Diagnostics on the Basis of the Frequency-Temperature Dependences of the Loss Angle Tangent of Heavily Moistured Oil-Impregnated Pressboard

Abstract

1. Introduction

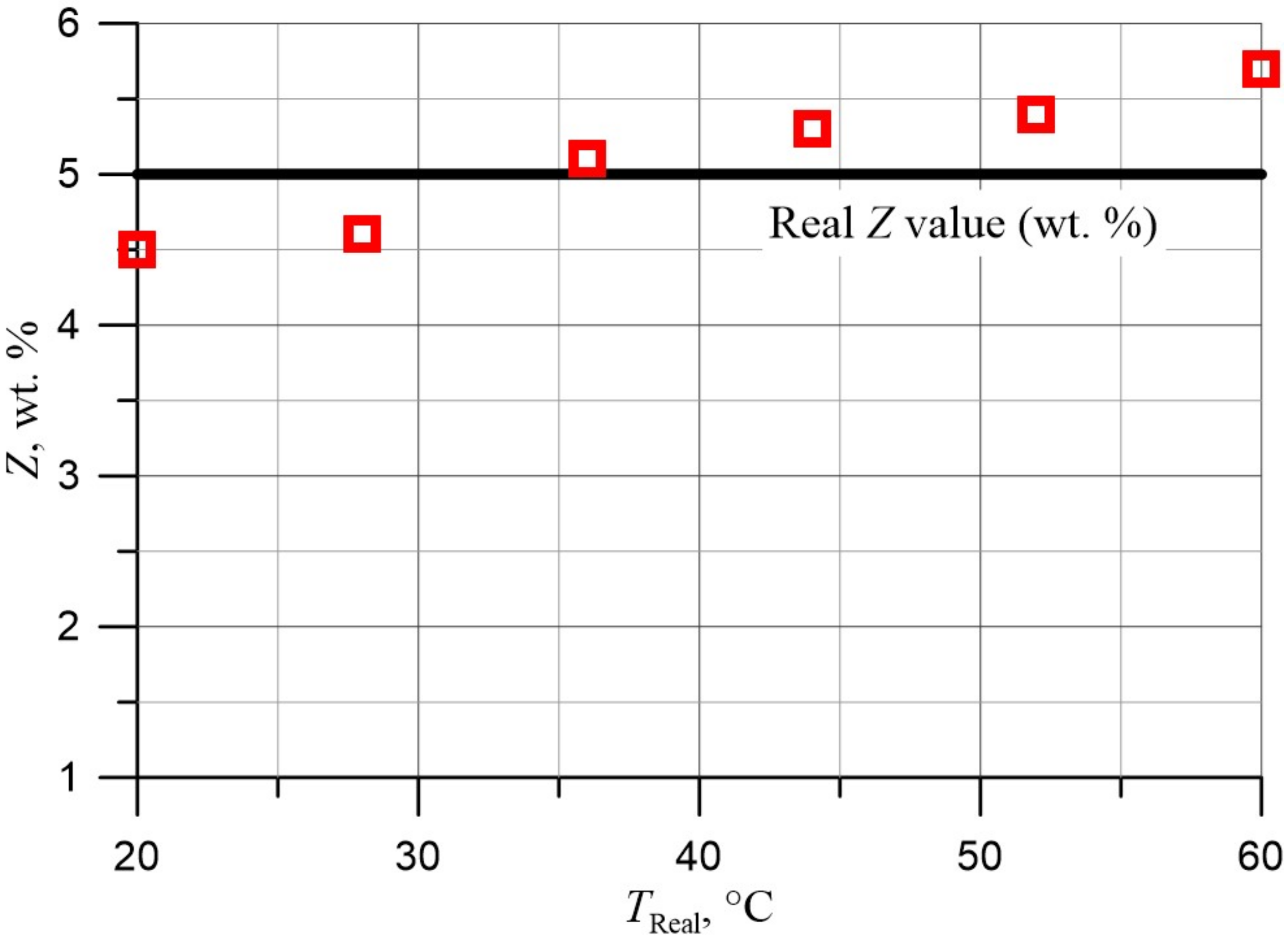

- The moisturize the pressboard in a manner as close as possible to the process of wetting the insulation in power transformers to a moisture content of (5.0 ± 0.2) wt. %. This value of moisture content was chosen because exceeding this value can lead to transformer failure.

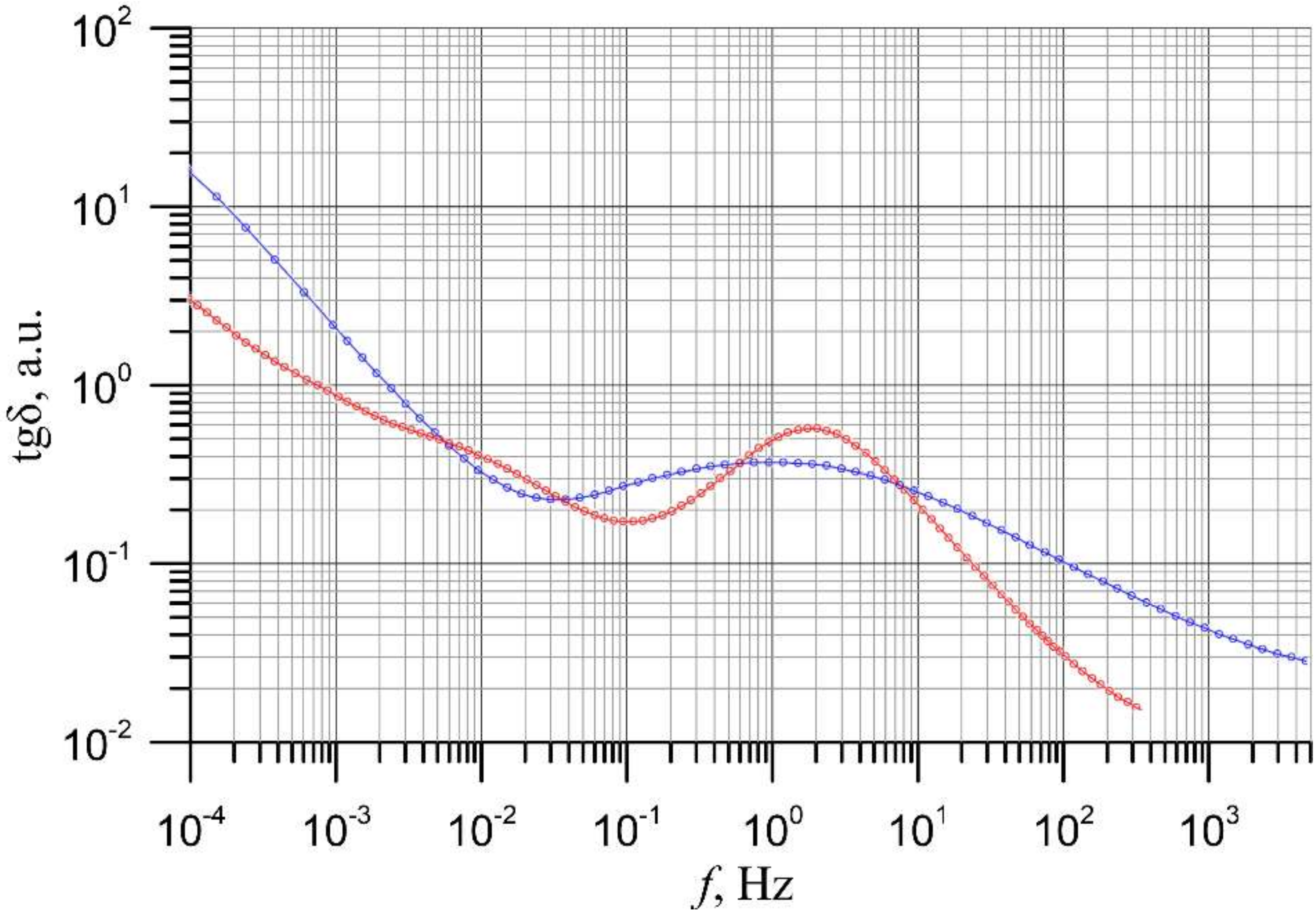

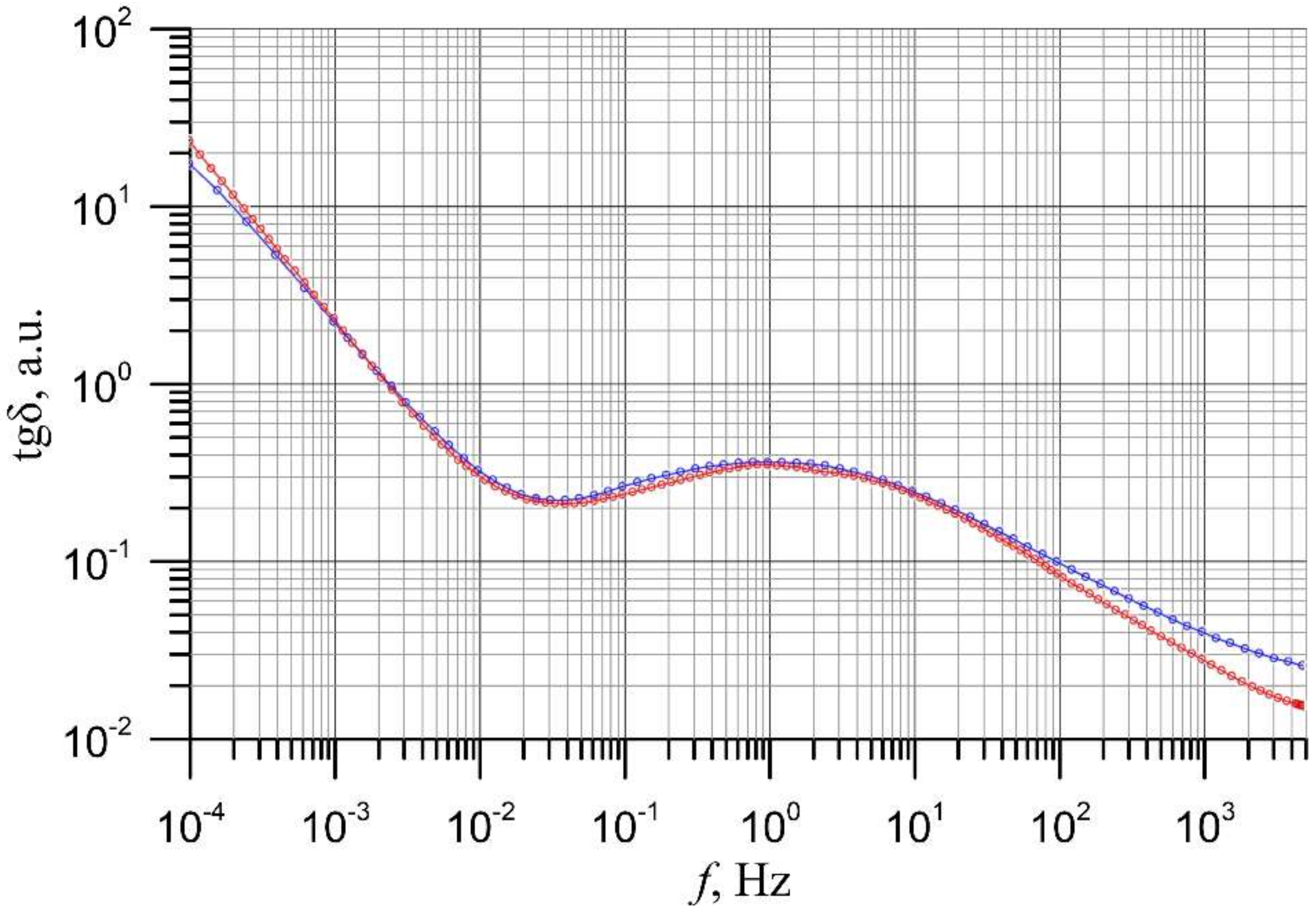

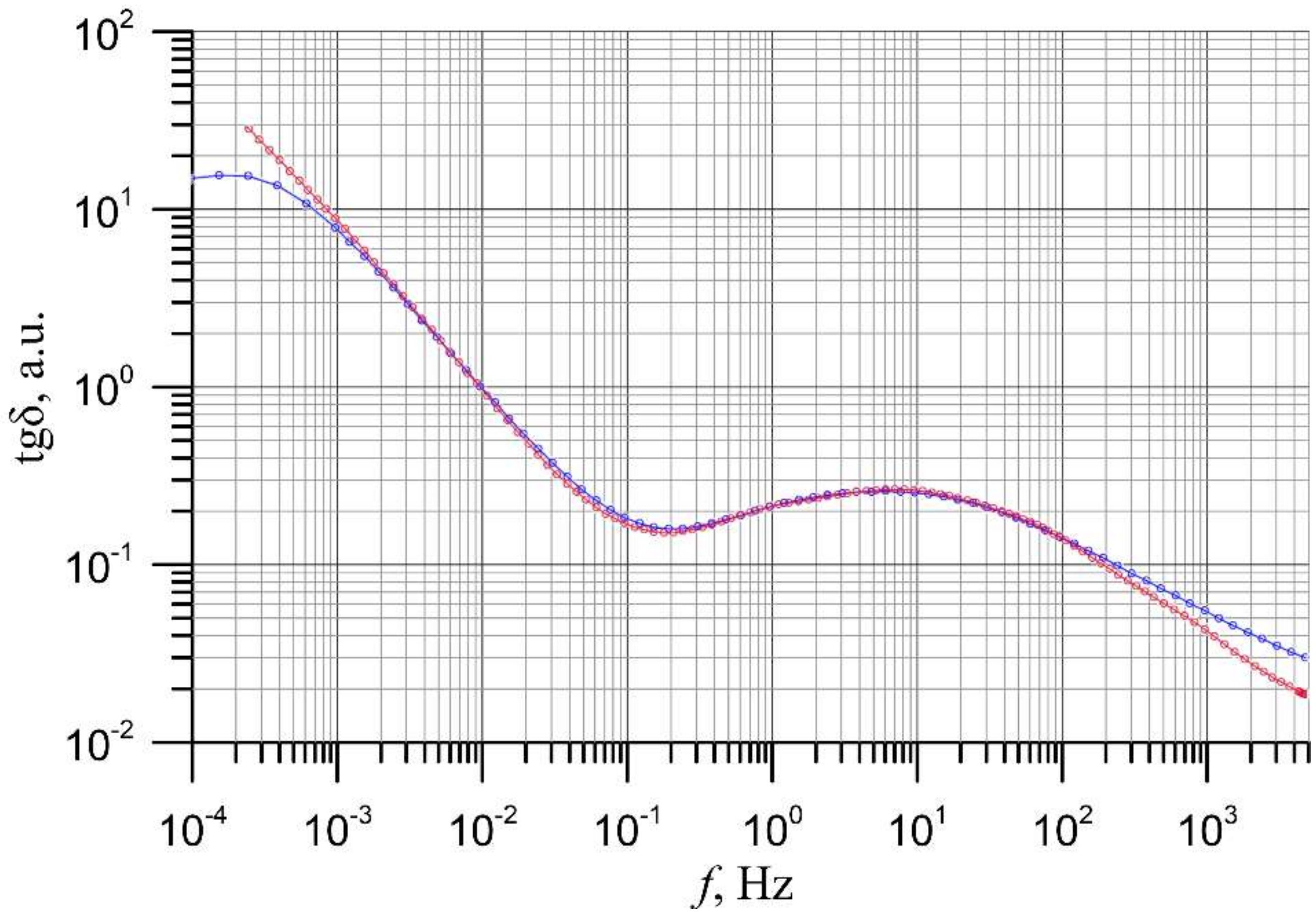

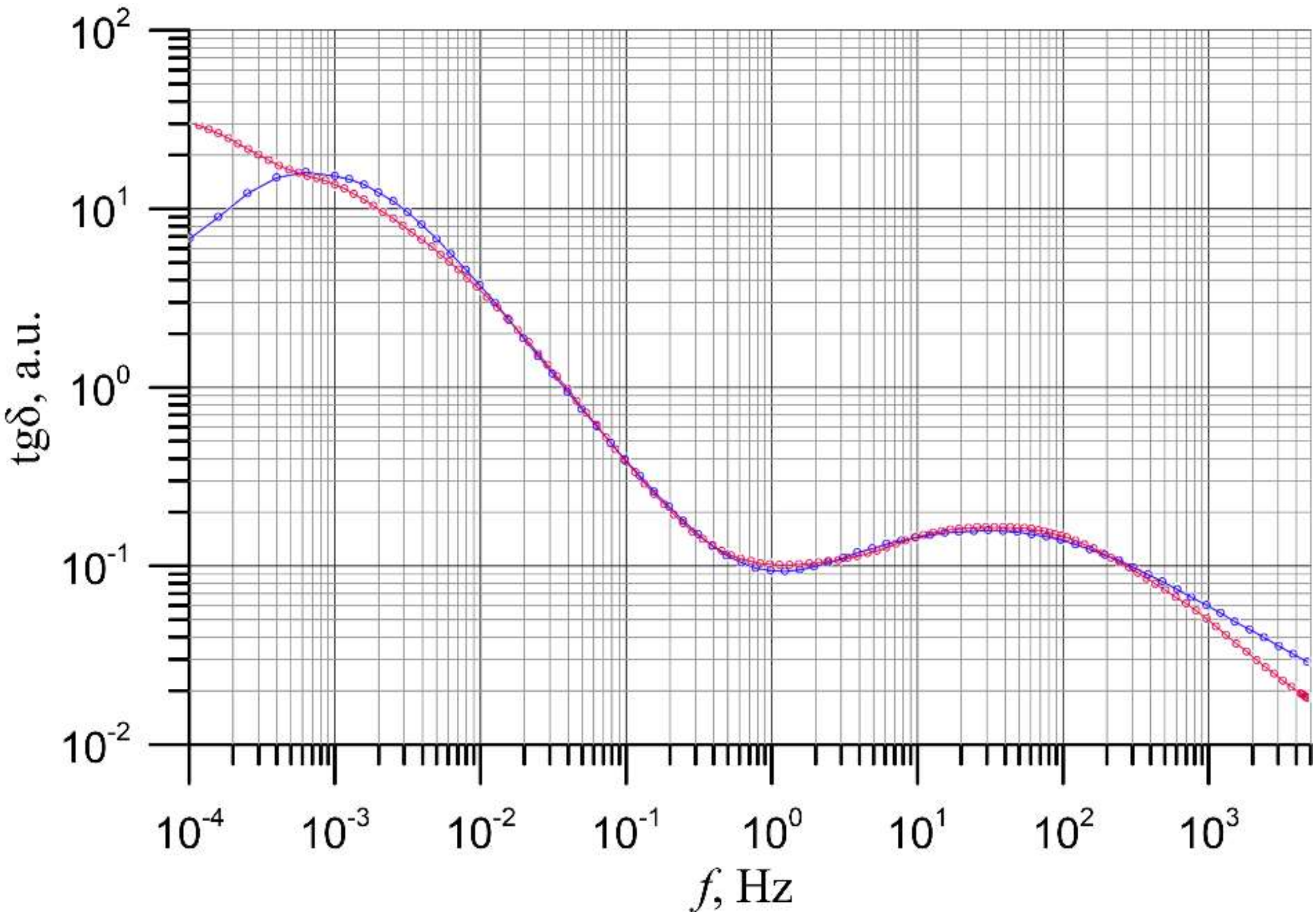

- To carry out precision measurements of the frequency-temperature dependences of the loss angle tangent of the composite with the Dirana meter.

- To match simulated waveforms with experimental waveforms using the meter software, estimating the moisture content of moisture-impregnated insulating oil. The quality of the moisture determination by the Dirana meter is gauged by comparing the results obtained with the actual moisture content.

2. Materials and Methods

2.1. Materials

2.2. Methods

2.3. Tangent Angle Loss Measurements of Insulating Materials. Theoretical Background

3. Study of Loss Tangent of Moistened Pressboard Impregnated by Oil

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Rouse, T.O. Mineral insulating oil in transformers. IEEE Electr. Insul. Mag. 1998, 14, 6–16. [Google Scholar] [CrossRef]

- Graczkowski, A.; Gielniak, J. Influence of impregnating liquids on dielectric response of impregnated cellulose insulation. In Proceedings of the IEEE International Conference on Solid Dielectrics-ICSD, Potsdam, Germany, 4–9 July 2010; pp. 513–516. [Google Scholar]

- Fabre, J.; Pichon, A. Deteriorating processes and products of paper in oil application to transformers. In Proceedings of the International Conference on Large High Voltage Electric Systems (CIGRE), Paris, France, 15–25 June 1960; p. 137. [Google Scholar]

- Liu, J.; Zhang, H.; Geng, C.; Fan, X.; Zhang, Y. Aging Assessment Model of Transformer Insulation Based on Furfural Indicator under Different Oil/Pressboard Ratios and Oil Change. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1061–1069. [Google Scholar] [CrossRef]

- Hussain, M.R.; Refaat, S.S.; Abu-Rub, H. Overview and Partial Discharge Analysis of Power Transformers: A Literature Review. IEEE Access. 2021, 9, 64587–64605. [Google Scholar] [CrossRef]

- Wolny, S.; Krotowski, A. Analysis of Polarization and Depolarization Currents of Samples of NOMEX®910 Cellulose–Aramid Insulation Impregnated with Mineral Oil. Energies 2020, 13, 6075. [Google Scholar] [CrossRef]

- Zukowski, P.; Rogalski, P.; Koltunowicz, T.N.; Kierczynski, K.; Subocz, J.; Zenker, M. Cellulose Ester Insulation of Power Transformers: Researching the Influence of Moisture on the Phase Shift Angle and Admittance. Energies 2020, 13, 5511. [Google Scholar] [CrossRef]

- Prevost, T.; Franchek, M. Conductor Insulation Tests in Oil Aramid vs. Kraft. IEEE Electr. Insul. Mag. 1989, 5, 10–14. [Google Scholar] [CrossRef]

- Przybylek, P.; Moranda, H.; Moscicka-Grzesiak, H.; Szczesniak, D. Application of Synthetic Ester for Drying Distribution Transformer Insulation-The Influence of Cellulose Thickness on Drying Efficiency. Energies 2019, 12, 3874. [Google Scholar] [CrossRef]

- Das, A.K.; Chatterjee, S. Impulse performance of synthetic esters based-nanofluid for power transformer. Mater. Res. Express 2018, 5, 125026. [Google Scholar] [CrossRef]

- Rozga, P.; Beroual, A.; Przybylek, P.; Jaroszewski, M.; Strzelecki, K. A Review on Synthetic Ester Liquids for Transformer Applications. Energies 2020, 13, 6429. [Google Scholar] [CrossRef]

- Cybulski, M.; Przybylek, P. Application of Molecular Sieves for Drying Transformers Insulated with Mineral Oil, Natural Ester, or Synthetic Ester. Energies 2021, 14, 1719. [Google Scholar] [CrossRef]

- Zukowski, P.; Kierczynski, K.; Koltunowicz, T.N.; Rogalski, P.; Subocz, J.; Korenciak, D. AC conductivity measurements of liquid-solid insulation of power transformers with high water content. Measurement 2020, 165, 108194. [Google Scholar] [CrossRef]

- Wolmarans, C.P.; Abrahams, R.; Pahlavanpour, B. Biodegradable electroinsulating fluids based on low viscosity hydrocarbons. Energetyka 2021, 9, 649–652. [Google Scholar]

- NYTRO® BIO 300X–The new bio-based alternative from Nynas. Transform. Technol. Mag. 2020, 46–51. Available online: https://www.transformer-technology.com/community-hub/in-focus/1642-nytro-bio-300x-the-new-bio-based-alternative-from-nynas.html (accessed on 20 February 2022).

- Fernández, I.; Ortiz, A.; Delgado, F.; Renedo, C.; Pérez, S. Comparative evaluation of alternative fluids for power transformers. Electr. Power Syst. Res. 2013, 98, 58–69. [Google Scholar] [CrossRef]

- MIDEL 7131 Increased Fire Safety; M&I Materials Ltd.: Manchester, UK, 2016.

- Liu, Q.; Wang, Z. Streamer characteristic and breakdown in synthetic and natural ester transformer liquids with pressboard interface under lightning impulse voltage. IEEE Trans. Dielectr. Electr. Insul. 2011, 18, 1908–1917. [Google Scholar] [CrossRef]

- Oommen, T.V. Moisture Equilibrium in Paper Oil Systems. In Proceedings of the 16th Electrical/Electronics Insulation Conference, Chicago, IL, USA, 3–6 October 1983; pp. 162–166. [Google Scholar]

- Rahman, M.F.; Nirgude, P. Partial discharge behaviour due to irregular-shaped copper particles in transformer oil with a different moisture content of pressboard barrier under uniform field. IET Gener. Transm. Distrib. 2019, 13, 5550–5560. [Google Scholar] [CrossRef]

- Hill, J.; Wang, Z.; Liu, Q.; Krause, C.; Wilson, G. Analysing the power transformer temperature limitation for avoidance of bubble formation. High Volt. 2019, 4, 210–216. [Google Scholar] [CrossRef]

- Garcia, B.; Villarroel, R.; Garcia, D. A Multiphysical model to study moisture dynamics in transformers. IEEE Trans. Power Deliv. 2019, 34, 1365–1373. [Google Scholar] [CrossRef]

- IEC 60814:2.0–Insulating Liquids–Oil-Impregnated Paper and Pressboard–Determination of Water by Automatic Coulometric Karl Fischer Titration. Available online: https://www.en-standard.eu/iec-60814-1997-insulating-liquids-oil-impregnated-paper-and-pressboard-determination-of-water-by-automatic-coulometric-karl-fischer-titration/ (accessed on 11 February 2022).

- Zheng, H.; Liu, J.; Zhang, Y.; Ma, Y.; Shen, Y.; Zhen, X.; Chen, Z. Effectiveness Analysis and Temperature Effect Mechanism on Chemical and Electrical-Based Transformer Insulation Diagnostic Parameters Obtained from PDC Data. Energies 2018, 11, 146. [Google Scholar] [CrossRef]

- Mishra, D.; Haque, N.; Baral, A.; Chakravorti, S. Assessment of interfacial charge accumulation in oil-paper interface in transformer insulation from polarization-depolarization current measurements. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1665–1673. [Google Scholar] [CrossRef]

- Zaengl, W.S. Applications of dielectric spectroscopy in time and frequency domain for HV power equipment. IEEE Electr. Insul. Mag. 2003, 19, 9–22. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.; Gao, J.; Zheng, H.; Li, Y. Accelerating frequency domain dielectric spectroscopy measurements on insulation of transformers through system identification. IET Sci. Meas. Technol. 2018, 12, 247–254. [Google Scholar] [CrossRef]

- Qi, B.; Dai, Q.; Li, C.; Zeng, Z.; Fu, M.; Zhuo, R. The Mechanism and Diagnosis of Insulation Deterioration Caused by Moisture Ingress into Oil-Impregnated Paper Bushing. Energies 2018, 11, 1496. [Google Scholar] [CrossRef]

- Liu, J.; Fan, X.; Zhang, Y.; Zhang, C.; Wang, Z. Aging evaluation and moisture prediction of oil-immersed cellulose insulation in field transformer using frequency domain spectroscopy and aging kinetics model. Cellulose 2020, 27, 7175–7189. [Google Scholar] [CrossRef]

- Zhukowski, P.; Subocz, J.; Kołtunowicz, T.N. Analysis of dielectric response in the frequency domain moist and oil impregnated pressboard. Prz. Elektrotechniczny 2012, 88 (Suppl. 11b), 251–254. [Google Scholar]

- Islam, M.M.; Lee, G.; Hettiwatte, S.N. A review of condition monitoring techniques and diagnostic tests for lifetime estimation of power transformers. Electr. Eng. 2018, 100, 581–605. [Google Scholar] [CrossRef]

- Gutten, M.; Brncal, P.; Sebok, M.; Kucera, M.; Korenciak, D. Analysis of insulating parameters of oil transformer by time and frequency methods. Diagnostyka 2020, 21, 51–56. [Google Scholar] [CrossRef]

- Martínez, M.; Pleite, J. Improvement of RVM test interpretation using a Debye equivalent circuit. Energies 2020, 13, 323. [Google Scholar] [CrossRef]

- RVM 5462-Advanced Automatic Recovery Voltage Meter for Diagnosis of Oil Paper Insulation, HAEFELY. Available online: http://mldt.pl/files/rvm.PDF (accessed on 20 January 2022).

- Broadbent, S.R.; Hammersley, J.M. Percolation processes: I. Crystals and mazes. Math. Proc. Camb. Philos. Soc. 1957, 53, 629–641. [Google Scholar] [CrossRef]

- Żukowski, P.; Kołtunowicz, T.N.; Kierczyński, K.; Subocz, J.; Szrot, M. Formation of water nanodrops in cellulose impregnated with insulating oil. Cellulose 2015, 22, 861–866. [Google Scholar] [CrossRef]

- Żukowski, P.; Kierczyński, K.; Kołtunowicz, T.N.N.; Rogalski, P.; Subocz, J. Application of elements of quantum mechanics in analysing AC conductivity and determining the dimensions of water nanodrops in the composite of cellulose and mineral oil. Cellulose 2019, 26, 2969–2985. [Google Scholar] [CrossRef]

- Żukowski, P.W.; Kantorow, S.B.; Kiszczak, K.; Mączka, D.; Rodzik, A.; Stelmakh, V.F.; Czarnecka-Such, E. Study of the Dielectric Function of Silicon Irradiated with a Large Dose of Neutrons. Phys. Status Solidi 1991, 128, K117–K121. [Google Scholar] [CrossRef]

- Zukowski, P.W.; Rodzik, A.; Shostak, Y.A. Dielectric constant and ac conductivity of semi-insulating Cd1-xMnxTe semiconductors. Semiconductors 1997, 31, 610–614. [Google Scholar] [CrossRef]

- Mitrofanov, G.A.; Strel’nikov, M.Y. Measurement of the dielectric loss-tangent of transformer oil. Ind. Lab. 2000, 66, 108–111. [Google Scholar]

- Life Management Techniques for Power Transformers. 2003. Available online: https://e-cigre.org/publication/227-life-management-techniques-for-power-transformers (accessed on 27 January 2022).

- Żukowski, P.; Kołtunowicz, T.N.; Kierczyński, K.; Rogalski, P.; Subocz, J.; Szrot, M.; Gutten, M.; Sebok, M.; Korenciak, D. Dielectric losses in the composite cellulose–mineral oil–water nanoparticles: Theoretical assumptions. Cellulose 2016, 23, 1609–1616. [Google Scholar] [CrossRef][Green Version]

- Rogalski, P.; Kierczyński, K.; Żukowski, P. Method of moistening an electrotechnical pressboard impregnated with insulating oil, RP Pat. 239240. Wiadomości Urzędu Patentowego 2021, 33, 7. (In Polish) [Google Scholar]

- Setayeshmehr, A.; Fofana, I.; Eichler, C.; Akbari, A.; Borsi, H.; Gockenbach, E. Dielectric spectroscopic measurements on transformer oil-paper insulation under controlled laboratory conditions. IEEE Trans. Dielectr. Electr. Insul. 2008, 15, 1100–1111. [Google Scholar] [CrossRef]

- Koch, M.; Prevost, T. Analysis of dielectric response measurements for condition assessment of oil-paper transformer insulation. IEEE Trans. Dielectr. Electr. Insul. 2012, 19, 1908–1915. [Google Scholar] [CrossRef]

- Blennow, J.; Ekanayake, C.; Walczak, K.; García, B.; Gubanski, S.M. Field experiences with measurements of dielectric response in frequency domain for power transformer diagnostics. IEEE Trans. Power Deliv. 2006, 21, 681–688. [Google Scholar] [CrossRef]

- Ekanayake, C.; Gubanski, S.M.; Graczkowski, A.; Walczak, K. Frequency Response of Oil Impregnated Pressboard and Paper Samples for Estimating Moisture in Transformer Insulation. IEEE Trans. Power Deliv. 2006, 21, 1309–1317. [Google Scholar] [CrossRef]

- Samarasinghe, W.M.S.C.; Kumara, J.R.S.S.; Fernando, M.A.R.M.; Gunawardena, A.U.A.W. Aging assesment of transformer pressboard insulation by micro-strip ring resonator at GHz frequencies. IEEE Trans. Dielectr. Electr. Insul. 2017, 24, 1923–1930. [Google Scholar] [CrossRef]

- Fafana, I.; Hemmatjou, H.; Meghnefi, F.; Farzaneh, M.; Setayeshmehr, A.; Borsi, H.; Gockkenbach, E. On the frequency domain dielectric response of oil-paper insulation at low temperatures. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 799–807. [Google Scholar] [CrossRef]

- Rogalski, P. Measurement Stand, Method and Results of Composite Electrotechnical Pressboard-Mineral Oil Electrical Measurements. Devices Methods Meas. 2020, 11, 187–195. [Google Scholar] [CrossRef]

- Zukowski, P.; Rogalski, P.; Kierczynski, K.; Koltunowicz, T.N. Precise Measurements of the Temperature Influence on the Complex Permittivity of Power Transformers Moistened Paper-Oil Insulation. Energies 2021, 14, 5802. [Google Scholar] [CrossRef]

- Zukowski, P.; Rogalski, P.; Koltunowicz, T.N.; Kierczynski, K.; Subocz, J.; Sebok, M. Influence of temperature on phase shift angle and admittance of moistened composite of cellulose and insulating oil. Measurement 2021, 185, 110041. [Google Scholar] [CrossRef]

- Zukowski, P.; Rogalski, P.; Koltunowicz, T.N.; Kierczynski, K.; Bondariev, V. Precise measurements of the temperature-frequency dependence of the conductivity of cellulose–insulating oil–water nanoparticles composite. Energies 2020, 14, 32. [Google Scholar] [CrossRef]

- Waygood, A. An Introduction to Electrical Science, 2nd ed.; Taylor & Francis Group: Abingdon, UK; Routledge: New York, NY, USA, 2019. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kołtunowicz, T.N.; Kierczynski, K.; Okal, P.; Patryn, A.; Gutten, M. Diagnostics on the Basis of the Frequency-Temperature Dependences of the Loss Angle Tangent of Heavily Moistured Oil-Impregnated Pressboard. Energies 2022, 15, 2924. https://doi.org/10.3390/en15082924

Kołtunowicz TN, Kierczynski K, Okal P, Patryn A, Gutten M. Diagnostics on the Basis of the Frequency-Temperature Dependences of the Loss Angle Tangent of Heavily Moistured Oil-Impregnated Pressboard. Energies. 2022; 15(8):2924. https://doi.org/10.3390/en15082924

Chicago/Turabian StyleKołtunowicz, Tomasz N., Konrad Kierczynski, Pawel Okal, Aleksy Patryn, and Miroslav Gutten. 2022. "Diagnostics on the Basis of the Frequency-Temperature Dependences of the Loss Angle Tangent of Heavily Moistured Oil-Impregnated Pressboard" Energies 15, no. 8: 2924. https://doi.org/10.3390/en15082924

APA StyleKołtunowicz, T. N., Kierczynski, K., Okal, P., Patryn, A., & Gutten, M. (2022). Diagnostics on the Basis of the Frequency-Temperature Dependences of the Loss Angle Tangent of Heavily Moistured Oil-Impregnated Pressboard. Energies, 15(8), 2924. https://doi.org/10.3390/en15082924