1. Introduction

The global human population is expected to increase from 7.8 billion to 10.9 billion throughout the course of the 21st century [

1]. The growth in the global population results in the greater consumption of resources and consequently drives an increasing municipal solid waste (MSW) stream [

2]. Furthermore, rapid urbanization and economic development accompany this global population rise and concentrate MSW into confined, metropolitan areas [

2,

3,

4]. Increased production and concentration of MSW in tandem with a rising composition complexity poses a glaring challenge for proper waste management [

5]. Of the globally estimated 2.01 billion tons of MSW currently generated annually, approximately 33% is not managed properly [

6].

Proper management of MSW is essential for preserving the welfare of society. MSW has the ability to affect air, water, and soil vectors that directly impact human health [

7], [

8]. The two predominant global means of managing MSW today are landfilling and incineration [

6]. Unfortunately, both means of management and disposal can lead to inadvertent negative effects even when conducting proper management procedures. Landfills are some of the most significant contributors to greenhouse gas emissions within the waste industry and, in developing countries, landfill methane is rising in conjunction with population, consumption, and landfill expansion [

2,

8,

9]. Waste incineration can cause a detriment to public health and the environment by creating sulfur oxides, nitrogen oxides, and particulate matter from the combustion process [

10,

11]. Additionally, the increasing complexity of the composition of MSW causes incineration to yield a wide range of toxic and carcinogenic contaminants such as polyvinyl chloride, heavy metals, organic chemicals, and polychlorinated dibenzodioxins (dioxins) and polychlorinated dibenzofurans (furans) [

2,

12,

13,

14,

15,

16].

While known to be a global issue, smaller systems and environments also experience this waste management dilemma. The United States Department of Defense (USDOD) has recognized the need for process improvement within all of its operating centers [

17,

18,

19,

20]. Some factors driving the USDOD to pursue process improvement within waste management include: concerns about burn pit exposure causing adverse human health effects, limited energy resources and land availability in contingency operation environments, desire for point-of-source waste-to-energy (WtE) technologies, security concerns, and an overall transition towards more sustainable operations [

21,

22,

23,

24,

25]. The National Aeronautics and Space Administration (NASA), in addition to other private and government space agencies, are concentrated on improving waste management processes. NASA and other space agencies desire this process improvement to ensure efficient use of resources in interplanetary space travel, and future colonization of terrestrial bodies, planets, and space stations [

26]. Facilities such as hospitals and airports also must focus efforts on improving their waste management practices. During the peak period, the COVID-19 pandemic created an estimated five-fold increase in the demand for daily medical waste disposal, which threatened the resilience of medical emergency systems in urban areas [

27]. Many airports generate waste volumes at the same rate as a small city, and regional and national governments in their jurisdiction emphasize waste diversion from landfills [

28]. This focus on waste diversion for numerous airports leads to their pursuit of sustainable waste management practices [

28].

One emerging technology that may help to solve the multivariate waste management problem is microwave induced plasma gasification (MIPG). MIPG is a WtE technology that utilizes plasma gasification as a thermal waste treatment process. Plasma gasification is a process that subjects the MSW to a plasma flame within a reactor where temperatures can exceed 10,000 K [

29]. Once exposed to the extreme temperatures within the reactor, the MSW is converted into two products: a syngas primarily composed of carbon monoxide and hydrogen, and an inert slag [

30]. Both products can be utilized as resources, promoting a sustainable waste management model. The syngas output can be utilized for energy production, and the inert slag can be used as a construction material [

31,

32]. The high temperature combustion is an enormous benefit for plasma gasification over other thermal waste treatment processes; this extreme temperature allows for hazardous and complex materials to be safely combusted without toxic emissions, dioxins, furans, or greenhouse gases [

33,

34]. Most MIPG systems initialize the plasma flame by inserting a tungsten rod that acts as a temporary electrode arrangement [

35,

36]. Once the plasma flame is initiated, the tungsten rod is removed and the plasma flame is maintained by a microwave and plasma-forming gases, rather than an electrode arrangement. This increases system resilience as electrode utilization and corrosion can cause multiple operational problems and efficiency losses in traditional plasma gasification systems [

30], [

37]. Additionally, MIPG systems maintain lower voltage requirements than other plasma generator methods and have a lower setup cost as the reactor can operate under atmospheric conditions [

30,

38]. One disadvantage of MIPG systems is that they are harder to scale than electrode-based systems [

39]. Although MIPG systems can control the diameter and temperature of the plasma flame by increasing power to the system, the length of the reactor can only be controlled by adjusting the reactor size [

40]. The diameter of the plasma flame is also constrained to the physical boundary of the reactor [

40].

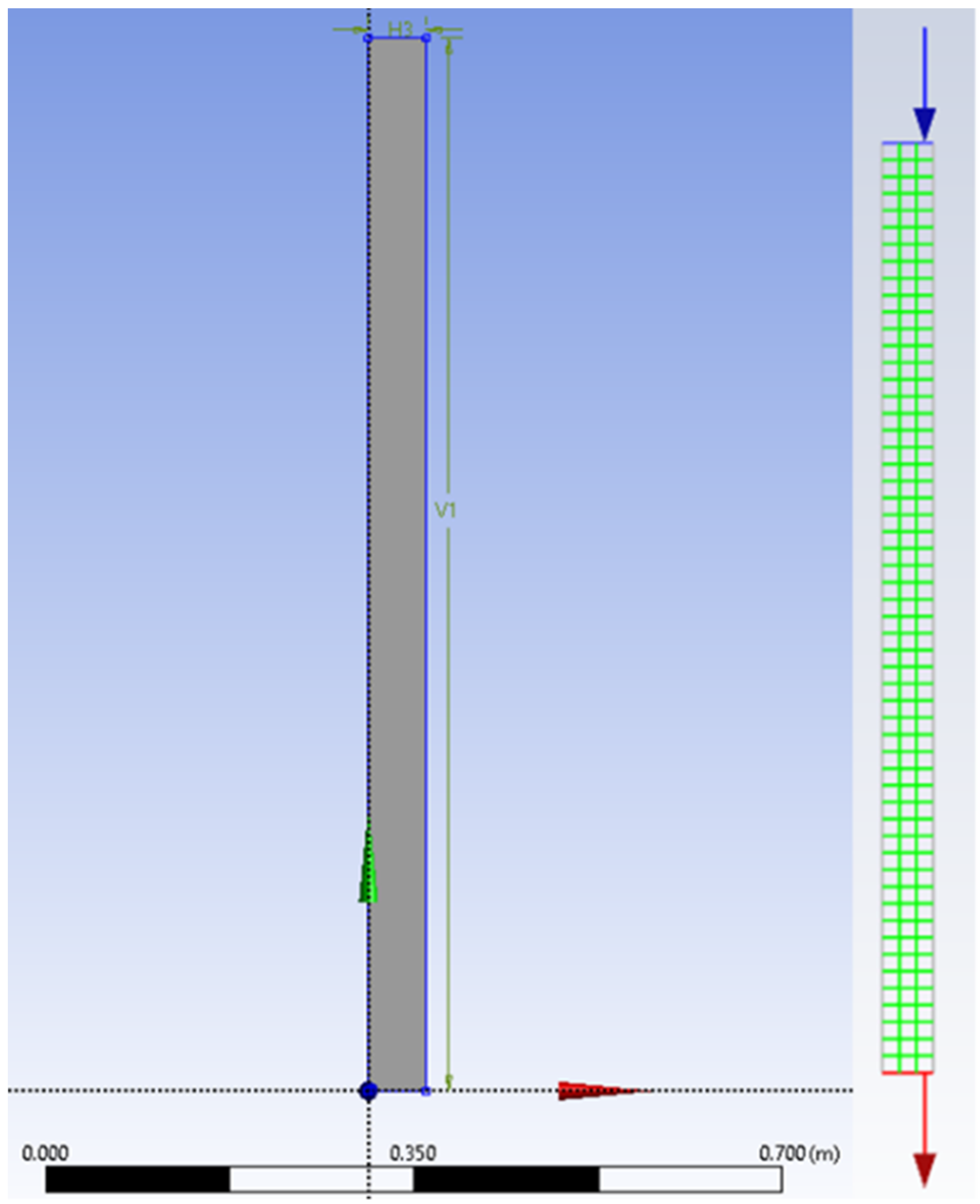

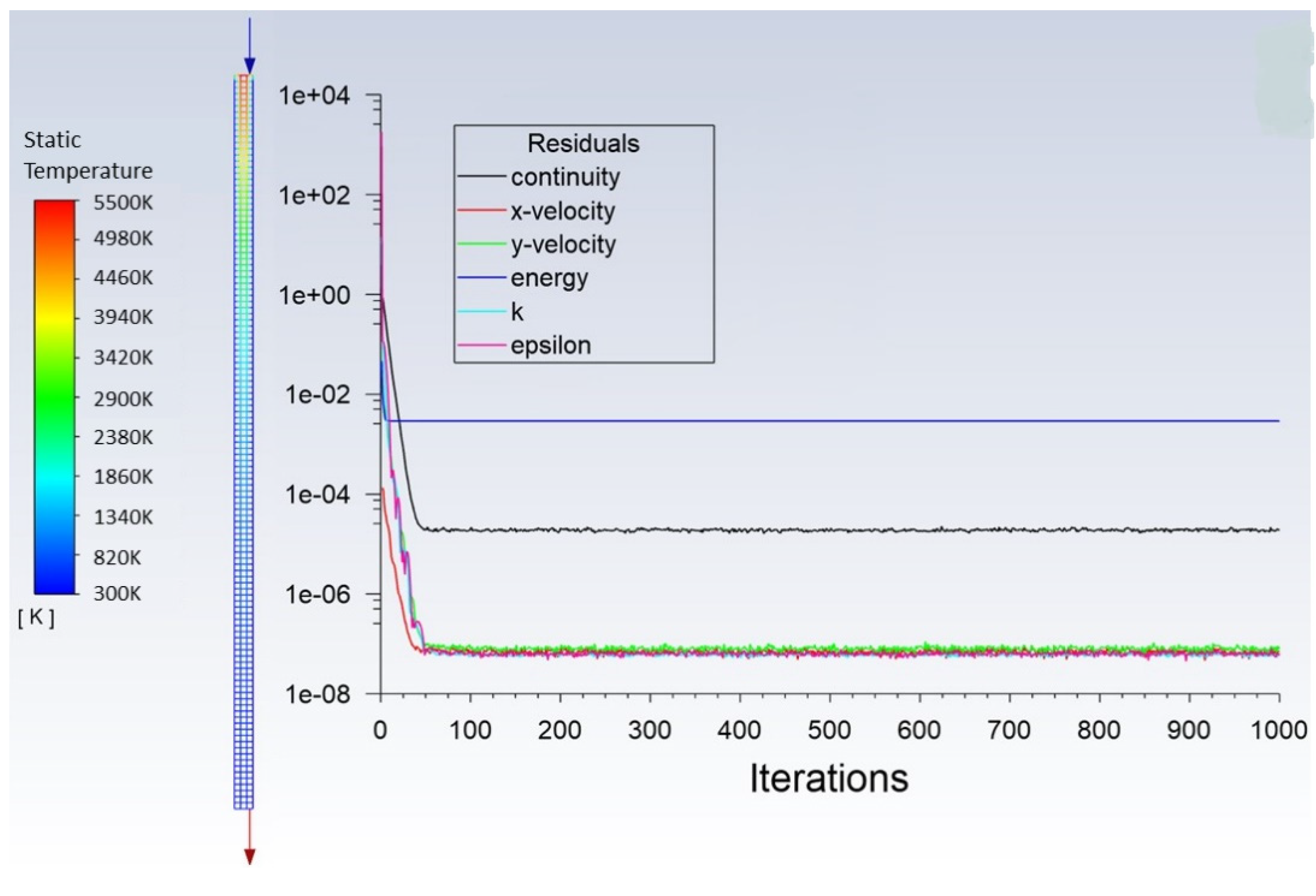

ANSYS Fluent is a software package that can be used to numerically model an MIPG system. Fluent is one of the most widely used computational fluid dynamics (CFD) modeling software packages in the world [

41]. CFD is a tool originally used for aerospace applications; however, it has been adopted heavily in both the environmental and chemical engineering fields for its rich reactor modeling and solver ability [

41,

42,

43,

44]. CFD modeling software uses a chosen solver method to solve partial differential equations for mass, momentum, and energy, and their theoretical and empirical correlations [

45]. When these models are synthesized, the physical–chemical phenomena that take place within an MIPG reactor can be simulated and observed [

46,

47]. By allowing the user to understand the multiphysics taking place within a MIPG reactor, expensive and tedious experimentation can be reduced and further optimized [

45]. ANSYS Fluent offers some benefits over other CFD modeling software, especially for first time users. ANSYS Fluent contains an intuitive and robust graphical user interface (GUI) and a highly integrated support system [

41]. Both the GUI and the support system aid the user to easily define solver settings for a model. A disadvantage of ANSYS Fluent is that it is a closed source platform, which can make it harder to modify the solver with user-defined functions (UDF) [

48,

49,

50]. For simulations that necessitate a high degree of personalization and where the user has a firm grasp of how to modify and customize open-source software, OpenFOAM is a great alternative CFD modeling software package [

41,

51,

52]. Machine-learning (ML) algorithms can be informed by numerical models in order to build an accurate representation of the modeled system [

53]. Additionally, the synthesis of ML and numerical models has the potential to accelerate high-fidelity fluid simulation, improve turbulence modeling, and enhance reduced-order models [

54]. ML algorithms identify patterns within a dataset. These algorithms have been shown to be very functional and accurate with non-linear and highly variable time-dependent data commonly found in plasma gasification reactors [

55,

56].

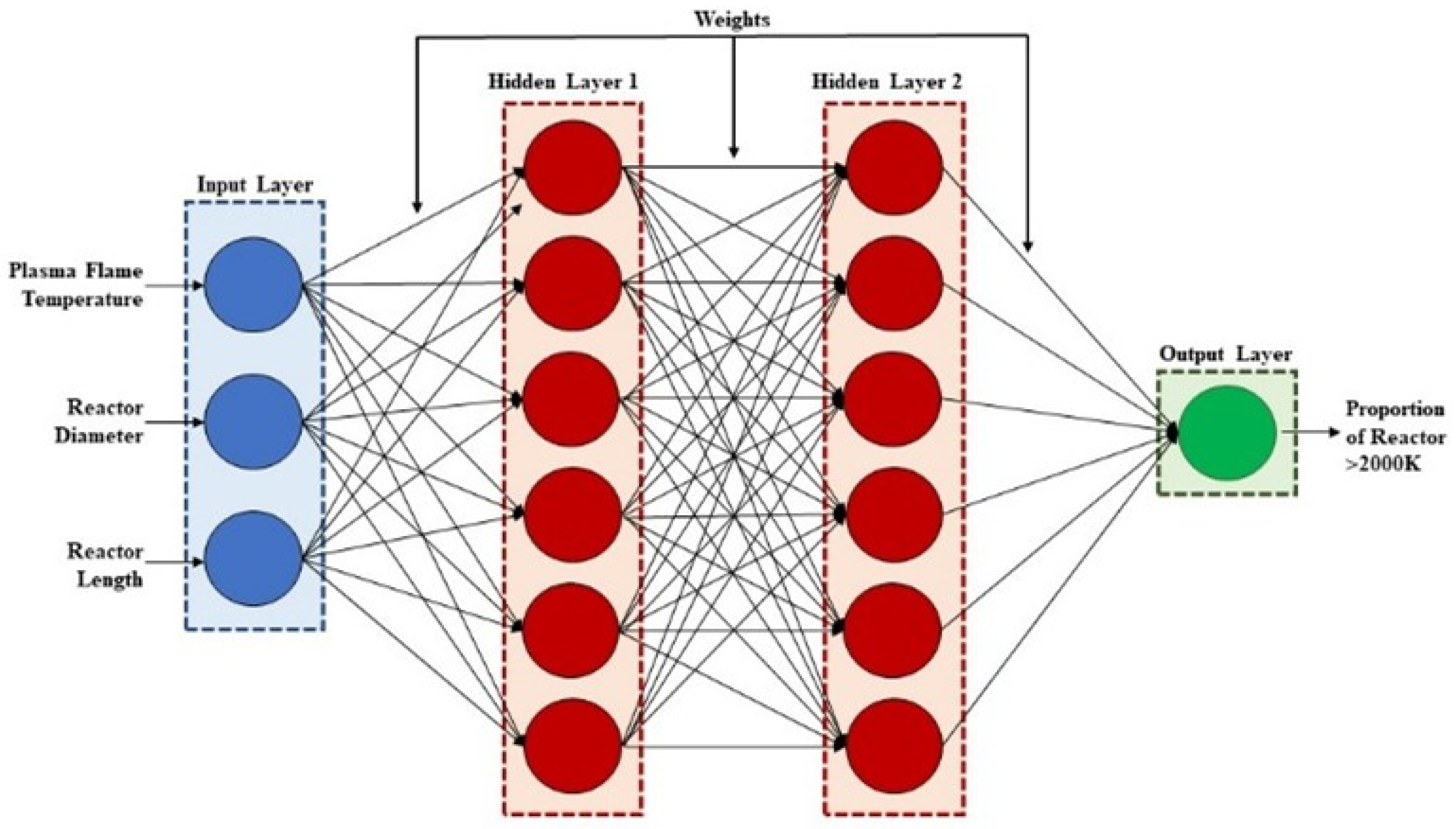

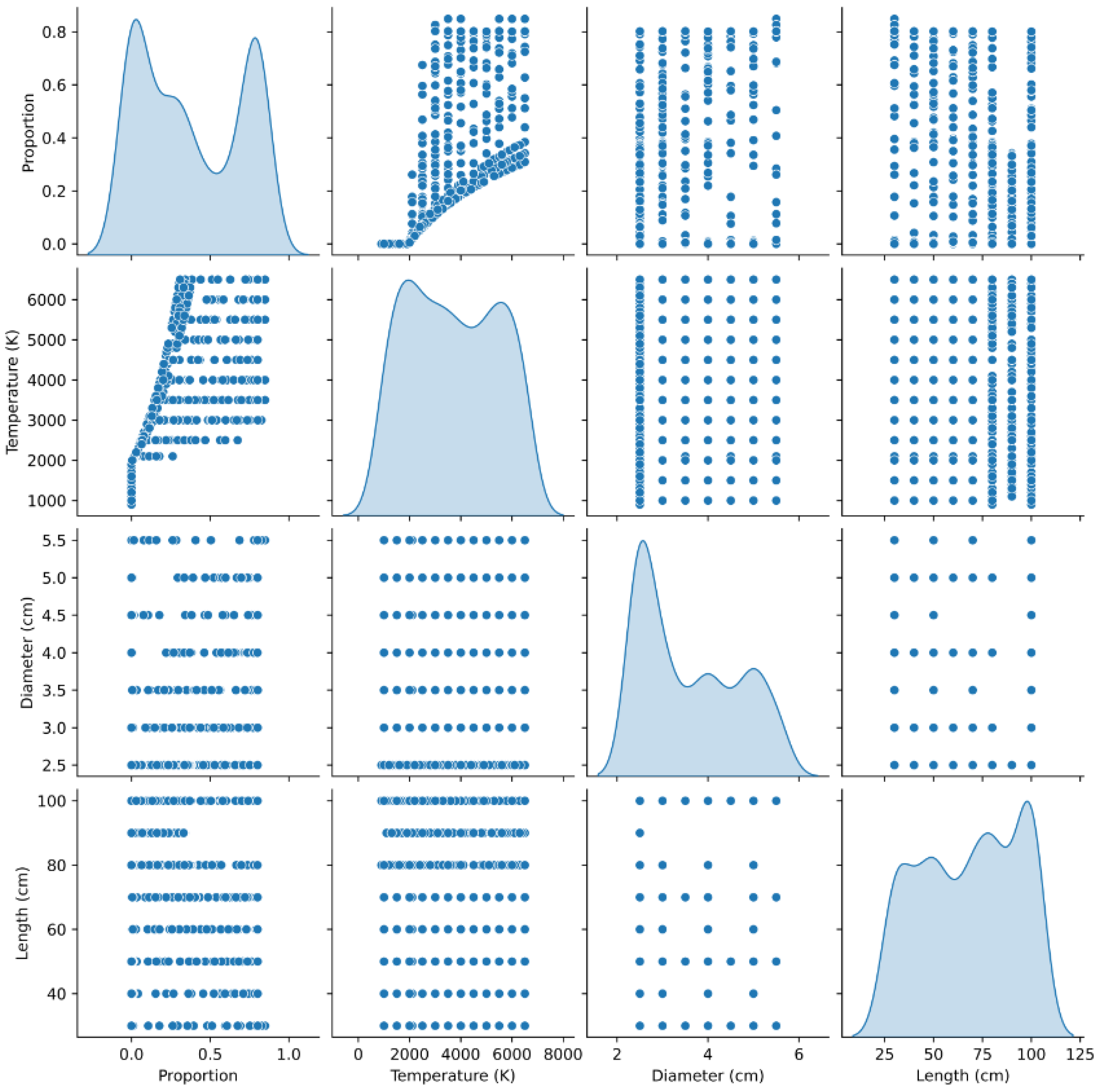

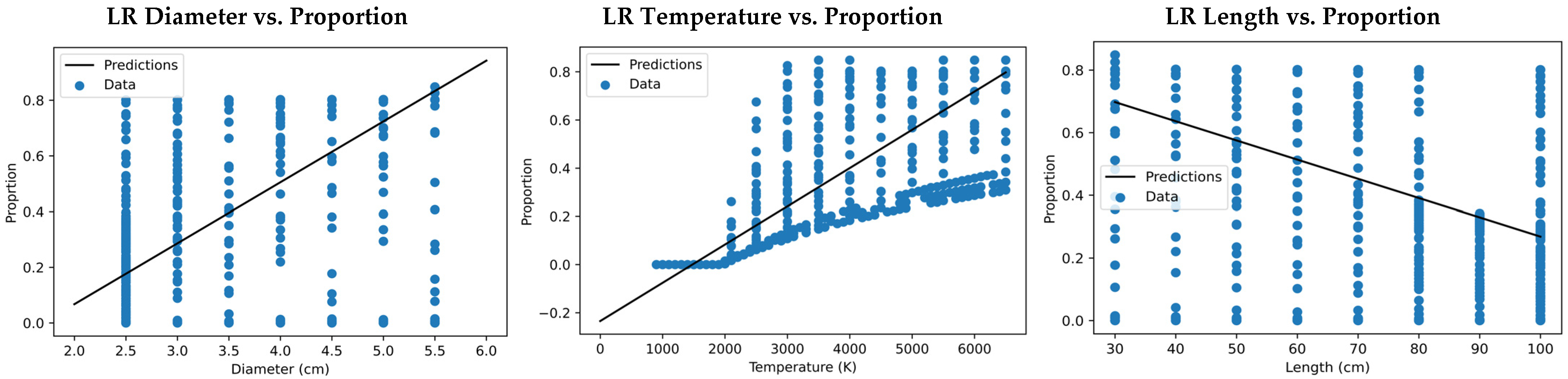

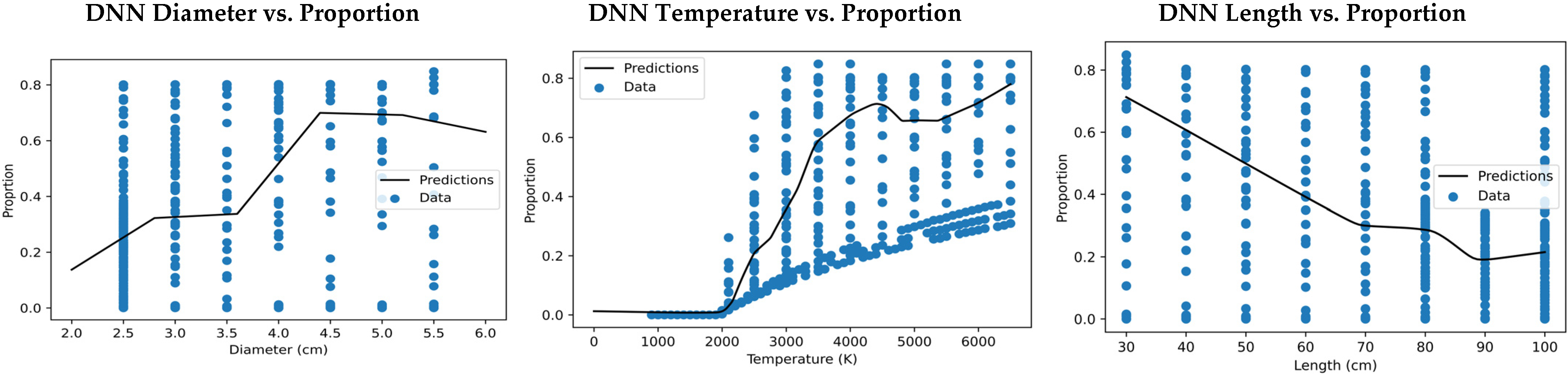

The purpose of this study was to compare ML algorithms that can predict the proportion of the area in the reactor that is above 2000 K within a two-dimensional (2D) MIPG reactor given geometry and temperature inputs. A total of 644 CFD models were simulated within ANSYS Fluent to create a dataset for the machine-learning algorithms. The geometry and temperature inputs within the CFD models were based on experimental MIPG (EMIPG) reactors from a literature review of 13 different experiments. Thermal plasma is commonly defined as the temperature range from approximately 2000 to 30,000 K and, by staying in this temperature range, full combustion of the waste can be achieved [

57]. A magnetron is responsible for providing the microwave to the reactor, and the power supply to it has a direct effect on the temperature of the plasma flame within the EMIPG [

58]. G.S. Ho et al. determined that fuel retention time, the amount of time that the MSW has in contact with the plasma flame, is the key parameter that affects plasma gasification performance [

38]. Therefore, a ML algorithm that can predict the area within an EMIPG reactor that is experiencing a proper combustion temperature range can aid future research by allowing the user to optimize the system by determining a proper waste input rate. Furthermore, this parameter can now be estimated via a simplified algorithm instead of a time-consuming CFD software that requires the user to have a level of proficiency in order to simulate a model. The novelty of this study is developing ML algorithms for EMIPG performance prediction; in particular, using geometry and reactor temperature parameters to predict the plasma ratio achieved without computationally intensive CFD simulations. An extensive literature review found no similar studies focusing on geometry.

4. Conclusions and Forward Look

The proportion of area greater than 2000 K within an EMIPG reactor given variable inputs of diameter, length, and plasma flame temperature were examined with a CFD model developed by ANSYS Fluent. To test the accuracy of this newly developed CFD model, the results of the dataset were then compared with the literature.

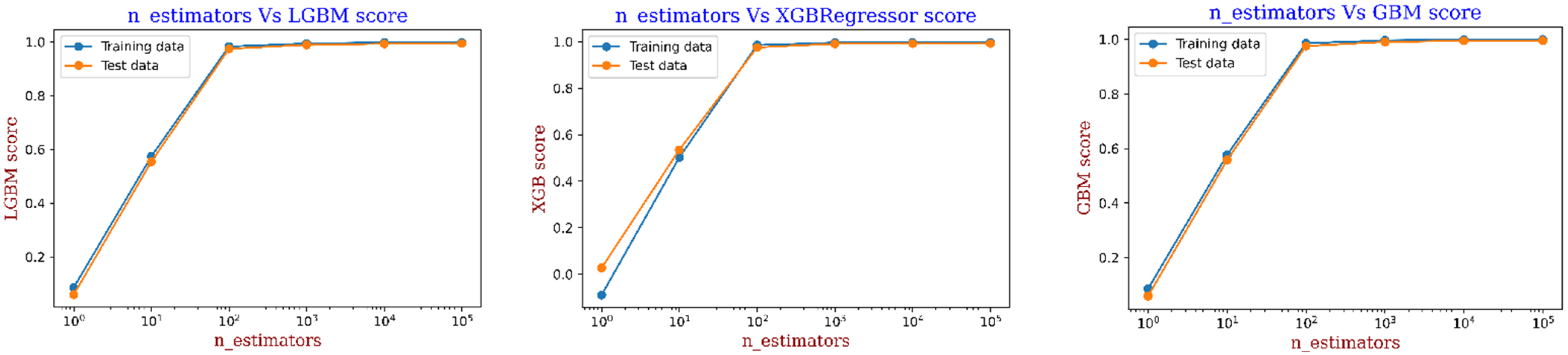

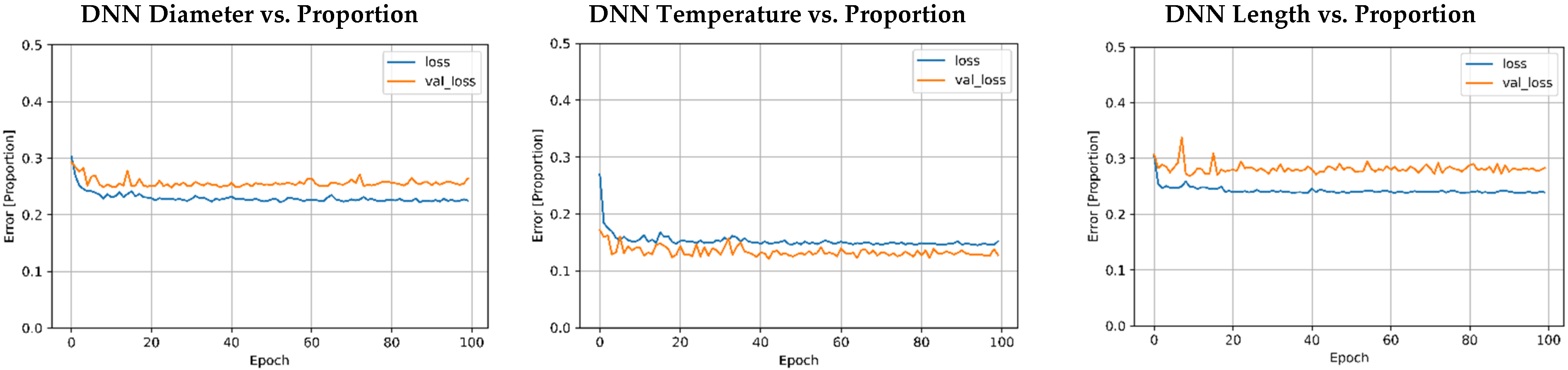

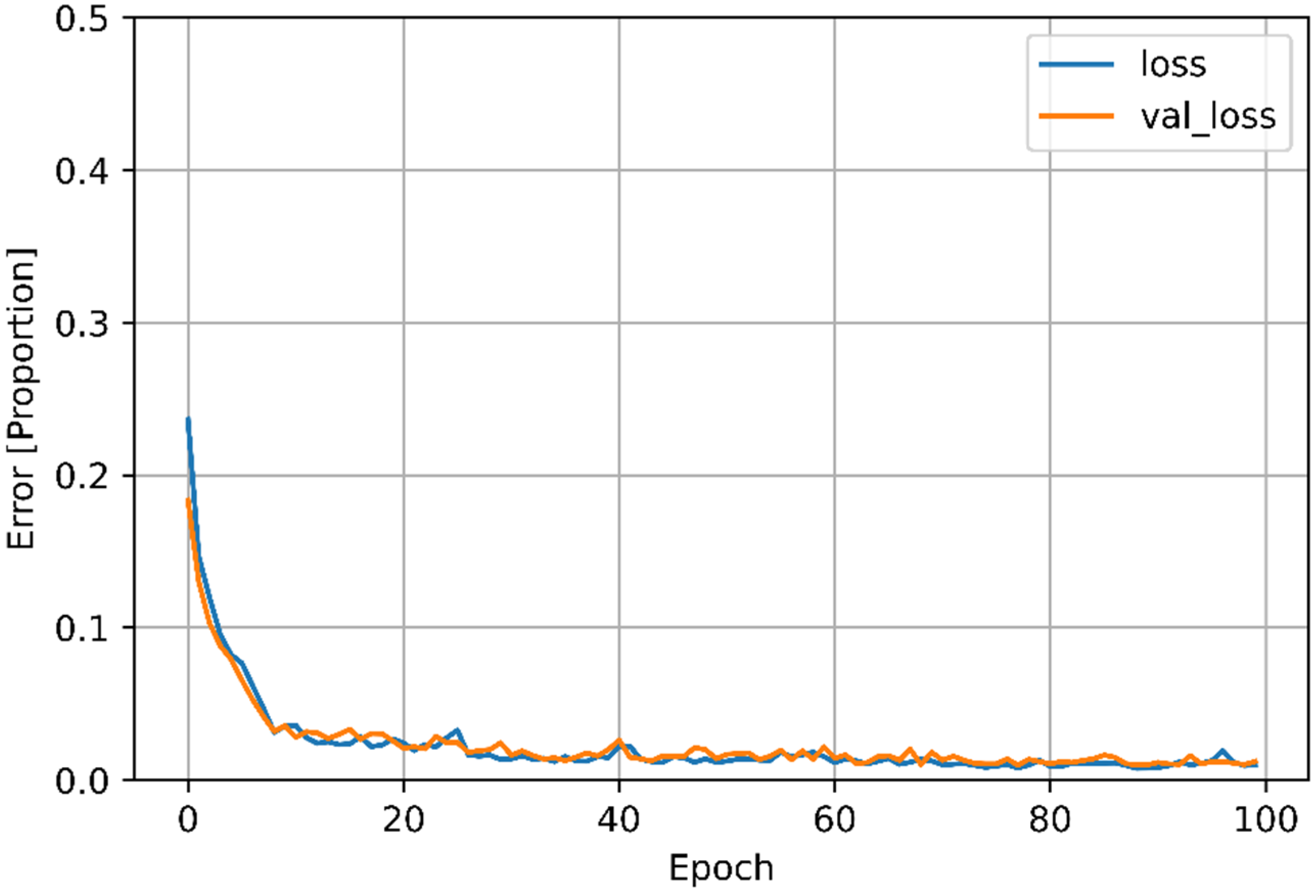

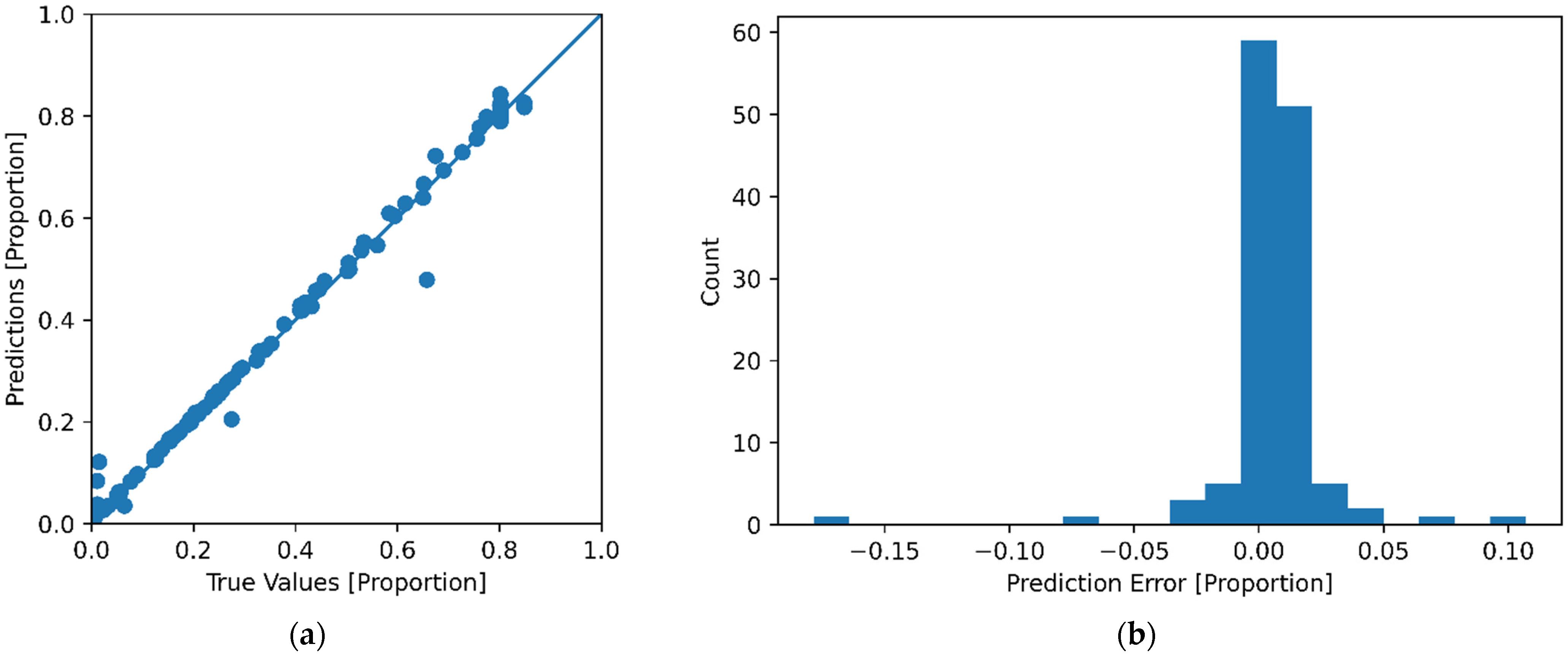

A dataset of 644 CFD modeling iterations containing three different input variables and one output variable was used to train six different ML models. The best ML model to predict the proportion of plasma flame within an EMIPG reactor was found to be the DNN model followed closely by the GBR model. The linear regression model proved to add contrast and show the advantages that non-linear ML models have in the accurate modeling of the non-linear and highly variable time-dependent data commonly found in plasma gasification reactors.

In conclusion, ML models can be used to provide accurate prediction algorithms for EMIPG reactors based on CFD solutions. The ML models allow a user who has no experience with CFD software to understand parameters effecting EMIPG reactors. More importantly, calculations that take a long time using the numerical methods in CFD software can be quickly and accurately modeled with ML models. This study demonstrated that, by using the input parameters of the diameter and length of an EMIPG reactor, and the temperature of the initialized plasma flame, the proportion of the EMIPG reactor that has optimal combustion conditions can be estimated.

More broadly, this study aims to demonstrate that CFD solutions can be synthesized with ML algorithms that are able to provide accurate and fast solutions for specific problems. The availability and ease of use of a ML algorithm can allow someone who has no technical experience in the CFD field to derive equivalent results. This allows for more availability of data and, hopefully, faster process improvement regarding sustainable future technologies such as WtE. Additionally, the incorporation of ML models with numerical solutions has the potential to improve overall solution accuracy and better represent the phenomena in real-life WtE systems. Future recommendations following this work include: creating a larger dataset in order to inform ML models, incorporating experimental data into ML datasets, utilizing ML models with other WtE technologies in order to better understand reactor phenomena, and focusing on other ML model predictive parameters within EMIPG and other WtE reactors.