Study on Anode Catalyst Layer Configuration for Proton Exchange Membrane Fuel Cell with Enhanced Reversal Tolerance and Polarization Performance

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

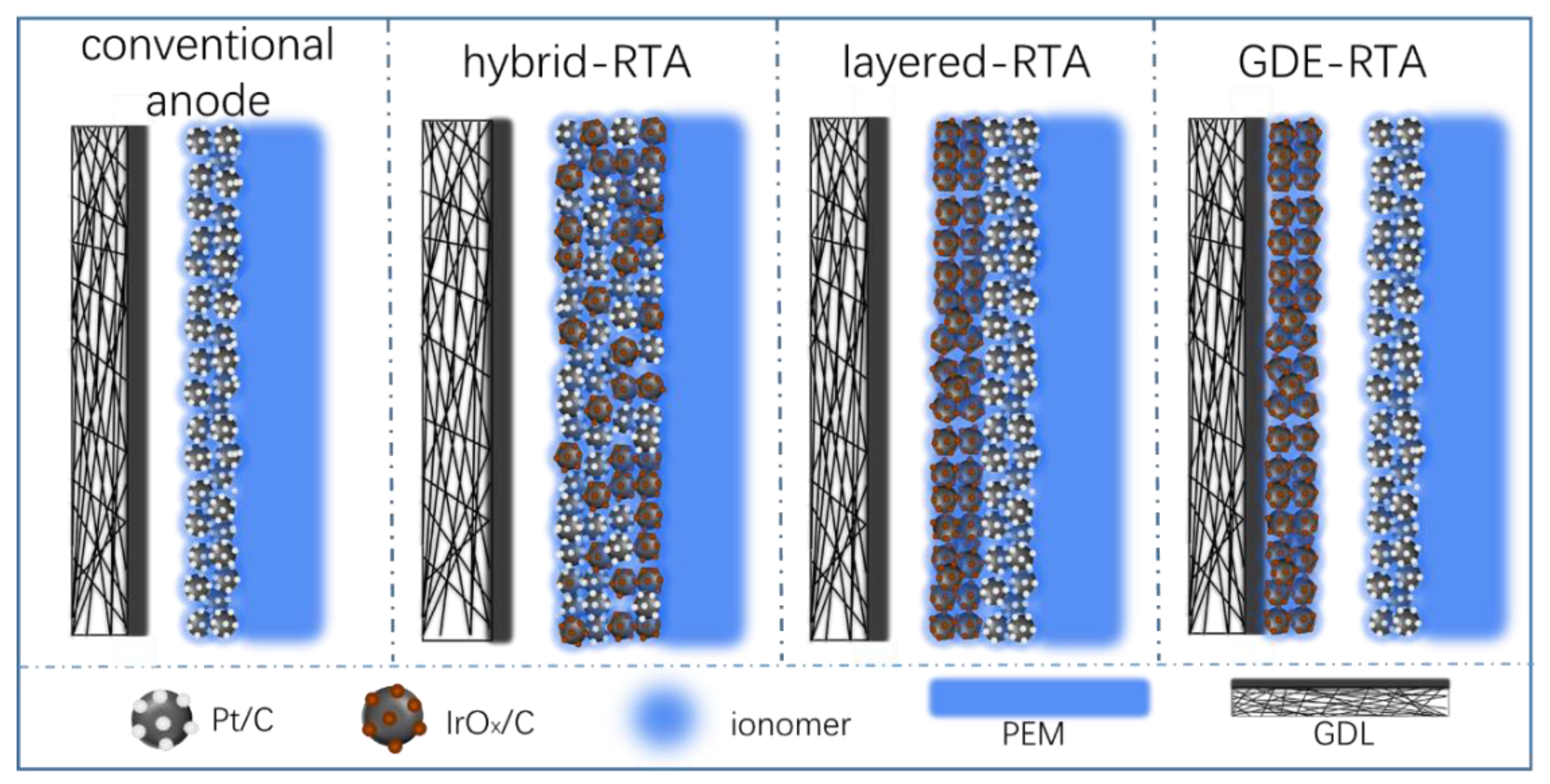

2.2. MEA Preparation

2.3. Reversal Tolerance Accelerated Stress Test (AST)

2.4. Electrochemical Diagnostics

2.5. Microstructure Characterizations

3. Results and Discussion

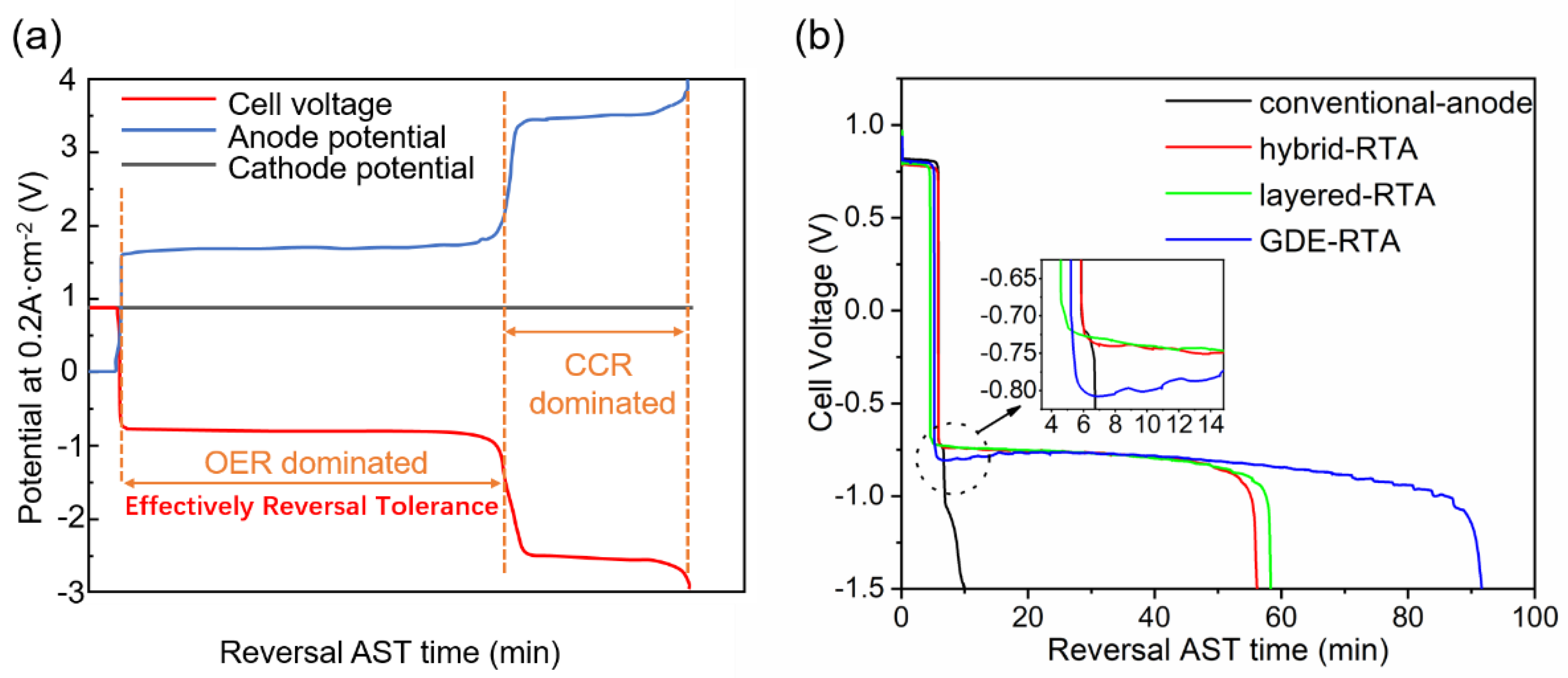

3.1. Reversal Durability of Prepared MEAs

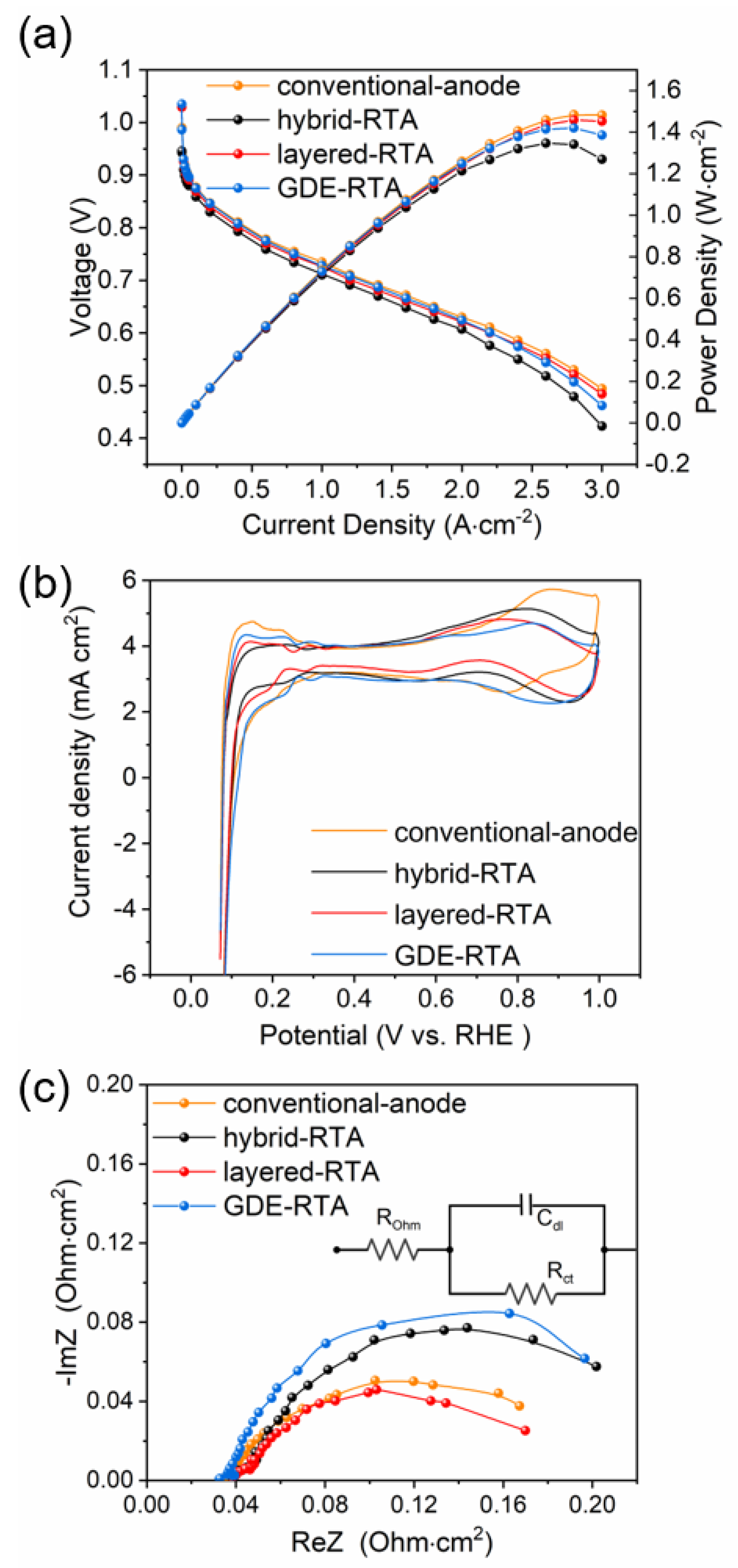

3.2. Electrochemical Characterization of Prepared MEAs

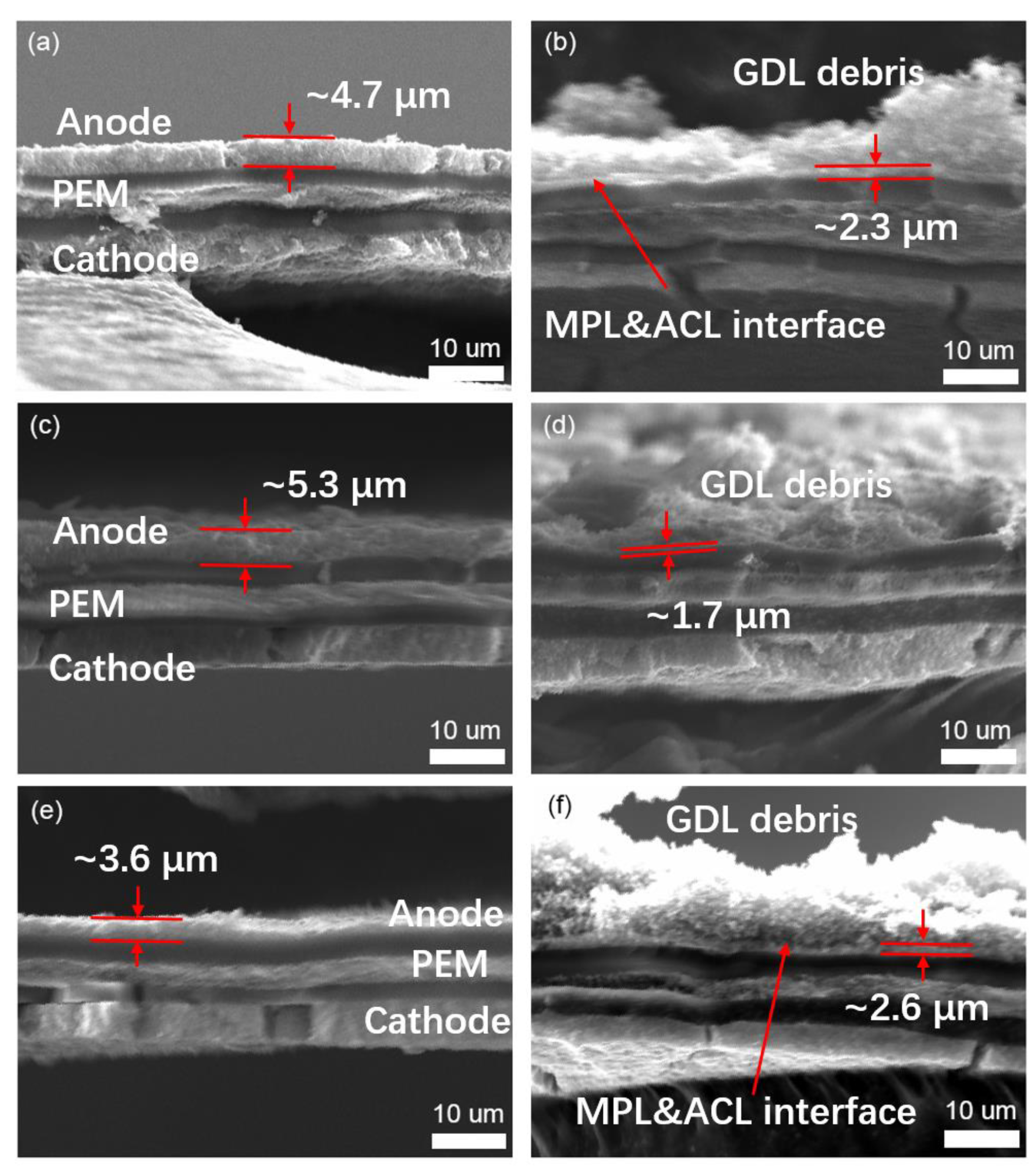

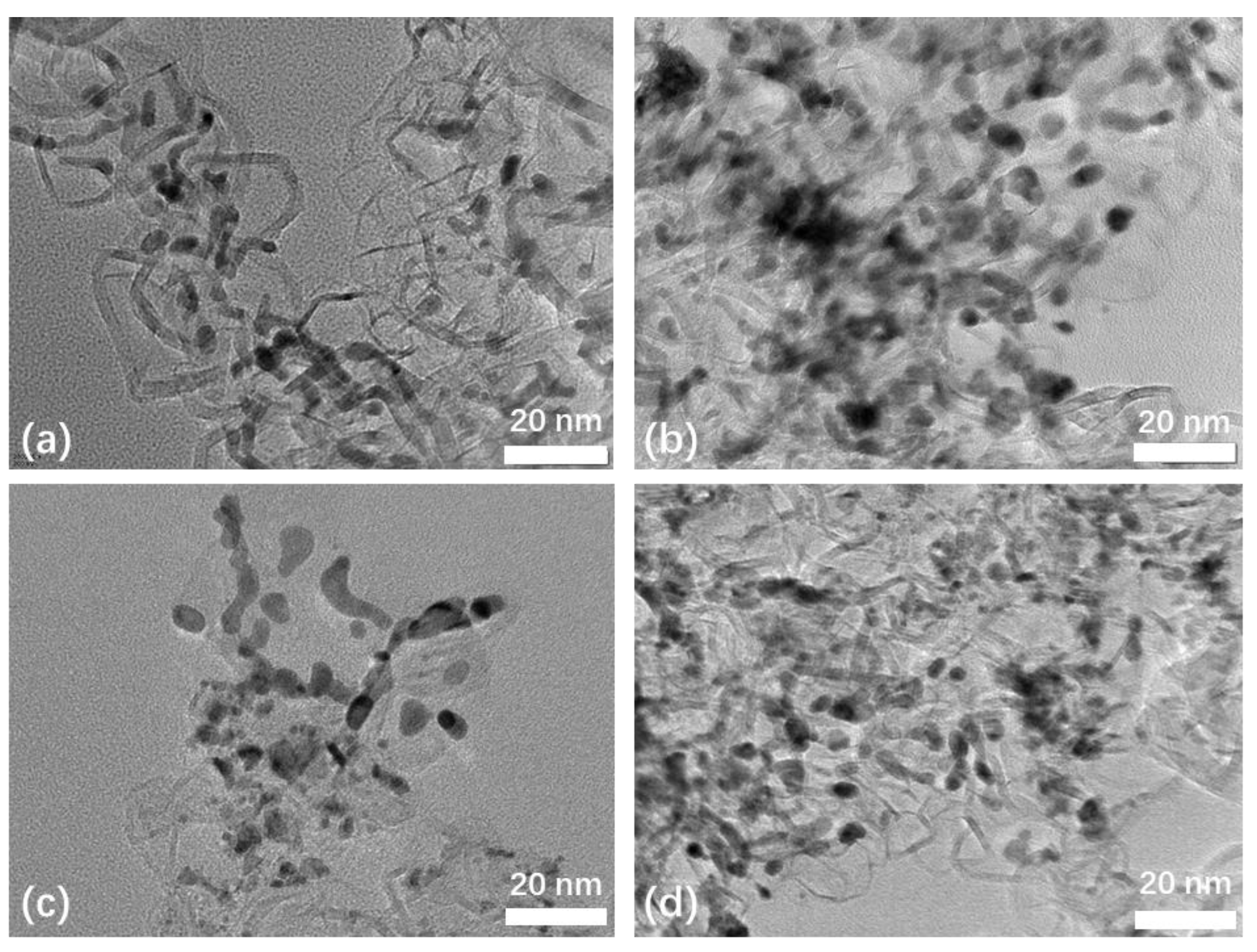

3.3. Micromorphology Characterization of Prepared MEAs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Wang, Y.; Diaz, D.F.R.; Chen, K.S.; Wang, Z. Materials, technological status, and fundamentals of PEM fuel cells—A review. Adroher. Mater. Today 2020, 32, 178–203. [Google Scholar] [CrossRef]

- Olabi, A.G.; Wilberforce, T.; Abdelkareem, M.A. Fuel cell application in the automotive industry and future perspective. Energy 2021, 214, 118955. [Google Scholar] [CrossRef]

- Zhao, J.; Li, X. A review of polymer electrolyte membrane fuel cell durability for vehicular applications: Degradation modes and experimental techniques. Energy Convers. Manag. 2019, 199, 112022. [Google Scholar]

- Wang, X.X.; Swihart, M.T.; Wu, G. Achievements, challenges and perspectives on cathode catalysts in proton exchange membrane fuel cells for transportation. Nat. Catal. 2019, 2, 578–589. [Google Scholar] [CrossRef]

- Park, J.-H.; Yim, S.-D.; Kim, T.; Park, S.-H.; Yoon, Y.-G.; Park, G.-G.; Yang, T.-H.; Park, E.-D. Understanding the mechanism of membrane electrode assembly degradation by carbon corrosion by analyzing the microstructural changes in the cathode catalyst layers and polarization losses in proton exchange membrane fuel cell. Electrochim. Acta 2012, 83, 294–304. [Google Scholar] [CrossRef]

- Zhao, X.; Hayashi, A.; Noda, Z.; Kimijima, K.; Yagi, I.; Sasaki, K. Evaluation of change in nanostructure through the heat treatment of carbon materials and their durability for the start/stop operation of polymer electrolyte fuel cells. Electrochim. Acta 2013, 97, 33–41. [Google Scholar] [CrossRef]

- Zhang, S.; Yuan, X.; Wang, H.; Merida, W.; Zhu, H.; Shen, J.; Wu, S.; Zhang, J. A review of accelerated stress tests of MEA durability in PEM fuel cells. Int. J. Hydrogen Energy 2009, 34, 388–404. [Google Scholar] [CrossRef]

- Wang, F.; Yang, D.; Li, B.; Zhang, H.; Hao, C.; Chang, F.; Ma, J. Investigation of the recoverable degradation of PEM fuel cell operated under drive cycle and different humidities. Int. J. Hydrogen Energy 2014, 39, 14441–14447. [Google Scholar] [CrossRef]

- Fan, X.; Zhao, M.; Li, T.; Zhang, L.; Jing, M.; Yuan, W.; Li, C. In situ self-assembled N-rich carbon on pristine graphene as a highly effective support and cocatalyst of short Pt nanoparticle chains for superior electrocatalytic activity toward methanol oxidation. Nanoscale 2021, 13, 18332–18339. [Google Scholar] [CrossRef]

- Jomori, S.; Nonoyama, N.; Yoshida, T. Analysis and modeling of PEMFC degradation: Effect on oxygen transport. J. Power Sources 2012, 215, 18–27. [Google Scholar] [CrossRef]

- Jung, N.; Chung, D.Y.; Ryu, J.; Yoo, S.J.; Sung, Y.-E. Pt-based nanoarchitecture and catalyst design for fuel cell applications. Nano Today 2014, 9, 433–456. [Google Scholar] [CrossRef]

- Cherevko, S.; Kulyk, N.; Mayrhofer, K.J.J. Durability of platinum-based fuel cell electrocatalysts: Dissolution of bulk and nanoscale platinum. Nano Energy 2016, 29, 275–298. [Google Scholar] [CrossRef]

- Jung, D.W.; Park, S.; Kim, S.H.; Kim, J.B.; Oh, E.S. Durability of polymer electrolyte membrane fuel cell with Pt/CNTs catalysts in cell reversal conditions by hydrogen starvation. Fuel Cells 2011, 11, 866–874. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, X.; Zhang, T.; Pei, P. The reactant starvation of the proton exchange membrane fuel cells for vehicular applications: A review. Energy Convers. Manage. 2019, 182, 282–298. [Google Scholar] [CrossRef]

- Ioroi, T.; Yasuda, K. Highly reversal-tolerant anodes using Ti4O7-supported platinum with a very small amount of water-splitting catalyst. J. Power Sources 2020, 450, 227656. [Google Scholar] [CrossRef]

- You, E.; Lee, S.W.; You, D.; Lee, B.; Pak, C. Effect of Metal Composition and Carbon Support on the Durability of the Reversal-Tolerant Anode with IrRu Alloy Catalyst. Catalysts 2020, 10, 932. [Google Scholar] [CrossRef]

- Hong, B.K.; Mandal, P.; Oh, J.-G.; Litster, S. On the impact of water activity on reversal tolerant fuel cell anode performance and durability. J. Power Sources 2016, 328, 280–288. [Google Scholar] [CrossRef]

- Jang, I.; Hwang, I.; Tak, Y. Attenuated degradation of a PEMFC cathode during fuel starvation by using carbon-supported IrO2. Electrochim. Acta 2013, 90, 148–156. [Google Scholar] [CrossRef]

- Tovini, M.F.; Damjanovic, A.M.; El-Sayed, H.A.; Speder, J.; Eickes, C.; Suchsland, J.-P.; Ghielmi, A.; Gasteiger, H.A. Degradation Mechanism of an IrO2 Anode Co-Catalyst for Cell Voltage Reversal Mitigation under Transient Operation Conditions of a PEM Fuel Cell. J. Electrochem. Soc. 2021, 168, 064521. [Google Scholar] [CrossRef]

- Mandal, P.; Hong, B.K.; Oh, J.-G.; Litster, S. Understanding the voltage reversal behavior of automotive fuel cells. J. Power Sources 2018, 397, 397–404. [Google Scholar] [CrossRef]

- Roh, C.-W.; Kim, H.-E.; Choi, J.; Lim, J.; Lee, H. Monodisperse IrOx deposited on Pt/C for reversal tolerant anode in proton exchange membrane fuel cell. J. Power Sources 2019, 443, 227270. [Google Scholar] [CrossRef]

- Labi, T.; van Schalkwyk, F.; Andersen, S.M.; Morgen, P.; Ray, S.C. Increasing fuel cell durability during prolonged and intermittent fuel starvation using supported IrOx. J. Power Sources 2021, 490, 229568. [Google Scholar] [CrossRef]

- Kim, H.-E.; Shin, S.; Lee, H. Pt-IrOx catalysts immobilized on defective carbon for efficient reversal tolerant anode in proton exchange membrane fuel cells. J. Catal. 2021, 395, 404–411. [Google Scholar] [CrossRef]

- Chen, W.; Cai, C.; Li, S.; Tan, J.; Pan, M. Thickness effects of anode catalyst layer on reversal tolerant performance in proton exchange membrane fuel cell. Int. J. Hydrogen Energy 2021, 46, 8749–8757. [Google Scholar] [CrossRef]

- Hu, L.; Hong, B.K.; Oh, J.-G.; Litster, S. Reversal Tolerant Anodes Using Protective Layers for Highly Robust Automotive Fuel Cells. ACS Appl. Energy Mater. 2021, 4, 119–127. [Google Scholar] [CrossRef]

- Zhou, X.; Yang, Y.; Li, B.; Zhang, C. Advanced Reversal Tolerant Anode in Proton Exchange Membrane Fuel Cells: Study on the Attenuation Mechanism during Fuel Starvation. ACS Appl. Mater. Inter. 2021, 13, 2455–2461. [Google Scholar] [CrossRef]

- Moore, C.E.; Afsahi, F.; Young, A.P.; Gyenge, E.L. Vibrating Powders: Electrochemical Quartz Crystal Microbalance Study of IrO2 and Pt/C Catalyst Layers for Voltage Reversal Tolerant Anodes in Fuel Cells. J. Phys. Chem. C 2019, 123, 23361–23373. [Google Scholar] [CrossRef]

- Lim, K.H.; Lee, W.H.; Jeong, Y.; Kim, H. Analysis of carbon corrosion in anode under fuel starvation using on-line mass spectrometry in polymer electrolyte membrane fuel cells. J. Electrochem. Soc. 2017, 164, F1580–F1586. [Google Scholar] [CrossRef]

- Linse, N.; Gubler, L.; Scherer, G.G.; Wokaun, A. The effect of platinum on carbon corrosion behavior in polymer electrolyte fuel cells. Electrochim. Acta 2011, 56, 7541–7549. [Google Scholar] [CrossRef]

- Li, W.; Lane, A.M. Investigation of Pt catalytic effects on carbon support corrosion of the cathode catalyst in PEM fuel cells using DEMS spectra. Electrochem. Commun. 2009, 11, 1187–1190. [Google Scholar] [CrossRef]

- Maillard, F.; Bonnefont, A.; Micoud, F. An EC-FTIR study on the catalytic role of Pt in carbon corrosion. Electrochem. Commun. 2011, 13, 1109–1111. [Google Scholar] [CrossRef]

- Zhao, S.; Yu, H.; Maric, R.; Danilovic, N.; Capuano, C.B.; Ayers, K.E.; Mustain, W.E. Calculating the electrochemically active surface area of iridium oxide in operating proton exchange membrane electrolyzers. J. Electrochem. Soc. 2015, 162, F1292–F1298. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.W.; Lee, B.H.; Kim, T.-Y.; Baik, C.; Kim, M.S.; Chai, G.S.; Pak, C. Multifunctional non-Pt ternary catalyst for the hydrogen oxidation and oxygen evolution reactions in reversal-tolerant anode. Catal. Commun. 2019, 130, 105758. [Google Scholar] [CrossRef]

- Cai, C.; Rao, Y.; Zhou, J.; Zhang, L.; Chen, W.; Wan, Z.; Tan, J.; Pan, M. Carbon corrosion: A novel termination mechanism of the water electrolysis plateau during voltage reversal. J. Power Sources 2020, 473, 228542. [Google Scholar] [CrossRef]

- Labata, M.F.; Li, G.; Ocon, J.; Chuang, P.-Y.A. Insights on platinum-carbon catalyst degradation mechanism for oxygen reduction reaction in acidic and alkaline media. J. Power Sources 2021, 487, 229356. [Google Scholar] [CrossRef]

- Kangasniemi, K.H.; Condit, D.A.; Jarvi, T.D. Characterization of vulcan electrochemically oxidized under simulated PEM fuel cell conditions. J. Electrochem. Soc. 2004, 151, E125–E132. [Google Scholar] [CrossRef]

| Samples | RTA Configuration | ACL on PEM | Anode GDL |

|---|---|---|---|

| Conventional anode | one-fold layer | Pt/C | ordinary |

| Hybrid-RTA | one-fold layer | Pt/C + IrOx/C | ordinary |

| Layered-RTA | layer-by-layer | Pt/C + IrOx/C | ordinary |

| GDE-RTA | separate locations | Pt/C | IrOx/C loaded |

| Samples | RTT | PPD | VBOT | ECSA | ROhm |

|---|---|---|---|---|---|

| (min) | (W cm−2) | (V) | (m2 g−1) | (Ω cm2) | |

| Conventional anode | 4.5 | 1.48 | 0.629 | 36.8 | 0.038 |

| Hybrid-RTA | 50 | 1.35 | 0.607 | 14.7 | 0.038 |

| Layered-RTA | 54 | 1.46 | 0.621 | 27.4 | 0.038 |

| GDE-RTA | 86 | 1.42 | 0.624 | 28.7 | 0.038 |

| Samples | PPD | VEOT | DR | ECSA | ROhm |

|---|---|---|---|---|---|

| (W cm−2) | (V) | (mV min−1) | (m2 g−1) | (Ω cm2) | |

| Conventional anode | 0.21 | - | - | 5.4 | 0.057 |

| Hybrid-RTA | 0.73 | 0.334 | 5.5 | 10.8 | 0.046 |

| Layered-RTA | 0.68 | 0.297 | 6.0 | 6.9 | 0.068 |

| GDE-RTA | 0.83 | 0.414 | 2.4 | 12.3 | 0.064 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheng, X.; Ru, C.; Zhao, H.; Jin, S.; Wang, B.; Wang, Y.; Han, L.; Jiao, K. Study on Anode Catalyst Layer Configuration for Proton Exchange Membrane Fuel Cell with Enhanced Reversal Tolerance and Polarization Performance. Energies 2022, 15, 2732. https://doi.org/10.3390/en15082732

Sheng X, Ru C, Zhao H, Jin S, Wang B, Wang Y, Han L, Jiao K. Study on Anode Catalyst Layer Configuration for Proton Exchange Membrane Fuel Cell with Enhanced Reversal Tolerance and Polarization Performance. Energies. 2022; 15(8):2732. https://doi.org/10.3390/en15082732

Chicago/Turabian StyleSheng, Xia, Chunyu Ru, Honghui Zhao, Shouyi Jin, Bowen Wang, Yupeng Wang, Linghai Han, and Kui Jiao. 2022. "Study on Anode Catalyst Layer Configuration for Proton Exchange Membrane Fuel Cell with Enhanced Reversal Tolerance and Polarization Performance" Energies 15, no. 8: 2732. https://doi.org/10.3390/en15082732

APA StyleSheng, X., Ru, C., Zhao, H., Jin, S., Wang, B., Wang, Y., Han, L., & Jiao, K. (2022). Study on Anode Catalyst Layer Configuration for Proton Exchange Membrane Fuel Cell with Enhanced Reversal Tolerance and Polarization Performance. Energies, 15(8), 2732. https://doi.org/10.3390/en15082732