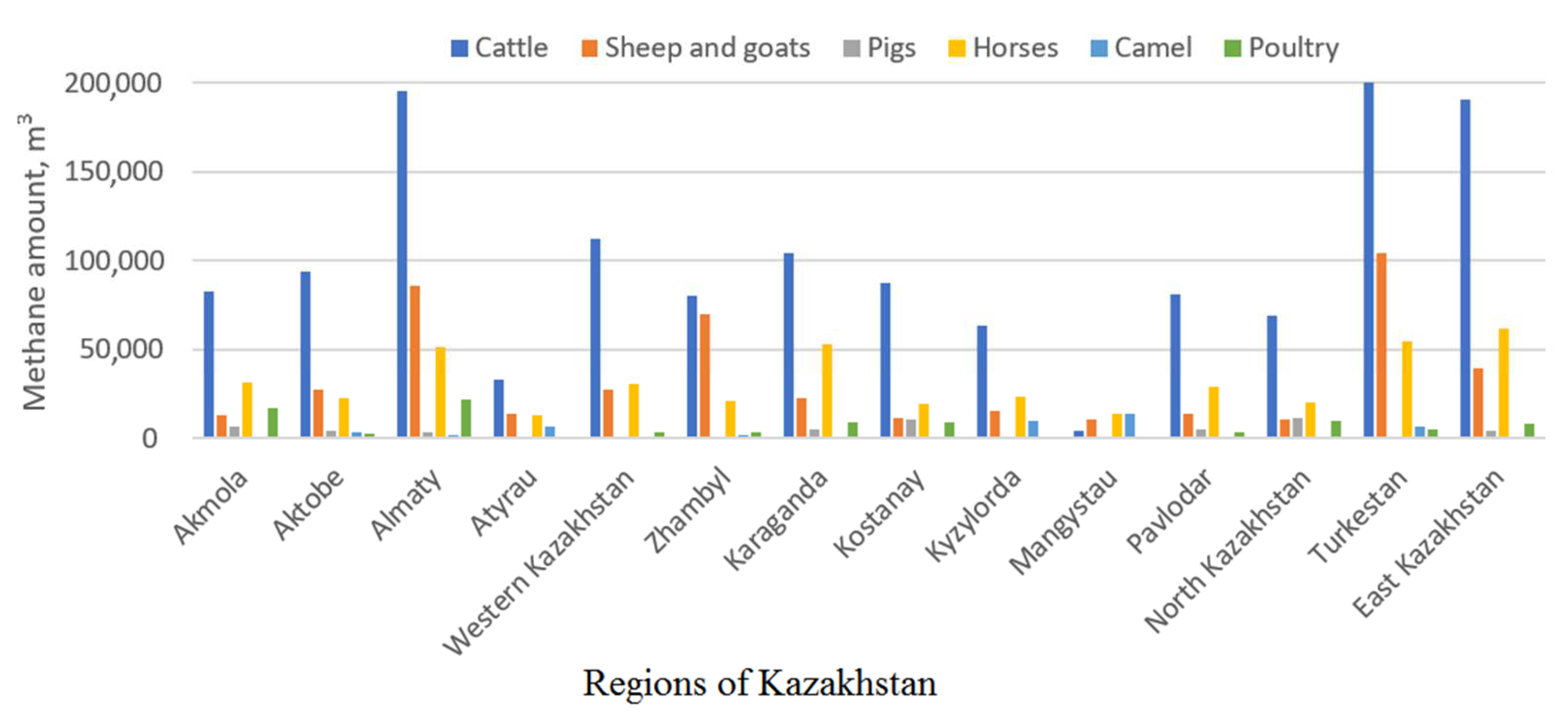

3.4. The Results of the Assessment of Methane Production

4. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Spiridonov, V.; Ćurić, M. Climate and Climate Change. In Fundamentals of Meteorology; Springer: Cham, Switzerland, 2021; pp. 377–397. [Google Scholar]

- Kenenbayev, S.B.; Yesenbayeva, G.L. Adaptation of priority research direction in agriculture to climate change in Kazakhstan. Int. J. Agric. Sci. Food Technol. 2020, 6, 46–49. [Google Scholar] [CrossRef]

- Consept for Transition of the Republic of Kazakhstan to Green Economy. 12 September 2013. Available online: https://www.osce.org/files/f/documents/7/e/104851.pdf (accessed on 20 March 2022).

- Karatayev, M.; Clarke, M. Current Energy Resources in Kazakhstan and the Future Potential of Renewables: A Review. Energy Procedia 2014, 59, 97–104. [Google Scholar] [CrossRef]

- Stigka, E.K.; Paravantis, J.A.; Mihalakakou, G.K. Social acceptance of renewable energy sources: A review of contingent valuation applications. Renew. Sustain. Energy Rev. 2014, 32, 100–106. [Google Scholar] [CrossRef]

- Luostarinen, S.; Normak, A.; Edström, M. Overview of Biogas Technology. Baltic MANURE WP6 Energy Potentials. 2011. Available online: https://www.build-a-biogas-plant.com/PDF/baltic_manure_biogas_final_total.pdf (accessed on 20 March 2022).

- Adeoti, O.; Ilori, M.O.; Oyebisi, T.O.; Adekoya, L.O. Engineering design and economic evaluation of a family-sized biogas project in Nigeria. Technovation 2000, 20, 103–108. [Google Scholar] [CrossRef]

- Rahman, M.M.; Hasan, M.M.; Paatero, J.V.; Lahdelma, R. Hybrid application of biogas and solar resources to fulfill household energy needs: A potentially viable option in rural areas of developing countries. Renew. Energy 2014, 68, 35–45. [Google Scholar] [CrossRef] [Green Version]

- O’Connor, S.; Ehimen, E.; Pillai, S.C.; Black, A.; Tormey, D.; Bartlett, J. Biogas production from small-scale anaerobic digestion plants on European farms. Renew. Sustain. Energy Rev. 2021, 139, 110580. [Google Scholar] [CrossRef]

- Matsui, K. Wood Resources Management: A Case Study of the Aral Region, Kazakhstan. Ph.D. Thesis, Kyoto University, Kyoto, Japan, 2019. [Google Scholar] [CrossRef]

- Kerimray, A.; De Miglio, R.; Rojas-Solórzano, L.; Gallachóir, B.Ó. Household energy consumption and energy poverty in Kazakhstan. In IAEE Energy Forum; International Association for Energy Economics: Cleveland, OH, USA, 2007. [Google Scholar]

- Dziuba, K.; Todorow, M.; Kowalik, A.; Góra, R.; Bojanowicz-Bablok, A.; Kijenska, L.M.; Tokarz, A.; Baranski, B.; Gworek, G. Carbon footprint in fertilizer production as a tool for reduction of GHG emissions. In Proceedings of the 22nd SETAC Europe LCA Case Study Symposium, Montpellier, France, 20–22 September 2016. [Google Scholar]

- Wood, S.; Cowie, A. A Review of Greenhouse Gas Emission Factors for Fertiliser Production; The Climate Technology Centre and Network (CTCN): Copenhagen, Denmark, 2004. [Google Scholar]

- Liang, Y.; Zhen, L.; Zhang, C.; Hu, Y. Consumption of products of livestock resources in Kazakhstan: Characteristics and influencing factors. Environ. Dev. 2020, 34, 100492. [Google Scholar] [CrossRef]

- Tazhibaev, S.; Musabekov, K.; Yesbolova, A.; Ibraimova, S.; Mergenbayeva, A.; Sabdenova, Z.; Seidahmetov, M. Issues in the Development of the Livestock Sector in Kazakhstan. Procedia Soc. Behav. Sci. 2014, 143, 610–614. [Google Scholar] [CrossRef] [Green Version]

- Xu, S.; He, L.; Ning, J.; Wang, X.; Jing, C.; Ao, W.; Hu, Q. BRI and International Cooperation in Industrial Capacity; Taylor & Francis: London, UK, 2020; pp. 57–87. [Google Scholar]

- Islyami, A.; Aldashev, A.; Thomas, T.S.; Dunston, S. Impact of Climate Change on Agriculture in Kazakhstan. Silk Road A J. Eurasian Dev. 2020, 2, 66–88. [Google Scholar] [CrossRef]

- Biogas Plants in Kazakhstan. 2021. Available online: https://inbusiness.kz/ru/post/gde-eshe-v-kazahstane-rabotayut-biogazovye-ustanovki (accessed on 20 March 2022).

- Ministry of National Economy of the Republic of Kazakhstan (Ed.) Regions of Kazakhstan; Ministry of National Economy of the Republic of Kazakhstan: Nur-Sultan, Kazakhstan, 2021.

- Rocha-Meneses, L.; Zannerni, R.; Inayat, A.; Abdallah, M.; Shanableh, A.; Ghenai, C.; Kamil, M.; Kikas, T. Current progress in anaerobic digestion reactors and parameters optimization. Biomass Convers. Biorefinery 2022, 1–24. [Google Scholar] [CrossRef]

- Rocha-Meneses, L.; Otor, O.F.; Bonturi, N.; Orupold, K.; Kikas, T. Bioenergy Yields from Sequential Bioethanol and Biomethane Production: An Optimized Process Flow. Sustainability 2019, 12, 272. [Google Scholar] [CrossRef] [Green Version]

- Najafi, B.; Ardabili, S.; Band, S. Spent mushroom compost (SMC) as a source for biogas production in Iran. Eng. Appl. Comput. Fluid Mech. 2019, 13, 967–982. [Google Scholar] [CrossRef] [Green Version]

- Nie, E.; He, P.; Zhang, H.; Hao, L.; Shao, L.; Lü, F. How does temperature regulate anaerobic digestion? Renew. Sustain. Energy Rev. 2021, 150, 111453. [Google Scholar] [CrossRef]

- Manyapu, V.; Kumar, A.; Kumar, R. Psychrophilic biomethanation for enhanced bioenergy production in cold regions. Clean Technol. Environ. Policy 2021, 1–16. [Google Scholar] [CrossRef]

- Garfí, M.; Ferrer-Martí, L.; Villegas, V.; Ferrer, I. Psychrophilic anaerobic digestion of guinea pig manure in low-cost tubular digesters at high altitude. Bioresour. Technol. 2011, 102, 6356–6359. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fjørtoft, K.; Morken, J.; Hanssen, J.F.; Briseid, T. Methane production and energy evaluation of a farm scaled biogas plant in cold climate area. Bioresour. Technol. 2014, 169, 72–79. [Google Scholar] [CrossRef] [PubMed]

- Martí-Herrero, J.; Alvarez, R.; Cespedes, R.; Rojas, M.R.; Conde, V.; Aliaga, L.; Balboa, M.; Danov, S. Cow, sheep and llama manure at psychrophilic anaerobic co-digestion with low cost tubular digesters in cold climate and high altitude. Bioresour. Technol. 2015, 181, 238–246. [Google Scholar] [CrossRef]

- Perrigault, T.; Weatherford, V.; Martí-Herrero, J.; Poggio, D. Towards thermal design optimization of tubular digesters in cold climates: A heat transfer model. Bioresour. Technol. 2012, 124, 259–268. [Google Scholar] [CrossRef]

- Aoki, K.; Umetsu, K.; Nishizaki, K.; Takahashi, J.; Kishimoto, T.; Tani, M.; Hamamoto, O.; Misaki, T. Thermophilic biogas plant for dairy manure treatment as combined power and heat system in cold regions. Int. Congr. Ser. 2006, 1293, 238–241. [Google Scholar] [CrossRef]

- Curry, N.; Pillay, P. Integrating solar energy into an urban small-scale anaerobic digester for improved performance. Renew. Energy 2015, 83, 280–293. [Google Scholar] [CrossRef]

- Martí-Herrero, J. Biodigestores Familiares: Guía de Diseño y Manual de Instalación (2008); Cooperación Técnica Alemana-GTZ: La Paz, Bolivia, 2015. [Google Scholar]

- Smith, A.; Skerlos, S.; Raskin, L. Anaerobic membrane bioreactor treatment of domestic wastewater at psychrophilic temperatures ranging from 15 °C to 3 °C. Environ. Sci. Water Res. Technol. 2014, 1, 56–64. [Google Scholar] [CrossRef]

- Guo, H.; Yu, Z.; Thompson, I.P.; Zhang, H. A contribution of hydrogenotrophic methanogenesis to the biogenic coal bed methane reserves of Southern Qinshui Basin, China. Appl. Microbiol. Biotechnol. 2014, 98, 9083–9093. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Saady, N.M.C.; Massé, D.I. Impact of organic loading rate on the performance of psychrophilic dry anaerobic digestion of dairy manure and wheat straw: Long-term operation. Bioresour. Technol. 2015, 182, 50–57. [Google Scholar] [CrossRef] [PubMed]

- Wei, S.; Zhang, H.; Cai, X.; Xu, J.; Fang, J.; Liu, H. Psychrophilic anaerobic co-digestion of highland barley straw with two animal manures at high altitude for enhancing biogas production. Energy Convers. Manag. 2014, 88, 40–48. [Google Scholar] [CrossRef]

- Jang, H.M.; Choi, Y.-K.; Kan, E. Effects of dairy manure-derived biochar on psychrophilic, mesophilic and thermophilic anaerobic digestions of dairy manure. Bioresour. Technol. 2018, 250, 927–931. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Guo, B.; Zhang, L.; Zhang, H.; Liu, Y. Microbial community dynamics in granular activated carbon enhanced up-flow anaerobic sludge blanket (UASB) treating municipal sewage under sulfate reducing and psychrophilic conditions. Chem. Eng. J. 2021, 405, 126957. [Google Scholar] [CrossRef]

- Demartini, E.; Gaviglio, A.; Gelati, M.; Cavicchioli, D. The Effect of Biogas Production on Farmland Rental Prices: Empirical Evidences from Northern Italy. Energies 2016, 9, 965. [Google Scholar] [CrossRef] [Green Version]

- Manesh, K.M.H.; Rezazadeh, A.; Kabiri, S. A feasibility study on the potential, economic, and environmental advantages of biogas production from poultry manure in Iran. Renew. Energy 2020, 159, 87–106. [Google Scholar] [CrossRef]

- Shibata, M.; Terada, F. Factors affecting methane production and mitigation in ruminants. Anim. Sci. J. 2010, 81, 2–10. [Google Scholar] [CrossRef]

- Noorollahi, Y.; Kheirrouz, M.; Asl, H.F.; Yousefi, H.; Hajinezhad, A. Biogas production potential from livestock manure in Iran. Renew. Sustain. Energy Rev. 2015, 50, 748–754. [Google Scholar] [CrossRef]

- Eriksson, O.; Hadin, Å.; Hennessy, J.; Jonsson, D. Life Cycle Assessment of Horse Manure Treatment. Energies 2016, 9, 1011. [Google Scholar] [CrossRef] [Green Version]

- Durán Aranguren, D.; Torres, M.A.C.; Sierra, R.; Gordillo, A.R.; Gordillo, G.; Rodríguez, M.O. Analysis of the Potential Biogas Production from Pig Manure in Pig Farms Located in Colombia. In Proceedings of the 29th European Biosmass Conference & Exhibition, online, 26–29 April 2021. [Google Scholar]

- Khan, M.U.; Ahmad, M.; Sultan, M.; Sohoo, I.; Ghimire, P.C.; Zahid, A.; Sarwar, A.; Farooq, M.; Sajjad, U.; Abdeshahian, P.; et al. Biogas Production Potential from Livestock Manure in Pakistan. Sustainability 2021, 13, 6751. [Google Scholar] [CrossRef]

- Bendová, H.; Friess, K.; Bara, J.E.; Izák, P. Single-step purification of raw biogas to biomethane quality by hollow fiber membranes without any pretreatment—An innovation in biogas upgrading. Sep. Purif. Technol. 2018, 203, 36–40. [Google Scholar]

- Jain, M.; Singh, R.; Tauro, P. Anaerobic digestion of cattle and sheep wastes. Agric. Wastes 1981, 3, 65–73. [Google Scholar] [CrossRef]

- Lemmer, A.; Oechsner, H.; Jungbluth, T. Investigation of the methane potential of horse manure. Agric. Eng. Int. CIGR J. 2013, 15, 161–172. [Google Scholar]

- Zhang, D.; Lin, C.; Zhang, Y.; Zhao, L.; Liu, H.; Liu, Z. Effect of organic loading rate on anaerobic digestion of pig manure: Methane production, mass flow, reactor scale and heating scenarios. J. Environ. Manag. 2018, 231, 646–652. [Google Scholar]

- Bedier, E.; Hasham, A. Practical Approach to Improve Biogas Produced from Poultry Manure. Int. J. Eng. Tech. Res. 2021, 9, 157–160. [Google Scholar]

- Norouzi, O.; Heidari, M.; Dutta, A. Technologies for the production of renewable natural gas from organic wastes and their opportunities in existing Canadian pipelines. Fuel Commun. 2022, 11, 100056. [Google Scholar] [CrossRef]

- Vögeli, Y.; Riu Lohri, C.; Gallardo, A.; Diener, S.; Zurbrugg, C. Anaerobic Digestion of Biowaste in Developing Countries: Practical Information and Case Studies; Eawag–Swiss Federal Institute of Aquatic Science and Technology: Dübendorf, Switzerland, 2014. [Google Scholar]

- Agriculture, Forestry and Fisheries in the Republic of Kazakhstan; Agency for Strategic Planning and Reforms of the Republic of Kazakhstan Bureau of National Statistics: Nur-Sultan, Kazakhstan, 2020.

- Umor, N.A.; Ismail, S.; Abdullah, S.; Huzaifah, M.H.R.; Huzir, N.M.; Mahmood, N.A.N.; Zahrim, A.Y. Zero waste management of spent mushroom compost. J. Mater. Cycles Waste Manag. 2021, 23, 1726–1736. [Google Scholar] [CrossRef]

- Xu, X.; Yuan, X.; Zhang, Q.; Wei, Q.; Liu, X.; Deng, W.; Wang, J.; Yang, W.; Deng, B.; Zhang, L. Biochar derived from spent mushroom substrate reduced N2O emissions with lower water content but increased CH4 emissions under flooded condition from fertilized soils in Camellia oleifera plantations. Chemosphere 2021, 287, 132110. [Google Scholar] [CrossRef]

- On Approval of the Maximum Allowable Load on the Total Area of Pastures. 15 May 2015. Available online: https://adilet.zan.kz/rus/docs/V1500011064 (accessed on 20 March 2022).

- Robinson, S.; Milner-Gulland, E.J.; Alimaev, I. Rangeland degradation in Kazakhstan during the Soviet era: Re-examining the evidence. J. Arid. Environ. 2003, 53, 419–439. [Google Scholar] [CrossRef] [Green Version]

- Norouzi, O.; Dutta, A. The Current Status and Future Potential of Biogas Production from Canada’s Organic Fraction Municipal Solid Waste. Energies 2022, 15, 475. [Google Scholar] [CrossRef]

- Robinson, S.; Bozayeva, Z.; Mukhamedova, N.; Djanibekov, N.; Petrick, M. Ranchers or pastoralists? Farm size, specialisation and production strategy amongst cattle farmers in south-eastern Kazakhstan. Pastoralism 2021, 11, 31. [Google Scholar] [CrossRef]

| Regions | Territory, Thousand km2 | Districts | Cities | Settlements | Villages |

|---|---|---|---|---|---|

| Akmola | 146.1 | 17 | 10 | 5 | 602 |

| Aktobe | 300.6 | 14 | 8 | - | 344 |

| Almaty | 223.6 | 17 | 10 | - | 732 |

| Atyrau | 118.6 | 7 | 2 | - | 159 |

| Western Kazakhstan | 151.3 | 12 | 2 | 3 | 435 |

| Zhambyl | 144.3 | 10 | 4 | - | 373 |

| Karaganda | 428.0 | 11 | 11 | 10 | 421 |

| Kostanay | 196.0 | 16 | 5 | 3 | 548 |

| Kyzylorda | 226.0 | 7 | 4 | 2 | 232 |

| Mangystau | 165.6 | 5 | 3 | - | 58 |

| Pavlodar | 124.8 | 10 | 3 | 4 | 354 |

| North Kazakhstan | 98 | 13 | 5 | - | 649 |

| Turkestan | 116.1 | 13 | 7 | - | 836 |

| East Kazakhstan | 283.2 | 15 | 10 | 3 | 711 |

| AAW (kg) Adult Animal Weight | MPC Manure Production Coefficient | (kg) Approximate Annual Manure Produced | |

|---|---|---|---|

| Cattle | 350 | 3.65 | 2226.5 |

| Sheep and goats | 70 | 3.36 | 235.2 |

| Horses | 454 | 3.2 | 5040 |

| Pigs | 50 | 5.7 | 720 |

| Poultry | 1.6 | 4.4 | 7.04 |

| Camels | 600 | 2.6 | 952 |

| Produced Biogas Amount, (m3/kg) | Methane Rate | CO2 Rate | |

|---|---|---|---|

| Cattle | 0.26–0.28 | 0.5–0.6 | 0.4–0.5 |

| Sheep and goats | 0.22–0.24 | 0.4–0.5 | 0.6–0.5 |

| Horses | 0.16–0.21 | 0.5–0.65 | 0.35–0.5 |

| Pigs | 0.3–0.4 | 0.6–0.7 | 0.3–0.4 |

| Poultry | 0.4–0.6 | 0.5–0.7 | 0.3–0.5 |

| Camels | 0.2–0.25 | 0.55–0.65 | 0.35–0.45 |

| Regions | Numbers of Livestock and Poultry, Thousands | |||||

|---|---|---|---|---|---|---|

| Cattle | Sheep and Goats | Pigs | Horses | Camel | Poultry | |

| Akmola | 434 | 535.2 | 99 | 202.1 | 0.1 | 8014.2 |

| Aktobe | 493.5 | 1127.1 | 58.4 | 144.3 | 17.8 | 1320.9 |

| Almaty | 1028.1 | 3511.8 | 53.3 | 327 | 7.4 | 10,311.2 |

| Atyrau | 173.4 | 567.6 | 0.4 | 83.9 | 32.5 | 455.6 |

| Western Kazakhstan | 591.5 | 1130.6 | 17.3 | 192.8 | 2.2 | 1442.8 |

| Zhambyl | 423.2 | 2861.8 | 20.9 | 136 | 6.9 | 1702 |

| Karaganda | 549.2 | 924.5 | 72.2 | 337.2 | 1.4 | 4080.8 |

| Kostanay | 462.4 | 463.6 | 165.8 | 122.9 | 0.2 | 4269 |

| Kyzylorda | 332.4 | 620.9 | 2.6 | 148.3 | 47.9 | 127.2 |

| Mangystau | 22 | 422.5 | 0.1 | 86.5 | 68.8 | 43.3 |

| Pavlodar | 426.6 | 551.6 | 73.7 | 184.6 | 0.1 | 1695.8 |

| North Kazakhstan | 365.5 | 419.3 | 173.9 | 130.9 | 0 | 4617.1 |

| Turkestan | 1052.9 | 4291.2 | 6.6 | 346.4 | 30.4 | 2175.4 |

| East Kazakhstan | 1004.5 | 1611.6 | 65.2 | 394.5 | 0.6 | 3877.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yerassyl, D.; Jin, Y.; Zhanar, S.; Aigul, K.; Saltanat, Y. The Current Status and Lost Biogas Production Potential of Kazakhstan from Anaerobic Digestion of Livestock and Poultry Manure. Energies 2022, 15, 3270. https://doi.org/10.3390/en15093270

Yerassyl D, Jin Y, Zhanar S, Aigul K, Saltanat Y. The Current Status and Lost Biogas Production Potential of Kazakhstan from Anaerobic Digestion of Livestock and Poultry Manure. Energies. 2022; 15(9):3270. https://doi.org/10.3390/en15093270

Chicago/Turabian StyleYerassyl, Dulatbay, Yu Jin, Sugirbaeva Zhanar, Kazambayeva Aigul, and Yessengaliyeva Saltanat. 2022. "The Current Status and Lost Biogas Production Potential of Kazakhstan from Anaerobic Digestion of Livestock and Poultry Manure" Energies 15, no. 9: 3270. https://doi.org/10.3390/en15093270

APA StyleYerassyl, D., Jin, Y., Zhanar, S., Aigul, K., & Saltanat, Y. (2022). The Current Status and Lost Biogas Production Potential of Kazakhstan from Anaerobic Digestion of Livestock and Poultry Manure. Energies, 15(9), 3270. https://doi.org/10.3390/en15093270