Solar Technology and District Cooling System in a Hot Climate Regions: Optimal Configuration and Technology Selection

Abstract

:1. Introduction

2. Literature Review

- ▪

- Develop a generalized model to optimize the design and operation of each configuration, and thus without the need for multi-models to imitate each one.

- ▪

- Develop and implement the performance indicators of the system based on the numerical results of the proposed model.

- ▪

- Compare the diverse configurations performances (economic, renewable energy use, and environmental) by considering the local context (energy price and available installation area).

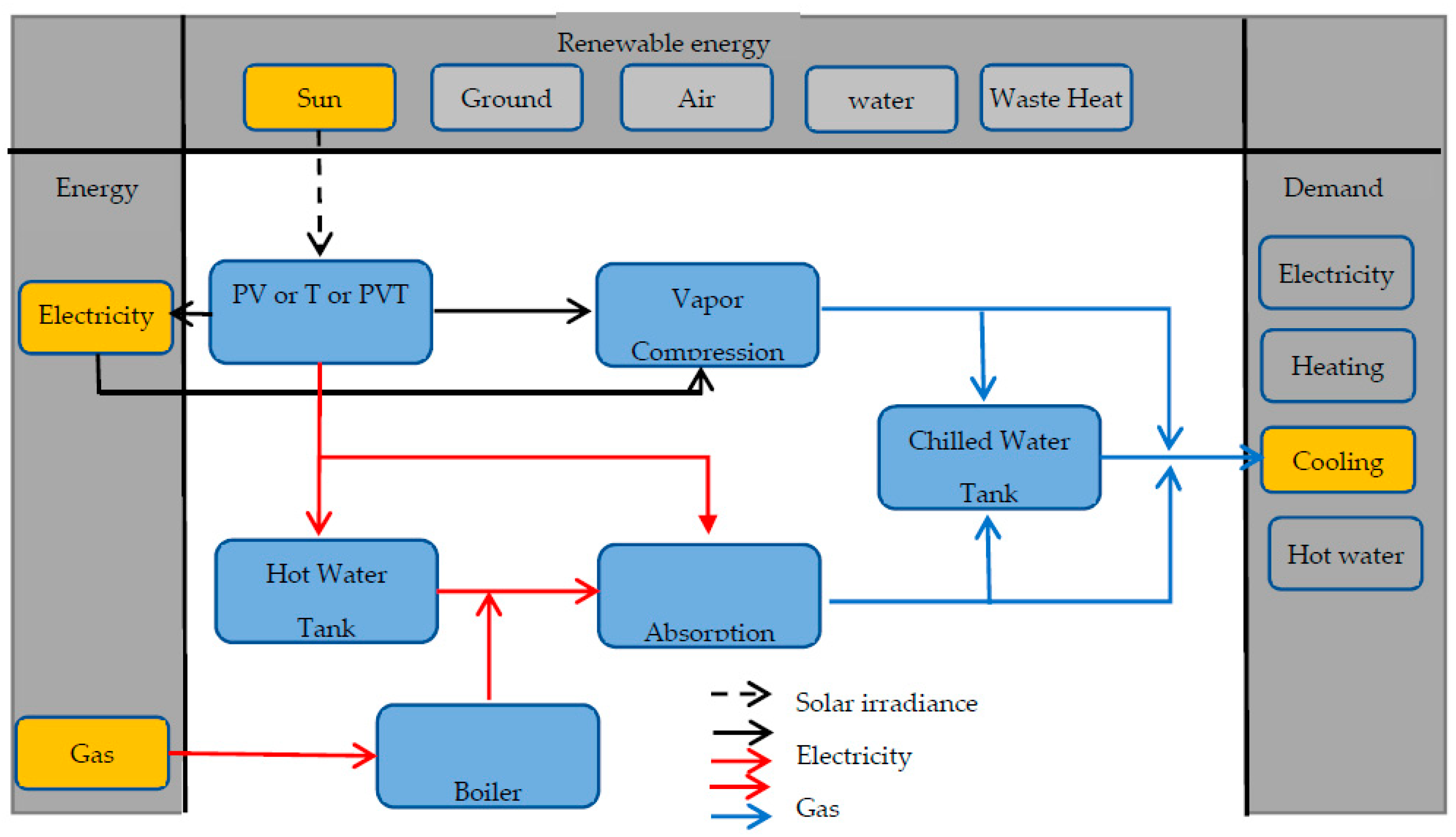

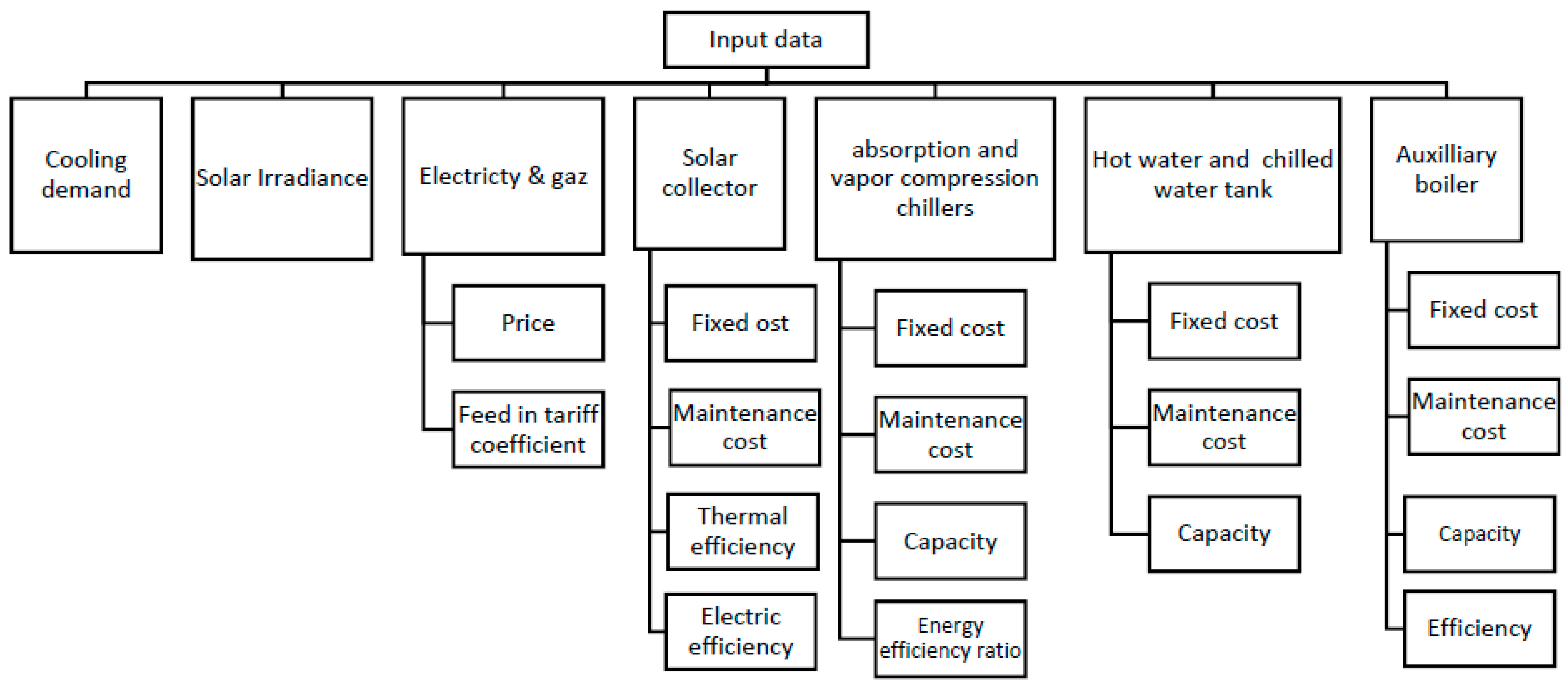

3. Problem Description and Formulation

3.1. Problem Formulation

3.1.1. Definition Block

3.1.2. Internal Block

3.1.3. Activities Block

3.1.4. Assessment Indicators

- -

- The solar electrical fraction is expressed as the ratio of the yield of electricity and electric chiller consumption: .

- -

- The solar thermal fraction is expressed as the yield heat and the absorption chiller consumption: .

- -

- The renewable energy fraction is expressed as the ratio of the sum of the heat and electricity yield and the sum of absorption and electric chillers consumption: .

- -

- The system’s final energy saving for gas is expressed as the ratio of the heat yield and the efficiency of the selected boiler. If the optimal system design does not include boiler, an efficiency reference of 0.85 is considered: .

- -

- The system’s final energy-saving for electricity equals the electricity yield: .

- -

- The non-renewable primary energy consumption (kWh oil-equivalents) is expressed as the sum of the primary energy of the gas and net electricity consumption. The primary energy consumption for gas is equal to the product of the quantity consumed and its cumulated energy demand (CED = 1.06). The primary energy consumption for electricity is equal to the product of the net quantity consumed and the cumulated energy demand for electricity (CED = 2.89) .

- -

- The global warming potential (Kg CO2-equivalents) is expressed as the sum of the global warming potential for each nonrenewable energy consumed. Similar to the calculation of the in the , the CED is replaced by the GWP factor for each type of non-renewable energy. ( and ). .

4. Numerical Results

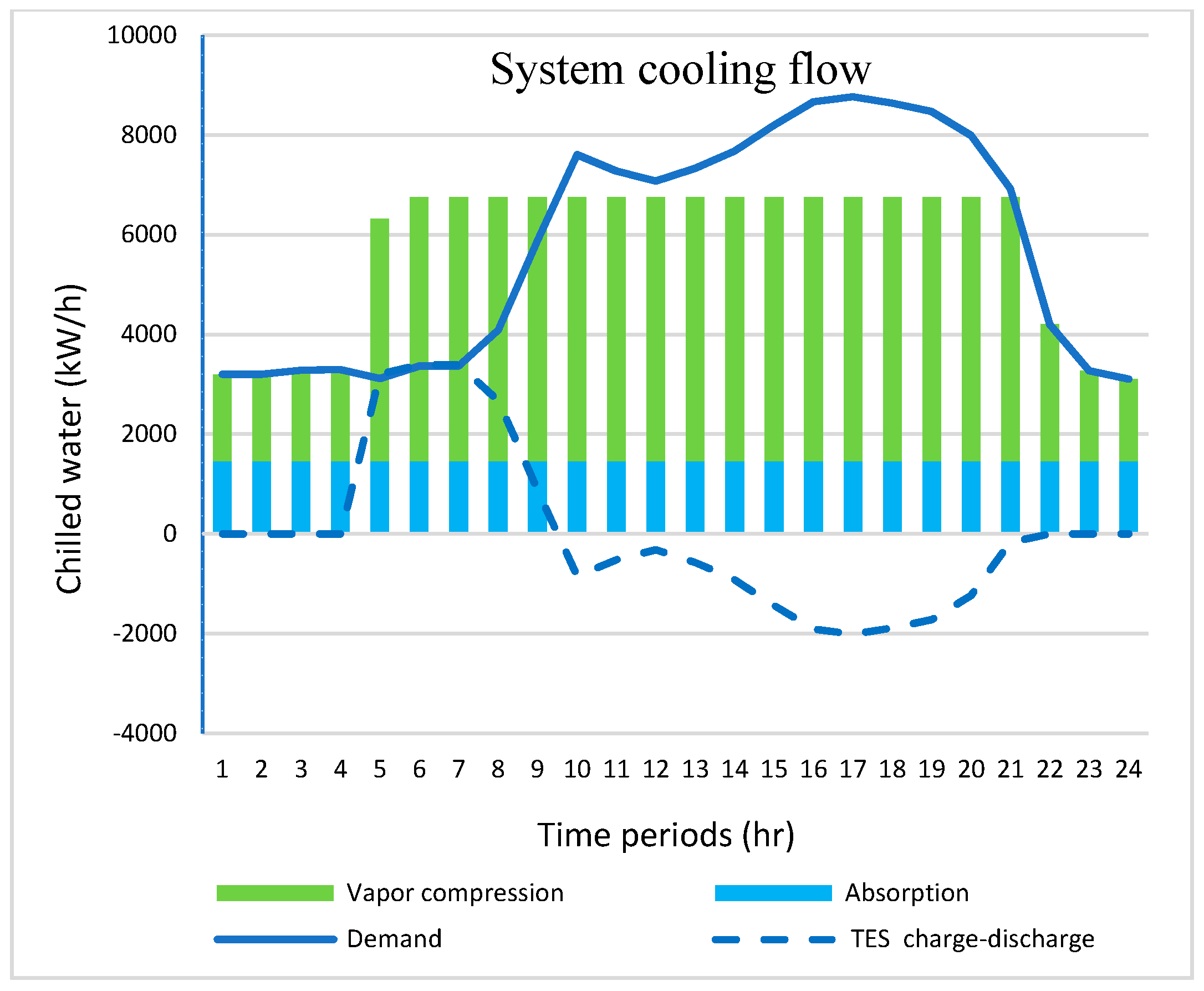

4.1. Integration of Hybrid Solar Collector and DCS

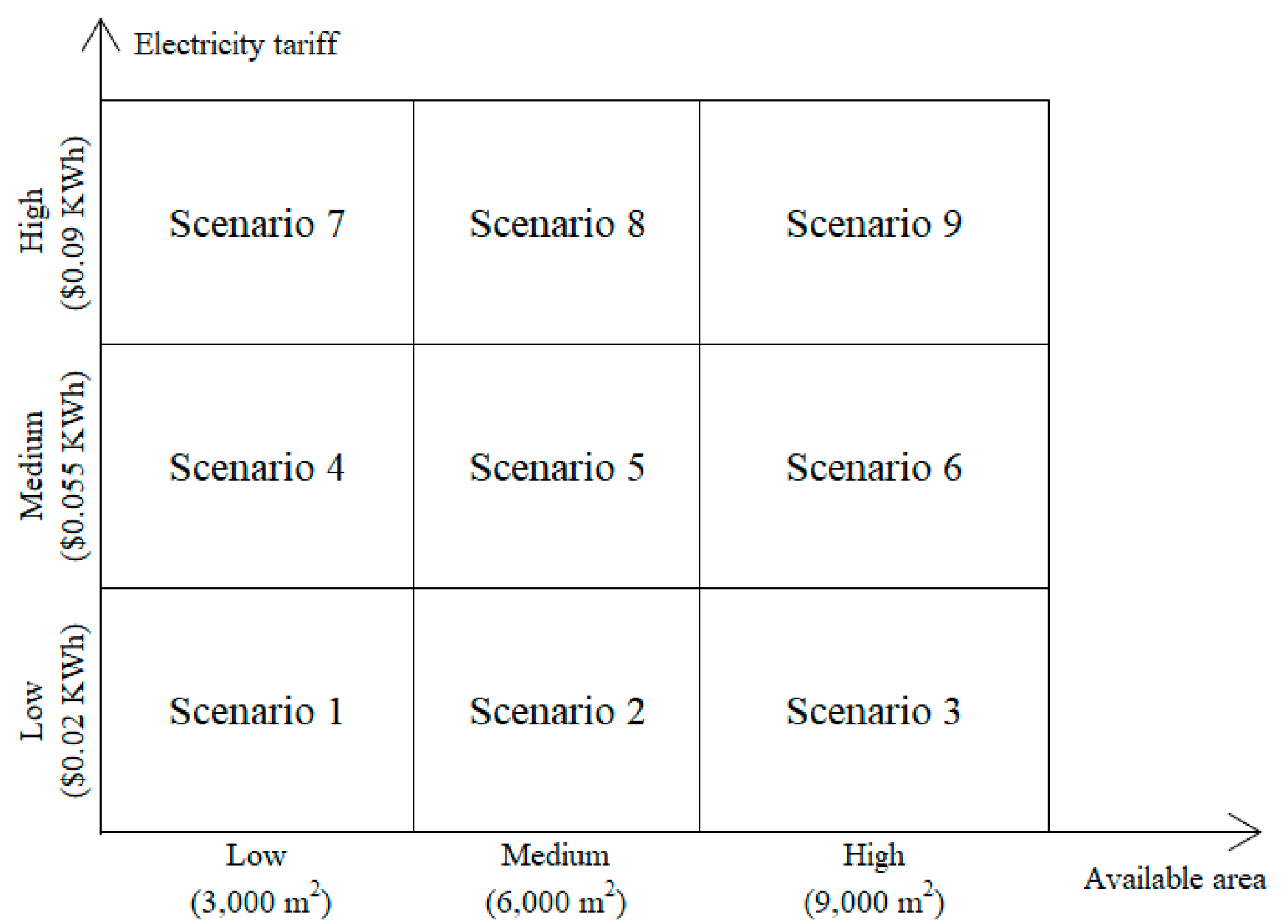

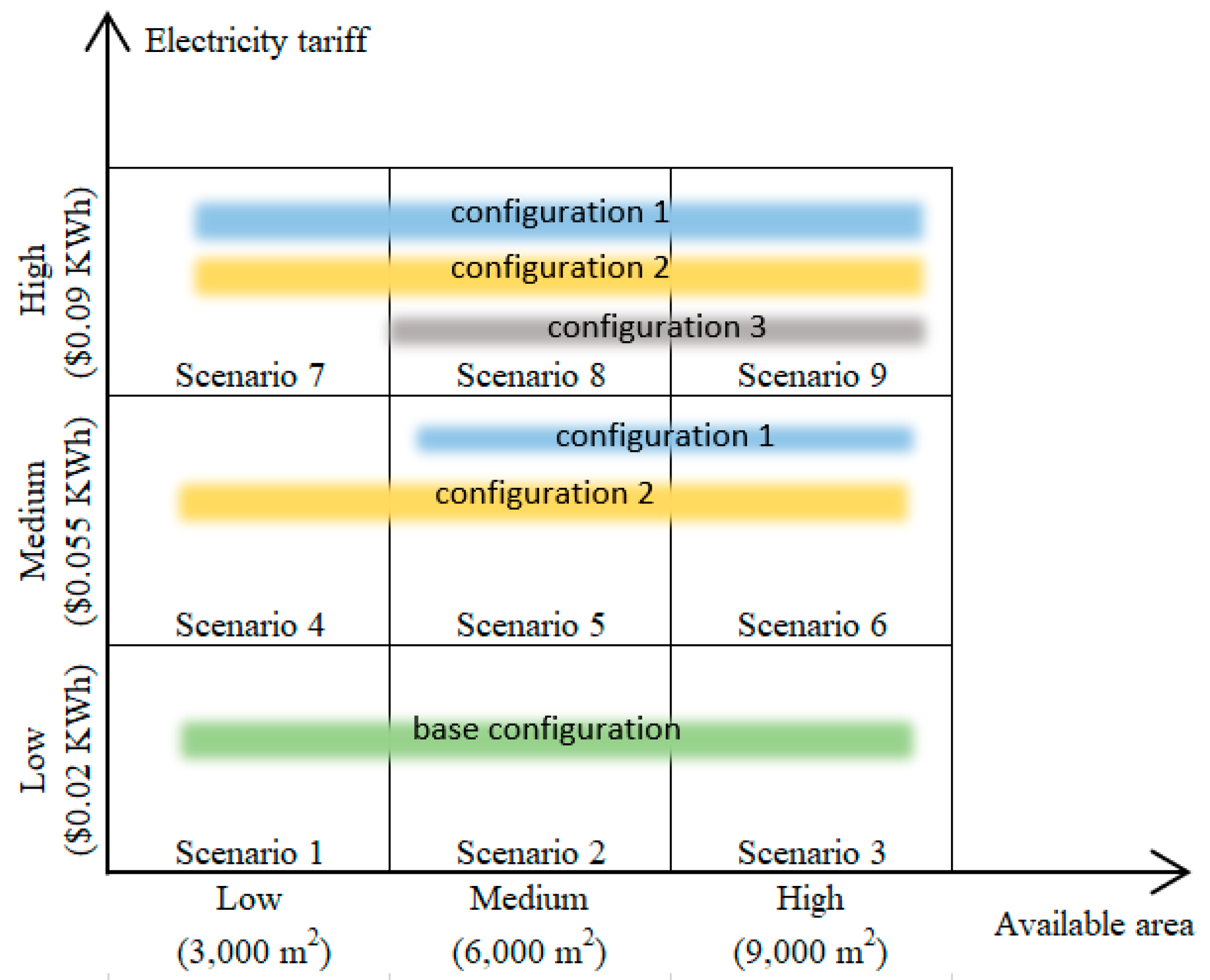

4.2. Scenarios and Configurations Assessment

4.2.1. Optimal Configuration (Economic Assessment)

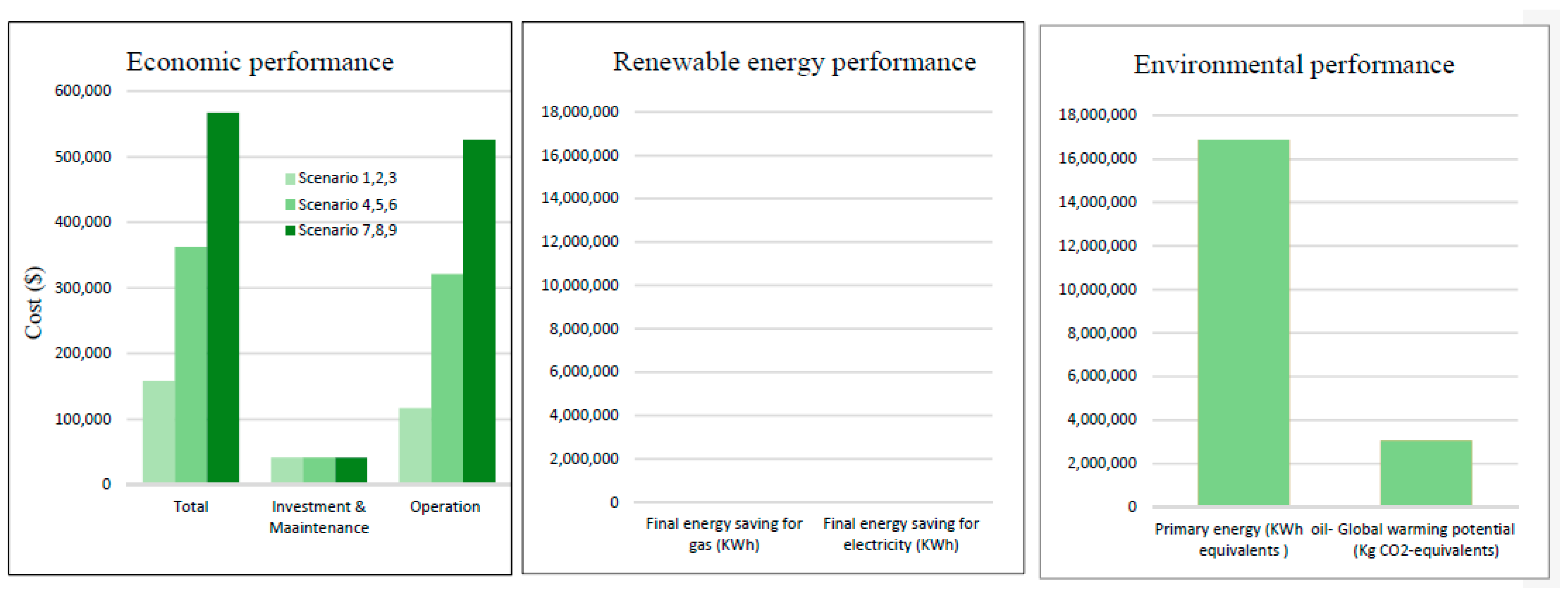

4.2.2. Base Configuration Performance

4.2.3. Economic Performance Comparison (Scenarios 4 to 9)

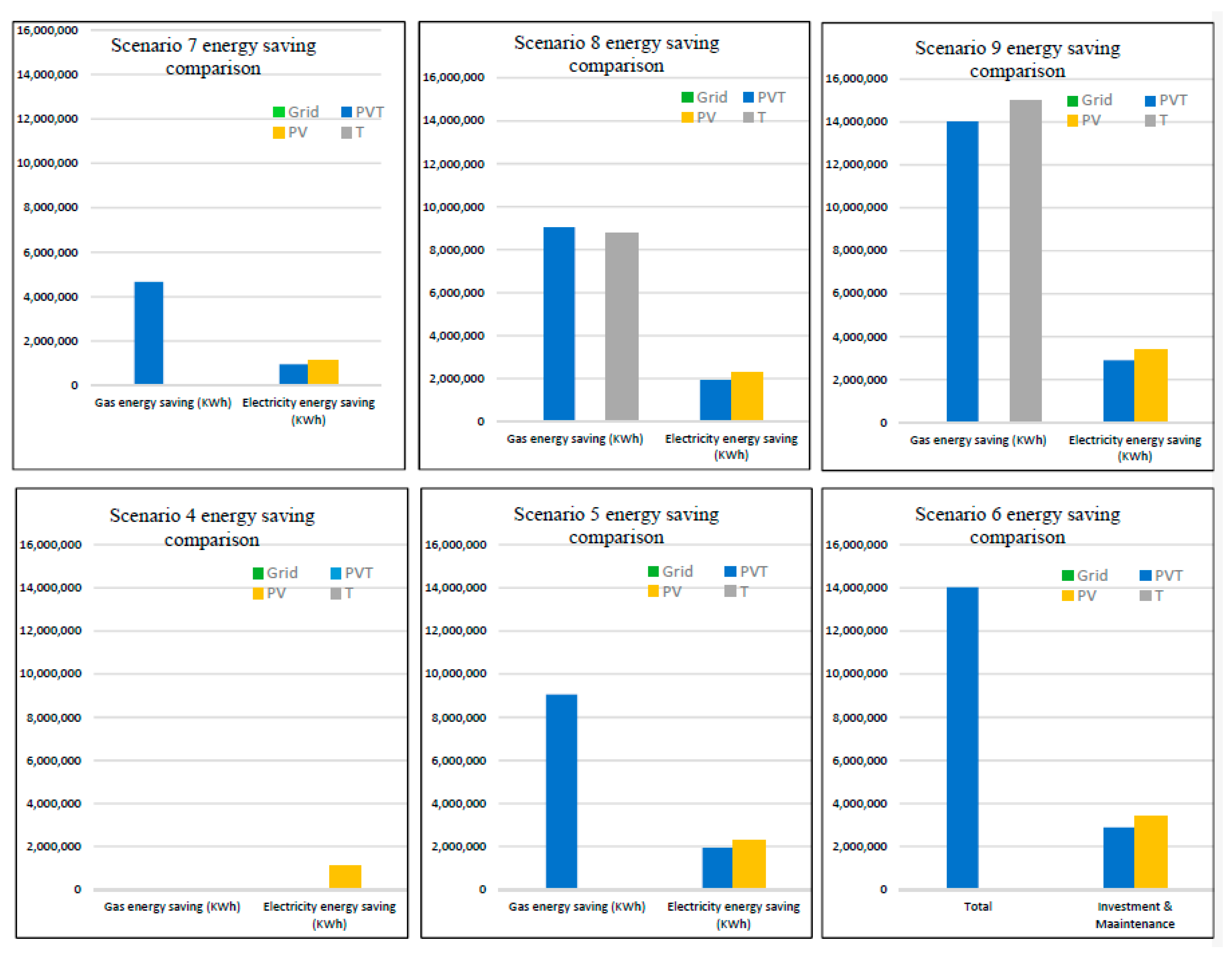

4.2.4. Energy Saved and Renewable Energy Fraction Comparison (Scenarios 4 to 9)

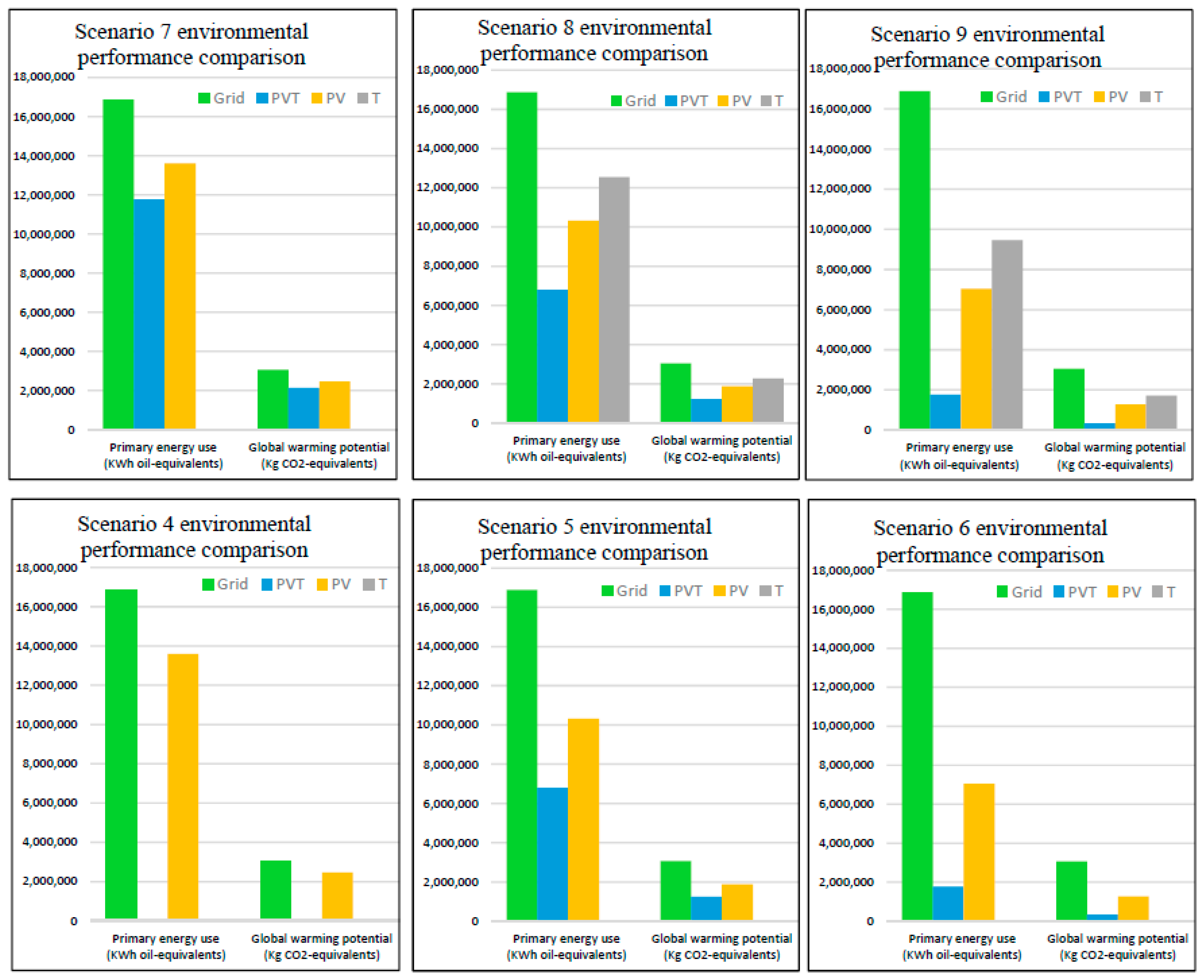

4.2.5. Environmental Performance Comparison (Scenarios 4 to 9)

5. Conclusions, Limitations, and Future Research

- -

- The electricity tariff and the available installation area impact the integration of solar energy. When electricity tariff is medium or high, the more installed the area is, the better it is for the total cost, renewable energy use, and the environmental impact.

- -

- At a low electricity tariff rate (subsidized), the conventional Grid-based DCS remains the most competitive among the other configurations. However, the environmental performance is the worst. The annual assessment of 10,000 kW district cooling system powered with grid-electricity shows that 16,882,130 kWh oil-equivalent of primary energy is consumed, which impacts the environment by 3,060,981 kg CO2-equivalent.

- -

- The PV-DCS configuration is the most competitive among solar-assisted cooling systems. The annual total cost is less by 2% to 4% than PVT-DCS configuration when electricity tariff is high, and less by 19% to 31% when electricity tariff is medium. It reduces the environmental impact compared to the Grid-DCS configuration by 58.3%, 38.87%, 19.43% when the installation area is high, medium, and low.

- -

- The PVT-DCS configuration has the lowest operation cost among solar-assisted cooling systems and is lower by 59% to 89% than the Grid-DCS configuration, when electricity tariff is medium, and by 30% to 90% when electricity tariff is high. The PVT system also has the best environmental performance by decreasing the primary energy use and the global warming potential by 89.5% compared to the Grid-DCS system, by 59.74% in medium installation area scenarios, and by 30.33% in the case of low installation area scenarios.

- -

- The T-DCS configuration is more economically competitive than the conventional Grid-DCS configuration only at high electricity tariffs and medium to high available installation areas. The total system cost is slightly less than the Grid-DCS configuration (−2%). Despite the high renewable energy fraction in the range 63.23% and 79.26%, respectively, for medium and high installation areas, the environmental performance is relatively lower than PVT and PV systems. The T system reduces the environmental impact by 43.76% and 25.71% when the installation area is high, and medium compared to the Grid-DCS configuration.

Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Latin symbols | |

| Cooling load demand (kW) | |

| Solar radiation (kW/m2) | |

| A | Maximum solar collector area (m2) |

| R | Interest rate (%) |

| n | Economic life (year) |

| Maximum Capacity (kW) | |

| Energy Efficiency Ratio (%) | |

| Fixed investment cost per installed unit ($) | |

| Fixed maintenance cost per installed unit ($) | |

| Price of energy career ($/kW) | |

| Binary variable for vapor compression chiller | |

| Binary variable for absorption chiller | |

| Binary variable for hot water tank | |

| Binary variable for chilled water | |

| Binary variable for auxiliary boiler | |

| Variable for solar collector installed area (m2) | |

| Variable for electricity flow (kW) | |

| Variable for gas flow (kW) | |

| Variable for heat flow (kW) | |

| Variable for heat inventory (kW) | |

| Variable for cool flow (kW) | |

| Variable for cool inventory (kW) | |

| Greek symbols | |

| Efficiency | |

| α | Feed in tariff coefficient |

| Subscripts and superscripts | |

| Time period (hour) | |

| Type of vapor compression chiller | |

| Type of absorption chiller | |

| Type of hot water tank | |

| Type of chilled water tank | |

| Type of auxiliary boiler | |

| Col | Type solar collector (T, PV, PVT) |

| Vc | Vapor compression chiller |

| Ab | Absorption chiller |

| Hwt | Hot water storage tank |

| Cwt | Chilled water storage tank |

| Bo | Auxiliary boiler |

| Grid | Electric grid |

| Bld | building |

| Ther | Thermal |

| Elec | Electricity |

| Gas | Fuel (natural gas) |

| Net | Net |

| Abbreviations | |

| CRF | Capital Recovery Factor |

| DCS | District Cooling System |

References

- International Energy Agency. The Future of Cooling Opportunities for Energy-Efficient air Conditioning. Available online: https://www.iea.org (accessed on 6 December 2021).

- Saffouri, F.; Bayram, I.S.; Koc, M. Quantifying the cost of cooling in Qatar. In Proceedings of the 2017 9th IEEE-GCC Conference and Exhibition (GCCCE), Manama, Bahrain, 8–11 May 2017; IEEE: Piscataway, NJ, USA; pp. 1–9. [Google Scholar]

- Bayram, I.S.; Saffouri, F.; Koc, M. Generation, analysis, and applications of high-resolution electricity load profiles in Qatar. J. Clean. Prod. 2018, 183, 527–543. [Google Scholar] [CrossRef] [Green Version]

- Rezaie, B.; Rosen, M.A. District heating and cooling: Review of technology and potential enhancements. Appl. Energy 2012, 93, 2–10. [Google Scholar] [CrossRef]

- Gang, W.; Wang, S.; Gao, D.; Xiao, F. Performance assessment of district cooling systems for a new development district at planning stage. Appl. Energy 2015, 140, 33–43. [Google Scholar] [CrossRef]

- The Planning and Statistics Authority. District Cooling System Statistics. Available online: https://www.psa.gov.qa/en/statistics/Statistical%20Releases/Environmental/CoolingStatistics/Cooling_Statistics_2018_AE.pdf (accessed on 6 December 2021).

- Eveloy, V.; Ayou, D.S. Sustainable district cooling systems: Status, challenges, and future opportunities, with emphasis on cooling-dominated regions. Energies 2019, 12, 235. [Google Scholar] [CrossRef] [Green Version]

- Gang, W.; Wang, S.; Xiao, F.; Gao, D.C. District cooling systems: Technology integration, system optimization, challenges and opportunities for applications. Renew. Sustain. Energy Rev. 2016, 53, 253–264. [Google Scholar] [CrossRef]

- Li, Y.; Rezgui, Y.; Zhu, H. District heating and cooling optimization and enhancement—Towards integration of renewables, storage and smart grid. Sustain. Energy Rev. 2017, 72, 281–294. [Google Scholar] [CrossRef]

- Inayat, A.; Raza, M. District cooling system via renewable energy sources: A review. Sustain. Energy Rev. 2019, 107, 360–373. [Google Scholar] [CrossRef]

- Mustafa, J.; Alqaed, S.; Almehmadi, F.A.; Jamil, B. Development and comparison of parametric models to predict global solar radiation: A case study for the southern region of Saudi Arabia. J. Therm. Anal. Calorim. 2022. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; PHallinan, K.; Elhashmi, R. Hybrid CHP/Geothermal Borehole System for Multi-Family Building in Heating Dominated Climates. Sustainability 2020, 12, 7772. [Google Scholar] [CrossRef]

- Saikia, K.; Vallès, M.; Fabregat, A.; Saez, R.; Boer, D. A bibliometric analysis of trends in solar cooling technology. Sol. Energy 2020, 199, 100–114. [Google Scholar] [CrossRef]

- Ramos, F.; Cardoso, A.; Alcaso, A. Hybrid photovoltaic-thermal collectors: A review. In Emerging Trends in Technological Innovation; Luis, M., Camarinha-Matos, P.P., Luis, R., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 314, pp. 477–484. [Google Scholar]

- Chow, T.T. A review on photovoltaic/thermal hybrid solar technology. Appl. Energy 2010, 87, 365–379. [Google Scholar] [CrossRef]

- Chow, T.T.; Tiwari, G.N.; Menezo, C. Hybrid solar: A review on photovoltaic and thermal power integration. Int. J. Photoenergy 2012, 2012, 307287. [Google Scholar] [CrossRef] [Green Version]

- Joshi, S.S.; Dhoble, A.S. Photovoltaic -thermal systems (PVT): Technology review and future trends. Renew. Sustain. Energy Rev. 2019, 92, 848–882. [Google Scholar] [CrossRef]

- Hamzat, A.K.; Sahin, A.Z.; Omisanya, M.I.; Alhems, L.M. Advances in PV and PVT cooling technologies: A review. Sustain. Energy Technol. Assess. 2021, 47, 101360. [Google Scholar] [CrossRef]

- Kumar, R.; Rosen, M.A. A critical review of photovoltaic–thermal solar collectors for air heating. Appl. Energy 2011, 88, 3603–3614. [Google Scholar]

- Ul Abdin, Z.; Rachid, A. A survey on applications of hybrid PV/t panels. Energies 2021, 14, 1205. [Google Scholar] [CrossRef]

- Herez, A.; El Hage, H.; Lemenand, T.; Ramadan, M.; Khaled, M. Review on photovoltaic/thermal hybrid solar collectors: Classifications, applications and new systems. Sol. Energy 2020, 207, 1321–1347. [Google Scholar] [CrossRef]

- Barbu, M.; Darie, G.; Siroux, M. A parametric study of a hybrid photovoltaic thermal (PVT) system coupled with a domestic hot water (DHW) storage tank. Energies 2020, 13, 6481. [Google Scholar] [CrossRef]

- Moreno, A.; Chemisana, D.; Fernández, E.F. Hybrid high-concentration photovoltaic-thermal solar systems for building applications. Appl. Energy 2021, 304, 117647. [Google Scholar] [CrossRef]

- Tiwari, S.; Agrawal, S.; Tiwari, G.N. PVT air collector integrated greenhouse dryers. Renew. Sustain. Energy Rev. 2018, 90, 142–159. [Google Scholar] [CrossRef]

- Alqaed, S.; Mustafa, J.; Almehmadi, F.A. Design and energy requirements of a photovoltaic-thermal powered water desalination plant for the middle east. Int. J. Environ. Res. Public Health 2021, 18, 1001. [Google Scholar] [CrossRef] [PubMed]

- Pakere, I.; Lauka, D.; Blumberga, D. Solar power and heat production via photovoltaic thermal panels for district heating and industrial plant. Energy 2018, 154, 424–432. [Google Scholar] [CrossRef]

- Alois, R. 2020 Subsidies for PVT Collectors in Selected Countries. Available online: https://www.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task60-D6-Subsidies-PVT.pdf (accessed on 6 December 2021).

- Lämmle, M.; Herrando, M.; Ryan, G. Basic Concepts of PVT Collector Technologies, Applications and Markets. Available online: https://www.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task60-D5-Basic-Concepts-of-PVT-Technologies.pdf (accessed on 6 December 2021).

- Hadorn, J.; Zenhusern, D. Collection of Documents Prepared along the Task for Industry and Market. Available online: https://www.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task60-Docs.pdf (accessed on 6 December 2021).

- Hadorn, J.; Lämmle, M.; Kramer, L.; Munz, G.; Ryan, G.; Herrando, M.; Brottier, L. Design Guidelines for PVT Collectors. Available online: https://www.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task60-B2-Design-Guidelines-for-PVT-Collectors.pdf (accessed on 6 December 2021).

- Al-Waeli, A.H.; Sopian, K.; Kazem, H.A.; Chaichan, M.T. Novel criteria for assessing PV/t solar energy production. Case Stud. Therm. Eng. 2019, 16, 100547. [Google Scholar] [CrossRef]

- Zenhäusern, D. Key Performance Indicators for PVT Systems. Available online: https://www.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task60-D1-Key-Performance-Indicators.pdf (accessed on 6 December 2021).

- Abid, M.; Khan, M.S.; Ratlamwala, T.A.H.; Malik, M.N.; Ali, H.M.; Cheok, Q. Thermodynamic analysis and comparison of different absorption cycles driven by evacuated tube solar collector utilizing hybrid nanofluids. Energy Convers. Manag. 2021, 246, 114673. [Google Scholar] [CrossRef]

- Asadi, J.; Amani, P.; Amani, M.; Kasaeian, A.; Bahiraei, M. Thermo-economic analysis and multi-objective optimization of absorption cooling system driven by various solar collectors. Energy Convers. Manag. 2018, 173, 715–727. [Google Scholar]

- Weber, C.; Berger, M.; Mehling, F.; Heinrich, A.; Núñez, T. Solar cooling with water–ammonia absorption chillers and concentrating solar collector—Operational experience. Int. J. Refrig. 2014, 39, 57–76. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Performance analysis and optimization of an absorption chiller driven by nanofluid-based solar flat plate collector. J. Clean. Prod. 2018, 174, 256–272. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Parametric analysis and optimization of a cooling system with ejector-absorption chiller powered by solar parabolic trough collectors. Energy Convers. Manag. 2018, 168, 329–342. [Google Scholar] [CrossRef]

- Shehadi, M. Optimizing solar cooling systems. Case Stud. Therm. Eng. 2020, 21, 100663. [Google Scholar] [CrossRef]

- Saleh, A.; Mosa, M. Optimization study of a single-effect water–lithium bromide absorption refrigeration system powered by flat-plate collector in hot regions. Energy Convers. Manag. 2014, 87, 29–36. [Google Scholar] [CrossRef]

- Iranmanesh, A.; Mehrabian, M.A. Optimization of a lithium bromide–water solar absorption cooling system with evacuated tube collectors using the genetic algorithm. Energy Build. 2014, 85, 427–435. [Google Scholar] [CrossRef]

- Alobaid, M.; Hughes, B.; Calautit, J.K.; O’Connor, D.; Heyes, A. A review of solar-driven absorption cooling with photovoltaic thermal systems. Renew. Sustain. Energy Rev. 2017, 76, 728–742. [Google Scholar] [CrossRef] [Green Version]

- Alghool, D.M.; Elmekkawy, T.Y.; Haouari, M.; Elomri, A. Optimization of design and operation of solar-assisted district cooling systems. Energy Convers. Manag. X 2020, 6, 100028. [Google Scholar] [CrossRef]

- Calderoni, M.; Dourlens-Qaranta, S.; Sreekumar, B.B.; Lennard, Z.; Rämä, M.; Klobut, K.; Wang, Z.; Duan, X.; Zhang, Y.; Nilsson, J.; et al. Sustainable District Cooling Guidelines; VTT: Espoo, Finland, 2019. [Google Scholar]

- Ismaen, R.; El Mekkawy, T.Y.; Pokharel, S.; Al-Salem, M. System requirements and optimization of multi-chillers district cooling plants. Energy 2022, 246, 123349. [Google Scholar] [CrossRef]

- Awjah Almehmadi, F.; Hallinan, K.P.; Mulford, R.B.; Alqaed, S.A. Technology to Address Food Deserts: Low Energy Corner Store Groceries with Integrated Agriculture Greenhouse. Sustainability 2020, 12, 7565. [Google Scholar] [CrossRef]

- Sameti, M.; Haghighat, F. Hybrid solar and heat-driven district cooling system: Optimal integration and control strategies. Sol. Energy 2019, 183, 260–275. [Google Scholar] [CrossRef]

- Ramschak, T. Available online: https://task60.iea-shc.org/Data/Sites/1/publications/IEA-SHC-Task60-A1-Existing-PVT-Systems-and-Solutions.pdf (accessed on 6 December 2021).

- Alghool, D.; Elmekkawy, T.; Haouari, M.; Elomri, A. Data of the design of solar-assisted district cooling systems. Data Brief 2020, 30, 105541. [Google Scholar] [CrossRef]

- KAHRAMA. Qatar General Electricity & Water Corporation. Available online: https://www.km.qa/CustomerService/Pages/Tariff.aspx (accessed on 6 December 2021).

- Natural Gas-Monthly Price (Qatari Riyal per Million Metric British Thermal Unit)-Commodity Prices-Price Charts, Data, and News-IndexMundi. Available online: https://www.indexmundi.com/ (accessed on 6 December 2021).

| Configuration | Integration |

|---|---|

| Configuration 1 | Integrated Photovoltaic Thermal (PVT) solar collector-district cooling system |

| Configuration 2 | Integrated Photovoltaic (PV) solar collector-district cooling system |

| Configuration 3 | Integrated Thermal (T) solar collector-district cooling system |

| Base configuration | Conventional district cooling system powered with grid electricity |

| Parameter | Integration | |||

|---|---|---|---|---|

| System | ||||

| Configuration 1 | Integrated Photovoltaic Thermal (PVT)-DCS | |||

| Configuration 2 | Integrated Photovoltaic (PV)-DCS | |||

| Configuration 3 | Integrated Thermal (T)-DCS | |||

| Base configuration | and ) or A = 0 | Conventional district cooling system Grid-DCS | ||

| Configuration | Solar Collector | Set Size | ||||||

|---|---|---|---|---|---|---|---|---|

| I | J | K | M | N | ||||

| Configuration 1 (PVT-DCS) | 0.70 | 0.18 | 300 $/m2 | 5 | 6 | 7 | 7 | 4 |

| Configuration 2 (PV-DCS) | 0.00 | 0.20 | 100 $/m2 | |||||

| Configuration 3 (T-DCS) | 0.75 | 0.00 | 250 $/m2 | |||||

| Base configuration (Grid–DCS) | 0.00 | 0.00 | 0 $ | |||||

| Base Configuration (Grid) | Configuration 1 (PVT) | |||

|---|---|---|---|---|

| Capacity/Amount | Efficiency | Capacity/Amount | Efficiency | |

| PVT | - | - | 6000 m2 | 0.7 and 0.18 |

| electric chiller | 6330 kW | 6.7 | 5300 kW | 6.7 |

| Absorption chiller | - | - | 1454 kW | 1.36 |

| Hot water TES | - | - | 63,000 kW | - |

| Chilled water TES | 63,000 kW | - | 63,000 kW | - |

| Boiler | - | - | - | - |

| Total cost | 362,822 | 343,758 | ||

| Investment & maintenance costs | 41,535 | 214,395 | ||

| Operation cost | 321,286 | 129,363 | ||

| Economic | Energy Indicators | Environmental Indicators | ||||||

|---|---|---|---|---|---|---|---|---|

| Total Cost ($) | (%) | (%) | (%) | kWh Equivalent | kWh Equivalent | kWh Oil-Equivalent | Kg CO2-Equivalent | |

| Configuration 1 | 343,758 | 45.07 | 100 | 80.36 | 9,055,221 | 1,930,012 | 6,797,412 | 1,232,472 |

| Base configuration | 362,822 | 0 | 0 | 0 | 0 | 0 | 16,882,130 | 3,060,981 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ismaen, R.; ElMekkawy, T.Y.; Pokharel, S.; Elomri, A.; Al-Salem, M. Solar Technology and District Cooling System in a Hot Climate Regions: Optimal Configuration and Technology Selection. Energies 2022, 15, 2657. https://doi.org/10.3390/en15072657

Ismaen R, ElMekkawy TY, Pokharel S, Elomri A, Al-Salem M. Solar Technology and District Cooling System in a Hot Climate Regions: Optimal Configuration and Technology Selection. Energies. 2022; 15(7):2657. https://doi.org/10.3390/en15072657

Chicago/Turabian StyleIsmaen, Rabah, Tarek Y. ElMekkawy, Shaligram Pokharel, Adel Elomri, and Mohammed Al-Salem. 2022. "Solar Technology and District Cooling System in a Hot Climate Regions: Optimal Configuration and Technology Selection" Energies 15, no. 7: 2657. https://doi.org/10.3390/en15072657

APA StyleIsmaen, R., ElMekkawy, T. Y., Pokharel, S., Elomri, A., & Al-Salem, M. (2022). Solar Technology and District Cooling System in a Hot Climate Regions: Optimal Configuration and Technology Selection. Energies, 15(7), 2657. https://doi.org/10.3390/en15072657