Does Agricultural Mechanization Improve the Green Total Factor Productivity of China’s Planting Industry?

Abstract

:1. Introduction

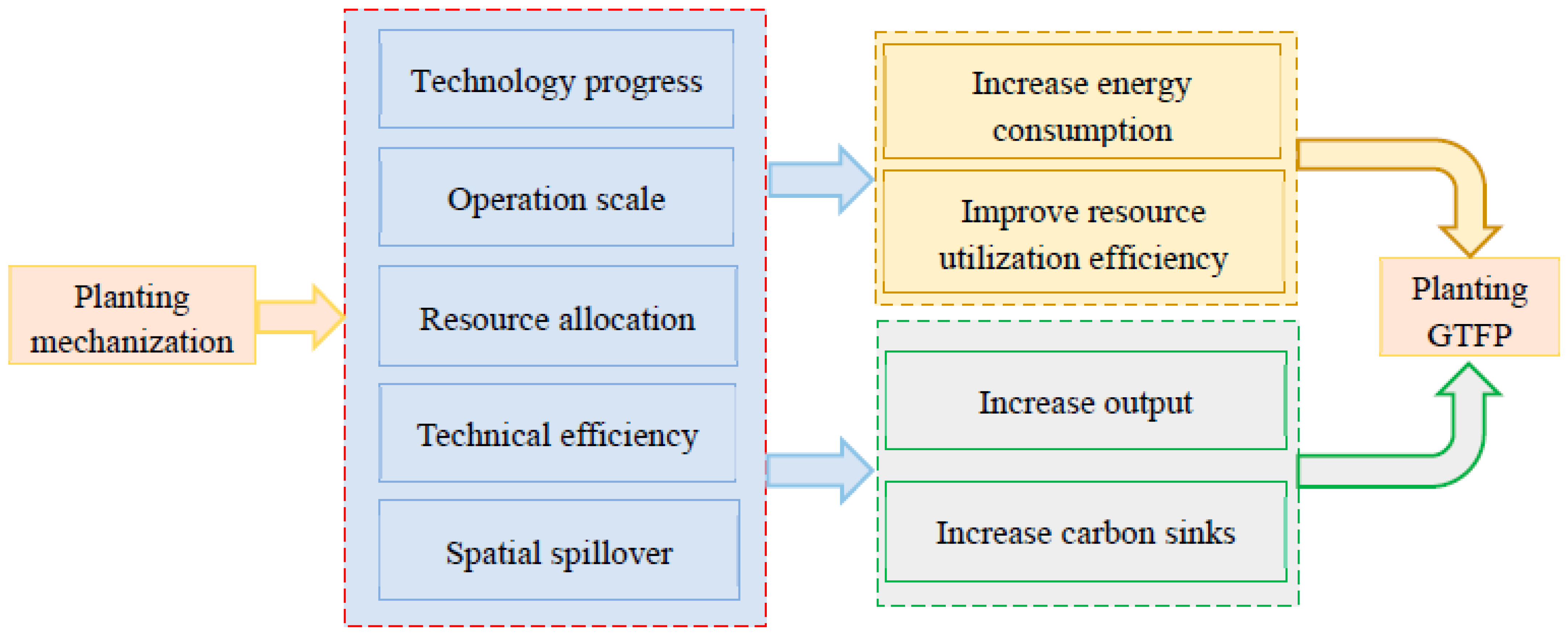

2. Literature Review and Mechanism Analysis

2.1. Planting GTFP

2.2. Decomposition of Planting GTFP

2.3. Planting GTFP Is Influenced by Mechanization through Technology Progress

2.4. Planting GTFP Is Influenced by Mechanization through Changing Operation Scale

2.5. Planting GTFP Is Influenced by Mechanization through Optimizing Resource Allocation

2.6. Planting GTFP Is Influenced by Mechanization through Improving Technical Efficiency

2.7. Planting GTFP Is Influenced by Mechanization through Spatial Spillover Effect

3. Methods and Data

3.1. Method

3.1.1. The Basic Econometric Model

3.1.2. Recursive Model for Mediating Effect Test

3.1.3. Spatial Econometric Model

3.2. Data

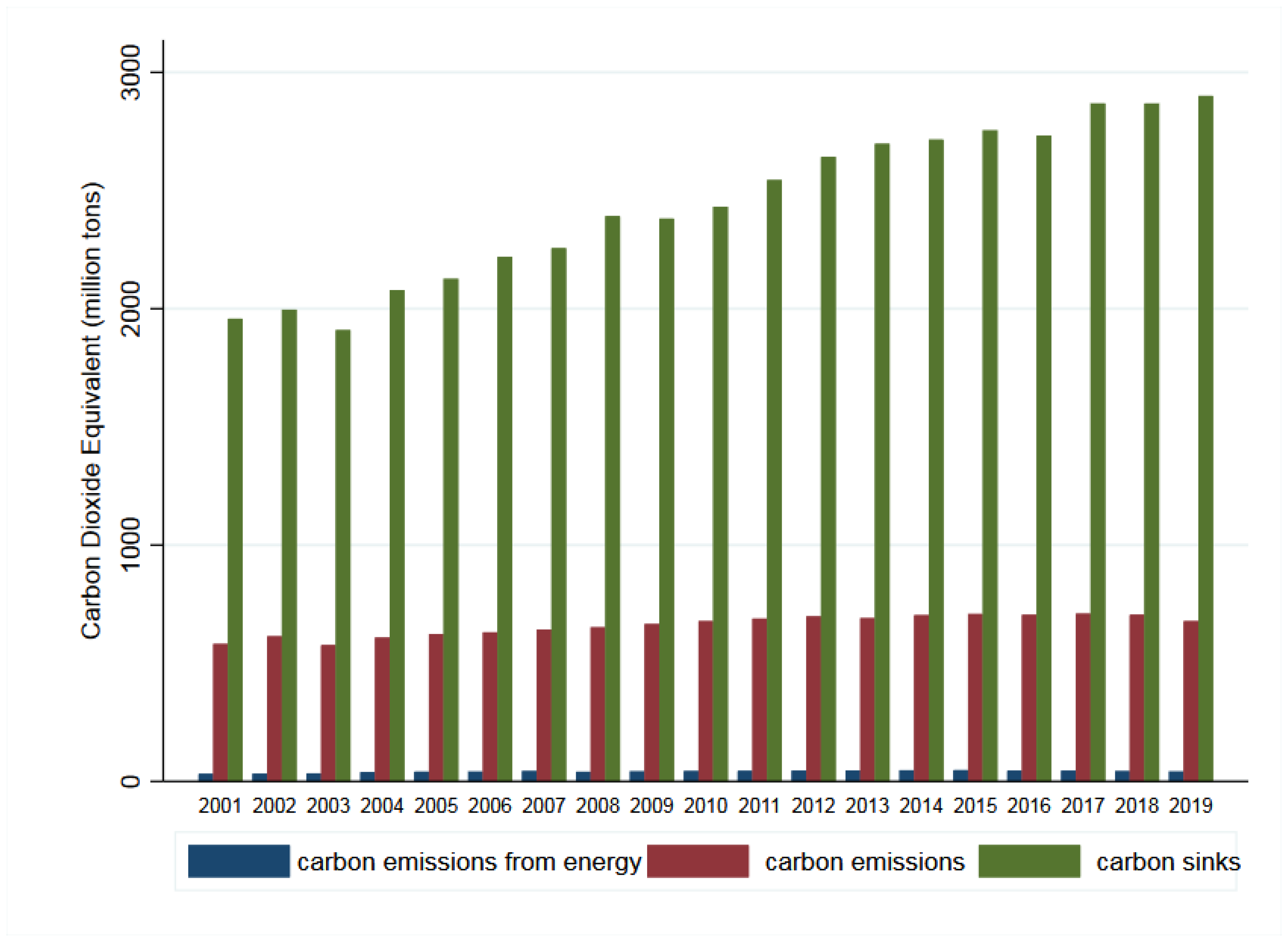

3.2.1. Dependent Variable

3.2.2. Independent Variable

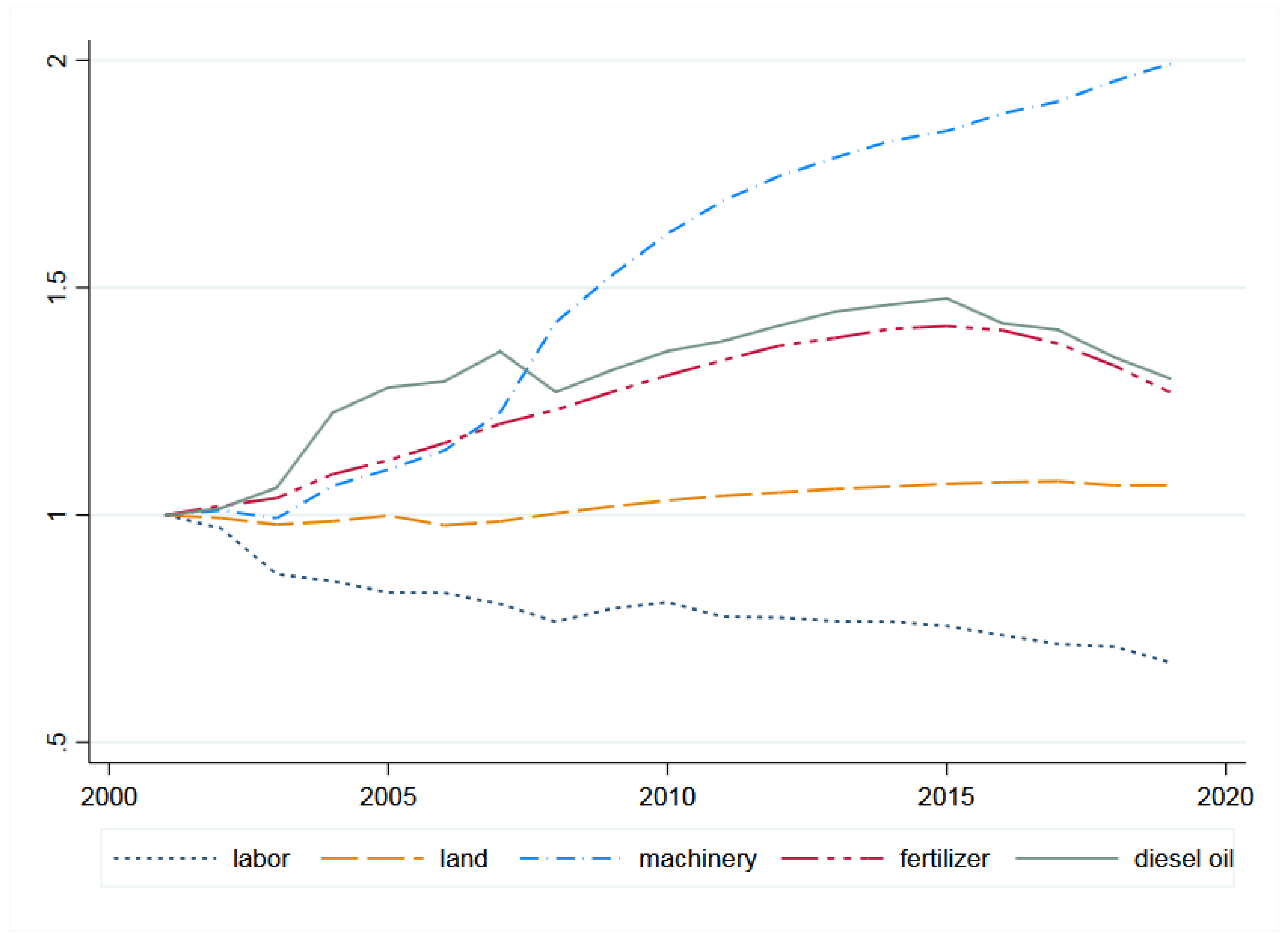

3.2.3. Instrument Variable

3.2.4. Intermediary Variables

3.2.5. Control Variables

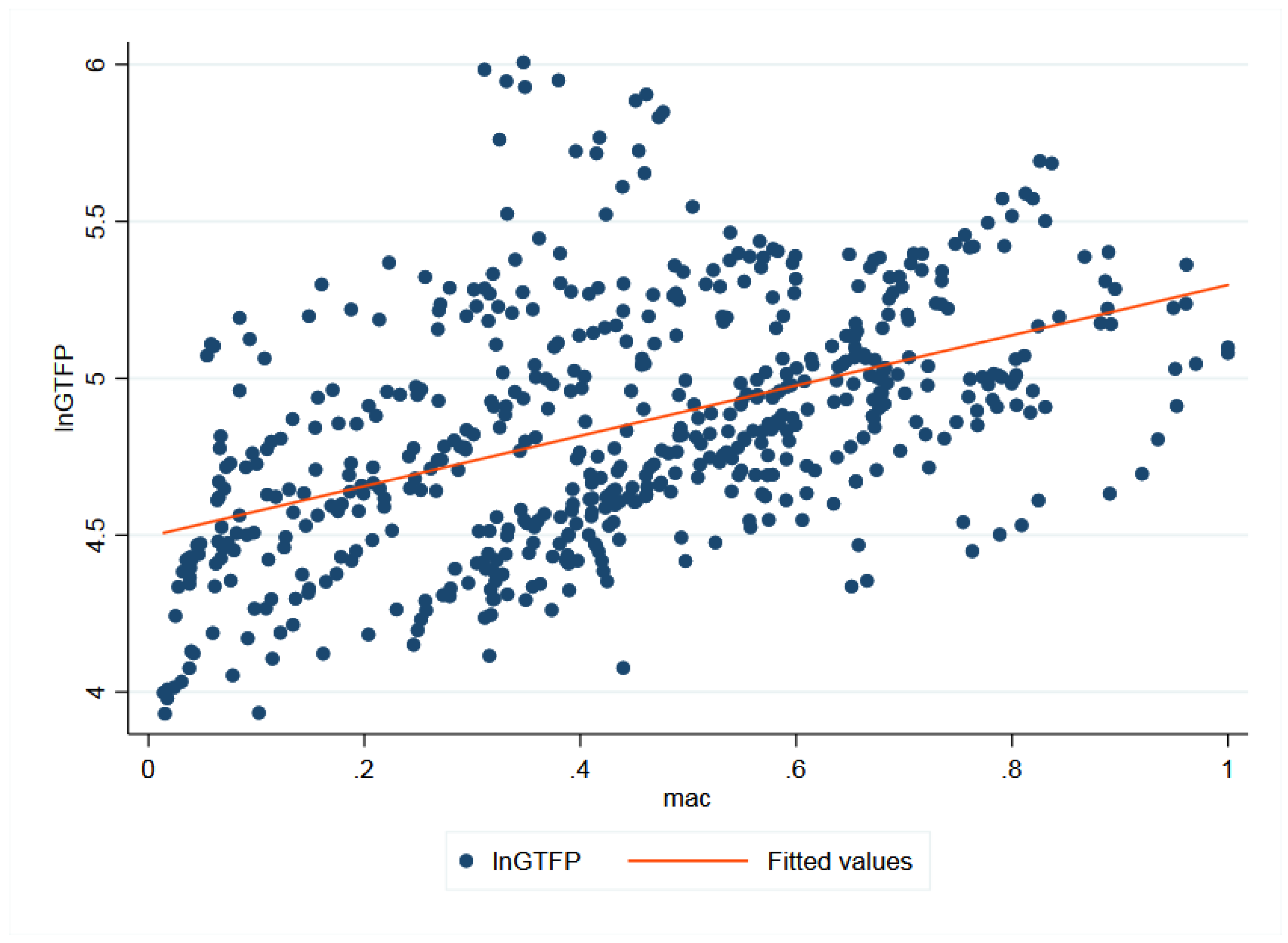

3.3. Data Description

4. Results

4.1. The Basic Regression Results

4.2. Mechanism Test

4.3. Heterogeneity Analysis

5. Discussion

5.1. Relationship between Mechanization, GTFP and Energy–Environment Performance

5.2. The Impact Mechanism of Mechanization on GTFP

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, F.; Xu, J. Green total factor productivity: A re-examination of quality of growth for provinces in China. China Econ. Rev. 2020, 62, 101454. [Google Scholar] [CrossRef]

- Ismael, M.; Srouji, F.; Boutabba, M.A. Agricultural technologies and carbon emissions: Evidence from Jordanian economy. Environ. Sci. Pollut. Res. 2018, 25, 10867–10877. [Google Scholar] [CrossRef] [PubMed]

- Akbar, U.; Li, Q.; Akmal, M.A.; Shakib, M.; Iqbal, W. Nexus between agro-ecological efficiency and carbon emissions transfer: Evidence from China. Environ. Sci. Pollut. Resh. 2021, 28, 18995–19007. [Google Scholar] [CrossRef] [PubMed]

- She, W.; Wu, Y.; Huang, H.; Chen, Z.; Cui, G.; Zheng, H.; Guan, C.; Chen, F. Integrative analysis of carbon structure and carbon sinks function for major crop production in China’s typical agriculture regions. J. Clean. Prod. 2017, 162, 702–708. [Google Scholar] [CrossRef]

- Song, M.; Li, H. Total factor productivity and the factors of green industry in Shanxi Province, China. Growth Chang. 2020, 51, 488–504. [Google Scholar] [CrossRef]

- Luo, F.; Guo, Y.; Yao, M.; Cai, W.; Wang, M.; Wei, W. Carbon emissions and driving forces of China’s power sector: Input-output model based on the disaggregated power sector. J. Clean. Prod. 2020, 268, 121925. [Google Scholar] [CrossRef]

- Wang, X.; Yamauchi, F.; Huang, J. Rising wages, mechanization, and the substitution between capital and labor: Evidence from small scale farm system in China. Agric. Econ. 2016, 47, 309–317. [Google Scholar] [CrossRef]

- Tang, L.; Wang, D. Optimization of County-Level Land Resource Allocation through the Improvement of Allocation Efficiency from the Perspective of Sustainable Development. Int. J. Environ. Res. Public Health 2018, 15, 2638. [Google Scholar] [CrossRef] [Green Version]

- Tan, M.; Zheng, L. Increase in economic efficiency of water use caused by crop structure adjustment in arid areas. J. Environ. Manag. 2019, 230, 386–391. [Google Scholar] [CrossRef]

- Balk, B.M. Scale Efficiency and Productivity Change. J. Prod. Anal. 2001, 15, 159–183. [Google Scholar] [CrossRef]

- Solow, R.M. Technical change and the aggregate production function. Rev. Econ. Stat. 1957, 39, 312–320. [Google Scholar] [CrossRef] [Green Version]

- Wang, X.; Sun, C.; Wang, S.; Zhang, Z.; Zou, W. Going Green or Going Away? A Spatial Empirical Examination of the Relationship between Environmental Regulations, Biased Technological Progress, and Green Total Factor Productivity. Int. J. Environ. Res. Public Health 2018, 15, 1917. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Liu, D.; Zhu, X.; Wang, Y. China’s agricultural green total factor productivity based on carbon emission: An analysis of evolution trend and influencing factors. J. Clean. Prod. 2021, 278, 123692. [Google Scholar] [CrossRef]

- Cullinane, K.; Wang, T.; Song, D.; Ji, P. The technical efficiency of container ports: Comparing data envelopment analysis and stochastic frontier analysis. Transp. Res. Part A Policy Pract. 2006, 40, 354–374. [Google Scholar] [CrossRef]

- Gong, B.; Sickles, R.C. Finite sample evidence on the performance of stochastic frontiers and data envelopment analysis using panel data. J. Econ. 1992, 51, 259–284. [Google Scholar] [CrossRef]

- Coelli, T.J.; Perelman, S. A comparison of parametric and non-parametric distance functions: With application to European railways. Eur. J. Oper. Res. 1999, 117, 326–339. [Google Scholar] [CrossRef]

- Moreira, V.H.; Bravo-Ureta, B.E. Total factor productivity change in dairy farming: Empirical evidence from southern Chile. J. Dairy Sci. 2016, 99, 8356–8364. [Google Scholar] [CrossRef] [Green Version]

- Liu, J.; Dong, C.; Liu, S.; Rahman, S.; Sriboonchitta, S. Sources of Total-Factor Productivity and Efficiency Changes in China’s Agriculture. Agriculture 2020, 10, 279. [Google Scholar] [CrossRef]

- Xu, X.; Huang, X.; Huang, J.; Gao, X.; Chen, L. Spatial-Temporal Characteristics of Agriculture Green Total Factor Productivity in China, 1998–2016: Based on More Sophisticated Calculations of Carbon Emissions. Int. J. Environ. Res. Public Health 2019, 16, 3932. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Miao, J.; Zhu, Z. Measuring green total factor productivity of China’s agricultural sector: A three-stage SBM-DEA model with non-point source pollution and CO2 emissions. J. Clean. Prod. 2021, 318, 128543. [Google Scholar] [CrossRef]

- Zhan, J.; Tian, X.; Zhang, Y.; Yang, X.; Qu, Z.; Tan, T. The Effects of Agricultural R&D on Chinese Agricultural Productivity Growth: New Evidence of Convergence and Implications for Agricultural R&D Policy. Can. J. Agric. Econ. 2017, 65, 453–475. [Google Scholar] [CrossRef]

- Liu, F.; Lv, N. The Threshold Effect Test of Human Capital on the Growth of Agricultural Green Total Factor Productivity: Evidence from China. Int. J. Electr. Eng. Educ. 2021, in press. [CrossRef]

- Fang, L.; Hu, R.; Mao, H.; Chen, S. How crop insurance influences agricultural green total factor productivity: Evidence from Chinese farmers. J. Clean. Prod. 2021, 321, 128977. [Google Scholar] [CrossRef]

- Battese, G.E.; Coelli, T.J. Frontier production functions, technical efficiency and panel data: With application to paddy farmers in India. J. Prod. Anal. 1992, 3, 153–169. [Google Scholar] [CrossRef]

- Qing, Y.; Chen, M.; Sheng, Y.; Huang, J. Mechanization services, farm productivity and institutional innovation in China. China Agric. Econ. Rev. 2019, 11, 536–554. [Google Scholar] [CrossRef]

- Wang, Q.; Jiang, R. Is China’s economic growth decoupled from carbon emissions? J. Clean. Prod. 2019, 225, 1194–1208. [Google Scholar] [CrossRef]

- Lu, H.; Xie, H.; He, Y.; Wu, Z.; Zhang, X. Assessing the impacts of land fragmentation and plot size on yields and costs: A translog production model and cost function approach. Agric. Syst. 2018, 161, 81–88. [Google Scholar] [CrossRef]

- Wu, Y.; Xi, X.; Tang, X.; Luo, D.; Gu, B.; Lam, S.; Peter, M.; Chen, D. Policy distortions, farm size, and the overuse of agricultural chemicals in China. Proc. Natl. Acad. Sci. USA 2018, 115, 7010. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zou, L.; Wang, Y. Spatial-temporal characteristics and influencing factors of agricultural eco-efficiency in China in recent 40 years. Land Use Policy 2020, 97, 104794. [Google Scholar] [CrossRef]

- Takeshima, H.; Adhikari, R.P.; Shivakoti, S.; Kaphle, B.D.; Kumar, A. Heterogeneous returns to chemical fertilizer at the intensive margins: Insights from Nepal. Food Policy 2017, 69, 97–109. [Google Scholar] [CrossRef]

- Yu, Y.; Jiang, T.; Li, S.; Li, X.; Gao, D. Energy-related CO2 emissions and structural emissions’ reduction in China’s agriculture: An input–output perspective. J. Clean. Prod. 2020, 276, 124169. [Google Scholar] [CrossRef]

- Shi, M.; Paudel, K.; Chen, F. Mechanization and efficiency in rice production in China. J. Int. Agric. 2021, 20, 1996–2008. [Google Scholar] [CrossRef]

- Tang, Y.; Lu, X.; Yi, J.; Wang, H.; Zhang, X.; Zheng, W. Evaluating the spatial spillover effect of farmland use transition on grain production—An empirical study in Hubei Province, China. Ecol. Indic. 2021, 125, 107478. [Google Scholar] [CrossRef]

- Cui, Y.; Khan, S.U.; Deng, Y.; Zhao, M.; Hou, M. Environmental improvement value of agricultural carbon reduction and its spatiotemporal dynamic evolution: Evidence from China. Sci. Total. Environ. 2021, 754, 142170. [Google Scholar] [CrossRef] [PubMed]

- Hayes, A.F. Beyond Baron and Kenny: Statistical Mediation Analysis in the New Millennium. Commun. Monogr. 2009, 76, 408–420. [Google Scholar] [CrossRef]

- Gong, B. Agricultural reforms and production in China: Changes in provincial production function and productivity in 1978–2015. J. Dev. Econ. 2018, 132, 18–31. [Google Scholar] [CrossRef]

- Cao, K.H.; Birchenall, J.A. Agricultural productivity, structural change, and economic growth in post-reform China. J. Dev. Econ. 2013, 104, 165–180. [Google Scholar] [CrossRef] [Green Version]

- Chari, A.; Liu, E.M.; Wang, S.; Wang, Y. Property Rights, Land Misallocation, and Agricultural Efficiency in China. Rev. Econ. Stud. 2021, 88, 1831–1862. [Google Scholar] [CrossRef]

- Kalirajan, K.P.; Obwona, M.B.; Zhao, S. A Decomposition of Total Factor Productivity Growth: The Case of Chinese Agricultural Growth before and after Reforms. Am. J. Agric. Econ. 1996, 78, 331–338. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, H. Productivity Growth in China’s Agriculture During 1985–2010. J. Int. Agric. 2013, 12, 1896–1904. [Google Scholar] [CrossRef]

- Toma, P.; Miglietta, P.P.; Zurlini, G.; Valente, D.; Petrosillo, I. A non-parametric bootstrap-data envelopment analysis approach for environmental policy planning and management of agricultural efficiency in EU countries. Ecol. Indic. 2017, 83, 132–143. [Google Scholar] [CrossRef]

- Tian, Y.; Zhang, J.; He, Y. Research on Spatial-Temporal Characteristics and Driving Factor of Agricultural Carbon Emissions in China. J. Int. Agric. 2014, 13, 1393–1403. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.; Li, M.; Su, K.; Li, X. Spatial-Temporal Characteristics of the Driving Factors of Agricultural Carbon Emissions: Empirical Evidence from Fujian, China. Energies 2019, 12, 3102. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Jiang, Y.; Yu, Z.; Shang, L. Analysis of Agriculture Total-Factor Energy Efficiency in China Based on DEA and Malmquist indices. Energy Proced. 2017, 142, 2397–2402. [Google Scholar] [CrossRef]

- Reza Anik, A.; Rahman, S.; Sarker, J.R. Five Decades of Productivity and Efficiency Changes in World Agriculture (1969–2013). Agriculture 2020, 10, 200. [Google Scholar] [CrossRef]

- Jiang, M.; Hu, X.; Chunga, J.; Lin, Z.; Fei, R. Does the popularization of agricultural mechanization improve energy-environment performance in China’s agricultural sector? J. Clean. Prod. 2020, 276, 124210. [Google Scholar] [CrossRef]

- Popkin, S.L. The Rational Peasant; University of California Press: Berkeley, CA, USA, 1979; pp. 1–31. [Google Scholar] [CrossRef]

| Variable Type | Variable | Abbreviation | Mean | Std. Dev. | Min | Max |

|---|---|---|---|---|---|---|

| Dependent variable | Log(planting GTFP) | lnGTFPit | 4.850 | 0.388 | 3.931 | 6.007 |

| Independent variable | mechanization | mac | 0.441 | 0.231 | 0.014 | 1 |

| Instrument variable | transportation infrastructure | inf | 32.707 | 22.153 | 4.568 | 121.937 |

| Intermediary variables | technology progress | tp | 0.558 | 0.266 | 0.139 | 1.416 |

| operation scale | os | 9.766 | 6.716 | 2.236 | 44.132 | |

| resource allocation | ra | 0.385 | 0.172 | 0.062 | 1.173 | |

| technical efficiency | tec | 0.678 | 0.153 | 0.438 | 0.986 | |

| Control variables | agricultural land management scale | sca | 6.843 | 6.026 | 0.929 | 30.643 |

| agricultural planting structure | pst | 0.651 | 0.129 | 0.328 | 0.971 | |

| rural human capital | hum | 7.372 | 0.727 | 4.811 | 9.731 | |

| regional economic development level | agdp | 0.011 | 0.006 | 0.003 | 0.033 | |

| part-time employment of labor force | ccj | 15.327 | 21.269 | 0.062 | 76.300 | |

| production risk | ris | 0.227 | 0.155 | 0.000 | 0.936 | |

| urban–rural income gap | inc | 2.874 | 0.572 | 1.850 | 5.120 |

| Method | OLS | 2SLS | ||

|---|---|---|---|---|

| Model | (1) | (2) | (3) | (4) |

| mac | 1.356 *** | 0.512 *** | 1.611 *** | 1.386 *** |

| (0.130) | (0.161) | (0.068) | (0.308) | |

| sca | 0.011 *** | 0.007 ** | ||

| (0.003) | (0.003) | |||

| pst | 0.396 * | −0.068 | ||

| (0.225) | (0.214) | |||

| hum | 0.077 *** | 0.002 | ||

| (0.023) | (0.029) | |||

| gdp | 32.690 *** | 12.205 | ||

| (5.990) | (9.733) | |||

| ccj | 0.002 *** | 0.001 | ||

| (0.001) | (0.000) | |||

| ris | −0.182 *** | −0.099 * | ||

| (0.053) | (0.053) | |||

| inc | −0.076 ** | 0.017 | ||

| (0.035) | (0.043) | |||

| R-squared | 0.706 | 0.812 | 0.681 | 0.735 |

| Coefficient of IV in the first stage | 0.007 *** | 0.002 *** | ||

| (0.000) | (0.000) | |||

| Value F in the first stage | 231.970 | 18.700 | ||

| Fixed province | Yes | |||

| Fixed year | Yes | |||

| Observations | 570 | |||

| Provinces | 30 | |||

| Dependent Variable | tp | os | ra | tec | lnGTFP | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | (1) | (2) | (3) | (4) | (5) | (6) | (7) | (8) | (9) | (10) |

| mac | 0.453 *** | 4.268 *** | 0.431 *** | −0.016 ** | 0.512 *** | 0.167 *** | 0.301 *** | 0.217 *** | 0.505 *** | 0.131 ** |

| (0.056) | (3.338) | (0.138) | (0.007) | (0.161) | (0.063) | (0.058) | (0.063) | (0.161) | (0.066) | |

| tp | 0.184 *** | 0.176 *** | ||||||||

| (0.033) | (0.030) | |||||||||

| os | 0.016 *** | 0.007 | ||||||||

| (0.004) | (0.004) | |||||||||

| ra | 0.522 *** | 0.063 | ||||||||

| (0.100) | (0.057) | |||||||||

| tec | −0.449 | −0.467 | ||||||||

| (0.477) | (0.069) | |||||||||

| R-squared | 0.683 | 0.747 | 0.562 | 0.181 | 0.812 | 0.752 | 0.750 | 0.760 | 0.813 | 0.930 |

| Control variable | Controlled | |||||||||

| Fixed province | Yes | |||||||||

| Fixed year | Yes | |||||||||

| Observations | 570 | |||||||||

| Provinces | 30 | |||||||||

| Adjacency Matrix | Geographical Distance Matrix | Economic Distance Matrix | |

|---|---|---|---|

| Model | (1) | (2) | (3) |

| spatial coefficient | 0.213 *** | 0.354 *** | 0.419 *** |

| (0.054) | (0.087) | (0.063) | |

| LR_Direct | 0.178 *** | 0.125 * | 0.200 *** |

| (0.066) | (0.074) | (0.069) | |

| LR_Indirect | 0.823 *** | 1.182 *** | 0.648 *** |

| (0.114) | (0.277) | (0.209) | |

| LR_Total | 1.000 *** | 1.307 *** | 0.848 *** |

| (0.119) | (0.275) | (0.222) | |

| R-squared | 0.565 | 0.549 | 0.607 |

| Non-Grain-Producing Area | Main Grain-Producing Area | Primary Mechanization | Intermediate Mechanization | Advanced Mechanization | |

|---|---|---|---|---|---|

| Model | (1) | (2) | (3) | (4) | (5) |

| mac | 0.335 *** | 0.704 *** | 0.826 *** | 0.929 *** | 1.139 *** |

| (0.091) | (0.082) | (0.132) | (0.121) | (0.356) | |

| sca | 0.013 *** | −0.006 | −0.002 | −0.021 * | 0.013 *** |

| (0.002) | (0.007) | (0.007) | (0.011) | (0.003) | |

| pst | 0.925 *** | 0.342 ** | 0.326 | 0.291 * | −0.427 |

| (0.182) | (0.145) | (0.216) | (0.161) | (0.416) | |

| hum | 0.116 *** | 0.047 *** | 0.009 | 0.066 *** | 0.063 |

| (0.025) | (0.017) | (0.022) | (0.020) | (0.052) | |

| agdp | 17.849 *** | 40.117 *** | 50.180 *** | 11.986 | −5.040 |

| (6.709) | (5.786) | (11.338) | (7.946) | (9.779) | |

| ccj | 0.003 *** | 0.002 *** | 0.002 *** | 0.001 *** | 0.002 ** |

| (0.000) | (0.000) | (0.001) | (0.000) | (0.001) | |

| ris | −0.224 *** | −0.172 *** | −0.110 ** | −0.192 *** | −0.223 * |

| (0.052) | (0.046) | (0.050) | (0.049) | (0.114) | |

| inc | −0.045 | −0.051 ** | −0.032 | −0.061 ** | −0.074 |

| (0.036) | (0.023) | (0.026) | (0.031) | (0.112) | |

| R-squared | 0.867 | 0.789 | 0.744 | 0.755 | 0.763 |

| Fixed province | Yes | ||||

| Fixed year | Yes | ||||

| Observations | 323 | 247 | 251 | 241 | 78 |

| Provinces | 17 | 13 | 23 | 25 | 11 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Zhang, Y.; Piao, H. Does Agricultural Mechanization Improve the Green Total Factor Productivity of China’s Planting Industry? Energies 2022, 15, 940. https://doi.org/10.3390/en15030940

Zhu Y, Zhang Y, Piao H. Does Agricultural Mechanization Improve the Green Total Factor Productivity of China’s Planting Industry? Energies. 2022; 15(3):940. https://doi.org/10.3390/en15030940

Chicago/Turabian StyleZhu, Yingyu, Yan Zhang, and Huilan Piao. 2022. "Does Agricultural Mechanization Improve the Green Total Factor Productivity of China’s Planting Industry?" Energies 15, no. 3: 940. https://doi.org/10.3390/en15030940

APA StyleZhu, Y., Zhang, Y., & Piao, H. (2022). Does Agricultural Mechanization Improve the Green Total Factor Productivity of China’s Planting Industry? Energies, 15(3), 940. https://doi.org/10.3390/en15030940