Hardware and Software Implementation for Solar Hot Water System in Northern Regions of Russia

Abstract

:1. Introduction

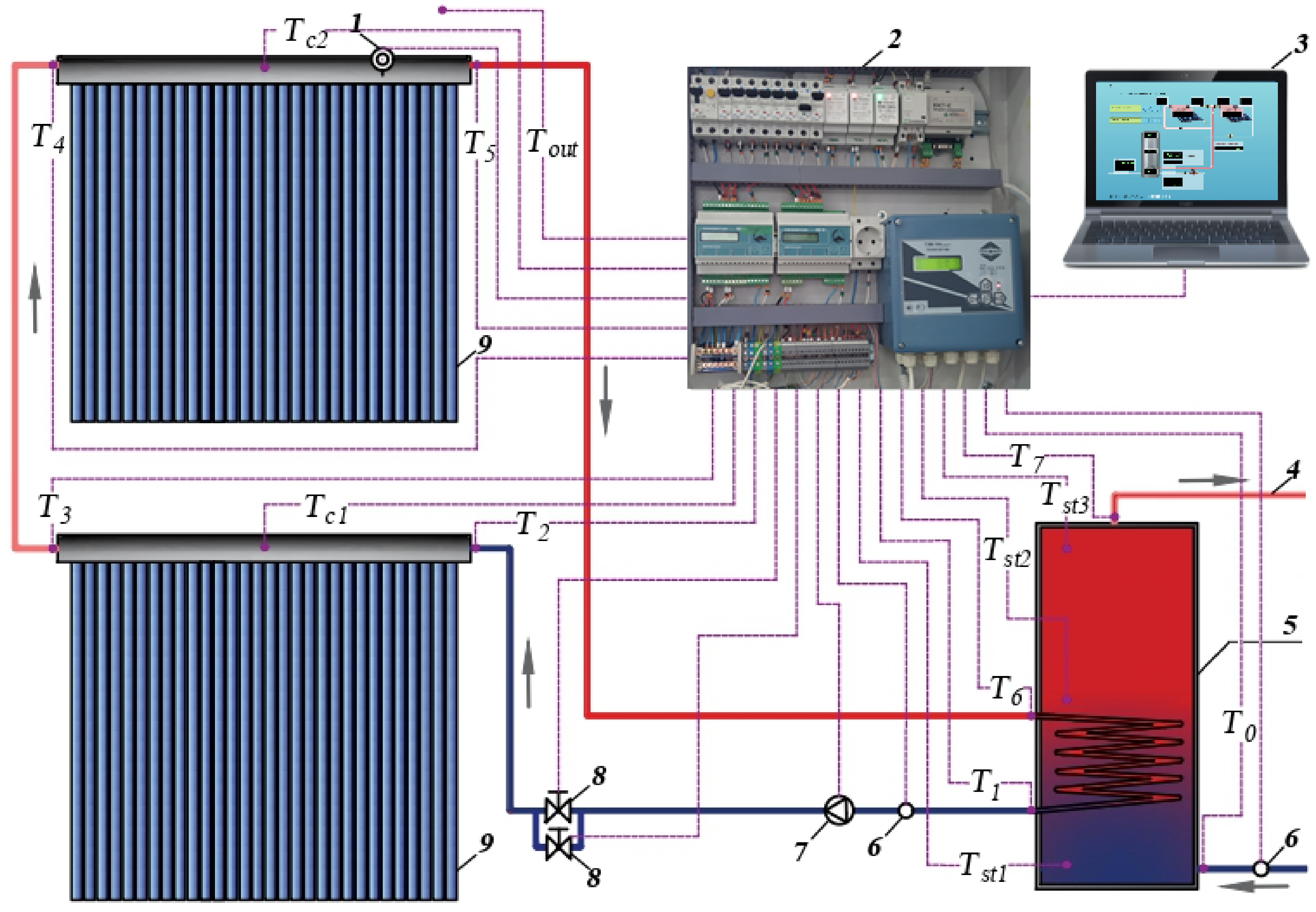

2. Materials and Methods

3. Results and Discussion

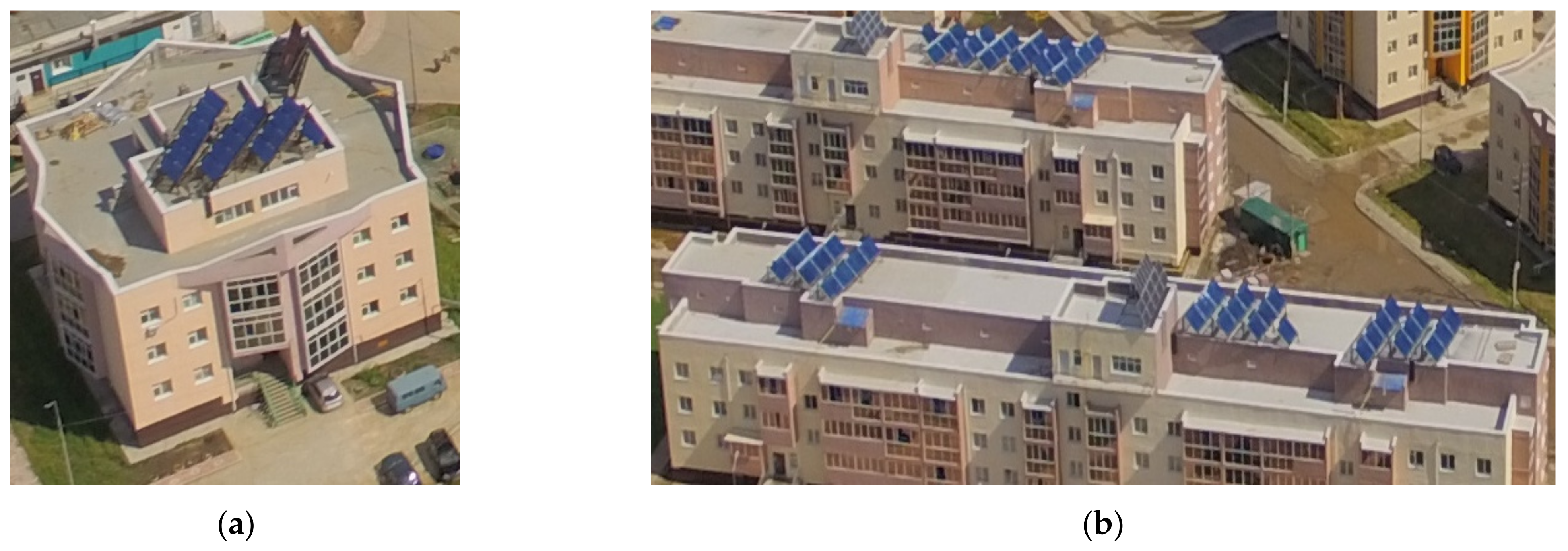

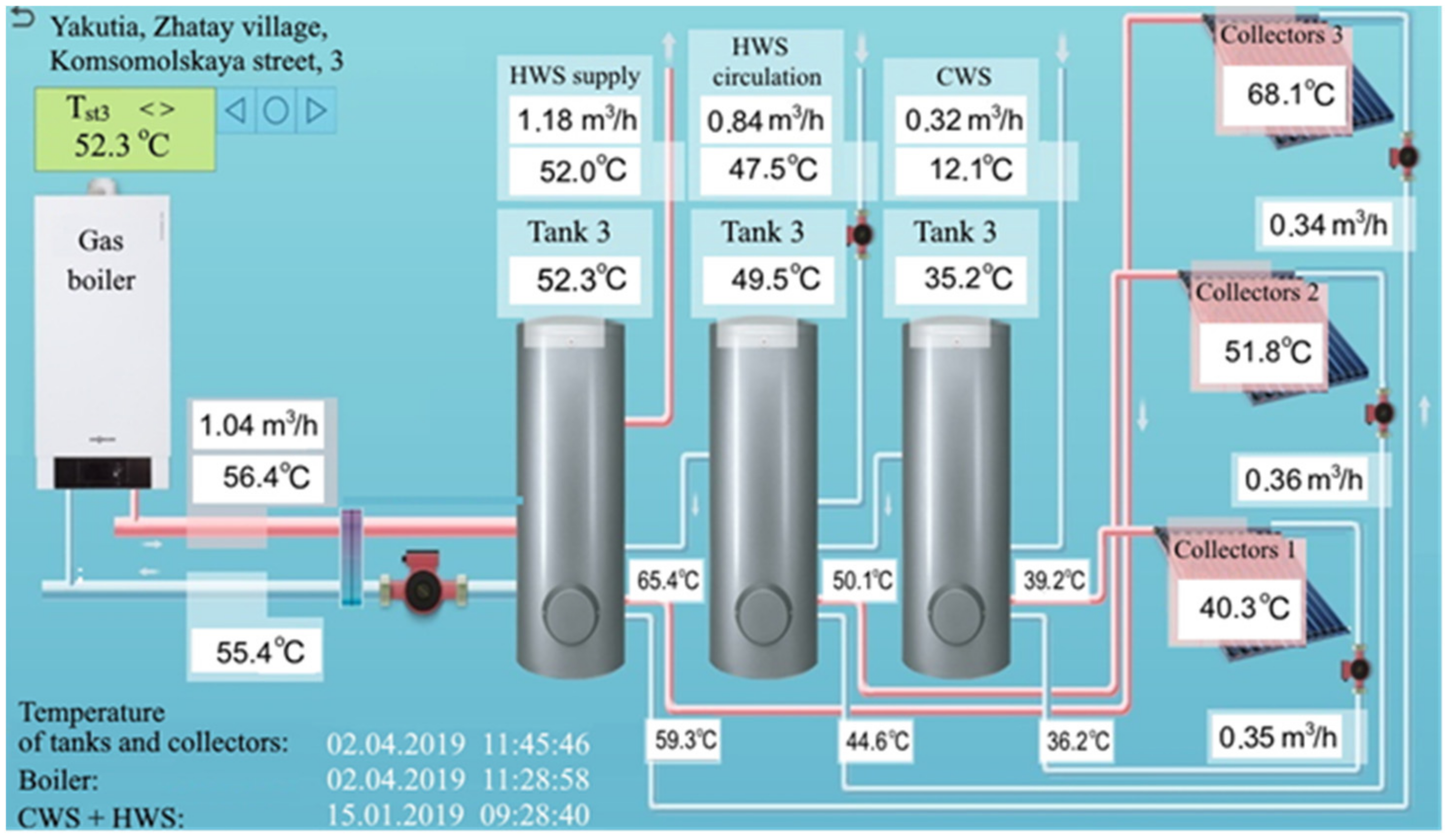

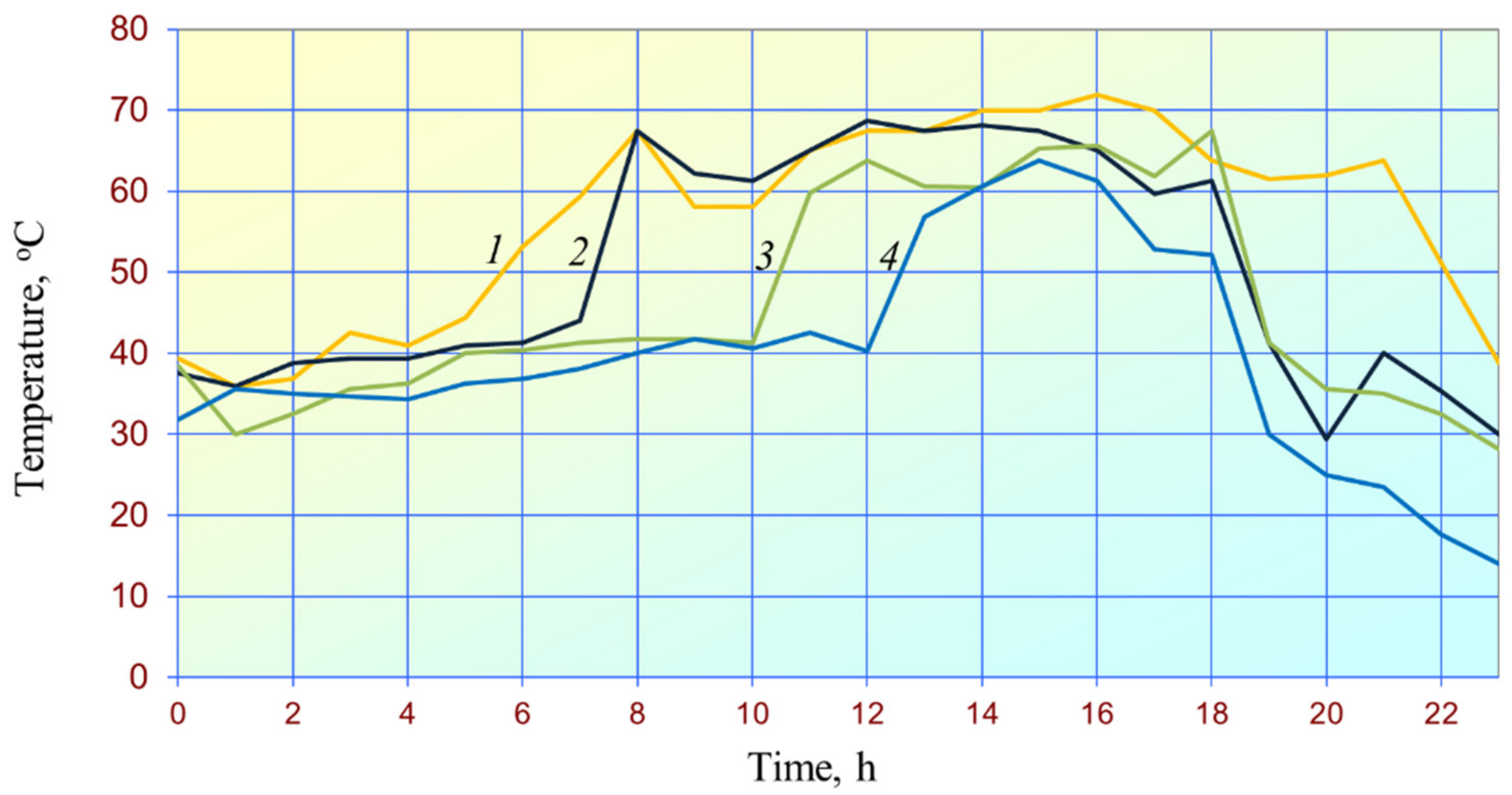

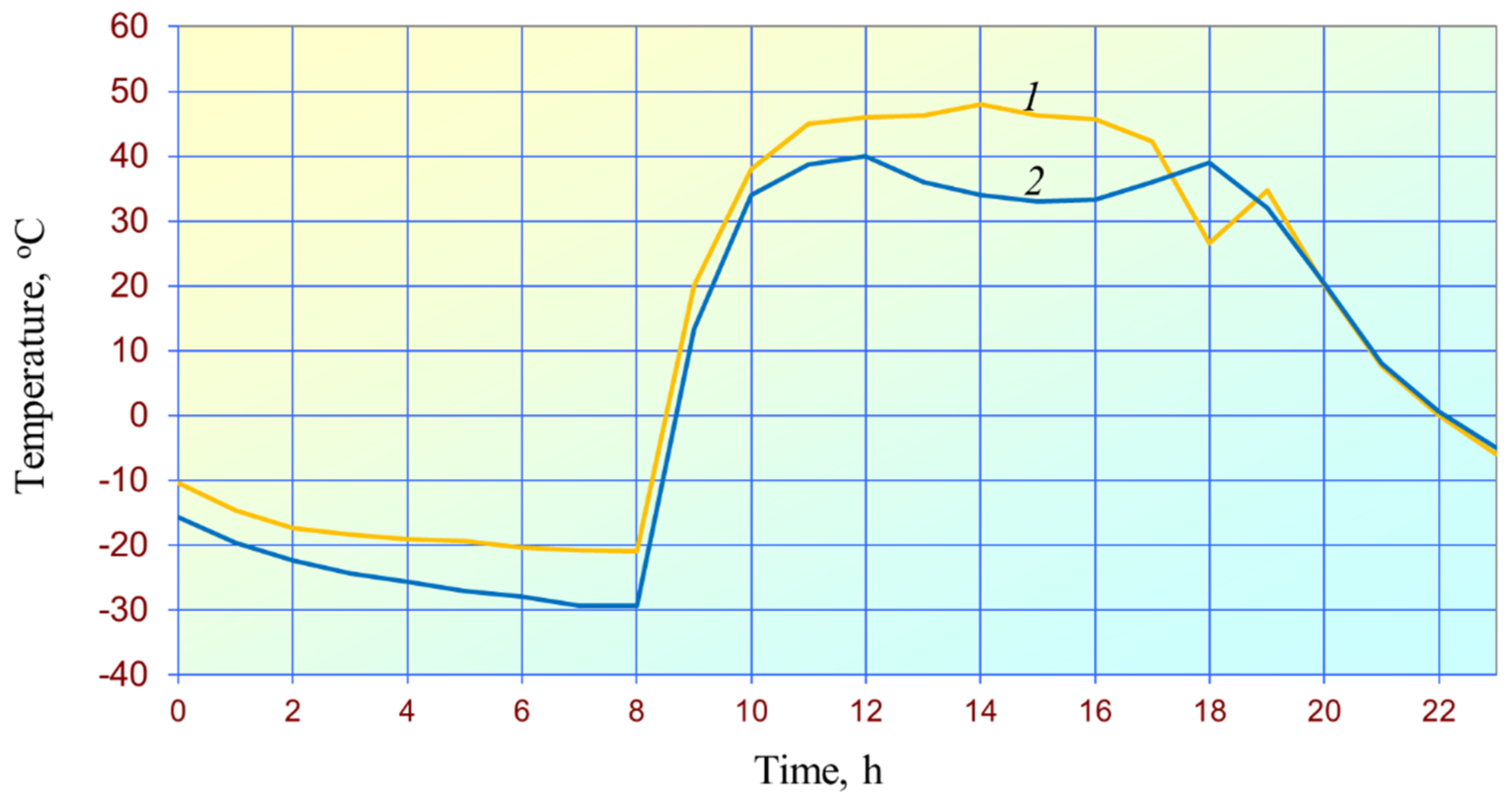

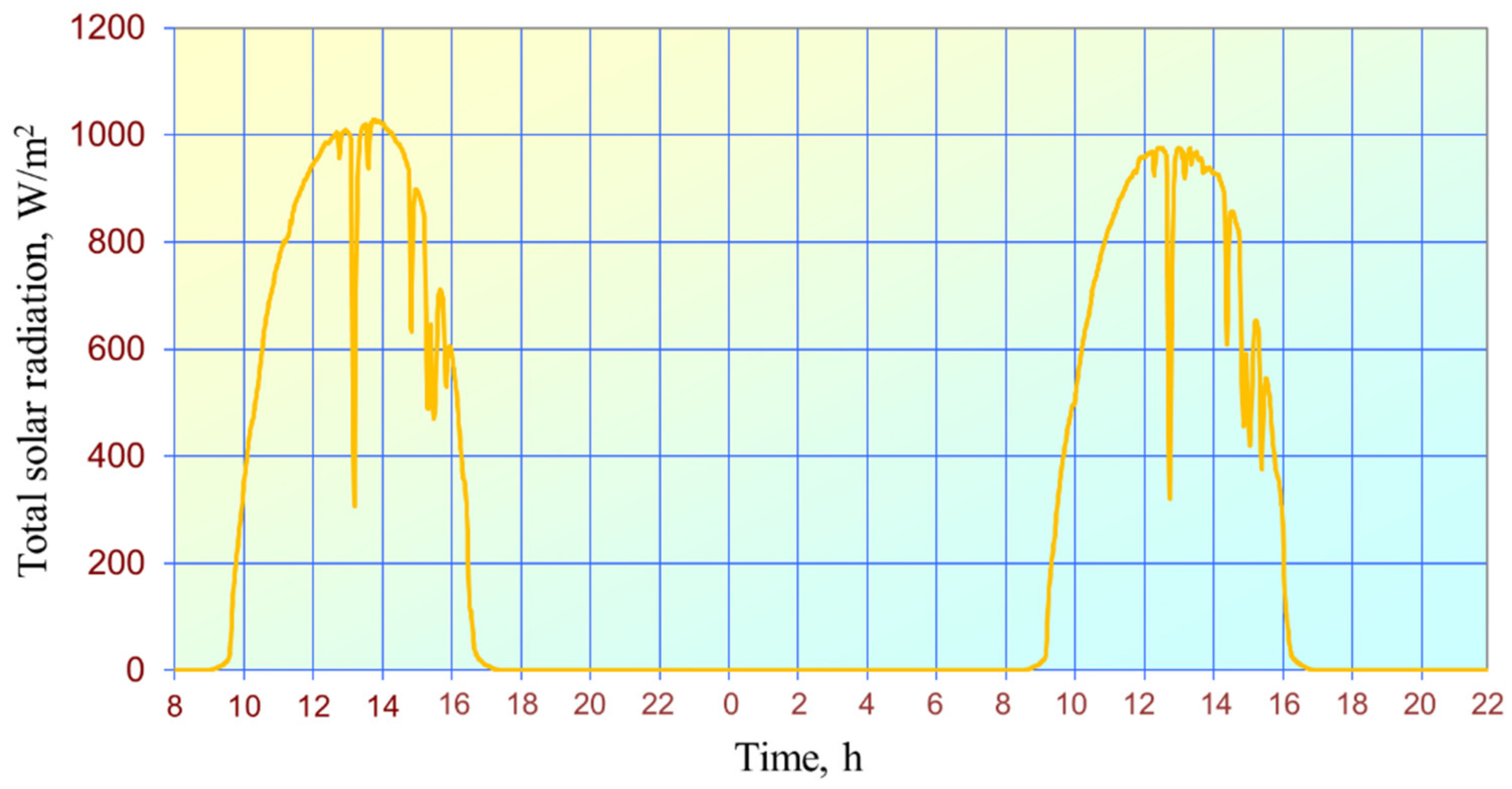

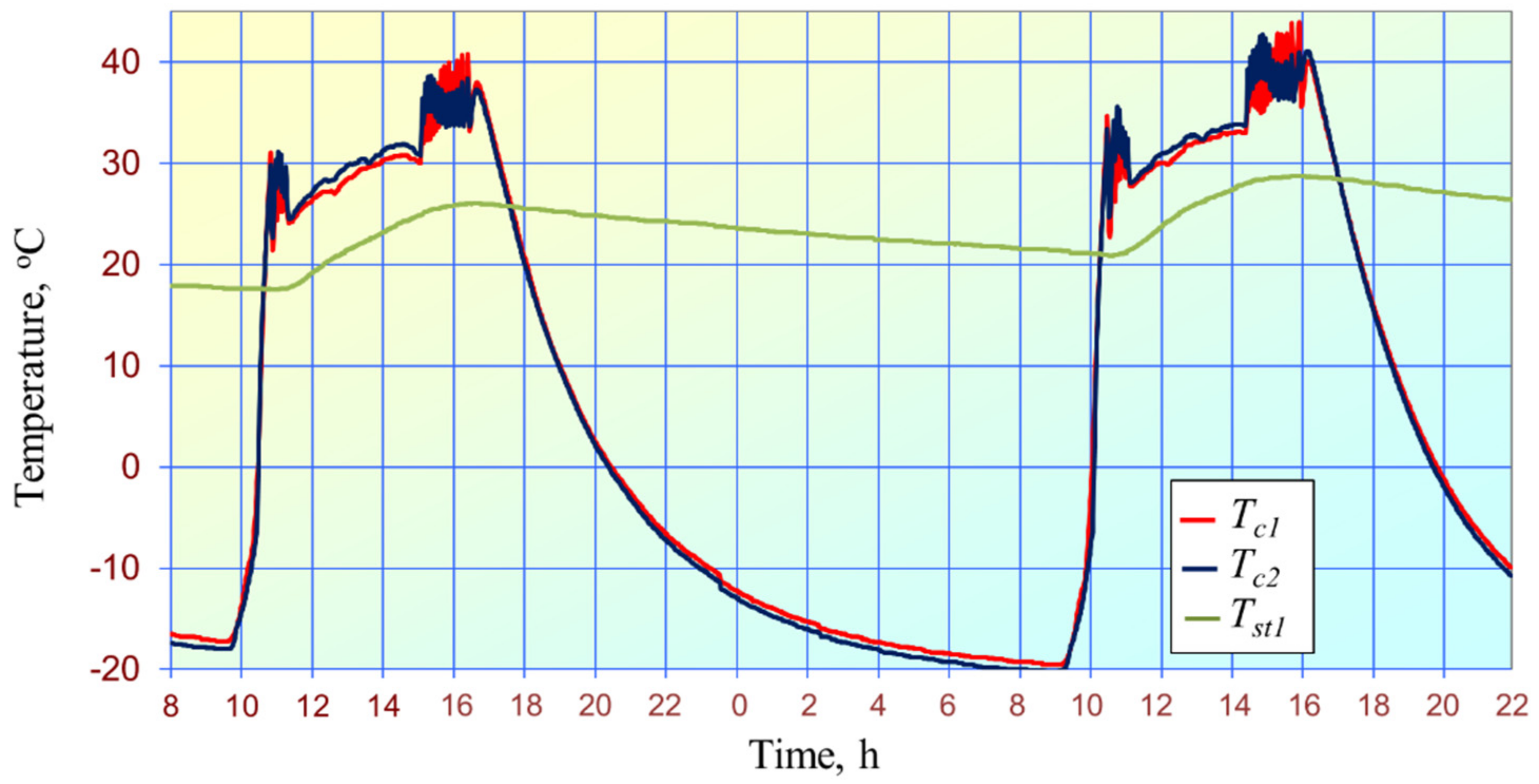

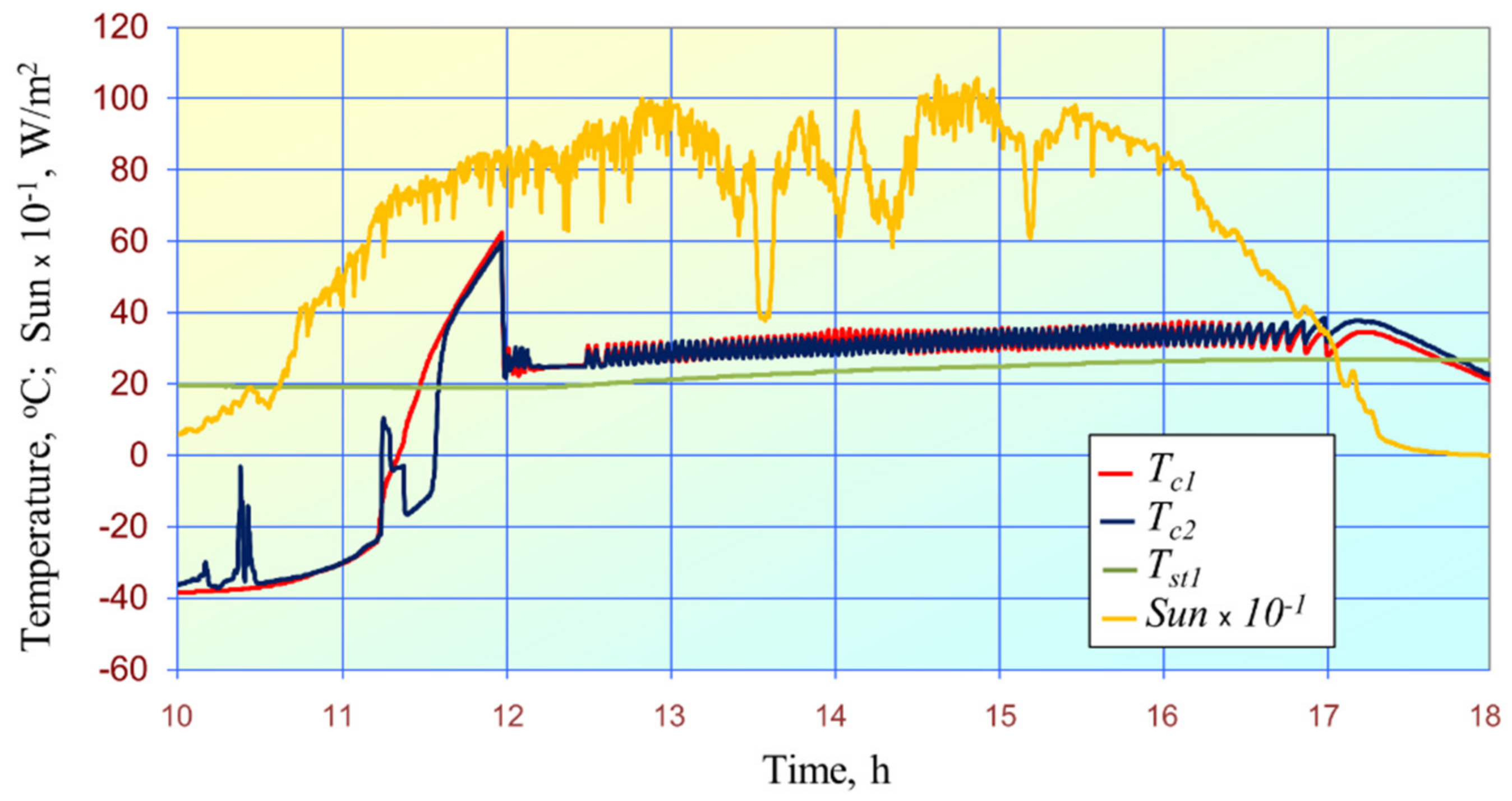

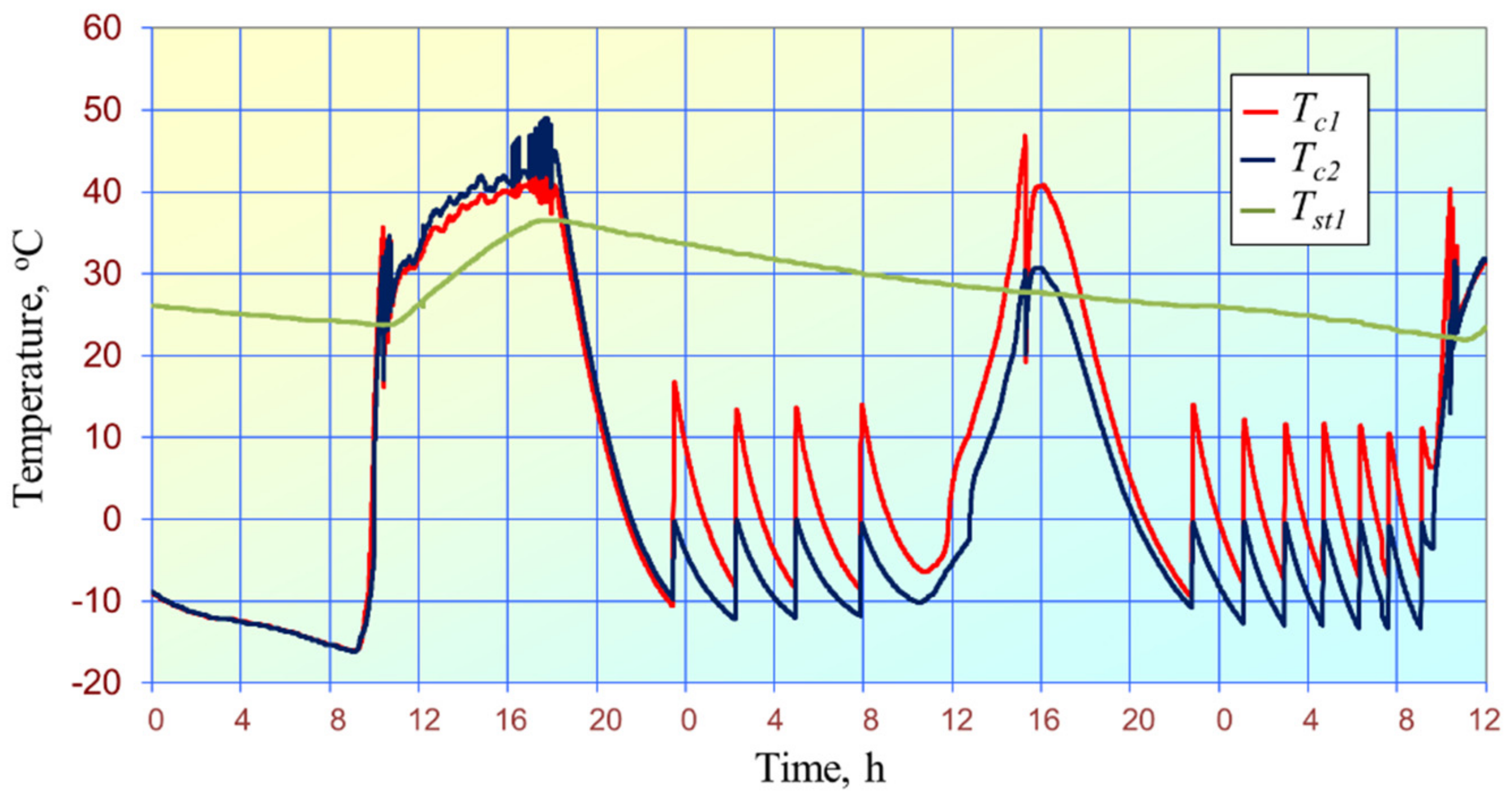

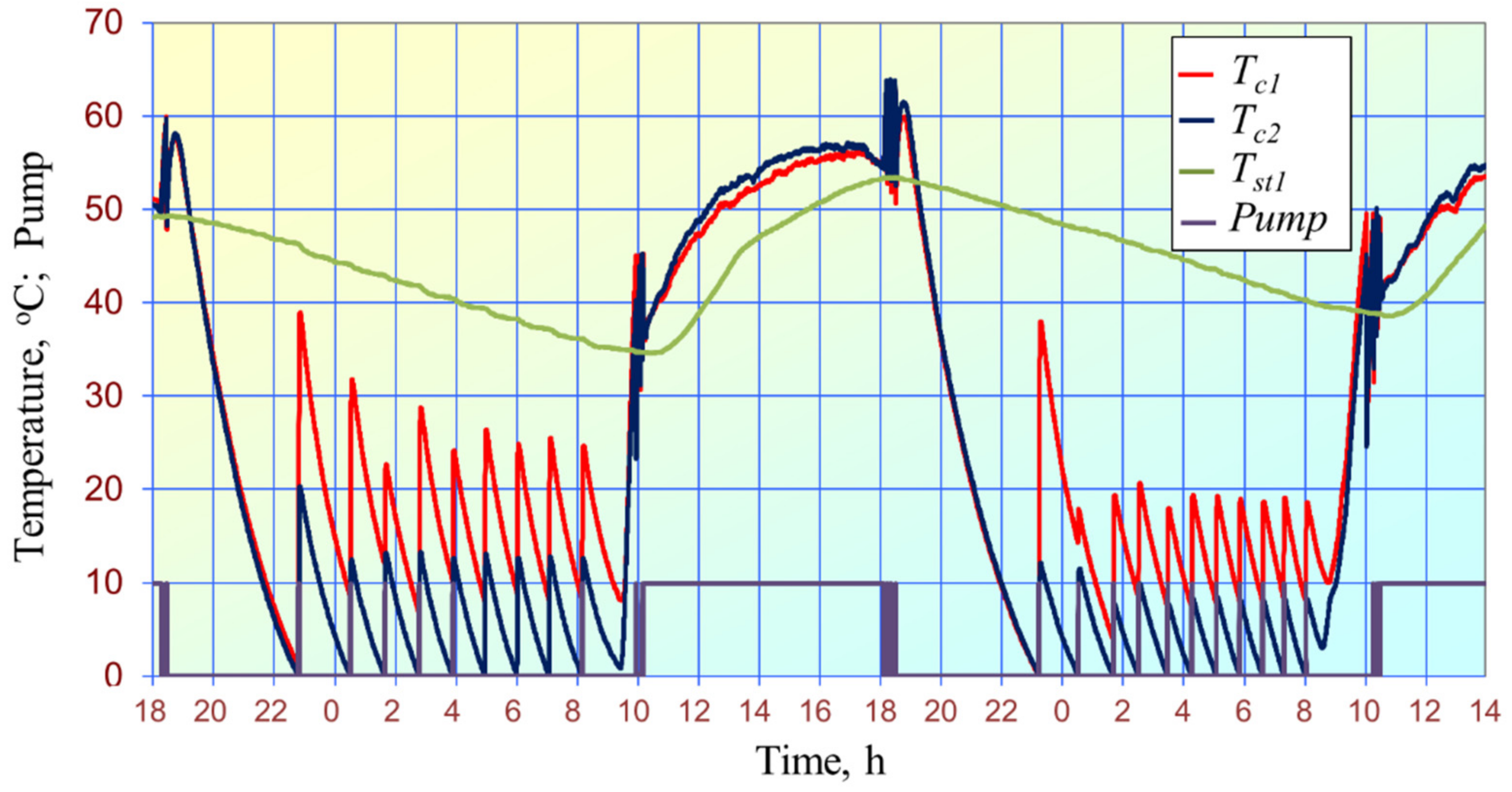

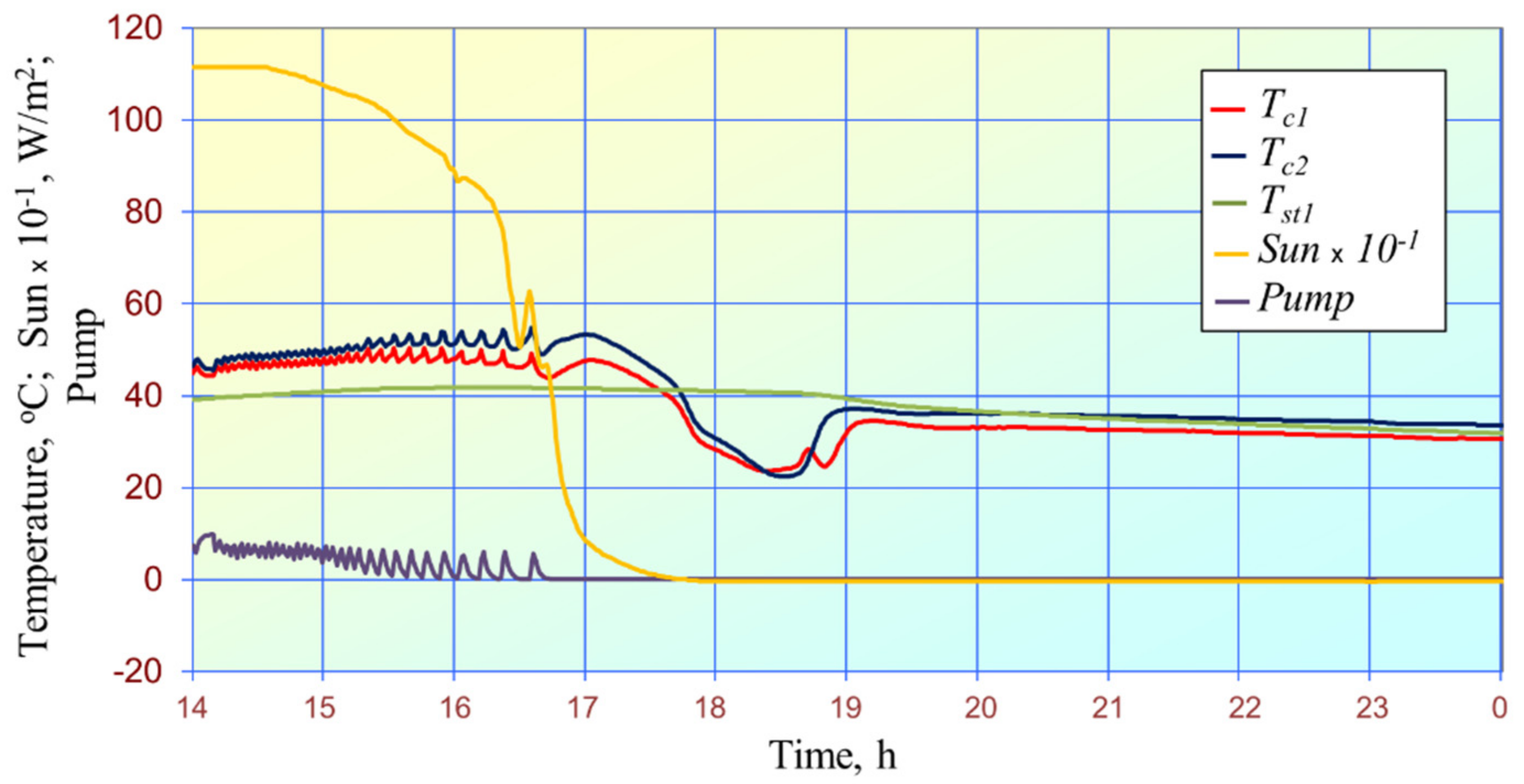

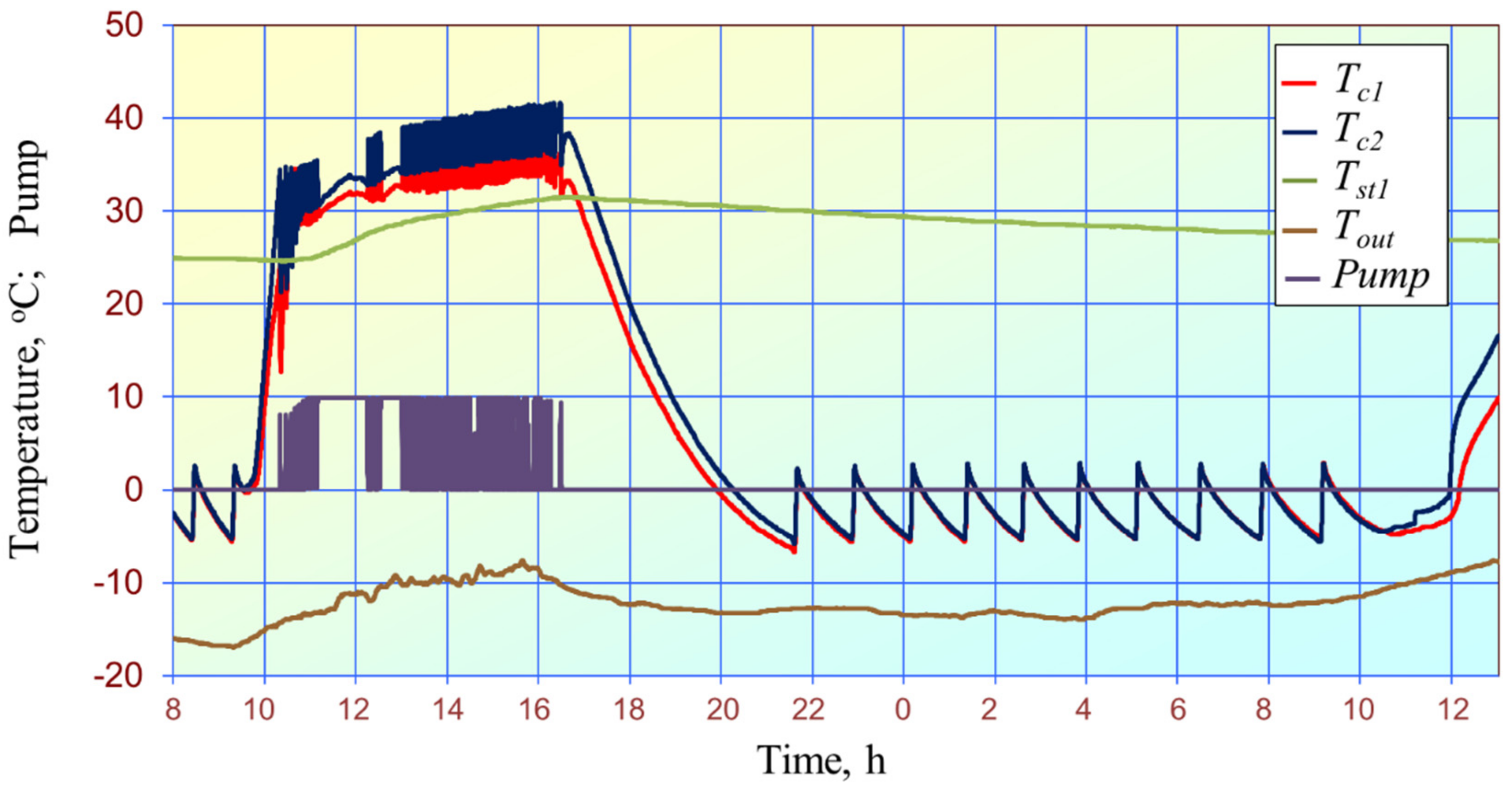

3.1. Results of Field Study in Yakutsk

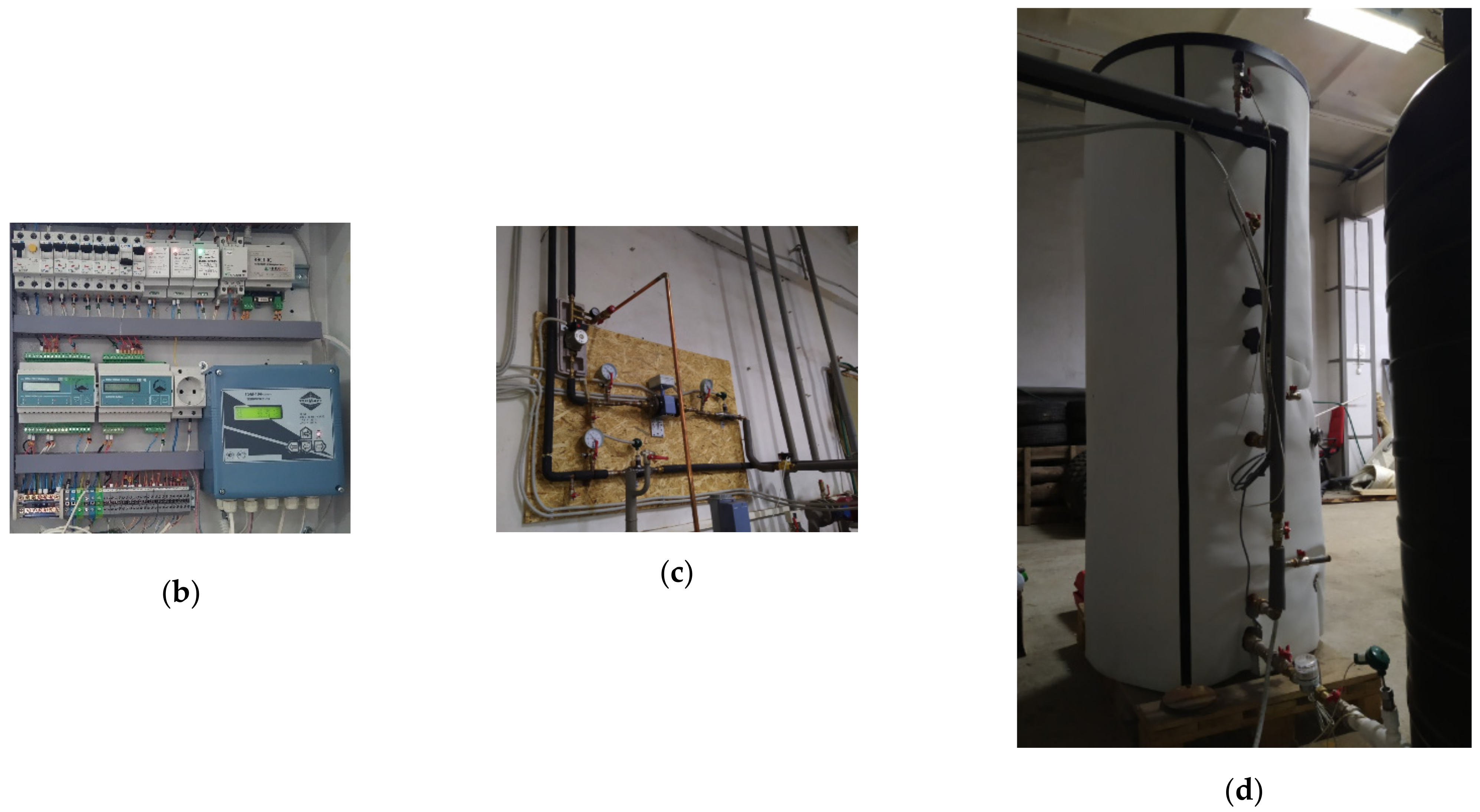

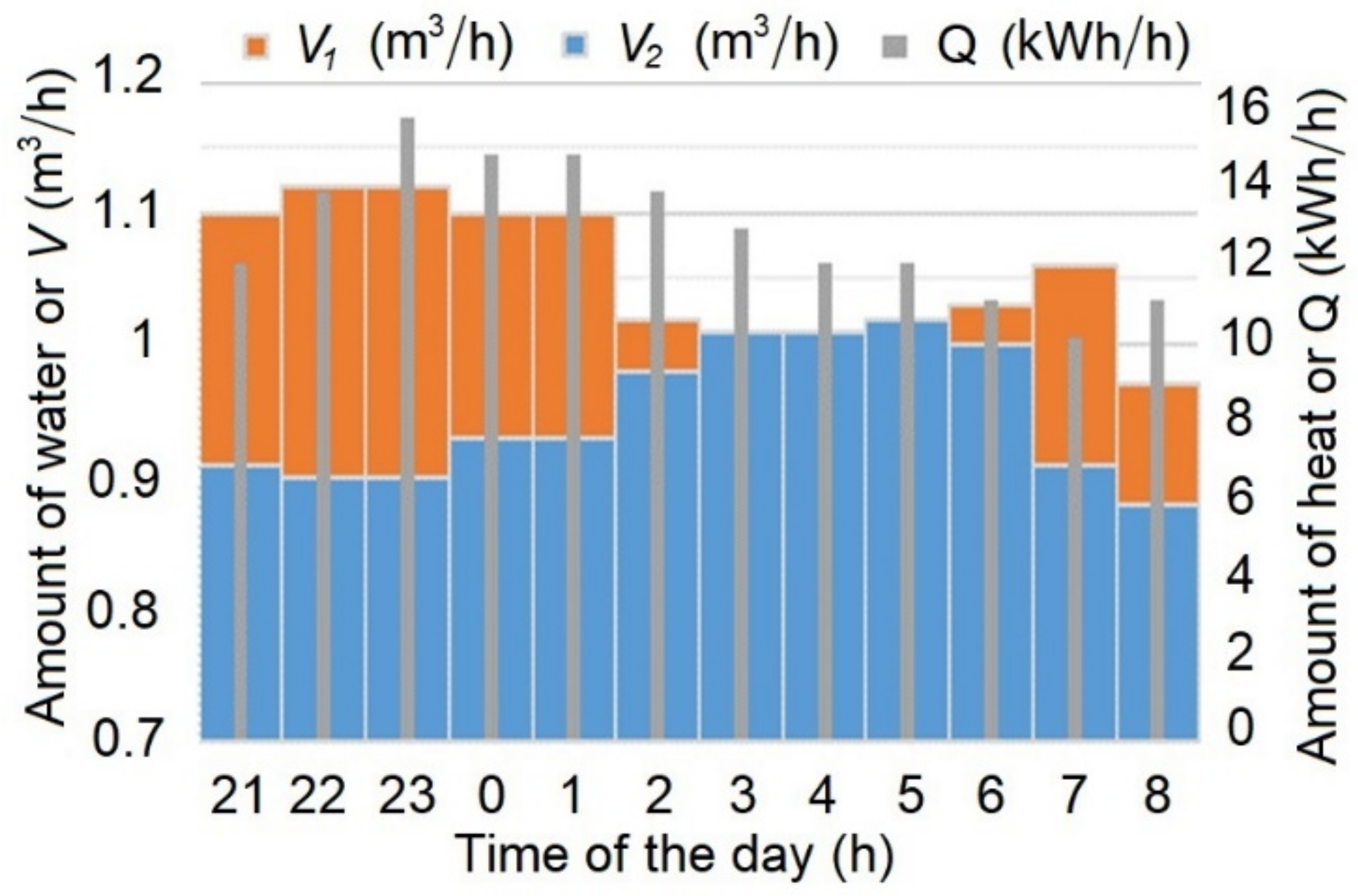

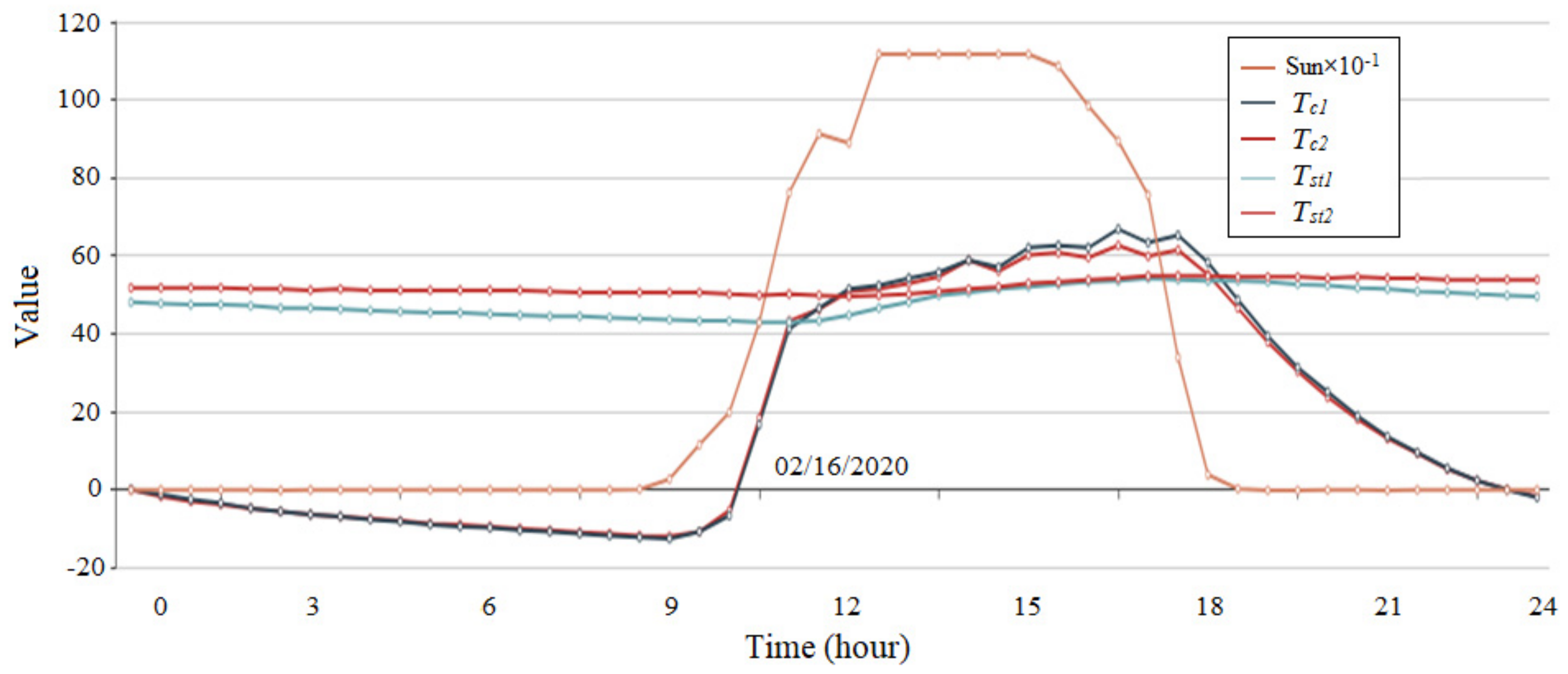

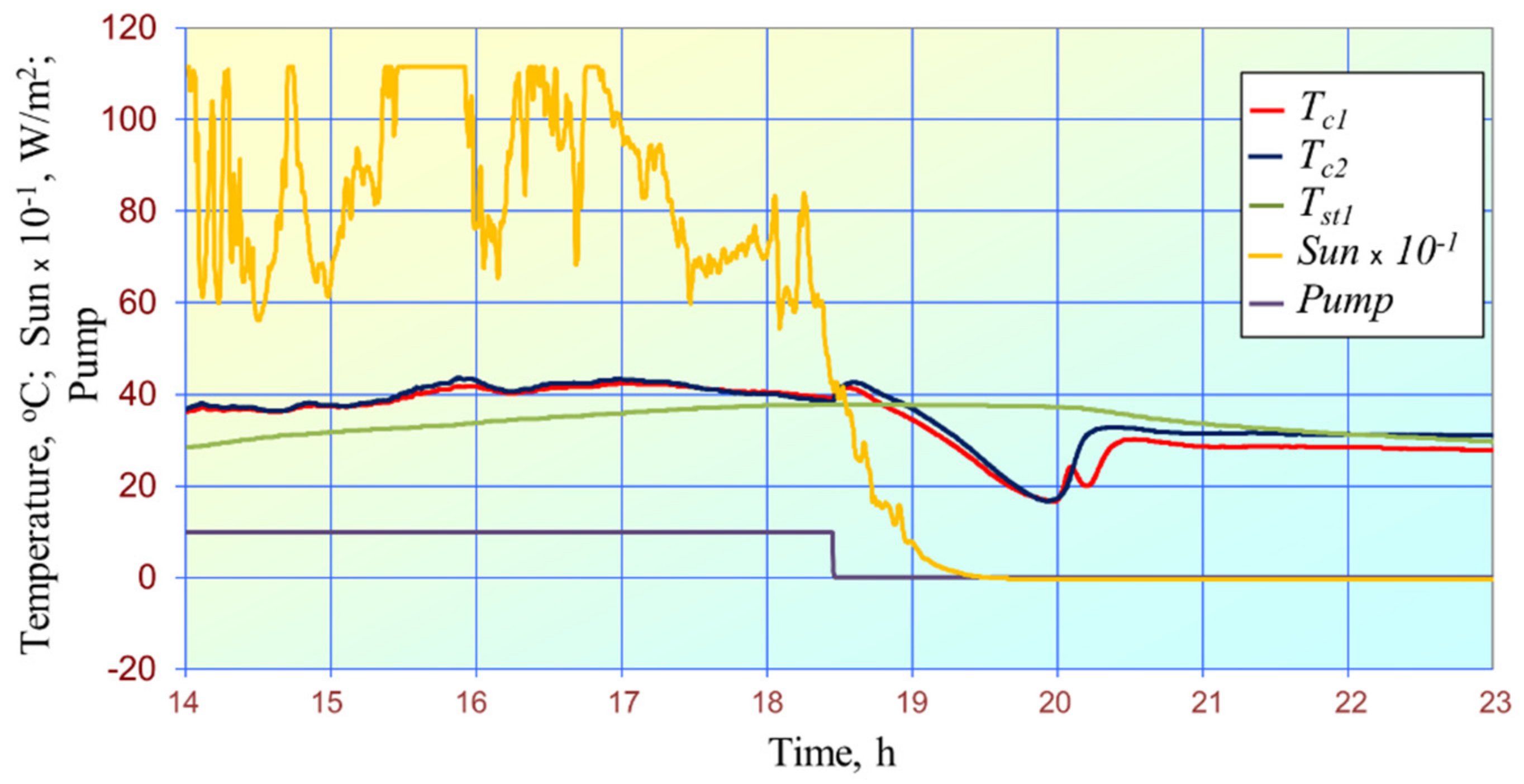

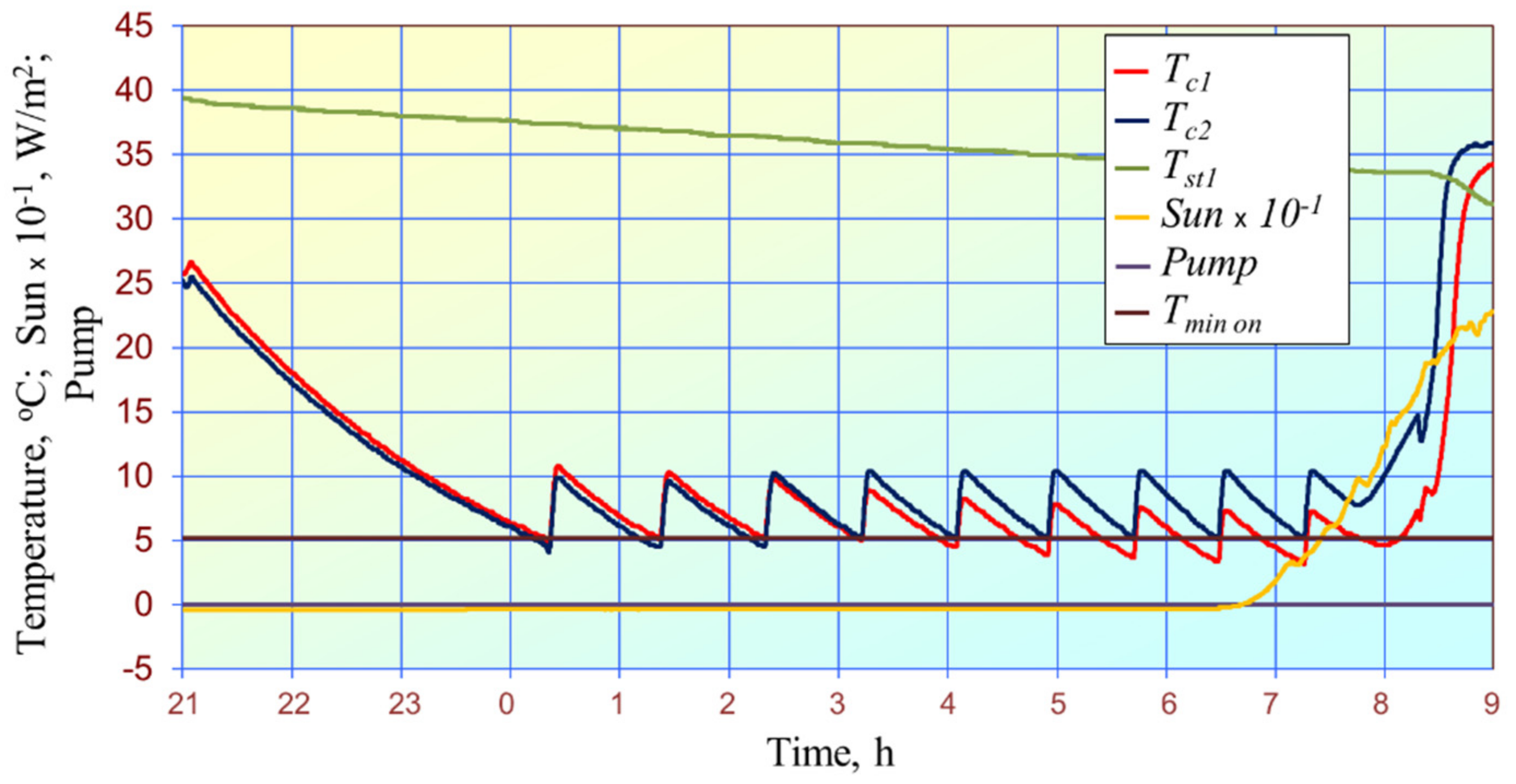

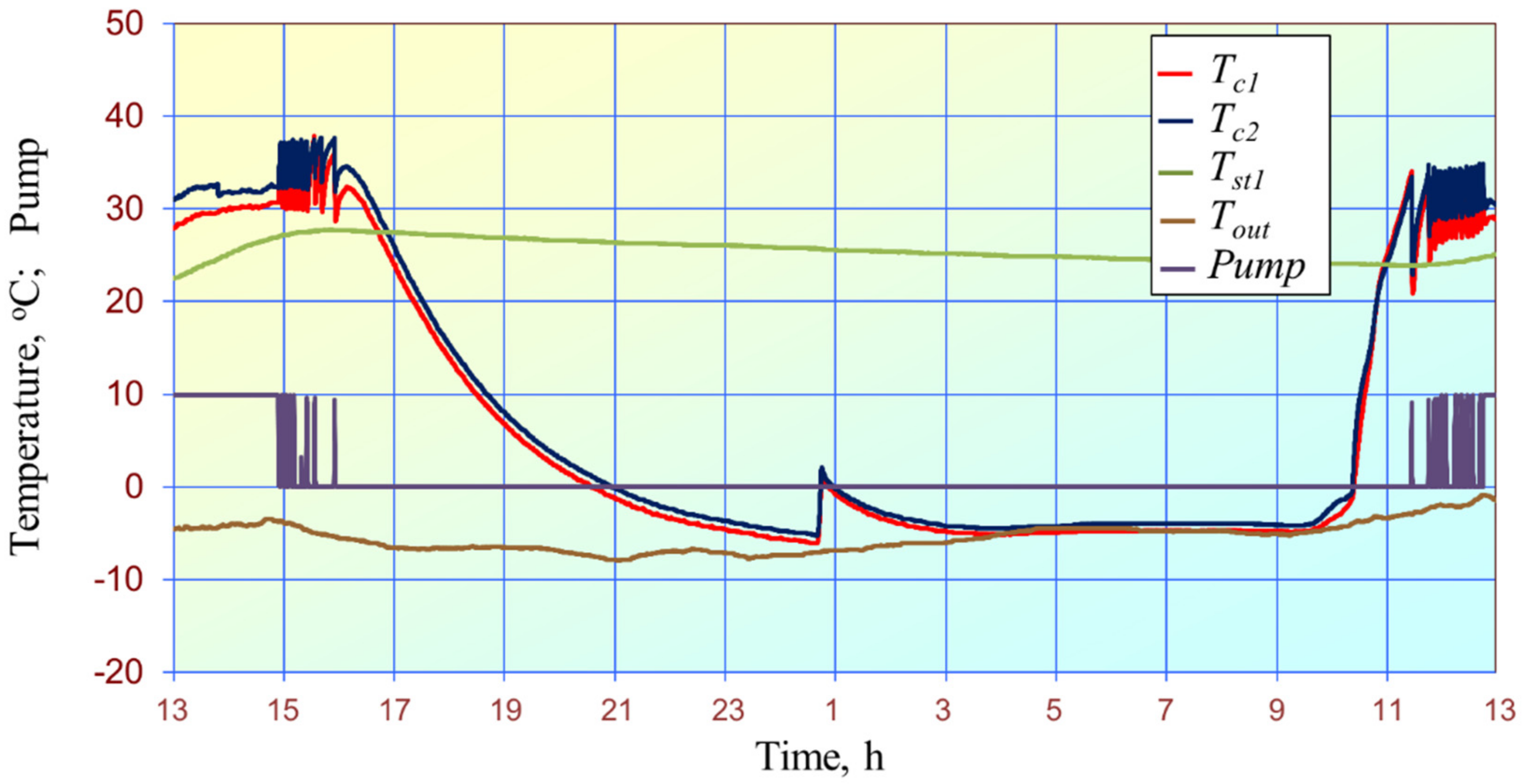

3.2. Results of Experimental Research in Tomsk

4. Discussion

- -

- Modelling of solar radiation to define its hourly values based on the data obtained from Tomsk weather station;

- -

- Development of a mathematical model and analysis of the annual thermal energy losses in the hydraulic circuit of collectors; a comparison of the calculation results with the experimental data obtained from the solar hot water system in the Kaftanchikovo village;

- -

- Development of a mathematical model and implementation of the frequency control for the engine speed of the circulating pump, depending on the solar radiation intensity.

5. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Tcvetkov, P. Climate Policy Imbalance in the Energy Sector: Time to Focus on the Value of CO2 Utilisation. Energies 2021, 14, 411. [Google Scholar] [CrossRef]

- Strielkowski, W.; Sherstobitova, A.; Rovny, P.; Evteeva, T. Increasing Energy Efficiency and Modernization of Energy Systems in Russia: A Review. Energies 2021, 14, 3164. [Google Scholar] [CrossRef]

- Khan, A.M.; Osińska, M. How to Predict Energy Consumption in BRICS Countries? Energies 2021, 14, 2749. [Google Scholar] [CrossRef]

- Qin, Z.; Ozturk, I. Renewable and Non-Renewable Energy Consumption in BRICS: Assessing the Dynamic Linkage between Foreign Capital Inflows and Energy Consumption. Energies 2021, 14, 2974. [Google Scholar] [CrossRef]

- Karacan, R.; Mukhtarov, S.; Barıs, I.; Isleyen, A.; Yardımcı, M.E. The Impact of Oil Price on Transition toward Renewable Energy Consumption? Evidence from Russia. Energies 2021, 14, 2947. [Google Scholar] [CrossRef]

- Brazovskaia, V.; Gutman, S.; Zaytsev, A. Potential Impact of Renewable Energy on the Sustainable Development of Russian Arctic Territories. Energies 2021, 14, 3691. [Google Scholar] [CrossRef]

- Fischer, R.; Elfgren, E.; Toffolo, A. Energy Supply Potentials in the Northern Counties of Finland, Norway and Sweden towards Sustainable Nordic Electricity and Heating Sectors: A Review. Energies 2018, 11, 751. [Google Scholar] [CrossRef] [Green Version]

- Swenson, R. The Solarevolution: Much More with Way Less, Right Now—The Disruptive Shift to Renewables. Energies 2016, 9, 676. [Google Scholar] [CrossRef] [Green Version]

- Haukkala, T. Does the sun shine in the High North? Vested interests as a barrier to solar energy deployment in Finland. Energy Res. Soc. Sci. 2015, 6, 50–58. [Google Scholar] [CrossRef]

- Wei, S.; Tien, P.W.; Calautit, J.K.; Wu, Y.; Boukhanouf, R. Vision-based detection and prediction of equipment heat gains in commercial office buildings using a deep learning method. Appl. Energy 2020, 277, 115506. [Google Scholar] [CrossRef]

- Abikoye, B.; Čuček, L.; Isafiade, A.J.; Kravanja, Z. Synthesis of solar thermal network for domestic heat utilisation. Chem. Eng. Trans. 2019, 76, 1015–1020. [Google Scholar] [CrossRef]

- Canale, L.; Di Fazio, A.R.; Russo, M.; Frattolillo, A.; Dell’Isola, M. An Overview on Functional Integration of Hybrid Renewable Energy Systems in Multi-Energy Buildings. Energies 2021, 14, 1078. [Google Scholar] [CrossRef]

- Porras-Prieto, C.J.; Benedicto-Schönemann, S.; Mazarrón, F.R.; Benavente, R.M. Profitability Variations of a Solar System with an Evacuated Tube Collector According to Schedules and Frequency of Hot Water Demand. Energies 2016, 9, 1053. [Google Scholar] [CrossRef] [Green Version]

- Popsueva, V.; Lopez, A.F.O.; Kosinska, A.; Nikolaev, O.; Balakin, B.V. Field Study on the Thermal Performance of Vacuum Tube Solar Collectors in the Climate Conditions of Western Norway. Energies 2021, 14, 2745. [Google Scholar] [CrossRef]

- Peña-Ramos, J.A.; Bagus, P.; Amirov-Belova, D. The North Caucasus Region as a Blind Spot in the “European Green Deal”: Energy Supply Security and Energy Superpower Russia. Energies 2021, 14, 17. [Google Scholar] [CrossRef]

- Decree of the President of the Russian Federation Dated 01.12.2016 No. 642 “On the Strategy of Scientific and Technological Development of the Russian Federation” (As Amended by the Decree of the President of the Russian Federation Dated 15.03.2021 No. 143). Available online: http://kremlin.ru/acts/bank/41449 (accessed on 20 May 2021).

- Energy Strategy of the Russian Federation until 2035. Approved by the Order of the Government of the Russian Federation Dated 9 June, 2020 No. 1523-r. Available online: https://minenergo.gov.ru/node/1026 (accessed on 9 June 2021).

- Gaweł, B.; Pali’ nski, A. Long-Term Natural Gas Consumption Forecasting Based on Analog Method and Fuzzy Decision Tree. Energies 2021, 14, 4905. [Google Scholar] [CrossRef]

- Cannone, S.F.; Lanzini, A.; Santarelli, M. A Review on CO2 Capture Technologies with Focus on CO2-Enhanced Methane Recovery from Hydrates. Energies 2021, 14, 387. [Google Scholar] [CrossRef]

- Kopteva, A.; Kalimullin, L.; Tcvetkov, P.; Soares, A. Prospects and Obstacles for Green Hydrogen Production in Russia. Energies 2021, 14, 718. [Google Scholar] [CrossRef]

- Seregin, A.I. Energy efficient town block in the far north conditions. Experience from the Republic of Sakha (Yakutia). Energy Sav. 2020, 8, 12–15. Available online: https://www.abok.ru/for_spec/articles.php?nid=7683 (accessed on 8 January 2021).

- Krivoshein, Y.O.; Tolstykh, A.V.; Tsvetkov, N.A.; Khutornoy, A.N. Efficiency of dual hot water systems with the use of solar evacuated tube collectors in the Northern territories. IOP Conf. Ser. Earth Environ. Sci. 2020, 408, 012011. [Google Scholar] [CrossRef] [Green Version]

- Tsvetkov, N.A.; Krivoshein, Y.O.; Khutornoi, A.N.; Boldyryev, S.; Petrova, A.V. Development of the Computer-Aided Application for the Use of Solar Energy in the Hot Water Supply System of Russian Permafrost Regions. Chem. Eng. Trans. 2020, 81, 943–948. [Google Scholar] [CrossRef]

- Tsvetkov, N.A.; Krivoshein, U.O.; Tolstykh, A.V.; Khutornoi, A.N.; Boldyryev, S. The calculation of solar energy used by hot water systems in permafrost region: An experimental case study for Yakutia. Energy 2020, 210, 118577. [Google Scholar] [CrossRef]

- Prokhorov, S.V.; Krivoshein, Y.O.; Shilin, A.A. Automatic Control of Hot Water Supply System on Solar Collectors (Conference Paper). In Proceedings of the International Multi-Conference on Industrial Engineering and Modern Technologies, FarEastCon 2019, Vladivostok, Russia, 1–4 October 2019. Category Number CFP19M35-ART; The Code 156113. [Google Scholar] [CrossRef]

- Climate of Russia. Wikipedia. Available online: https://ru.wikipedia.org/wiki/Климат_Рoссии (accessed on 6 August 2021).

- Maraj, A.; Londo, A.; Gebremedhin, A.; First, C. Energy performance analysis of a forced circulation solar water heating system equipped with a heat pipe evacuated tube collector under the Mediterranean climate conditions. Renew. Energy 2019, 140, 874–883. [Google Scholar] [CrossRef]

- Tomsk Weather Archives. Available online: https://pogoda.vtomske.ru/tomsk/25/01 (accessed on 16 August 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsvetkov, N.; Boldyryev, S.; Shilin, A.; Krivoshein, Y.; Tolstykh, A. Hardware and Software Implementation for Solar Hot Water System in Northern Regions of Russia. Energies 2022, 15, 1446. https://doi.org/10.3390/en15041446

Tsvetkov N, Boldyryev S, Shilin A, Krivoshein Y, Tolstykh A. Hardware and Software Implementation for Solar Hot Water System in Northern Regions of Russia. Energies. 2022; 15(4):1446. https://doi.org/10.3390/en15041446

Chicago/Turabian StyleTsvetkov, Nikolay, Stanislav Boldyryev, Aleksandr Shilin, Yuriy Krivoshein, and Aleksandr Tolstykh. 2022. "Hardware and Software Implementation for Solar Hot Water System in Northern Regions of Russia" Energies 15, no. 4: 1446. https://doi.org/10.3390/en15041446

APA StyleTsvetkov, N., Boldyryev, S., Shilin, A., Krivoshein, Y., & Tolstykh, A. (2022). Hardware and Software Implementation for Solar Hot Water System in Northern Regions of Russia. Energies, 15(4), 1446. https://doi.org/10.3390/en15041446