Characteristics and Affecting Factors of K2qn1 Member Shale Oil Reservoir in Southern Songliao Basin, China

Abstract

:1. Introduction

2. Geological Setting

3. Samples and Methods

3.1. Samples

3.2. Methods

3.2.1. XRD

3.2.2. N2GA

3.2.3. SEM

3.2.4. Analysis of SEM Images

3.2.5. TOC

4. Results

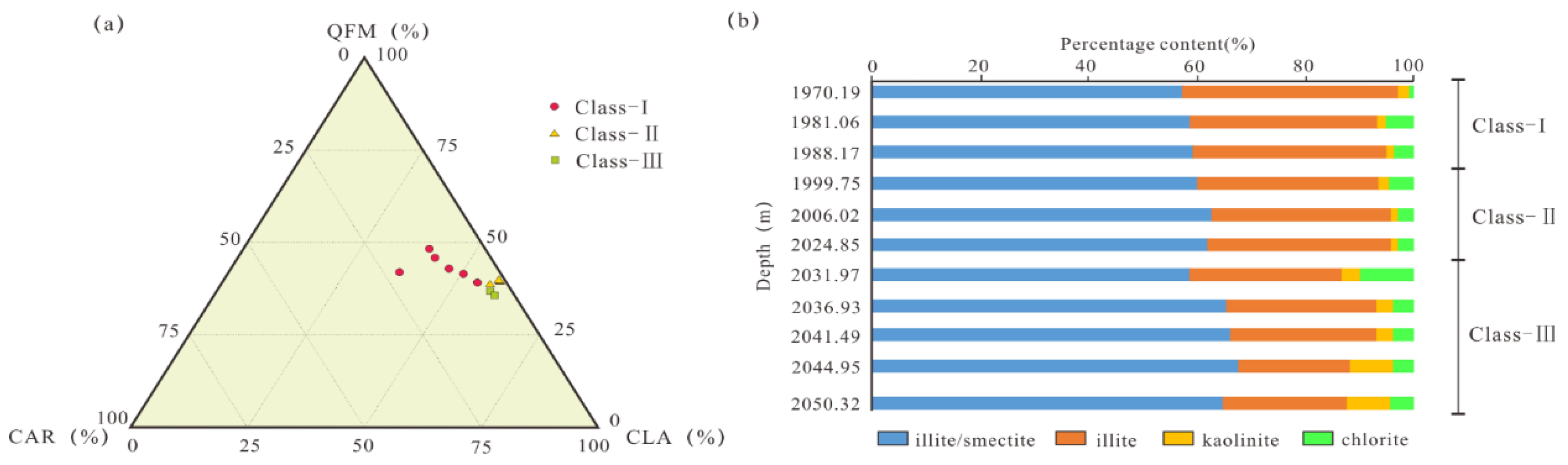

4.1. Petrologic Characteristics of the Reservoirs

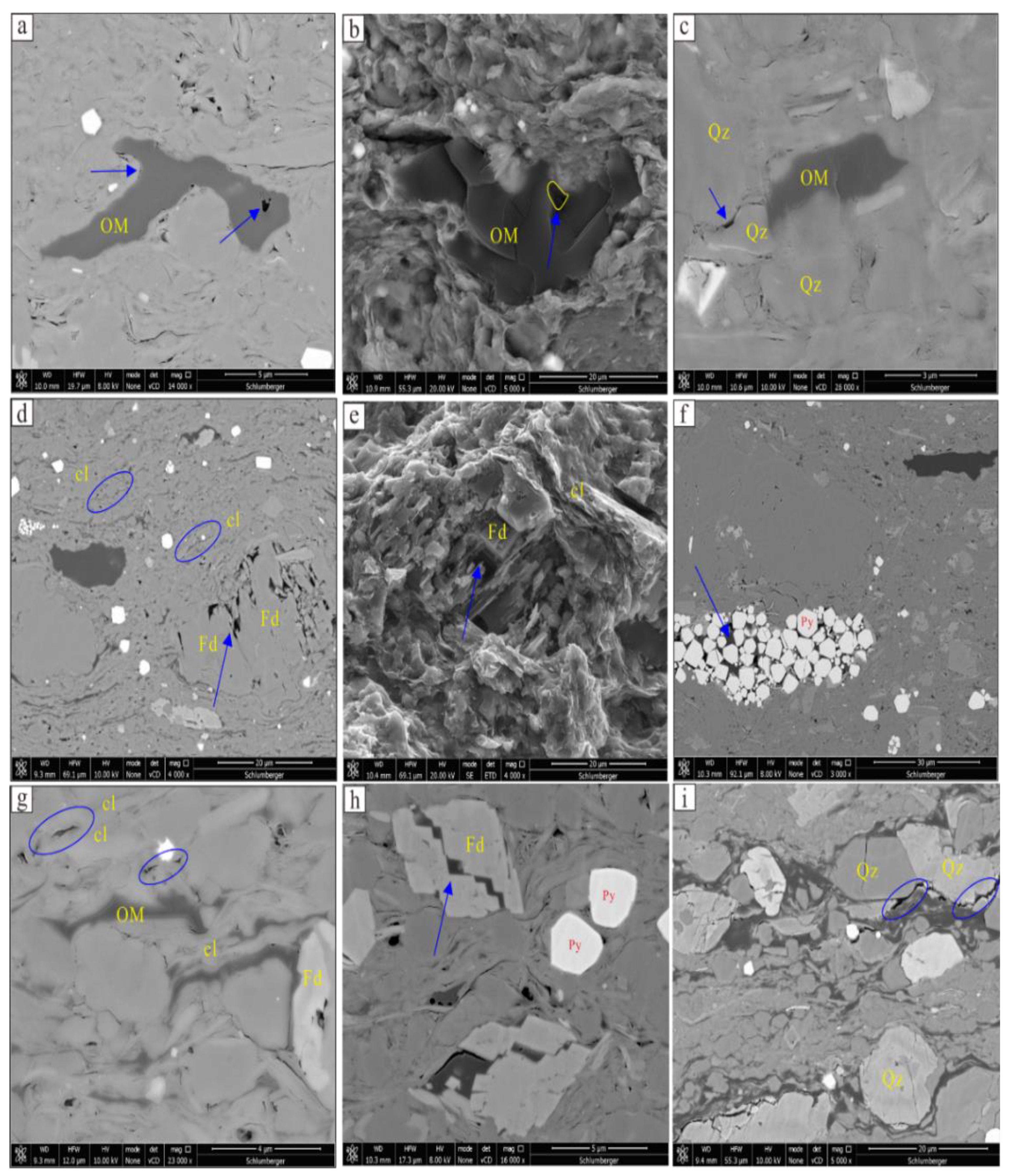

4.2. Types of Reservoir Space

4.2.1. Organic Pore

Types of Organic Pore

Quantitative Characterization of Organic Matter Pores

4.2.2. Inorganic Matter Pore

4.2.3. Micro-Fissures

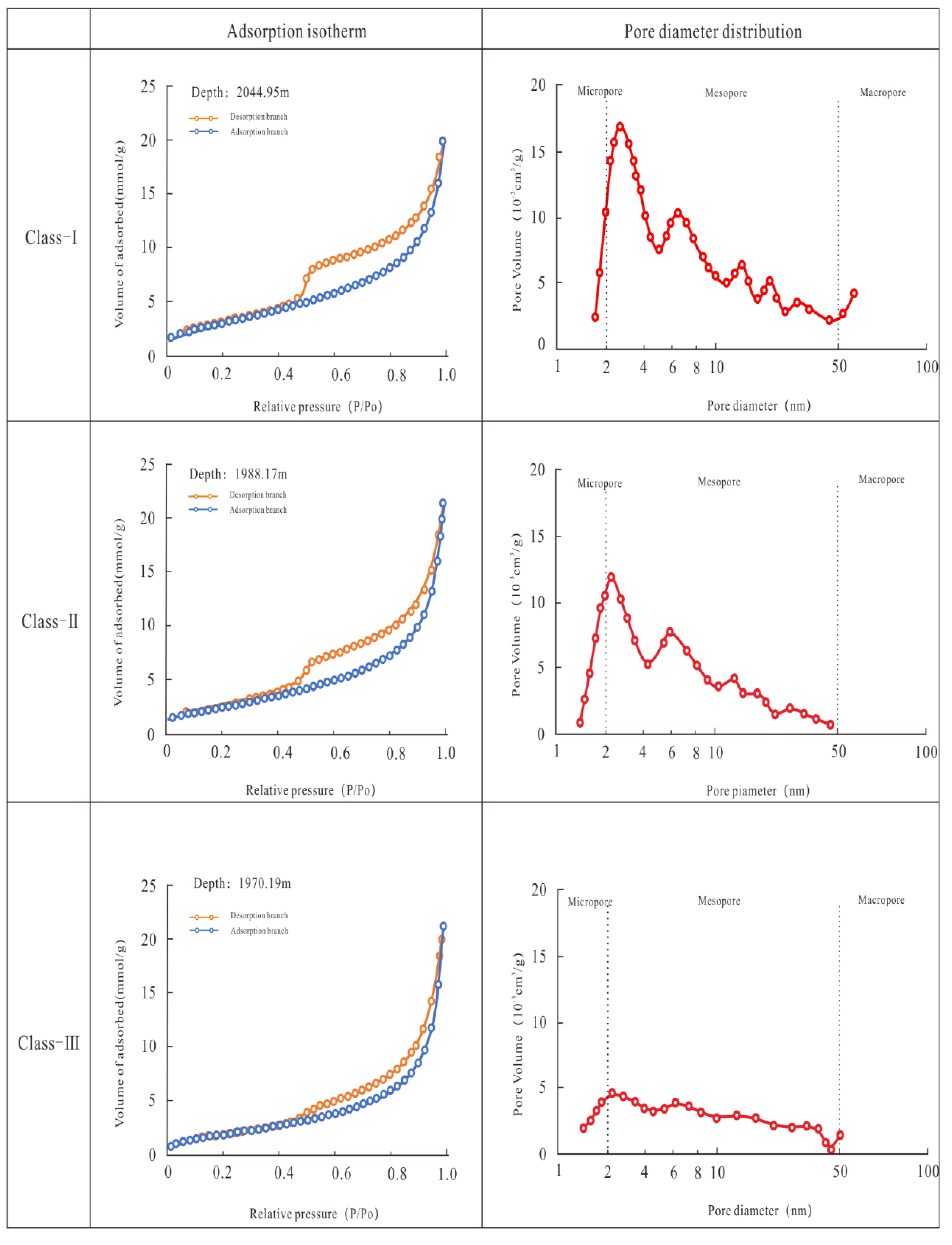

4.3. Features of Pore Structure

4.3.1. Features of Pore Sizes

4.3.2. Quantitative Characterization of Pore Structure

5. Discussion

5.1. Pore Structure Differences between Marine and Lacustrine Shales

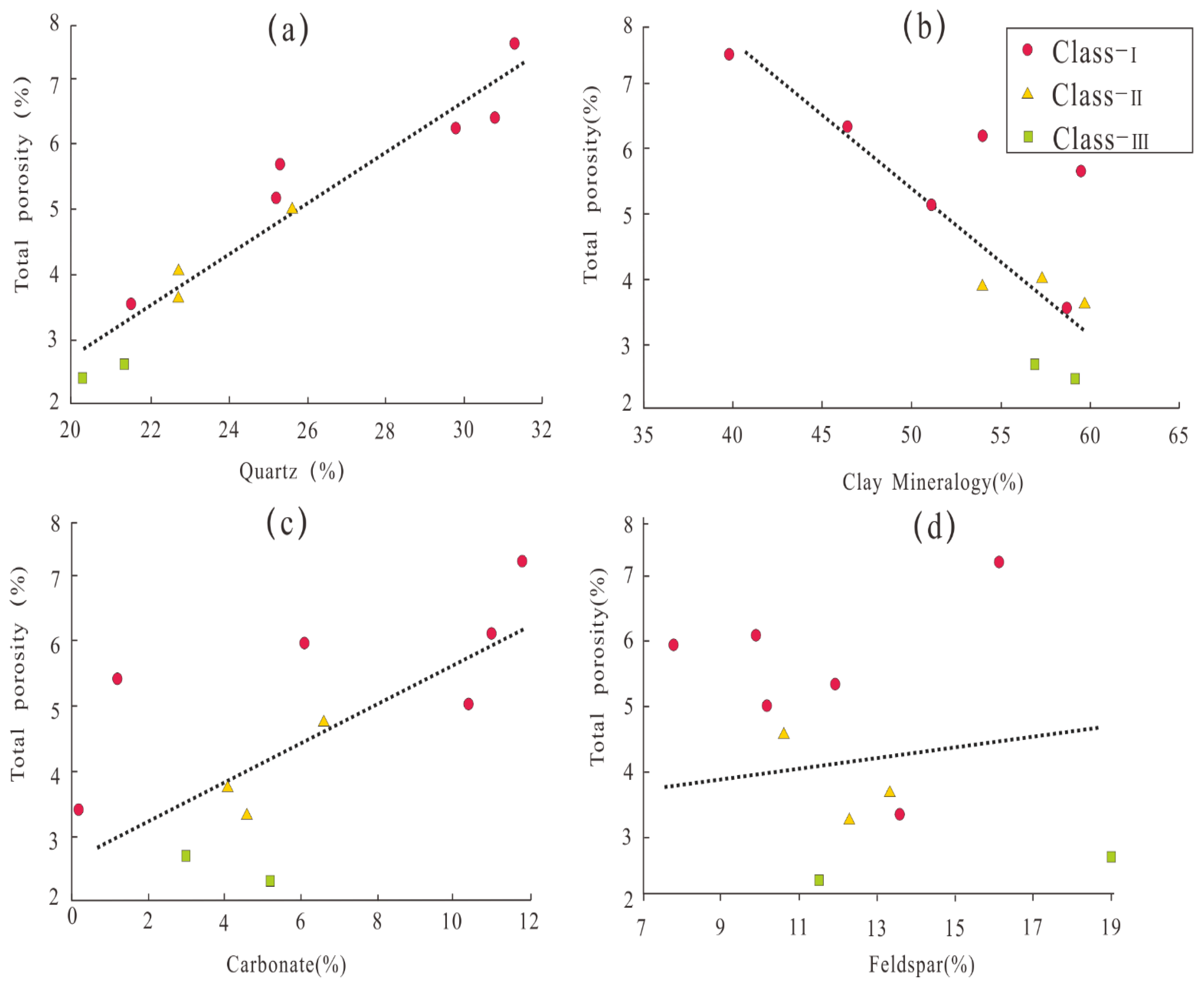

5.2. Effects of Mineral Components on Reservoir Quality

5.2.1. Quartz

5.2.2. Clay Minerals

5.2.3. Carbonate Minerals

5.2.4. Feldspar Minerals

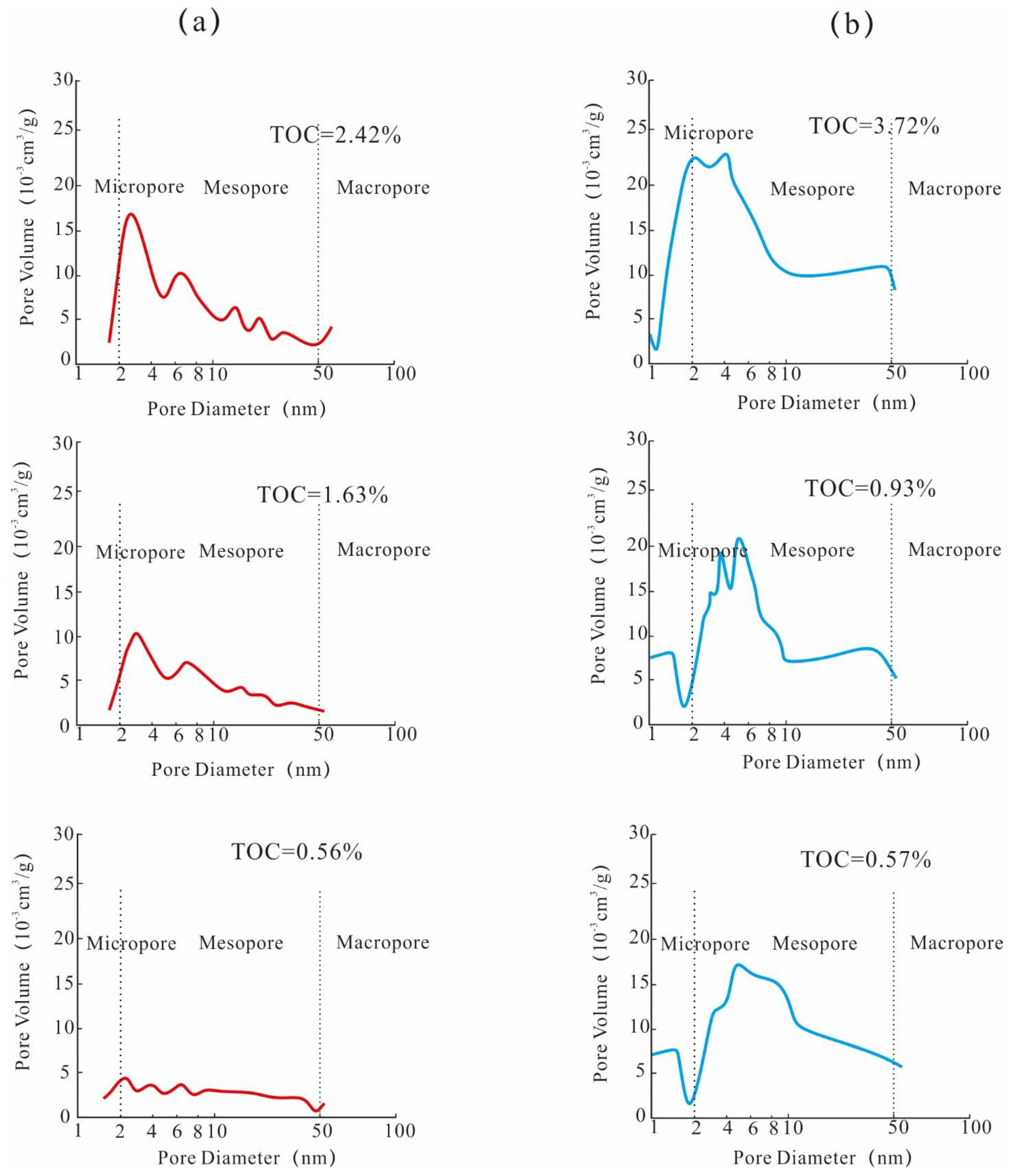

5.3. Effect of TOC on Organic Matter Pore

5.4. Effects of Diagenetic Processes on Reservoir Quality

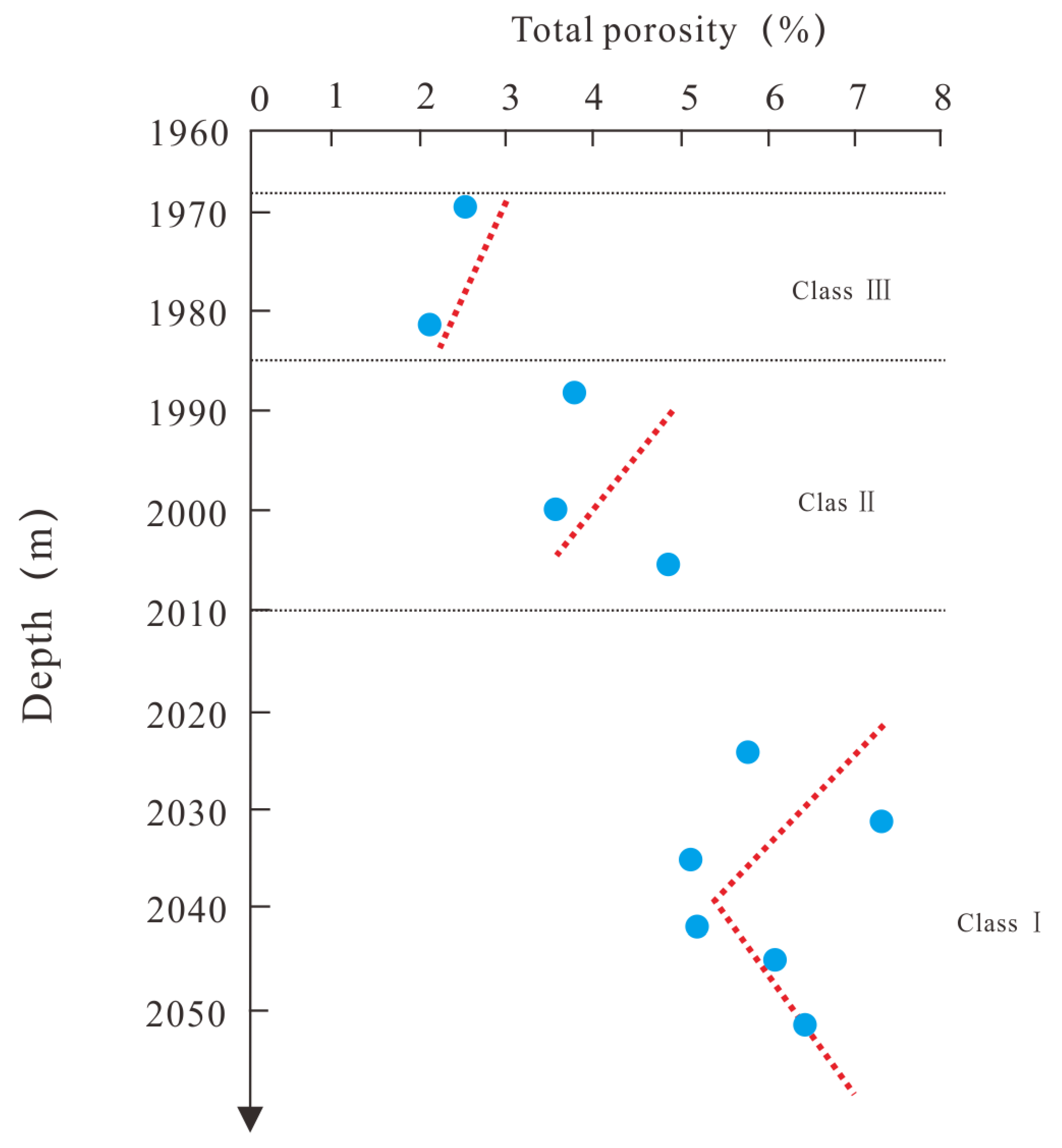

5.4.1. Compaction

5.4.2. Cementation

5.4.3. Dissolution

6. Conclusions

- (1)

- Shale samples from the Class-I sweet spot section in K2qn1 Member of the Da’an area, southern Songliao Basin are mainly made up of silica-bearing clayey hybrid shale and are characterized by high contents of siliceous and carbonate minerals and low content of clay minerals. Shale samples from the Class-II sweet spot section and Class-III reservoir have higher contents of clay minerals and are silica-bearing clayey shale. The clay minerals in the shale samples mainly consist of illite-smectite mixed layer and illite. Besides, they also contain a small amount of chlorite, indicating that the K2qn1 Member in this area has ended early diagenesis and is in the late episode of the middle diagenesis B stage.

- (2)

- The reservoir space in K2qn1 Member shale of this area includes organic matter pores, inorganic matter pores, and micro-fissures. The shale samples from Class-I and II sweet spot sections have mainly inorganic pores, in which residual intergranular pores and intragranular dissolve pores take dominance. Shale samples from the Class-III non-sweet spot section have the highest clay mineral contents, the poorest anti-compaction capacity, mainly organic matter pores, and lower total pore volume. Shale samples from the Class-I sweet spot section have more organic pores than those from the Class-II sweet spot section. Shale samples from the Class-III non-sweet spot section have the lowest development degree of organic matter pore, but organic matter pores make the greatest contribution to the total porosity of these samples.

- (3)

- Shale samples from K2qn1 Member have mainly H2 and H4 types of N2GA hysteresis loops. Shale samples from Class-I and II sweet spot sections have largely H2 type hysteresis loops, while those from Class-III non-sweet spot section have mostly H4 type hysteresis loops. That means high quality shale reservoirs have much larger pore volumes than poor quality shale reservoirs.

- (4)

- The pore structures of marine shale and lacustrine shale are obviously different, and the development characteristics of lacustrine shale pore structures are more influenced by mineral components.

- (5)

- The main factors controlling the shale oil reservoirs in K2qn1 Member of the Da’an shale oil demonstration area are mineral composition, TOC, and diagenesis of the shale. Quartz and carbonate minerals are conducive to the formation of a high-quality reservoir, while clay minerals have a negative impact on reservoir quality. TOC is the material base and main control factor for the formation of organic matter pore, but the higher the TOC, the smaller the size of organic matter pore will be. Compaction has a destructive effect on the reservoir, while dissolution has a constructive effect.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guilera, R. Flow units: From conventional to tight-gas to shale-gas to tight-oil to shale-oil reservoirs. SPE Reserv. Eval. Eng. 2014, 17, 190–208. [Google Scholar] [CrossRef]

- Zhao, W.; Hu, S.; Hou, L.; Yang, T.; Li, X.; Guo, B.; Yang, Z. Types and resource potential of continental shale oil in China and its boundary with tight oil. Pet. Explor. Dev. 2020, 47, 1–11. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Cui, J.; Zhu, R.; Hou, L.; Tao, S.; Yuan, X.; Wu, S.; Lin, S.; Wang, L.; et al. Formation mechanism, geological characteristics and development strategy of nonmarine shale oil in China. Pet. Explor. Dev. 2013, 40, 15–27. [Google Scholar] [CrossRef]

- Jarvie, D.M. . Shale Resource Systems for Oil and Gas: Part 2—Shale-oil Resource Systems. In Shale Reservoirs—Giant Resources for the 21st Century; Breyer, J.A., Ed.; AAPG Memoir; American Association of Petroleum Geologists: Tulsa, OK, USA, 2012; Volume 97, pp. 89–119. [Google Scholar] [CrossRef]

- Altun, N.E.; Hicyilmaz, C.; Hwang, J.-Y.; BaǦci, A.S.; Kök, M.V. Oil shales in the world and turkey; reserves, current situation and future prospects: A review. Oil Shale 2006, 23, 211–227. [Google Scholar]

- Zhang, L.; Zhao, Q.; Peng, S.; Qiu, Z.; Feng, C.; Zhang, Q.; Wang, Y.; Dong, D.; Zhou, S. Paleoenvironment and Organic Matter Accumulation Mechanism of Marine–Continental Transitional Shales: Outcrop Characterizations of the Carboniferous–Permian Strata, Ordos Basin, North China. Energies 2021, 14, 7445. [Google Scholar] [CrossRef]

- Zha, X.; Lai, F.; Gao, X.; Gao, Y.; Jiang, N.; Luo, L.; Li, Y.; Wang, J.; Peng, S.; Luo, X.; et al. Characteristics and Genetic Mechanism of Pore Throat Structure of Shale Oil Reservoir in Saline Lake—A Case Study of Shale Oil of the Lucaogou Formation in Jimsar Sag, Junggar Basin. Energies 2021, 14, 8450. [Google Scholar] [CrossRef]

- Jia, C.; Zou, C.; Yang, Z.; Zhu, R.; Chen, Z.; Zhang, B.; Jiang, L. Significant progress of continental petroleum geological theory in basins of Central and Western China. Pet. Explor. Dev. 2018, 45, 573–588. [Google Scholar] [CrossRef]

- Liu, B.; Bai, L.; Chi, Y.; Jia, R.; Fu, X.; Yang, L. Geochemical characterization and quantitative evaluation of shale oil reservoir by two-dimensional nuclear magnetic resonance and quantitative grain fluorescence on extract: A case study from the Qingshankou Formation in Southern Songliao Basin, northeast China. Mar. Pet. Geol. 2019, 109, 561–573. [Google Scholar] [CrossRef]

- Liu, B.; Sun, J.; Zhang, Y.; He, J.; Fu, X.; Yang, L.; Xing, J.; Zhao, X. Reservoir space and enrichment model of shale oil in the first member of Cretaceous Qingshankou Formation in the Changling Sag, southern Songliao Basin, NE China. Pet. Explor. Dev. 2021, 48, 608–624. [Google Scholar] [CrossRef]

- Pollastro, R.M.; Jarvie, D.M.; Hill, R.J.; Adams, C.W. Geologic framework of the Mississippian Barnett Shale, Barnett-Paleozoic total petroleum system, Bend arch–Fort Worth Basin, Texas. AAPG Bull. 2007, 91, 405–436. [Google Scholar] [CrossRef]

- Walls, J.D.; Diaz, E.; Derzhi, N.; Grader, A.; Dvorkin, J.; Arredondo, S.; Carpio, G.; Sinclair, S. Eagle Ford Shale Reservoir Properties from Digital Rock Physics. First Break 2011, 29, 6. [Google Scholar] [CrossRef]

- Adeyilola, A.; Nordeng, S.; Onwumelu, C.; Nwachukwu, F.; Gentzis, T. Geochemical, petrographic and petrophysical characterization of the Lower Bakken Shale, Divide County, North Dakota. Int. J. Coal Geol. 2020, 224, 103477. [Google Scholar] [CrossRef]

- Cai, S.; Xiao, Q.; Zhu, W.; Zhu, H.; Chen, J.; Chen, Q.; Jiang, X. Shale Reservoir Characteristics and Main Controlling Factors of Longmaxi Formation, Southern Sichuan Basin. Acta Sedimentol. Sin. 2021, 39, 1100–1110. [Google Scholar]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar] [CrossRef]

- Curtis, M.E.; Sondergeld, C.H.; Ambrose, R.J.; Rai, C.S. Microstructural investigation of gas shales in two and three dimensions using nanometer-scale resolution imaging Microstructure of Gas Shales. AAPG Bull. 2012, 96, 665–677. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef] [Green Version]

- Niu, B.; Bao, Z.; Yu, D.; Zhang, C.; Long, M.; Su, J.; Li, Y. Hierarchical modeling method based on multilevel architecture surface restriction and its application in point-bar internal architecture of a complex meandering river. J. Pet. Sci. Eng. 2021, 205, 108808. [Google Scholar] [CrossRef]

- Ding, C.; He, J.; Wu, H. Nanometer Pore Structure Characterization of Taiyuan Formation Shale in the Lin-Xing Area Based on Nitrogen Adsorption Experiments. Minerals 2021, 11, 298. [Google Scholar] [CrossRef]

- Wang, Y.; Cheng, H.; Hu, Q.; Liu, L.; Jia, L.; Gao, S.; Wang, Y. Pore structure heterogeneity of Wufeng-Longmaxi shale, Sichuan Basin, China: Evidence from gas physisorption and multifractal geometries. J. Pet. Sci. Eng. 2021, 208, 109313. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, Y.P. Characterization of pore structure, gas adsorption, and spontaneous imbibition in shale gas reservoirs. J. Pet. Sci. Eng. 2017, 159, 197–204. [Google Scholar] [CrossRef]

- Wang, P.-J.; Mattern, F.; Didenko, N.A.; Zhu, D.-F.; Singer, B.; Sun, X.-M. Tectonics and cycle system of the Cretaceous Songliao Basin: An inverted active continental margin basin. Earth-Sci. Rev. 2016, 159, 82–102. [Google Scholar] [CrossRef] [Green Version]

- Zhang, L.; Bao, Z.; Dou, L.; Xu, Q. Diagenetic alterations related to sedimentary architecture of deltaic distributary channels in red beds of the Cretaceous Yaojia Formation, Songliao Basin. J. Pet. Sci. Eng. 2021, 203, 108564. [Google Scholar] [CrossRef]

- Zhang, L.; Bao, Z.; Dou, L.; Zang, D.; Mao, S.; Song, J.; Zhao, J.; Wang, Z. Sedimentary characteristics and pattern of distributary channels in shallow water deltaic red bed succession: A case from the Late Cretaceous Yaojia formation, southern Songliao Basin, NE China. J. Pet. Sci. Eng. 2018, 171, 1171–1190. [Google Scholar] [CrossRef]

- Wang, M.; Xue, H.; Tian, S.; Wilkins, R.W.; Wang, Z. Fractal characteristics of Upper Cretaceous lacustrine shale from the Songliao Basin, NE China. Mar. Pet. Geol. 2015, 67, 144–153. [Google Scholar] [CrossRef]

- Jia, J.; Bechtel, A.; Liu, Z.; Strobl, S.A.; Sun, P.; Sachsenhofer, R. Oil shale formation in the Upper Cretaceous Nenjiang Formation of the Songliao Basin (NE China): Implications from organic and inorganic geochemical analyses. Int. J. Coal Geol. 2013, 113, 11–26. [Google Scholar] [CrossRef]

- Liu, B.; Lü, Y.-f.; Ran, Q.; Dai, C.-l.; Li, M.; Wang, M. Geological conditions and exploration potential of shale oil in Qingshankou Formation, Northern Songliao Basin. Oil Gas Geol. 2014, 35, 280–285. [Google Scholar]

- Wu, H.; Lin, T.; Bai, Y.; Zhang, J.; Liu, X. Analyses of the mudstone (shale) oil exploration potential in North Songliao Basin. Pet. Geol. Oilfield Dev. Daqing 2019, 38, 78–86. [Google Scholar]

- Lu, S.; Huang, W.; Chen, F.; Li, J.; Wang, M.; Xue, H.; Wang, W.; Cai, X. Classification and evaluation criteria of shale oil and gas resources: Discussion and application. Pet. Explor. Dev. 2012, 39, 268–276. [Google Scholar] [CrossRef]

- Foscolos, A.; Powell, T.; Gunther, P. The use of clay minerals and inorganic and organic geochemical indicators for evaluating the degree of diagenesis and oil generating potential of shales. Geochim. Cosmochim. Acta 1976, 40, 953–966. [Google Scholar] [CrossRef]

- Ambrose, R.J.; Hartman, R.C.; Campos, M.D.; Akkutlu, I.Y.; Sondergeld, C.H. Shale Gas-in-Place Calculations Part I: New Pore-Scale Considerations. SPE J. 2012, 17, 219–229. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef] [Green Version]

- Fu, Y.; Jiang, Y.; Dong, D.; Hu, Q.; Lei, Z.; Peng, H.; Gu, Y.; Ma, S.; Wang, Z.; Yin, X.; et al. Microscopic pore-fracture configuration and gas-filled mechanism of shale reservoirs in the western Chongqing area, Sichuan Basin, China. Pet. Explor. Dev. 2021, 48, 1063–1076. [Google Scholar] [CrossRef]

- Ross, D.J.K.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Pet. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Milliken, K.L.; Rudnicki, M.; Awwiller, D.N.; Zhang, T.W. Organic matter-hosted pore system, Marcellus Formation (Devonian), Pennsylvania. AAPG Bull. 2013, 97, 177–200. [Google Scholar] [CrossRef]

- Han, J.; Chen, B.; Zhao, X.; Zheng, C.; Zhang, J. Development characteristics and influential factors of organic pores in the Permian shale in the Lower Yangtze Region. Nat. Gas Ind. 2017, 37, 17–26. [Google Scholar]

- Guo, X. Rules of two-factor enrichment for Marine shale gas in southern China: Understanding from the Longmaxi Formation shale gas in Sichuan Basin and its surrounding area. Acta Geol. Sin. 2014, 88, 1209–1218. [Google Scholar]

- Mccreesh, C.A.; Ehrlich, R.; Crabtree, S.J.; Mccreesh, C.A.; Ehrlich, R.; Crabtree, S.J. Petrography and reservoir physics II: Relating thin section porosity to capillary pressure, the association between pore types and throat size. Ann. Biol. Clin. 1991, 15, 83–88. [Google Scholar]

- Perrin, J.-C.; Benson, S.M. An Experimental Study on the Influence of Sub-Core Scale Heterogeneities on CO2 Distribution in Reservoir Rocks. Transp. Porous Media 2010, 82, 93–109. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, L.; Cheng, H. Gas Adsorption Characterization of Pore Structure of Organic-rich Shale: Insights into Contribution of Organic Matter to Shale Pore Network. Nonrenewable Resour. 2021, 30, 2377–2395. [Google Scholar] [CrossRef]

- Dang, S.T.; Sondergeld, C.H.; Rai, C.S. A New Approach to Measuring Organic Density. Petrophysics 2016, 57, 112–120. [Google Scholar]

- Wang, P.; Jiang, Z.; Ji, W.; Zhang, C.; Yuan, Y.; Chen, L.; Yin, L. Heterogeneity of intergranular, intraparticle and organic pores in Longmaxi shale in Sichuan Basin, South China: Evidence from SEM digital images and fractal and multifractal geometries. Mar. Pet. Geol. 2016, 72, 122–138. [Google Scholar] [CrossRef]

- Gu, Y.; Ding, W.; Tian, Q.; Xu, S.; Zhang, W.; Zhang, B.; Jiao, B. Developmental characteristics and dominant factors of natural fractures in lower Silurian marine organic-rich shale reservoirs: A case study of the Longmaxi formation in the Fenggang block, southern China. J. Pet. Sci. Eng. 2020, 192, 107277. [Google Scholar] [CrossRef]

- Fassel, V.A. International Union of Pure and Applied Chemistry. Analytical Chemistry Division. Commission on Spectrochemical and Other Optical Procedures for Analysis. Nomenclature, symbols, units and their usage in spectrochemical analysis. II. Data interpretation. (Rules approved 1975). Anal. Chem. 1976, 48, 2294–2296. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, J.; Han, S.; Wang, X.; Wang, L.; Yu, W.; Wang, Z. Compositional controls on pore-size distribution by nitrogen adsorption technique in the Lower Permian Shanxi Shales, Ordos Basin. J. Nat. Gas Sci. Eng. 2016, 34, 1369–1381. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Zhang, S.; Hu, C.; Du, L.; Liu, H. Characterization of pore structures in shales through nitrogen adsorption experiment. Nat. Gas Ind. 2013, 33, 135–140. [Google Scholar]

- Zhang, X.; Lu, X.; Zhang, L.; Liu, Q. Occurrences of Shale Gas and Their Petroleum Geological Significance. Adv. Earth Sci. 2010, 25, 597. [Google Scholar]

- Yang, R.; He, S.; Hu, Q.; Hu, D.; Zhang, S.; Yi, J. Pore characterization and methane sorption capacity of over-mature organic-rich Wufeng and Longmaxi shales in the southeast Sichuan Basin, China. Mar. Pet. Geol. 2016, 77, 247–261. [Google Scholar] [CrossRef]

- Fu, H.; Wang, X.; Zhang, L.; Gao, R.; Li, Z.; Xu, T.; Zhu, X.; Xu, W.; Li, Q. Investigation of the factors that control the development of pore structure in lacustrine shale: A case study of block X in the Ordos Basin, China. J. Nat. Gas Sci. Eng. 2015, 26, 1422–1432. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.; Wang, Q.; Zhang, R.; Krooss, B. Pore structure characteristics of lower Silurian shales in the southern Sichuan Basin, China: Insights to pore development and gas storage mechanism. Int. J. Coal Geol. 2016, 156, 12–24. [Google Scholar] [CrossRef]

- Cao, Y.; Yuan, G.; Li, X.; Wang, Y.; Xi, K.; Wang, X.; Jia, Z.; Yang, T. Characteristics and origin of abnormally high porosity zones in buried Paleogene clastic reservoirs in the Shengtuo area, Dongying Sag, East China. Pet. Sci. 2014, 11, 346–362. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Littke, R. Numerical simulation of the thermal maturation, oil generation and migration in the Songliao Basin, Northeastern China. Mar. Pet. Geol. 1999, 16, 771–792. [Google Scholar] [CrossRef]

- Xie, X.; Jiao, J.J.; Tang, Z.; Zheng, C. Evolution of abnormally low pressure and its implications for the hydrocarbon system in the southeast uplift zone of Songliao basin, China. AAPG Bull. 2003, 87, 99–119. [Google Scholar]

- Morad, S.; Al-Ramadan, K.; Ketzer, J.M.; De Ros, L.F. The impact of diagenesis on the heterogeneity of sandstone reservoirs: A review of the role of depositional facies and sequence stratigraphy. AAPG Bull. 2010, 94, 1267–1309. [Google Scholar] [CrossRef]

- Kordi, M.; Turner, B.; Salem, A.M. Linking diagenesis to sequence stratigraphy in fluvial and shallow marine sandstones: Evidence from the Cambrian–Ordovician lower sandstone unit in southwestern Sinai, Egypt. Mar. Pet. Geol. 2011, 28, 1554–1571. [Google Scholar] [CrossRef]

- Morad, S.; Ketzer, J.; De Ros, L. Linking Diagenesis to Sequence Stratigraphy; John Wiley & Sons: Hoboken, NJ, USA, 2012; pp. 1–36. [Google Scholar]

- Worden, R.; Griffiths, J.; Wooldridge, L.; Utley, J.; Lawan, A.; Muhammed, D.; Simon, N.; Armitage, P. Chlorite in sandstones. Earth-Sci. Rev. 2020, 204, 103105. [Google Scholar] [CrossRef]

| Number | Depth (m) | TOC (%) | Total Porosity (%) | Whole Rock Mineralogy (%) | Clay (Phyllosilicate) Mineralogy (%) | Class of Sweet Spot Section | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Quartz | K-Feldspar | PlagioClase | Calcite | Siderite | Fe-Dolomite | Dolo- Mite | Pyrite | Total Non-Clay | Kaolinite | Chlorite | Illite/SMectite (I/S) | Illite | |||||

| 1 | 1970.19 | 0.76 | 3.01 | 20.3 | 0 | 10.7 | 5.2 | 2.9 | 0.0 | 0.0 | 2.0 | 41.1 | 1 | 1 | 57 | 42 | Class-III |

| 2 | 1981.06 | 0.56 | 2.91 | 21.5 | 0 | 12.3 | 1.5 | 1.0 | 1.3 | 1.8 | 1.9 | 41.3 | 2 | 5 | 58 | 36 | |

| 3 | 1988.17 | 1.80 | 3.52 | 22.7 | 1 | 12.6 | 0.0 | 1.1 | 0.2 | 0.0 | 1.8 | 39.4 | 2 | 4 | 59 | 36 | Class-II |

| 4 | 1999.75 | 1.63 | 3.88 | 22.7 | 0 | 13.4 | 3.9 | 1.0 | 0.2 | 0.0 | 1.3 | 42.5 | 2 | 5 | 60 | 33 | |

| 5 | 2006.02 | 1.76 | 4.90 | 25.6 | 0 | 11.5 | 6.6 | 0.5 | 0.0 | 0.0 | 1.9 | 46.1 | 1 | 3 | 63 | 33 | |

| 6 | 2024.85 | 2.10 | 5.57 | 25.3 | 0 | 11.9 | 1.2 | 0.7 | 0.0 | 0.0 | 1.4 | 40.5 | 2 | 3 | 62 | 34 | Class-I |

| 7 | 2031.97 | 2.23 | 7.40 | 31.3 | 0 | 16.1 | 11.8 | 0.0 | 0.0 | 0.0 | 1.0 | 60.2 | 4 | 10 | 58 | 29 | |

| 8 | 2036.93 | 2.00 | 5.05 | 25.2 | 0 | 19.0 | 11.4 | 0.0 | 0.6 | 0.0 | 1.7 | 57.9 | 3 | 3 | 63 | 31 | |

| 9 | 2041.49 | 2.09 | 5.17 | 21.3 | 0 | 10.2 | 19.9 | 0.0 | 0.5 | 0.0 | 1.4 | 53.3 | 2 | 4 | 64 | 30 | |

| 10 | 2044.95 | 2.42 | 6.27 | 30.8 | 0 | 9.90 | 18.7 | 0.0 | 1.0 | 1.7 | 1.4 | 63.5 | 7 | 4 | 65 | 24 | |

| 11 | 2050.32 | 1.98 | 6.12 | 29.8 | 0 | 7.80 | 5.9 | 0.0 | 0.2 | 0.0 | 2.2 | 45.9 | 8 | 5 | 60 | 27 | |

| Class of Sweet Spot Section | Depth (m) | TOC (%) | Rock Density (g/cm3) | Organic Matter Density (g/cm3) | Organic Matter Fraction (%) | Organic Matter Porosity (%) | Total Porosity (%) | Ratio of Organic Matter Pore (%) | Average Ratio of Organic Porosity (%) |

|---|---|---|---|---|---|---|---|---|---|

| Class-III | 1970.19 | 0.76 | 2.568 | 1.2 | 0.058 | 0.095 | 2.43 | 3.90 | 5.03 |

| 1981.06 | 0.56 | 2.662 | 1.2 | 0.118 | 0.146 | 2.37 | 6.17 | ||

| Class-II | 1988.17 | 1.80 | 2.641 | 1.2 | 0.031 | 0.122 | 3.88 | 3.15 | 3.43 |

| 1999.75 | 1.63 | 2.762 | 1.2 | 0.035 | 0.129 | 3.52 | 3.68 | ||

| 2006.02 | 1.76 | 2.784 | 1.2 | 0.042 | 0.170 | 4.90 | 3.46 | ||

| Class-I | 2024.85 | 2.10 | 2.521 | 1.2 | 0.042 | 0.186 | 5.57 | 3.35 | 3.36 |

| 2031.97 | 2.23 | 2.412 | 1.2 | 0.046 | 0.206 | 7.40 | 2.79 | ||

| 2036.93 | 2.00 | 2.657 | 1.2 | 0.046 | 0.223 | 5.05 | 4.02 | ||

| 2041.49 | 2.09 | 2.594 | 1.2 | 0.045 | 0.204 | 5.17 | 3.95 | ||

| 2044.95 | 2.42 | 2.584 | 1.2 | 0.035 | 0.184 | 6.27 | 2.93 | ||

| 2050.32 | 1.98 | 2.597 | 1.2 | 0.045 | 0.191 | 6.12 | 3.12 |

| Pore Type | Shape of Pore (Fissure) | Features of Pore Diameter or Fissure Width | Origin | |

|---|---|---|---|---|

| Organic matter pore | Migrated organic matter pore | In circle, triangle, and polygon shapes | 20–200 nm in general | Formed when liquid hydrocarbon generated by kerogen during gas generation stage migrated, and filled in residual intergranular pores, and intragranular pores |

| Primary organic matter pore | In narrow slit shape | Less than 10 nm | Formed as the primary solid organic matter (kerogen) left during shale deposition expelled hydrocarbon under thermal effect | |

| Inorganic matter pore | intergranular pore | Largely in narrow slit and polygon shapes | Less than 62 μm | These pores are residual primary pores after compaction of mineral particles in certain arrangement, and are commonly seen in between quartz, feldspar, and clay mineral particles |

| Intragranular pore | In sheet and irregular shapes | 200–2000 nm | Formed by dissolution of quartz, feldspar, calcite, and dolomite | |

| Intercrystalline pore | In sheet, narrow slit or triangle polygon shapes | 100–300 μm | They are residual pores formed due to loose packing and compaction resistance of particles during crystal growth, and are commonly seen in pyrite, and dolomite crystals | |

| Micro-fissure | Diagenetic micro-fissure | In long strip, saw teeth, and irregular shapes | More than 1nm long, and 50–200 μm wide | Formed along edges of brittle minerals and clay minerals as rock shrinks in volume during diagenesis |

| Tectonic micro-fissure | In network and polygonal line shapes | More than 5nm long, and 20–500 μm wide | Formed dure to tectonic disruption, they are tensional micro-fissures and often filled by calcite and quartz | |

| Class of Sweet Spot Section | BET Surface Area (m2/g) | Total Pore Volume (10−3cm3/g) | Average Pore Diameter (nm) | Percentage of Pores in Different Diameter Ranges (%) | ||

|---|---|---|---|---|---|---|

| Micro-Pores | Small Pores | Medium Pores | ||||

| Class-I | 3.8974–7.2049 (4.5645) ① | 7.45–16.78 (11.26) | 4.22–13.45 (8.01) | 30.65–40.54 (32.26) | 40.45–50.65 (45.28) | 10.45–30.57 (22.46) |

| Class-II | 3.8933–6.1624 (4.0424) | 6.48–13.54 (10.36) | 4.00–12.55 (6.68) | 28.45–58.63 (40.32) | 29.04-57.24 (43.44) | 5.74–31.21 (16.24) |

| Class-III | 1.0372–1.2668 (1.2514) | 5.46–6.86 (5.82) | 2.16–7.86 (4.21) | 29.65–84.21 (55.42) | 16.87–48.68 (28.60) | 5.29–36.12 (15.98) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Bao, Z.; Wei, Z.; Wang, H.; Zhao, W.; Dong, W.; Shen, Z.; Wu, F.; Tian, W.; Li, L. Characteristics and Affecting Factors of K2qn1 Member Shale Oil Reservoir in Southern Songliao Basin, China. Energies 2022, 15, 2269. https://doi.org/10.3390/en15062269

Li Z, Bao Z, Wei Z, Wang H, Zhao W, Dong W, Shen Z, Wu F, Tian W, Li L. Characteristics and Affecting Factors of K2qn1 Member Shale Oil Reservoir in Southern Songliao Basin, China. Energies. 2022; 15(6):2269. https://doi.org/10.3390/en15062269

Chicago/Turabian StyleLi, Zhongcheng, Zhidong Bao, Zhaosheng Wei, Hongxue Wang, Wanchun Zhao, Wentao Dong, Zheng Shen, Fan Wu, Wanting Tian, and Lei Li. 2022. "Characteristics and Affecting Factors of K2qn1 Member Shale Oil Reservoir in Southern Songliao Basin, China" Energies 15, no. 6: 2269. https://doi.org/10.3390/en15062269

APA StyleLi, Z., Bao, Z., Wei, Z., Wang, H., Zhao, W., Dong, W., Shen, Z., Wu, F., Tian, W., & Li, L. (2022). Characteristics and Affecting Factors of K2qn1 Member Shale Oil Reservoir in Southern Songliao Basin, China. Energies, 15(6), 2269. https://doi.org/10.3390/en15062269