Power Generation Prediction of Building-Integrated Photovoltaic System with Colored Modules Using Machine Learning

Abstract

1. Introduction

2. Colored BIPV Systems with Data Measuring Equipment

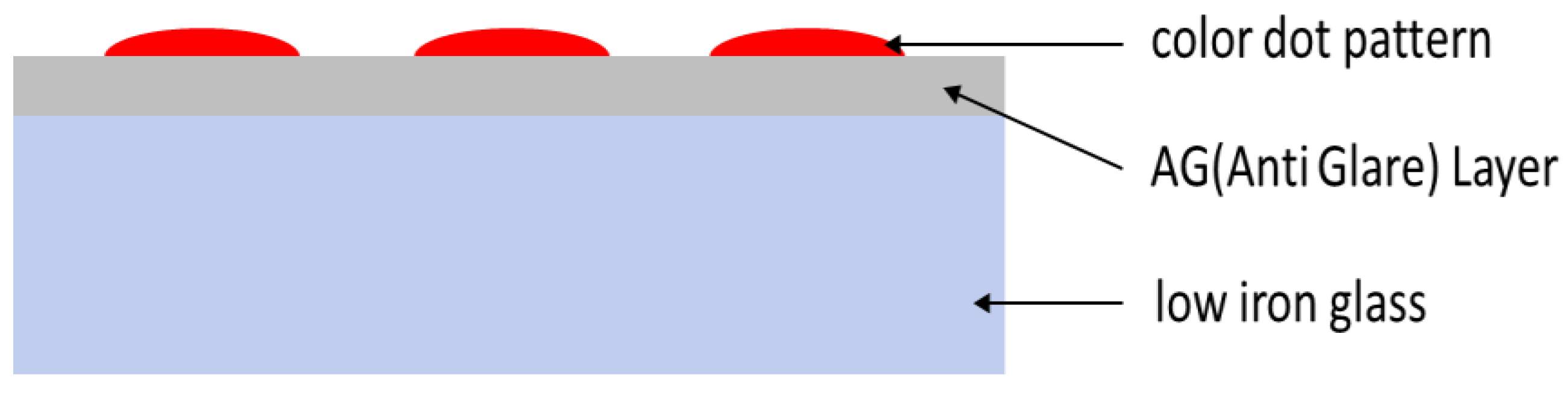

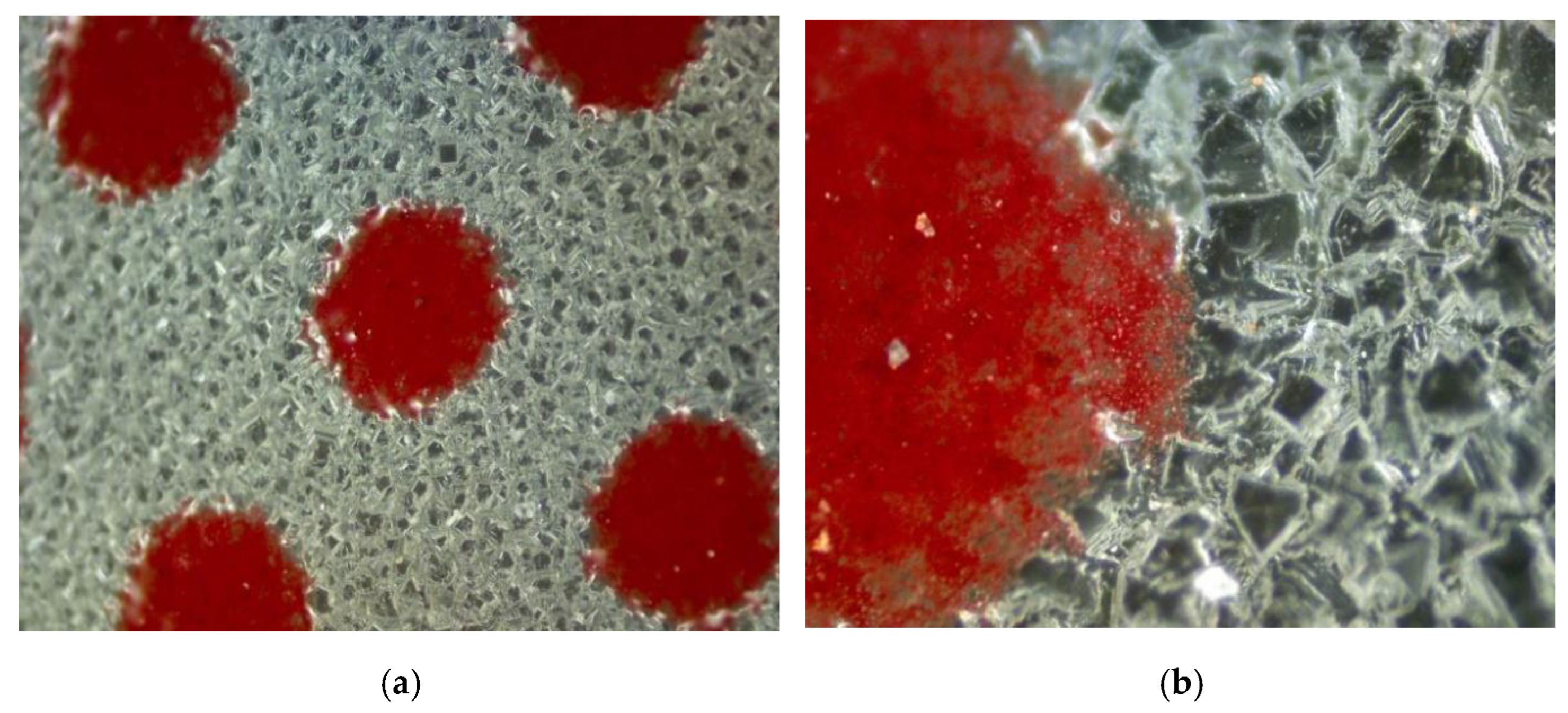

2.1. A Colored BIPV Module Implementation Method and Structure

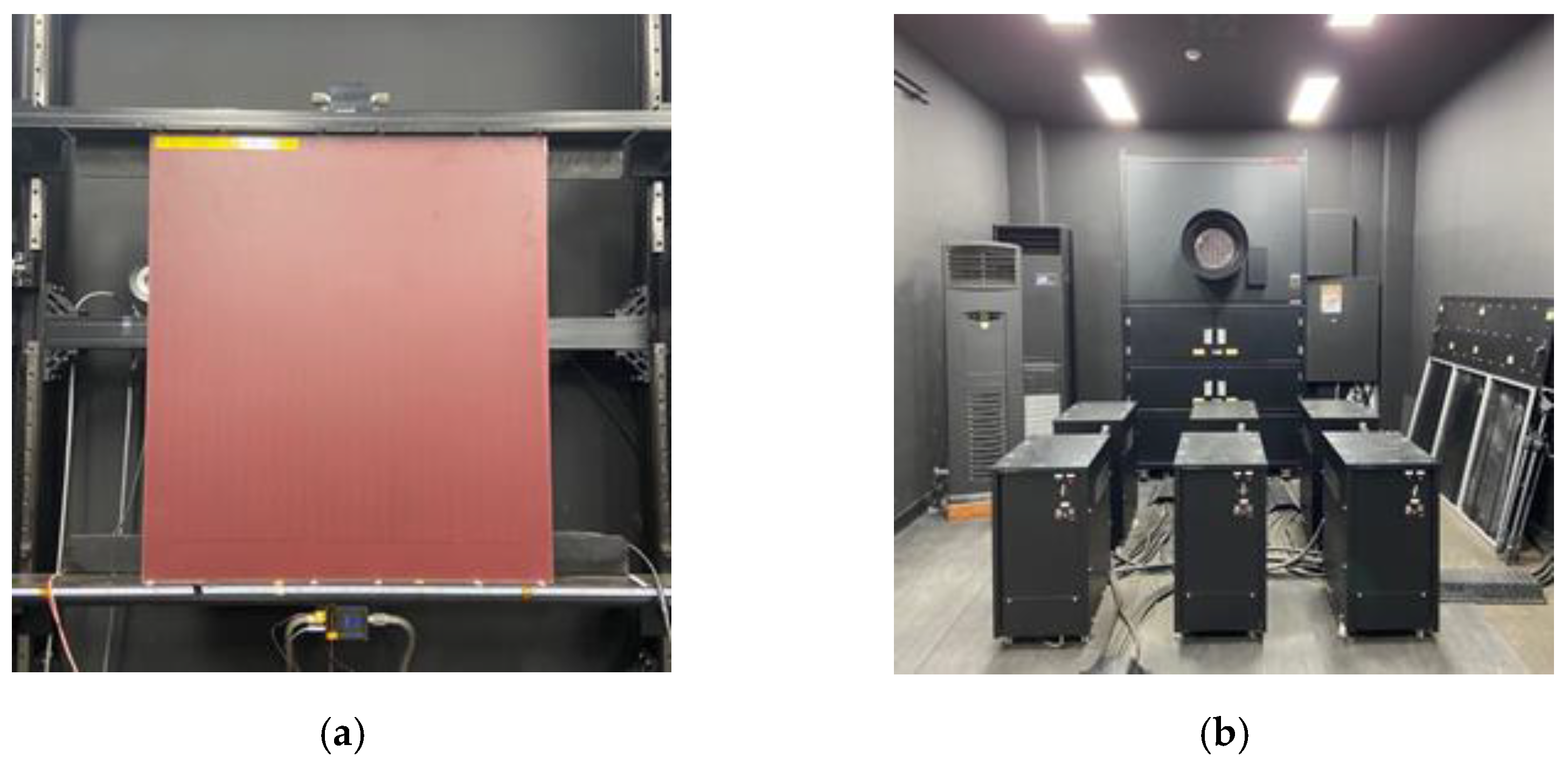

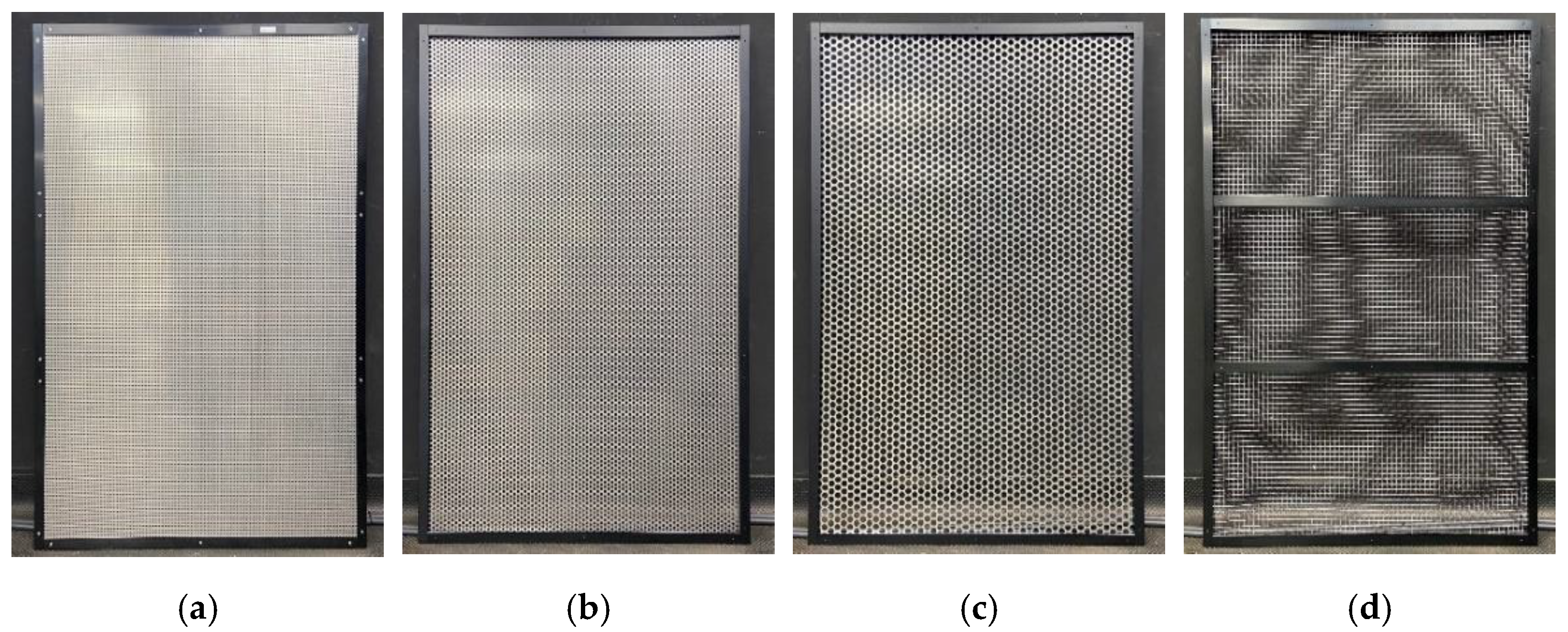

2.2. BIPV System Integration

2.3. Data Measuring Equipment

3. Power Generation Prediction Model

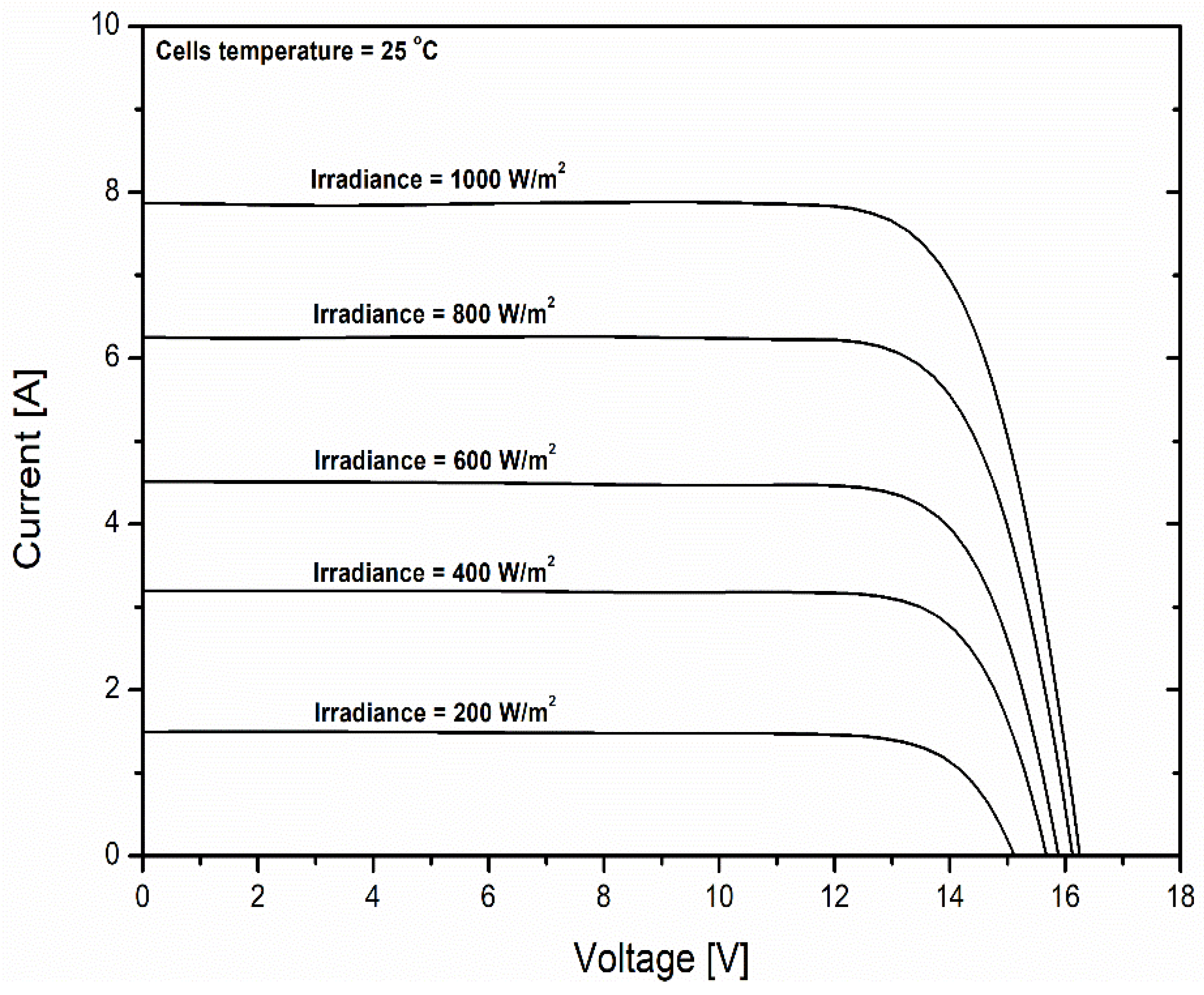

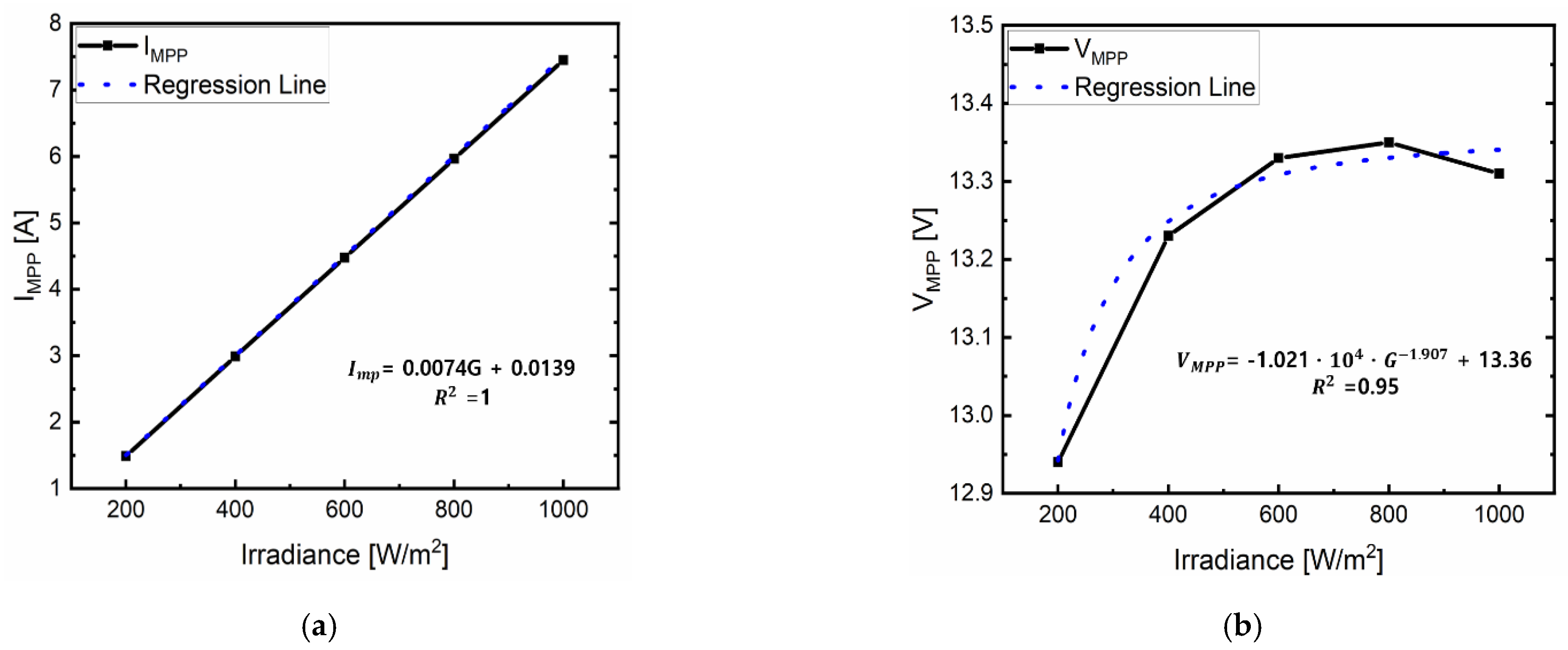

3.1. Proposed Simulation Model Using the I–V Curve

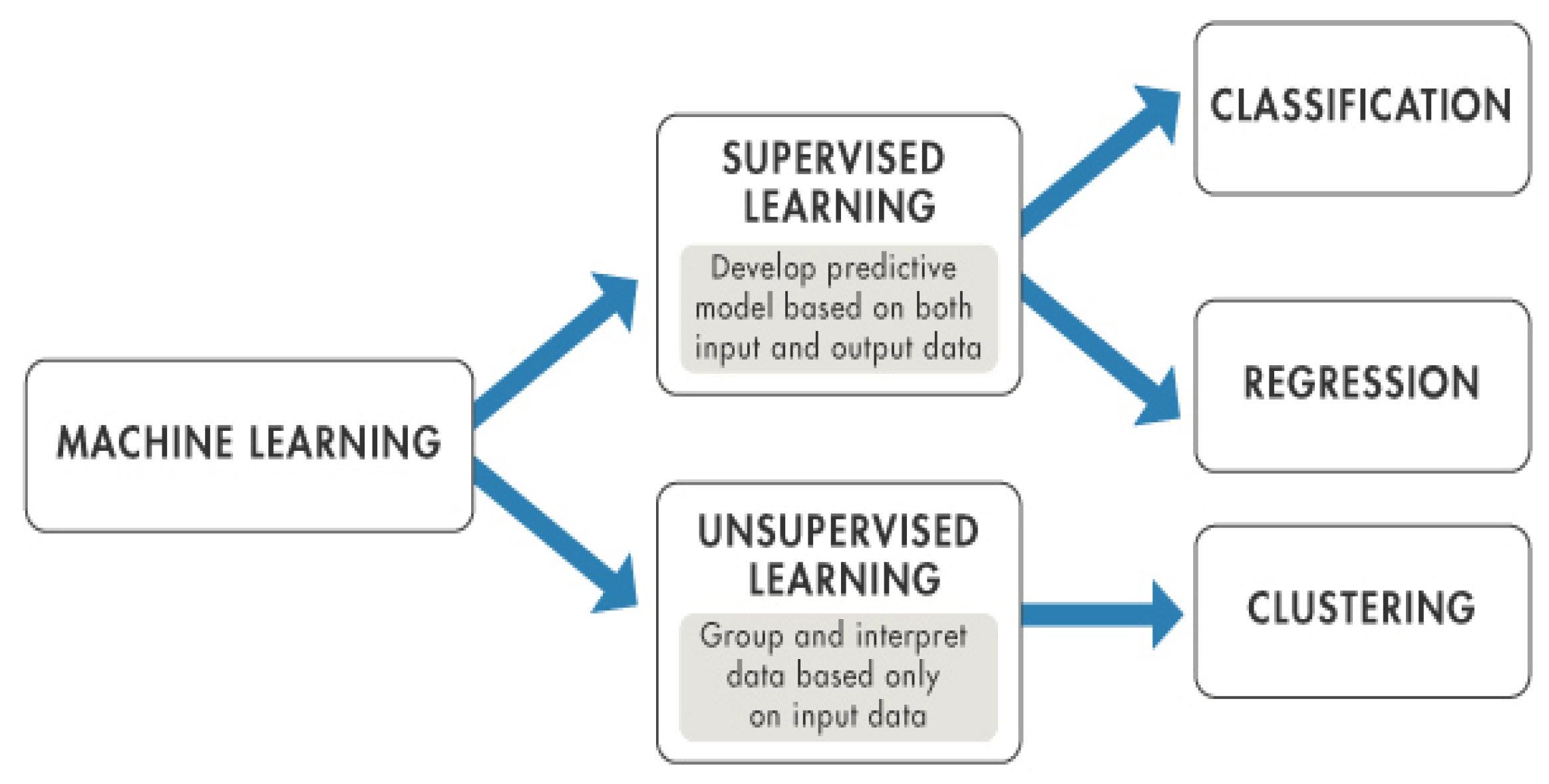

3.2. Proposed Machine Learning Model Using Historical Data

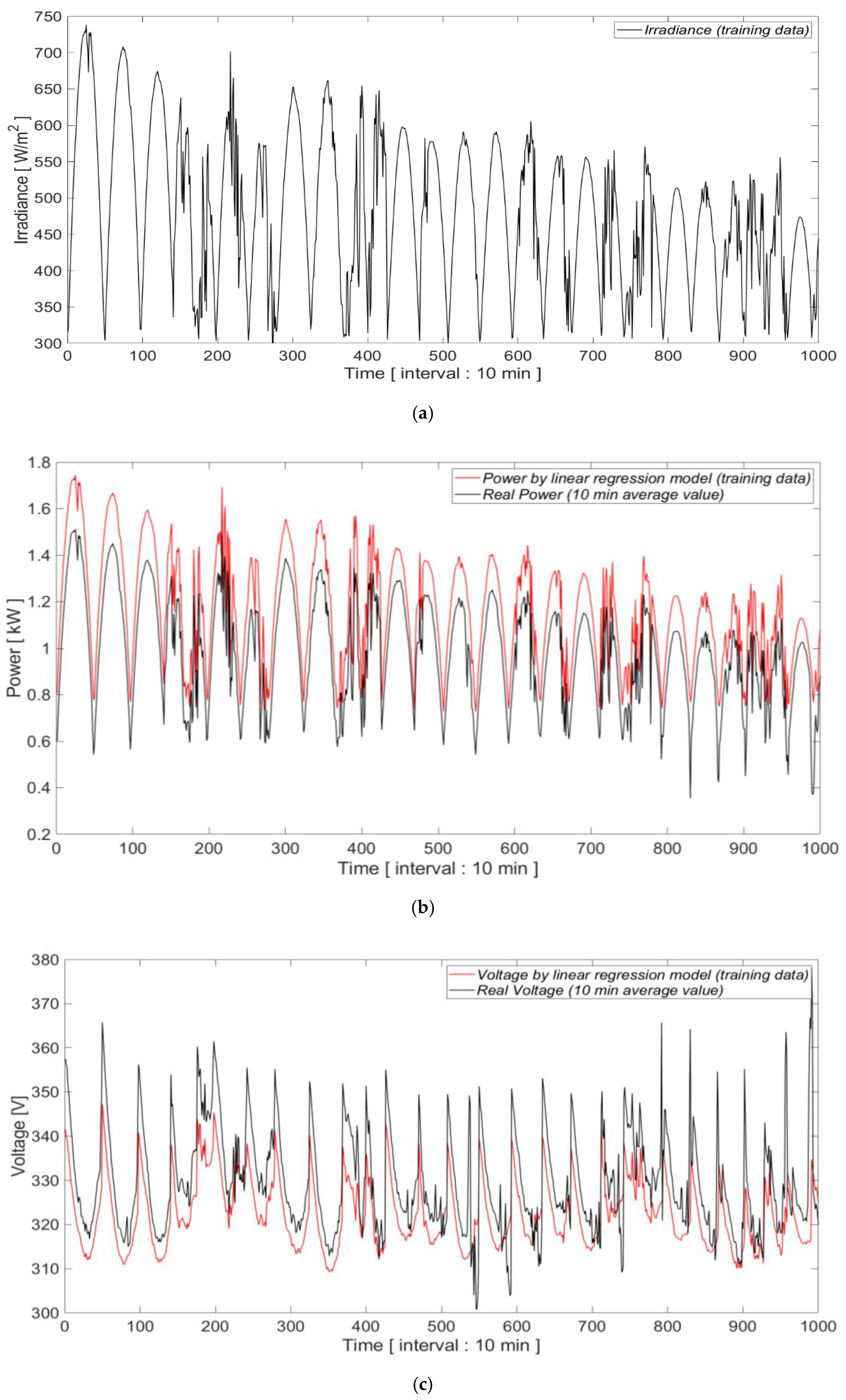

4. Data Analysis and Discussion

5. Results

- (1)

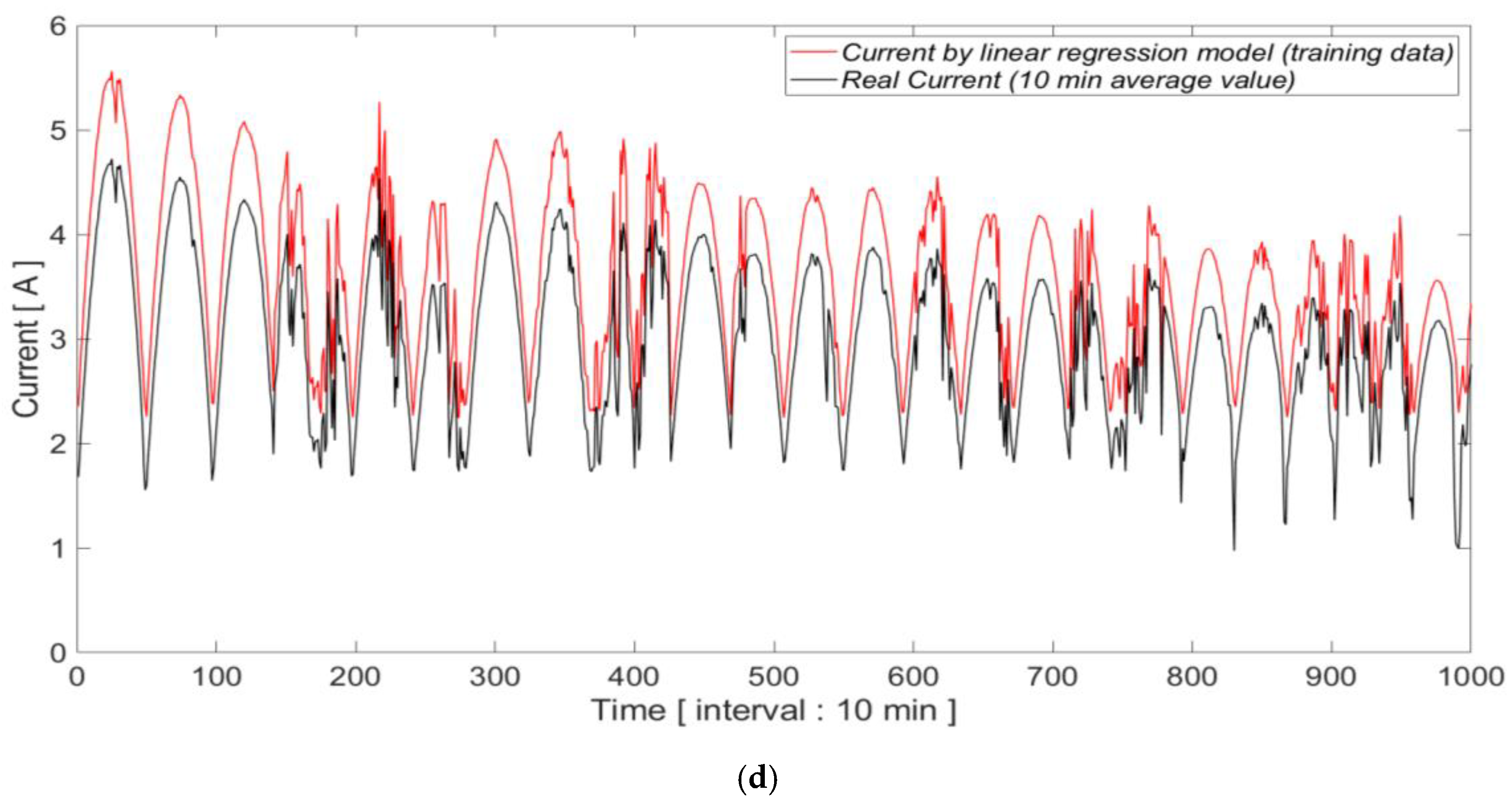

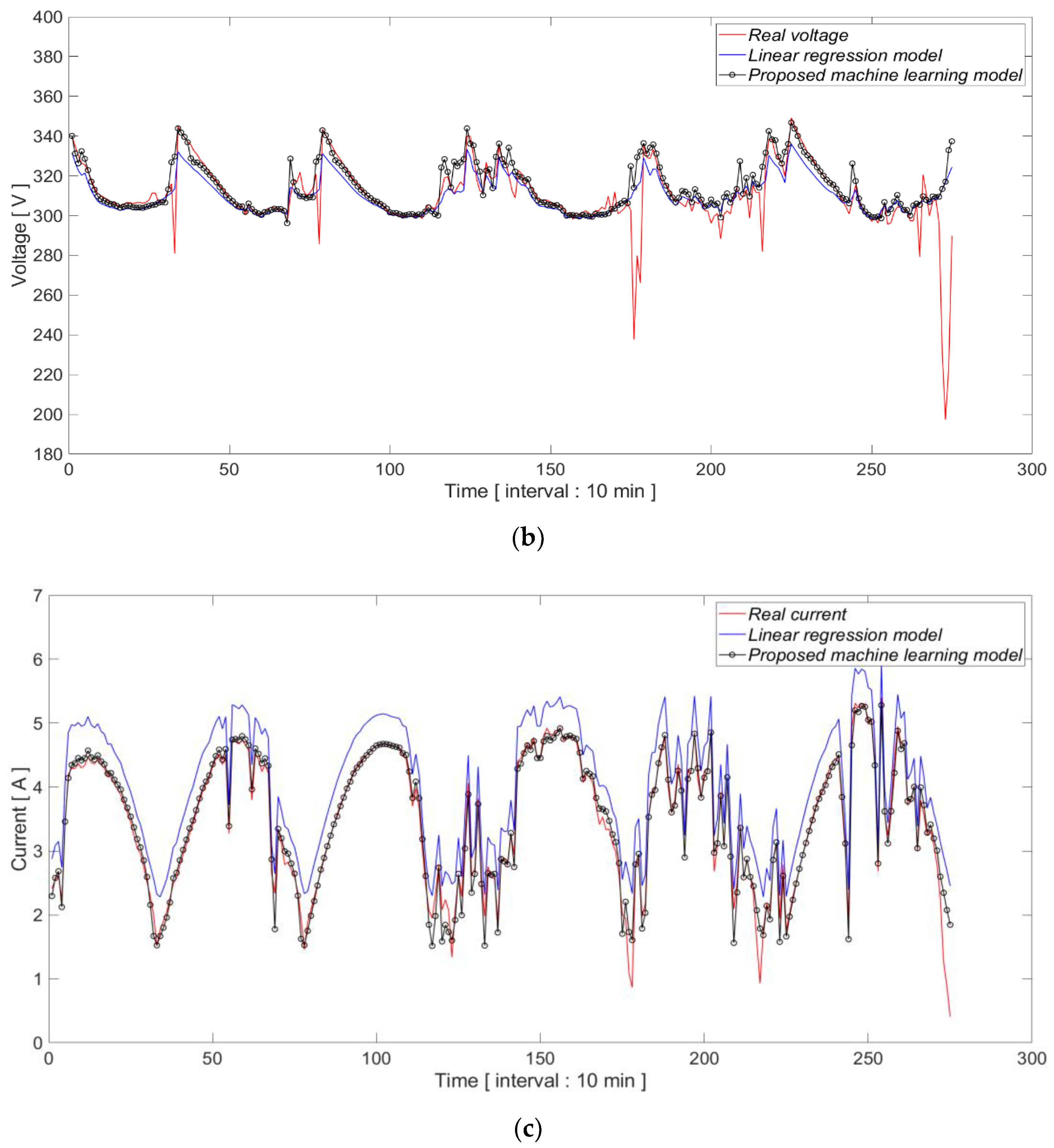

- The surface dots of the colored BIPV module created shadows when the sun’s rays hit it, which lowered the real power. Therefore, the proposed linear regression model that predicts the power generation using the irradiance measured by a pyranometer showed a large error in the power generation predictions for the colored BIPV system. In addition, the data was acquired as a 10 min average, and the operation of the inverter was stop in the severe fluctuation of irradiance or low current section.

- (2)

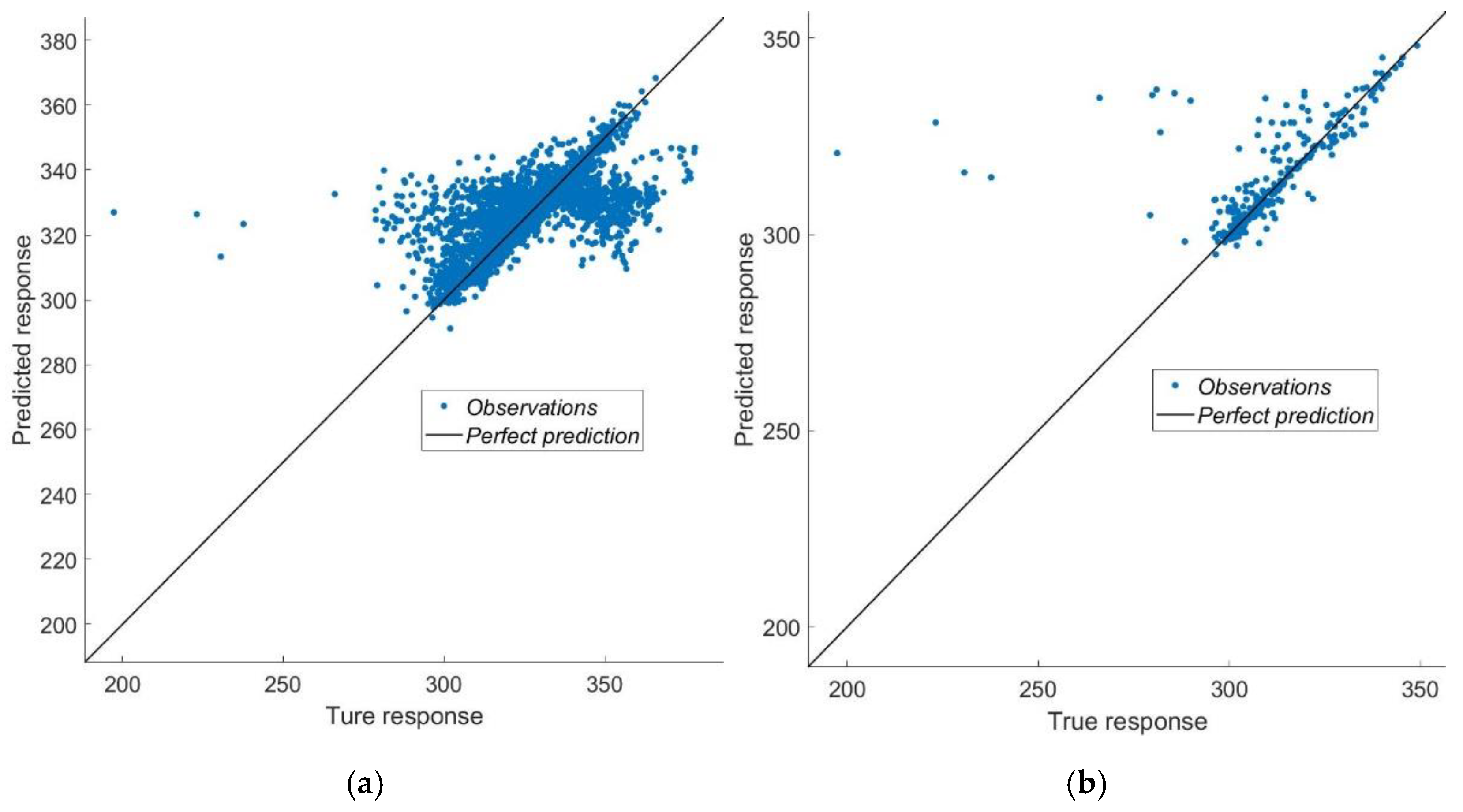

- To minimize the influence of factors that lower the output prediction accuracy, neural network ML is used. An ML model was proposed to reflect the output characteristics of the colored module. The proposed ML model predicts voltage and current, and the irradiance, module temperature, and voltage, and current data were calculated by a linear regression model as training data.

- (3)

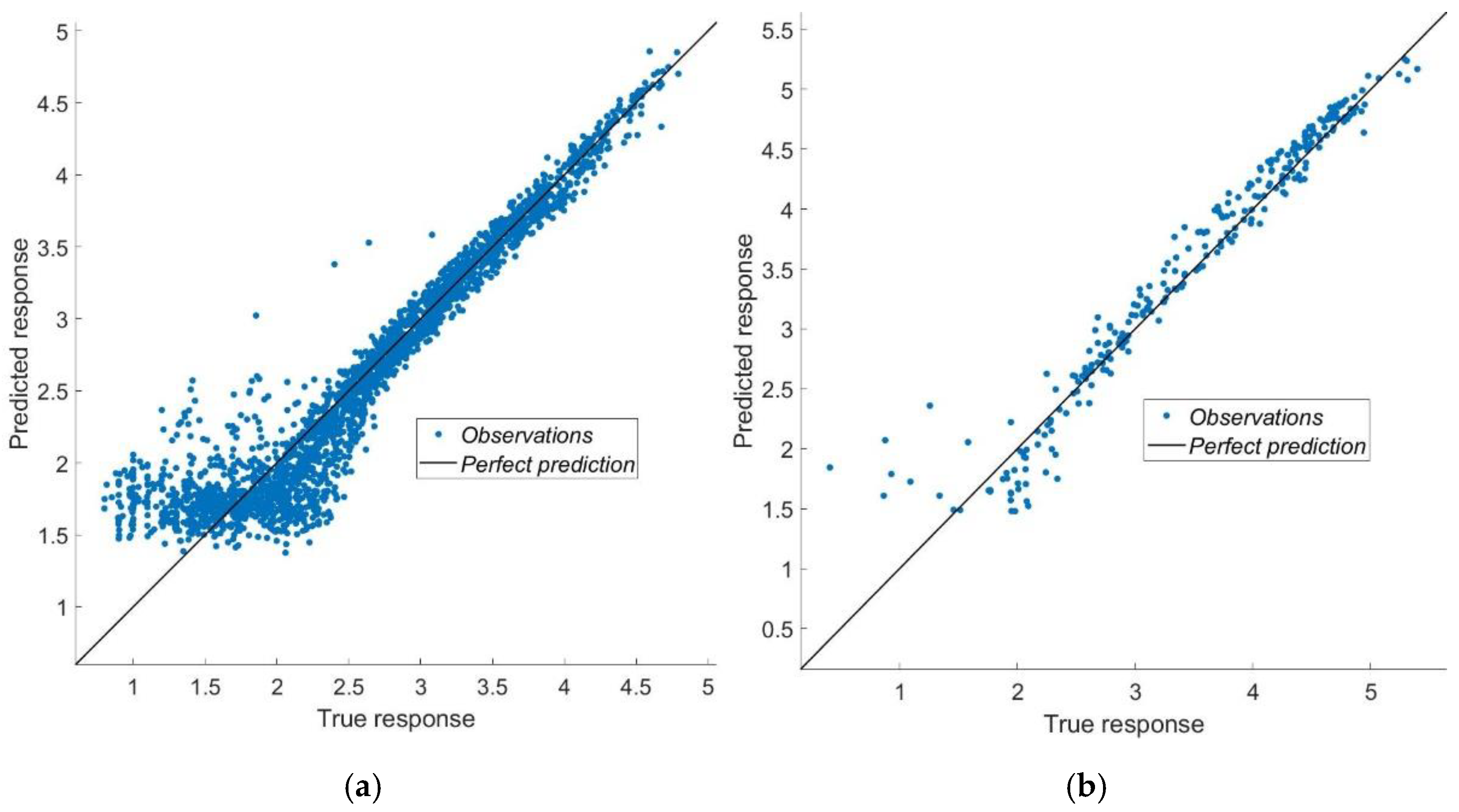

- As a result of comparing the prediction value of the linear regression model and the prediction value of the ML model for the testing data, it was confirmed that the ML model predicts values that are closer to the actual power, voltage, and current than the linear regression model. The R2 values for the voltage and current values of the proposed ML model were 5% higher for voltage and 2% higher for current. The RMSE of the ML model for power generation was 0.0754 kW, the RMSE of the simulation model was 0.1581 kW, and the error rate of the ML model was reduced by more than 50% compared to the simulation model.

- (4)

- The proposed ML model can predict the power generation of a vertically installed BIPV system with a colored module created with dots on glass with a high level of accuracy. For accurate power predictions, this method can easily determine the failure of a BIPV system and reduce energy losses via routine maintenance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Key World Energy Statistics. 2020. Available online: https://www.iea.org/reports/key-world-energy-statistics-2020 (accessed on 11 January 2022).

- Gholami, H.; Røstvik, H.N.; Steemers, K. The Contribution of Building-Integrated Photovoltaics (BIPV) to the Concept of Nearly Zero-Energy Cities in Europe: Potential and Challenges Ahead. Energies 2021, 14, 6015. [Google Scholar] [CrossRef]

- Amado, M.; Poggi, F.; Amado, A.R.; Breu, S. A Cellular Approach to Net-Zero Energy Cities. Energies 2017, 10, 1826. [Google Scholar] [CrossRef]

- Todorovic, B. Towards zero energy buildings: New and retrofitted existing buildings. In Proceedings of the 2011 IEEE 3rd International Symposium on Exploitation of Renewable Energy Sources (EXPRES), Subotica, Serbia, 11–12 March 2011; pp. 7–14. [Google Scholar]

- Debbarma, M.; Sudhakar, K.; Baredar, P. Comparison of BIPV and BIPVT: A review. Resour. Technol. 2017, 3, 263–271. [Google Scholar] [CrossRef]

- Liang, Z.; Chen, D.; Liang, X.; Yang, Z.; Shen, H.; Shi, J. Crystalline Si solar cells based on solar grade silicon materials. Renew. Energy 2010, 35, 2297–2300. [Google Scholar] [CrossRef]

- Liu, J.; Yao, Y.; Xiao, S.; Gu, X. Review of status developments of high-efficiency crystalline silicon solar cells. J. Phys. D Appl. Phys. 2018, 51, 123001. [Google Scholar] [CrossRef]

- Ansari, M.I.H.; Qurashi, A.; Nazeeruddin, M.K. Frontiers, opportunities, and challenges in perovskite solar cells: A critical review. J. Photochem. Photobiol. C Photochem. Rev. 2018, 35, 1–24. [Google Scholar] [CrossRef]

- Li, R.; Li, C.; Liu, M.; Vivo, P.; Zheng, M.; Dai, Z.; Zhan, J.; He, B.; Li, H.; Yang, W.; et al. Hydrogen-Bonded Dopant-Free Hole Transport Material Enables Efficient and Stable Inverted Perovskite Solar Cells. CCS Chem. 2021, 3, 3309–3319. [Google Scholar] [CrossRef]

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.; del Caño, T.; Rico, E.; et al. A key review of building integrated photovoltaic (BIPV) systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858. [Google Scholar] [CrossRef]

- Fath, K.; Stengel, J.; Sprenger, W.; Wilson, H.R.; Schultmann, F.; Kuhn, T. A method for predicting the economic potential of (building-integrated) photovoltaics in urban areas based on hourly Radiance simulations. Sol. Energy 2015, 116, 357–370. [Google Scholar] [CrossRef]

- Kuhn, T.E.; Erban, C.; Heinrich, M.; Eisenlohr, J.; Ensslen, F.; Neuhaus, D.H. Review of technological design options for building integrated photovoltaics (BIPV). Energy Build. 2021, 231, 110381. [Google Scholar] [CrossRef]

- Pelle, M.; Lucchi, E.; Maturi, L.; Astigarraga, A.; Causone, F. Colored BIPV technologies: Methodological and exper-imental assessment for architecturally sensitive areas. Energies 2020, 13, 4506. [Google Scholar] [CrossRef]

- Forero, N.; Hernández, J.; Gordillo, G. Development of a monitoring system for a PV solar plant. Energy Convers. Manag. 2006, 47, 2329–2336. [Google Scholar] [CrossRef]

- Rezk, H.; Tyukhov, I.; Al-Dhaifallah, M.; Tikhonov, A. Performance of data acquisition system for monitoring PV system parameters. Measurement 2017, 104, 204–211. [Google Scholar] [CrossRef]

- Aste, N.; Del Pero, C.; Leonforte, F.; Manfren, M. A simplified model for the estimation of energy production of PV systems. Energy 2013, 59, 503–512. [Google Scholar] [CrossRef]

- Kim, G.G.; Choi, J.H.; Park, S.Y.; Bhang, B.G.; Nam, W.J.; Cha, H.L.; Ahn, H.K. Prediction model for PV performance with correlation analysis of environmental variables. IEEE J. Photovolt. 2019, 9, 832–841. [Google Scholar] [CrossRef]

- Lappalainen, K.; Wang, G.C.; Kleissl, J. Estimation of the largest expected photovoltaic power ramp rates. Appl. Energy 2020, 278, 115636. [Google Scholar] [CrossRef]

- Marcos, J.; Marroyo, L.; Lorenzo, E.; Alvira, D.; Izco, E. From irradiance to output power fluctuations: The PV plant as a low pass filter. Prog. Photovolt. Res. Appl. 2011, 19, 505–510. [Google Scholar] [CrossRef]

- Huang, C.; Chen, H.; Chan, C.; Chou, C.; Chiang, C. Thermal Model Based Power-Generated Prediction by Using Meteorological Data in BIPV System. Energy Procedia 2011, 12, 531–537. [Google Scholar] [CrossRef][Green Version]

- Kurukuru, V.S.B.; Haque, A.; Khan, M.A.; Sahoo, S.; Malik, A.; Blaabjerg, F. A Review on Artificial Intelligence Applications for Grid-Connected Solar Photovoltaic Systems. Energies 2021, 14, 4690. [Google Scholar] [CrossRef]

- Lee, D.; Jeong, J.; Yoon, S.H.; Chae, Y.T. Improvement of short-term BIPV power predictions using feature engineering and a recurrent neural network. Energies 2019, 12, 3247. [Google Scholar] [CrossRef]

- Kabilan, R.; Chandran, V.; Yogapriya, J.; Karthick, A.; Gandhi, P.P.; Mohanavel, V.; Rahim, R.; Manoharan, S. Short-Term Power Prediction of Building Integrated Photovoltaic (BIPV) System Based on Machine Learning Algorithms. Int. J. Photoenergy 2021, 2021, 5582418. [Google Scholar] [CrossRef]

- Khandakar, A.; EH Chowdhury, M.; Khoda Kazi, M.; Benhmed, K.; Touati, F.; Al-Hitmi, M.; Gonzales, J.S. Machine learning based photovoltaics (PV) power prediction using different environmental parameters of Qatar. Energies 2019, 12, 2782. [Google Scholar] [CrossRef]

- Garoudja, E.; Chouder, A.; Kara, K.; Silvestre, S. An enhanced machine learning based approach for failures detection and diagnosis of PV systems. Energy Convers. Manag. 2017, 151, 496–513. [Google Scholar] [CrossRef]

| Color | (W) | (V) | (A) | (V) | (A) | Fill Factor (%) |

|---|---|---|---|---|---|---|

| Red | 99.18 | 16.24 | 7.84 | 13.31 | 7.45 | 77.89 |

| Dark Gray | 99.25 | 16.25 | 7.84 | 13.32 | 7.45 | 77.86 |

| Light Gray | 99.62 | 16.16 | 7.97 | 13.26 | 7.52 | 77.32 |

| Sky Blue | 99.35 | 16.22 | 7.86 | 13.33 | 7.45 | 77.93 |

| Group 1 | Group 2 | Group 3 | |

|---|---|---|---|

| (W) | 99 | 99 | 99 |

| (A) | 7.45 | 7.45 | 7.45 |

| (V) | 13.31 | 13.31 | 13.31 |

| (A) | 7.84 | 7.84 | 7.84 |

| (V) | 16.24 | 16.24 | 16.24 |

| Temperature coefficient (%/°C) | 0.3 | 0.3 | 0.3 |

| Cell number | 24 | 24 | 24 |

| Series module number | 26 | 28 | 26 |

| Parallel module number | 1 | 1 | 1 |

| Capacity (kW) | 2.50 | 2.69 | 2.50 |

| DC | MPPT voltage range | 100 V~400 V |

| Maximum Voltage | 500 V | |

| Maximum current | 18 A | |

| AC | Rated power | 3.5 kW |

| Maximum efficiency | 97% ≤~ |

| Specification | Value |

|---|---|

| Spectral Range | 400 to 1100 nm |

| Sensitivity | 60 to 100 μV/W/m2 |

| Response Time | <500 ns |

| Non-linearity | 0 to 1000 W/m2 |

| Maximum solar irradiance | 2000 W/m2 |

| Operational Temperature range | −40 °C to + 80 °C |

| Directional response | <10 W/m2 (up to 80° with 1000 W/m2 beam) |

| Field of view | 180° |

| Non-stability | <2% (change/year) |

| Specification | Value |

|---|---|

| Temperature Range | −200 °C to 1250 °C (−328 °F to 2282 °F) |

| Std. Limits of Error | Greater of 2.2 °C or 0.75% |

| Spec. Limits of Error | Grater of 1.1 °C or 0.4% |

| Irradiance (W/m2) | (W) | (V) | (A) | Fill Factor (%) |

|---|---|---|---|---|

| 1000 | 99.2 | 13.31 | 7.452 | 77.9 |

| 800 | 79.6 | 13.35 | 5.964 | 78.8 |

| 600 | 59.7 | 13.33 | 4.477 | 79.5 |

| 400 | 39.5 | 13.23 | 2.989 | 80.3 |

| 200 | 19.3 | 12.94 | 1.487 | 80.7 |

| Time | Power | Voltage | Current | Irradiance | Temperature |

|---|---|---|---|---|---|

| xxx | xxx | xxx | xxx | xxx | xxx |

| Machine Learning Model | Target Variable | Input Variable |

|---|---|---|

| Classic method | Power | Irradiance |

| Temperature | ||

| Proposed method | Voltage | Irradiance |

| Temperature | ||

| Voltage for estimation | ||

| Current | Irradiance | |

| Temperature | ||

| Current for estimation |

| Voltage Model | RMSE | MAE | R2 |

|---|---|---|---|

| Validation (training) | 13.906 (V) | 9.1902 (V) | 0.37 |

| Test | 13.73 (V) | 9.4955 (V) | 0.33 |

| Voltage Model | RMSE | MAE | R2 |

|---|---|---|---|

| Validation (training) | 13.451 (V) | 8.5375 (V) | 0.41 |

| Test | 13.27 (V) | 8.5375 (V) | 0.38 |

| Current Model | RMSE | MAE | R2 |

|---|---|---|---|

| Validation (training) | 0.28619 (A) | 0.20708 (A) | 0.90 |

| Test | 0.29343 (A) | 0.21655 (A) | 0.88 |

| Current Model | RMSE | MAE | R2 |

|---|---|---|---|

| Validation (training) | 0.26119 (A) | 0.17455 (A) | 0.92 |

| Test | 0.26437 (A) | 0.17761 (A) | 0.90 |

| Model | RMSE | MAE |

|---|---|---|

| Linear regression model | 0.1581 (kW) | 0.1372 (kW) |

| Proposed ML model | 0.0754 (kW) | 0.0372 (kW) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, W.-G.; Shin, J.-Y.; Hwang, H.-M.; Park, C.-H.; Ko, S.-W. Power Generation Prediction of Building-Integrated Photovoltaic System with Colored Modules Using Machine Learning. Energies 2022, 15, 2589. https://doi.org/10.3390/en15072589

Shin W-G, Shin J-Y, Hwang H-M, Park C-H, Ko S-W. Power Generation Prediction of Building-Integrated Photovoltaic System with Colored Modules Using Machine Learning. Energies. 2022; 15(7):2589. https://doi.org/10.3390/en15072589

Chicago/Turabian StyleShin, Woo-Gyun, Ju-Young Shin, Hye-Mi Hwang, Chi-Hong Park, and Suk-Whan Ko. 2022. "Power Generation Prediction of Building-Integrated Photovoltaic System with Colored Modules Using Machine Learning" Energies 15, no. 7: 2589. https://doi.org/10.3390/en15072589

APA StyleShin, W.-G., Shin, J.-Y., Hwang, H.-M., Park, C.-H., & Ko, S.-W. (2022). Power Generation Prediction of Building-Integrated Photovoltaic System with Colored Modules Using Machine Learning. Energies, 15(7), 2589. https://doi.org/10.3390/en15072589