Assessment of Environmental Loads in the Life Cycle of a Retail and Service Building

Abstract

:1. Introduction

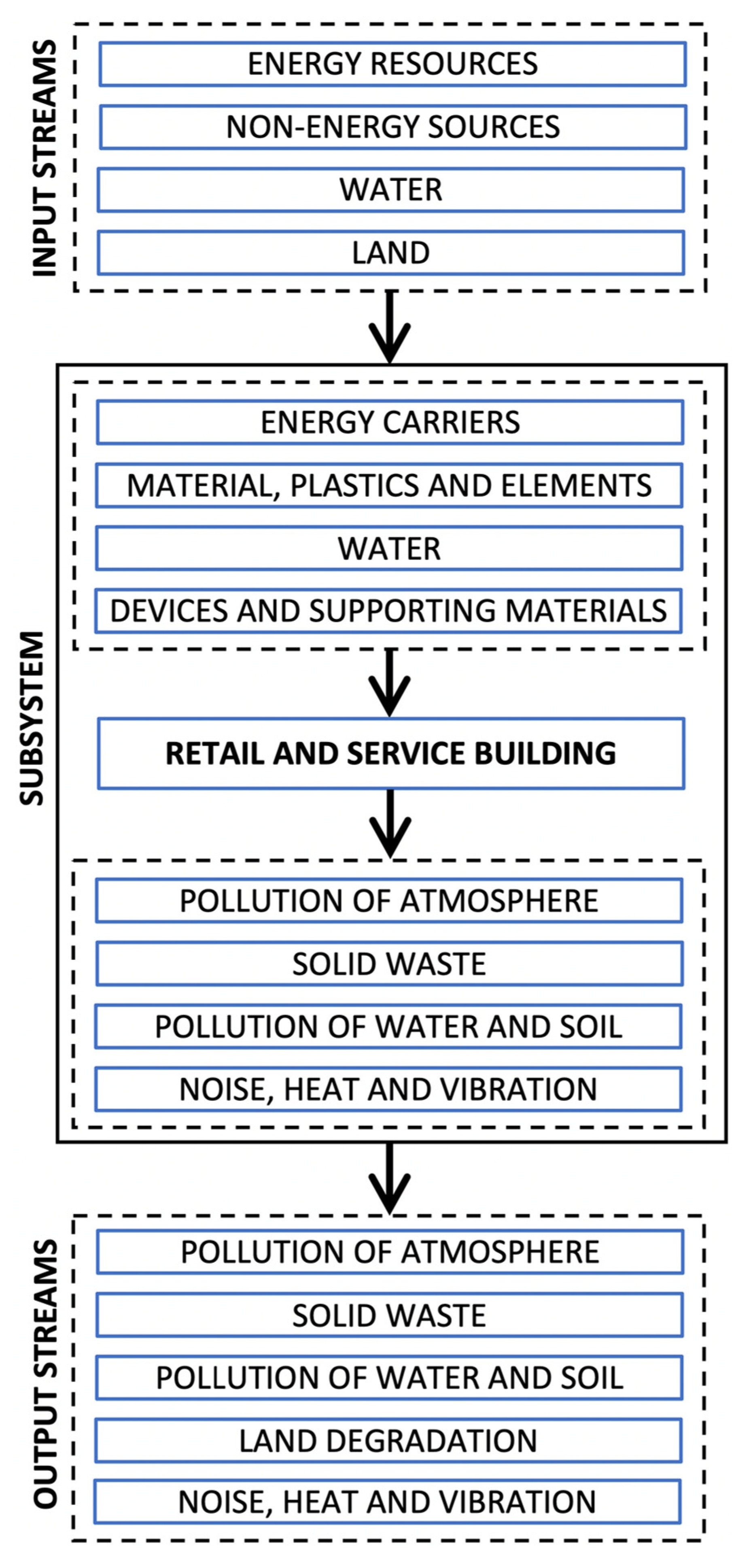

2. Materials and Methods

2.1. Research Object and Methods

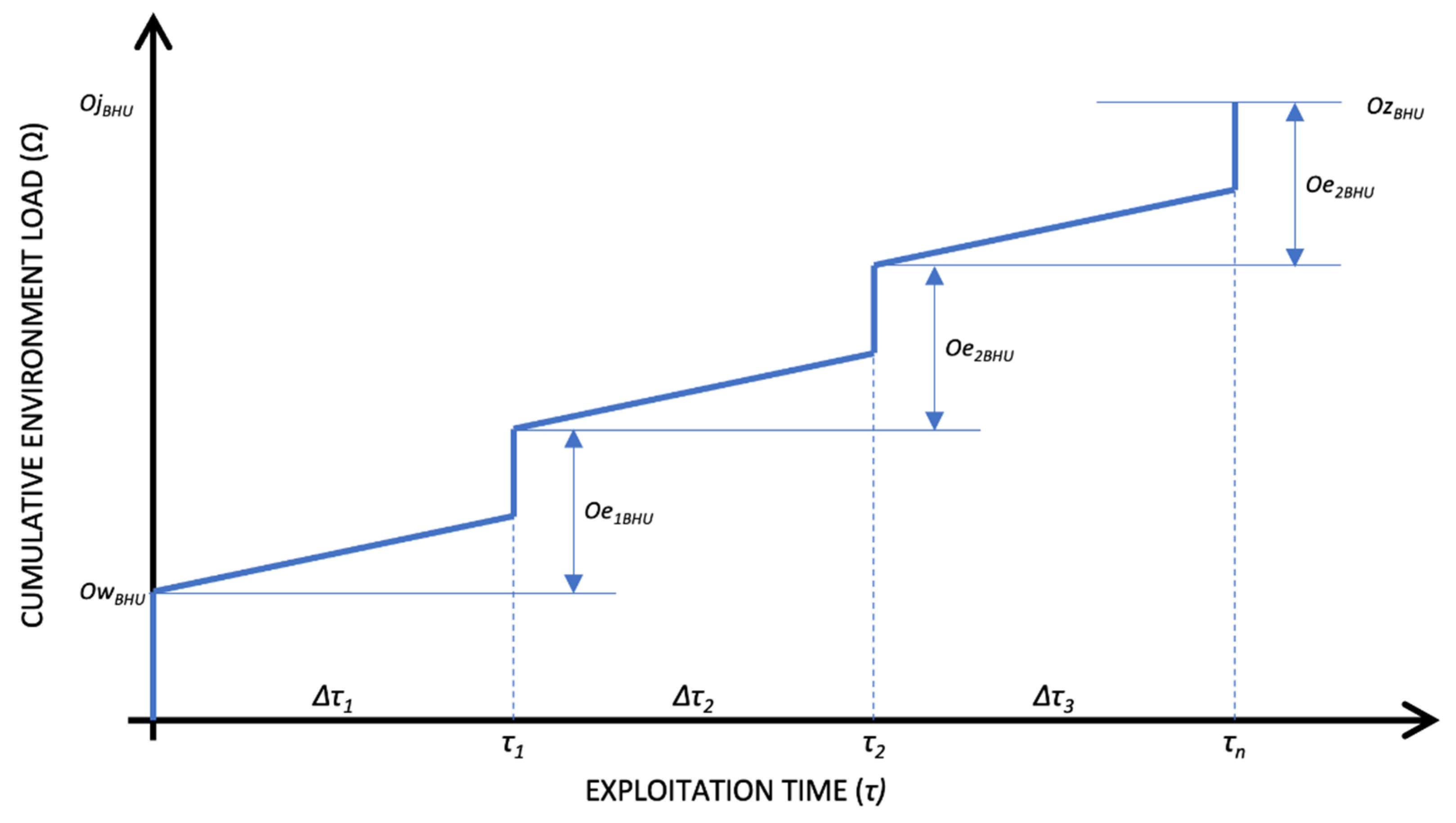

- OwBHU—cumulative environmental load in the production phase, including production of plastics, materials and elements as well as the construction of building objects;

- OeBHU—cumulative environmental load in the operation phase, taking into account the consumption of energy and matter during use and periodic repairs;

- OzBHU—cumulative environmental load in the post-consumer phase, for example, landfilling or recycling [15].

2.2. Determination of Goal and Scope

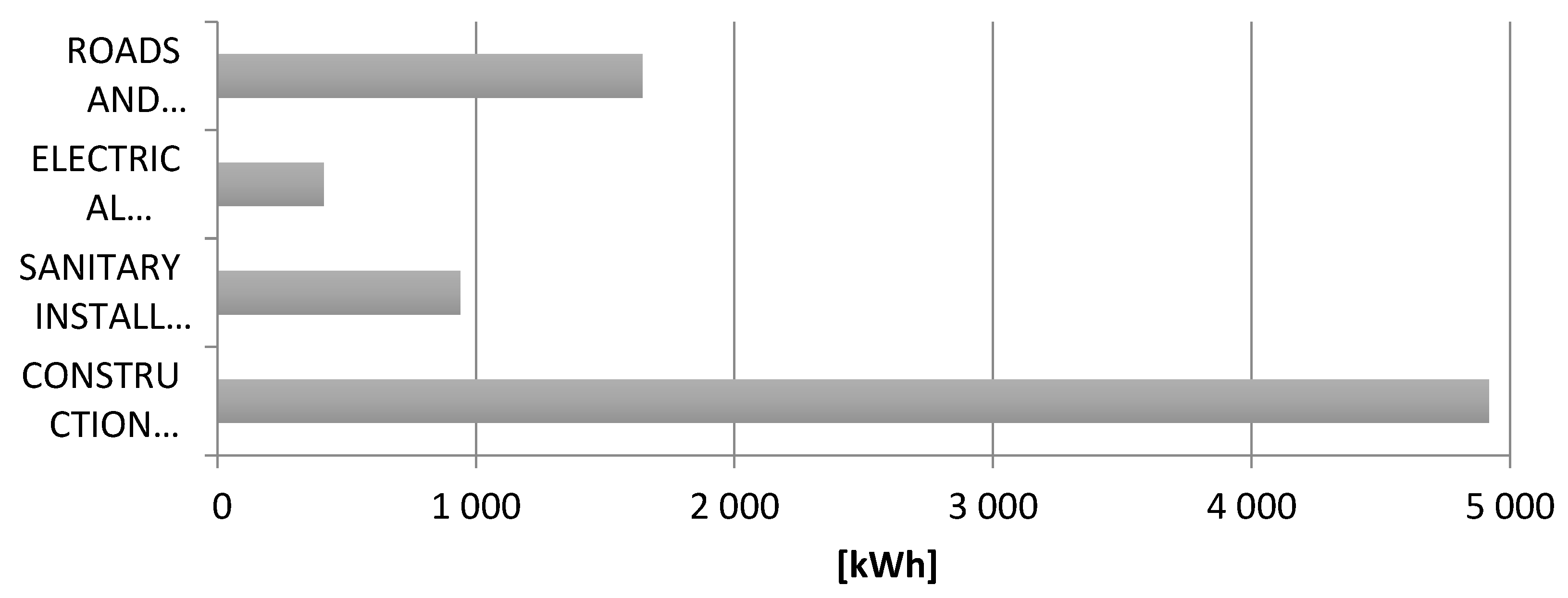

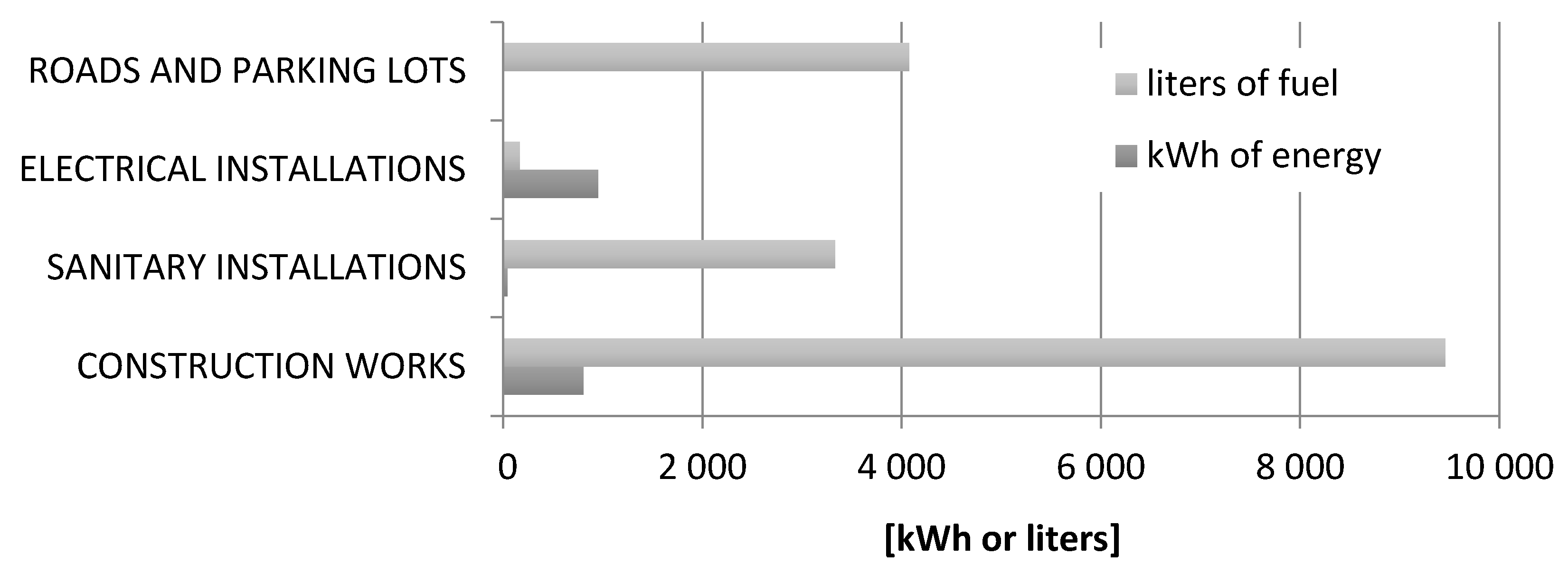

2.3. Life Cycle Inventory (LCI)

2.4. Life Cycle Impact Assessment (LCIA)

2.5. Interpretation

3. Results

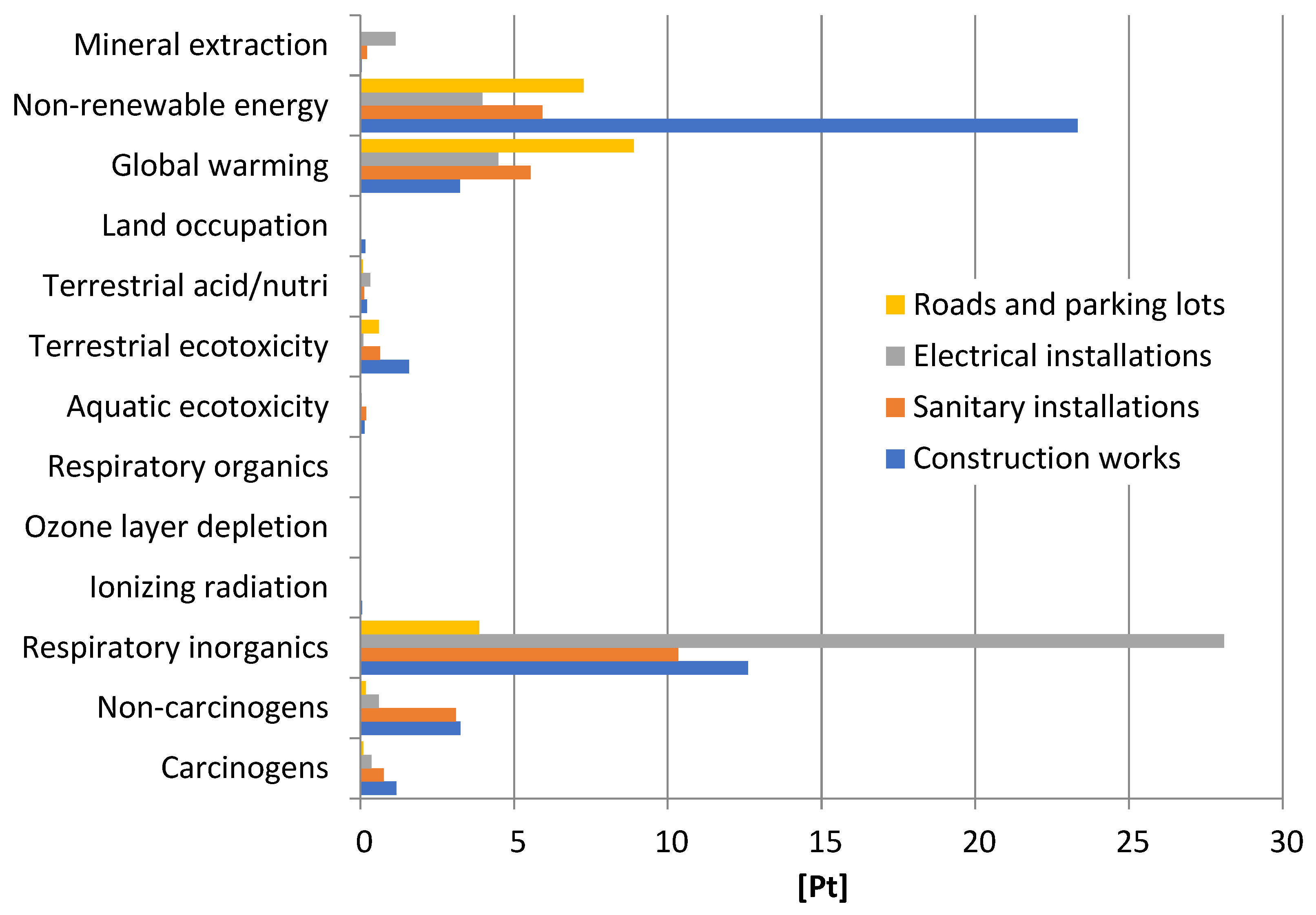

3.1. Characterization

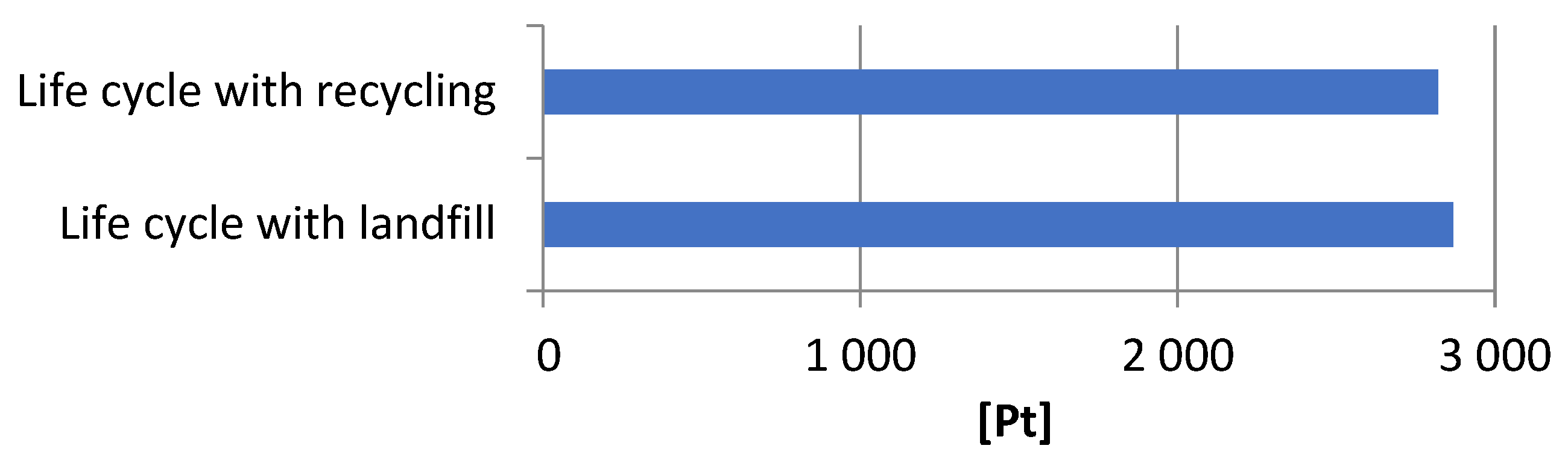

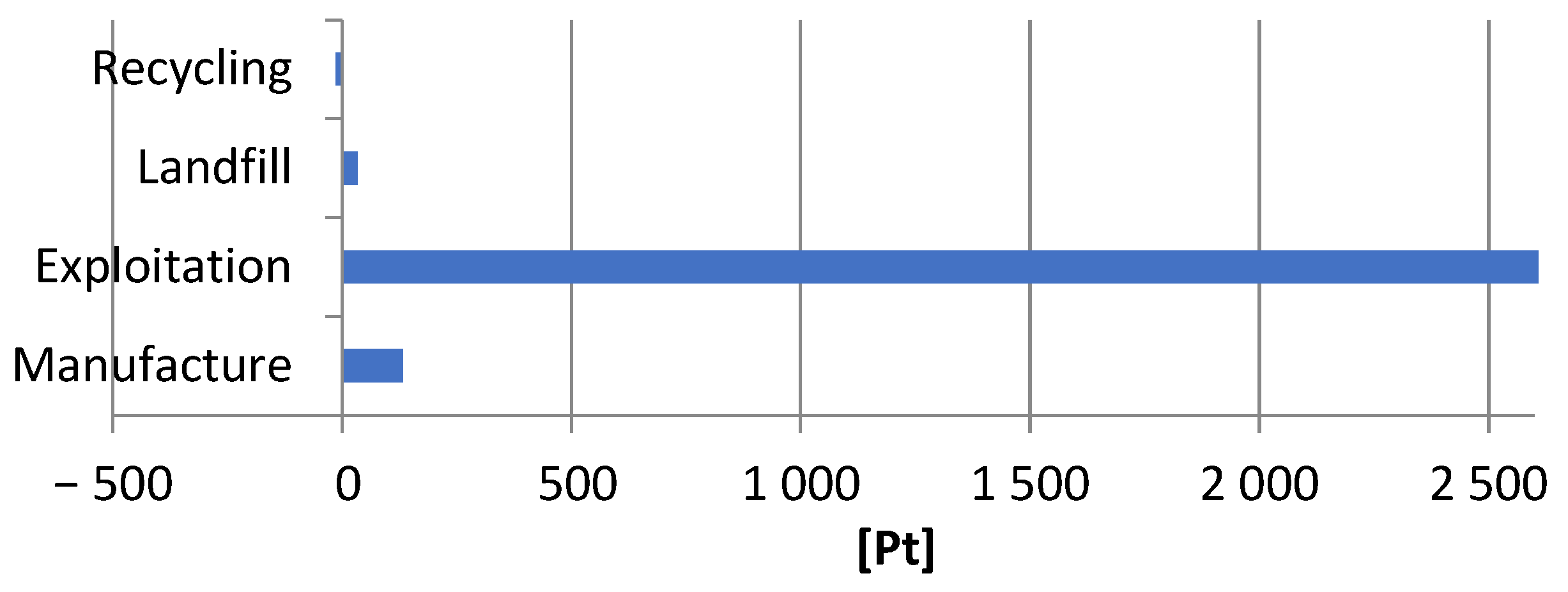

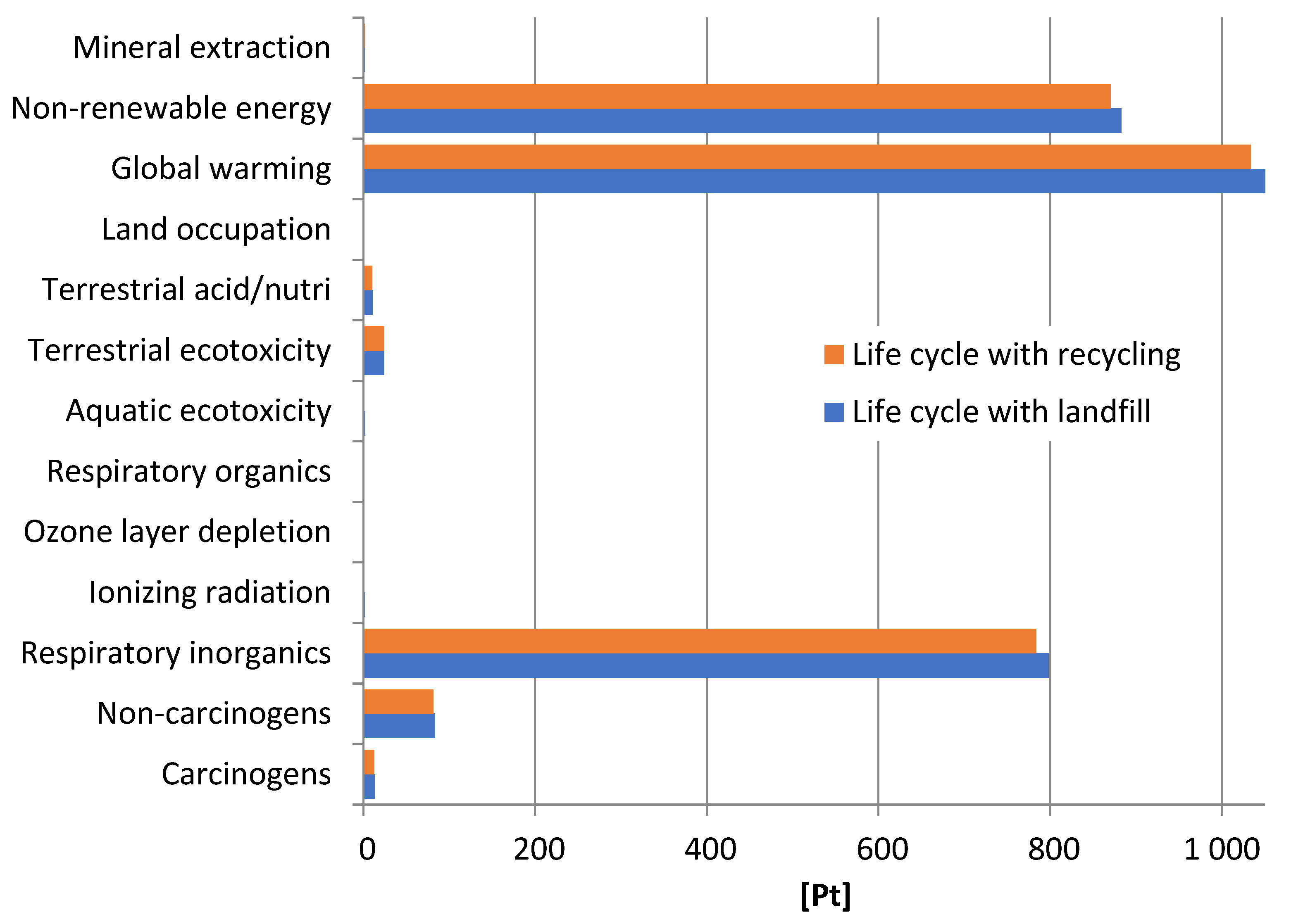

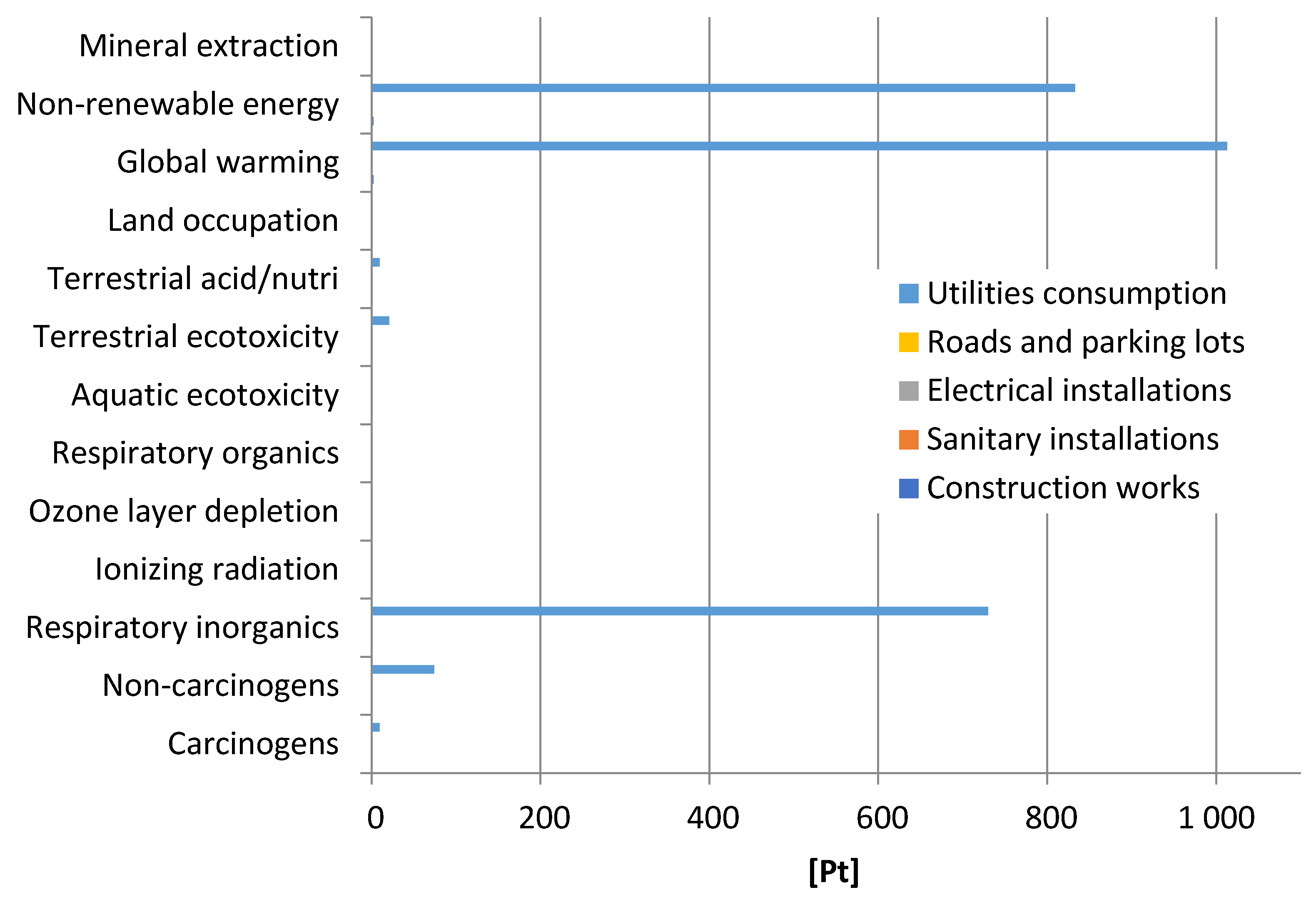

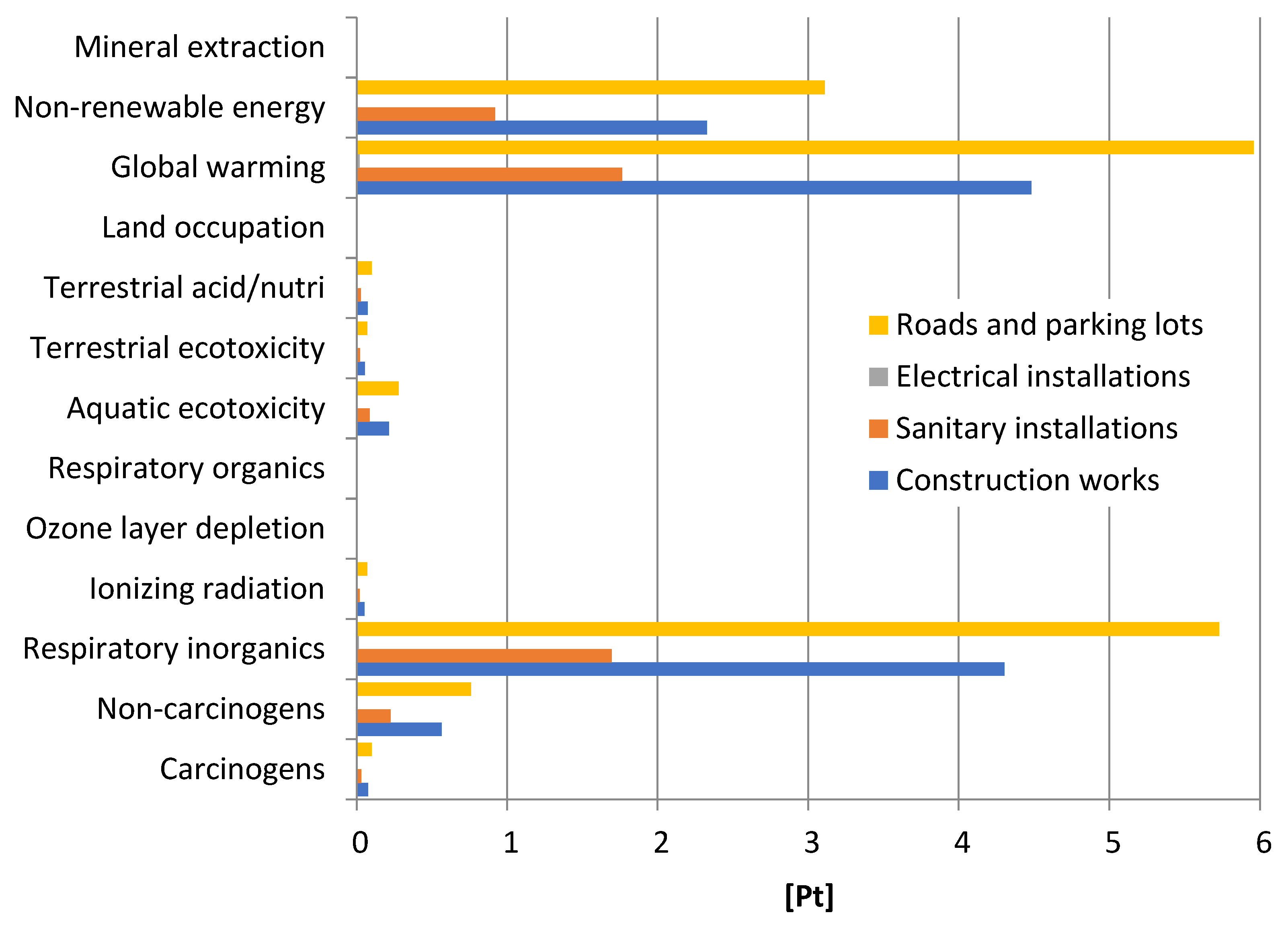

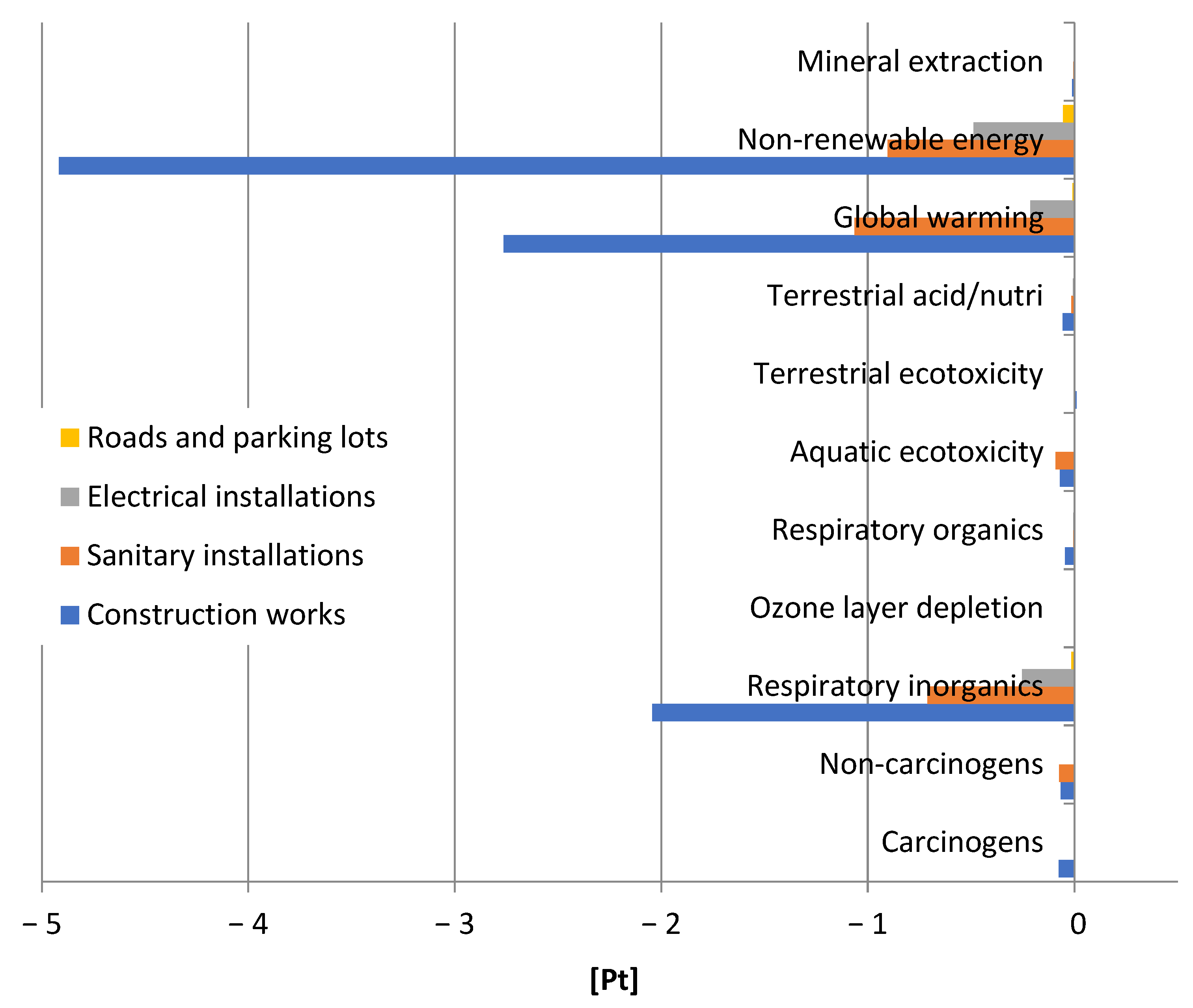

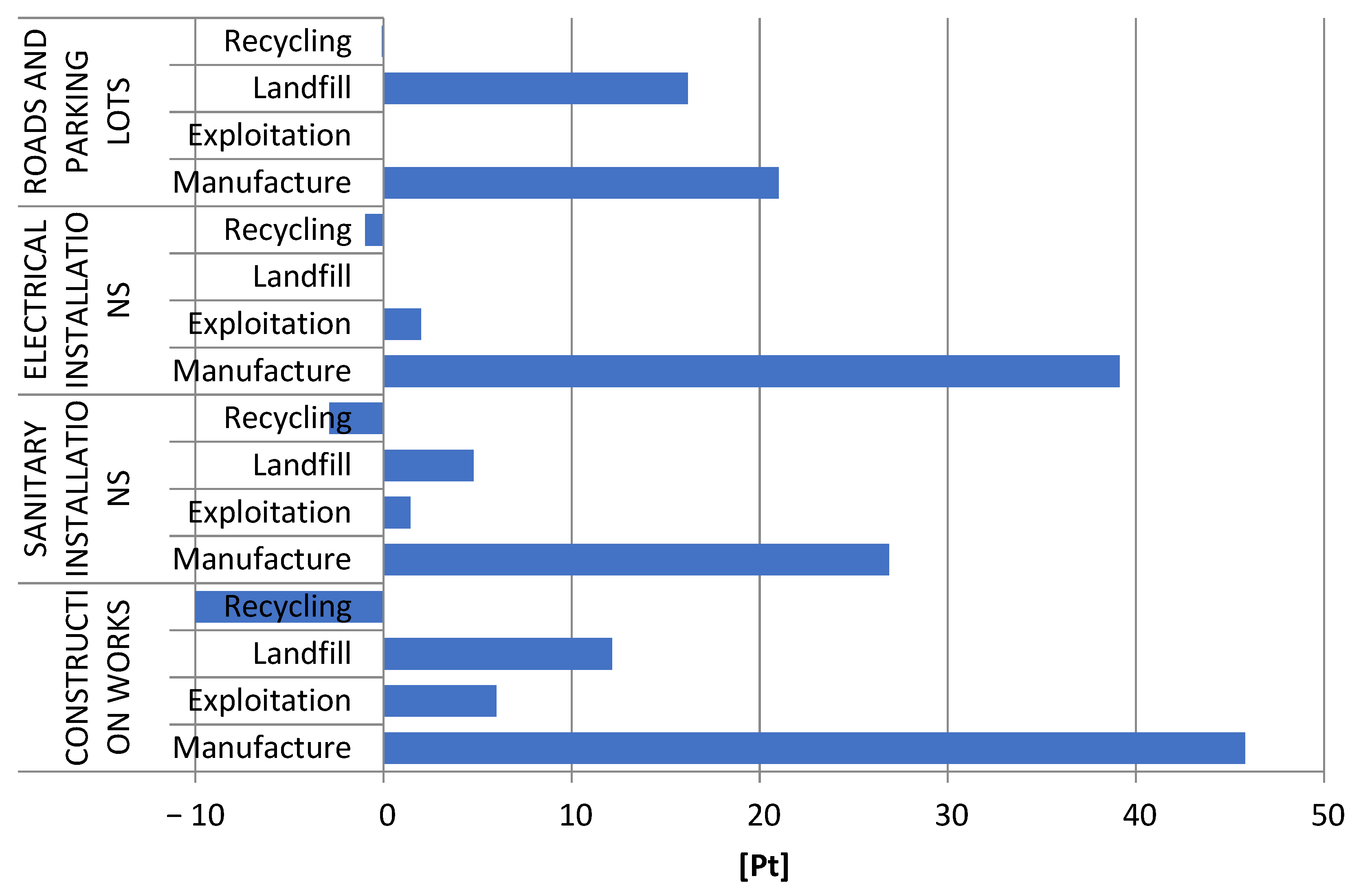

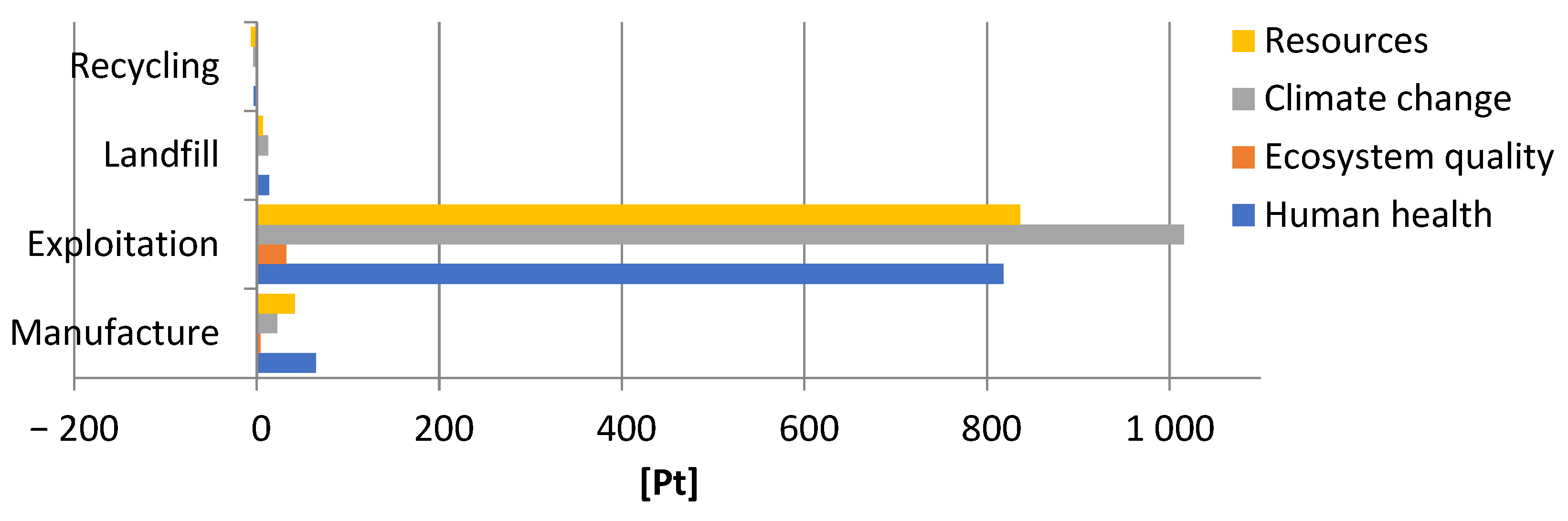

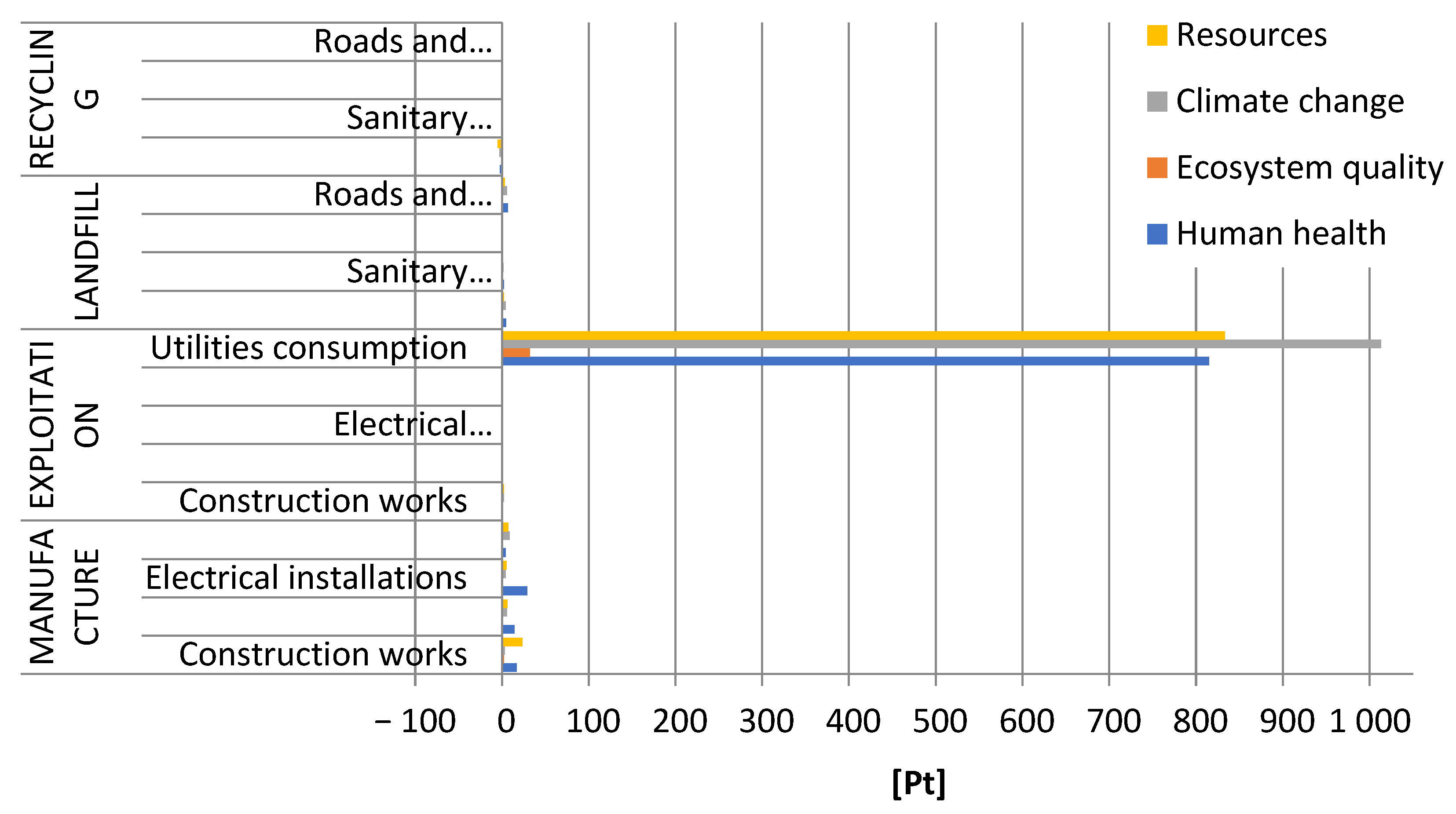

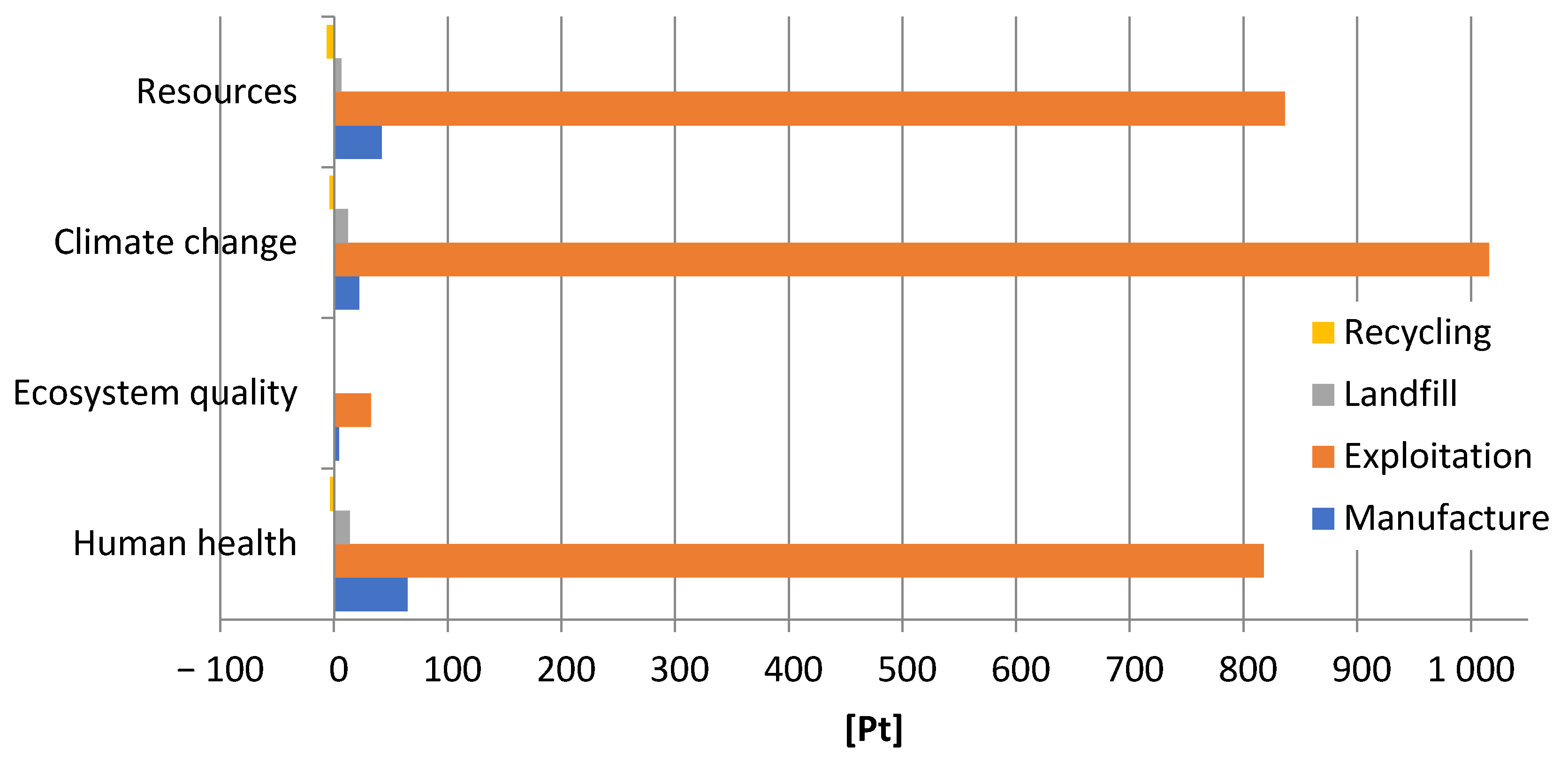

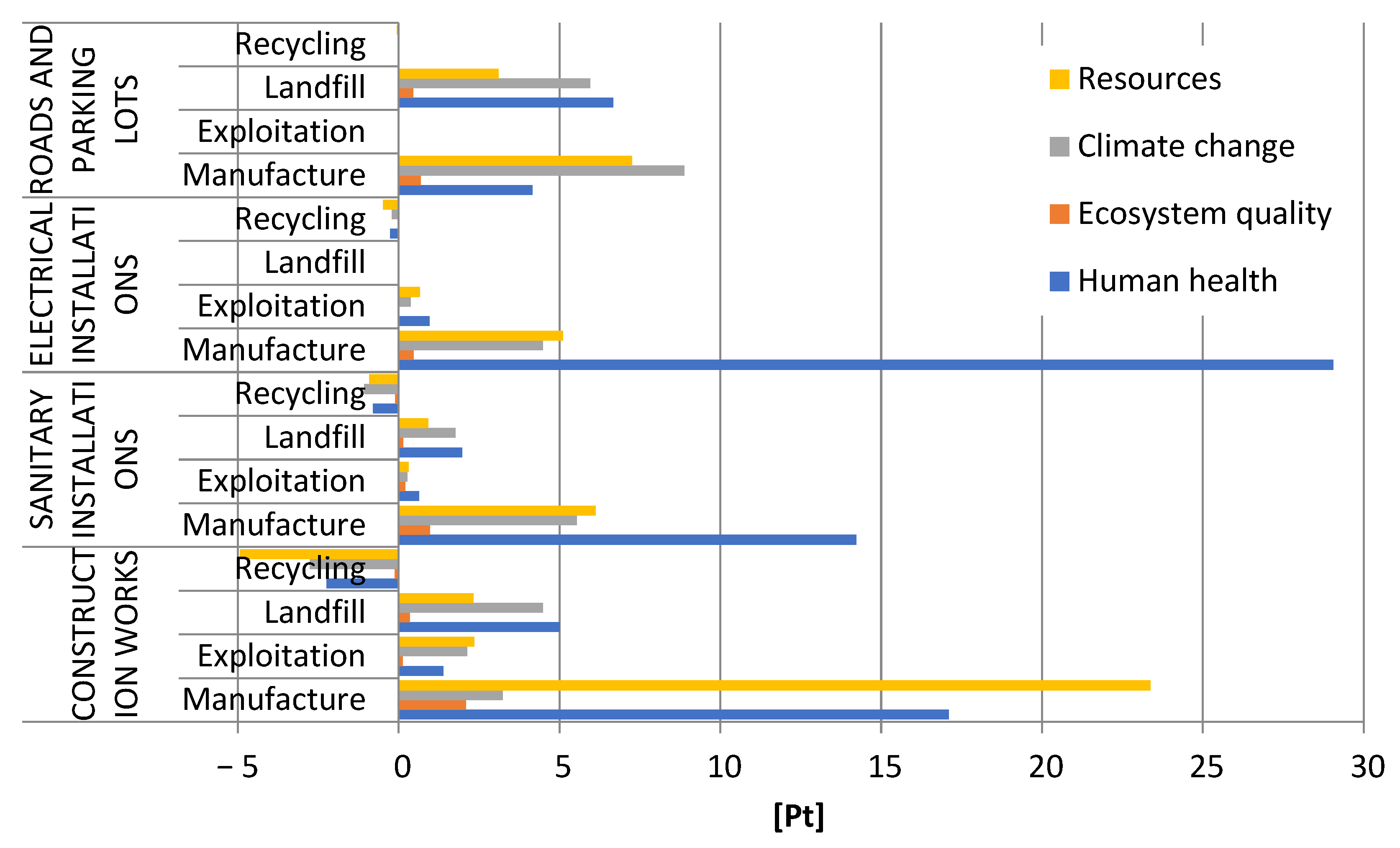

3.2. Grouping and Weighing—Impact Categories

3.3. Grouping and Weighing—Areas of Influence

4. Summary

5. Conclusions

- -

- Use of non-waste or low-waste technologies;

- -

- Use of non-toxic substances or those with possibly low toxicity;

- -

- Recovery of plastics, materials and components used at different phases of the life cycle of buildings and as much waste generated during their lifetime as possible;

- -

- Using analogous processes, methods and technologies that have been successfully applied in other facilities;

- -

- Tracking scientific and technological development;

- -

- Reduction in energy and material consumption throughout the life cycle;

- -

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pharino, C. Challenges for Sustainable Solid Waste Management; Springer Nature Singapore: Singapore, 2017; pp. 1–27. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, S. Green Technologies and Environmental Sustainability; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–43. [Google Scholar] [CrossRef]

- McLellan, B. Sustainable Future for Human Security. Environment and Resources; Springer Nature Singapore: Singapore, 2018; pp. 29–47. [Google Scholar] [CrossRef]

- Yang, M.; Yu, X. Energy Efficiency. Benefits for Environment and Society; Springer: London, UK, 2015; pp. 11–42. [Google Scholar] [CrossRef]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and Durability Properties of Concretes Incorporating Natural Zeolite; Archives of Civil and Mechanical Engineering: Amsterdam, The Netherlands, 2016; pp. 554–562. [Google Scholar] [CrossRef]

- Ekardt, F. Sustainability. Transformation, Governance, Ethics, Law; Springer Nature Switzerland: Cham, Switzerland, 2020; pp. 61–109. [Google Scholar] [CrossRef]

- Marczuk, A.; Misztal, W.; Słowik, T.; Piekarski, W.; Bojanowska, M.; Jackowska, I. Chemical determinants of the use of recycled vehicle components. Przem. Chem. 2015, 10, 1867–1871. [Google Scholar] [CrossRef]

- Guinée, J.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Rydberg, T. Life Cycle Assessment: Past, present, and future. Environ. Sci. Technol. 2011, 1, 90–96. [Google Scholar] [CrossRef]

- Kulczycka, J.; Lelek, Ł.; Lewandowska, A.; Zarębska, J. Life Cycle Assessment of municipal solid waste management—comparison of results using different LCA models. Pol. J. Environ. Stud. 2015, 1, 125–140. [Google Scholar] [CrossRef]

- Dastbaz, M.; Gorse, C. Sustainable Ecological Engineering Design; Springer International Publishing: Cham, Switzerland, 2016; pp. 45–123. [Google Scholar] [CrossRef]

- Flizikowski, J.; Bieliński, K. Technology and Energy Sources Monitoring: Control, Efficiency and Optimization; IGI Global: Hershey, PA, USA, 2013; pp. 6–29. ISBN 9781466626645. [Google Scholar]

- Frankl, P.; Rubik, F. Life Cycle Assessment in Industry and Business; Springer: Berlin/Heidelberg, Germany, 2000; pp. 43–51. [Google Scholar] [CrossRef]

- Curran, M.A. Goal and Scope Definition in Life Cycle Assessment; Springer Science + Business Media: Dordrecht, The Netherlands, 2017; pp. 1–167. [Google Scholar] [CrossRef]

- Kłos, Z. Ecobalancial assessment of chosen packaging processes in food industry. Int. J. Life Cycle Assess 2002, 7, 309. [Google Scholar] [CrossRef]

- Górzyński, J. Podstawy Analizy Środowiskowej Wyrobów i Obiektów; Wydawnictwa Naukowo-Techniczne: Warsaw, Poland, 2007; pp. 5–487. ISBN 978-83-204-3252-9. (In Polish) [Google Scholar]

- Klostermann, J.E.M.; Tukker, A. Product Innovation and Eco-Efficiency; Springer Science + Business Media: Dordrecht, The Netherlands, 2008; pp. 199–223. [Google Scholar] [CrossRef]

- Goedkoop, M.; Oele, M.; Vieira, M.; Leijting, J.; Ponsioen, T.; Meijer, E. Introduction into LCA Methodology and Practice with SimaPro, SimaPro User Manual; PréConsultants: Amersfoort, The Netherlands, 2016; Available online: Pre-sustainability.com/download/SimaPro8IntroductionToLCA.pdf (accessed on 10 July 2021).

- Klinglmair, M.; Sala, S.; Brandão, M. Assessing resource depletion in LCA: A review of methods and methodological issues. Int. J. Life Cycle Assess 2014, 19, 580–592. [Google Scholar] [CrossRef]

- ISO 14040:2006: Environmental Management—Life Cycle Assessment—Principles and Framework. Available online: Iso.org/standard/37456.html (accessed on 17 July 2021).

- ISO 14044:2006: Environmental Management—Life Cycle Assessment—Requirements and Guidelines. Available online: Iso.org/standard/38498.html (accessed on 17 July 2021).

- Ulgiati, S.; Raugei, M.; Bargigli, S. Overcoming the in adequacy of single-criterion approaches to Life Cycle Assessment. Ecol. Modell. 2006, 3, 432–442. [Google Scholar] [CrossRef]

- Guineé, J. Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Springer Science + Business Media: Berlin, Germany, 2002; pp. 5–644. [Google Scholar] [CrossRef]

- Jolliet, O.; Margni, M.; Charles, R.; Humbert, S.; Payet, J.; Rebitzer, G.; Rosenbaum, R. IMPACT 2002+: A new life cycle impact assessment methodology. Int. J. Life Cycle Assess 2003, 8, 324–329. [Google Scholar] [CrossRef] [Green Version]

- Kurczewski, P.; Kłos, Z. Technical objects classification for environmental analyses. Zag. Ekspl. Masz. 2005, 2, 127–138. [Google Scholar]

- Fernández, R.Á.; Zubelzu, S.; Martínez, R. Carbon Footprint and the Industrial Life Cycle; Springer International Publishing: Cham, Switzerland, 2017; pp. 3–176. [Google Scholar] [CrossRef]

- Tomporowski, A.; Flizikowski, J.; Kruszelnicka, W.; Piasecka, I.; Kasner, R.; Mroziński, A.; Kovalyshyn, S. Destructiveness of profits and outlays associated with operation of offshore wind electric power plant. Part 1: Identification of a model and its components. Pol. Marit. Res. 2018, 2, 132–139. [Google Scholar] [CrossRef] [Green Version]

- Goedkoop, M.; Oele, M.; Vieira, M.; Leijting, J.; Ponsioen, T.; Meijer, E. SimaPro 7. Tutorial; PréConsultants: Amersfoort, The Netherlands, 2016; Available online: Pre-sustainability.com/download/SimaPro8Tutorial.pdf (accessed on 10 July 2021).

- Rebitzer, G.; Loerincik, Y.; Jolliet, O. Input-Output Life Cycle Assessment: From Theory to Applications. Int. J. Life Cycle Assess 2002, 3, 174–176. [Google Scholar] [CrossRef] [Green Version]

- Recchia, L.; Boncinelli, P.; Cini, E.; Vieri, M.; Garbati Pegna, F.; Sarri, D. Multicriteria Analysis and LCA Techniques; Springer: London, UK, 2011; pp. 5–25. [Google Scholar] [CrossRef]

- Finkbeiner, M. Special Types of Life Cycle Assessment; Springer Science + Business Media: Dordrecht, The Netherlands, 2016; pp. 115–332. [Google Scholar] [CrossRef]

- Hauschild, M.; Rosenbaum, R.K.; Olsen, S. Life Cycle Assessment. Theory and Practice; Springer Science + Business Media: Dordrecht, The Netherlands, 2018; pp. 9–55. [Google Scholar] [CrossRef]

- Tomporowski, A.; Piasecka, I.; Flizikowski, J.; Kasner, R.; Kruszelnicka, W.; Mroziński, A.; Bieliński, K. Comparison analysis of blade life cycles of land-based and offshore wind power plants. Pol. Marit. Res. 2018, 25, 225–233. [Google Scholar] [CrossRef] [Green Version]

- Sasmal, J. Resources, Technology and Sustainability; Springer Nature Singapore: Singapore, 2016; pp. 79–235. [Google Scholar] [CrossRef]

- Affolderbach, J.; Schulz, C. Green Building Transitions; Springer International Publishing: Cham, Switzerland, 2018; pp. 3–45. [Google Scholar] [CrossRef]

- Bauer, M.; Mösle, P.; Schwarz, M. Green Building; Springer: Berlin/Heidelberg, Germany, 2010; pp. 8–143. [Google Scholar] [CrossRef]

- Motoasca, E.; Agarwal, A.K.; Breesch, H. Energy Sustainability in Built and Urban Environments; Springer Nature Singapore: Singapore, 2019; pp. 139–164. [Google Scholar] [CrossRef]

- Plastrik, P.; Cleveland, J. Life After Carbon. The Next Global Transformation of Cities; Island Press: Washington, DC, USA, 2018; pp. 13–213. [Google Scholar] [CrossRef]

- Yang, F.; Chen, L. High-Rise Urban Form and Microclimate; Springer Nature Singapore: Singapore, 2020; pp. 3–74. [Google Scholar] [CrossRef]

- Mercader-Moyano, P. Sustainable Development and Renovation in Architecture; Springer International Publishing: Cham, Switzerland, 2017; pp. 227–449. [Google Scholar] [CrossRef]

- Oladokun, M.G.; Aigbavboa, C. Simulation-Based Analysis of Energy and Carbon Emissions in the Housing Sector. A System Dynamics Approach; Springer International Publishing: Cham, Switzerland, 2018; pp. 1–225. [Google Scholar] [CrossRef]

- Matsumoto, M.; Masui, K.; Fukushige, S.; Kondoh, S. Sustainability Through Innovation in Product Life Cycle Design; Springer Nature Singapore: Singapore, 2017; pp. 385–536. [Google Scholar] [CrossRef]

- Piasecka, I.; Bałdowska-Witos, P.; Piotrowska, K.; Tomporowski, A. Eco-energetical life cycle assessment of materials and components of photovoltaic power plant. Energies 2020, 13, 1385. [Google Scholar] [CrossRef] [Green Version]

- Drück, H.; Mathur, J.; Panthalookaran, V. Green Buildings and Sustainable Engineering; Springer Nature Singapore: Singapore, 2020; pp. 139–245. [Google Scholar] [CrossRef]

- Graczyk, M.; Rybaczewska-Błażejowska, M. Continual improvement as a pillar of environmental management. Management 2010, 1, 297–305. [Google Scholar]

- Littlewood, J.; Howlett, R.J.; Capozzoli, A.; Jain, L.C. Sustainability in Energy and Buildings; Springer Nature Singapore: Singapore, 2020; pp. 37–47. [Google Scholar] [CrossRef]

| Media | Average Annual Consumption | Forecast Consumption 40 Years of Operation | Unit |

|---|---|---|---|

| Gas | 11,366 | 454,640 | m3 |

| Electricity | 212,583 | 8,503,320 | kWh |

| Impact Category | Unit | Life Cycle with Landfill | Life Cycle with Recycling |

|---|---|---|---|

| Carcinogens | kg C2H3Cl eq | 3.27 × 104 | 3.19 × 104 |

| Non-carcinogens | kg C2H3Cl eq | 2.10 × 105 | 2.06 × 105 |

| Respiratory inorganics | kg PM 2.5 eq | 8.09 × 103 | 7.94 × 103 |

| Ionizing radiation | Bq C-14 eq | 3.87 × 107 | 3.38 × 107 |

| Ozone layer depletion | kg CFC-11 eq | 3.71 × 10−1 | 3.51 × 10−1 |

| Respiratory organics | kg C2H4 eq | 7.26 × 102 | 5.06 × 102 |

| Aquatic ecotoxicity | kg TEG water | 5.06 × 108 | 3.03 × 108 |

| Terrestrial ecotoxicity | kg TEG soil | 4.18 × 107 | 4.15 × 107 |

| Terrestrial acid/nutri | kg SO2 eq | 1.39 × 105 | 1.35 × 105 |

| Land occupation | m2 org. arable | 1.20 × 104 | 1.20 × 104 |

| Aquatic acidification | kg SO2 eq | 6.05 × 104 | 5.87 × 104 |

| Aquatic eutrophication | kg PO4 P-lim | 2.80 × 102 | 4.23 × 101 |

| Global warming | kg CO2 eq | 1.04 × 107 | 1.02 × 107 |

| Non-renewable energy | MJ primary | 1.35 × 108 | 1.33 × 108 |

| Mineral extraction | MJ surplus | 2.17 × 105 | 2.14 × 105 |

| Impact Category | Unit | Manufacture | Exploitation | Landfill | Recycling |

|---|---|---|---|---|---|

| Carcinogens | kg C2H3Cl eq | 6.04 × 103 | 2.61 × 104 | 5.21 × 102 | −1.93 × 102 |

| Non-carcinogens | kg C2H3Cl eq | 1.80 × 104 | 1.88 × 105 | 3.93 × 103 | −3.61 × 102 |

| Respiratory inorganics | kg PM 2.5 eq | 5.56 × 102 | 7.42 × 103 | 1.19 × 102 | −3.06 × 101 |

| Ionizing radiation | Bq C-14 eq | 3.60 × 106 | 3.02 × 107 | 4.89 × 106 | × |

| Ozone layer depletion | kg CFC-11 eq | 8.64 × 10−2 | 2.79 × 10−1 | 5.11 × 10−3 | −1.50 × 10−2 |

| Respiratory organics | kg C2H4 eq | 9.56 × 101 | 5.99 × 102 | 3.09 × 101 | −1.89 × 102 |

| Aquatic ecotoxicity | kg TEG water | 1.01 × 108 | 2.46 × 108 | 1.59 × 108 | −4.44 × 107 |

| Terrestrial ecotoxicity | kg TEG soil | 5.05 × 106 | 3.65 × 107 | 2.52 × 105 | 2.26 × 104 |

| Terrestrial acid/nutri | kg SO2 eq | 9.66 × 103 | 1.26 × 105 | 2.67 × 103 | −1.05 × 103 |

| Land occupation | m2 org. arable | 2.55 × 103 | 9.45 × 103 | 7.30 × 100 | × |

| Aquatic acidification | kg SO2 eq | 5.88 × 103 | 5.30 × 104 | 1.58 × 103 | −1.75 × 102 |

| Aquatic eutrophication | kg PO4 P-lim | 1.48 × 101 | 2.85 × 101 | 2.36 × 102 | −1.06 × 100 |

| Global warming | kg CO2 eq | 2.19 × 105 | 1.01 × 107 | 1.21 × 105 | −4.01 × 104 |

| Non-renewable energy | MJ primary | 6.15 × 106 | 1.28 × 108 | 9.67 × 105 | −9.68 × 105 |

| Mineral extraction | MJ surplus | 2.12 × 105 | 4.73 × 103 | 3.55 × 101 | −2.48 × 103 |

| Impact Category | Unit | Manufacture | |||

|---|---|---|---|---|---|

| Construction Works | Sanitary Installations | Electrical Installations | Roads and Parking Lots | ||

| Carcinogens | kg C2H3Cl eq | 2.95 × 103 | 1.93 × 103 | 9.17 × 102 | 2.39 × 102 |

| Non-carcinogens | kg C2H3Cl eq | 8.24 × 103 | 7.85 × 103 | 1.50 × 103 | 4.28 × 102 |

| Respiratory inorganics | kg PM 2.5 eq | 1.28 × 102 | 1.05 × 102 | 2.85 × 102 | 3.92 × 101 |

| Ionizing radiation | Bq C-14 eq | 1.68 × 106 | 8.27 × 105 | 2.30 × 105 | 8.63 × 105 |

| Ozone layer depletion | kg CFC-11 eq | 5.97 × 10−2 | 1.44 × 10−2 | 2.54 × 10−3 | 9.80 × 10−3 |

| Respiratory organics | kg C2H4 eq | 4.27 × 101 | 2.30 × 101 | 4.01 × 100 | 2.59 × 101 |

| Aquatic ecotoxicity | kg TEG water | 3.69 × 107 | 5.06 × 107 | 1.08 × 107 | 2.97 × 106 |

| Terrestrial ecotoxicity | kg TEG soil | 2.75 × 106 | 1.11 × 106 | 1.61 × 105 | 1.04 × 106 |

| Terrestrial acid/nutri | kg SO2 eq | 2.83 × 103 | 1.67 × 103 | 4.13 × 103 | 1.03 × 103 |

| Land occupation | m2 org. arable | 1.96 × 103 | 2.46 × 102 | 2.97 × 102 | 4.14 × 101 |

| Aquatic acidification | kg SO2 eq | 1.07 × 103 | 1.08 × 103 | 3.49 × 103 | 2.38 × 102 |

| Aquatic eutrophication | kg PO4 P-lim | 7.11 × 100 | 2.97 × 100 | 3.51 × 10−1 | 4.41 × 100 |

| Global warming | kg CO2 eq | 3.21 × 104 | 5.48 × 104 | 4.44 × 104 | 8.80 × 104 |

| Non-renewable energy | MJ primary | 3.55 × 106 | 9.00 × 105 | 6.04 × 105 | 1.10 × 106 |

| Mineral extraction | MJ surplus | 6.50 × 103 | 3.16 × 104 | 1.74 × 105 | 5.61 × 101 |

| Impact Category | Unit | Exploitation | ||||

|---|---|---|---|---|---|---|

| Construction Works | Sanitary Installations | Electrical Installations | Roads and Parking Lots | Utilities Consumption | ||

| Carcinogens | kg C2H3Cl eq | 1.91 × 102 | 6.85 × 101 | 1.71 × 103 | 2.58 × 10−1 | 2.41 × 104 |

| Non-carcinogens | kg C2H3Cl eq | 1.88 × 102 | 2.16 × 102 | 1.24 × 100 | 9.30 × 10−1 | 1.88 × 105 |

| Respiratory inorganics | kg PM 2.5 eq | 1.22 × 101 | 5.24 × 100 | 2.97 × 100 | 5.71 × 10−2 | 7.40 × 103 |

| Ionizing radiation | Bq C-14 eq | 5.70 × 105 | 7.73 × 104 | 2.09 × 101 | 2.78 × 103 | 2.95 × 107 |

| Ozone layer depletion | kg CFC-11 eq | 1.26 × 10−1 | 8.52 × 10−4 | 1.40 × 10−7 | 1.35 × 10−4 | 1.52 × 10−1 |

| Respiratory organics | kg C2H4 eq | 6.66 × 100 | 3.13 × 100 | 7.19 × 10−1 | 2.10 × 10−1 | 5.89 × 102 |

| Aquatic ecotoxicity | kg TEG water | 2.64 × 106 | 6.54 × 105 | 4.66 × 105 | 3.24 × 104 | 2.42 × 108 |

| Terrestrial ecotoxicity | kg TEG soil | 1.34 × 105 | 3.45 × 105 | 2.42 × 102 | 1.28 × 103 | 3.60 × 107 |

| Terrestrial acid/nutri | kg SO2 eq | 2.63 × 102 | 7.58 × 101 | 7.84 × 101 | 1.04 × 100 | 1.26 × 105 |

| Land occupation | m2 org. arable | 2.54 × 102 | 6.08 × 101 | 2.96 × 101 | 6.61 × 10−1 | 9.10 × 103 |

| Aquatic acidification | kg SO2 eq | 8.64 × 101 | 2.28 × 101 | 2.00 × 101 | 4.79 × 10−1 | 5.29 × 104 |

| Aquatic eutrophication | kg PO4 P-lim | 7.38 × 10−1 | 1.53 × 10−1 | 5.28 × 10−2 | 8.61 × 10−4 | 2.76 × 101 |

| Global warming | kg CO2 eq | 2.11 × 104 | 2.66 × 103 | 3.67 × 103 | 5.32 × 101 | 1.00 × 107 |

| Non-renewable energy | MJ primary | 3.58 × 105 | 4.56 × 104 | 1.00 × 105 | 1.39 × 103 | 1.27 × 108 |

| Mineral extraction | MJ surplus | 2.47 × 102 | 1.88 × 103 | 1.00 × 100 | 2.37 × 10−2 | 2.60 × 103 |

| Impact Category | Unit | Landfill | |||

|---|---|---|---|---|---|

| Construction Works | Sanitary Installations | Electrical Installations | Roads and Parking Lots | ||

| Carcinogens | kg C2H3Cl eq | 1.90 × 102 | 7.56 × 101 | 6.13 × 10−1 | 2.55 × 102 |

| Non-carcinogens | kg C2H3Cl eq | 1.43 × 103 | 5.71 × 102 | 4.44 × 100 | 1.93 × 103 |

| Respiratory inorganics | kg PM 2.5 eq | 4.36 × 101 | 1.72 × 101 | 1.53 × 10−1 | 5.81 × 101 |

| Ionizing radiation | Bq C-14 eq | 1.78 × 106 | 7.08 × 105 | 5.53 × 103 | 2.40 × 106 |

| Ozone layer depletion | kg CFC-11 eq | 1.88 × 10−3 | 7.37 × 10−4 | 6.69 × 10−6 | 2.49 × 10−3 |

| Respiratory organics | kg C2H4 eq | 1.14 × 101 | 4.45 × 100 | 4.29 × 10−2 | 1.50 × 101 |

| Aquatic ecotoxicity | kg TEG water | 5.89 × 107 | 2.38 × 107 | 1.81 × 105 | 7.58 × 107 |

| Terrestrial ecotoxicity | kg TEG soil | 9.30 × 104 | 3.72 × 104 | 2.95 × 102 | 1.21 × 105 |

| Terrestrial acid/nutri | kg SO2 eq | 9.80 × 102 | 3.86 × 102 | 3.48 × 100 | 1.30 × 103 |

| Land occupation | m2 org. arable | 2.66 × 100 | 1.06 × 100 | 8.35 × 10−3 | 3.58 × 100 |

| Aquatic acidification | kg SO2 eq | 5.77 × 102 | 2.29 × 102 | 2.26 × 100 | 7.72 × 102 |

| Aquatic eutrophication | kg PO4 P-lim | 8.58 × 101 | 3.43 × 101 | 2.56 × 10−1 | 1.16 × 102 |

| Global warming | kg CO2 eq | 4.44 × 104 | 1.75 × 104 | 2.10 × 102 | 5.90 × 104 |

| Non-renewable energy | MJ primary | 3.54 × 105 | 1.40 × 105 | 1.20 × 103 | 4.72 × 105 |

| Mineral extraction | MJ surplus | 1.29 × 101 | 5.14 × 100 | 3.83 × 10−2 | 1.74 × 101 |

| Impact Category | Unit | Recycling | |||

|---|---|---|---|---|---|

| Construction Works | Sanitary Installations | Electrical Installations | Roads and Parking Lots | ||

| Carcinogens | kg C2H3Cl eq | −1.94 × 102 | 2.79 × 100 | −9.74 × 100 | 7.86 × 100 |

| Non-carcinogens | kg C2H3Cl eq | −1.68 × 102 | −1.86 × 102 | −1.00 × 101 | 3.84 × 100 |

| Respiratory inorganics | kg PM 2.5 eq | −2.07 × 101 | −7.20 × 100 | −2.56 × 100 | −1.55 × 10−1 |

| Ionizing radiation | Bq C-14 eq | −1.18 × 10−2 | −2.09 × 10−3 | −1.00 × 10−3 | −1.20 × 10−4 |

| Ozone layer depletion | kg CFC-11 eq | −1.51 × 102 | −1.82 × 101 | −1.79 × 101 | −2.29 × 100 |

| Respiratory organics | kg C2H4 eq | −1.90 × 107 | −2.50 × 107 | −1.02 × 106 | 5.76 × 105 |

| Aquatic ecotoxicity | kg TEG water | 1.79 × 104 | 1.60 × 103 | 2.80 × 103 | 2.96 × 102 |

| Terrestrial ecotoxicity | kg TEG soil | −7.59 × 102 | −1.85 × 102 | −1.01 × 102 | −8.37 × 100 |

| Terrestrial acid/nutri | kg SO2 eq | −1.12 × 102 | −4.90 × 101 | −1.36 × 101 | −4.66 × 10−1 |

| Land occupation | m2 org. arable | −5.84 × 10−1 | −4.26 × 10−1 | −5.52 × 10−2 | 4.42 × 10−3 |

| Aquatic acidification | kg SO2 eq | −2.74 × 104 | −1.05 × 104 | −2.11 × 103 | −9.15 × 101 |

| Aquatic eutrophication | kg PO4 P-lim | −7.47 × 105 | −1.38 × 105 | −7.43 × 104 | −8.44 × 103 |

| Global warming | kg CO2 eq | −1.63 × 103 | −7.80 × 102 | −6.23 × 101 | −3.83 × 10−2 |

| No | Substance | Compartment | Construction Works | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | −4.40 × 100 | 2.19 × 10−1 | × | −2.48 × 100 |

| 2 | Carbon dioxide, in ground | Air | 7.22 × 100 | 1.84 × 100 | 2.77 × 100 | × |

| 3 | Carbon monoxide | Air | 5.71 × 10−2 | × | × | −2.48 × 10−2 |

| 4 | Carbon monoxide, in ground | Air | 7.58 × 10−3 | × | 5.14 × 10−3 | × |

| 5 | Dinitrogen monoxide | Air | 2.74 × 10−2 | 5.37 × 10−3 | 1.48 × 10−1 | 2.33 × 10−3 |

| 6 | Ethane, hexafluoro-, HFC-116 | Air | 3.10 × 10−2 | 2.46 × 10−3 | 1.94 × 10−6 | × |

| 7 | Methane | Air | 6.85 × 10−2 | 3.43 × 10−3 | × | −6.16 × 10−2 |

| 8 | Methane, in ground | Air | 8.23 × 10−2 | 2.89 × 10−2 | 1.55 × 100 | × |

| 9 | Methane, tetrafluoro-, CFC-14 | Air | 1.38 × 10−1 | 1.10 × 10−2 | 8.60 × 10−6 | −2.00 × 10−1 |

| 10 | Sulfur hexafluoride | Air | × | × | 3.33 × 10−3 | × |

| 11 | Remaining substances | × | 7.91 × 10−3 | 1.66 × 10−2 | 3.01 × 10−4 | −2.68 × 10−4 |

| TOTAL | 3.24 × 100 | 2.13 × 100 | 4.48 × 100 | −2.76 × 100 | ||

| No | Substance | Compartment | Sanitary Installations | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | 2.67 × 100 | 2.58 × 10−2 | × | −9.29 × 10−1 |

| 2 | Carbon dioxide, in ground | Air | 2.62 × 100 | 2.36 × 10−1 | 1.09 × 100 | × |

| 3 | Carbon monoxide | Air | 2.13 × 10−2 | × | × | −1.19 × 10−2 |

| 4 | Carbon monoxide, in ground | Air | × | 8.36 × 10−4 | × | × |

| 5 | Dinitrogen monoxide | Air | 1.38 × 10−2 | 1.33 × 10−3 | 5.89 × 10−2 | −2.69 × 10−5 |

| 6 | Ethane, hexafluoro-, HFC-116 | Air | 1.94 × 10−2 | × | 7.71 × 10−7 | × |

| 7 | Methane | Air | 7.14 × 10−2 | 6.15 × 10−4 | × | −2.93 × 10−2 |

| 8 | Methane, in ground | Air | 1.96 × 10−2 | 3.13 × 10−3 | 6.12 × 10−1 | × |

| 9 | Methane, tetrafluoro-, CFC-14 | Air | 9.33 × 10−2 | 6.04 × 10−4 | 3.43 × 10−6 | × |

| 10 | Remaining substances | × | 5.48 × 10−3 | 5.35 × 10−4 | 3.46 × 10−3 | −9.48 × 10−2 |

| TOTAL | 5.53 × 100 | 2.69 × 10−1 | 1.76 × 100 | −1.06 × 100 | ||

| No | Substance | Compartment | Electrical Installations | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | 4.19 × 100 | 3.33 × 10−1 | × | −2.05 × 10−1 |

| 2 | Carbon dioxide, in ground | Air | 2.10 × 10−1 | 2.54 × 10−2 | 1.26 × 10−2 | × |

| 3 | Carbon monoxide | Air | 6.87 × 10−3 | 6.42 × 10−4 | × | −2.04 × 10−3 |

| 4 | Dinitrogen monoxide | Air | 5.03 × 10−3 | × | 4.45 × 10−4 | 3.48 × 10−4 |

| 5 | Ethane, hexafluoro-, HFC-116 | Air | 8.46 × 10−3 | × | 6.03 × 10−9 | × |

| 6 | Methane | Air | 2.05 × 10−2 | 9.04 × 10−3 | × | −5.91 × 10−3 |

| 7 | Methane, in ground | Air | 4.50 × 10−3 | 1.94 × 10−3 | 8.21 × 10−3 | × |

| 8 | Methane, tetrafluoro-, CFC-14 | Air | 3.77 × 10−2 | × | 2.68 × 10−8 | −1.08 × 10−3 |

| 9 | Remaining substances | × | 4.27 × 10−4 | 8.19 × 10−5 | 3.11 × 10−5 | −2.28 × 10−5 |

| TOTAL | 4.48 × 100 | 3.71 × 10−1 | 2.13 × 10−2 | −2.14 × 10−1 | ||

| No | Substance | Compartment | Roads and Parking Lots | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | −2.07 × 10−1 | 4.12 × 10−3 | × | −9.29 × 10−3 |

| 2 | Carbon dioxide, in ground | Air | 9.02 × 100 | 1.13 × 10−3 | 3.68 × 100 | × |

| 3 | Carbon monoxide | Air | × | 1.86 × 10−5 | × | × |

| 4 | Dinitrogen monoxide | Air | 1.48 × 10−2 | × | 1.99 × 10−1 | 4.64 × 10−5 |

| 5 | Methane | Air | × | 8.51 × 10−5 | × | × |

| 6 | Methane, in ground | Air | 5.60 × 10−2 | 1.89 × 10−5 | 2.07 × 100 | × |

| 7 | Remaining substances | × | 9.60 × 10−3 | 1.35 × 10−5 | 1.17 × 10−2 | 1.88 × 10−7 |

| TOTAL | 8.89 × 100 | 5.38 × 10−3 | 5.96 × 100 | −9.24 × 10−3 | ||

| No | Substance | Compartment | Construction Works | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | −4.40 × 100 | 2.19 × 10−1 | × | −2.48 × 100 |

| 2 | Carbon dioxide, in ground | Air | 7.22 × 100 | 1.84 × 100 | 2.77 × 100 | × |

| 3 | Carbon monoxide | Air | 5.71 × 10−2 | × | × | −2.48 × 10−2 |

| 4 | Carbon monoxide, in ground | Air | 7.58 × 10−3 | × | 5.14 × 10−3 | × |

| 5 | Dinitrogen monoxide | Air | 2.74 × 10−2 | 5.37 × 10−3 | 1.48 × 10−1 | 2.33 × 10−3 |

| 6 | Ethane, hexafluoro-, HFC-116 | Air | 3.10 × 10−2 | 2.46 × 10−3 | 1.94 × 10−6 | × |

| 7 | Methane | Air | 6.85 × 10−2 | 3.43 × 10−3 | × | −6.16 × 10−2 |

| 8 | Methane, in ground | Air | 8.23 × 10−2 | 2.89 × 10−2 | 1.55 × 100 | × |

| 9 | Methane, tetrafluoro-, CFC-14 | Air | 1.38 × 10−1 | 1.10 × 10−2 | 8.60 × 10−6 | −2.00 × 10−1 |

| 10 | Sulfur hexafluoride | Air | × | × | 3.33 × 10−3 | × |

| 11 | Remaining substances | × | 7.91 × 10−3 | 1.66 × 10−2 | 3.01 × 10−4 | −2.68 × 10−4 |

| TOTAL | 3.24 × 100 | 2.13 × 100 | 4.48 × 100 | −2.76 × 100 | ||

| No | Substance | Compartment | Sanitary Installations | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | 2.67 × 100 | 2.58 × 10−2 | × | −9.29 × 10−1 |

| 2 | Carbon dioxide, in ground | Air | 2.62 × 100 | 2.36 × 10−1 | 1.09 × 100 | × |

| 3 | Carbon monoxide | Air | 2.13 × 10−2 | × | × | −1.19 × 10−2 |

| 4 | Carbon monoxide, in ground | Air | × | 8.36 × 10−4 | × | × |

| 5 | Dinitrogen monoxide | Air | 1.38 × 10−2 | 1.33 × 10−3 | 5,89 × 10−2 | −2.69 × 10−5 |

| 6 | Ethane, hexafluoro-, HFC-116 | Air | 1.94 × 10−2 | × | 7.71 × 10−7 | × |

| 7 | Methane | Air | 7.14 × 10−2 | 6.15 × 10−4 | × | −2.93 × 10−2 |

| 8 | Methane, in ground | Air | 1.96 × 10−2 | 3.13 × 10−3 | 6.12 × 10−1 | × |

| 9 | Methane, tetrafluoro-, CFC-14 | Air | 9.33 × 10−2 | 6.04 × 10−4 | 3.43 × 10−6 | × |

| 10 | Remaining substances | × | 5.48 × 10−3 | 5.35 × 10−4 | 3.46 × 10−3 | −9.48 × 10−2 |

| TOTAL | 5.53 × 100 | 2.69 × 10−1 | 1.76 × 100 | −1.06 × 100 | ||

| No | Substance | Compartment | Electrical Installations | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | 4.19 × 100 | 3.33 × 10−1 | × | −2.05 × 10−1 |

| 2 | Carbon dioxide, in ground | Air | 2.10 × 10−1 | 2.54 × 10−2 | 1.26 × 10−2 | × |

| 3 | Carbon monoxide | Air | 6.87 × 10−3 | 6.42 × 10−4 | × | −2.04 × 10−3 |

| 4 | Dinitrogen monoxide | Air | 5.03 × 10−3 | × | 4.45 × 10−4 | 3.48 × 10−4 |

| 5 | Ethane, hexafluoro-, HFC-116 | Air | 8.46 × 10−3 | × | 6.03 × 10−9 | × |

| 6 | Methane | Air | 2.05 × 10−2 | 9.04 × 10−3 | × | −5.91 × 10−3 |

| 7 | Methane, in ground | Air | 4.50 × 10−3 | 1.94 × 10−3 | 8.21 × 10−3 | × |

| 8 | Methane, tetrafluoro-, CFC-14 | Air | 3.77 × 10−2 | × | 2.68 × 10−8 | −1.08 × 10−3 |

| 9 | Remaining substances | × | 4.27 × 10−4 | 8.19 × 10−5 | 3.11 × 10−5 | −2.28 × 10−5 |

| TOTAL | 4.48 × 100 | 3.71 × 10−1 | 2.13 × 10−2 | −2.14 × 10−1 | ||

| No | Substance | Compartment | Roads and Parking LOTS | |||

|---|---|---|---|---|---|---|

| Manufacture | Exploitation | Landfill | Recycling | |||

| 1 | Carbon dioxide | Air | −2.07 × 10−1 | 4.12 × 10−3 | × | −9.29 × 10−3 |

| 2 | Carbon dioxide, in ground | Air | 9.02 × 100 | 1.13 × 10−3 | 3.68 × 100 | × |

| 3 | Carbon monoxide | Air | × | 1.86 × 10−5 | × | × |

| 4 | Dinitrogen monoxide | Air | 1.48 × 10−2 | × | 1.99 × 10−1 | 4.64 × 10−5 |

| 5 | Methane | Air | × | 8.51 × 10−5 | × | × |

| 6 | Methane, in ground | Air | 5.60 × 10−2 | 1.89 × 10−5 | 2.07 × 100 | × |

| 7 | Remaining substances | × | 9.60 × 10−3 | 1.35 × 10−5 | 1.17 × 10−2 | 1.88 × 10−7 |

| TOTAL | 8.89 × 100 | 5.38 × 10−3 | 5.96 × 100 | −9.24 × 10−3 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tomporowski, D.; Kasner, R.; Franus, W.; Doerffer, K. Assessment of Environmental Loads in the Life Cycle of a Retail and Service Building. Energies 2022, 15, 3144. https://doi.org/10.3390/en15093144

Tomporowski D, Kasner R, Franus W, Doerffer K. Assessment of Environmental Loads in the Life Cycle of a Retail and Service Building. Energies. 2022; 15(9):3144. https://doi.org/10.3390/en15093144

Chicago/Turabian StyleTomporowski, Daniel, Robert Kasner, Wojciech Franus, and Krzysztof Doerffer. 2022. "Assessment of Environmental Loads in the Life Cycle of a Retail and Service Building" Energies 15, no. 9: 3144. https://doi.org/10.3390/en15093144

APA StyleTomporowski, D., Kasner, R., Franus, W., & Doerffer, K. (2022). Assessment of Environmental Loads in the Life Cycle of a Retail and Service Building. Energies, 15(9), 3144. https://doi.org/10.3390/en15093144