Characteristics and Origins of the Difference between the Middle and High Rank Coal in Guizhou and Their Implication for the CBM Exploration and Development Strategy: A Case Study from Dahebian and Dafang Block

Abstract

:1. Introduction

2. Materials and Method

2.1. Samples and Data Sources

2.2. Methods

3. Results and Discussion

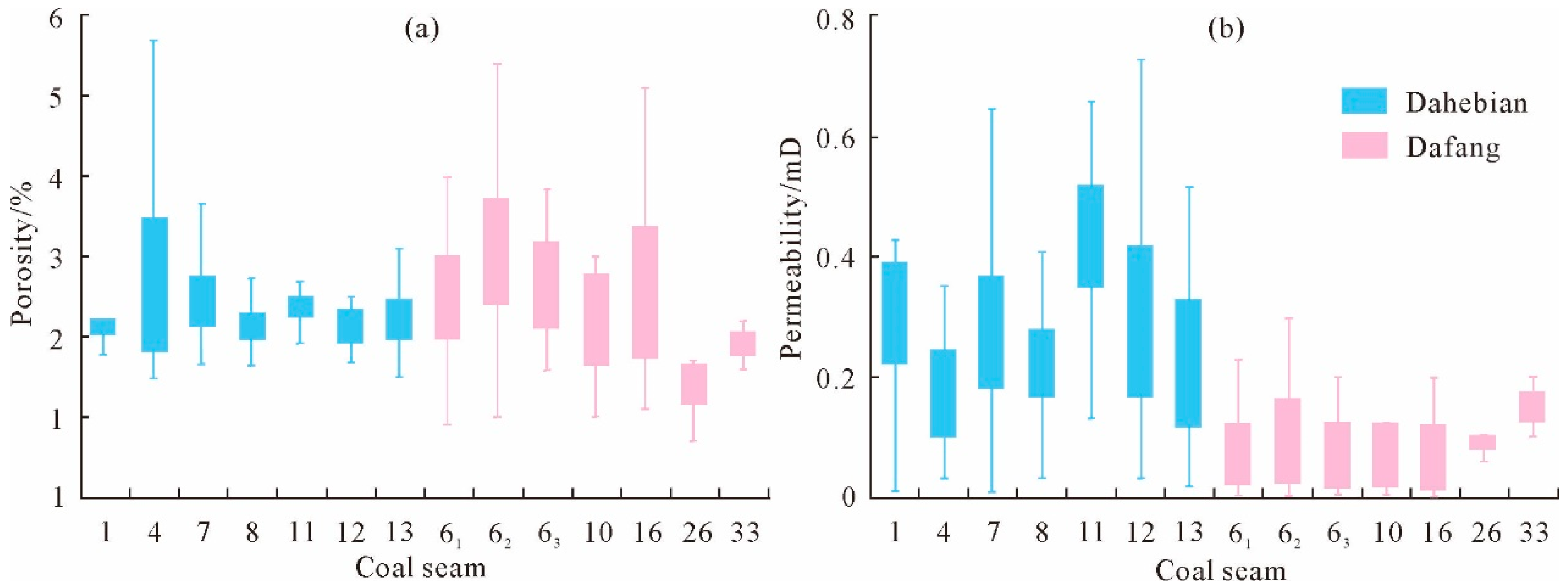

3.1. Different Characteristics between the Middle and High-Rank Coals

3.2. Origins of Different Geological Characteristics between Middle- and High-Rank Coals

3.2.1. Different Sedimentary Environment

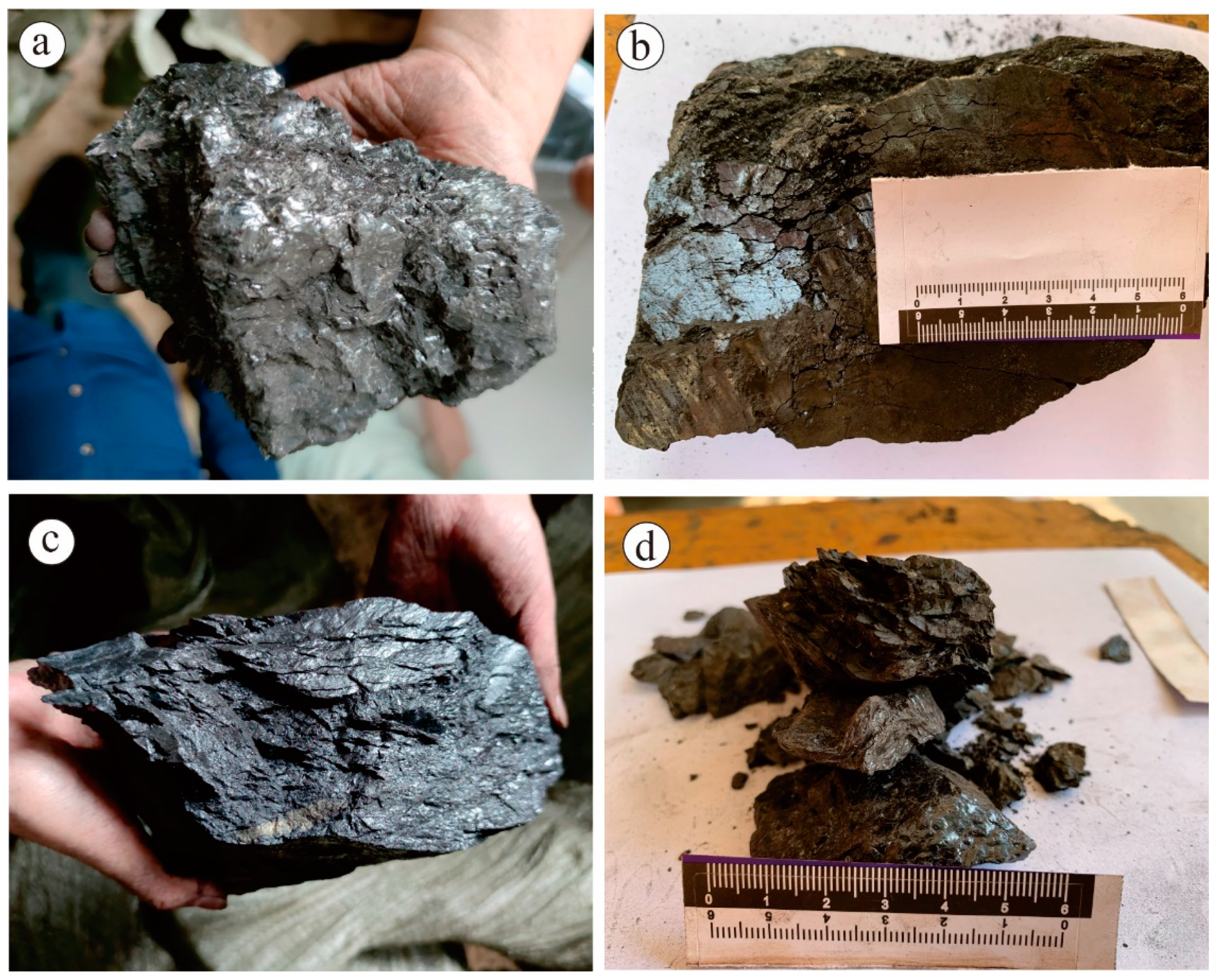

3.2.2. Tectonic Effects on Coal Rank and Structure

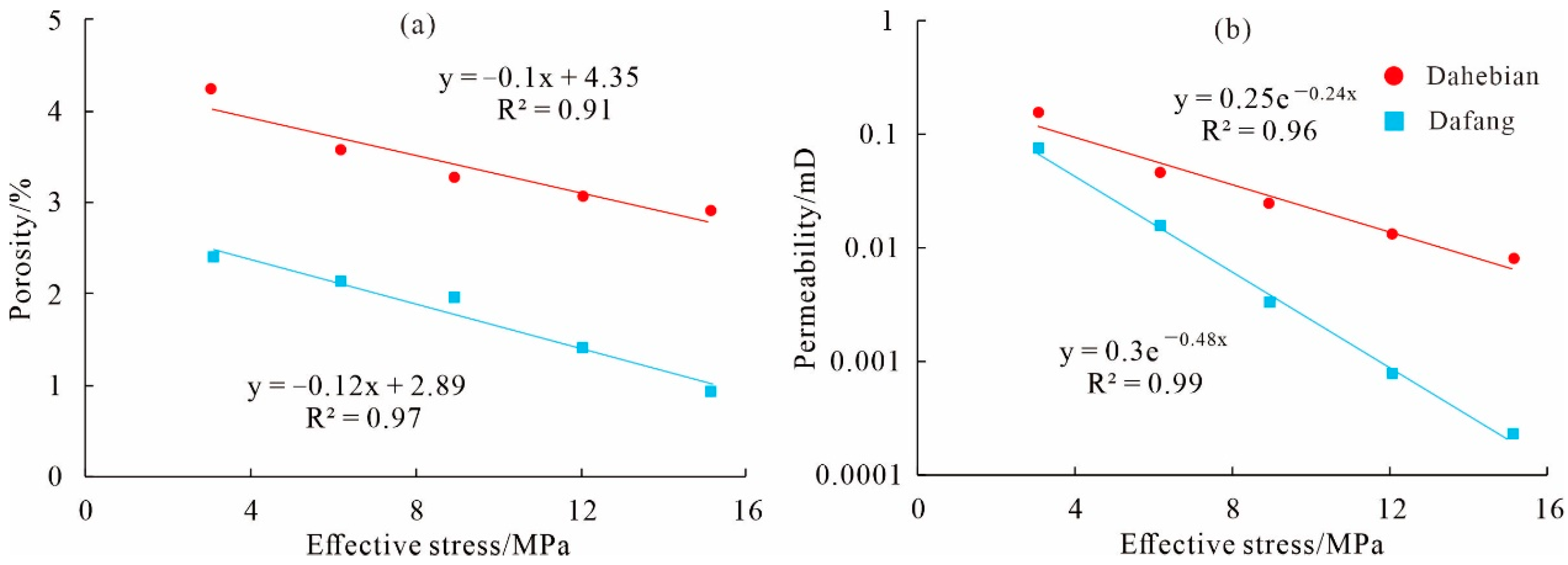

3.2.3. Effect of Depth on Gas Content and Permeability between the Middle- and High-Rank Coal

3.3. Model of Enrichment and High Yield of CBM in Guizhou

3.4. Geological Suitable CBM Exploration and Development Strategies in Guizhou

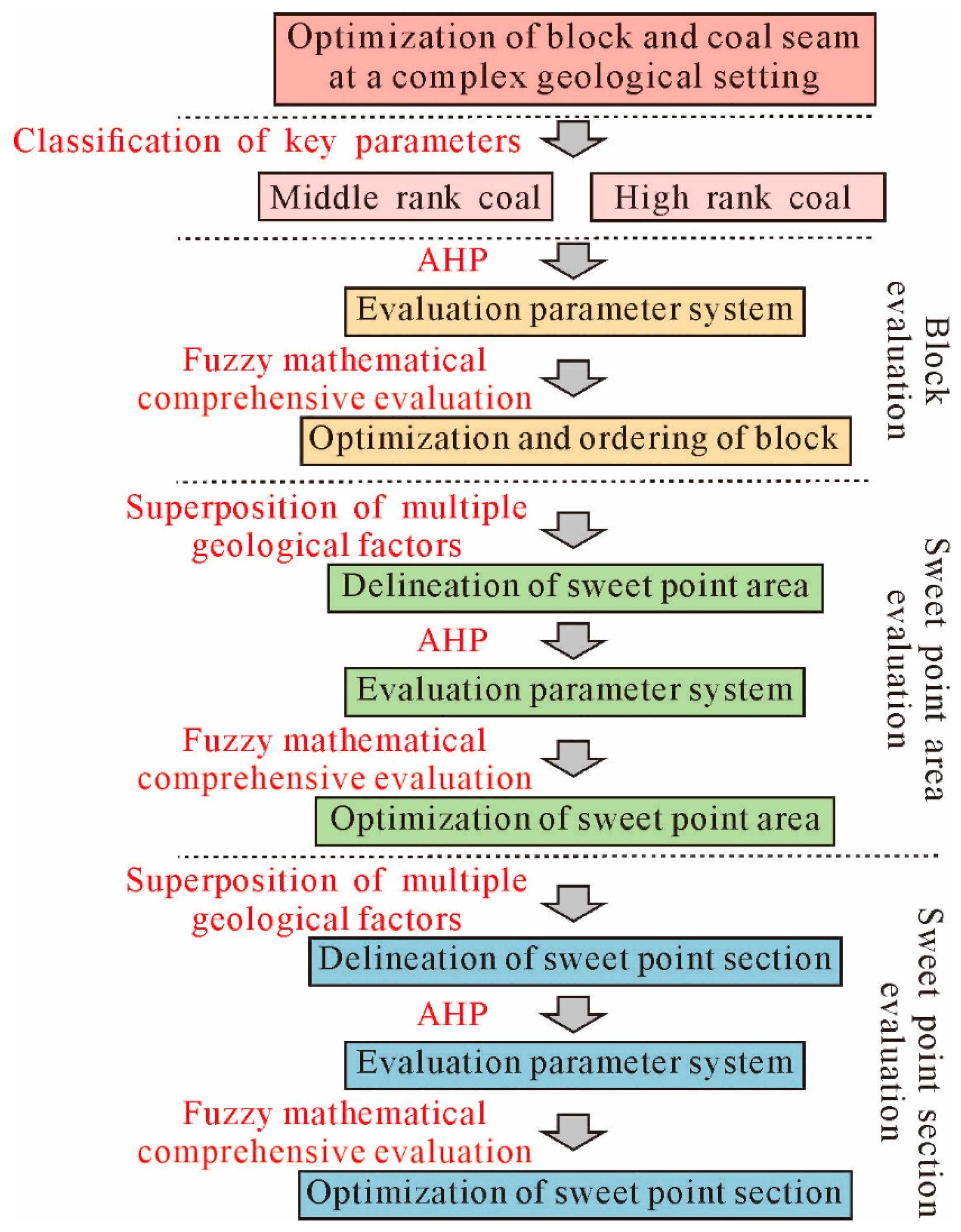

3.4.1. Optimization of Block and Coal Seam for CBM Exploration and Development Based on Coal Rank Classification

3.4.2. Multiple Coal Seams Commingling Production with Pressure Relief of Tectonically Deformed Coal

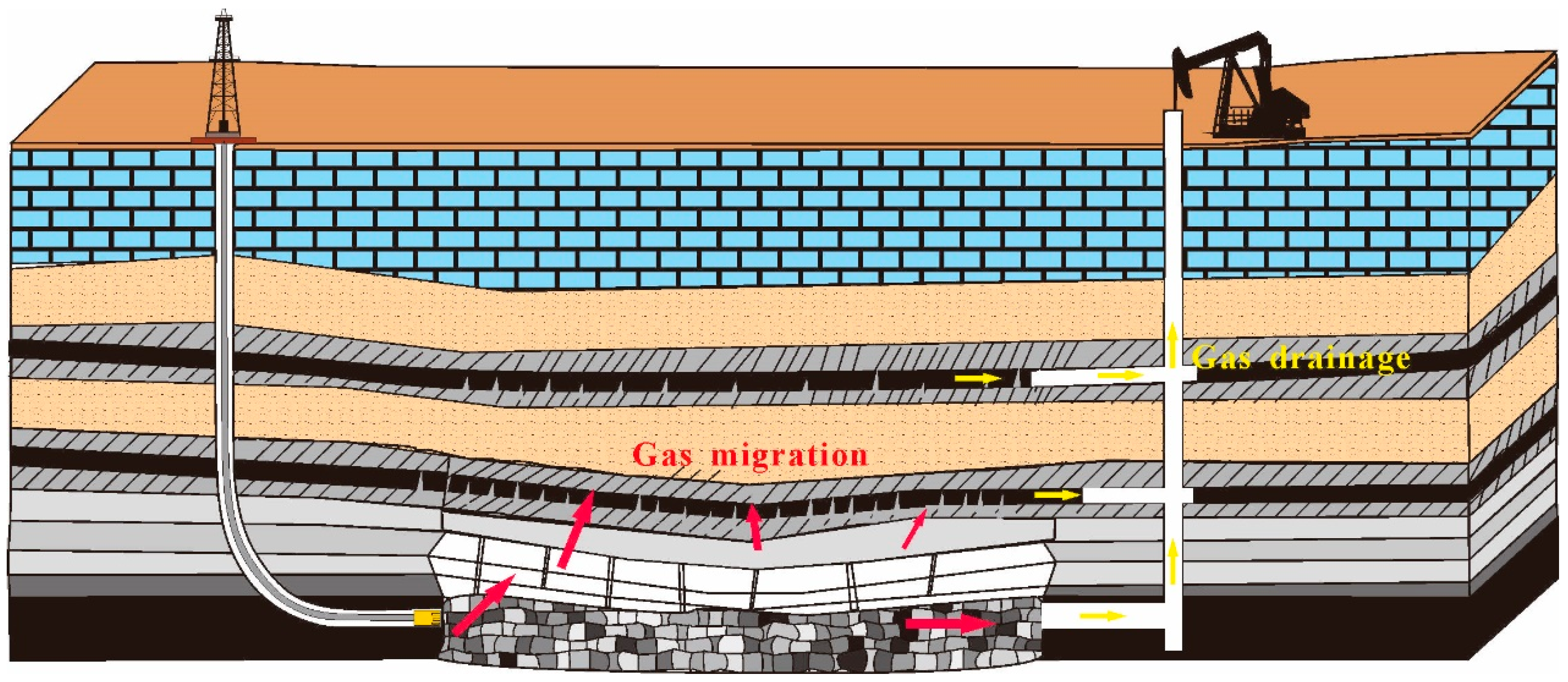

3.4.3. Surface–Underground CBM Three-Dimensional Drainage Development in Coal Mine Area

4. Conclusions

- (1)

- The geological differences in the middle- and high-rank coal CBM in Guizhou are mainly reflected in the number of coal layers, maceral, coal structure, and their influence on gas-bearing capacity and permeability. Compared to the middle-rank coal in the Dahebian Block, the Dafang high-rank coal shows more coal layers (30–66), and a higher vitrinite (2.94–3.42%) and gas content (17.84–23.75 m3/t), but a lower thickness (9.5 m), a lower permeability (0.02–0.64 mD), and a wider tectonically deformed coal distribution;

- (2)

- Although the sedimentary environment was the transitional sedimentary facies system in most of Guizhou during the Late Permian, the frequent transgression–regression and terrigenous source input resulted in a significant difference in coal occurrence, maceral, and qualities. The distribution of coal rank shows a high affinity with deep faults, and the uneven tectonic subsidence and its related thermal anomaly result in an X-type distribution of coal rank. The distribution and damage degree of the tectonically deformed coal are also related to these faults;

- (3)

- The favorable configuration of structure, hydrology, and depth promotes enrichment and high CBM yield in Guizhou. However, there are differences in depth for CBM enrichment and high yield between middle-rank coal (<500 m) and high-rank coal (600–800 m). The coupling relationship between permeability and gas content controlled by depth is the fundamental reason for the difference in depth for CBM enrichment and high yield between the middle- and high-rank coal;

- (4)

- We provided three new concepts for the efficient exploration and development of CBM in Guizhou; namely, (a) the optimization of block and coal seam for CBM exploration and development (classification–successive optimization–analytical hierarchy process), (b) the multi-layer CBM development with the pressure relief of tectonically deformed coal, and (c) surface–underground CBM three-dimensional drainage development in coal mines.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guizhou Daily. Available online: http://szb.gzrbs.com.cn/pc/cont/202102/27/content_6542.html (accessed on 27 February 2021).

- Shao, L.; Hua, F.; Yi, T.; Guo, L.; Wang, X. Sequence-paleogeography and coal accumulation of Lopingian in Guizhou Province. Coal Geol. Explor. 2021, 49, 45–56. [Google Scholar]

- Chen, Y.; Qin, Y.; Li, Z.; Chang, H.; Luo, Z. Magma thermal metamorphism of the Longtan formation coals in Zhijin Guizhou. J. China Univ. Min. Technol. 2012, 41, 406–414. [Google Scholar]

- Tang, S.; Tang, D.; Xu, H.; Tao, S.; Li, S.; Geng, Y. Geological mechanisms of the accumulation of coalbed methane induced by hydrothermal fluids in the western Guizhou and eastern Yunnan regions. J. Nat. Gas Sci. Eng. 2016, 33, 644–656. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Jiang, B.; Lin, S.; Lan, F.; Wang, J. Structural controls on CBM reservoirs in Faer coal mine, Southwest China. J. Earth Sci. 2013, 24, 437–448. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, Y.; You, Z.; Yang, Z. Distribution characteristics of in situ stress field and vertical development unit division of CBM in Western Guizhou, China. Nat. Resour. Res. 2021, 30, 3659–3671. [Google Scholar] [CrossRef]

- Song, L.; Tang, D.; Xu, H.; Yang, Z. The pore-fracture system properties of CBM reservoirs in the Panguan Syncline, Guizhou, China. Geosci. Front. 2012, 3, 853–862. [Google Scholar]

- Li, S.; Tang, D.; Pan, Z.; Xu, H.; Guo, L. Evaluation of CBM potential of different reservoirs in western Guizhou and eastern Yunnan, China. Fuel 2015, 139, 257–267. [Google Scholar] [CrossRef]

- Chen, S.; Tang, D.; Tao, S.; Chen, Z.; Xu, H.; Li, S. Coal Reservoir Heterogeneity in Multicoal Seams of the Panguan Syncline, Western Guizhou, China: Implication for the Development of Superposed CBM-Bearing Systems. Energy Fuels 2018, 32, 8241–8253. [Google Scholar] [CrossRef]

- Tan, Y.; Pan, Z.; Liu, J.; Zhou, F.; Connell, L.D.; Sun, W.; Haque, A. Experimental study of impact of anisotropy and heterogeneity on gas flow in coal. Part II: Permeability. Fuel 2018, 230, 397–409. [Google Scholar] [CrossRef]

- Jia, B.; Xian, C. Permeability measurement of the fracture-matrix system with 3D embedded discrete fracture model. Pet. Sci. 2022. [Google Scholar] [CrossRef]

- Jia, B.; Chen, Z.; Xian, C. Investigations of CO2 storage capacity and flow behavior in shale formation. J. Pet. Sci. Eng. 2022, 208, 109659. [Google Scholar] [CrossRef]

- Li, M.; Jiang, B.; Lin, S.; Wang, J.; Ji, M.; Qiu, Z. Tectonically deformed coal types and pore structures in Puhe and Shanchahe coal mines in western Guizhou. Min. Sci. Technol. 2011, 21, 353–357. [Google Scholar] [CrossRef]

- Ju, W.; Yang, Z.; Qin, Y.; Yi, T.; Zhang, Z. Characteristics of in-situ stress state and prediction of the permeability in the Upper Permian CBM reservoir, western Guizhou region, SW China. J. Pet. Sci. Eng. 2018, 165, 199–211. [Google Scholar] [CrossRef]

- Shen, Y.; Qin, Y.; Guo, Y.; Yi, T.; Yuan, X.; Shao, Y. Characteristics and sedimentary control of a CBM-bearing system in lopingian (late permian) coal-bearing strata of western Guizhou Province. J. Nat. Gas Sci. Eng. 2016, 33, 8–17. [Google Scholar] [CrossRef]

- Ren, P.; Xu, H.; Tang, D.; Li, Y.; Chen, Z. Pore structure and fractal characterization of main coal-bearing synclines in western Guizhou, China. J. Nat. Gas Sci. Eng. 2019, 63, 58–59. [Google Scholar] [CrossRef]

- Ju, W.; Yang, Z.; Shen, Y.; Yang, H.; Wang, G.; Zhang, X.; Wang, S. Mechanism of pore pressure variation in multiple coal reservoirs, western Guizhou region, South China. Front. Earth Sci. 2021, 15, 770–789. [Google Scholar] [CrossRef]

- Qin, Y.; Xiong, M.; Yi, T.; Yang, Z.; Wu, C. On unattached multiple superposed coalbed-methane system: In a case of the Shuigonghe Syncline, Zhijin-Nayong coalfield, Guizhou. Geol. Rev. 2008, 54, 65–70. [Google Scholar]

- Shen, Y.; Qin, Y.; Guo, Y.; Yi, T.; Shao, Y.; Jin, H. Sedimentary controlling factor of unattached multiple superimposed coalbed-methane system formation. Earth Sci.-J. China Univ. Geosci. 2012, 37, 573–579. [Google Scholar]

- Zhou, P.; Jin, J.; Luo, K.; Gao, W.; Chen, J. Unattached multiple layer superimposed coalbed methane system in Songhe mine, west Guizhou. Coal Geol. Explor. 2017, 45, 66–69. [Google Scholar]

- Shan, Y.; Bi, C.; Chi, H.; Wang, F.; Li, H. Geological characteristics of CBM and optimization for favorable productive intervals of Yangmeishu syncline in Liupanshui area. Nat. Gas Geosci. 2018, 29, 122–129. [Google Scholar]

- Wang, S.; Gao, W.; Guo, T.; Bao, S.; Jin, J.; Xu, Q. The discovery of shale gas, coalbed gas and tight sandstone gas in Permian Longtan Formation, northern Guizhou Province. Geol. China 2020, 47, 249–250. [Google Scholar]

- Cheng, W.; Yang, R.; Cui, Y.; Fu, H.; Zhang, T. Characteristic of Late Permian coal quality from Bijie, Guizhou Province, SW China, and its significance for paleoenvironment. Acta Geol. Sin. 2013, 87, 1763–1777. [Google Scholar]

- Fang, X.; Wu, C.; Jiang, X.; Liu, N.; Zhou, D.; Ju, Y. Characteristics of in situ stress and its influence on coal seam permeability in the Liupanshui Coalfield, Western Guizhou. Energy Sci. Eng. 2021, 9, 1773–1786. [Google Scholar] [CrossRef]

- Teichmüller, M. The genesis of coal from the viewpoint of coal petrology. Int. J. Coal Geol. 1989, 12, 1–87. [Google Scholar] [CrossRef]

- Yang, Q.; Ren, D.; Pan, Z. Preliminary investigation on the metamorphism of Chinese Coals. Int. J. Coal Geol. 1982, 2, 31–48. [Google Scholar] [CrossRef]

- Chen, X. Distribution law and genesis of Permian coal in Guizhou. Coal Geol. Explor. 1995, 23, 21–24. [Google Scholar]

- Xiong, M.; Qin, Y.; Yi, T. Sedimentary patterns and structural controls of late permian coal-bearing strata in Guizhou, China. J. China Univ. Min. Technol. 2006, 35, 778–782. [Google Scholar]

- Zeng, R.; Zhao, J.; Zhuang, X. Quality of Late Permian coal and its controlling factors in Shuicheng mining district of Liupanshui area, Guizhou. Acta Petrol. Sin. 1998, 14, 549–558. [Google Scholar]

- Li, M.; Jiang, B.; Liu, J.; Zhu, P.; Cheng, G. Geological models and structural controls of tectonically deformed coal in Tucheng syncline, western Guizhou Province. J. China Coal Soc. 2018, 43, 1565–1571. [Google Scholar]

- Zhou, P.; Gao, W.; Deng, L.; Fu, W. Regional distribution and geotectonic control of Late Permian tectonically deformed coal in Zhina coalfield. Coal Geol. Explor. 2020, 48, 29–34. [Google Scholar]

- Jia, T.; Wang, W.; Yan, J.; Tang, C. The rule of tectonic control and the zoning division of coal mine gas occurrence in Guizhou Province. Earth Sci. Front. 2014, 21, 281–288. [Google Scholar]

- Song, Y.; Liu, S.; Ma, X.; Ju, Y.; Hong, F.; Jiang, L. Accumulation models for CBM in medium- to high-rank coals: Examples from the southern Qinshui Basin and southeastern Ordos Basin. Aust. J. Earth Sci. 2018, 65, 575–590. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Krooss, B.-M.; Busch, A.; Gaschnitz, R. Evolution of methane sorption capacity of coal seams as a function of burial history-a case study from the Campine Basin, NE Belgium. Int. J. Coal Geol. 2006, 66, 179–203. [Google Scholar] [CrossRef]

- Han, S.; Sang, S.; Zhou, P.; Liang, J. The evolutionary history of methane adsorption capacity with reference to deep Carboniferous-Permian coal seams in the Jiyang Sub-basin: Combined implementation of basin modeling and adsorption isotherm experiments. J. Pet. Sci. Eng. 2017, 158, 634–646. [Google Scholar] [CrossRef]

- Liu, D.; Yao, Y.; Cai, Y.; Zhang, B.; Zhang, K.; Li, J. Characteristics of porosity and permeability and their geological control of Permo-Carboniferous coals in the north China. Geoscience 2010, 24, 1198–1203. [Google Scholar]

- Fan, Q.; Cai, Y.; Bei, J.; Wang, W.; Zhang, X. Pore and Fracture Structure of Coal Reservoir Constrained by Coal Metamorphism. Geoscience 2020, 34, 273–280. [Google Scholar]

- Sun, F.; Li, W.; Sun, Q.; Sun, B.; Tian, W.; Chen, Y.; Chen, Z. Low-rank CBM exploration in Jiergalangtu sag, Erlian basin. Acta Pet. Sin. 2017, 38, 485–492. [Google Scholar]

- Wang, B.; Yao, H.; Wang, H.; Zhao, Y.; Li, M.; Hu, Q.; Fan, M.; Yang, C. Favorable and major geological controlling factors for CBM accumulation and high production in the Chengzhuang Block, Qinshui Baisn. Oil Gas Geol. 2018, 39, 366–372. [Google Scholar]

- Wu, C.; Liu, X.; Zhang, S. Construction of index system of “Hierarchical progressive” geological selection of CBM in multiple seam area of eastern Yunnan and western Guizhou. J. China Coal Soc. 2018, 43, 1647–1653. [Google Scholar]

- Shao, L.; Wang, X.; Zhang, J.; Hou, H.; Tang, Y.; Wang, J.; Lin, Y. CBM accumulation characteristics and exploration target selection in northeastern Yunnan, China. Nat. Gas Ind. 2018, 38, 17–27. [Google Scholar]

- Shi, J.; Durucan, S.; Sinka, I.C. Key parameters controlling CBM cavity well performance. Int. J. Coal Geol. 2002, 49, 19–31. [Google Scholar] [CrossRef]

- Meng, Z.; Li, G.; Yang, Y.; Li, C.; Qiao, Y. Study on key technology for surface extraction of CBM in coal mine goaf from Sihe Wells Area, Jincheng. Coal Sci. Technol. 2021, 49, 240–247. [Google Scholar]

- Sang, S.; Zhou, X.; Liu, S.; Wang, H.; Cao, L.; Liu, H.; Li, Z.; Zhu, S.; Liu, C.; Huang, H.; et al. Research advances in theory and technology of the stress release applied extraction of CBM from tectonically deformed coals. J. China Coal Soc. 2020, 45, 2531–2543. [Google Scholar]

- Wu, H. Study and practice on technology of three-zones linkage 3D CBM drainage in coal mining area. J. China Coal Soc. 2011, 36, 1312–1316. [Google Scholar]

- Li, G.; He, H.; Liu, G.; Jiao, H.; Liu, X. Three region linkage three-dimensional gas drainage theory and mode of coal bed methane in coal mining area. Coal Sci. Technol. 2012, 40, 7–11. [Google Scholar]

- He, T.; Wang, B.; Tian, Y. Development and issues with coal and coal-bed methane simultaneous exploitation in Jincheng mining area. J. China Coal Soc. 2014, 39, 1779–1785. [Google Scholar]

| Geological Parameters | Dahebian Block | Dafang Block | |

|---|---|---|---|

| Occurrence | Total thickness of coal/m | 14.24–17.54/16.08 | 3.97–13.75/9.50 |

| Depth/m | 600–1200/800 | 400–1000/600 | |

| Number of coal layer | 14–29/18 | 23–50/35 | |

| Average coal interval/m | 4.79–108.71/25.78 | 11.64–57.84/34.74 | |

| Total thickness of coal measure/m | 200.70–257.28/232.97 | 166.14–261.50/204.14 | |

| Coal properties | Vitrinite reflectance/% | 0.73–0.97/0.82 | 3.03–3.69/3.32 |

| Vitrinite content/% | 38.53–63.95/53.81 | 79.74–92.84/83.96 | |

| Ash content/% | 11.27–39.05/25.16 | 23.75–28.63/26.05 | |

| Sulfur content/% | 0.24–5.91/3.1 | 1.32–2.76/1.94 | |

| Coal reservoir parameters | Gas content/m3·t−1 | 8.39–14.92/11.66 | 17.84–23.75/20.8 |

| Permeability/mD | 0.03–0.66/0.3 | 0.016–0.43/0.17 | |

| Gas saturability/% | 70.45–102.42/83.34 | 75.59–84.8/78.33 | |

| Langmuir volume/cm3·g−1 | 10.57–18.72/14.52 | 28.18–35.14/32.04 | |

| Langmuir pressure/MPa | 2.48–3.09/2.71 | 2.28–2.51/2.38 | |

| Tectonically deformed coal development | Weak | Medium–well developed | |

| Pressure gradient/MPa·100 m−1 | 0.87–1.32/1 | 0.82–0.93/0.89 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, F.; Sang, S.; Han, S.; Wu, Z.; Zhang, J.; Xiang, W.; Xu, A. Characteristics and Origins of the Difference between the Middle and High Rank Coal in Guizhou and Their Implication for the CBM Exploration and Development Strategy: A Case Study from Dahebian and Dafang Block. Energies 2022, 15, 3181. https://doi.org/10.3390/en15093181

Zhao F, Sang S, Han S, Wu Z, Zhang J, Xiang W, Xu A. Characteristics and Origins of the Difference between the Middle and High Rank Coal in Guizhou and Their Implication for the CBM Exploration and Development Strategy: A Case Study from Dahebian and Dafang Block. Energies. 2022; 15(9):3181. https://doi.org/10.3390/en15093181

Chicago/Turabian StyleZhao, Fuping, Shuxun Sang, Sijie Han, Zhangli Wu, Jinchao Zhang, Wenxin Xiang, and Ang Xu. 2022. "Characteristics and Origins of the Difference between the Middle and High Rank Coal in Guizhou and Their Implication for the CBM Exploration and Development Strategy: A Case Study from Dahebian and Dafang Block" Energies 15, no. 9: 3181. https://doi.org/10.3390/en15093181

APA StyleZhao, F., Sang, S., Han, S., Wu, Z., Zhang, J., Xiang, W., & Xu, A. (2022). Characteristics and Origins of the Difference between the Middle and High Rank Coal in Guizhou and Their Implication for the CBM Exploration and Development Strategy: A Case Study from Dahebian and Dafang Block. Energies, 15(9), 3181. https://doi.org/10.3390/en15093181