Current and Stray Flux Combined Analysis for the Automatic Detection of Rotor Faults in Soft-Started Induction Motors

Abstract

:1. Introduction

2. Materials and Methods

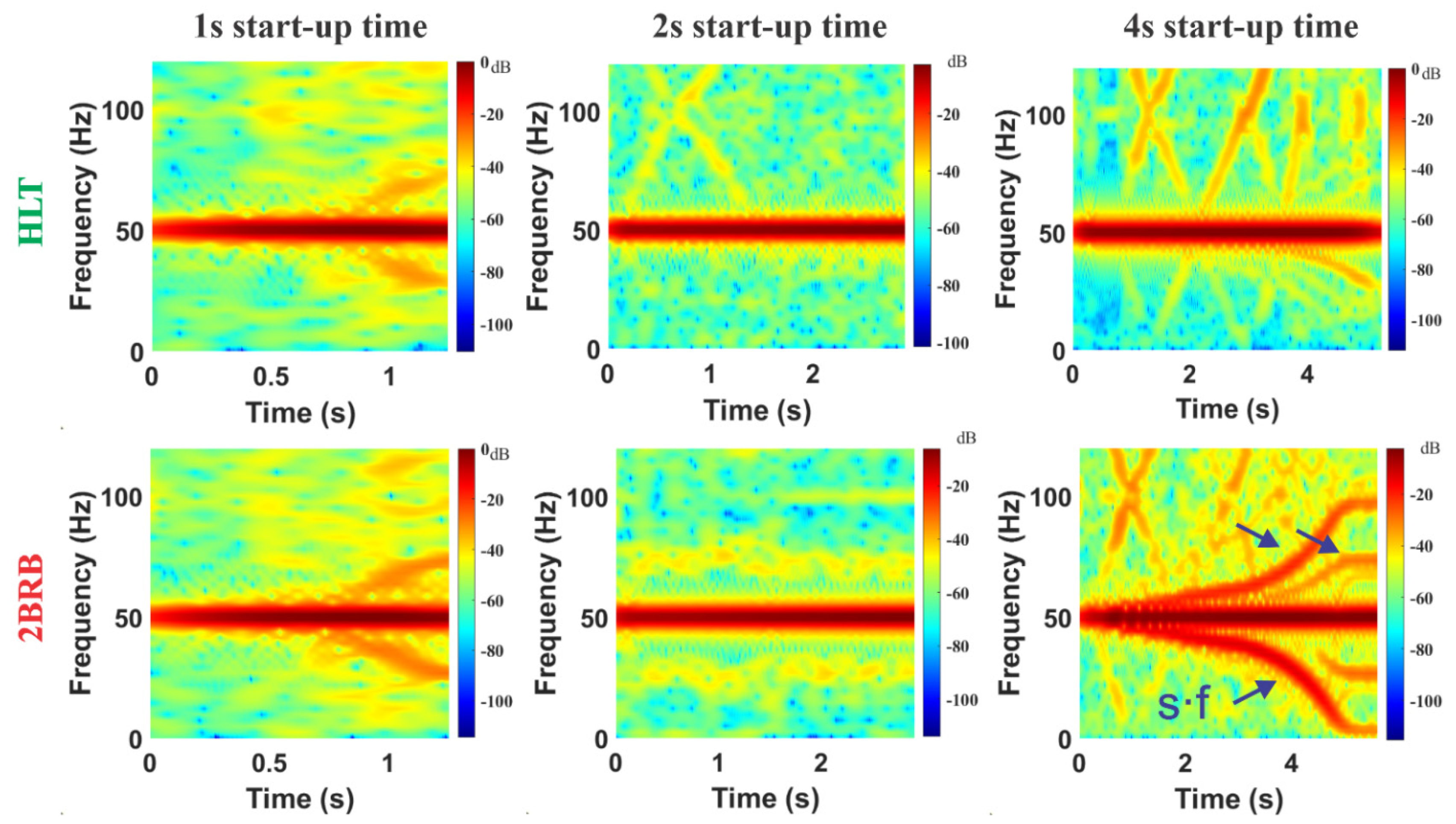

2.1. Current Monitoring for Broken Rotor Bars

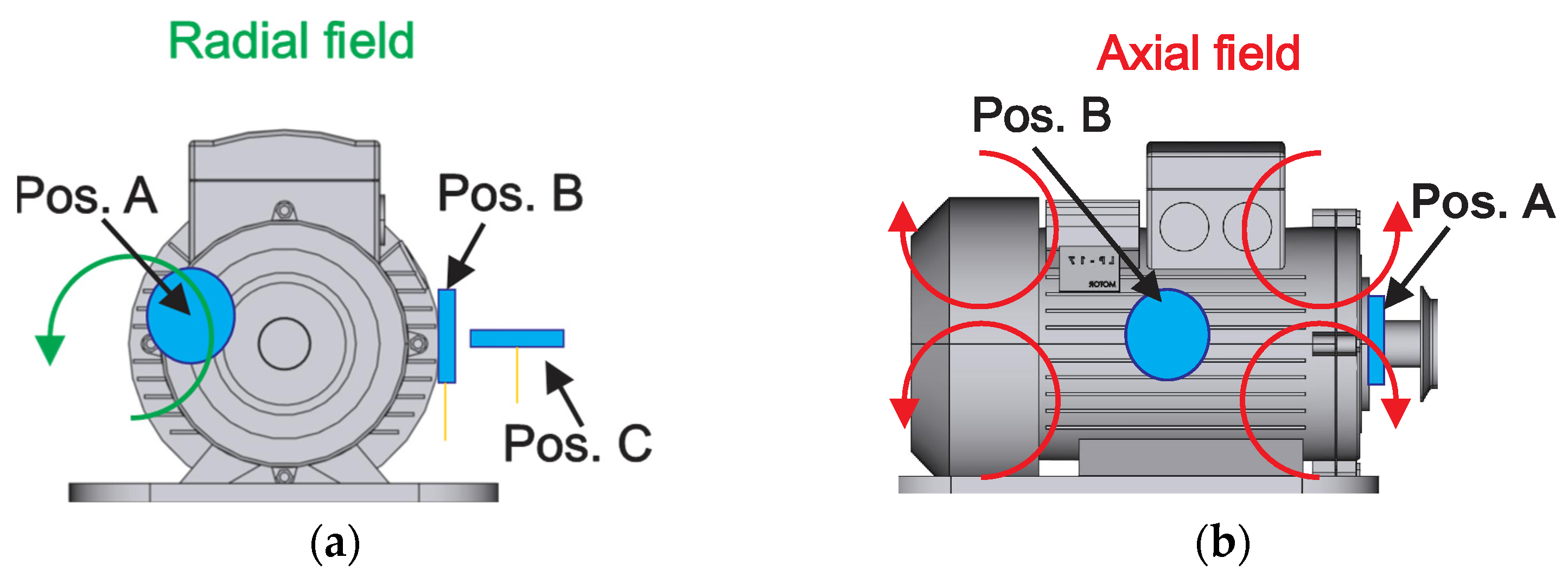

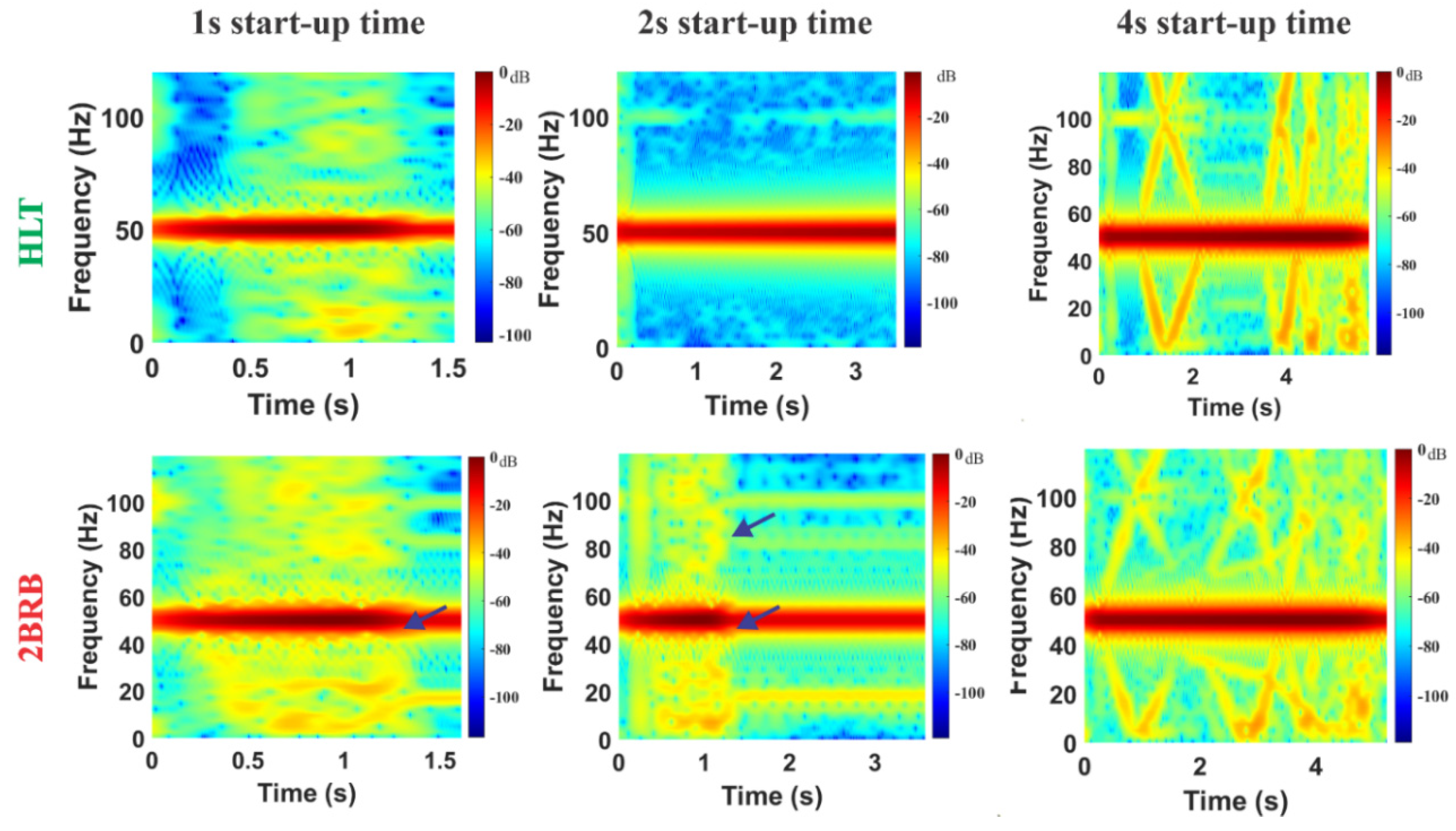

2.2. Stray Flux Signals Analysis

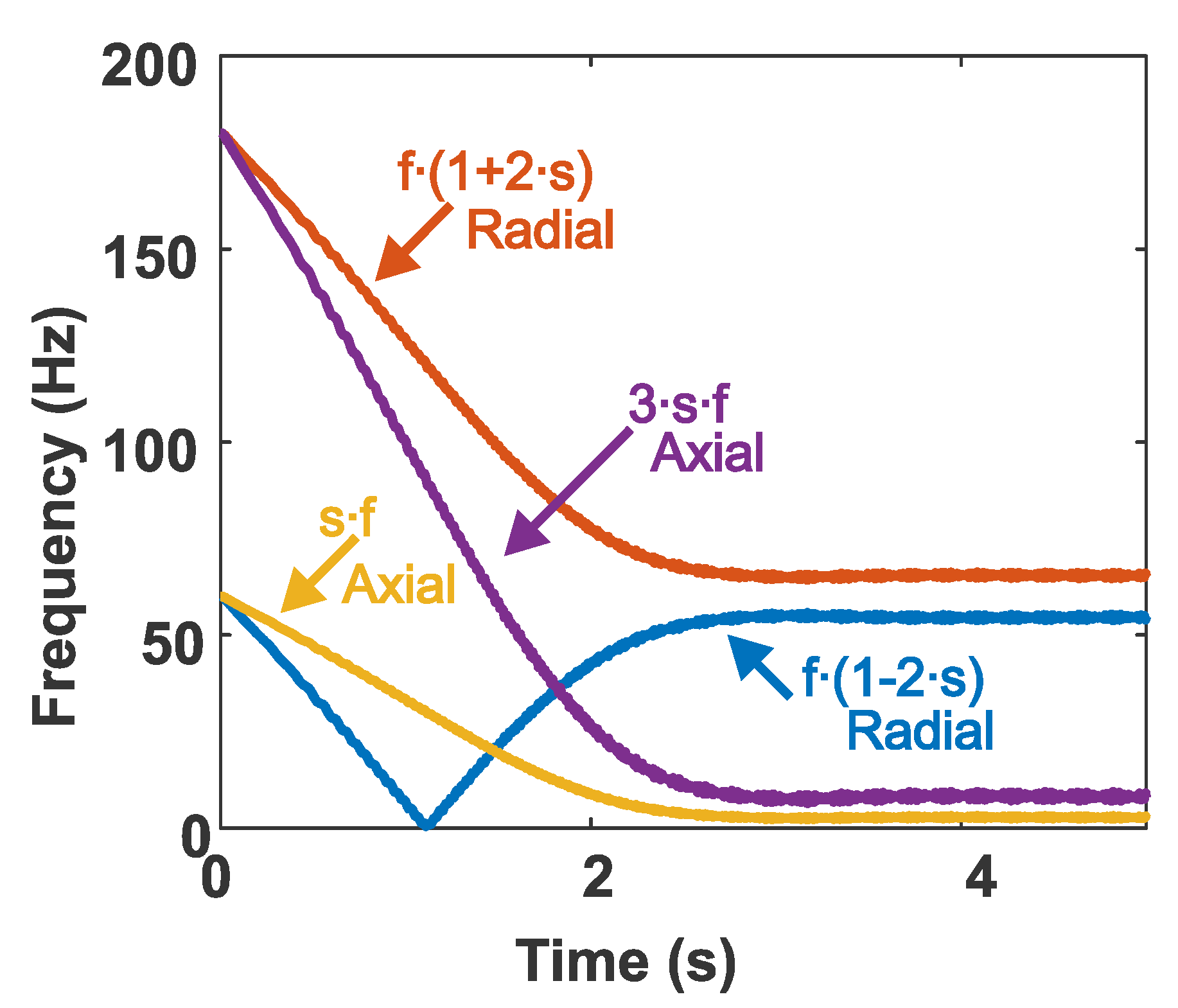

2.3. Theoretical Fault-Related Frequency Evolution during Start-Up

- Frequency components of axial nature () [19]. These frequency components may be observed at one and three times the slip frequency, given by Equation (3) and Equation (4), respectively, and can be observed in the axial stray flux signals.where slip and power supply frequency.

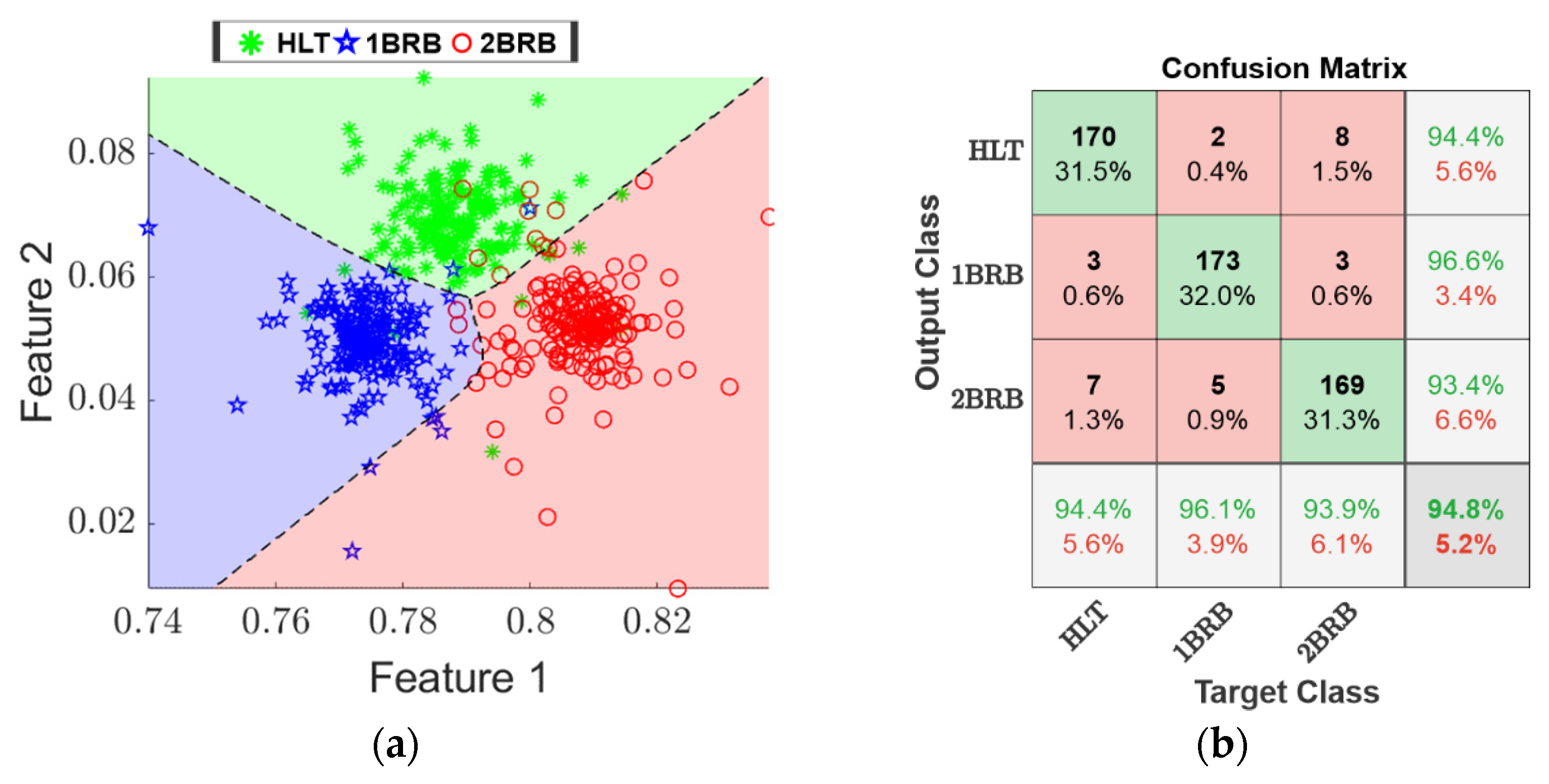

2.4. Linear Discriminant Analysis

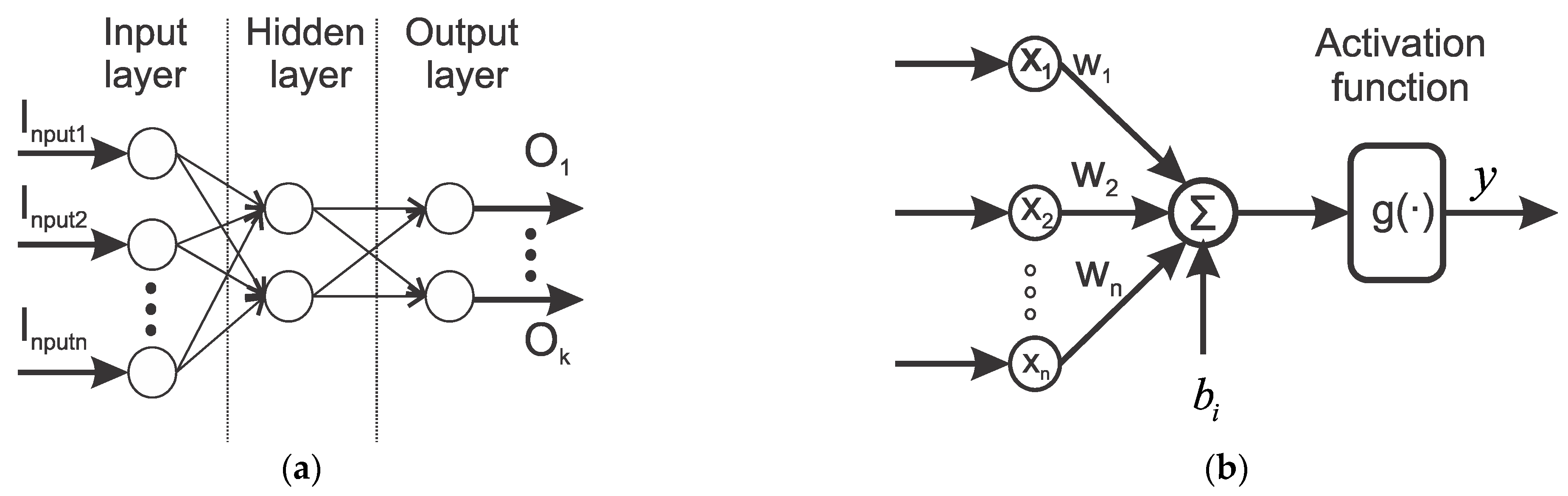

2.5. Artificial Neural Network

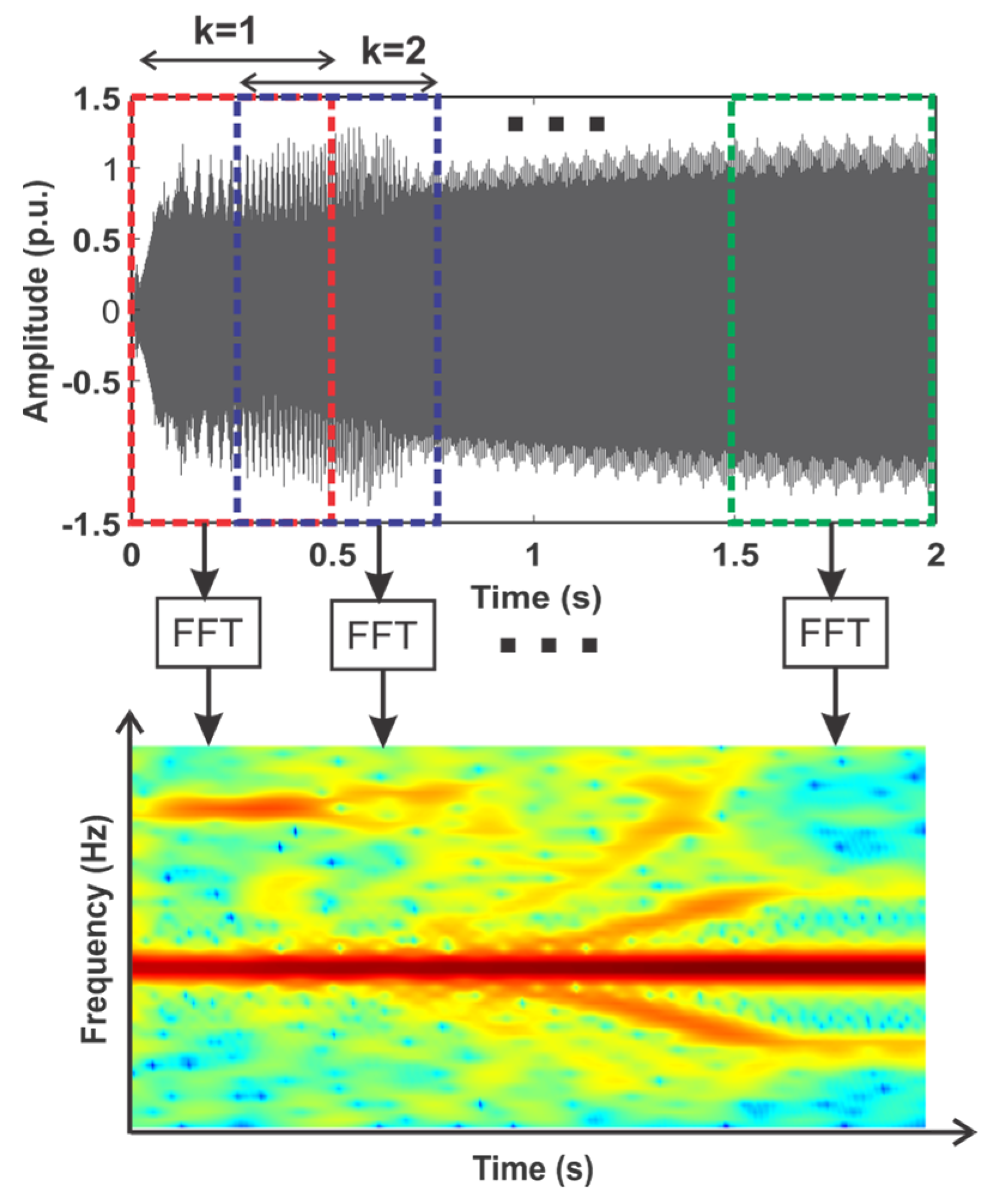

2.6. Short-Time Fourier Transform

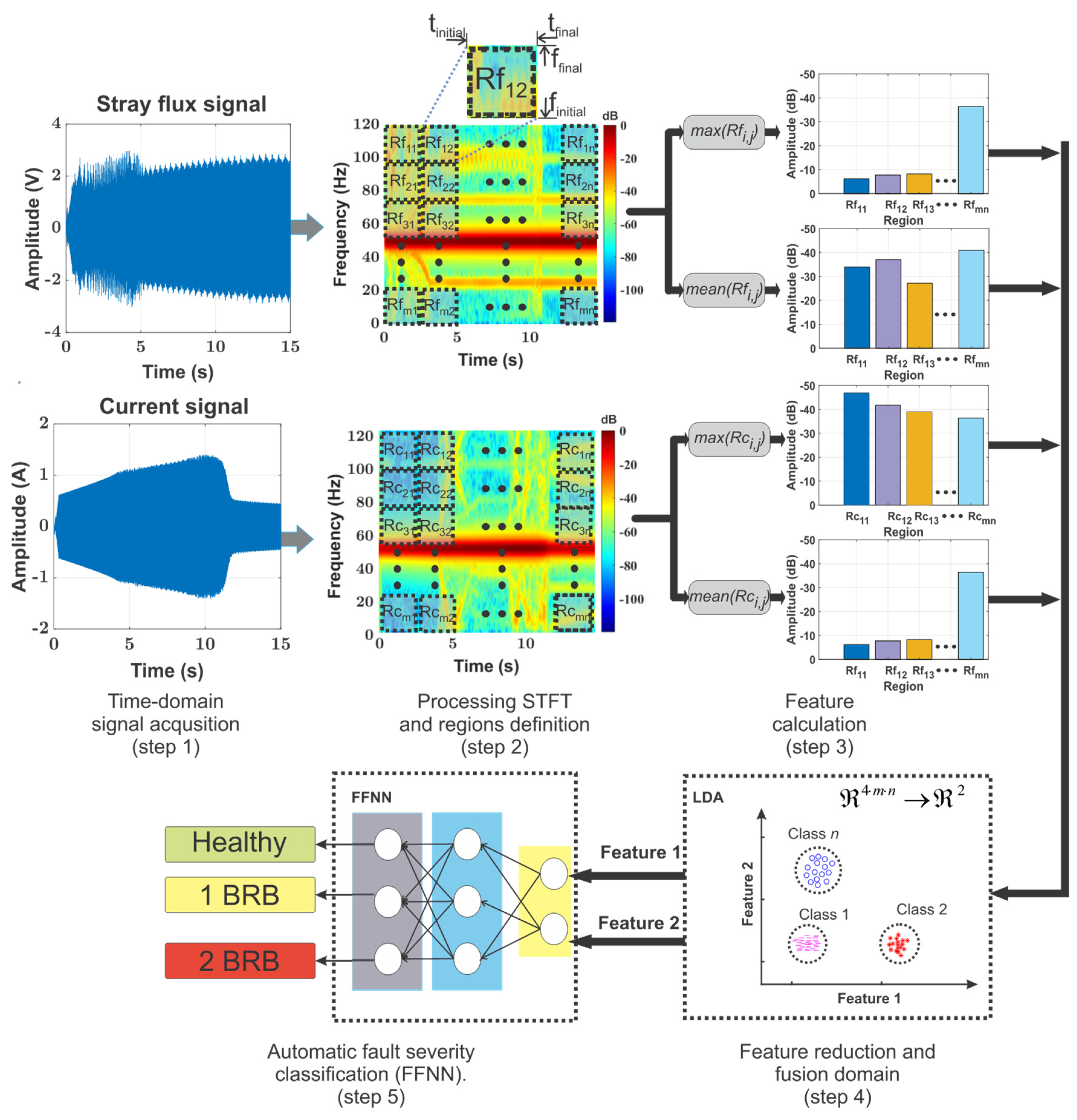

3. Proposed Methodology

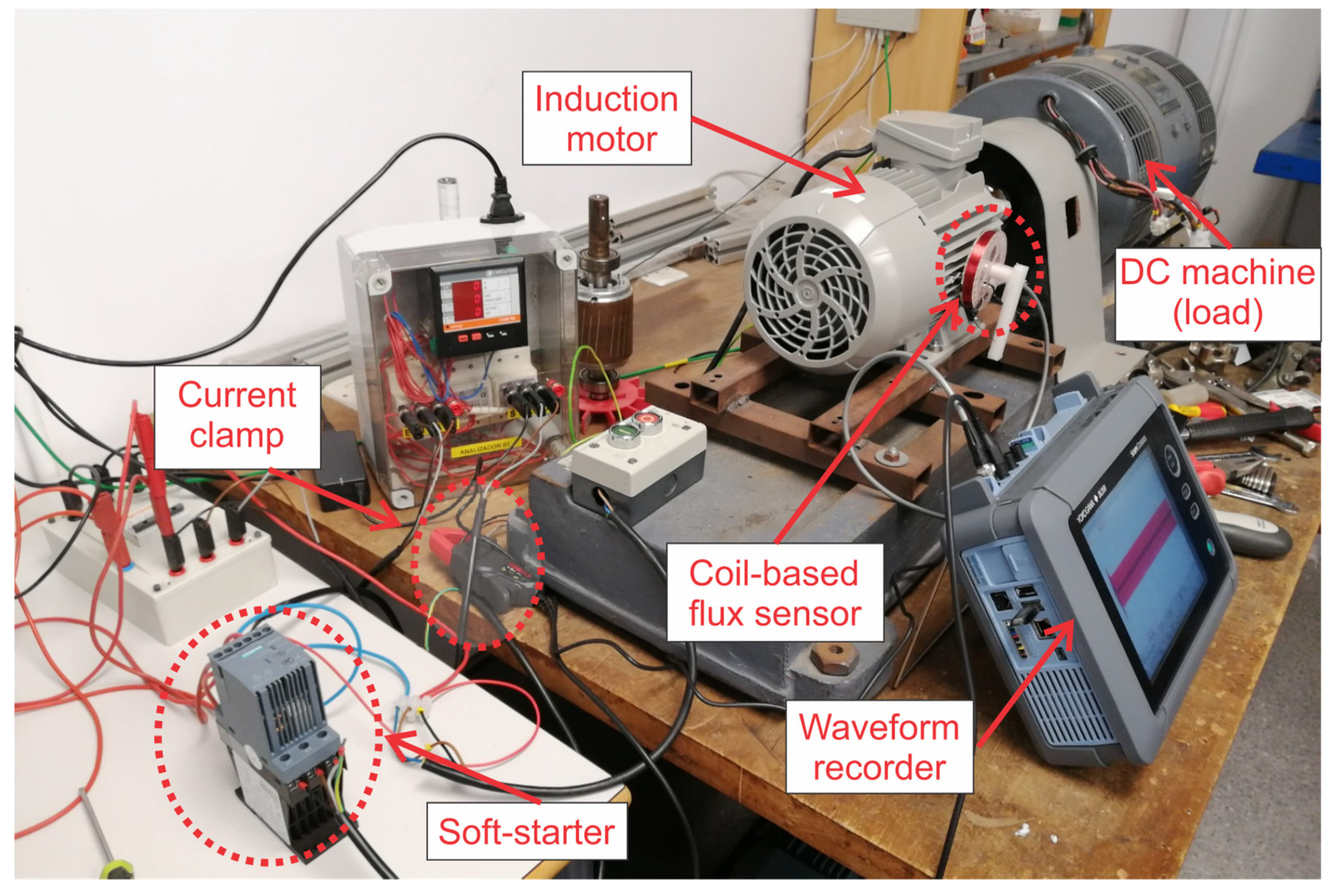

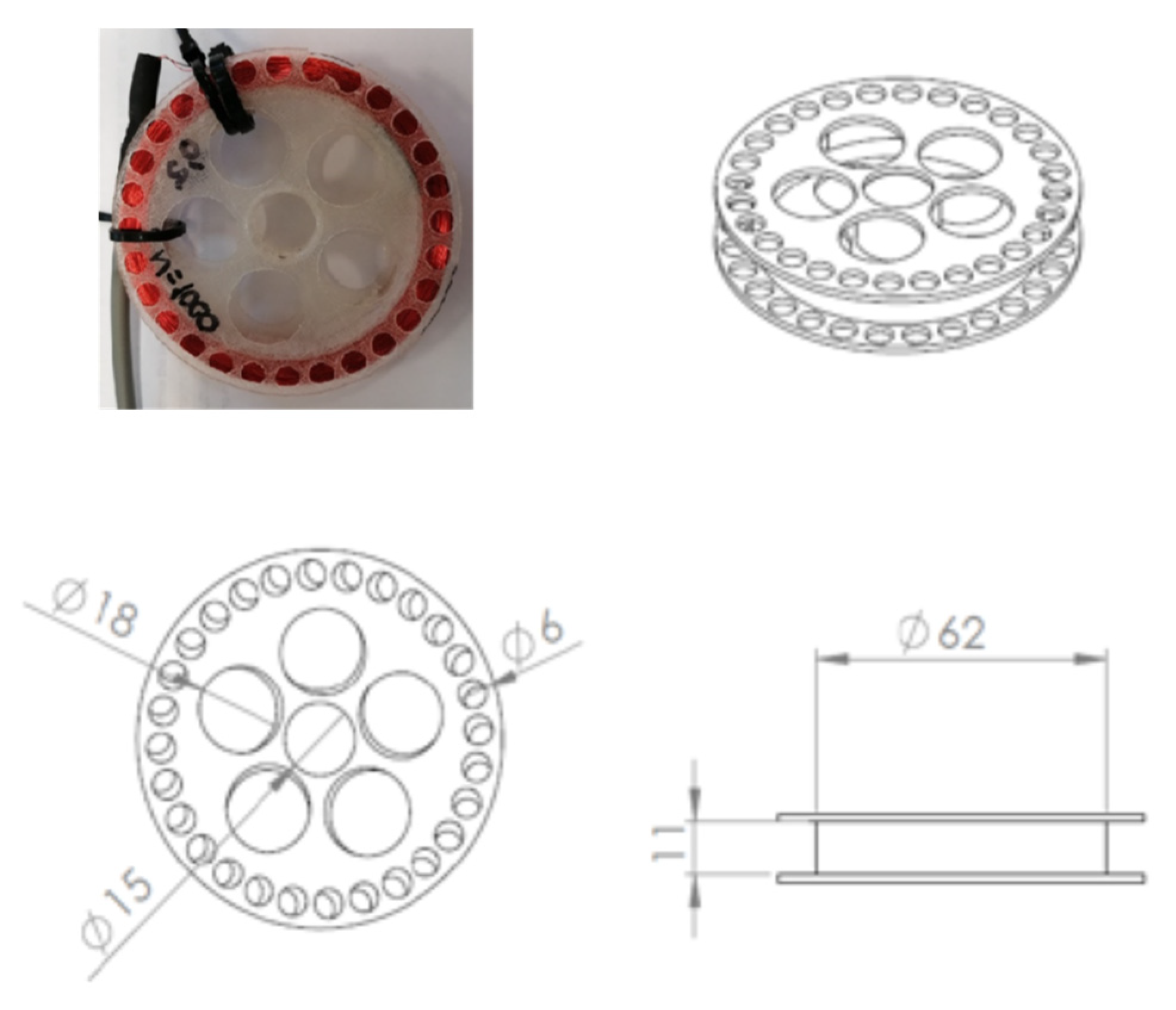

- Step 1. Acquire current and magnetic flux signals (obtained in the vicinity of the motor frame, in axial + radial direction) simultaneously under the start-up transients by means of an oscilloscope, a magnetic flux sensor, and a current sensor. A coil-based sensor is the one used during the experimentation of this paper, which is described in detail in the next section.

- Step 2. Apply a time-frequency decomposition tool to obtain a time-frequency map of the captured stray flux and current signals; in this paper the STFT is computed by applying Equation (7). The STFT is selected since it can be easily implemented in programmable logic devices, and it allows a clear visualization of the fault components evolution.

- Step 3. Using Equations (8)–(11), compute the proposed indicators: , , , in each region of interest, in order to characterize the fault-related pattern evolution for the stray flux and current signals. The regions of interest are obtained by dividing the t-f map into a grid of rows by columns. These regions of interest are in areas covered by the start-up transient. During the startup transient, the current reaches a high value in its amplitude, and it decreases until it arrives at steady state. Therefore, in using the envelope of the current signal, this part can be automatically isolated by setting a limit value (obtained through the last samples) equal to the maximum envelope amplitude at steady state. The intersection of this limit value with the time axis will be nearly at the end of the start-up transient.

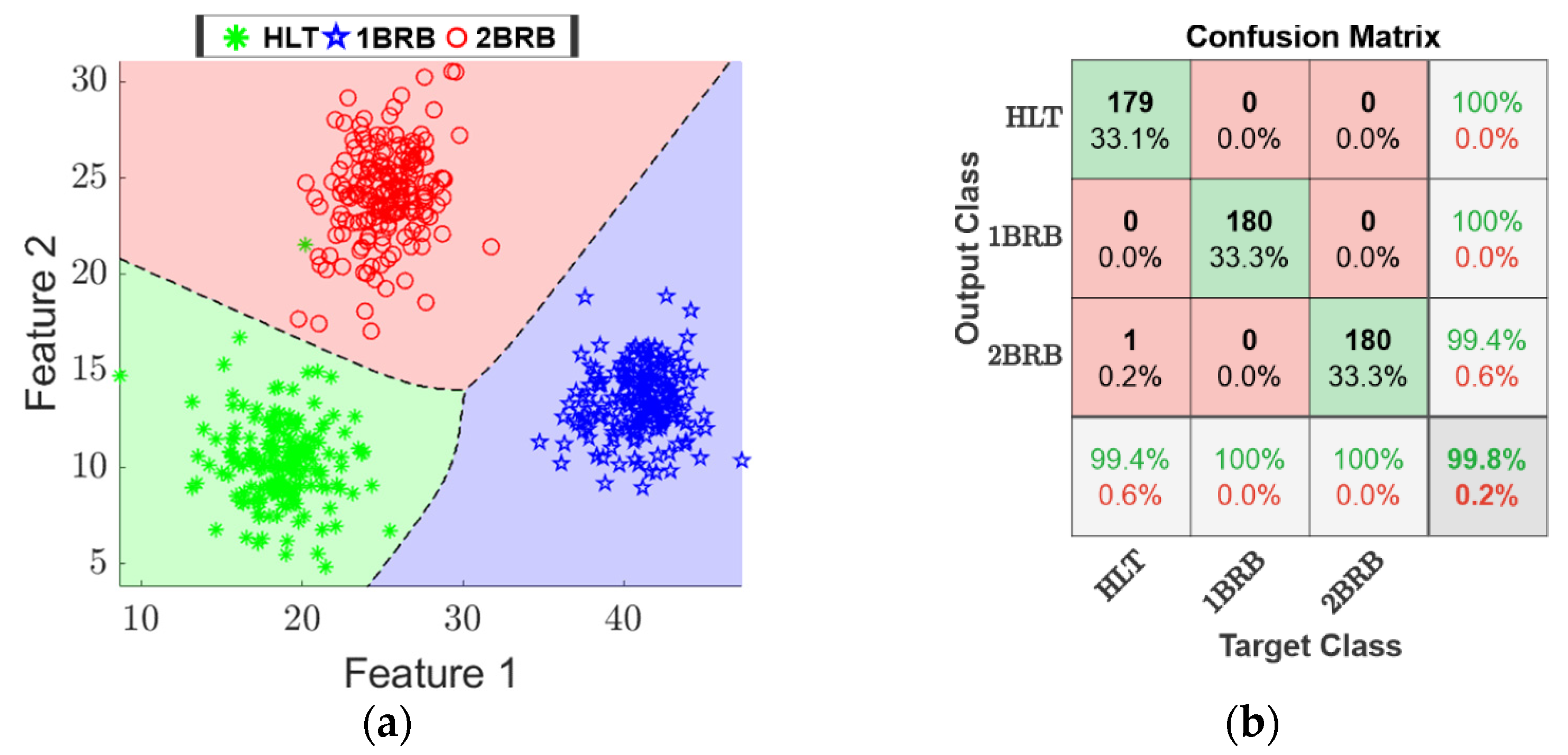

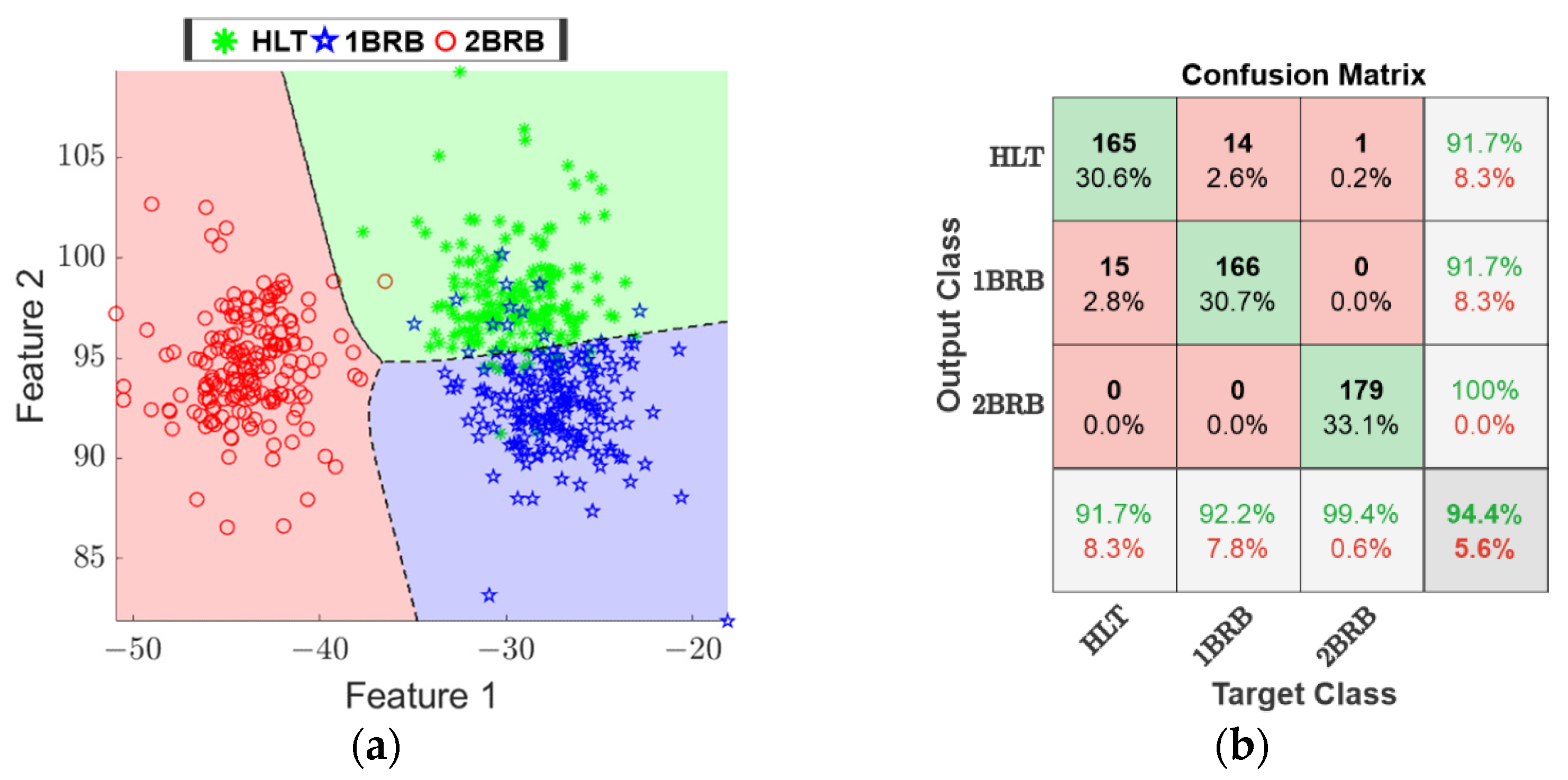

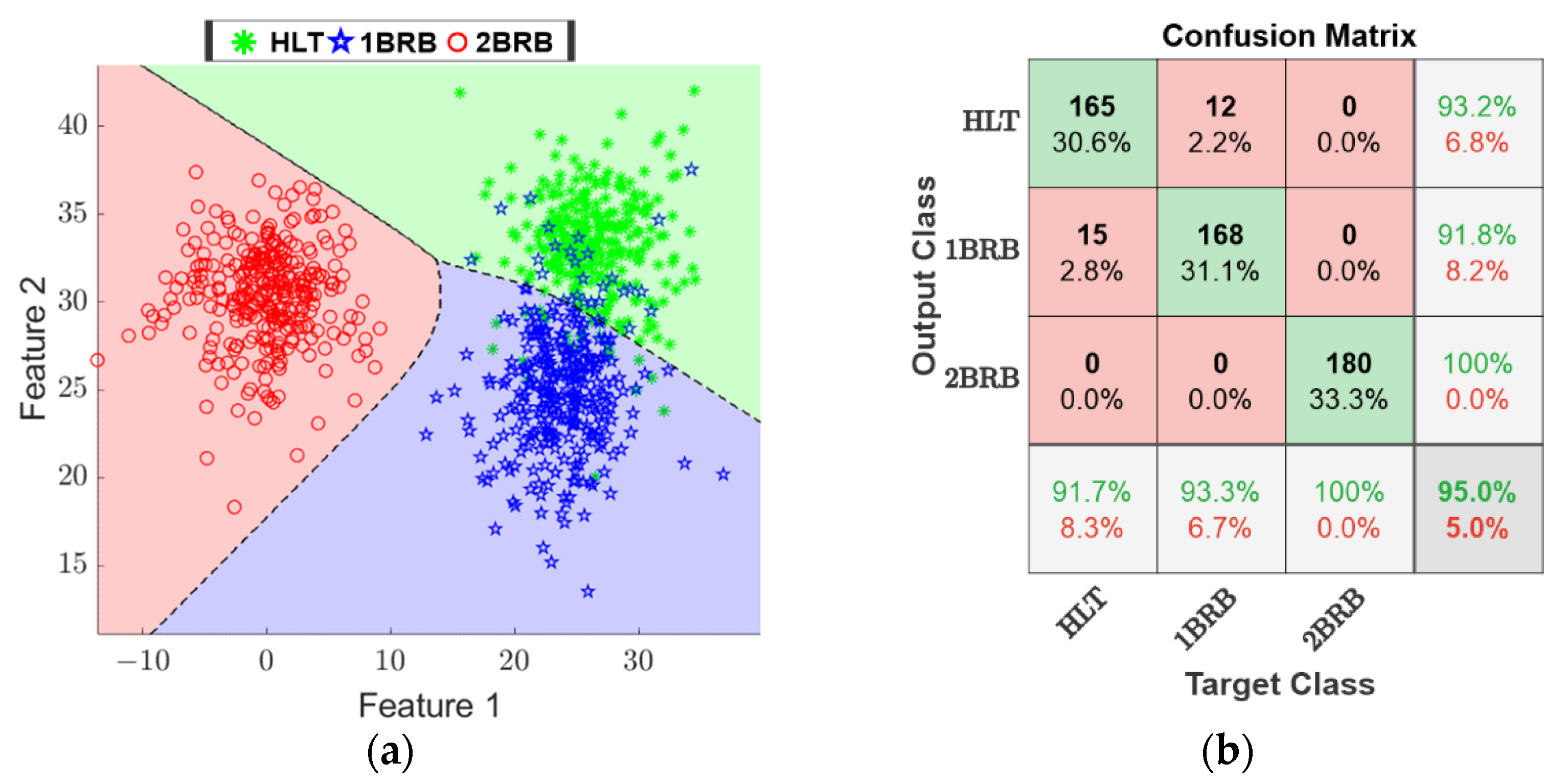

- Step 4. Perform a feature reduction and fusion signals by applying an LDA, as described in Section 2.3. After that, a two-dimensional projection is obtained, in which the maximization of the data separability is achieved for the considered classes: healthy motor, one broken rotor bar, and two broken rotor bars. This projection allows the data clustering between the different fault severities to be observed, since the main projection axes are selected to be Feature 1 and Feature 2, respectively.

- Step 5. Perform an automatic classification of the motor condition status: healthy, one broken rotor bar, and two broken rotor bars, by means of the proposed indicators. For the purposes of this paper, an FFNN with hyperbolic tangent sigmoid and SoftMax activation functions in the hidden and output layers are used, respectively. The FFNN architecture is selected due to its simplicity, the low computation resources demanded by its calculation, and the ease of its implementation in hardware devices.

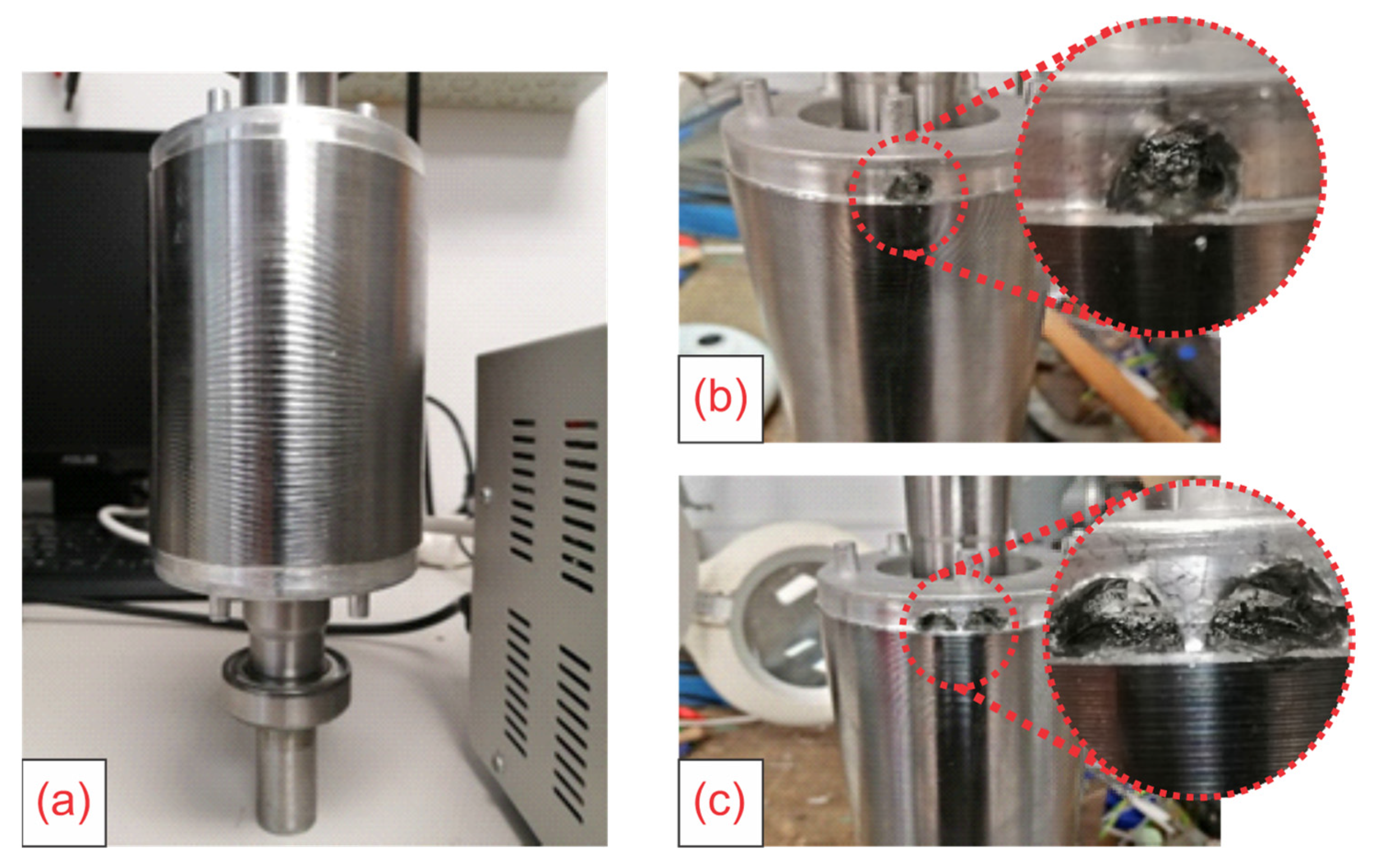

4. Experimental Setup

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Perez-Ramirez, C.A.; Camarena-Martinez, D.; Garcia-Perez, A.; Romero-Troncoso, R.J. Fractal dimension and fuzzy logic systems for broken rotor bar detection in induction motors at start-up and steady-state regimes. Meas. Sci. Technol. 2017, 28, 75001. [Google Scholar] [CrossRef]

- Park, Y.; Yang, C.; Kim, J.; Kim, H.; Lee, S.B.; Gyftakis, K.N.; Panagiotou, P.A.; Kia, S.H.; Capolino, G.-A. Stray flux monitoring for reliable detection of rotor faults under the influence of rotor axial air ducts. IEEE Trans. Ind. Electron. 2019, 66, 7561–7570. [Google Scholar] [CrossRef]

- Larabee, B.; Pellegrino, B.; Flick, B. Induction motor starting methods and issues. In Proceedings of the Record of Conference Papers Industry Applications Society 52nd Annual Petroleum and Chemical Industry Conference, Denver, CO, USA, 12–14 September 2005; pp. 217–222. [Google Scholar] [CrossRef]

- Corral-Hernandez, J.A.; Antonino-Daviu, J.; Pons-Llinares, J.; Climente-Alarcon, V.; Francés-Galiana, V. Transient-Based Rotor Cage Assessment in Induction Motors Operating with Soft Starters. IEEE Trans. Ind. Appl. 2015, 51, 3734–3742. [Google Scholar] [CrossRef]

- Corral-Hernandez, J.A.; Antonino-Daviu, J. Startup-based rotor fault detection in soft-started induction motors for different soft-starter topologies. In Proceedings of the IECON 2016-42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 6977–6982. [Google Scholar] [CrossRef]

- Stone, Y.G.C.; Stranges, M.K.W.; Dunn, D.G. Common Questions on Partial Discharge Testing. IEEE Ind. Appl. Mag. 2016, 22, 14–19. [Google Scholar] [CrossRef]

- Benbouzid, M.E.H. A review of induction motors signature analysis as a medium for faults detection. IEEE Trans. Ind. Electron. 2000, 47, 984–993. [Google Scholar] [CrossRef] [Green Version]

- Capolino, A.; Romary, R.; Hénao, H.; Pusca, R. State of the art on stray flux analysis in faulted electrical machines. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019; pp. 181–187. [Google Scholar] [CrossRef]

- Zamudio-Ramírez, I.; Osornio-Ríos, R.A.; Antonino-Daviu, J.A.; Quijano-Lopez, A. Smart-sensor for the automatic detection of electromechanical faults in induction motors based on the transient stray flux analysis. Sensors 2020, 20, 1477. [Google Scholar] [CrossRef] [Green Version]

- Rivera-Guillen, J.R.; de Santiago-Perez, J.J.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Romero-Troncoso, R.J. Enhanced FFT-based method for incipient broken rotor bar detection in induction motors during the startup transient. Measurement 2018, 124, 277–285. [Google Scholar] [CrossRef]

- Henao, H.; Capolino, G.-A.; Fernandez-Cabanas, M.; Filippetti, F.; Bruzzese, C.; Strangas, E.; Pusca, R.; Estima, J.; Riera-Guasp, M.; Hedayati-Kia, S. Trends in fault diagnosis for electrical machines: A review of diagnostic techniques. IEEE Ind. Electron. Mag. 2014, 8, 31–42. [Google Scholar] [CrossRef]

- Zamudio-Ramirez, R.A.; Osornio-Rios, J.A.; Antonino-Daviu, J.A. Smart Sensor for Fault Detection in Induction Motors Based on the Combined Analysis of Stray-Flux and Current Signals: A Flexible, Robust Approach. IEEE Ind. Appl. Mag. 2022, 28, 56–66. [Google Scholar] [CrossRef]

- Ince, T. Real-time broken rotor bar fault detection and classification by shallow 1D convolutional neural networks. Electr. Eng. 2019, 101, 599–608. [Google Scholar] [CrossRef]

- Valtierra-Rodriguez, M.; Rivera-Guillen, J.R.; Basurto-Hurtado, J.A.; De-Santiago-Perez, J.J.; Granados-Lieberman, D.; Amezquita-Sanchez, J.P. Convolutional neural network and motor current signature analysis during the transient state for detection of broken rotor bars in induction motors. Sensors 2020, 20, 3721. [Google Scholar] [CrossRef] [PubMed]

- Pasqualotto, D.; Navarro, A.N.; Zigliotto, M.; Antonino-Daviu, J.A.; Biot-Monterde, V. Fault Detection in Soft-started Induction Motors using Convolutional Neural Network Enhanced by Data Augmentation Techniques. In Proceedings of the IECON 2021—47th Annual Conference of the IEEE Industrial Electronics Society, Toronto, TO, Canada, 13–16 October 2021; Volume 2021. [Google Scholar] [CrossRef]

- Asad, T.; Vaimann, A.; Belahcen, A.; Kallaste, A.; Rassõlkin, M.; Iqbal, M.N. The cluster computation-based hybrid fem–analytical model of induction motor for fault diagnostics. Appl. Sci. 2020, 10, 7572. [Google Scholar] [CrossRef]

- Burnett, R.; Watson, J.F.; Elder, S. The detection and location of rotor faults within three phase induction motors. In Proceedings of the International Conference on Electrical Machines, Paris, France, 17–20 October 1994; pp. 288–293. [Google Scholar]

- Biot-Monterde, V.; Navarro-Navarro, Á.; Antonino-Daviu, J.A.; Razik, H. Stray flux analysis for the detection and severity categorization of rotor failures in induction machines driven by soft-starters. Energies 2021, 14, 5757. [Google Scholar] [CrossRef]

- Ceban, A.; Pusca, R.; Romary, R. Study of rotor faults in induction motors using external magnetic field analysis. IEEE Trans. Ind. Electron. 2012, 59, 2082–2093. [Google Scholar] [CrossRef]

- Bellini, A.; Filippetti, F.; Franceschini, G.; Tassoni, C.; Kliman, G.B. Quantitative evaluation of induction motor broken bars by means of electrical signature analysis. IEEE Trans. Ind. Appl. 2001, 37, 1248–1255. [Google Scholar] [CrossRef]

- Lee, S.B.; Shin, J.; Park, Y.; Kim, H.; Kim, J. Reliable Flux based Detection of Induction Motor Rotor Faults from the 5th Rotor Rotational Frequency Sideband. IEEE Trans. Ind. Electron. 2020, 68, 7874–7883. [Google Scholar] [CrossRef]

- Jiang, C.; Li, S.; Habetler, T.G. A review of condition monitoring of induction motors based on stray flux. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; Volume 2017, pp. 5424–5430. [Google Scholar] [CrossRef]

- Park, Y.; Lee, S.B.; Yun, J.; Sasic, M.; Stone, G.C. Air Gap Flux-Based Detection and Classification of Damper Bar and Field Winding Faults in Salient Pole Synchronous Motors. IEEE Trans. Ind. Appl. 2020, 56, 3506–3515. [Google Scholar] [CrossRef]

- Henao, H.; Demian, C.; Capolino, G.A. A frequency-domain detection of stator winding faults in induction machines using an external flux sensor. IEEE Trans. Ind. Appl. 2003, 39, 1272–1279. [Google Scholar] [CrossRef]

- Romary, R.; Roger, D.; Brudny, J.-F. Analytical computation of an AC machine external magnetic field. EPJ Appl. Phys. 2009, 47, 3. [Google Scholar] [CrossRef]

- Bellini, A.; Concari, C.; Franceschini, G.; Tassoni, C.; Toscani, A. Vibrations, currents and stray flux signals to asses induction motors rotor conditions. In Proceedings of the IECON 2006-32nd Annual Conference on IEEE Industrial Electronics, Paris, France, 6–10 November 2006; Volume 2, pp. 4963–4968. [Google Scholar] [CrossRef]

- Romary, R.; Pusca, R.; Lecointe, J.P.; Brudny, J.F. Electrical machines fault diagnosis by stray flux analysis. In Proceedings of the 2013 IEEE Workshop on Electrical Machines Design, Control and Diagnosis, WEMDCD 2013, Paris, France, 11–12 March 2013; pp. 247–256. [Google Scholar] [CrossRef]

- Zamudio-Ramirez, I.; Osornio-Rios, R.A.A.; Antonino-Daviu, J.A.; Razik, H.; de Jesus Romero-Troncoso, R. Magnetic Flux Analysis for the Condition Monitoring of Electric Machines: A Review. IEEE Trans. Ind. Inform. 2021, 3203, 2895–2908. [Google Scholar] [CrossRef]

- Goktas, T.; Arkan, M.; Mamis, M.S.; Akin, B. Separation of induction motor rotor faults and low frequency load oscillations through the radial leakage flux. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; Volume 2017, pp. 3165–3170. [Google Scholar] [CrossRef]

- Song, X.; Liu, Z.; Yang, X.; Yang, J.; Qi, Y. Extended semi-supervised fuzzy learning method for nonlinear outliers via pattern discovery. Appl. Soft Comput. J. 2015, 29, 245–255. [Google Scholar] [CrossRef]

- Jin, X.; Zhao, M.; Chow, T.W.S.; Pecht, M. Motor bearing fault diagnosis using trace ratio linear discriminant analysis. IEEE Trans. Ind. Electron. 2014, 61, 2441–2451. [Google Scholar] [CrossRef]

- Camarena-Martinez, D.; Valtierra-Rodriguez, M.; Garcia-Perez, A.; Osornio-Rios, R.A.; Romero-Troncoso, R.D.J. Empirical mode decomposition and neural networks on FPGA for fault diagnosis in induction motors. Sci. World J. 2014, 2014, 908140. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Herrera, A.L.; Ferrucho-Alvarez, E.R.; Ledesma-Carrillo, L.M.; Mata-Chavez, R.I.; Lopez-Ramirez, M.; Cabal-Yepez, E. Multiple Fault Detection in Induction Motors through Homogeneity and Kurtosis Computation. Energies 2022, 15, 1541. [Google Scholar] [CrossRef]

- Pasqualotto, D.; Navarro, A.N.; Zigliotto, M.; Antonino-Daviu, J.A. Automatic Detection of Rotor Faults in Induction Motors by Convolutional Neural Networks applied to Stray Flux Signals. In Proceedings of the 2021 22nd IEEE International Conference on Industrial Technology (ICIT), Valencia, Spain, 10–12 March 2021; Volume 2021, pp. 148–153. [Google Scholar] [CrossRef]

- Lopez-Ramirez, M.; Ledesma-Carrillo, L.M.; Garcia-Guevara, F.M.; Munoz-Minjares, J.; Cabal-Yepez, E.; Villalobos-Pina, F.J. Automatic Early Broken-Rotor-Bar Detection and Classification Using Otsu Segmentation. IEEE Access 2020, 8, 112624–112632. [Google Scholar] [CrossRef]

- Camarena-Martinez, D.; Perez-Ramirez, C.A.; Valtierra-Rodriguez, M.; Amezquita-Sanchez, J.P.; Romero-Troncoso, R.D.J. Synchrosqueezing transform-based methodology for broken rotor bars detection in induction motors. Meas. J. Int. Meas. Confed. 2016, 90, 519–525. [Google Scholar] [CrossRef]

| Power (kW) | 1.1 |

| Frequency (Hz) | 50 |

| Voltage (V) | 400 |

| Current (A) | 2.4 |

| Speed (rpm) | 1440 |

| Connection | Star |

| Number of Pole Pairs | 2 |

| Soft-Starter Model | Start-Up Transient Duration (s) | Initial Applied Voltage |

|---|---|---|

| Schneider | 5 | 30% |

| Schneider | 4 | 40, 50% |

| Schneider | 3 | 55% |

| Schneider | 2 | 67, 50% |

| Schneider | 1 | 80% |

| ABB | 20 | 40% |

| ABB | 10 | 55% |

| ABB | 1 | 70% |

| Omron | 1 | 72% |

| Omron | 12, 5 | 58% |

| Omron | 25 | 44% |

| SIEMENS | 0 | 100% |

| SIEMENS | 5 | 70% |

| SIEMENS | 10 | 50% |

| SIEMENS | 20 | 40% |

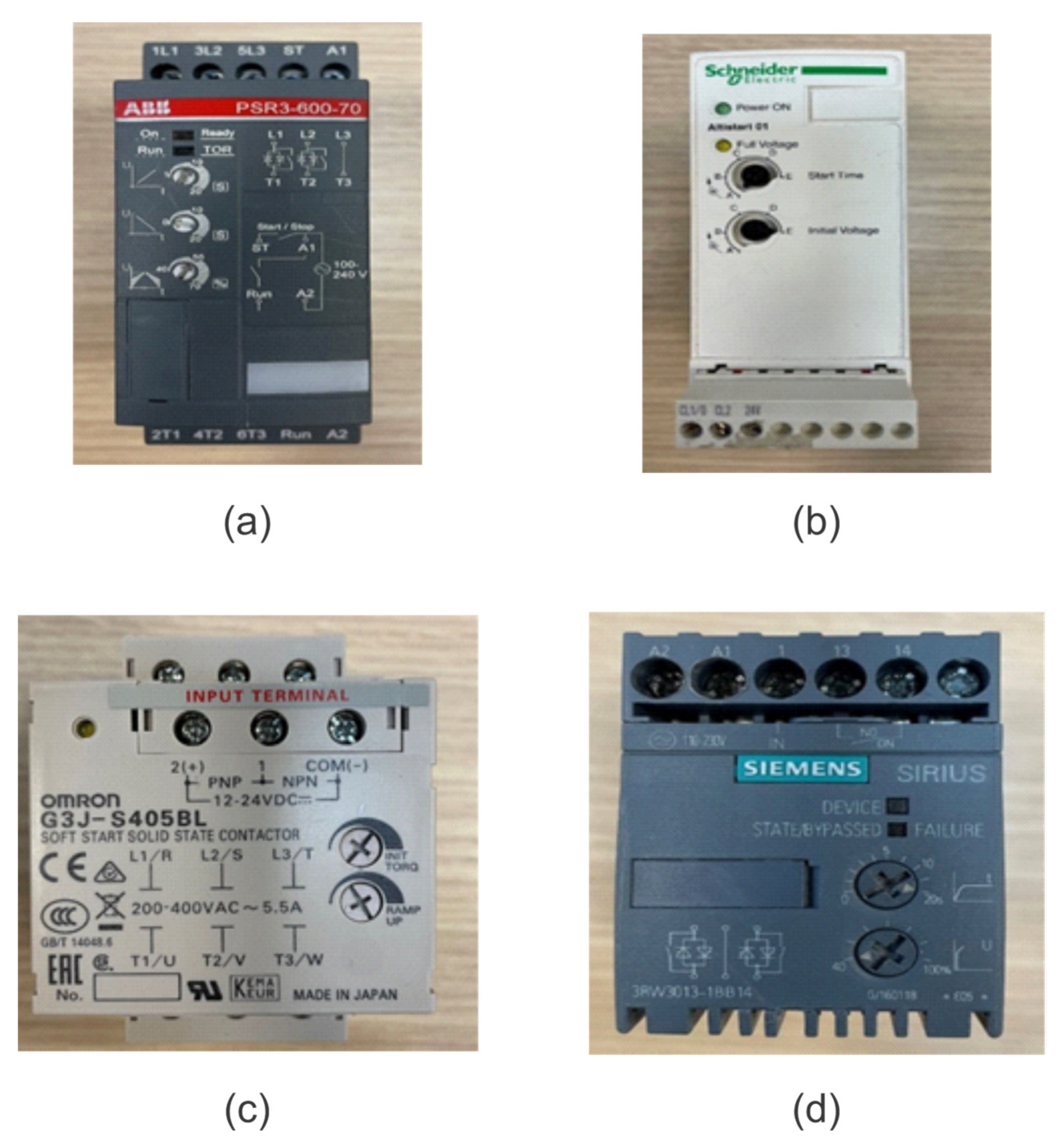

| Manufacturer | Siemens | ABB | Omron | Schneider |

|---|---|---|---|---|

| Model type | 3RW3013-1BB14 | PSR3-600-70 | G3J-S405BL | ATS01N109FT |

| Country of production | Germany | China | Japan | Germany |

| Number of controlled phases | 2 | 2 | 3 | 1 |

| Frequency (Hz) | 50 | 50 | 50 | 50 |

| Power (kW) | 1.5 | 1.5 | 2.2 | 4 |

| Voltage (V) | 380–400 | 380–400 | 380–400 | 400 |

| Maximum current (A) | 3.6 | 3.9 | 5.5 | 9 |

| Voltage ramp duration (s) | 0–20 | 1–20 | 1–25 | 1–5 |

| T-F Map Grid Size | Overall Classification Efficiency (%) | ||||

|---|---|---|---|---|---|

| ABB | Omron | Schneider | Siemens | ||

| 3 | 83.6 | 72.8 | 74.6 | 79.2 | |

| 4 | 4 | 96.3 | 74.1 | 84.8 | 79.4 |

| 5 | 5 | 96.4 | 83.6 | 86.9 | 87.3 |

| 6 | 6 | 97.5 | 83.6 | 90.4 | 93.8 |

| 7 | 7 | 99.1 | 85.2 | 91.1 | 94.1 |

| 8 | 8 | 99.8 | 94.4 | 95.0 | 94.8 |

| 9 | 9 | 98.1 | 91.4 | 92.0 | 94.8 |

| Reference | Methodology | Accuracy Rate | Start-Up Method | Signal Analyzed |

|---|---|---|---|---|

| Martinez et al. [33] | Homogeneity, kurtosis, ANN | 100% | DOL | Current |

| Zamudio et al. [12] | STFT, FFNN | 95% | DOL | Current and Stray Flux |

| Pasqualotto et al. [34] | CNN, STFT, data augmentation techniques | 66.7% | DOL | Stray Flux |

| Pasqualotto et al. [15] | CNN, STFT, data augmentation techniques | 94.4% | Soft-Starters | Stray Flux |

| Zamudio et al. [9] | STFT, FFNN | 97% | DOL | Stray Flux |

| Lopez et al. [35] | Multi-STFT, Otsu Segmentation, Normal-distribution | 100% | DOL | Current |

| Valtierra et al. [14] | STFT, CNN | 100% | DOL | Current |

| Camarena et al. [36] | Wavelet Transform, Correlation Pearson | 99% | DOL | Current |

| Ince et al. [13] | CNN, back-propagation (BP) algorithm | 97.87% | DOL | Current |

| Rivera et al. [10] | Tooth-FFT, Pearson correlation | 97.5% | DOL | Current |

| Proposed Approach | STFT, FFNN, arithmetic mean and maximum value | 94.4% | Soft-starter | Current and Stray Flux |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Navarro-Navarro, A.; Zamudio-Ramirez, I.; Biot-Monterde, V.; Osornio-Rios, R.A.; Antonino-Daviu, J.A. Current and Stray Flux Combined Analysis for the Automatic Detection of Rotor Faults in Soft-Started Induction Motors. Energies 2022, 15, 2511. https://doi.org/10.3390/en15072511

Navarro-Navarro A, Zamudio-Ramirez I, Biot-Monterde V, Osornio-Rios RA, Antonino-Daviu JA. Current and Stray Flux Combined Analysis for the Automatic Detection of Rotor Faults in Soft-Started Induction Motors. Energies. 2022; 15(7):2511. https://doi.org/10.3390/en15072511

Chicago/Turabian StyleNavarro-Navarro, Angela, Israel Zamudio-Ramirez, Vicente Biot-Monterde, Roque A. Osornio-Rios, and Jose A. Antonino-Daviu. 2022. "Current and Stray Flux Combined Analysis for the Automatic Detection of Rotor Faults in Soft-Started Induction Motors" Energies 15, no. 7: 2511. https://doi.org/10.3390/en15072511

APA StyleNavarro-Navarro, A., Zamudio-Ramirez, I., Biot-Monterde, V., Osornio-Rios, R. A., & Antonino-Daviu, J. A. (2022). Current and Stray Flux Combined Analysis for the Automatic Detection of Rotor Faults in Soft-Started Induction Motors. Energies, 15(7), 2511. https://doi.org/10.3390/en15072511