Effects of Polyoxymethylene Dimethyl Ethers Addition in Diesel on Real Driving Emission and Fuel Consumption Characteristics of a CHINA VI Heavy-Duty Vehicle

Abstract

:1. Introduction

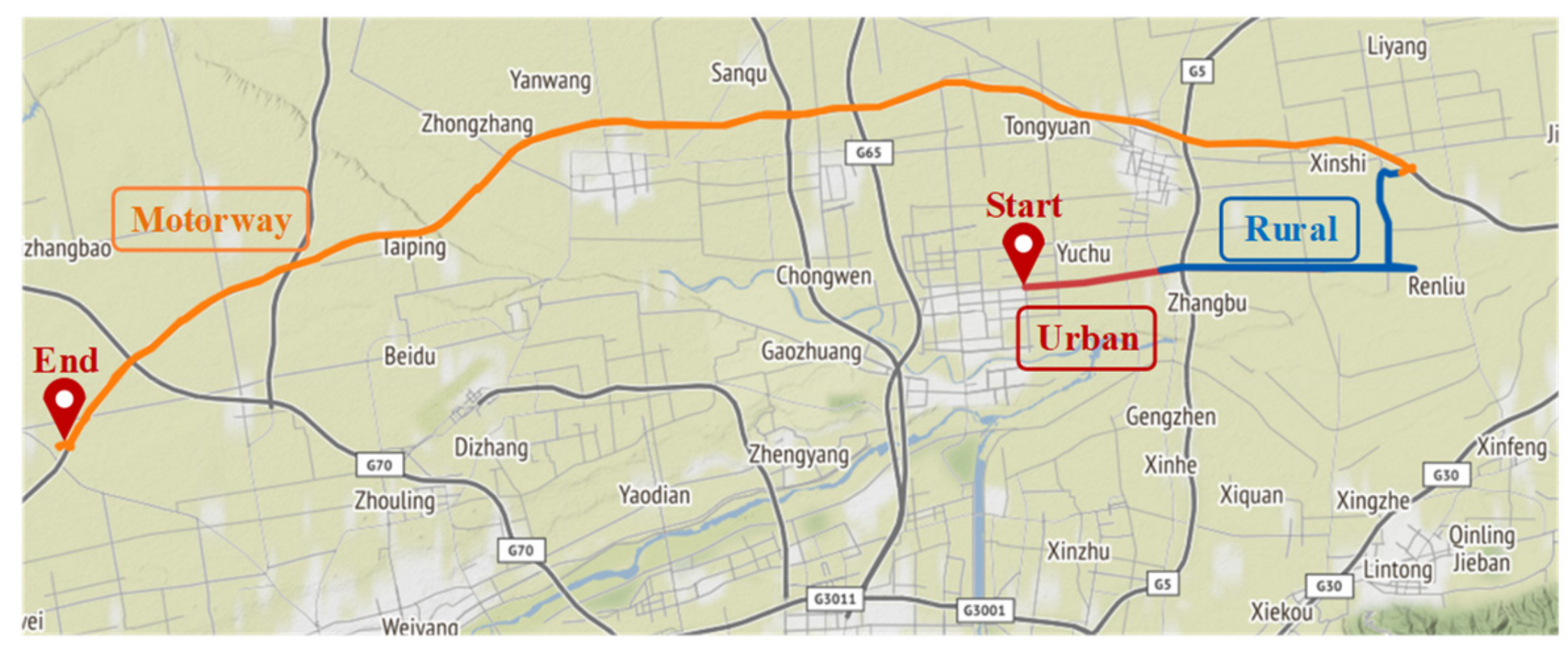

2. Experimental Setup and Data Processing

2.1. Test Fuels

2.2. Test Engine and Vehicle

2.3. Test Process

2.4. Introduction to PEMS

2.5. Data Processing

2.6. Establishment of Transient Engine Maps

2.7. Evaluation of Engine Emission and Fuel Economy

3. Results

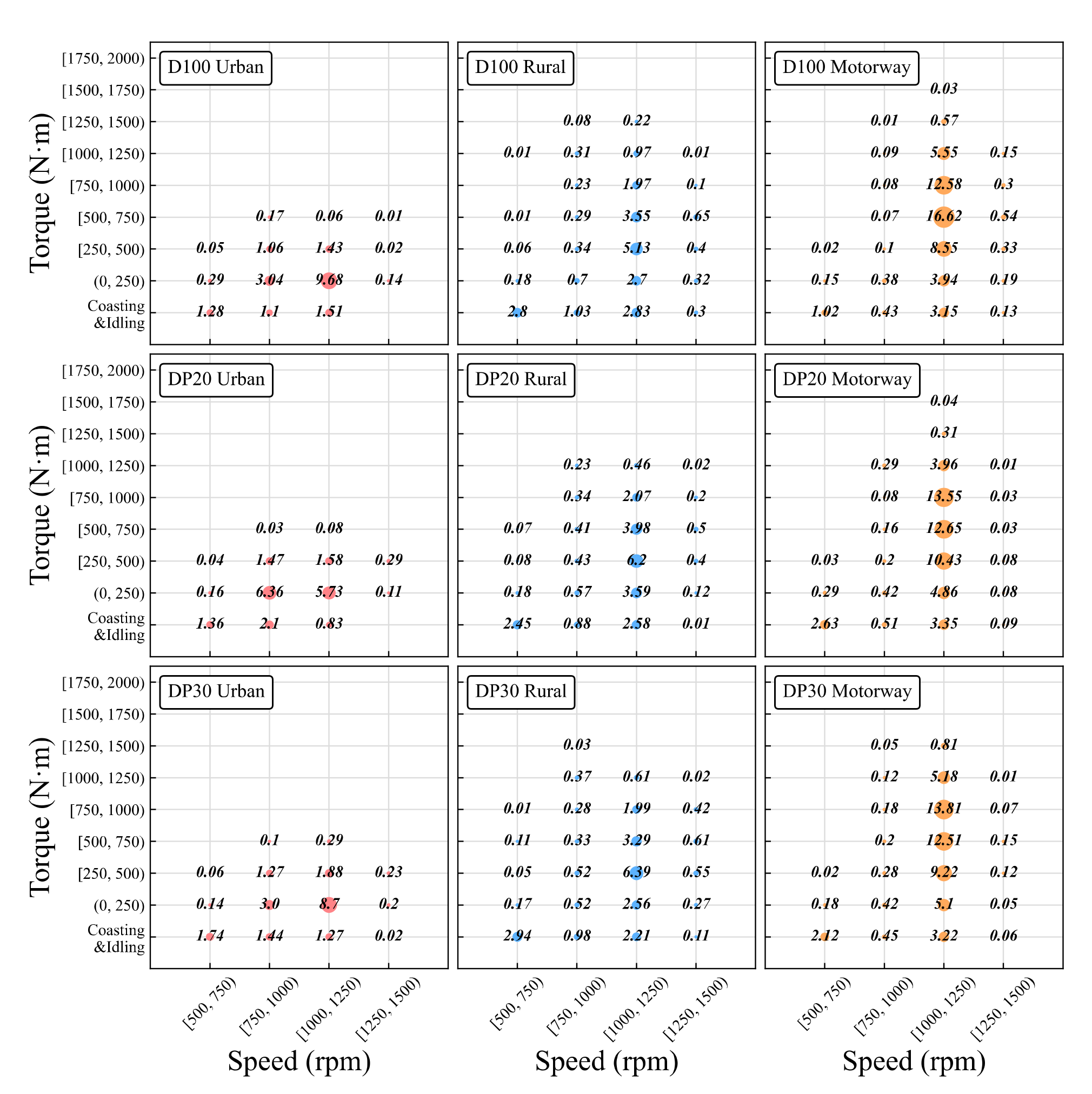

3.1. Engine Operation Condition Statistics

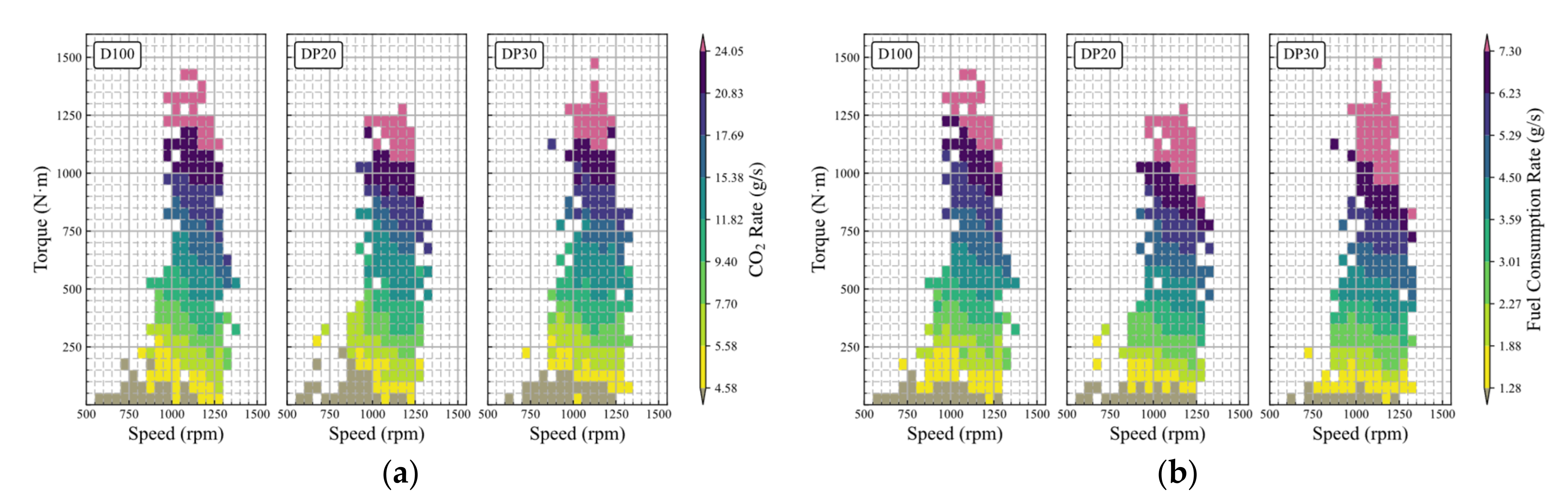

3.2. CO2 Emission and Fuel Consumption Rates

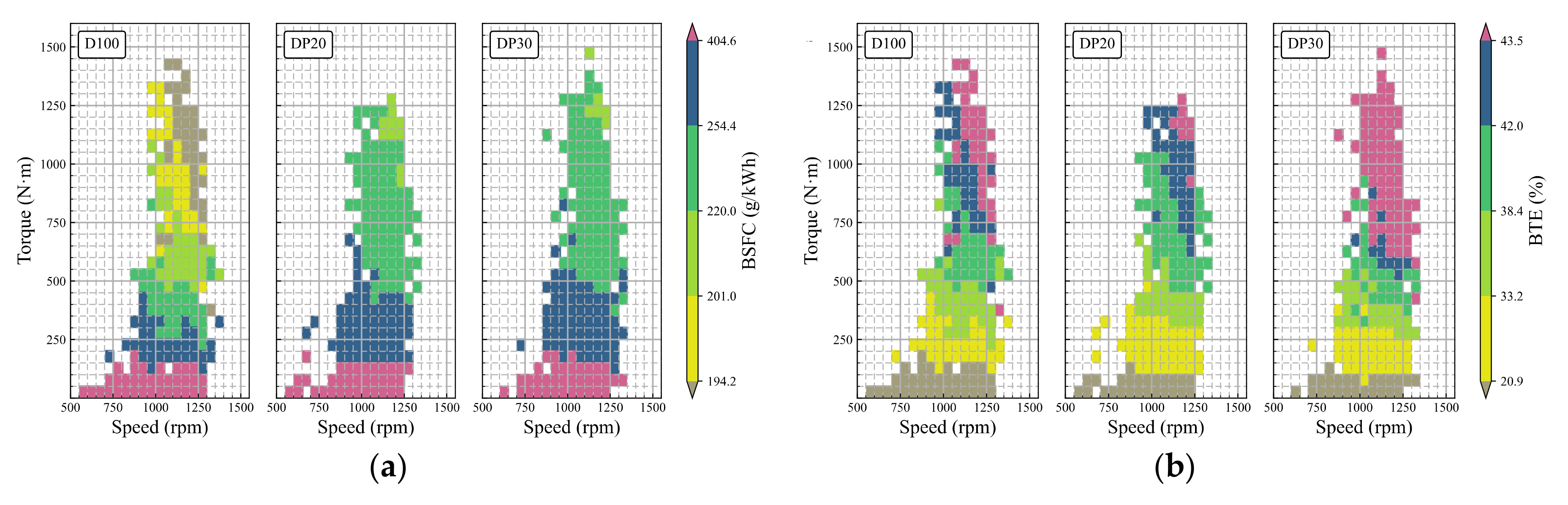

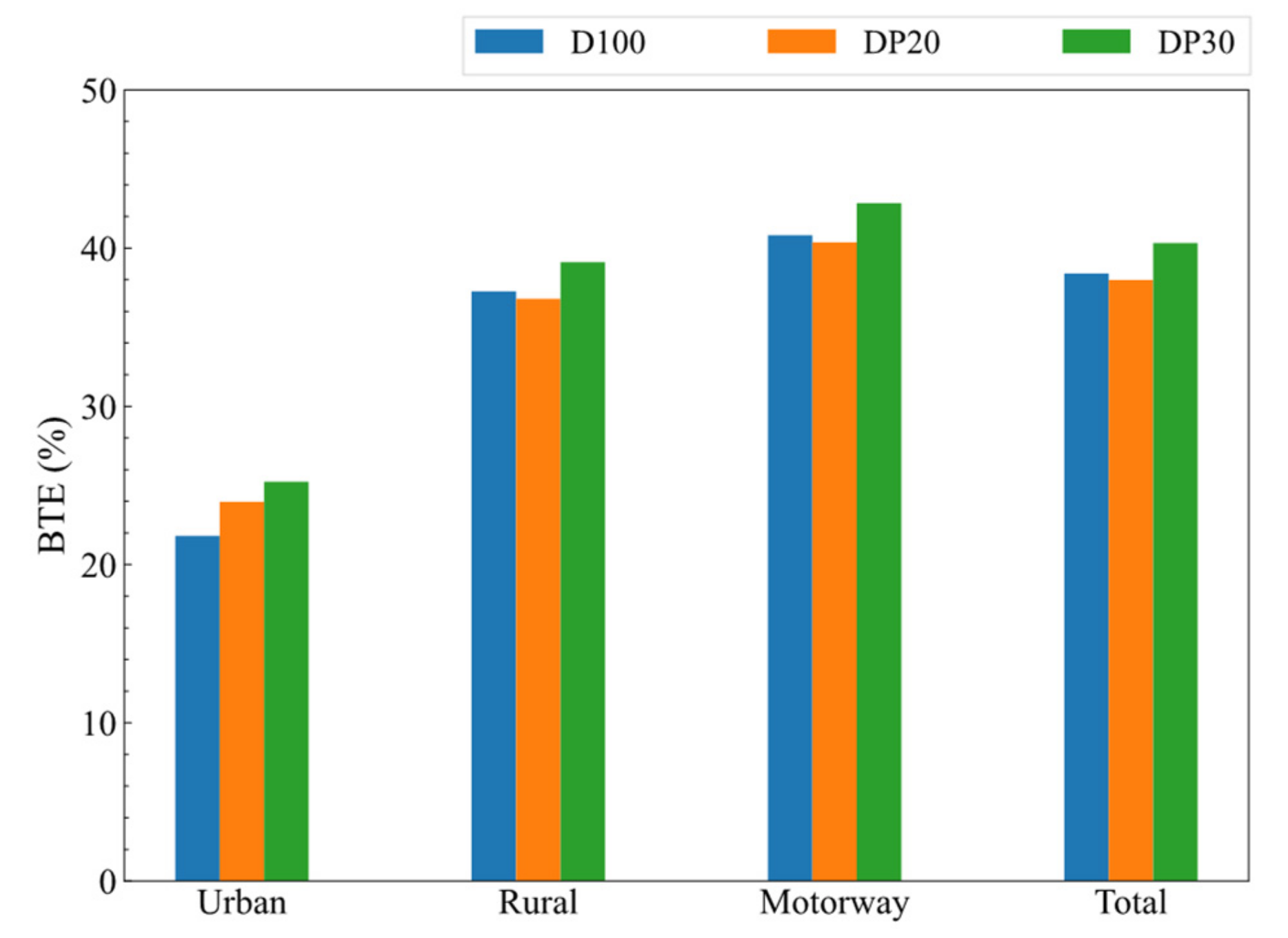

3.3. Characteristics of BSFC and BTE

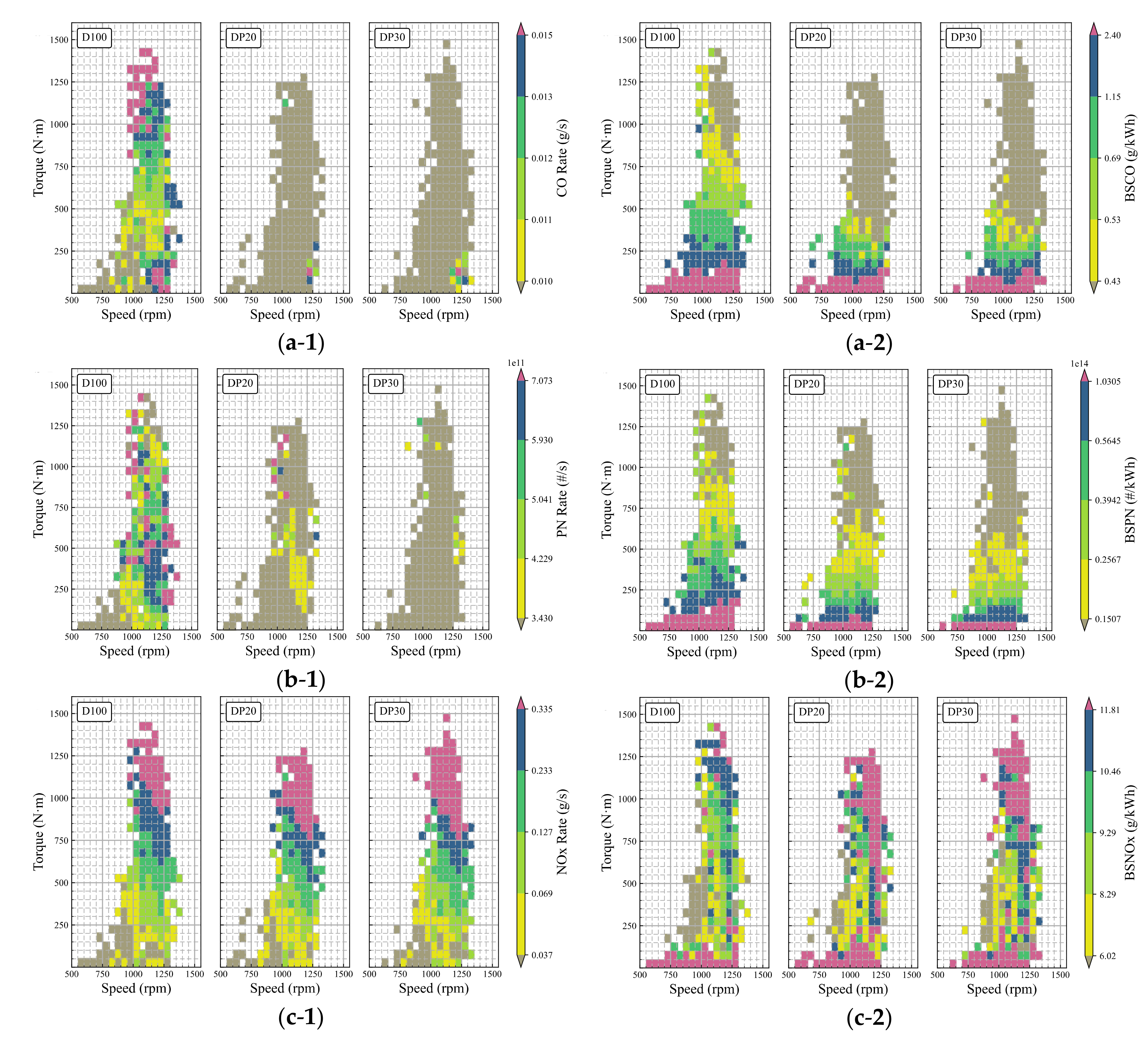

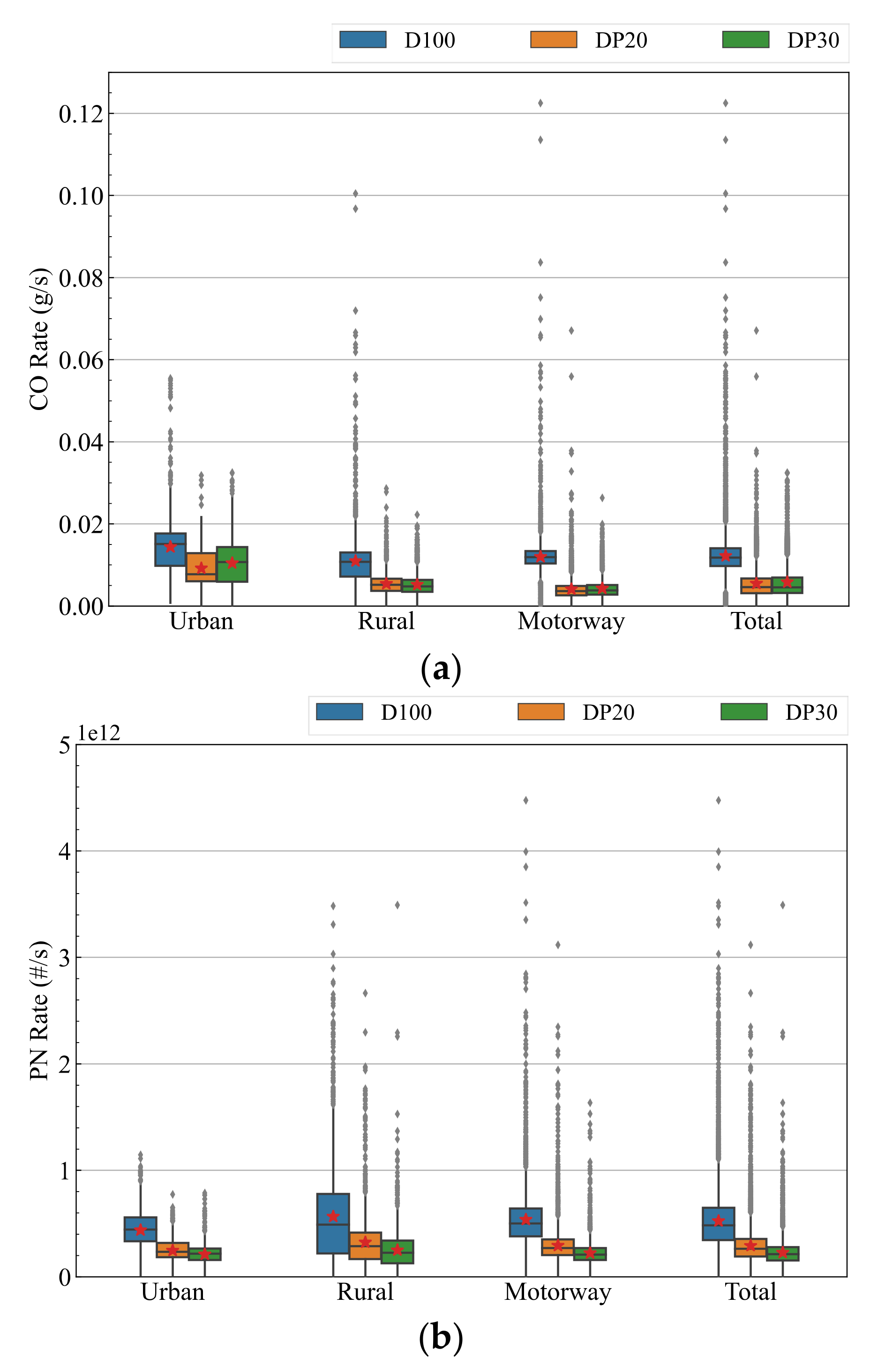

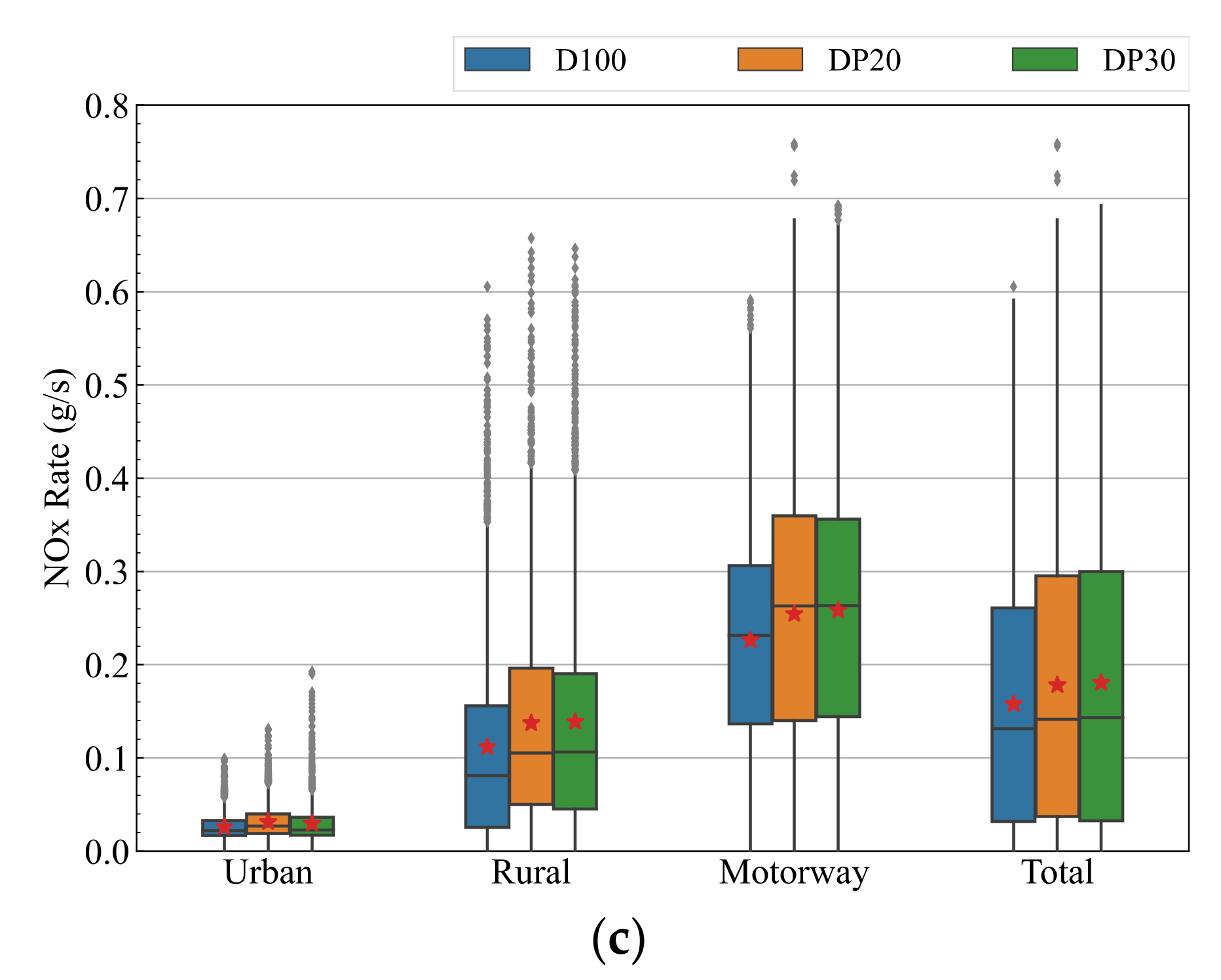

3.4. Engine CO, PN and NOx Emission Characteristics

4. Discussion

5. Conclusions

- (1)

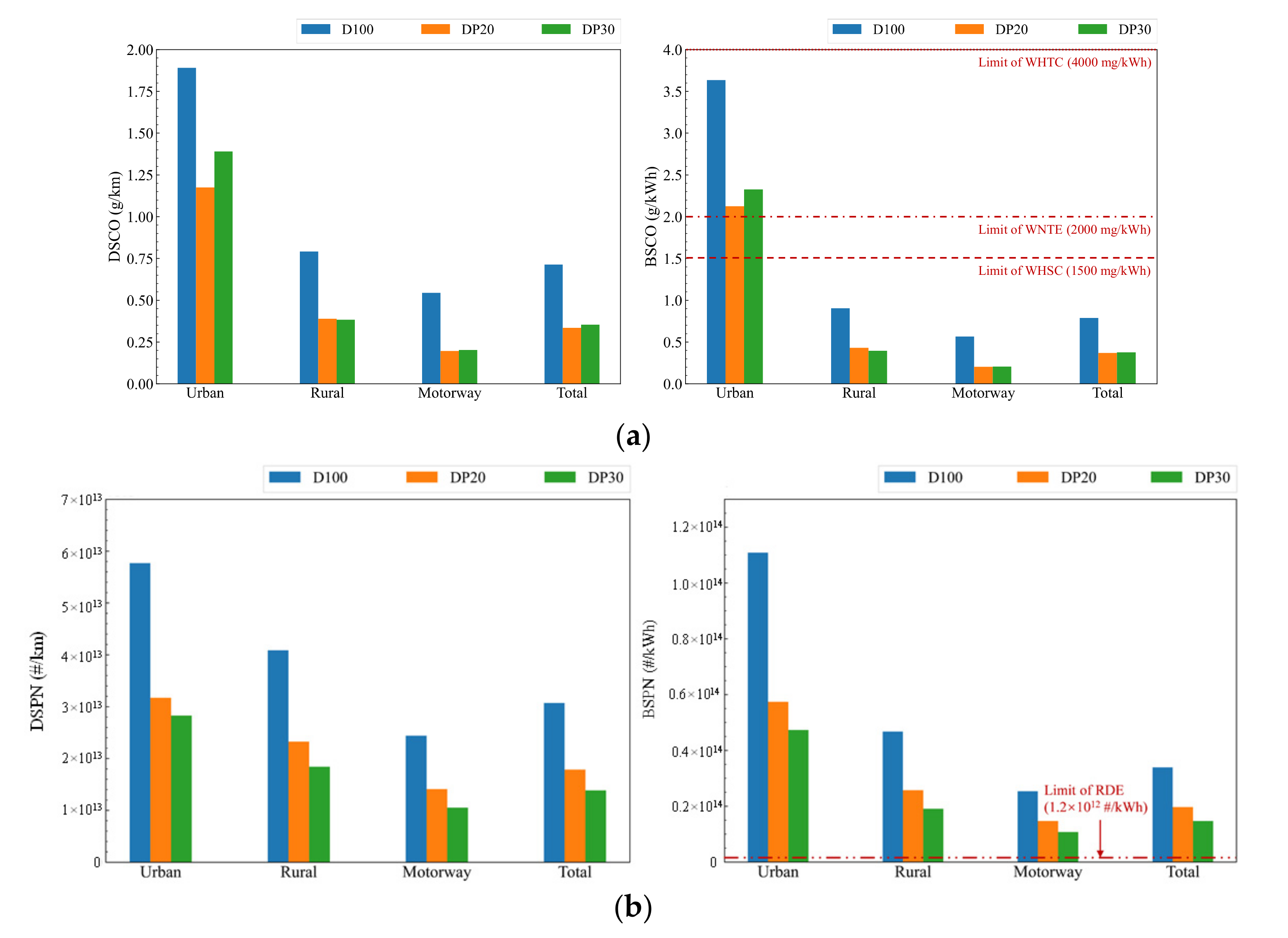

- The addition of PODE had a fairly obvious inhibitory effect on the transient CO and PN emissions in a considerable range of operating conditions. However, even if PODE/diesel blends were used, the low load condition (0–250 N·m) was still the area with the highest BSCO and BSPN emissions.

- (2)

- Under real driving conditions, the usage of PODE/diesel blends can increase BSNOx emissions in a wide range of operating conditions, which makes the high load condition (>750 N·m) high emission areas of BSNOx.

- (3)

- Regardless of the fuel type, the CO and PN emissions in the urban section were the highest. From the perspective of the entire test route, the addition of PODE can reduce the emissions of CO and PN by about 50%. On the contrary, the NOx emissions were the highest in the motorway section. The usage of blended fuels can increase the overall NOx emissions by no more than 20%.

- (4)

- The addition of PODE can lead to an increase in fuel consumption due to its lower LHV. The averaged BTE of the whole RDE test, however, reached 40.3%, which was better than 38.4% of the pure diesel operation when fueled with the DP30.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| BTE | brake thermal efficiency |

| BS ** | brake specific ** (g/kWh or #/kWh) |

| CO | carbon monoxide |

| CO2 | carbon dioxide |

| CN | cetane number |

| CAN | controller area network |

| DOC | diesel oxidation catalyst |

| DPF | diesel particulate filter |

| DS ** | distance specific ** (g/km or #/km) |

| ECU | engine control units |

| EFM | exhaust flow measurement unit |

| EGR | exhaust gas recirculation |

| GPS | global position system |

| HDV | heavy-duty vehicles |

| Hi-SCR | high-efficiency selective catalytic reduction |

| LHV | lower heating value (MJ/kg) |

| NOx | nitrogen oxides |

| OBD | on-board diagnostic |

| PM | particulate matter |

| PN | particle number |

| PODE | polyoxymethylene dimethyl ethers |

| PEMS | portable emission measurement system |

| RDE | real driving emission |

| THC | total hydrocarbon |

References

- Kirsch, S. Running out? Rethinking resource depletion. Extr. Ind. Soc. 2020, 7, 838–840. [Google Scholar] [CrossRef]

- Gao, W.; Liu, J.; Sun, P.; Wang, T.; Chen, L.; Wang, B.; Kang, T.; Liu, S.; Shi, K. Numerical simulation on NO and soot formation process of a diesel engine with polyoxymethylene dimethyl ethers-diesel blend fuel. Energy Sources Part A Recovery Util. Environ. Eff. 2020, 1–16. [Google Scholar] [CrossRef]

- IARC Working Group on the Evaluation of Carcinogenic Risks to Humans. Diesel and Gasoline Engine Exhausts and Some Nitroarenes. Iarc Monographs on the Evaluation of Carcinogenic Risks to Humans. IARC Monogr. Eval. Carcinog. Risks Hum. 2014, 105, 9. [Google Scholar]

- Burnett, R.; Chen, H.; Szyszkowicz, M.; Fann, N.; Hubbell, B.; Pope, C.A.; Apte, J.S.; Brauer, M.; Cohen, A.; Weichenthal, S.; et al. Global estimates of mortality associated with long-term exposure to outdoor fine particulate matter. Proc. Natl. Acad. Sci. USA 2018, 115, 9592–9597. [Google Scholar] [CrossRef] [Green Version]

- Anenberg, S.C.; Henze, D.K.; Tinney, V.; Kinney, P.L.; Raich, W.; Fann, N.; Malley, C.S.; Roman, H.; Lamsal, L.; Duncan, B.; et al. Estimates of the Global Burden of Ambient PM2.5, Ozone, and NO2 on Asthma Incidence and Emergency Room Visits. Environ. Health Perspect. 2018, 126, 107004. [Google Scholar] [CrossRef] [Green Version]

- Pelletier, S.; Jabali, O.; Laporte, G. The electric vehicle routing problem with energy consumption uncertainty. Transp. Res. Part B Methodol. 2019, 126, 225–255. [Google Scholar] [CrossRef]

- Barbosa, F.C. Heavy Duty Diesel Emission Standards Regulation Evolution Review—Current Outcomes and Future Perspectives; SAE International: Warrendale, PA, USA, 2020. [Google Scholar] [CrossRef]

- Ziegler, M. The combustion engine has not by any means reached the end of the line. MTZ Worldw. 2021, 82, 26–29. [Google Scholar] [CrossRef]

- Xiao, H.; Guo, F.; Li, S.; Wang, R.; Yang, X. Combustion performance and emission characteristics of a diesel engine burning biodiesel blended with n-butanol. Fuel 2019, 258, 115887. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, Y.; Zhang, X.; Jin, C.; Zheng, Z. Effect of diesel/PODE/ethanol blends on combustion and emissions of a heavy duty diesel engine. Fuel 2019, 257, 116064. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Li, Y.; Zheng, Y.; He, T.; Wang, J. Recent progress in the application in compression ignition engines and the synthesis technologies of polyoxymethylene dimethyl ethers. Appl. Energy 2019, 233–234, 599–611. [Google Scholar] [CrossRef]

- Frei, M.S.; Capdevila-Cortada, M.; García-Muelas, R.; Mondelli, C.; López, N.; Stewart, J.A.; Curulla Ferré, D.; Pérez-Ramírez, J. Mechanism and microkinetics of methanol synthesis via CO2 hydrogenation on indium oxide. J. Catal. 2018, 361, 313–321. [Google Scholar]

- Li, D.; Gao, Y.; Liu, S.; Ma, Z.; Wei, Y. Effect of polyoxymethylene dimethyl ethers addition on spray and atomization characteristics using a common rail diesel injection system. Fuel 2016, 186, 235–247. [Google Scholar] [CrossRef]

- Liu, J.; Sun, P.; Huang, H.; Meng, J.; Yao, X. Experimental investigation on performance, combustion and emission characteristics of a common-rail diesel engine fueled with polyoxymethylene dimethyl ethers-diesel blends. Appl. Energy 2017, 202, 527–536. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Li, Y.; Zheng, Z.; Xue, Z.; Shang, H.; Yao, M. Effects of diesel/PODE (polyoxymethylene dimethyl ethers) blends on combustion and emission characteristics in a heavy duty diesel engine. Fuel 2016, 177, 206–216. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Wang, J.; He, X.; Zheng, Y.; Tang, Q.; Wang, J. Performance, combustion and emission characteristics of a diesel engine fueled with polyoxymethylene dimethyl ethers (PODE3-4)/diesel blends. Energy 2015, 88, 793–800. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Zhang, J.; Wang, J.; Shuai, S. Study on combustion and emission characteristics of Polyoxymethylene Dimethyl Ethers/diesel blends in light-duty and heavy-duty diesel engines. Appl. Energy 2017, 185, 1393–1402. [Google Scholar] [CrossRef]

- Chen, H.; Su, X.; Li, J.; Zhong, X. Effects of gasoline and polyoxymethylene dimethyl ethers blending in diesel on the combustion and emission of a common rail diesel engine. Energy 2019, 171, 981–999. [Google Scholar] [CrossRef]

- Chen, H.; Huang, R.; Huang, H.; Pan, M.; Teng, W. Potential improvement in particulate matter’s emissions reduction from diesel engine by addition of PODE and injection parameters. Appl. Therm. Eng. 2019, 150, 591–604. [Google Scholar] [CrossRef]

- Rosero, F.; Fonseca, N.; López, J.-M.; Casanova, J. Real-world fuel efficiency and emissions from an urban diesel bus engine under transient operating conditions. Appl. Energy 2020, 261, 114442. [Google Scholar] [CrossRef]

- Badshah, H.; Posada, F.; Muncrief, R. Current State NOₓ Emissions from In-Use Heavy-Duty Diesel Vehicles in the United States; International Council on Clean Transportation (ICCT): Washington, DC, USA, 2019. [Google Scholar]

- Mendoza-Villafuerte, P.; Suarez-Bertoa, R.; Giechaskiel, B.; Riccobono, F.; Bulgheroni, C.; Astorga, C.; Perujo, A. NOx, NH3, N2O and PN real driving emissions from a Euro VI heavy-duty vehicle. Impact of regulatory on-road test conditions on emissions. Sci. Total Environ. 2017, 609, 546–555. [Google Scholar] [CrossRef]

- Grigoratos, T.; Fontaras, G.; Giechaskiel, B.; Zacharof, N. Real world emissions performance of heavy-duty Euro VI diesel vehicles. Atmos. Environ. 2019, 201, 348–359. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment. Limits and Measurement Methods for Emissions from Diesel Fueled Heavy-Duty Vehicles (CHINA VI); Ministry of Ecology and Environment: Beijing, China, 2018; Volume GB17691-2018.

- Söderena, P.; Nylund, N.O.; Pettinen, R.; Mäkinen, R. Real Driving NOx Emissions from Euro VI Diesel Buses. SAE Tech. Pap. Ser. 2018, 2018. [Google Scholar] [CrossRef]

- Yu, Q.; Yang, Y.; Xiong, X.; Sun, S.; Liu, Y.; Wang, Y. Assessing the impact of multi-dimensional driving behaviors on link-level emissions based on a Portable Emission Measurement System (PEMS). Atmos. Pollut. Res. 2021, 12, 414–424. [Google Scholar] [CrossRef]

- Rosero, F.; Fonseca, N.; López, J.-M.; Casanova, J. Effects of passenger load, road grade, and congestion level on real-world fuel consumption and emissions from compressed natural gas and diesel urban buses. Appl. Energy 2021, 282, 116195. [Google Scholar] [CrossRef]

- Bishop, J.D.K.; Stettler, M.E.J.; Molden, N.; Boies, A.M. Engine maps of fuel use and emissions from transient driving cycles. Appl. Energy 2016, 183, 202–217. [Google Scholar] [CrossRef] [Green Version]

- Seo, J.; Park, J.; Park, J.; Park, S. Emission factor development for light-duty vehicles based on real-world emissions using emission map-based simulation. Environ. Pollut. 2021, 270, 116081. [Google Scholar] [CrossRef]

- McCaffery, C.; Zhu, H.; Li, C.; Durbin, T.D.; Johnson, K.C.; Jung, H.; Brezny, R.; Geller, M.; Karavalakis, G. On-road gaseous and particulate emissions from GDI vehicles with and without gasoline particulate filters (GPFs) using portable emissions measurement systems (PEMS). Sci. Total Environ. 2020, 710, 136366. [Google Scholar] [CrossRef] [Green Version]

- Giechaskiel, B.; Clairotte, M.; Valverde-Morales, V.; Bonnel, P.; Kregar, Z.; Franco, V.; Dilara, P. Framework for the assessment of PEMS (Portable Emissions Measurement Systems) uncertainty. Environ. Res. 2018, 166, 251–260. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Valverde, V.; Clairotte, M. Real Driving Emissions (RDE): 2020 Assessment of Portable Emissions Measurement Systems (PEMS) Measurement Uncertainty; Luxembourg Publications Office of the European Union: Luxembourg, 2021. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Lähde, T.; Melas, A.D.; Valverde, V.; Clairotte, M. Uncertainty of laboratory and portable solid particle number systems for regulatory measurements of vehicle emissions. Environ. Res. 2021, 197, 111068. [Google Scholar] [CrossRef]

- Albin Rajasingham, T. SI and CI Engine Control Architectures. In Nonlinear Model Predictive Control of Combustion Engines: From Fundamentals to Applications; Springer International Publishing: Cham, Switzerland, 2021; pp. 175–194. [Google Scholar] [CrossRef]

- Giechaskiel, B.; Bonnel, P.; Perujo, A.; Dilara, P. Solid Particle Number (SPN) Portable Emissions Measurement Systems (PEMS) in the European Legislation: A Review. Int. J. Environ. Res. Public Health 2019, 16, 4819. [Google Scholar] [CrossRef] [Green Version]

- Pavlovic, J.; Fontaras, G.; Broekaert, S.; Ciuffo, B.; Ktistakis, M.A.; Grigoratos, T. How accurately can we measure vehicle fuel consumption in real world operation? Transp. Res. Part D Transp. Environ. 2021, 90, 102666. [Google Scholar] [CrossRef]

- McGill, R.; Tukey, J.W.; Larsen, W.A. Variations of Box Plots. Am. Stat. 1978, 32, 12–16. [Google Scholar] [CrossRef]

- Xie, M.; Ma, Z.J.; Wang, Q.H.; Liu, J.C.; Liu, S.H. Investigation of Engine Combustion and Emission Performance Fuelled with Neat PODE and PODE/Diesel Blend. J. Xi’an Jiaotong Univ. 2017, 51, 32–37. [Google Scholar] [CrossRef]

- Wang, T.; Liu, J.; Sun, P.; Ji, Q.; Gao, W.; Yang, C. Influence of injection parameters on combustion, gaseous emissions and particle size distribution of a CRDI diesel engine operating with PODE/diesel blends. Fuel 2020, 281, 118733. [Google Scholar] [CrossRef]

- Zhu, Y.; Lin, D.; Wei, X.; Zhang, W. Effect of PODE on Combustion and Emission Characteristics of a Turbo–Charged Intercooled Diesel Engine. J. Shanghai Jiao Tong Univ. 2017, 51, 33. [Google Scholar]

- Zhao, Y.; Xie, Y.; Wang, X.; Li, Z.; Niu, T.; Liu, S. Energy balance analysis, combustion characteristics, and particulate number concentration-NOx trade-off of a heavy-duty diesel engine fueled with various PODEn/diesel blends. Energy Convers. Manag. 2020, 225, 113489. [Google Scholar] [CrossRef]

| Property | D100 | PODE | DP20 | DP30 |

|---|---|---|---|---|

| Molecular formula | C10~C21 | CH3O(CH2O)nCH3 | - | - |

| Oxygen content (wt%) 1 | ≈0 | 45.46 | 9.09 | 13.64 |

| Density at 20 °C (g/cm3) 2 | 0.82 | 1.04 | 0.86 | 0.87 |

| Cetane number | ≥51 3 | 76 | >51 | >51 |

| Lower heating value (MJ/kg) | 42.59 4 | 17.83 4 | 37.64 1 | 35.16 1 |

| Engine Parameter | Value |

|---|---|

| Manufacturer | WEICHAI Power |

| Model | WP12.460 |

| Bore (mm) × Stroke (mm) | 126 × 155 |

| Cylinders | Inline-6 |

| Displacement (L) | 11.596 |

| Compression ratio | 17 |

| Rated speed (rpm) | 1900 |

| Rated power (kW) | 338 |

| Max torque (N·m) | 2200 |

| Aftertreatment system | DOC + DPF + Hi-SCR |

| Emission standard | CHINA VI |

| Vehicle Parameter | Value |

|---|---|

| Model | M3000 |

| Model year | 2020 |

| Classification | N3 |

| Transmission | 12-Speed Manual |

| Drive axle | 11.5 t Single-reduction drive axle (3.7) |

| Weight of the tractor (kg) | 8330 |

| Weight of the trailer (kg) | 6070 |

| Curb weight (kg) | 14,400 |

| Urban | Rural | Motorway | Total | ||

|---|---|---|---|---|---|

| D100 | Distance (km) | 13.21 (8.8%) | 30.50 (20.4%) | 105.89 (70.8%) | 149.60 |

| Time (s) | 1735 (19.8%) | 2204 (25.2%) | 4813 (55.0%) | 8752 | |

| AVG. Velocity (km/h) | 27.41 | 49.82 | 79.20 | 61.54 | |

| DP20 | Distance (km) | 14.16 (9.6%) | 32.57 (22.0%) | 101.45 (68.4%) | 148.18 |

| Time (s) | 1811 (20.1%) | 2317 (25.8%) | 4862 (54.1%) | 8990 | |

| AVG. Velocity (km/h) | 28.15 | 50.61 | 75.12 | 59.34 | |

| DP30 | Distance (km) | 13.54 (9.2%) | 30.83 (21.1%) | 102.07 (69.7%) | 146.44 |

| Time (s) | 1805 (20.4%) | 2250 (25.3%) | 4821 (54.3%) | 8876 | |

| AVG. Velocity (km/h) | 27.00 | 49.33 | 76.22 | 59.40 |

| The Type of Analysis | Measurement Principle | Instrument |

|---|---|---|

| CO/CO2 concentration | NDIR | AVL gas PEMS 493 |

| NOx (NO/NO2) concentration | NDUV | AVL gas PEMS 493 |

| PN concentration | Diffusion charger | AVL PN PEMS 496 |

| Exhaust flow | - | EFM |

| Fuel consumption rate | - | OBD |

| Engine speed | - | OBD |

| Engine torque | - | OBD |

| Vehicle geographic location | - | GPS |

| Sensors | Accuracy |

|---|---|

| CO | 0–1499 ppm: ±30 ppm 1500–49,999 ppm: ±2% |

| CO2 | 0–9.99 vol%: ±0.06 vol% 10–20 vol%: ±2% |

| NO | ±0.2% Full Scale or ±2% (Whichever is larger) |

| NO2 | ±0.2% Full Scale or ±2% (Whichever is larger) |

| PN concentration | Typically around ±5% (excluding technical tolerance) [32,35] |

| Exhaust flow | ±0.5% Full Scale or ±2% (Whichever is larger) |

| Fuel consumption rate | Within ±5% [36] |

| Engine speed | ±1 rpm |

| Engine torque | Within ±5% [24] |

| Vehicle distance | About 2.8% |

| DP20 | DP30 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| NOx | BSNOx | PN | BSPN | BTE ** | NOx | BSNOx | PN | BSPN | BTE ** | |

| ppm | g/kWh | N/cm3 | #/kWh | - | ppm | g/kWh | N/cm3 | #/kWh | - | |

| S * | −7.3% | - | −56.7% | - | +1.1% | −11.6% | - | −64.4% | - | +1.8% |

| T * | - | +17.9% | - | −41.9% | −0.4% | +14.7% | - | −56.6% | +1.9% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gu, H.; Liu, S.; Wei, Y.; Liu, X.; Zhu, X.; Li, Z. Effects of Polyoxymethylene Dimethyl Ethers Addition in Diesel on Real Driving Emission and Fuel Consumption Characteristics of a CHINA VI Heavy-Duty Vehicle. Energies 2022, 15, 2379. https://doi.org/10.3390/en15072379

Gu H, Liu S, Wei Y, Liu X, Zhu X, Li Z. Effects of Polyoxymethylene Dimethyl Ethers Addition in Diesel on Real Driving Emission and Fuel Consumption Characteristics of a CHINA VI Heavy-Duty Vehicle. Energies. 2022; 15(7):2379. https://doi.org/10.3390/en15072379

Chicago/Turabian StyleGu, Haoming, Shenghua Liu, Yanju Wei, Xibin Liu, Xiaodong Zhu, and Zheyang Li. 2022. "Effects of Polyoxymethylene Dimethyl Ethers Addition in Diesel on Real Driving Emission and Fuel Consumption Characteristics of a CHINA VI Heavy-Duty Vehicle" Energies 15, no. 7: 2379. https://doi.org/10.3390/en15072379

APA StyleGu, H., Liu, S., Wei, Y., Liu, X., Zhu, X., & Li, Z. (2022). Effects of Polyoxymethylene Dimethyl Ethers Addition in Diesel on Real Driving Emission and Fuel Consumption Characteristics of a CHINA VI Heavy-Duty Vehicle. Energies, 15(7), 2379. https://doi.org/10.3390/en15072379