Advanced sealing technology influences engine performance and is a crucial link to meeting the thrust-to-weight ratio, fuel consumption, durability and life of aero engines [

1,

2]. In the future, 50% of the performance improvement potential of aero engines will depend on the improvement of sealing technology and the reduction in leakage [

3]. It can be seen that sealing technology is one of the breakthrough directions that can significantly improve the performance of the engine [

4,

5,

6].

Sealing technology can be divided into dynamic sealing and static sealing. Dynamic seals are used to seal the tips of compressor blades or turbine blades [

7]. Dynamic sealing mainly includes grate sealing, graphite sealing, brushing type sealing, fingertip sealing, end face sealing, and other sealing technologies. Zhang et al. [

8] used the quasi-labyrinth seal technology to control the surface flow of the scraper and analyzed the influence of the surface leakage on the aero-thermal performance of the end wall and the cooling of the suction side surface model for the blade. Yue et al. [

9] studied the influence of the brush seal structure on the sealing performance. Wang et al. [

10,

11] proposed an anisotropic porous media model for fingertip seal leakage analysis. Li et al. [

12] experimentally analyzed fingertip seals’ leakage and wear characteristics in cold and hot conditions. Nayak et al. [

13,

14] used numerical simulation methods to study the effects of stepped labyrinth seal leakage, swirl development and wind resistance temperature rises and analyzed the rotation effect of smooth honeycomb cells and honeycomb cells under different sealing clearances and speeds. Meffert et al. [

15] conducted an experimental study on the static and dynamic deformation of the radial shaft seal, thereby expanding the understanding of the performance of the seal ring under different static and dynamic position deviations. Dong et al. [

16] designed and established a new type of steam turbine bite ring engineering sealing and corresponding experimental bench, and based on the k-ω SST turbulence model, numerically studied and experimentally verified the leakage characteristics of the rim seal. Chougule et al. [

17] proposed an improved scheme for the labyrinth seal with variable teeth and high straight teeth. Vinogradov et al. [

18] proposed a radial end face contact seal design method for the deformation of aero-engine supporting elements under different working conditions. Andres et al. [

19] introduced an improved gas sealing rotor dynamic performance experimental device and showed the five-tooth gas seal leakage and cavity pressure measurement results. In order to improve the sealing performance, Zhang et al. [

20] proposed a hybrid labyrinth seal with two specially designed side teeth installed on the staggered labyrinth seal. Jia et al. [

21] proposed a new type of T-labyrinth seal to reduce the excitation force caused by the flow in the seal area, thereby reducing the vibration of the aero-engine rotor. Wang et al. [

22] numerically investigated the influence of four types of pre-swirls on the leakage, flow field, and fluid-induced force of a rotary straight-through labyrinth gas seal (RSTLGS) using the proposed steady computational fluid dynamics (CFD) method based on the three-dimensional models of the RSTLGS. Qiao et al. [

23] used a computational fluid dynamics (CFD) model to consider the labyrinth seal leakage channels (two shoulder seals, one interstage sealing, and one balanced piston seal) and the flow characteristics of the second stage after the four-stage centrifugal compressor. Gaowen Liu et al. [

24,

25,

26] studied the influence of the pressure ratio and Reynolds number on the flow characteristics of the compressor interstage grate seal. Sun et al. [

27] studied the calculation model of the air network of the compressor interstage grate sealed air network under a swirling flow and wind resistance temperature rise. Many scholars have also conducted research on the sealing and leakage characteristics resulting from heat distribution and overall structure.

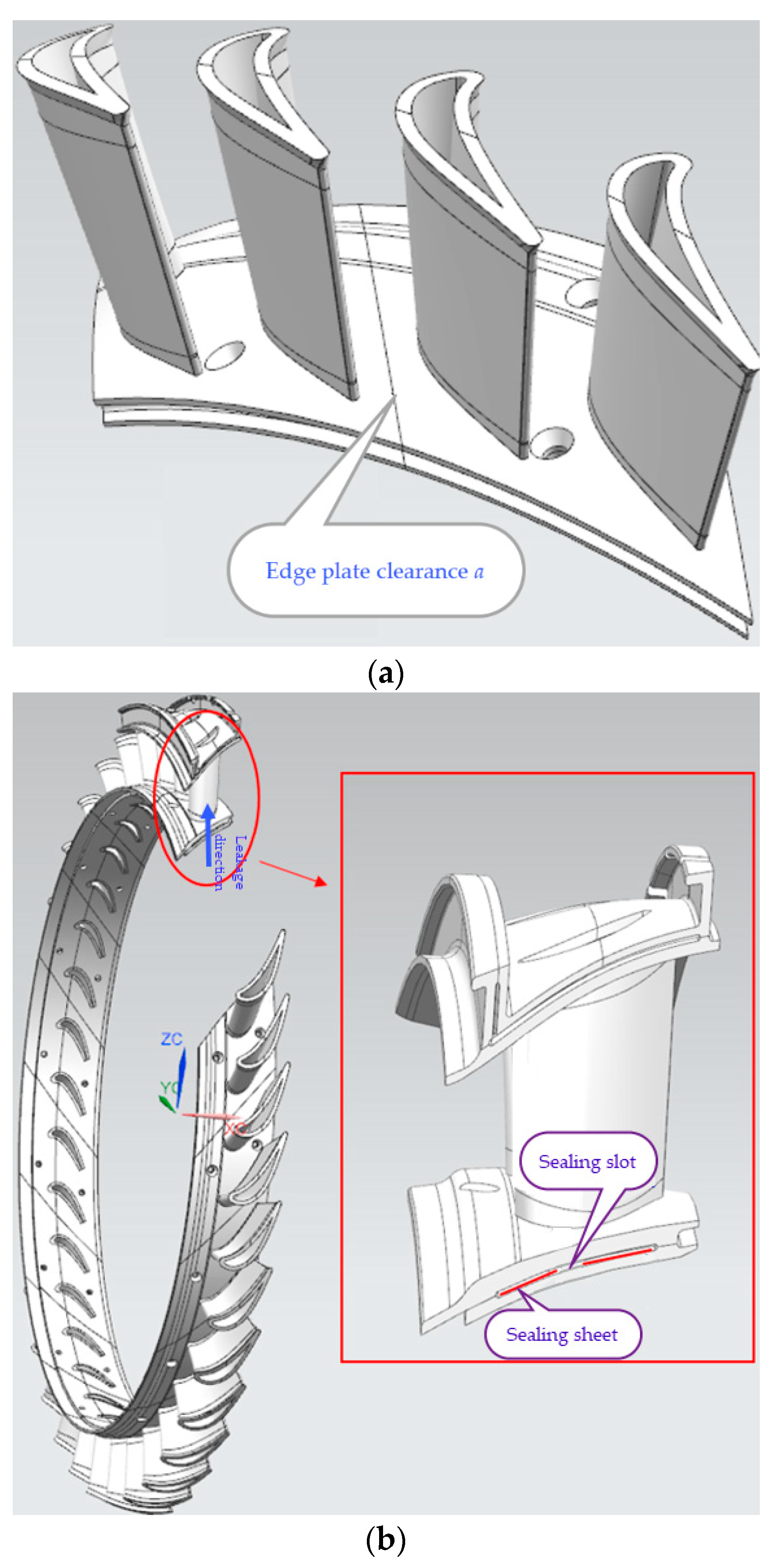

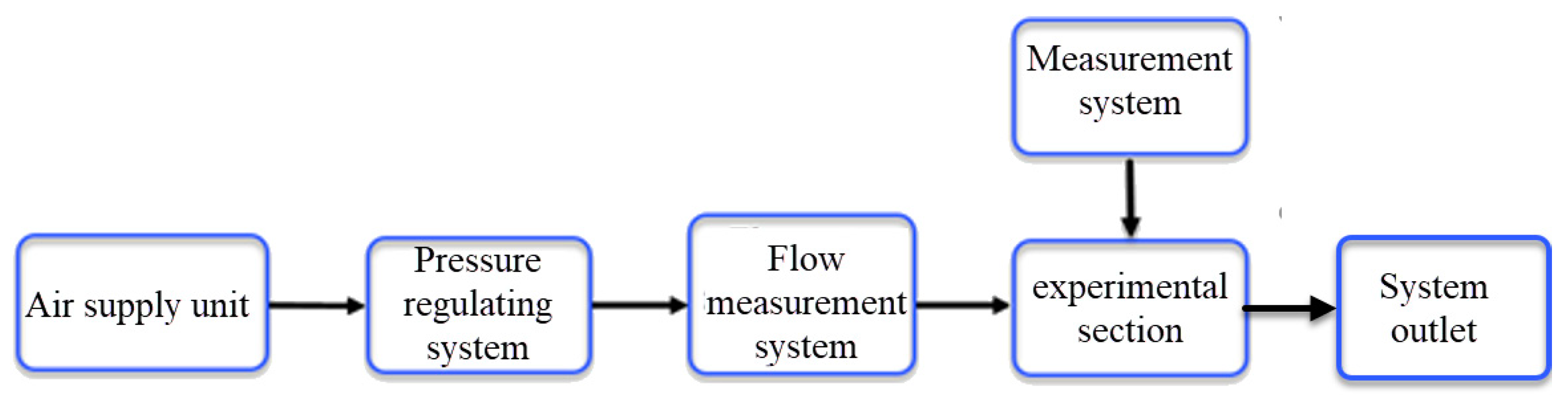

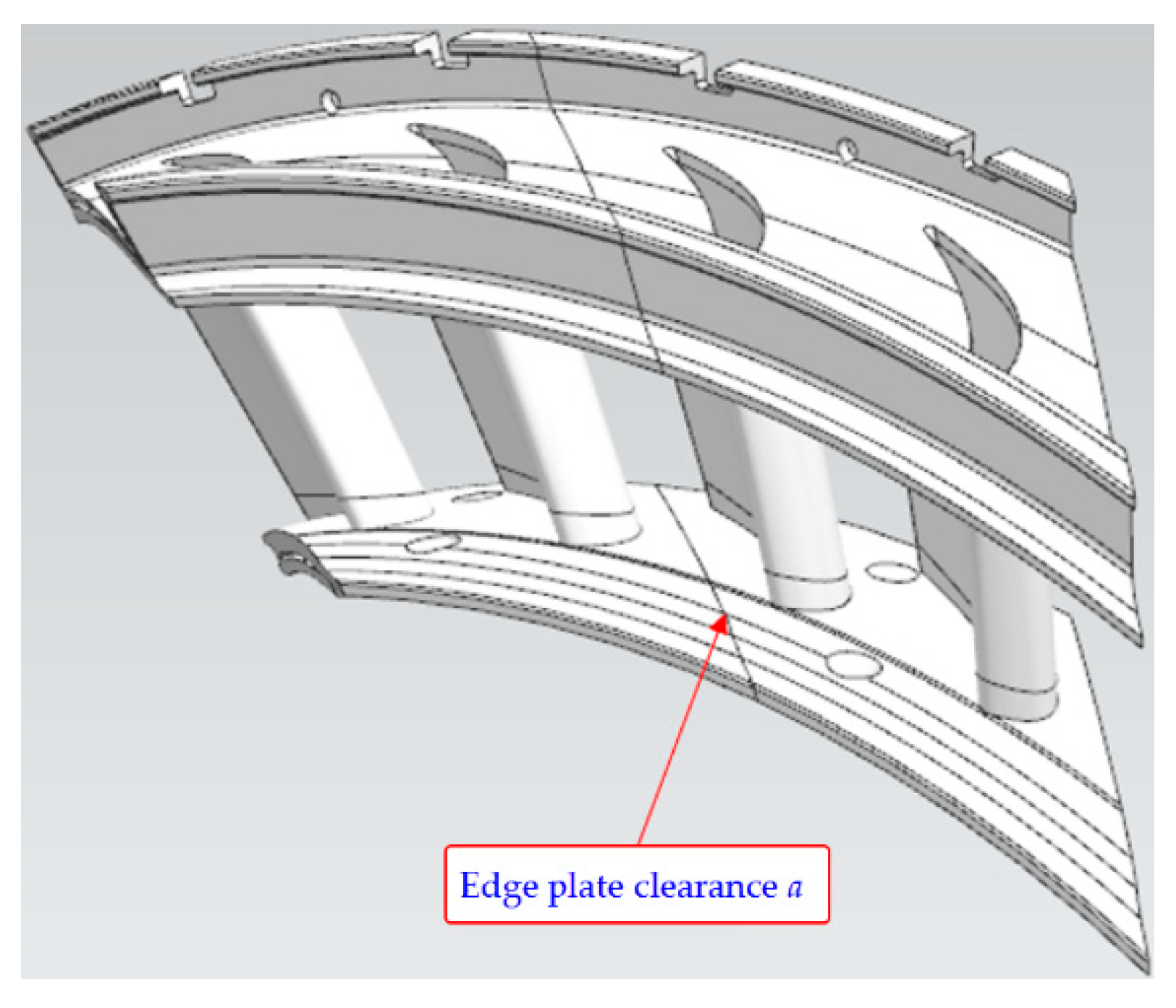

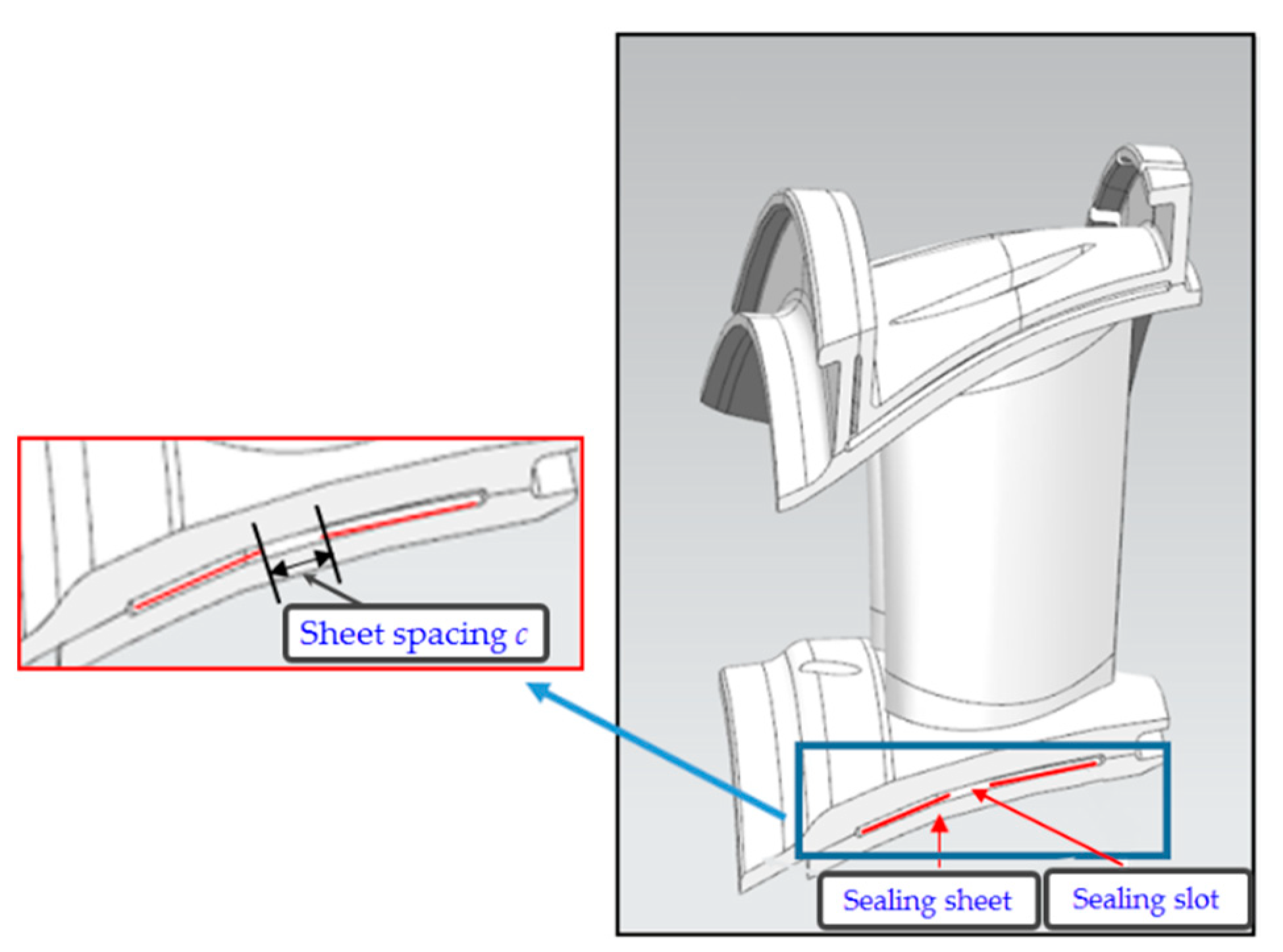

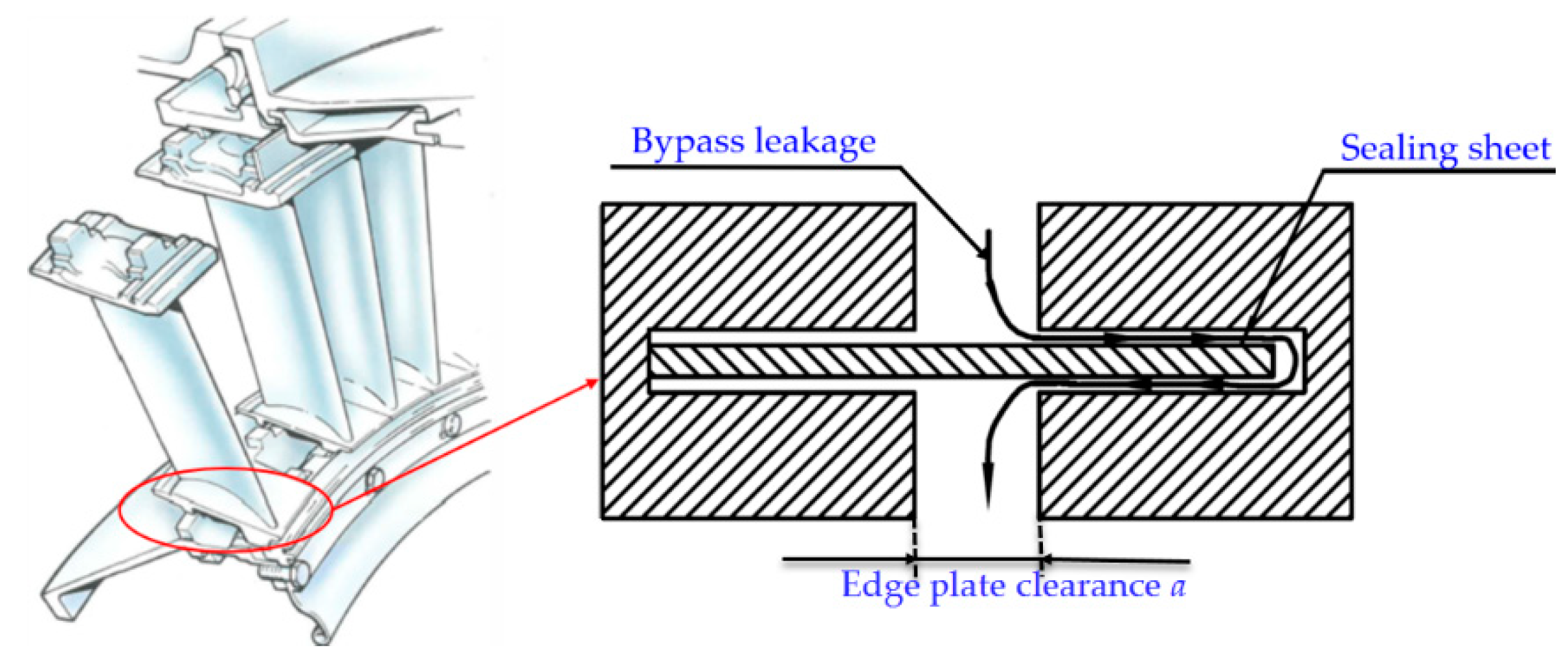

In the engine, static sealing is mostly used at the interface of static components (combustion chambers, nozzles, edge plates, fairings, etc.) to reduce leakage. For static sealing components, it is necessary to consider less wear and higher sealing effect during their lifetime in the presence of vibration. In addition, a certain margin should be reserved for thermal expansion and dislocation in the design. Effective sealing of these static interfaces can not only improve the efficiency and output power of the engine but also ensure the temperature distribution of the main intermediate stage turbine flow channels. At present, the research direction of most scholars lies in the leakage characteristics of different dynamic sealing structures, W sealing rings, elastic combined sealing, and other static sealing structures. However, few researchers have studied the leakage characteristics of static sealing structures, especially sealing sheet structures. Sealing sheets, also known as edge plate sealing and slot sealing, are a common static sealing technique. Research on sealing sheets structures focuses primarily on flow stability and the thermodynamics and aerodynamics of sealing fluids. Deng et al. [

28] analyzed the influence of pressure fluctuations in the compressor or combustion chamber on the stable leakage characteristics of the sealing sheets. The aerodynamic and thermodynamic performances are of importance for engine safety operation [

29,

30,

31]. Zhang et al. [

32] revealed the influence of sealed airflow on the turbine’s flow field structure and aerodynamic performance. Especially, the thermal problem of high temperature is always a hot topic of engine research [

33,

34,

35]. Joachimiak et al. [

36] discussed the thermodynamic phenomena of gas flow in the sealing sheets. They analyzed it under irreversible adiabatic conditions and proposed a total enthalpy balance equation. However, there are few studies on the leakage characteristics of the turbine blade edge plate clearance. Although Zhou et al. [

37,

38] analyzed the leakage characteristics of the edge plate sealing of the turbine blade through experiments, he only obtained the influence of different displacements and edge plate clearance of the single-piece sealing plate on its leakage characteristics.

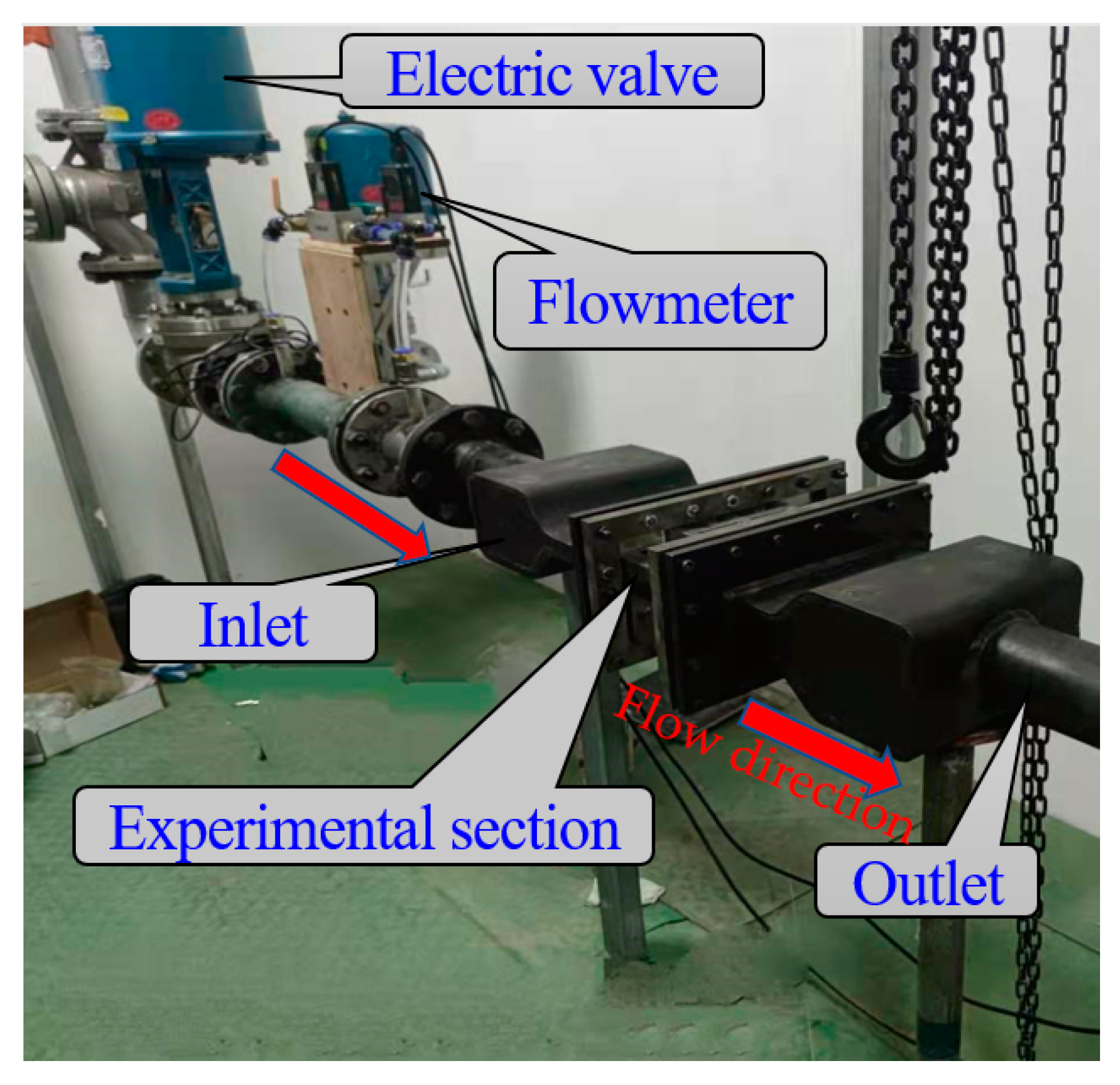

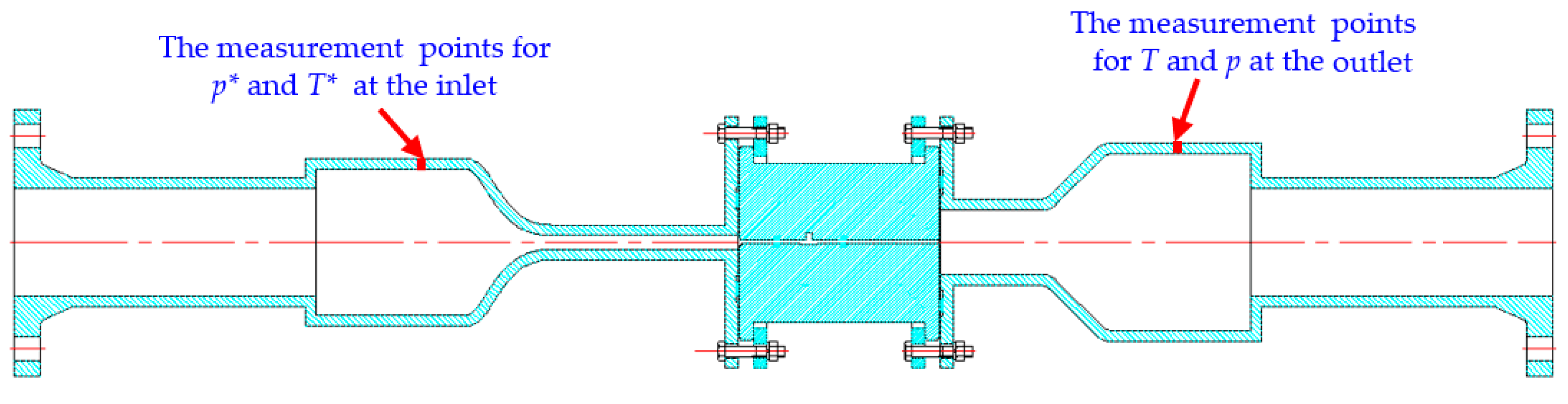

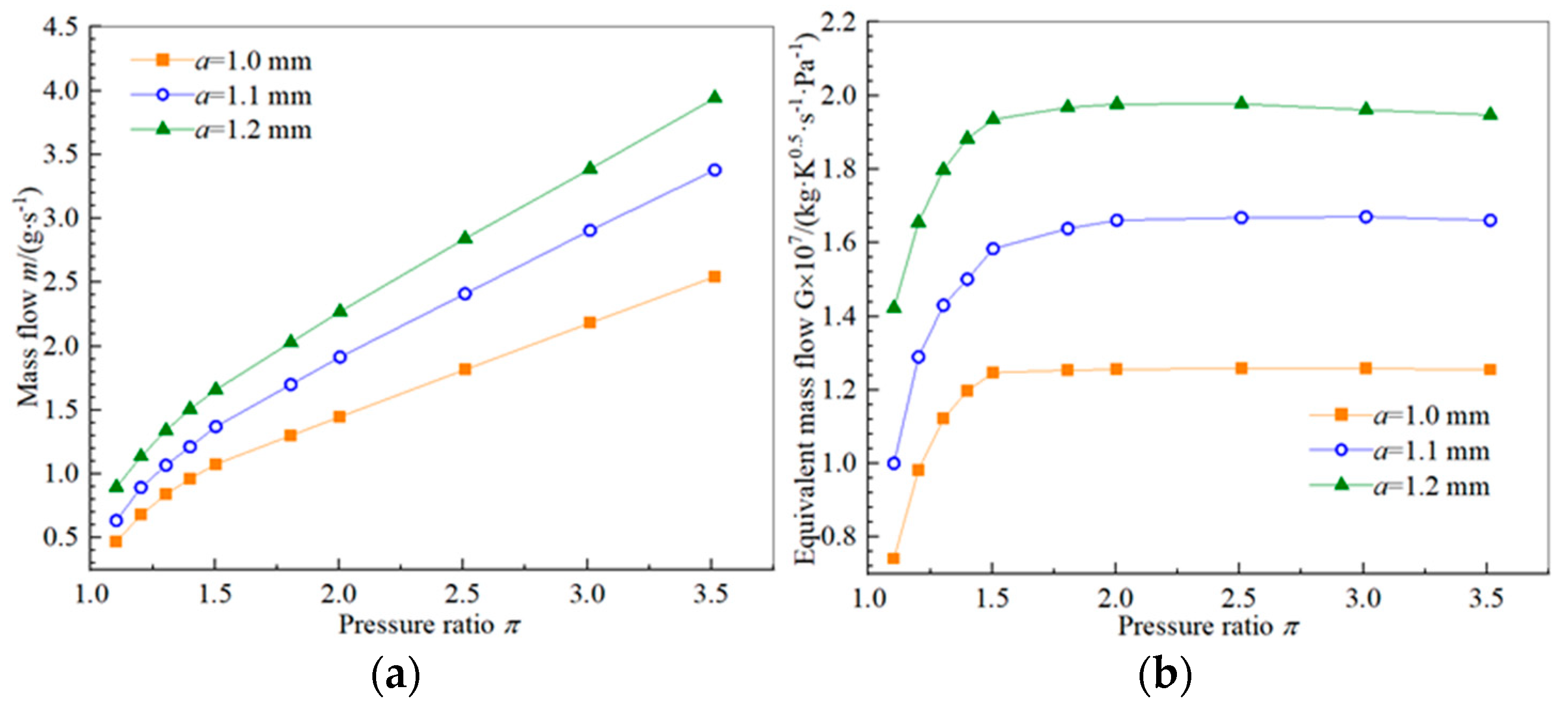

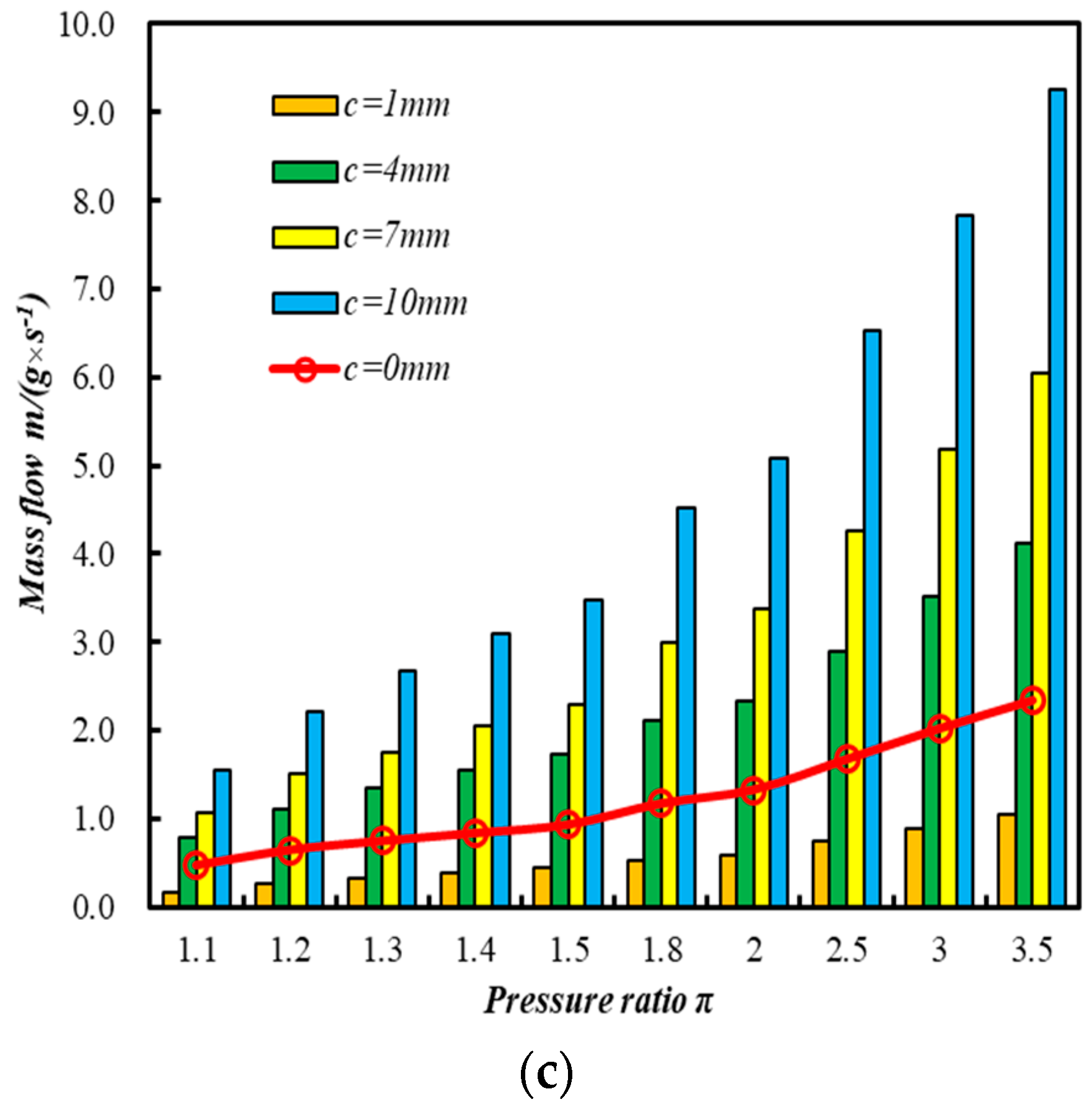

Due to the structural complexity of the sealing slot and the turbine blade edge plate, sealing sheets can be segmented or overlapped to facilitate assembly. This is more than a single sealing sheet. The current research on the leakage characteristics of the sealing sheet structure is limited to the leakage characteristics of a single sealing sheet. The effect of combined sealing geometry on leakage characteristics of the seal slot has not been studied. Therefore, the influence of the geometric structure of the combined sealing sheet on leakage cannot be determined at present. As a result of the inaccurate estimation of leakage, the economic performance of the whole engine is greatly reduced. In order to quantitatively analyze the influence of the combined sealing sheet on the leakage characteristics of the complex static sealing structure, this paper takes the common turbine edge static sealing structure as the research object and studies the influence of edge plate clearance and sheet spacing on leakage characteristics of the two-piece segmented sealing plate structure. In other words, it is the influence of the edge plate clearance and the sheet spacing on the sealing effect of the turbine blade edge plates. It is of significance to the installation and design of the engine turbine blades.