1. Introduction

Power systems are rapidly evolving into smart grids (SGs) that combine a digital communication network, which enables bidirectional communication between electricity producers and consumers, with power grids installed with distributed generation (DG) systems that maximize the efficiency of energy use. Several algorithms have been proposed for the protection and control of power grids with tree structures [

1,

2].

However, these algorithms cannot be applied directly, because the SGs, equipped with DG systems, exhibit different fault phenomena than those occurring in the existing power grids. In particular, the fault phenomena depend on the number of installed DG systems and their location. To solve this problem, new algorithms for protection and control of SGs have been proposed [

3,

4,

5]. Unlike the protection and control algorithms, which use unidirectional communication, for existing power grids, the algorithms for SGs can utilize bidirectional communication between power facilities, including protection devices (PDs) and DGs. This makes the protection and control algorithms highly complex and difficult to implement. Accordingly, to apply the proposed algorithms to an actual SG, reliability must be ensured through sufficient and diverse fault analysis and tests performed on the SG.

Firstly, the developed algorithms are modelled and simulated via a software-based simulation approach. In this approach, the power system is modeled using software tools such as EMTP-RV [

6,

7] or PSCAD/EMTDC [

8], and the overall performance is verified by modeling the proposed algorithm and then applying it to the system model. Although this approach is easy to apply in the laboratory, it is difficult to guarantee reliability unless the dynamic characteristics of the system are perfectly modeled by the best experts. Furthermore, it is impossible to test the power control device to which the algorithm is applied, directly. Additionally, testing the algorithm using the communication function of the SG is impractical. Secondly, a hardware-based approach can be considered. Although this method is used to assess the reliability of a system, it cannot be applied, because of a huge spreading effect that is observed when applied on a large-scale actual system. Therefore, a demonstration test site is required. However, the scale and configuration of the demonstration test site are significantly limited by the high costs and length of time required to construct such a demonstration test site. Given that the system voltage is high (23 kV) and has a limited configuration, it is difficult to satisfy the various special system configuration conditions required by new algorithms for SGs. Moreover, it is impossible for researchers to conduct experimental tests freely because of the accompanied risks, which may arise when such a system is operated by an operator who does not have expertise. Recently, hardware in the loop system has received significant attention [

9,

10] because of its hybrid approach, in which the performance of the new algorithms can be tested by providing input/output (IO) signals, from a modeled system based on a real time digital simulator (RTDS) to a hardware device developed through IO interfaces.

However, this approach is also likely to experience the same problems as the software approach mentioned before because the RTDS generates system dynamics based on software tools. To overcome this problem, a laboratory test environment is required to perform stable testing of the reliability of a power control device to which a new algorithm is applied under real-time voltage and current signals obtaining from the electrical dynamics of an actual SG. Additionally, a two-way communication test environment is required to test a new control strategy based on the bidirectional communication of the SG as well.

To date, several studies on miniaturization of systems or devices have been conducted in the fields of electronic devices [

11,

12], aerospace engineering [

13], optics [

14], and mechanics [

15]. The miniaturization of sensors, computers, electric motors, microphones, medical devices, and robots has provided significantly innovative and successful solutions. In the biomedical field, a micro total analysis system, known as a “lab on a chip”, is proposed to reduce space and energy. Such a system is portable and integrates several processes that are performed in the laboratory to analyze and evaluate the samples and miniaturize them into a single device [

16,

17]. Furthermore, several successful research results have also been presented in the field of robotics based on miniaturized sensors and activators [

18,

19]. Recently, several studies on miniaturization in the power grids have been demonstrated [

20,

21]. Especially Ko (2018) [

20], who proposed a new and efficient downscaling method for the miniaturization of SGs and presented the design results of a micro SG simulator based on the proposed method. This proposed micro SG simulator has a size that is one thousandth that of the SG, allowing free and safe experimentation with the new operation control algorithms in the laboratory. Ko et al. [

21] proposed a miniaturized PD, known as a micro PD, to meet the specifications of the micro SG simulator. This micro PD plays the same roles as those of the circuit breaker (CB) and recloser or section switches on the micro SG simulator. However, the micro DG that plays the role of DG in the micro SG simulator, which is essential in verifying the control algorithms of the SG experimentally, remains hitherto unexplored. Several researchers proposed grid connection methodologies of DG for SG [

22,

23,

24]; however, they cannot be applied directly to the micro SG simulator because of the large differences in the size and power levels of the DG systems. To realize this new method, a miniaturization method that can downscale the size and power levels to that of a micro SG simulator needs to be developed. In particular, whether or not control algorithms such as the grid synchronization and PQ control algorithms, applied to the SGs, are effective even at the micro SG simulator level should be verified. Such a verification would allow us to conversely infer that the control algorithms verified in the micro SG simulator have the same validity when applied to the SG.

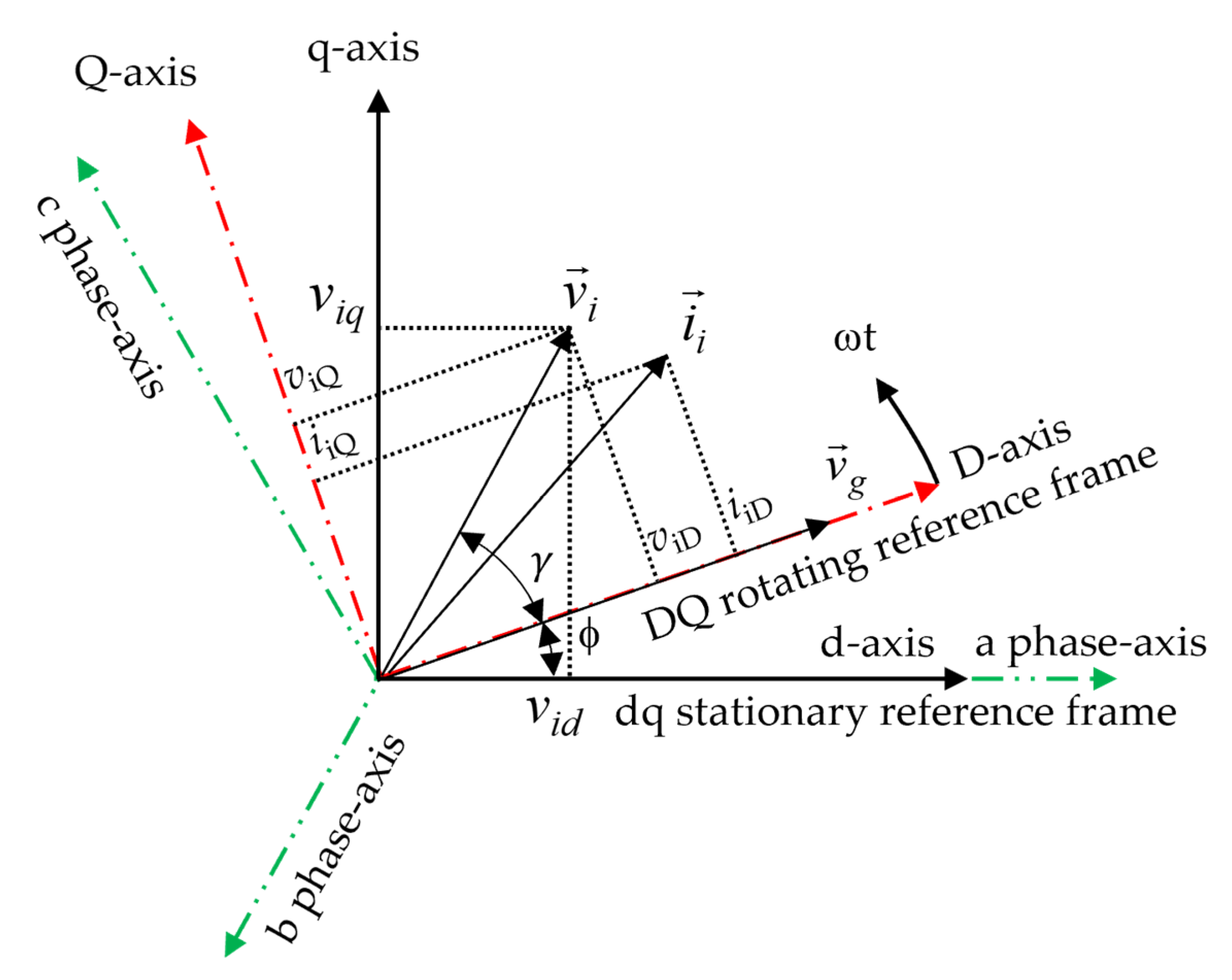

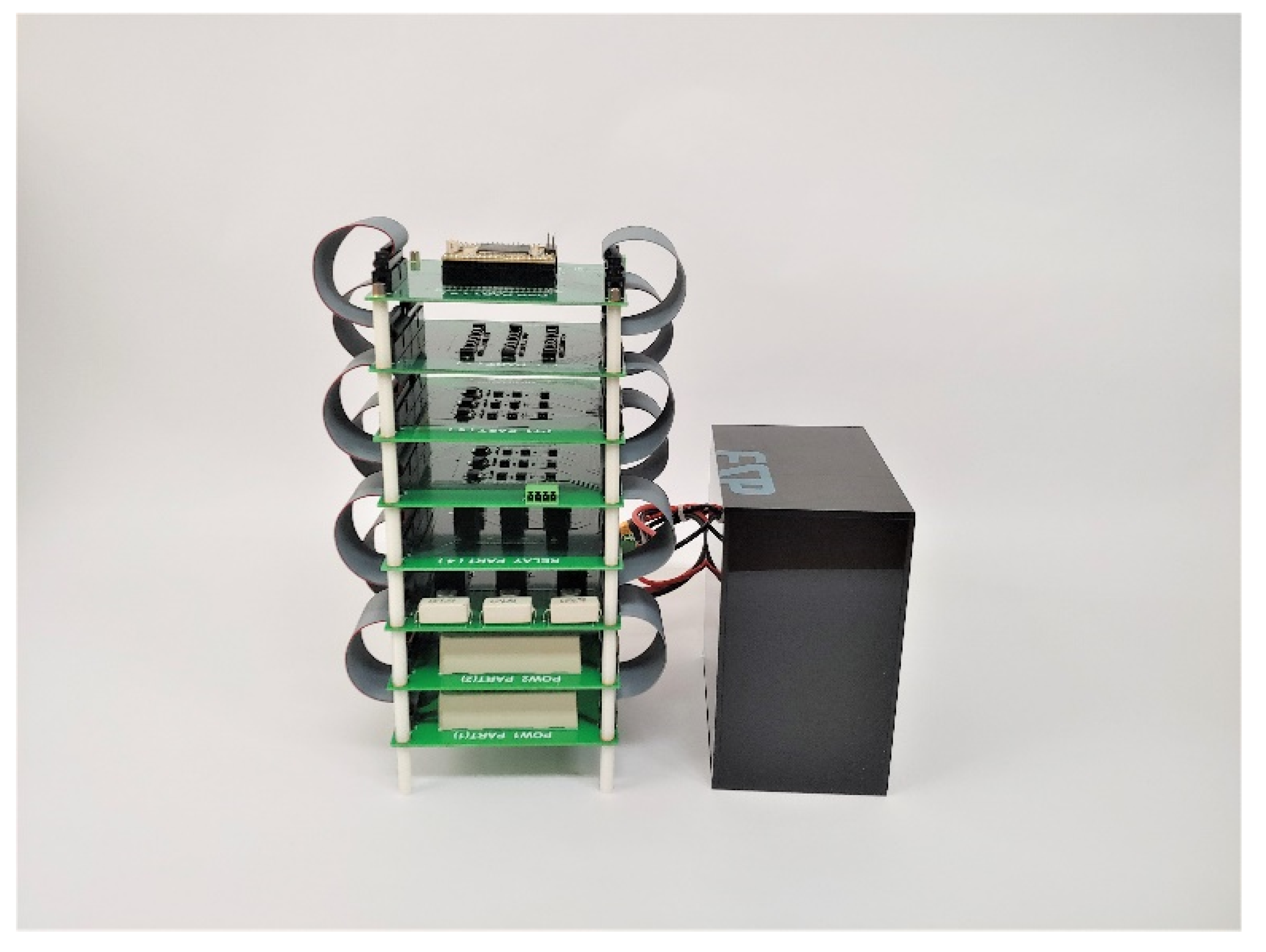

Accordingly, herein, a miniaturization method for developing a micro DG that plays the role of DG in the micro SG simulator is proposed. In this study, first, the micro DG system was designed with a multi-layer structure, in which each function is implemented in several layers to satisfy the size requirements. Second, the grid synchronization and PQ control algorithms, required for the DG, were developed based on the DQ transformation. Third, the effectiveness of the developed algorithm was verified through EMTP modeling and simulation. Fourth, a three-phase 19 V power system was experimentally built, and based on this, one micro DG system was developed through experimental verification. Finally, through grid synchronization and PQ control experiments, it was verified that the micro DG based on the proposed miniaturization method could be applied as a DG of the micro SG simulator. Simultaneously, the dynamic electrical characteristics were analyzed during the connection operation to verify that the micro DG on the micro SG simulator shows the same electrical characteristics as those of the DGs of the SG.

2. Equivalent Model of Smart Grid Connected with DG

In this paper, the SG is defined as a distribution system with distributed generations that is connected by a digital communication network. In particular, the DG source is represented as a battery source because it is assumed that the DG includes a single battery, and a constant output is possible regardless of variable weather conditions due to the battery.

Figure 1 shows the configuration of a representative SG connected with DG.

In

Figure 1, E

DC is the battery voltage of the DG, VSI is a three-phase voltage source inverter for converting DC power to AC power, and the power filter is a filter to limit the harmonic current flowing from the DG to the SG. In addition, DG CB represents a CB used to connect or separate the DG system from the SG, and “Grid” indicates a three-phase AC power source. The smart-grid-connected operation control of the DG can be divided into two modes. The first mode is a synchronization mode that matches the magnitude and phase of the output voltage of the three-phase inverter to those of the SG voltage. Here, synchronization is required to prevent reactive crossflow, due to voltage magnitude difference, or synchronization current, due to phase difference. After the synchronization is complete, the DG CB is closed to connect the SG with the DG.

The second mode is the PQ control mode used to transmit the required active power and reactive power to the SG at the request of the utility.

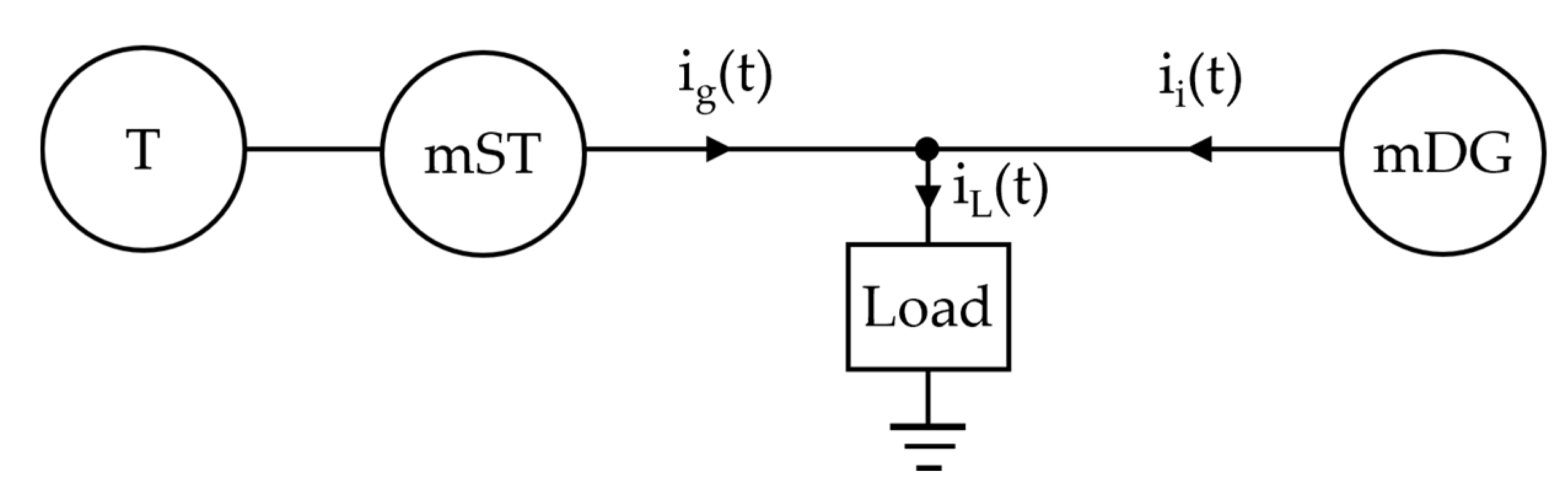

Figure 2 shows the equivalent model of a SG with DG after the DG CB is closed.

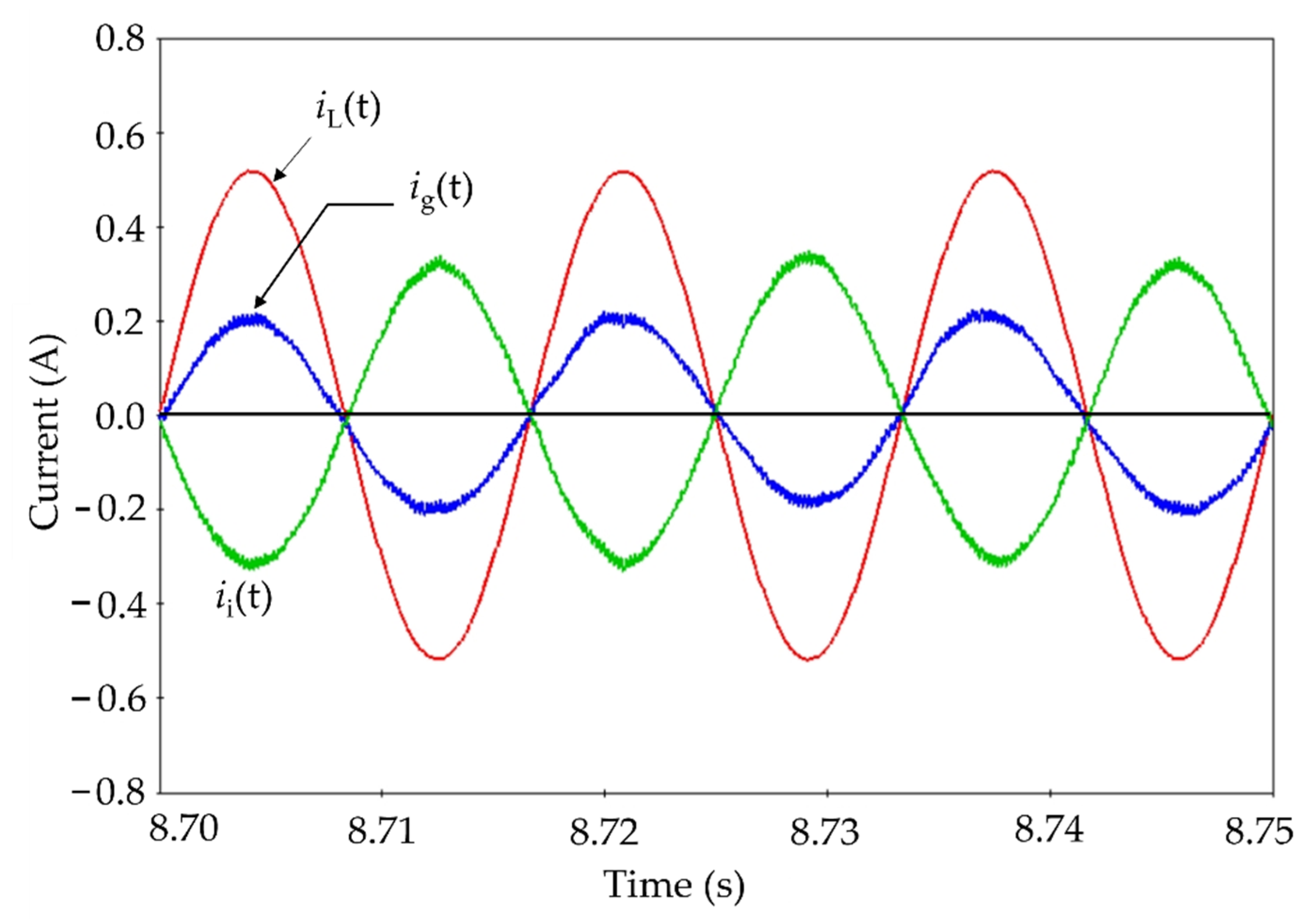

The output current of the three-phase PQ-controlled inverter is injected into the grid load through the distribution line of the SG. Simultaneously, the grid current is injected into the grid load through the distribution line from the bank transformer of the SG. After the DG CB is closed (as shown in

Figure 2), E

i(t) becomes equal to E

g(t), thus, the load current i

L(t) can be expressed using Equation (1).

Here, ii(t) is the inverter output current, ig(t) is the SG line current, Zi is inverter’ output impedance, Zg is SG line impedance, and ZL is the load impedance. Accordingly, for the micro DG on the micro SG simulator to play the same role as that of the DG of the SG, it must have a synchronization function for system connection as well as a PQ control function. In particular, Equation (1) must be satisfied for PQ control under the interconnection operation

3. Design of a Micro DG

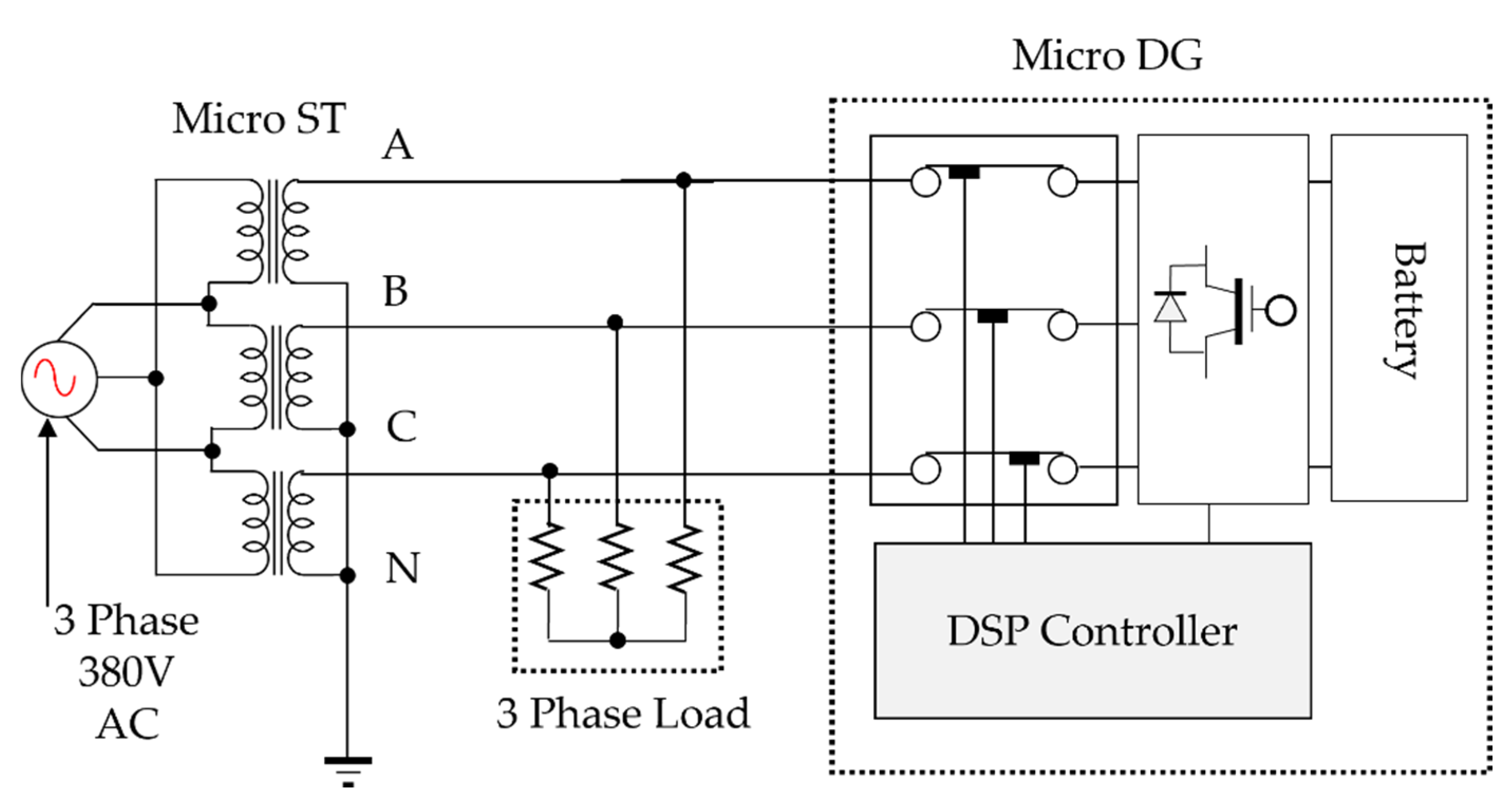

Figure 3 shows the configuration of a micro SG simulator designed with a size of 2 m × 2 m, reduced to 1/1000 of that of the SG via downscaling [

20]. A micro substation transformer (micro ST) is a power transformer designed for a micro SG simulator, which has three-phase Δ-Y wiring, a capacity of 190 VA, an output voltage of 19 V, and six distribution lines (micro DLs) as its basic specifications. Here, 19 V is a voltage determined to minimize the size of the protective devices based on the micro SG simulator design procedure.

In

Figure 3, D

i means the

ith micro DG, and the number and location of the micro DGs can be freely added or changed according to the test characteristics, independent of the configuration shown in

Figure 3. In this figure, FCL and R represent the fault current limiter and recloser, respectively, and symbols

![Energies 15 01511 i001 Energies 15 01511 i001]()

and

![Energies 15 01511 i002 Energies 15 01511 i002]()

represent the section and tie switches, respectively; the micro PDs act as CBs, reclosers, section switches or tie switches; AFG is a device that artificially generates any fault at any location on the micro SG simulator.

The micro DG can be realized by reducing the size of the DG and by lowering the electrical level of the DG to meet the design specifications of the micro SG simulator shown in

Figure 3. Accordingly, the micro DG is designed with a rated voltage of 19 V and a rated frequency of 60 Hz. Currently, the electric power companies are demanding that the capacity of the DG be increased to a maximum of 30% of the distribution line capacity in the near future. According to this trend, the output capacity of the micro DG is determined to be 7.5 VA, which is 30% of that of the micro DL capacity.

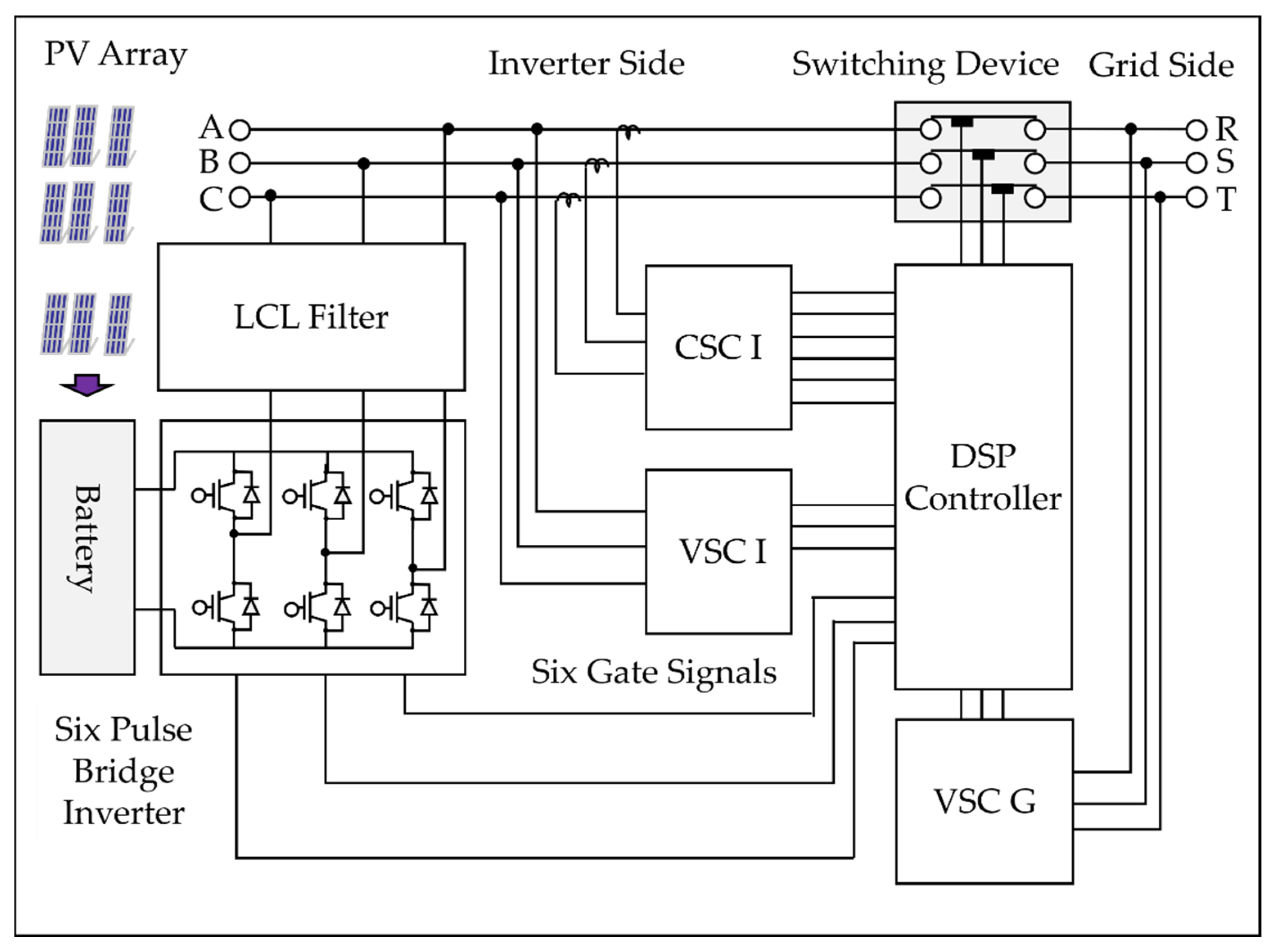

Figure 4 shows the configuration of the proposed micro DG, which consists of a micro inverter, an LCL filter, a power switching device, and a battery.

3.1. Design of the Micro Inverter

Generally, DG includes one inverter as a key element to convert DC power into AC power and supply it to the SG. The micro inverter in the micro SG simulator must play the basic roles of the DG inverter used in the SG. These basic roles include grid synchronization, protection and coordination, and PQ control based on connection operation with the micro SG simulator. To perform these basic roles through connection operation with the micro SG simulator, the micro inverter is designed as a three-phase six-pulse voltage source inverter with a 19 V output voltage, 60 Hz output frequency, and 7.5 W output capacity to satisfy the design specifications of the micro DG as mentioned before.

A voltage sensing circuit VSC I is designed to measure the three-phase voltages of the micro inverter, and a voltage sensing circuit VSC G is designed to measure the three-phase voltages of the micro SG simulator. Their maximum measurable voltage is determined in the range of 1.5 to 2 pu for the nominal phase voltage of the micro SG simulator. Considering the variations in the supply voltage and unexpected overvoltage, 2 pu is adopted as the upper limit of the voltage range. Given that the line-to-line voltage of the micro SG simulator is 19 V, the measurement range for the phase voltage sensing circuits is designed to be 22 Vrms. Furthermore, a current sensing circuit CSC I is designed to measure the three-phase currents of the micro inverter. Its measuring range is designed to be 30 Arms by considering the maximum fault current of the micro SG simulator. In addition, a DSP-based controller is designed to perform the SPWM control of the six-pulse voltage source inverter and to execute the open/close control of the power switching device. This is required to operate and control the grid connection operation based on the voltage and current information provided from these voltage and current measurement circuits.

3.2. Design of the Micro Power Switching Device

The power switching device is designed to connect the micro DG to the micro SG simulator or to prevent the micro DG from any faults on the micro SG simulator. The minimum operating current of the power switching device, I

Dmoc, can be determined by Equation (2).

Here, α is the safety factor of the operating current to protect the micro DG from external faults. In general, α = 1 is determined in the case of an inrush current suppression circuit, but α = 2 is obtained when no inrush current circuit is considered. As Vi = 19 Vrms and Pi = 7.5 W, the minimum operating current of the power switching device is designed to be 700 mArms, and its breaking capacity is determined to be 5 Arms because the fault current is suppressed by the LCL filter.

3.3. Design of the Battery

The battery is designed to be 13 × 10 cm

2 to meet the design specifications of the micro DG. The DC-link voltage of the battery must be designed so that the output voltage of the micro inverter can sufficiently follow the voltage of the micro SG simulator. The micro inverter, LCL filter, and micro SG simulator are connected in a cascading structure. If the output voltage of the inverter follows the grid voltage of the micro SG simulator in the SPWM inverter, then the battery voltage E

DC can be determined by Equation (3) as:

In Equation (3), M = 0.75, which is the maximum allowable magnitude control ratio of the output voltage to the input voltage in the PWM inverter [

25]; β represents the safety factor, and it is determined as the sufficient voltage in consideration of the voltage changes in the supply power or the voltage drop of the inductor. Here, based on experimental experience, it is determined as 1. Accordingly, from Equation (3), the battery voltage E

DC is determined to be approximately 62 V.

3.4. Design of the LCL Filter

The LCL filter is designed to remove the harmonic currents flowing from the inverter to the micro SG simulator. Compared to the LC filter, the LCL filter has the advantage of a reduced size and low switching frequency. Initially, the LCL filter is designed according to the LCL filter design procedure proposed in [

25,

26,

27].

Here, the allowable ripple rate, γ, of the inverter-side inductor, the grid’s maximum power factor variation μ, and the harmonic attenuation rate, δ, of the output current to the input injection current of the grid-side inductor are determined to be 20 [%], 5 [%], and 20 [%], respectively. Subsequently, the LCL parameters are modified appropriately through repeated experiments.

Table 1 shows the design specifications of the micro DG, determined based on the micro DG design procedure described above. In

Table 1, V

i is line-to-line voltage of the micro inverter.

7. Conclusions

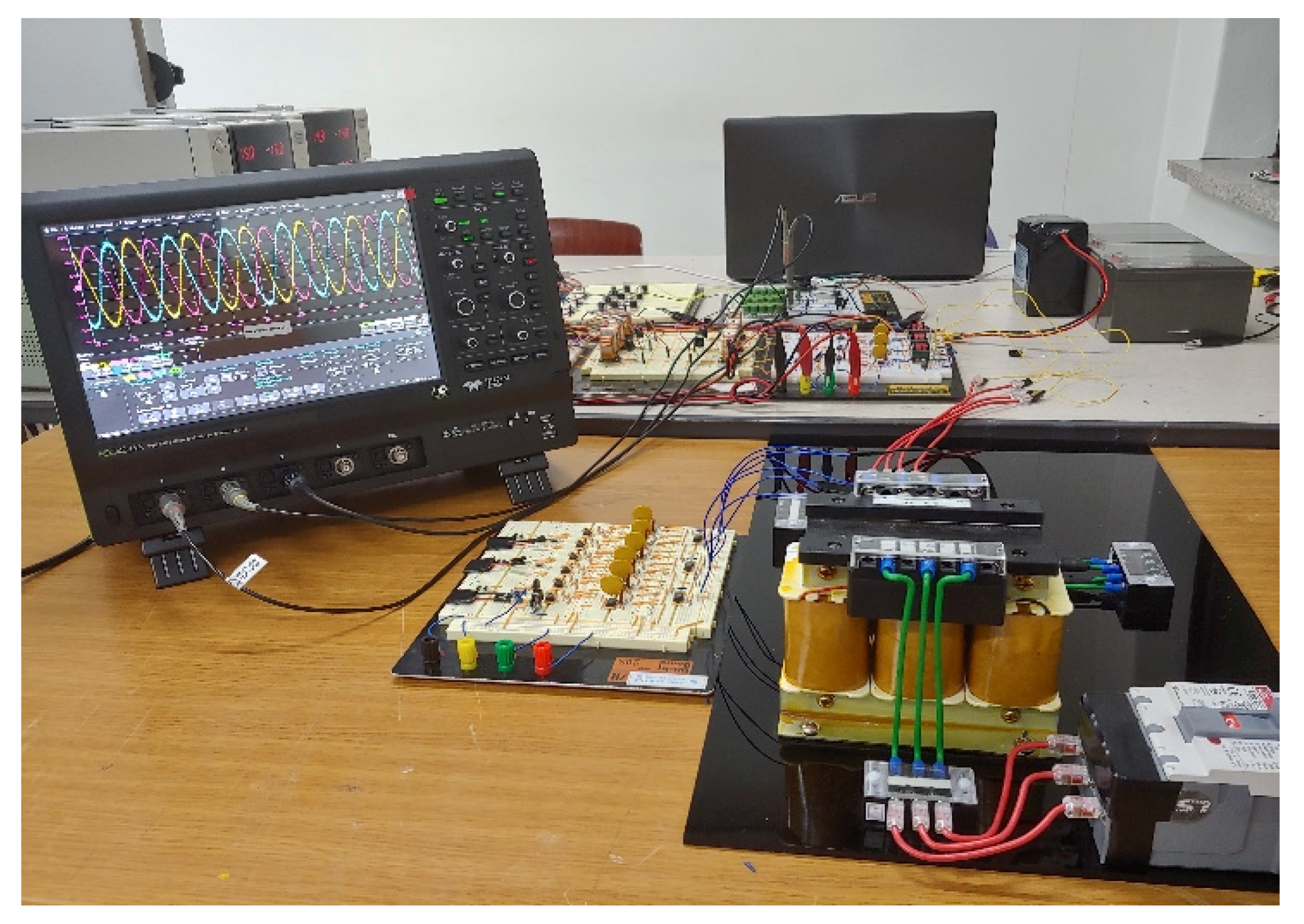

In this paper, a method is proposed for the miniaturization of DG, required to develop a micro DG. Using this proposed method, a micro DG was designed and developed as a three-phase structure with an output voltage of 19 V and a rated capacity of 7.5 W in accordance with the design specifications of a micro SG simulator. In particular, the micro DG was developed with a size of 13 × 20 cm2 by designing each function of the micro inverter on a 13 × 13 cm2 circuit board with a multi-layered structure. A DQ frame-based synchronization was performed, and a PQ control algorithm was developed for operating the micro DG and micro SG simulator in connected mode.

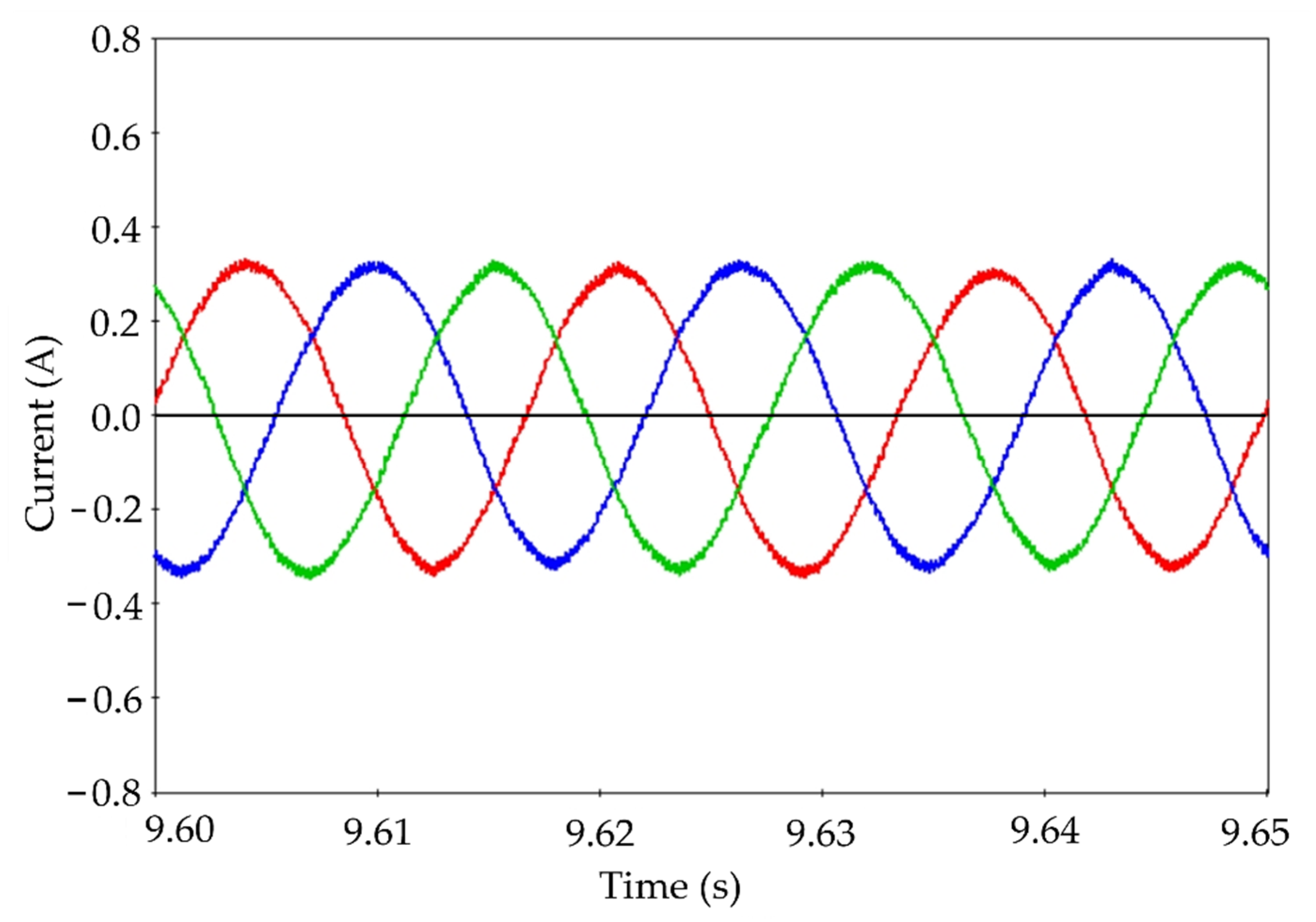

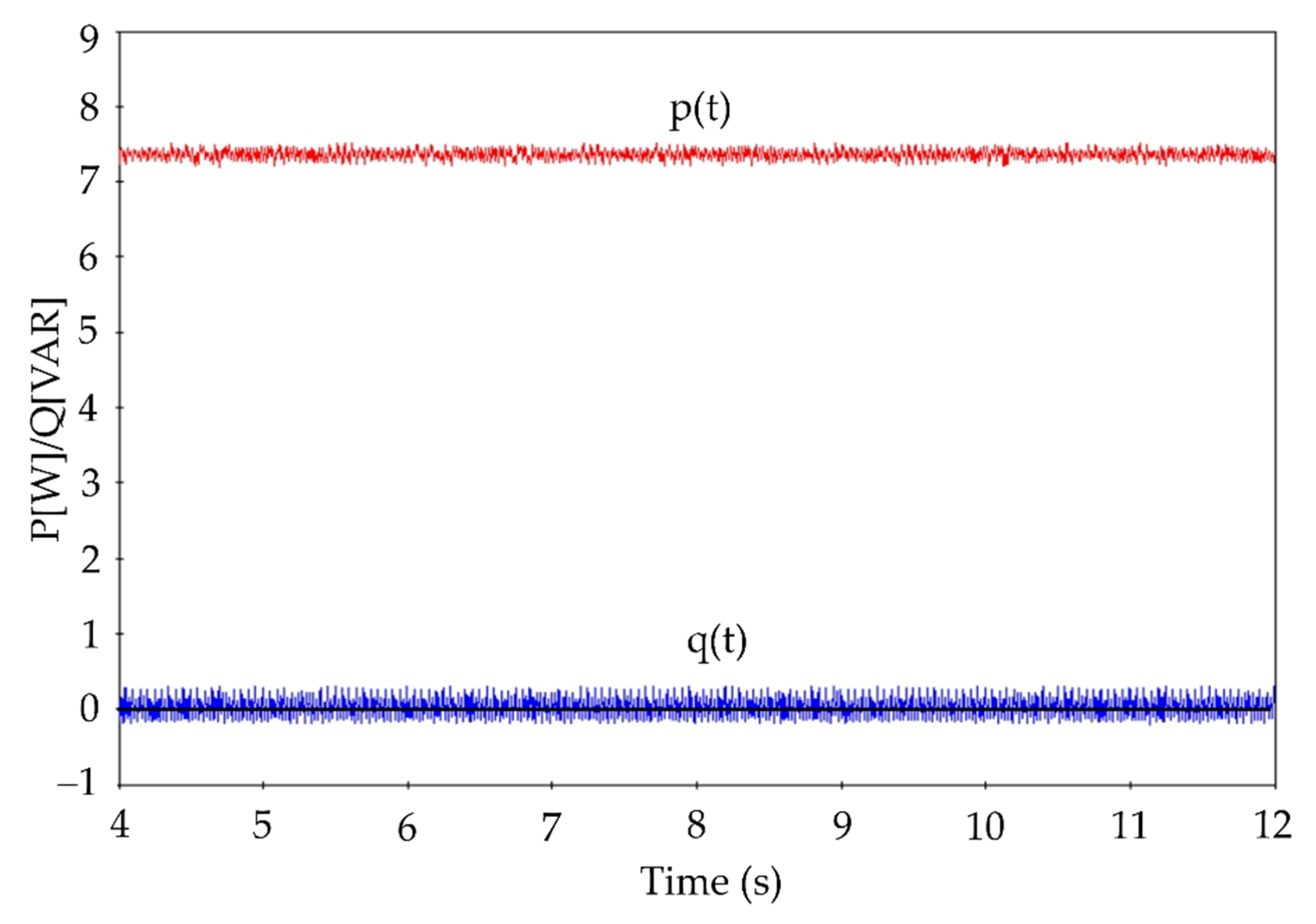

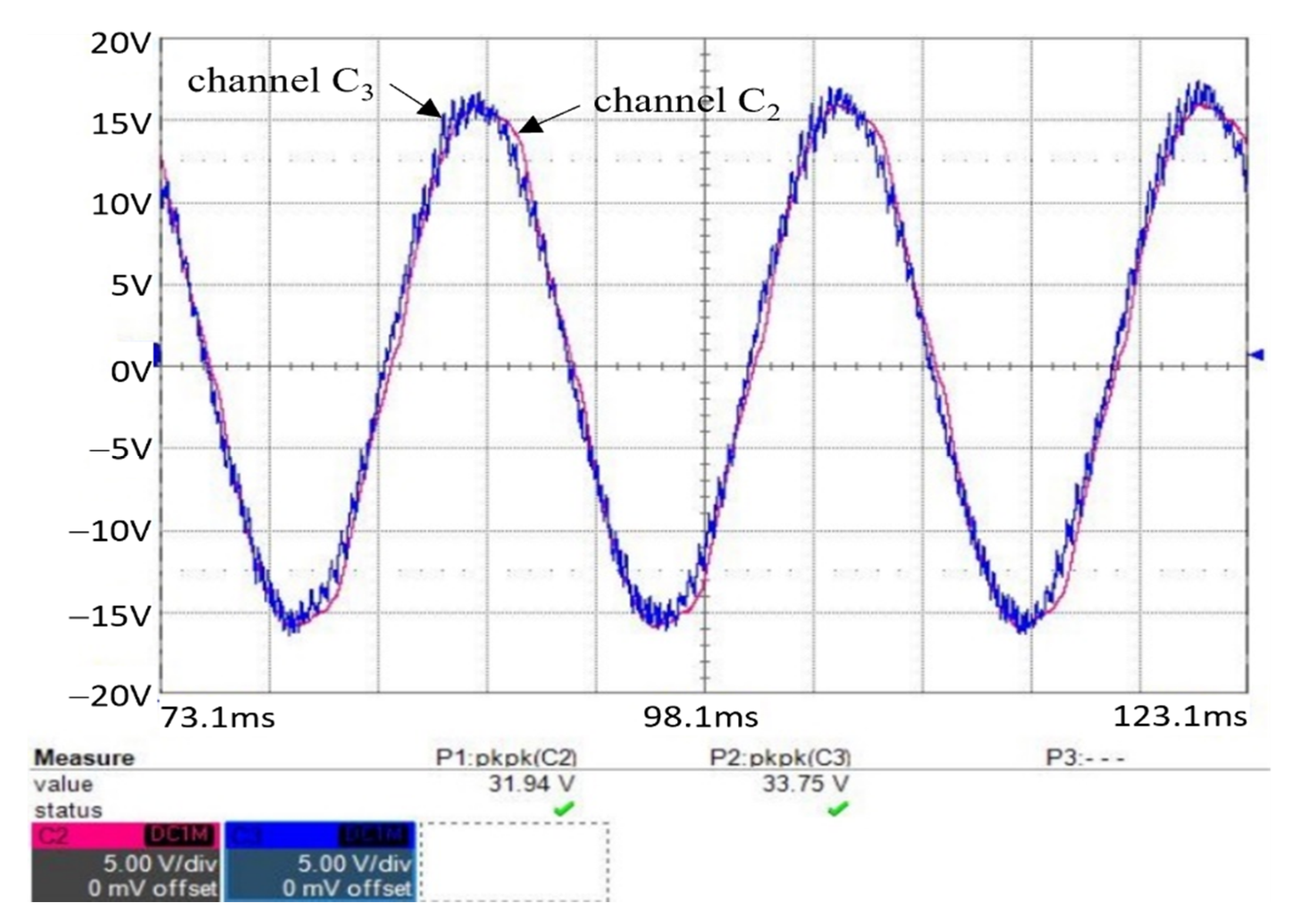

Initially, a micro DG was modeled as an EMTP model, and the validity of the developed algorithm was verified through EMTP-RV simulation. It was confirmed that the magnitude and phase of the output voltage of the micro inverter were the same as those of the test-system voltage. Further, it was identified that the output of the micro inverter model accurately followed the PQ control command of 7.5 W. These results verify the effectiveness of the developed algorithm. Based on this algorithm, a prototype of the DG was prepared, and a test system, based on a test line corresponding to the micro SG simulator, was constructed. Using the test system, it was confirmed that the magnitude and phase of the output voltage of the micro inverter matched exactly those of the test-system voltage. Moreover, the active and reactive powers of the micro inverter could be controlled within 10% of the maximum allowable error range using the PQ control command. Furthermore, the dynamic electrical characteristics of the DG–SG connected system were found to be approximately the same as those observed when a micro DG was connected and operated with the micro SG simulator.

In conclusion, it was established that the proposed method for the miniaturization of DG was highly effective, and the subsequently developed micro DG could be successfully applied in a micro SG simulator. Thus, it is expected that the micro DG, prepared using the proposed method, can serve as a DG for developing new operation control algorithms for SGs.

and

and  represent the section and tie switches, respectively; the micro PDs act as CBs, reclosers, section switches or tie switches; AFG is a device that artificially generates any fault at any location on the micro SG simulator.

represent the section and tie switches, respectively; the micro PDs act as CBs, reclosers, section switches or tie switches; AFG is a device that artificially generates any fault at any location on the micro SG simulator.