Abstract

The reservoir heterogeneity of Q oilfield is more severe after long-term water injection development, and water flooding is ineffective. In this study, the combined technologies of profile control, profile control and flooding, and oil displacement were proposed to improve the water flooding development effect. Then, the influence of the well pattern type on the remaining oil distribution, after development, was investigated. Cr3+ polymer gel, which has an optimal gel-forming effect, was used as the profile control agent. Moreover, the entire molecular structure had a “network” structure. A polymer microsphere was used as a profile control and flooding agent, which showed a good hydration expansion capacity. The initial particle size distribution had a range of 7.2–11.1 μm, and the expansion multiple was 4.35–5.64 after 7 days. The surfactant was an oil displacement agent, and the interfacial tension was approximately 5.08–5.11 × 10−1 mN/m. After the “profile control + profile control and flooding + oil displacement” technologies, the horizontal well pattern had a large seepage area. The effect of expanding the sweep volume was significant, and the remaining oil saturation in each stage was lower than those of the vertical and horizontal–vertical combined well patterns. Compared with the first water flooding stage, the remaining oil saturation values of the three permeable layers changed by 11.9%, 17.3%, and 19.8% during the subsequent water flooding stage.

1. Introduction

A single sand body encountered in Q oilfield is a composite channel sand body, which has positive and composite rhythms. The formation is composed of meandering river facies, and the reservoir porosity is approximately 25–45%, with an average value of 35%. The pore permeability has a range of approximately 100–11,487 × 10−3 μm2, with an average value of 3000 × 10−3 μm2 [1,2,3]. The crude oil of Q oilfield is heavy, and it has a high viscosity, density, and gum asphaltene content, as shown in Table 1. Moreover, it has low sulfur content, wax content, and freezing point. Q oilfield is a low-amplitude structural reservoir with a low oil column height, where the oil, gas, and water systems and local natural energy are complex. Moreover, the edge and bottom water is relatively active [4,5].

Table 1.

Oil analysis, Q Oilfield.

To date, the study area has had a high water content, and further development and adjustment technologies are urgently needed. According to a reservoir geological analysis, the high water content of Q oilfield is mainly due to an increase in the reserve proportion of the bottom water reservoir after the drilling of development wells compared to that during the overall development scheme stage of ODP [6,7,8,9]. Simultaneously, a set of layer series was used to jointly produce different types of reservoirs. In addition, the low oil column height of the bottom water reservoir, large oil–water viscosity ratio, and large Kv/Kh values led to a rapid increase in the water content of the oilfield [10,11]. After long-term high-intensity liquid injection, the reservoir rock structure in this block is severely damaged, and large pores or dominant channels are formed between some injection and production wells, which severely affect the development of water and polymer flooding. Profile control and water shutoff technologies are urgently required to improve the sweeping effect of the injection liquid [12,13,14,15].

Polymer materials, reservoir engineering, chemical analysis, and physical simulation were used as the means to meet the technical requirements of target reservoir development, theoretically guided by physical chemistry. The properties of the polymer gel, polymer microspheres, and surfactant were examined using the target reservoir’s geology and fluid as the objects of the simulation. The polymer gel was used as a large pore plugging agent. Polymer microspheres were used for micro-profile control, and displacement agents and surfactants were used as oil displacement agents. In this study, the effects of profile control, profile control and flooding, oil displacement, and the well pattern type on the remaining oil saturation and distribution were examined. The results provide theoretical and technical support for the development of Q oilfield.

2. Experimental Procedures

2.1. Materials

Cr3+ polymer gel was used as the profile control agent. Polymer microspheres were used for the profile control and flooding agent, and the surfactant was used as the oil displacement agent. The polymer was partially hydrolyzed polyacrylamide and was produced by PetroChina Daqing Refining and Chemical Company, with a relative molecular weight of 1900 × 104 (referred to as a “high-score” polymer). Moreover, the effective content was 88%. Organic chromium with a Cr3+ content of 2.7% was obtained from the China National Offshore Oil Corporation (CNOOC). The polymer microspheres were supramolecular microspheres that were synthesized in the laboratory. The surfactant was non-ionic with an effective content of 40%, as provided by CNOOC (Beijing, China).

The water used in the experiment was injection water from the Bohai oilfield; the results of the quality analysis are summarized in Table 2.

Table 2.

Water quality analysis.

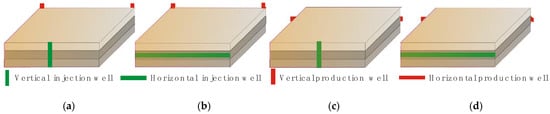

A 3D physical simulation model, which consisted of quartz sand cemented with epoxy resin, and had a height, width, and length of 6, 32, and 32 cm, respectively, was used in the oil displacement experiments [16,17,18,19]. This model was composed of three small sublayers with permeabilities of 8, 3, and 1 µm2. The thickness of each sublayer was 2.0 cm. Figure 1 shows the structure of the physical model.

Figure 1.

Illustrations of 3D simulation physical model: (a) vertical well pattern, (b) injection with horizontal well and production with vertical well, (c) injection with vertical well and production with horizontal well, and (d) horizontal well pattern.

2.2. Apparatus

The main equipment used for the experiment included an HJ-6 multi-head magnetic stirrer, HW-IIIA thermostat, HH-S2 temperature water bath, Brookfield viscometer (LVDV-II + PRO, New York, NY, USA), Hitachi scanning electron microscope (S-3400n, Tokyo, Japan), biological microscope (OPTEC BDS400, Suzhou, China), and spin drop interfacial tension meter (KINO TX-500, Boston, MA, USA).

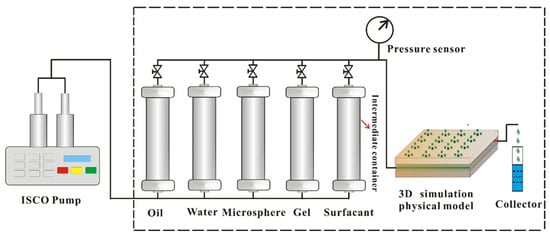

The equipment used for the oil displacement experiment included an ISCO pump, a pressure sensor, and middle containers. With the exception of the ISCO pump, which remained at room temperature, all of the equipment was placed in a thermostatically controlled oven at 60 °C. Figure 2 shows a diagram of the experimental process.

Figure 2.

Experimental process diagram.

2.3. Procedures

2.3.1. Polymer Gel Properties

The polymer gel was prepared using injection water, with polymer and Cr3+ crosslinker concentrations of 2000 and 3000 mg/L, respectively. The viscosity of the solution was measured regularly using an LVDV–II + Pro Brookfield viscometer at 60 °C, and its shear rate was 7.35 s−1. The polymer gel was frozen and sublimated at 70 °C, and the samples were photographed using gold. The microstructure was observed and typical areas were photographed using a scanning electron microscope.

2.3.2. Polymer Microsphere Properties

Polymer microspheres were prepared using injection water with a concentration of 3000 mg/L. Before each test, the microsphere solution was stirred for 3–5 min, a small amount of the sample was placed on a glass slide using a syringe, and the morphology and diameter of the microspheres were observed using a biological microscope. The samples were left at 60 °C for 1, 3, 5, or 7 days. The particle diameter was measured, and the expansion multiple was calculated according to the following formula [20]:

2.3.3. Surfactant Properties

A surfactant solution was prepared using injection water with a concentration of 3000 mg/L. The interfacial tension between the surfactant and crude oil was measured using a TX-500c spin drop interfacial tension meter at 60 °C, and the appearance of the emulsion was observed using a biological microscope.

2.3.4. Remaining Oil Saturation and Distribution Experiment

The experimental steps to evaluate the influence of the well pattern type on the remaining oil saturation and distribution are as follows:

- (1)

- The dried 3D physical simulation model was weighed before and after saturation with water at room temperature, and the pore volume (PV) and porosity were calculated according to the weight difference.

- (2)

- Each 3D physical simulation model was saturated with crude oil and aged at 60 °C for 24 h to prepare it for use. The oil saturation of each sample was then calculated.

- (3)

- Water was injected into the physical model, the produced liquid was collected until the water content reached 80%, and the resistivity values of the electrodes at various parts of the core were measured to calculate the oil saturation.

- (4)

- The polymer gel, polymer microspheres, and surfactant were injected into the physical model. The resistivity values of the electrodes at various parts of the core were measured, and the oil saturation was calculated.

- (5)

- Water was injected into the physical model, and the produced liquid was collected until the water content reached 98%. The resistivity values of the electrodes at various parts of the core were measured, and the oil saturation was calculated.

3. Experimental Results Analysis

3.1. Polymer Gel Properties

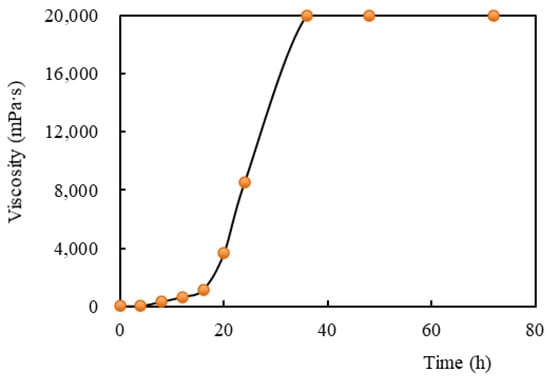

3.1.1. Viscosity and Gel Strength

The polymer gel was prepared using injection water with polymer and Cr3+ crosslinking agent concentrations of 2000 and 3000 mg/L, respectively. Figure 3 shows the relationship between the viscosity and time for the polymer gel. It can be seen that the viscosity of the polymer gel gradually increased over time. The viscosity began to increase after a reaction time of 4 h, which indicated that the crosslinking reaction between the polymer molecular chains and Cr3+ crosslinking agent occurred and formed a “regional” network of molecular aggregates. The viscosity of the polymer gel increased significantly from 44.1 to 342.3 mPa·s after 8 h, and the polymer gel could be completely gelled after 36 h, with the viscosity exceeding 20,000 mPa·s.

Figure 3.

The relationship between viscosity and time of polymer gel.

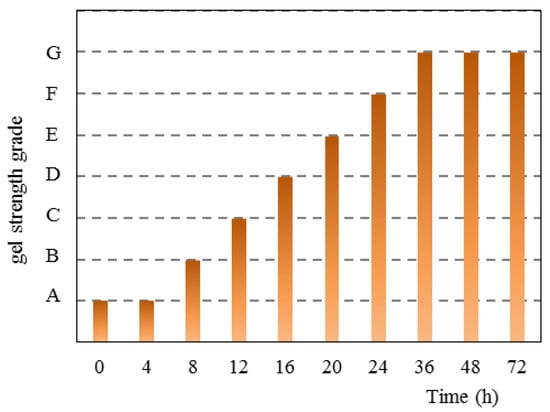

The gel strength grade of the polymer gel after gelation is presented in Table 3. Figure 4 shows the gel strengths. In addition, the gel strength gradually increased over time. At the initial stage of gelation, the gel strength was Grade A, in which there might be some non-adhesive, large gel blocks in the solution. During the 4 and 36 h periods, the gel strength changed from grade B to grade F. When the bottle was vertically inverted, the gel could not flow to the bottle cap. Thus, the polymer gel had an excellent gelling effect.

Table 3.

Gel strength grade standard.

Figure 4.

The relationship between gel strength and time of polymer gel.

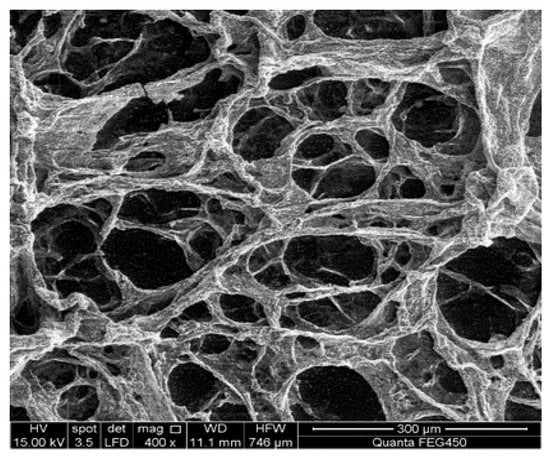

3.1.2. SEM

Figure 5 shows a scanning electron microscopy (SEM) image of the polymer gel. As shown in the figure, polymer gel molecules formed a spatial network structure in the solution. This was mainly due to the crosslinking reaction between the carboxyl groups on the polymer molecular chains and crosslinking agent molecules. After the reaction, molecular thread groups were formed, the molecular rigidity was enhanced, and the intermolecular aggregates were closer. The ability to wrap water molecules was enhanced, and the entire molecular structure had a “network” structure. The existence of these microstructures makes the moisture in the polymer gel system more firmly bound to the mesh. At the same time, it also enhanced the stability of water in the three-dimensional mesh of gelatin under the high-temperature environment, thus enhancing the stability of the polymer gel system.

Figure 5.

SEM image of polymer gel.

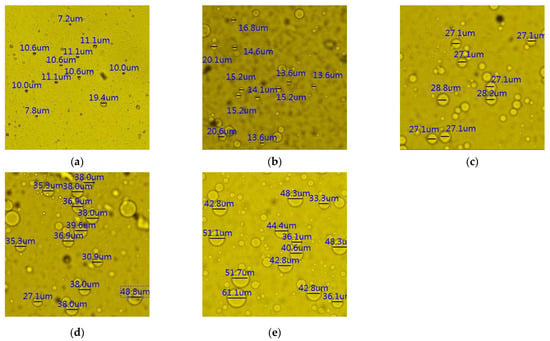

3.2. Polymer Microsphere Properties

Polymer microspheres were prepared using injection water with a concentration of 3000 mg/L. The appearance and particle sizes of the polymer microspheres are shown in Figure 6 and Table 4, wherein the hydration and expansion abilities of the polymer microspheres can be observed. The initial particle size distribution had a range of 7.2–11.1 μm. With an increase in the hydration time, the particle size of the polymer microspheres gradually increased. The particle size increased quickly in the initial stage and gradually in the later stage. The hydration expansion particle size range was 40.6–48.3 μm after 7 days, and the expansion multiple was 4.35–5.64. Thus, the microspheres showed an optimal hydration expansion capacity.

Figure 6.

Polymer microsphere appearance at different hydration times: (a) initial, (b) after 1 day, (c) after 3 days, (d) after 5 days, (e) after 7 days.

Table 4.

Relationship between polymer microsphere particle size and hydration time.

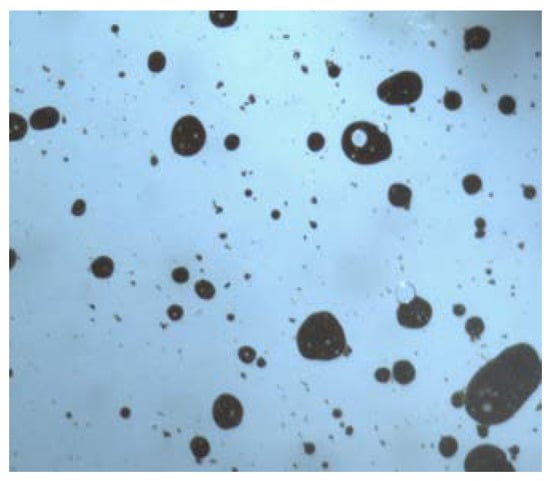

3.3. Surfactant Properties

The surfactant solution was prepared using injection water with a concentration of 3000 mg/L. Table 5 lists the interfacial tension values. The interfacial tension between the surfactant solution and crude oil gradually decreased with increasing test time. When the test time reached 80 min, the interfacial tension was almost stable, which was approximately 10−2 × 10−1 mN/m, and the final value fell in the range of approximately 5.08–5.11 × 10−1 mN/m. The surfactant effectively reduced the interfacial tension. The surfactant solution and crude oil were mixed at an oil-to-water ratio of 3:7, and then the emulsion was stirred at 7000 rpm for 15 min. The appearance of the emulsion was observed using a biological microscope. The distribution of oil and water is shown in Figure 7. Emulsification occurred when the surfactant solution was mixed with the crude oil, forming an O/W emulsion. Thus, it could reduce the viscosity of the crude oil and improve its fluidity.

Table 5.

Relationship between polymer microsphere particle size and hydration time.

Figure 7.

The appearance of the emulsion.

3.4. Remaining Oil Saturation and Distribution

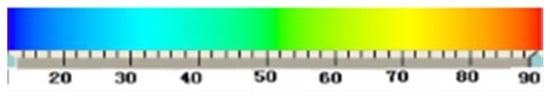

Cr3+ polymer gel was used as a large pore plugging agent, with a polymer concentration of 2000 mg/L and Cr3+ crosslinker concentration of 3000 mg/L. Polymer microspheres were used as a micro-profile control and flooding agent at a concentration of 3000 mg/L, and the surfactant was used as an oil displacement agent, with a concentration of 3000 mg/L. The combination of “profile control + profile control and flooding + oil displacement” was applied to the cores. The remaining oil saturation results for the different well pattern types are listed in Table 6, Table 7, Table 8 and Table 9. The relationship between the oil saturation value and color is shown in Figure 8. The remaining oil distributions of each layer after the first and final water flooding stages are shown in Figure 9, Figure 10, Figure 11, Figure 12, Figure 13, Figure 14, Figure 15 and Figure 16.

Table 6.

The remaining oil saturation (%) results of Figure 1.

Table 7.

The remaining oil saturation (%) results of Figure 2.

Table 8.

The remaining oil saturation (%) results of Figure 3.

Table 9.

The remaining oil saturation (%) results of Figure 4.

Figure 8.

The relationship between oil saturation value and color.

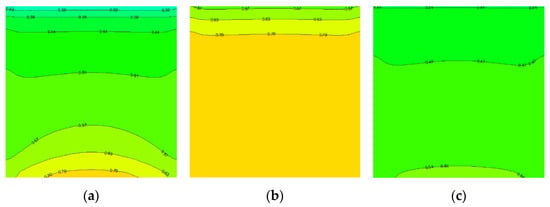

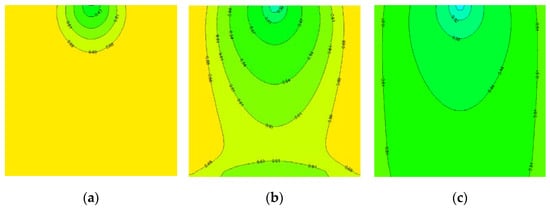

Figure 9.

Remaining oil distribution of each layer after water flooding stage of Figure 1: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

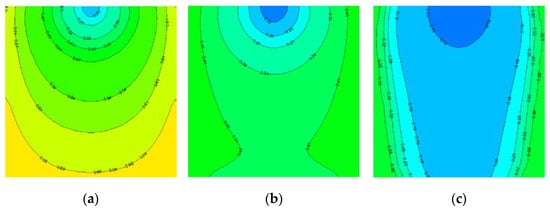

Figure 10.

Remaining oil distribution of each layer after subsequent water flooding stage of Figure 1: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

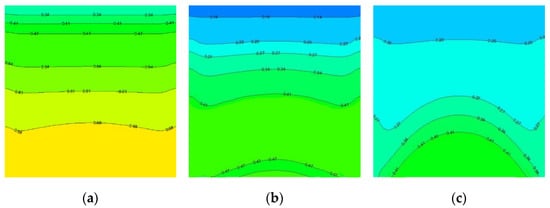

Figure 11.

Remaining oil distribution of each layer after water flooding stage of Figure 2: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

Figure 12.

Remaining oil distribution of each layer after subsequent water flooding stage of Figure 2: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

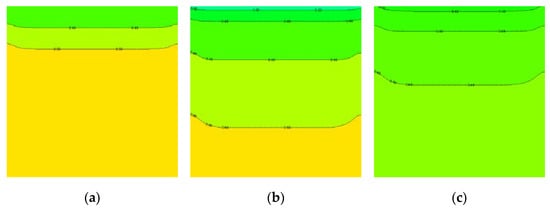

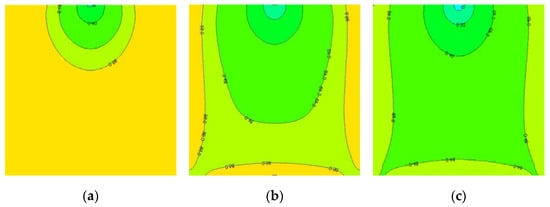

Figure 13.

Remaining oil distribution of each layer after water flooding stage of Figure 3: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

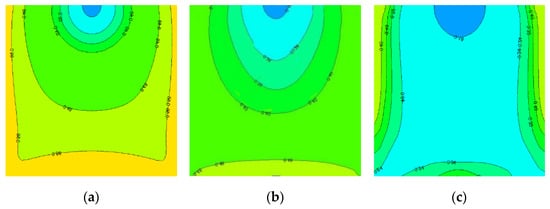

Figure 14.

Remaining oil distribution of each layer after subsequent water flooding stage of Figure 3: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

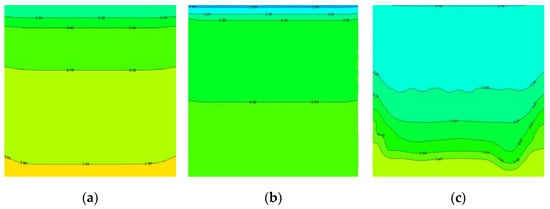

Figure 15.

Remaining oil distribution of each layer after water flooding stage of Figure 4: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

Figure 16.

Remaining oil distribution of each layer after subsequent water flooding stage of Figure 4: (a) low-permeability layer, (b) medium-permeability layer, (c) high-permeability layer.

In Figure 1, it can be seen from Table 6 and Figure 9 and Figure 10 that during the Cr3+ polymer gel injection stage, the retention of the profile control agent in the high-permeability layer increased with the injection amount, seepage resistance, and liquid absorption pressure difference in the medium- and low-permeability layers. Thus, the amount of liquid absorption increased and the sweep volume expanded. Owing to the above-mentioned reasons, the oil saturation of the high-permeability layer significantly decreased by 2.2%, whereas that of the medium- and low-permeability layers slightly changed by 0.4%. After the polymer microsphere injection, the remaining oil saturation was further reduced because of retention. In the surfactant injection stage, a large seepage resistance could not be produced because of the poor retention capacity, but the optimal oil washing effect reduced the oil saturation. Finally, the oil saturation of the high permeability layer decreased by 5.0%, whereas that of the medium permeability layer significantly decreased by 8.5%. In the surfactant flooding stage, the oil saturation of the low-permeability layer was significant (5.0%). The analysis showed that because the horizontal well had a large seepage area, the injection water advanced evenly. The polymer gel had an optimal plugging effect on the high-permeability layer, which caused the microspheres and surfactant to turn into medium- and low-permeability layers. This not only expanded the sweep volume but also improved the oil washing efficiency, and the remaining oil in the medium- and low-permeability layers was significantly reduced.

In Figure 2, it can be seen from Table 7 and Figure 11 and Figure 12, that after the water flooding stage, the oil saturation of the high-permeability layer decreased significantly, followed by the medium- and low-permeability layers. When the polymer gel was injected into the horizontal well, the liquids could advance evenly, the “fingering phenomenon” was not obvious, and the oil–water interface of each layer was almost linear and uniform. In the area near the injection well, the two wings of the water coning were relatively flat and steep when closer to the production well. The oil saturation of the high-permeability layer decreased by 2.2%, while that of the medium- and low-permeability layers decreased slightly. After the injection of the polymer microspheres, the oil saturation in the medium-permeability layer decreased significantly by 8.4%. Thus, the polymer gel effectively plugged the high-permeability layer near the injection well, which promoted subsequent liquid injection into the medium-permeability layer. This expanded the sweep volume and adjusted the heterogeneity between the medium- and low-permeability layers. The surfactant mainly entered the medium- and low-permeability layers, and the high oil-washing efficiency led to an obvious reduction in the oil saturation of the medium- and low-permeability layers by 2% and 5.2%, respectively. In the final water flooding stage, the injected water mainly entered the medium- and low-permeability layers and further reduced the remaining oil saturation in these two layers.

In Figure 3, as seen in Table 8 and Figure 13 and Figure 14, the oil saturation of the high-permeability layer decreased by 2.0% and 7.1% during the two stages of polymer gel and microsphere injection, respectively. The medium- and low-permeability layers were not evident. After the injection of the surfactant, the liquid flowed into the medium- and low-permeability layers, and their oil saturation decreased by 2.2 and 5.0%, respectively.

In Figure 4, as shown in Table 9 and Figure 15 and Figure 16, the injection water flowed along the main flow line, and the remaining oil saturation was low. In contrast, the remaining oil saturation was high on both sides of the line. Crude oil production in the high-permeability layer improved significantly, followed by that in the medium- and low-permeability layers. During the injection of the polymer gel, the oil saturation of the high-permeability layer significantly decreased by 2.2%. The main changes were concentrated near the injection wells. After the surfactant injection, the oil saturation of the high-, medium-, and low-permeability layers decreased by 5.1, 2.4, and 2.8%, respectively. In the final water flooding stage, the oil saturation of these three layers decreased further. The analysis showed that the polymer gel had an optimal plugging effect on the high-permeability layer near the injection well and promoted the entry of microspheres and surfactants into the medium- and low-permeability layers. This not only expanded the sweep volume but also improved the oil washing efficiency, resulting in a significant reduction in the oil remaining in these two layers.

In summary, compared with Figure 2, the remaining oil saturation after water flooding was lower in Figure 1, Figure 3, and Figure 4. Figure 2 used a horizontal well pattern, and the injection and production wells had the largest seepage areas. The effect of expanding the sweep volume was appropriate, and the remaining oil saturation at each stage was low. In Figure 1, the injection and production wells were horizontal and vertical, respectively. The seepage area and expanding sweep volume at the injection end were large, but it was difficult to flood the area near the oil well, and the oil saturation was higher than that in Figure 2. In Figure 3, the injection and production wells were vertical and horizontal, respectively. It was difficult to flood near the vertical well, and the amount of remaining oil was more than that when using Figure 2. Figure 4 adopted the well pattern of one vertical injection well and two vertical oil wells. The affected area at the injection end was small, and the seepage resistance was large. In addition, it was difficult to flood areas around the injection and two oil wells. Therefore, the remaining oil saturation at each stage was higher than that with the other figures. The remaining oil saturation exhibited different trends at different chemical injection stages.

4. Conclusions

In view of the development characteristics and existing problems of strong injection and production in Q oilfield, it is necessary to develop a channeling sealing, profile control and flooding, and oil displacement technology system more suitable for the current characteristics of Q oilfield, and form an integrated technology and method of plugging, profile control, and flooding suitable for Q oilfield, so as to provide technical support for Q oilfield to control the natural decline and stabilize basic production. In this study, the following conclusions were obtained:

- (1)

- When the polymer concentration was 3000 mg/L, the polymer gel was formed by a reaction with the Cr3+ crosslinking agent, the final gelling viscosity was greater than 20,000 mPa·s, and the gel strength grade reached grade G.

- (2)

- The polymer microspheres had an initial particle size distribution in the range of 7.2–11.1 μm, the hydration expansion particle sizes were in the range of 40.6–48.3 μm after 7 days, and the expansion multiple was 4.35–5.64.

- (3)

- The interfacial tension between the surfactant and crude oil was approximately 5.08 –5.11 × 10−1 mN/m, and emulsification occurred after the surfactant solution was mixed with crude oil, forming an O/W emulsion.

- (4)

- Polymer gel had a good plugging effect on the highly permeable layer; the polymer gel can drive the polymer microspheres and surfactant after plugging into the medium- and low-permeability layers.

- (5)

- In the 3D physical simulation models, compared with the vertical and horizontal–vertical combined well patterns, the reduction in the remaining oil saturation after water flooding and different technologies was the largest when using the horizontal well pattern.

- (6)

- The monitoring results for the remaining oil distribution showed that the remaining oil after water flooding was mainly distributed in the medium- and low-permeability layers longitudinally and two wings away from the mainstream line on the plane.

Author Contributions

Conceptualization, X.L.; methodology, X.W.; software, K.Y.; validation, H.F.; formal analysis, K.X.; investigation, M.H.; resources, H.F.; data curation, K.X.; writing—original draft preparation, W.C.; writing—review and editing, W.C.; visualization, M.H.; supervision, X.W.; project administration, X.L.; funding acquisition, H.F. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the fifth batch of the open fund project of the State Key Laboratory of Offshore Oil Exploration (CCL2021RCPS0510KQN), Guiding Innovation Fund of Northeast Petroleum University (2021YDL-07), and Start-Up Funding Project for Talent Introduction and Scientific Research of Northeast Petroleum University (13051202007).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Gan, L.; Su, J.; Xie, Y.; Li, C.; He, K.; Lai, Y. Interlayers of meandering river reservoir: A case from Qinhuangdao 32-6 oilfield. Lithol. Reserv. 2017, 29, 128–134. [Google Scholar] [CrossRef]

- Hu, G.; Wang, H.; Fan, T.; Gao, Y.; Chen, F.; Xiao, D.; Zhang, X. Analysis of fluvial compound sand-body architecturehierarchy in offshore oil field. J. Palaeoge 2021, 23, 810–823. [Google Scholar] [CrossRef]

- Hu, G.; Xiao, D.; Fan, T.; Song, L.; Chen, F.; Jing, Y.; Gao, Y. New theory and method of fluvial reservoir architecture study: Concepts, contents and characterization of offshore oilfieldfluvial compound sand-body architecture. J. Palaeoge 2019, 21, 143–159. [Google Scholar] [CrossRef]

- Rovere, M.; Pellegrini, C.; Chiggiato, J.; Campiani, E.; Trincardi, F. Impact of dense bottom water on a continental shelf: An example from the sw adriatic margin. Mar. Geol. 2018, 408, 123–143. [Google Scholar] [CrossRef]

- Wang, T.; Li, H.X.; Li, L.; Chi, H.M.; Zhang, W.Q. Visualization study on the bottom-water coning in large-scale cavity of fracture-cavernous reservoirs. J. Eng. Thermophys. 2012, 33, 989–992. [Google Scholar]

- Hu, G.; Fan, T.; Chen, F.; Jing, Y.; Song, L.; Liang, X.; Xiao, D. Theory of composite sand body architecture and its applicationto oilfield development. Oil Gas Geol. 2018, 39, 1–10. [Google Scholar] [CrossRef]

- Shi, L.; Yu, G.; Yuan, F.; Xue, Y. Experimental method and its application on threshold pressure gradient foroffshore sandstone in heavy oil reservoir: A case study of QHD32-6 oilfield. Pet. Geo Rec. Effi. 2014, 21, 82–85. [Google Scholar] [CrossRef]

- Zhang, G.; Shi, L.; Yu, G.; Lu, C.; Wang, Q.; Zhang, W. Analysis and evaluation on recovery ratio sensibility of the offishoresandstone of heavy oil reservoir-case of QHD32-6 oilfield. Pet. Geo Rec. Effi. 2012, 19, 90–93. [Google Scholar] [CrossRef]

- Zhang, J.; An, G.; Geng, Z.; Zhang, W.; Pan, C. Discussion on high efficient water flooding development mode of the typical continental sedimentary oil-fields in China offshore. China Offshore Oil Gas 2017, 29, 70–77. [Google Scholar] [CrossRef]

- Babu, N.; Lin, P.; Abutaqiya, M.; Sisco, C.; Wang, J.; Vargas, F. Systematic investigation of asphaltene deposition in wellbore and near-wellbore region of a deepwater oil reservoir under gas injection. part 2: Computational fluid dynamics modeling of asphaltene deposition. Energy Fuels 2018, 33, 3645–3661. [Google Scholar] [CrossRef]

- Kumar, M.; Hoang, V.; Satik, C.; Rojas, D. High mobility ratio water flood performance prediction: Challenges and new insights. SPE Reserv. Eval. Eng. 2008, 11, 186–196. [Google Scholar] [CrossRef]

- Haghshenas, M.; Sepehrnoori, K.; Bryant, S.; Farhadinia, M. Modeling and Simulation of Nitrate Injection for Reservoir-Souring Remediation. SPE J. 2012, 17, 817–827. [Google Scholar] [CrossRef]

- Ali, M.; Ali, M.; Riyaz, K.; Mohammad, H. Pore-Scale Monitoring of Wettability Alteration by Silica Nanoparticles During Polymer Flooding to Heavy Oil in a Five-Spot Glass Micromode. Transp. Porous Med. 2011, 87, 653–664. [Google Scholar] [CrossRef]

- Son, H.; Kim, H.; Lee, G.; Kim, J.; Sung, W. Enhanced oil recovery using nanoparticle-stabilized oil/water emulsions. Korean J. Chem. Eng. 2014, 31, 338–342. [Google Scholar] [CrossRef]

- Forsythe, J.; Kenyon-Roberts, S.; O’Donnell, M.; Betancourt, S.; Masurek, N.; Gisolf, A.; Bennett, B.; Nelson, R.; Canas, J.; Reddy, C.; et al. Biodegradation and water washing in a spill-fill sequence of oilfields. Fuel 2019, 23, 707–719. [Google Scholar] [CrossRef]

- Cao, W.; Xie, K.; Lu, X.; Liu, Y.; Zhang, Y. Effect of Profile-Control Oil-Displacement Agent on Increasing Oil Recovery and Its Mechanism. Fuel 2019, 237, 1151–1160. [Google Scholar] [CrossRef]

- Xie, K.; Cao, B.; Lu, X.; Zhang, Y.; Li, Q.; Song, K.; Liu, J.; Wang, W.; Lv, J.; Na, R. Matching Between the Diameter of the Aggregates of Hydrophobically Associating Polymers and Reservoir Pore-Throat Size during Polymer Flooding in an Offshore Oilfield. J. Pet. Sci. Eng. 2019, 177, 558–569. [Google Scholar] [CrossRef]

- Xie, K.; Lu, X.; Li, Q.; Jiang, W.; Yu, Q. Analysis of Reservoir Applicability of Hydrophobically Associating Polymer. SPE J. 2016, 21, 1–9. [Google Scholar] [CrossRef]

- Cao, B.; Lu, X.; Xie, K.; Ding, H.; Xiao, Z.; Cao, W.; Zhou, Y.; He, X.; Li, Y.; Li, H. The pore-scale mechanisms of surfactant-assisted spontaneous and forced imbibition in water-wet tight oil reservoirs. J. Pet. Sci. Eng. 2022, 213, 110371. [Google Scholar] [CrossRef]

- Zhu, D.; Hou, J.; Chen, Y.; Zhao, S.; Bai, B. In Situ Surface Decorated Polymer Microsphere Technology for Enhanced Oil Recovery in High-Temperature Petroleum Reservoirs. Energy Fuels 2018, 32, 3312–3321. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).