Underground Mine Tunnel Modelling Using Laser Scan Data in Relation to Manual Geometry Measurements

Abstract

1. Introduction

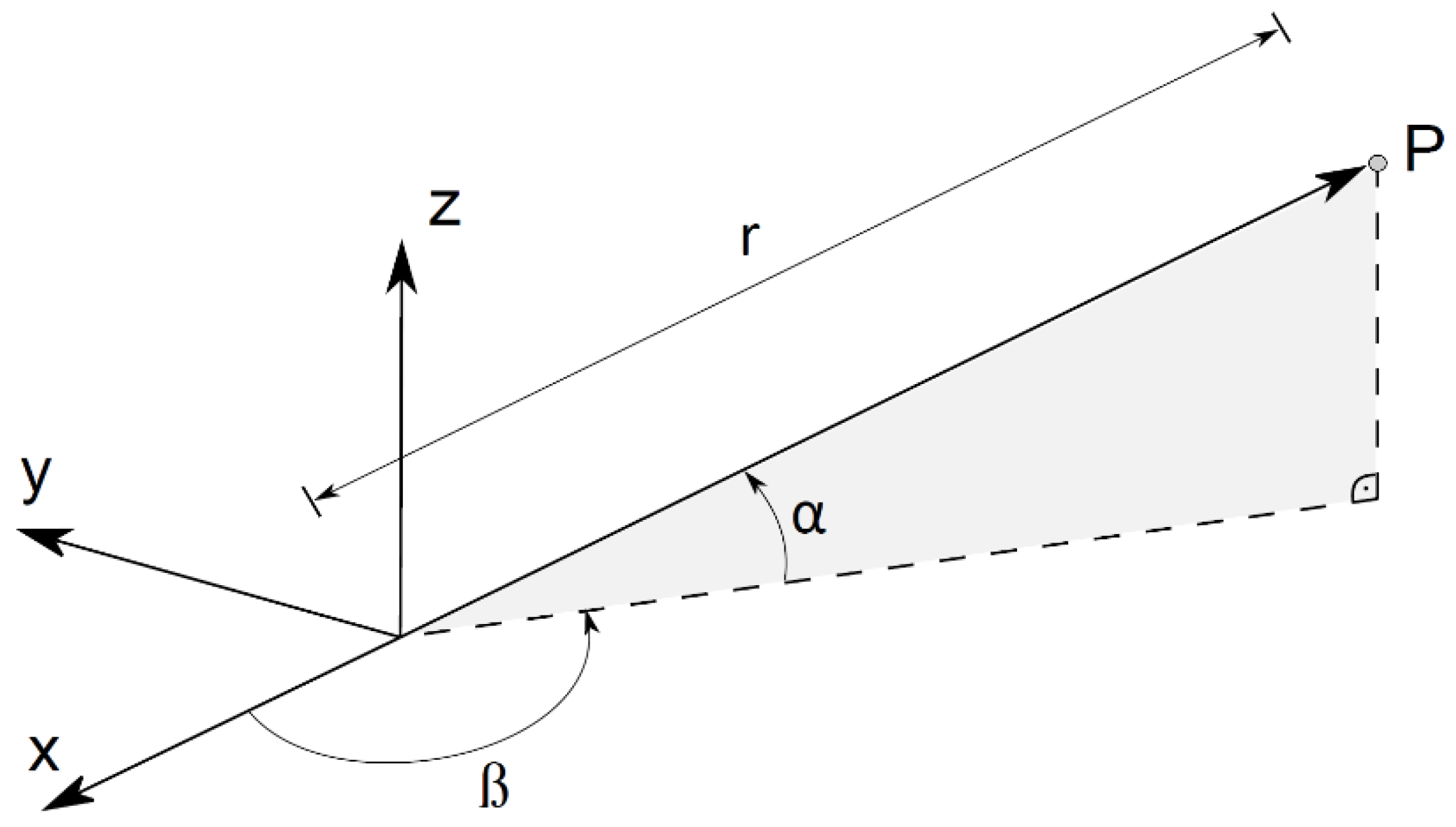

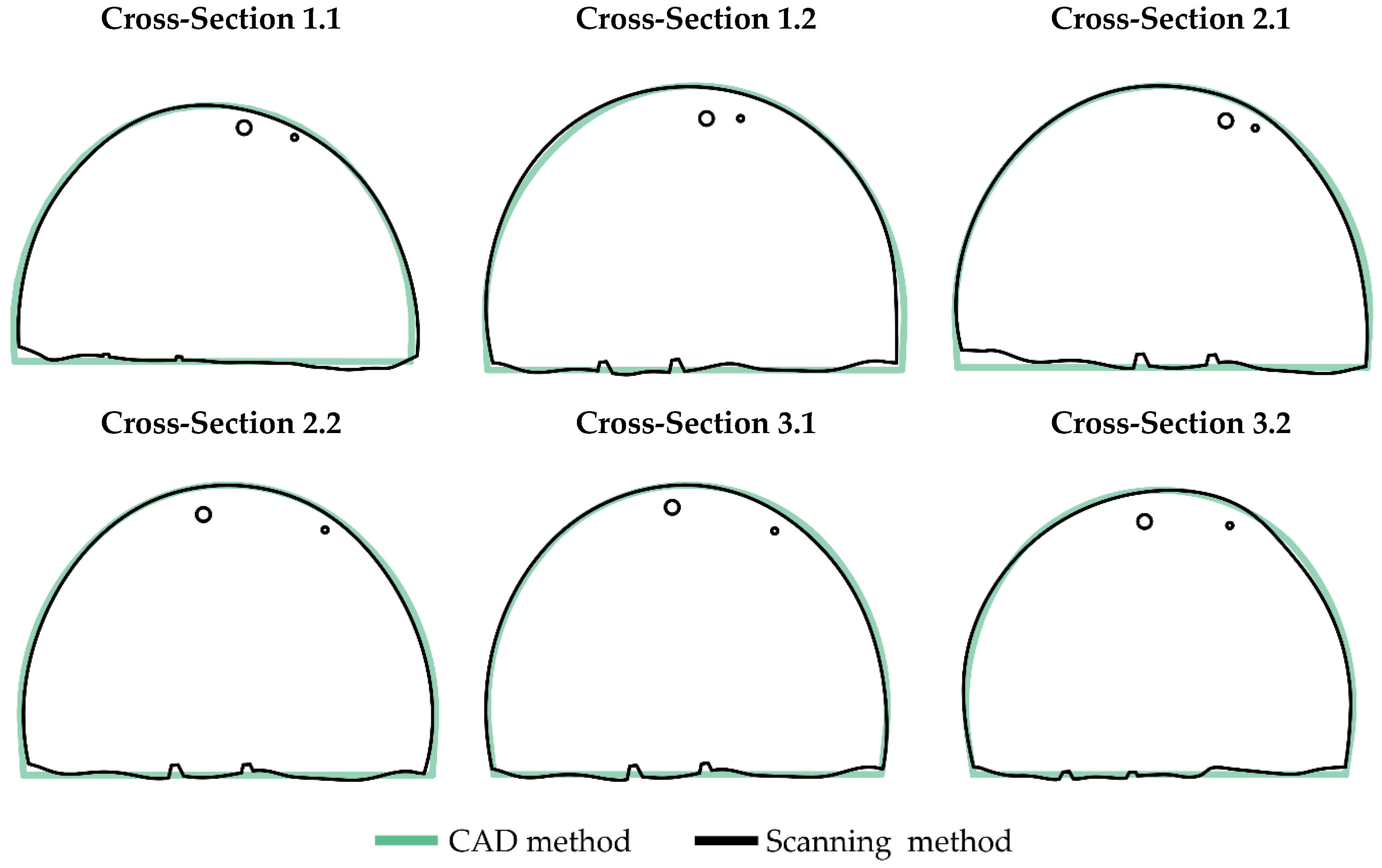

2. Measurements of Mine Tunnel Geometry Using Terrestrial Laser Scanning

2.1. Measuring Device

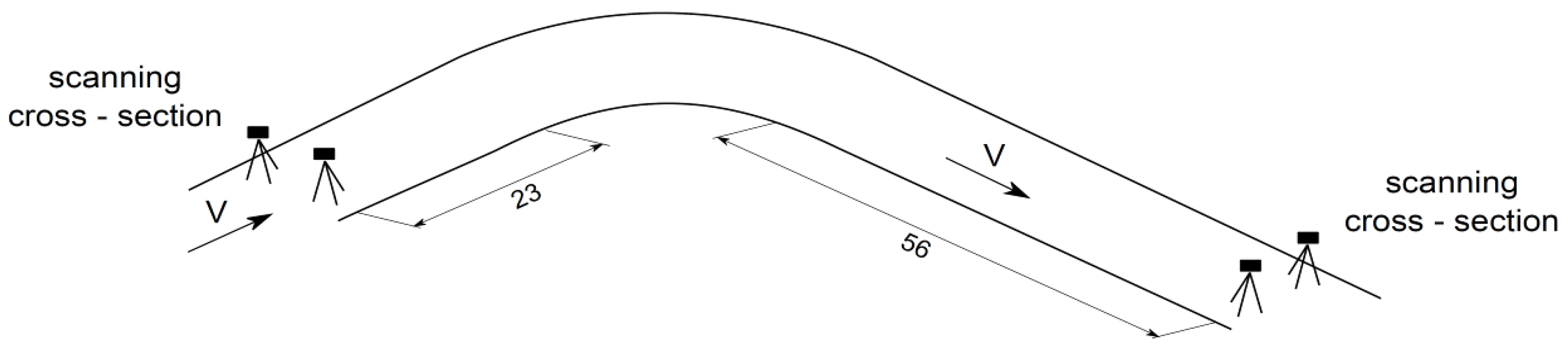

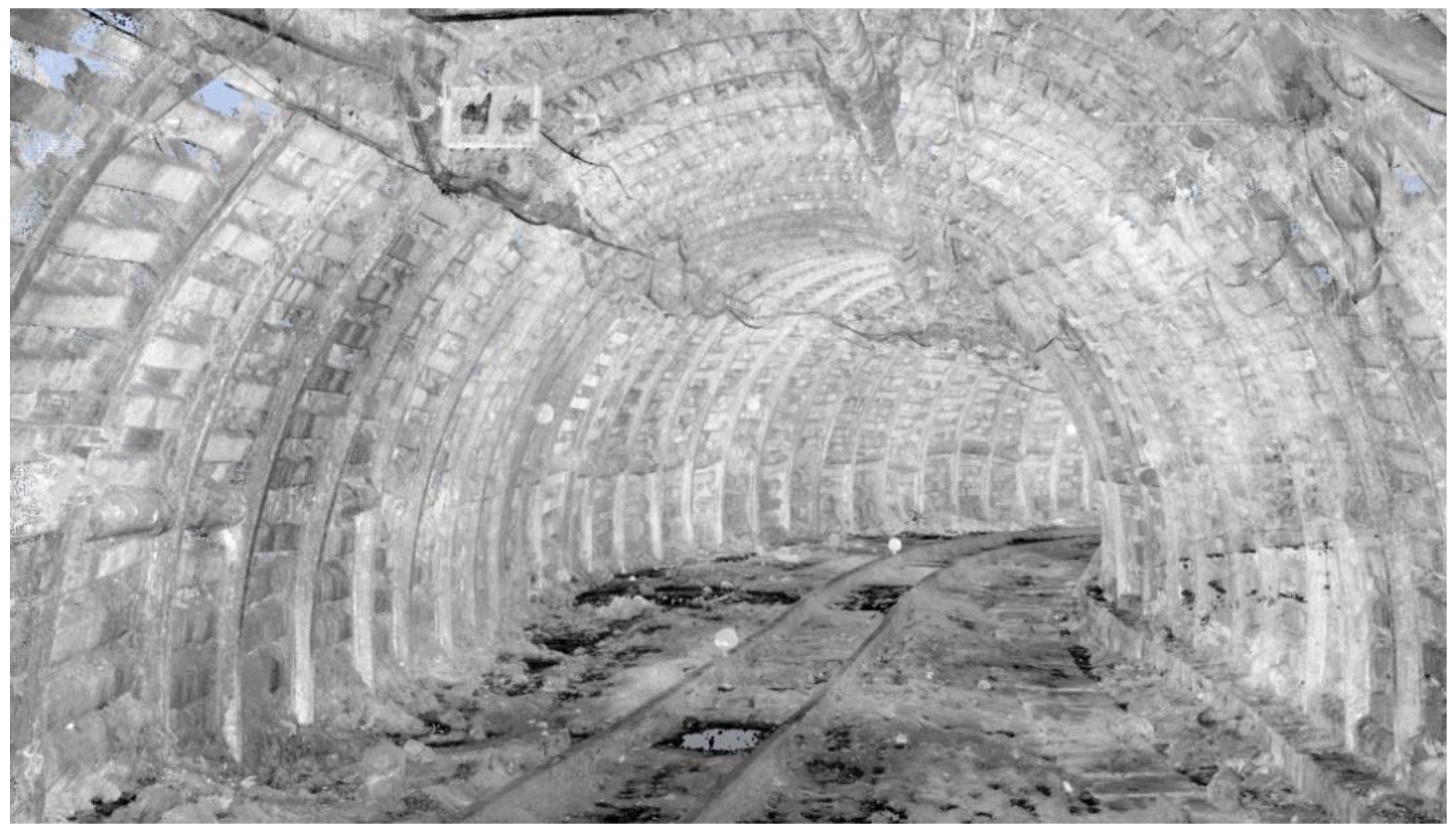

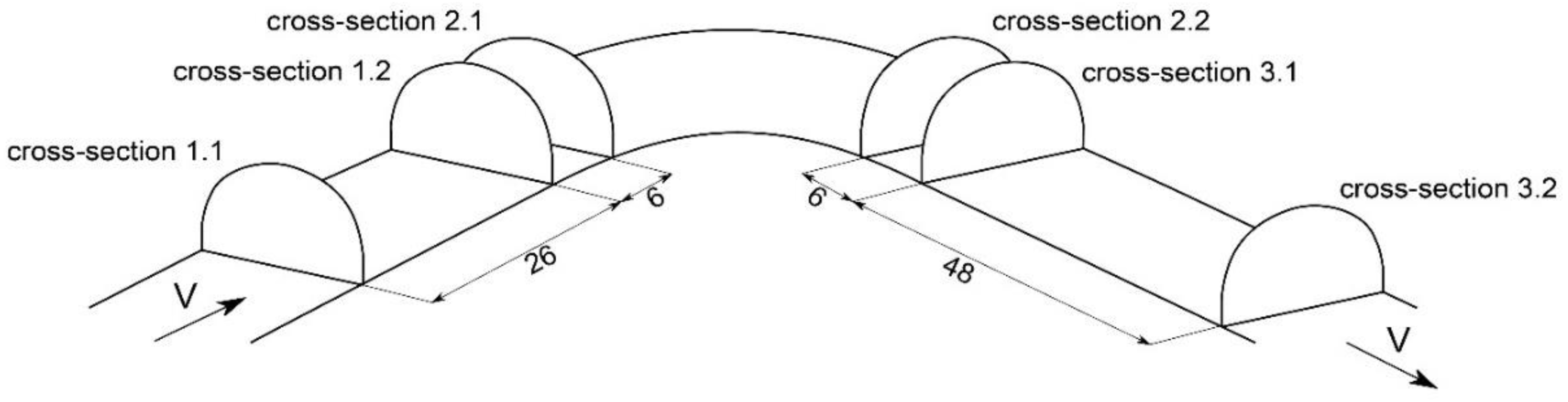

2.2. The Measurement Site

2.3. Processing of Laser Scanning Data

- −

- Section 1, before the turn;

- −

- Section 2, the turn;

- −

- Section 3, after the turn.

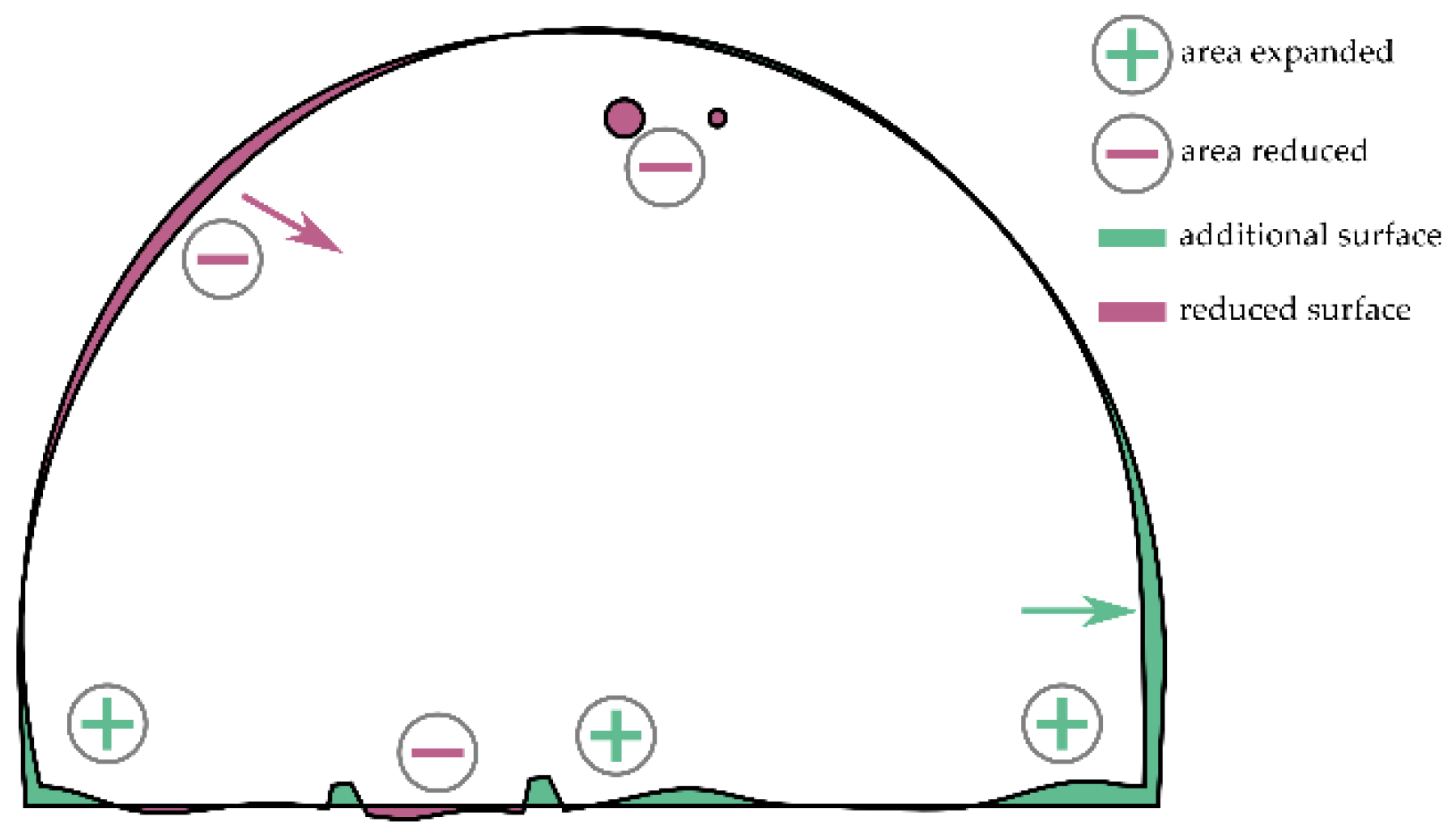

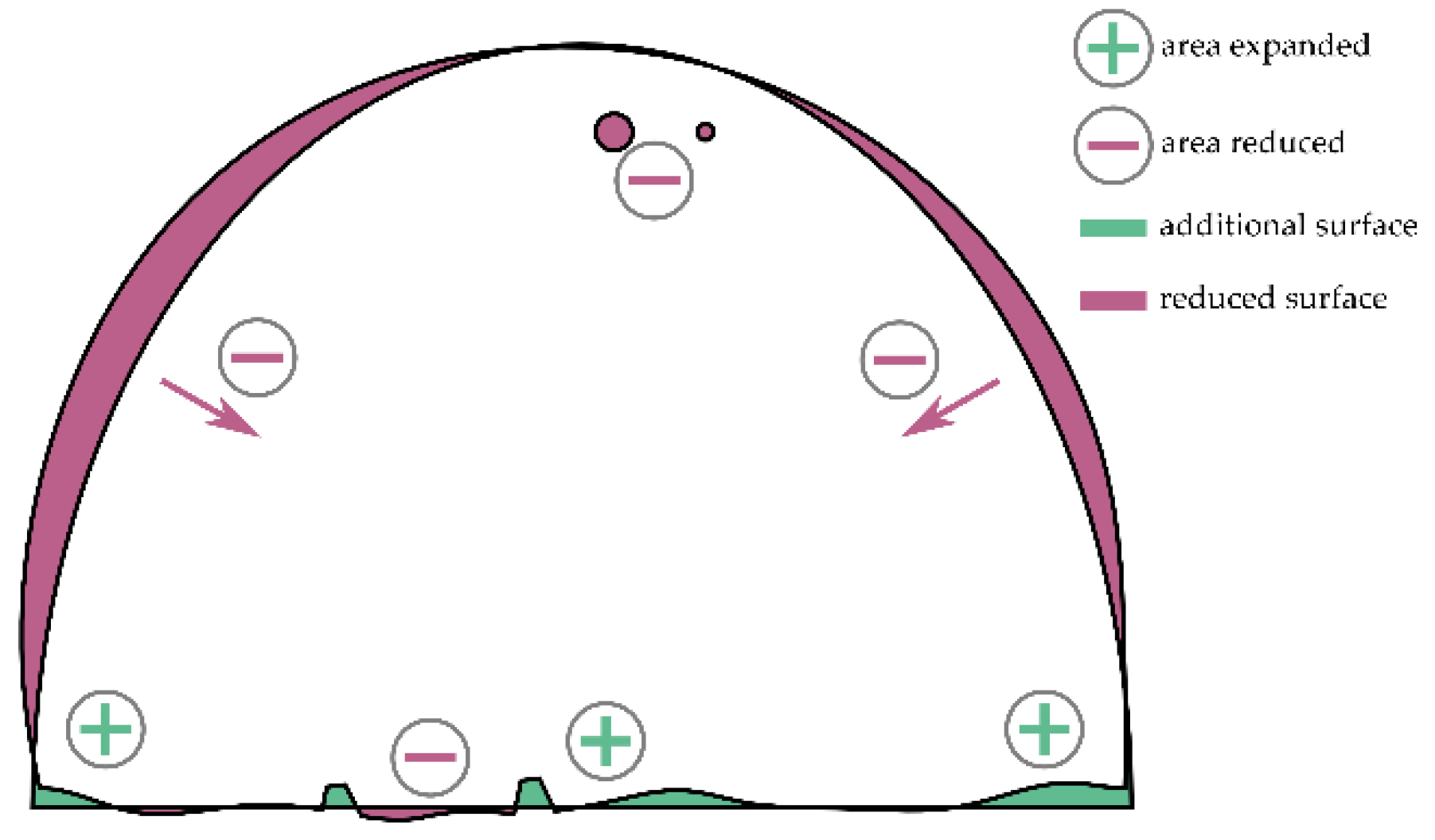

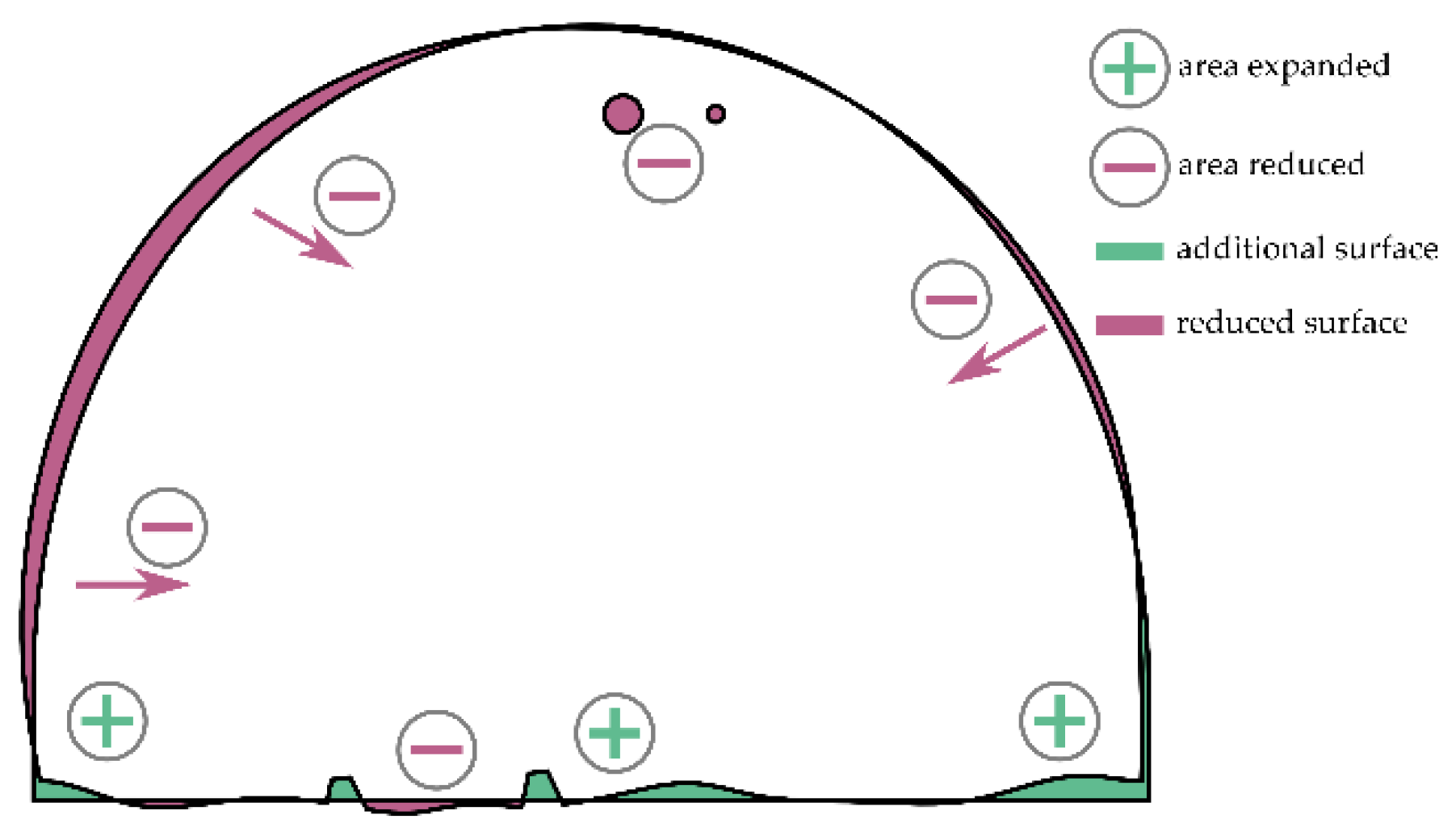

3. Methods of Determining the Cross-Section Area of the Mine Tunnel

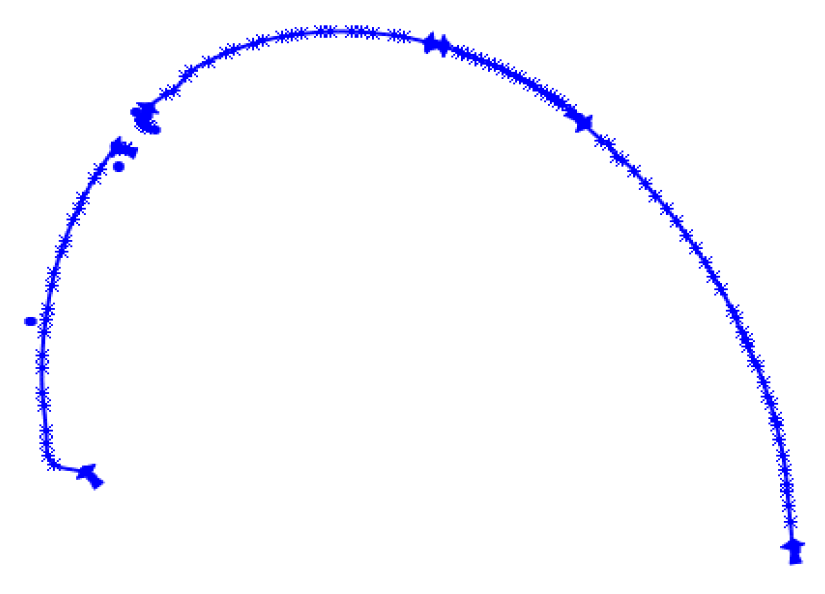

3.1. Reconstruction with Use of Point Cloud

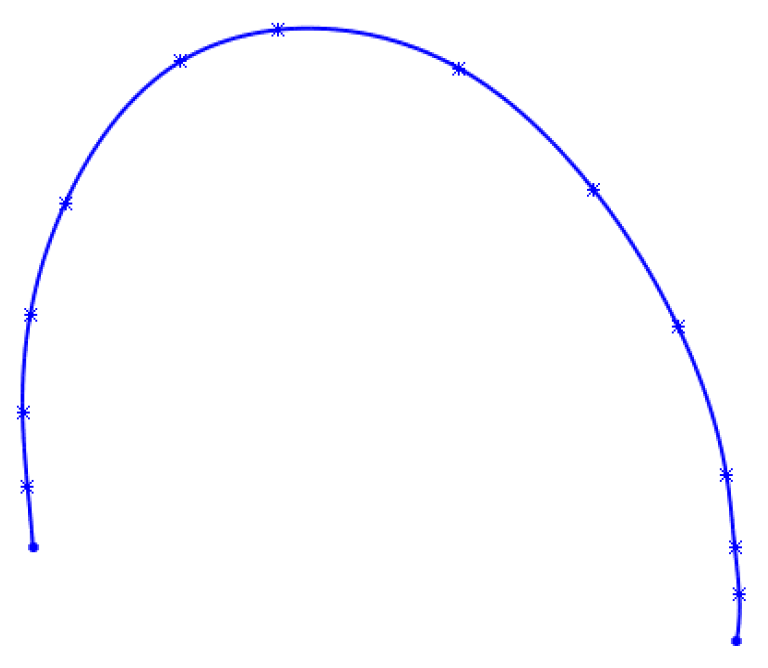

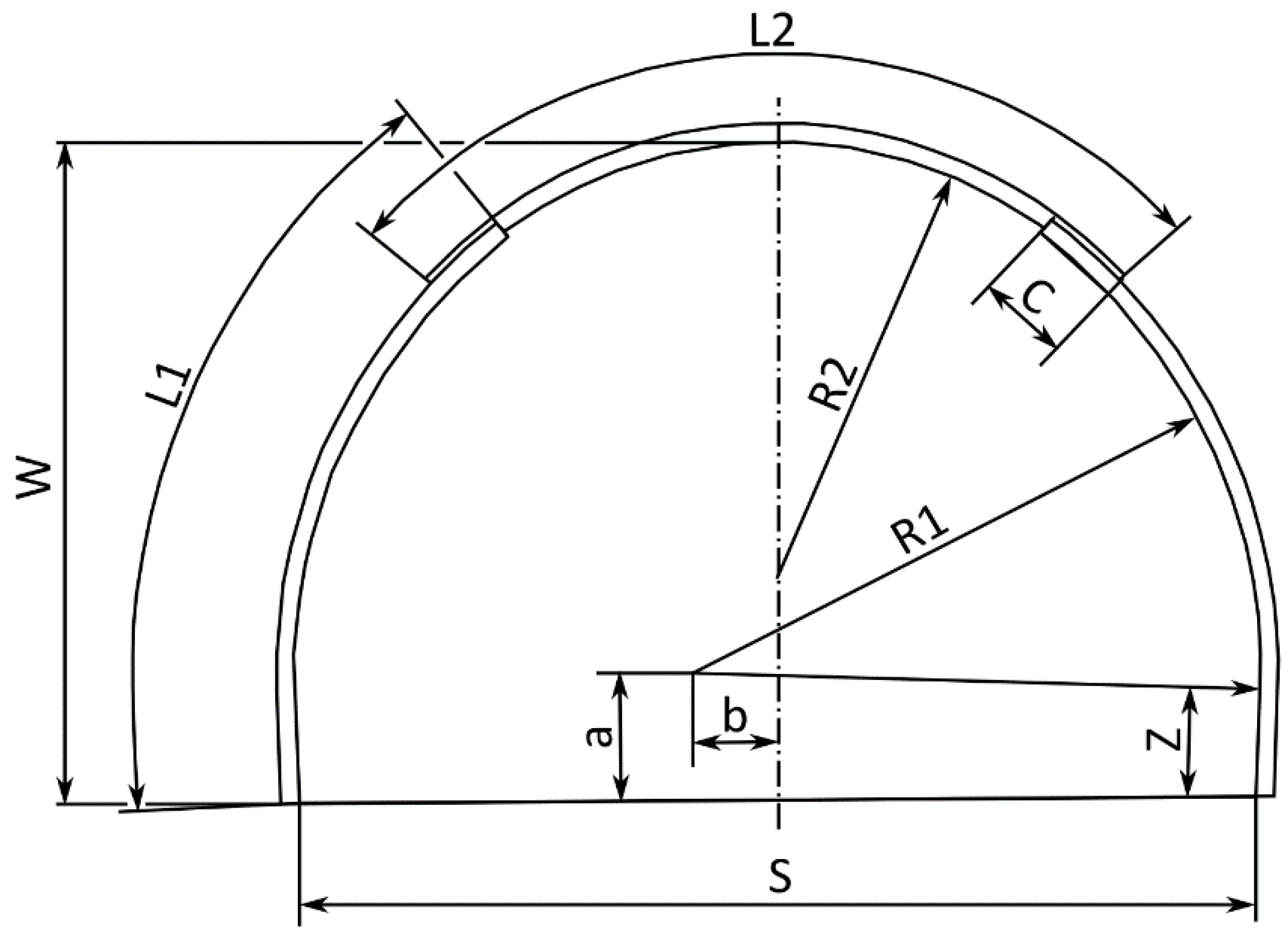

3.2. The Area as a Result of Parametric Sketch and Integration Method Using CAD

- S—width of the arch

- W—height of the arch

- R1—radius of the side part of the arch

- L1—length of the side part of the arch

- Z—length of the straight section of the side part of the arch

- R2—radius of the roof part of the arch

- L2—length of the roof part of the arch

- C—length of the arch’s tab

- a, b—center coordinates of the arch’s side part. These values depend on the height and width during fitting of the arch to the actual shape of the mine tunnel

3.3. Analytical Methods

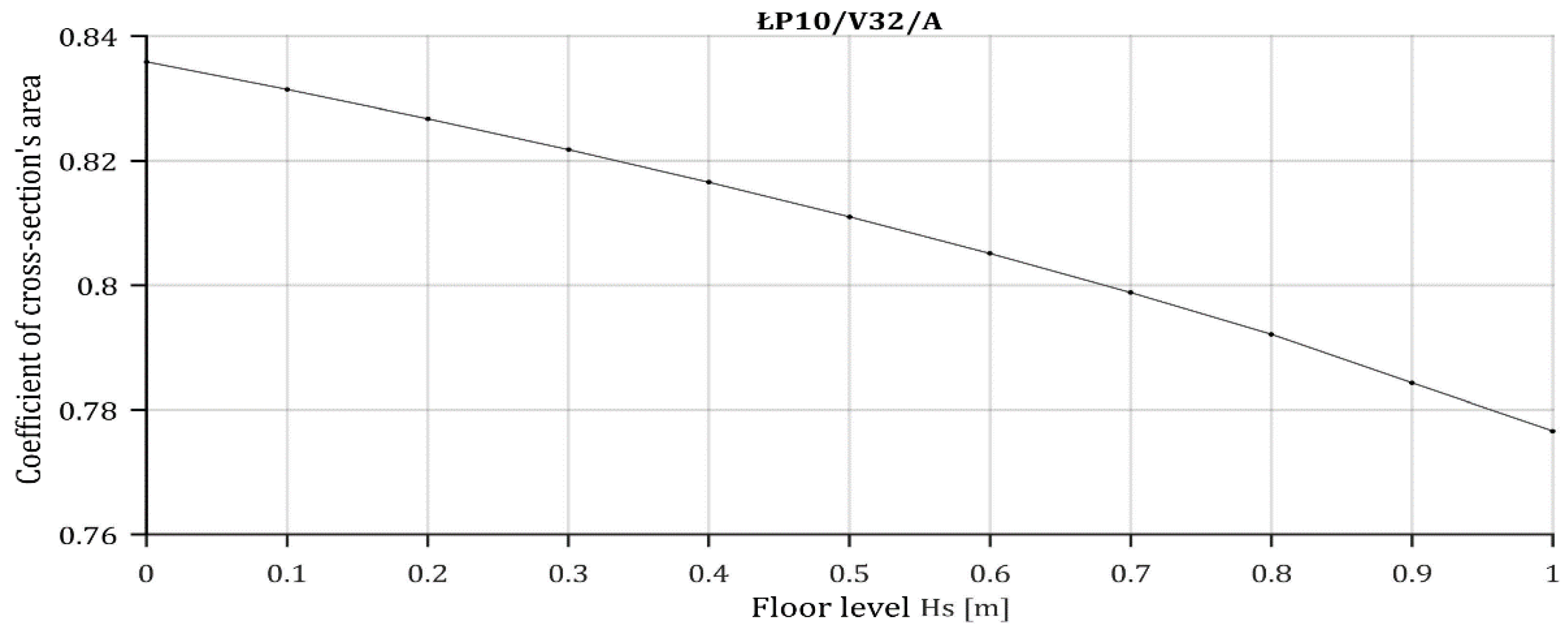

3.3.1. Empirical Method

- H—height of mine tunnel

- W—width of mine tunnel

3.3.2. Approximation by a Semi-Ellipse

- H—height of mine tunnel

- W—width of mine tunnel

3.3.3. Approximation by a Semi-Ellipse with Attached Straight Sections

- H—height of mine tunnel

- W—width of mine tunnel

- Z—length of straight section of side part of arch

4. Results

- —cross-section number

- —calculated cross-section area using CAD and analytical methods

- —measured cross-section area using scanning method

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hasheminasab, F.; Bagherpour, R.; Aminossadati, S.M. Numerical simulation of methane distribution in development zones of underground coal mines equipped with auxiliary ventilation. Tunn. Undergr. Space Technol. 2019, 89, 68–77. [Google Scholar] [CrossRef]

- Wang, X.; Kulatilake, P.; Song, W.-D. Stability investigations around a mine tunnel through three-dimensional discontinuum and continuum stress analyses. Tunn. Undergr. Space Technol. 2012, 32, 98–112. [Google Scholar] [CrossRef]

- Wang, X.; Cai, M. Numerical modeling of seismic wave propagation and ground motion in underground mines. Tunn. Undergr. Space Technol. 2017, 68, 211–230. [Google Scholar] [CrossRef]

- Mo, S.; Sheffield, P.; Corbett, P.; Ramandi, H.L.; Oh, J.; Canbulat, I.; Saydam, S. A numerical investigation into floor buckling mechanisms in underground coal mine roadways. Tunn. Undergr. Space Technol. 2020, 103, 103497. [Google Scholar] [CrossRef]

- Ozturk, C. Support design of underground openings in an asphaltite mine. Tunn. Undergr. Space Technol. 2013, 38, 288–305. [Google Scholar] [CrossRef]

- Xie, H.; Zhao, J.; Zhou, H.; Ren, S.; Zhang, R. Secondary utilizations and perspectives of mined underground space. Tunn. Undergr. Space Technol. 2020, 96, 103129. [Google Scholar] [CrossRef]

- Gallwey, J.; Eyre, M.; Coggan, J. A machine learning approach for the detection of supporting rock bolts from laser scan data in an underground mine. Tunn. Undergr. Space Technol. 2021, 107, 103656. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhong, S.; Pan, P.-Z.; Shi, Y.; Guo, H.; Kou, Y. Observe the temporal evolution of deep tunnel’s 3D deformation by 3D laser scanning in the Jinchuan No. 2 Mine. Tunn. Undergr. Space Technol. 2020, 97, 103237. [Google Scholar] [CrossRef]

- Xue, Y.; Liu, J.; Ranjith, P.G.; Zhang, Z.; Gao, F.; Wang, S. Experimental investigation on the nonlinear characteristics of energy evolution and failure characteristics of coal under different gas pressures. Bull. Eng. Geol. Environ. 2022, 81, 38. [Google Scholar] [CrossRef]

- Kukutsch, R.; Kajzar, V.; Konicek, P.; Waclawik, P.; Ptacek, J. Possibility of convergence measurement of gates in coal mining using terrestrial 3D laser scanner. J. Sustain. Min. 2015, 14, 30–37. [Google Scholar] [CrossRef]

- Khalymendyk, I.; Baryshnikov, A. The mechanism of roadway deformation in conditions of laminated rocks. J. Sustain. Min. 2018, 17, 41–47. [Google Scholar] [CrossRef]

- Dziurzyński, W.; Skotniczny, P.; Krawczyk, J.; Gawor, M.; Pałka, T.; Ostrogórski, P.; Kruczkowski, J.; Janus, J. Wytyczne Rozmieszczenia Anemometrów Stacjonarnych Wzdłuż Długości Wyrobiska Kopalni Jak I W Samym Polu Przekroju Poprzecznego Wyrobiska. In Zasady Pomiarów Przepływów Powietrza W Wyrobiskach Kopalnianych. Wybrane Sposoby Kontroli I Kalibracji Przyrządów Pomiarowych; Strata Mechanics Research Institute of the Polish Academy of Sciences: Kraków, Poland, 2017. [Google Scholar]

- Ostrogórski, P. Consideration of the shape and height of the floor in result of measuring the cross-sectional area for rings type ŁP. Trans. Strata Mech. Res. Inst. 2015, 17, 1–2. [Google Scholar]

- Krach, A.; Krawczyk, J.; Kruczkowski, J.; Pałka, T. Variability of the velocity field and volumetric flow rate in air ways of underground mines. Arch. Min. Sci. 2006, 1. [Google Scholar]

- Walentek, A.; Janoszek, T.; Prusek, S.; Wrana, A. Influence of longwall gateroad convergence on the process of mine ventilation network-model tests. Int. J. Min. Sci. Technol. 2019, 29, 585–590. [Google Scholar] [CrossRef]

- Pytlik, A. Comparative bench testing of steel arch support systems with and without rock bolt reinforcements. Arch. Min. Sci. 2019, 64, 4. [Google Scholar]

- Janus, J. The Application of Laser Scanning in The Process of Constructing A Mine Drift Numerical Model. In Proceedings of the 24th World Mining Congress-Underground Mining, Brazilian Mining Association, Rio de Janeiro, Brazil, 18–21 October 2016. [Google Scholar]

- Janus, J. Modelling of Flow Phenomena in Mine Drifts Using the Results of Laser Scanning. Ph.D. Thesis, Strata Mechanics Research Institute of Polish Academy of Sciences, Kraków, Poland, 2018. [Google Scholar]

- Wierzbiński, K. Wpływ geometrii chodnika wentylacyjnego i sposobu jego likwidacji na rozkład stężenia metanu w rejonie wylotu ze ściany przewietrzane sposobem U w świetle obliczeń numerycznych CFD. Zeszyty Naukowe Instytutu Gospodarki Surowcami Mineralnymi i Energią Polskiej Akademii Nauk. 2016, 94, 217–228. [Google Scholar]

- Janus, J.; Krawczyk, J. Numerical modeling of flow phenomena in mine drift using laser scan results. In Proceedings of the 11th International Mine Ventilation Congress; Science Press: Beijing, China, 2018. [Google Scholar] [CrossRef]

- Skotniczny, P. Three-dimensional numerical simulation of the mass exchange between longwall headings and goafs, in the presence of methane drainage in A U-type ventilated longwall. Arch. Min. Sci. 2013, 58, 705–718. [Google Scholar] [CrossRef]

- Klapa, P.; Mitka, B. Application of terrestrial laser scanning to the development and updating of the base map. Geodesy Cartogr. 2017, 66, 59–71. [Google Scholar] [CrossRef]

- Gargoum, S.A.; Karsten, L. Virtual assessment of sight distance limitations using LiDAR technology: Automated obstruction detection and classification. Autom. Constr. 2021, 125, 103579. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, D.; Shi, Y.; Zhang, Z.; Jin, F.; Yun, T.; Xu, S.; Kang, Z.; Zhang, L. A flexible architecture for extracting metro tunnel cross sections from terrestrial laser scanning point clouds. Remote Sens. 2019, 11, 297. [Google Scholar] [CrossRef]

- Xu, L.; Gong, J.; Na, J.; Yang, Y.; Tan, Z.; Pfeifer, N.; Zheng, S. Shield tunnel convergence diameter detection based on self-driven mobile laser scanning. Remote Sens. 2022, 14, 767. [Google Scholar] [CrossRef]

- Jia, D.; Zhang, W.; Liu, Y. Systematic approach for tunnel deformation monitoring with terrestrial laser scanning. Remote Sens. 2021, 13, 3519. [Google Scholar] [CrossRef]

- Helming, P.; von Freyberg, A.; Sorg, M.; Fischer, A. Wind Turbine tower deformation measurement using terrestrial laser scanning on a 3.4 MW wind turbine. Energies 2021, 14, 3255. [Google Scholar] [CrossRef]

- Farahani, B.V.; Barros, F.; Sousa, P.; Cacciari, P.P.; Tavares, P.; Futai, M.M.; Moreira, P. A coupled 3D laser scanning and digital image correlation system for geometry acquisition and deformation monitoring of a railway tunnel. Tunn. Undergr. Space Technol. 2019, 91, 102995. [Google Scholar] [CrossRef]

- Michalak, D.; Gomez Herrero, J.A. Innovative solutions need an innovative approach–3D printing technology, example of use and conclusion from implementation in an organization. Min. Mach. 2020, 162, 2. [Google Scholar]

- Xu, J.; Ding, L.; Love, P. Digital reproduction of historical building ornamental components: From 3D scanning to 3D printing. Autom. Constr. 2017, 76, 85–96. [Google Scholar] [CrossRef]

- Pejić, M. Design and optimisation of laser scanning for tunnels geometry inspection. Tunn. Undergr. Space Technol. 2013, 37, 199–206. [Google Scholar] [CrossRef]

- Janus, J.; Krawczyk, J. Measurement and simulation of flow in a section of a mine gallery. Energies 2021, 14, 4894. [Google Scholar] [CrossRef]

- Rozmus, M.; Tokarczyk, J.; Michalak, D.; Dudek, M.; Szewerda, K.; Rotkegel, M.; Lamot, A.; Rošer, J. Application of 3D scanning, computer simulations and virtual reality in the redesigning process of selected areas of underground transportation routes in coal mining industry. Energies 2021, 14, 2589. [Google Scholar] [CrossRef]

- Faro Laser Scanner FOCUS 3D—Manual; FARO Technologies Inc.: Lake Mary, FL, USA, 2010.

- Roca-Pardiñas, J.; Argüelles-Fraga, R.; de Asís López, F.; Ordóñez, C. Analysis of the influence of range and angle of incidence of terrestrial laser scanning measurements on tunnel inspection. Tunn. Undergr. Space Technol. 2014, 43, 133–139. [Google Scholar] [CrossRef]

- Chen, B.; Deng, K.; Fan, H.; Hao, M. Large-scale deformation monitoring in mining area by D-InSAR and 3D laser scanning technology integration. Int. J. Min. Sci. Technol. 2013, 23, 555–561. [Google Scholar] [CrossRef]

- Monsalve, J.J.; Baggett, J.; Bishop, R.; Ripepi, N. Application of laser scanning for rock mass characterization and discrete fracture network generation in an underground limestone mine. Int. J. Min. Sci. Technol. 2018, 29, 131–137. [Google Scholar] [CrossRef]

- Olszyna, G.; Sioma, A.; Tytko, A. Laser measurement system for the diagnostics of mine hoist components. Arch. Min. Sci. 2014, 59, 337–346. [Google Scholar] [CrossRef][Green Version]

- Chi, H.; Zhan, K.; Shi, B. Automatic guidance of underground mining vehicles using laser sensors. Tunn. Undergr. Space Technol. 2012, 27, 142–148. [Google Scholar] [CrossRef]

- Heyduk, A. Laser triangulation in 3-dimensional granulometric analysis. Arch. Min. Sci. 2016, 61, 15–27. [Google Scholar] [CrossRef][Green Version]

- Lenda, G.; Lewińska, P.; Siwiec, J. Accuracy of merging point clouds at the maximum range of a scanner with limited pos-sibilities of target placement. Arch. Civ. Eng. 2019, 65, 4. [Google Scholar]

- Janus, J. Construction the Numerical Models Geometry by Using Terrestrial Laser Scanning; Selected Issues Related to Mining and Clean Coal Technology; AGH University of Science and Technology: Krakow, Poland, 2016. [Google Scholar]

- Horyl, P.; Šňupárek, R.; Maršálek, P.; Pacześniowski, K. Simulation of laboratory tests of steel arch support. Arch. Min. Sci. 2017, 62, 163–176. [Google Scholar] [CrossRef]

- Roszczynialski, W.; Trutwin, W.; Wacławik, J. Kopalniane Pomiary Wentylacyjne; Śląsk: Katowice, Poland, 1992. [Google Scholar]

| S [m] | W [m] | R1 [m] | L1 [m] | Z [m] | R2 [m] | L2 [m] | C [m] |

|---|---|---|---|---|---|---|---|

| 4.7 | 3.3 | 2.8 | 3.2 | 0.5 | 2.2 | 3.8 | 0.45 |

| Cross-Section 1.1 [m2] | Difference [m2] | Cross-Section 1.2 [m2] | Difference [m2] | Cross-Section 2.1 [m2] | Difference [m2] | |

|---|---|---|---|---|---|---|

| Scanning method | 11.26 | 0 | 13.20 | 0 | 12.66 | 0 |

| CAD method | 11.38 | 0.12 | 13.30 | 0.101 | 13.00 | 0.34 |

| Empirical method | 11.08 | −0.18 | 12.65 | −0.547 | 12.52 | −0.14 |

| Semi-ellipse | 10.88 | −0.38 | 12.42 | −0.779 | 12.26 | −0.40 |

| Semi-ellipse with straight sections | 11.39 | 0.13 | 12.93 | −0.266 | 12.77 | 0.11 |

| Cross-Section 2.2 [m2] | Difference [m2] | Cross-Section 3.1 [m2] | Difference [m2] | Cross-Section 3.2 [m2] | Difference [m2] | |

|---|---|---|---|---|---|---|

| Scanning method | 13.18 | 0 | 12.99 | 0 | 13.18 | 0 |

| CAD method | 13.49 | 0.31 | 13.03 | 0.046 | 13.49 | 0.31 |

| Empirical method | 12.87 | −0.31 | 12.53 | −0.462 | 12.87 | −0.31 |

| Semi-ellipse | 12.61 | −0.57 | 12.30 | −0.692 | 12.61 | −0.57 |

| Semi-ellipse with straight sections | 13.12 | −0.06 | 12.80 | −0.193 | 13.12 | −0.06 |

| CAD Method [%] | Empirical Method [%] | Approximation by a Semi-Ellipse [%] | Approximation by a Semi-Ellipse with Attached Straight Sections [%] | |

|---|---|---|---|---|

| Cross-Section 1.1 | 1.07 | −1.60 | −3.37 | 1.15 |

| Cross-Section 2.1 | 2.35 | −2.35 | −4.32 | −0.46 |

| Cross-Section 2.1 | 0.77 | −4.15 | −5.90 | −2.02 |

| Cross-Section 2.2 | 2.69 | −1.11 | −3.16 | 0.87 |

| Cross-Section 3.1 | 0.35 | −3.56 | −5.33 | −1.49 |

| Cross-Section 3.2 | 1.00 | −3.78 | −5.55 | −1.63 |

| CAD Method [%] | Empirical Method [%] | Approximation by a Semi-Ellipse [%] | Approximation by a Semi-Ellipse with Attached Straight Sections [%] | |

|---|---|---|---|---|

| Mean relative error | 1.37 | 2.76 | 4.61 | 1.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janus, J.; Ostrogórski, P. Underground Mine Tunnel Modelling Using Laser Scan Data in Relation to Manual Geometry Measurements. Energies 2022, 15, 2537. https://doi.org/10.3390/en15072537

Janus J, Ostrogórski P. Underground Mine Tunnel Modelling Using Laser Scan Data in Relation to Manual Geometry Measurements. Energies. 2022; 15(7):2537. https://doi.org/10.3390/en15072537

Chicago/Turabian StyleJanus, Jakub, and Piotr Ostrogórski. 2022. "Underground Mine Tunnel Modelling Using Laser Scan Data in Relation to Manual Geometry Measurements" Energies 15, no. 7: 2537. https://doi.org/10.3390/en15072537

APA StyleJanus, J., & Ostrogórski, P. (2022). Underground Mine Tunnel Modelling Using Laser Scan Data in Relation to Manual Geometry Measurements. Energies, 15(7), 2537. https://doi.org/10.3390/en15072537