Comparison of Selected Technologies to Improve the Quality of Exhaust Gases from Landfill Gas Combustion

Abstract

:1. Introduction

2. Materials and Methods

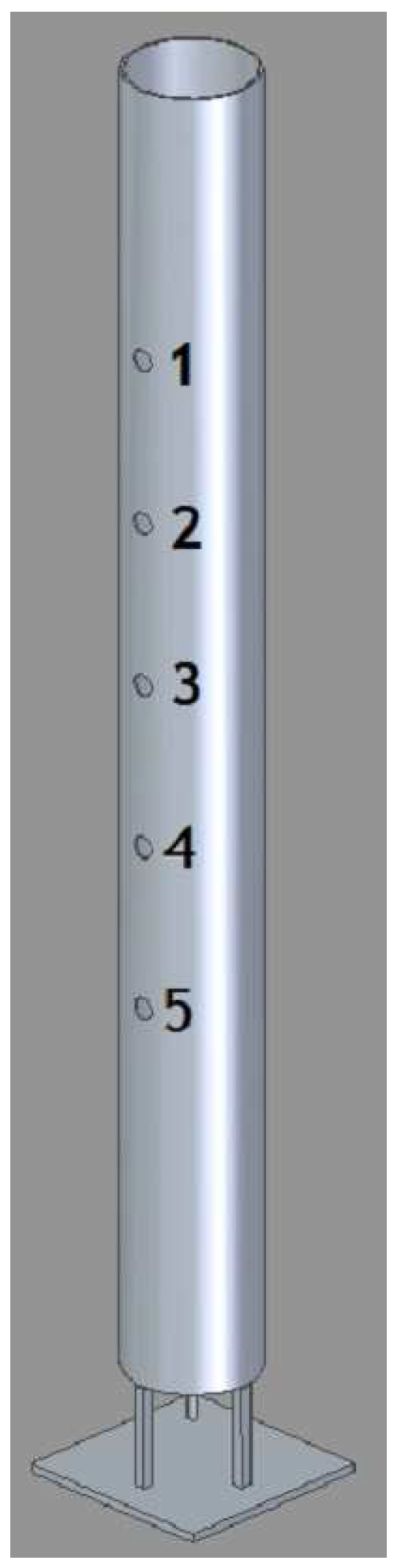

2.1. Description of the Test Stand

2.2. Applied Catalytic Additives

2.3. Measurement of the Exhaust Gases Quality

2.4. Measurement of the Particulate Matter Content in Exhaust Gases

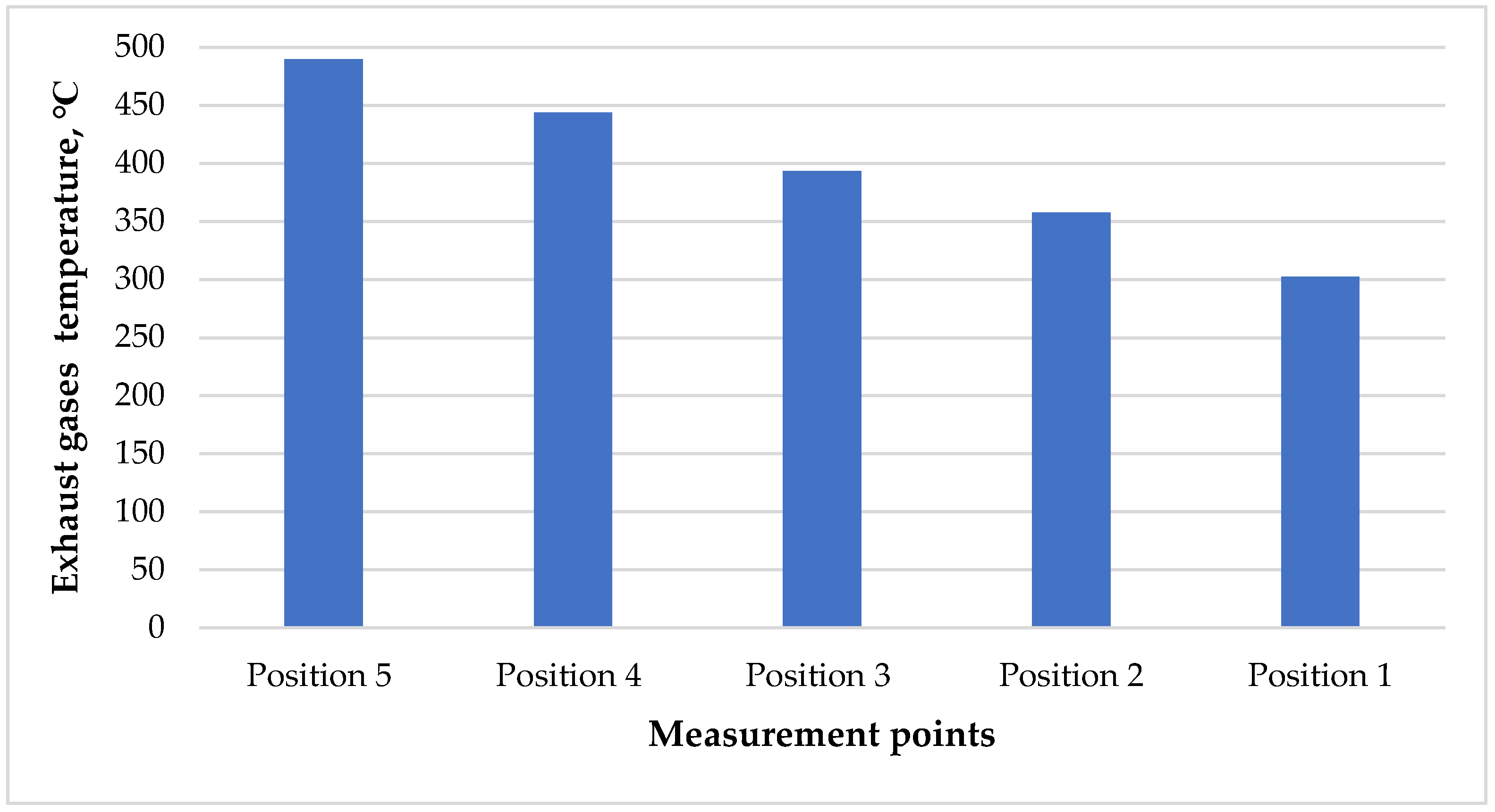

2.5. Measurement of the Exhaust Gases Temperature

3. Results

3.1. Exhaust Gases Temperature

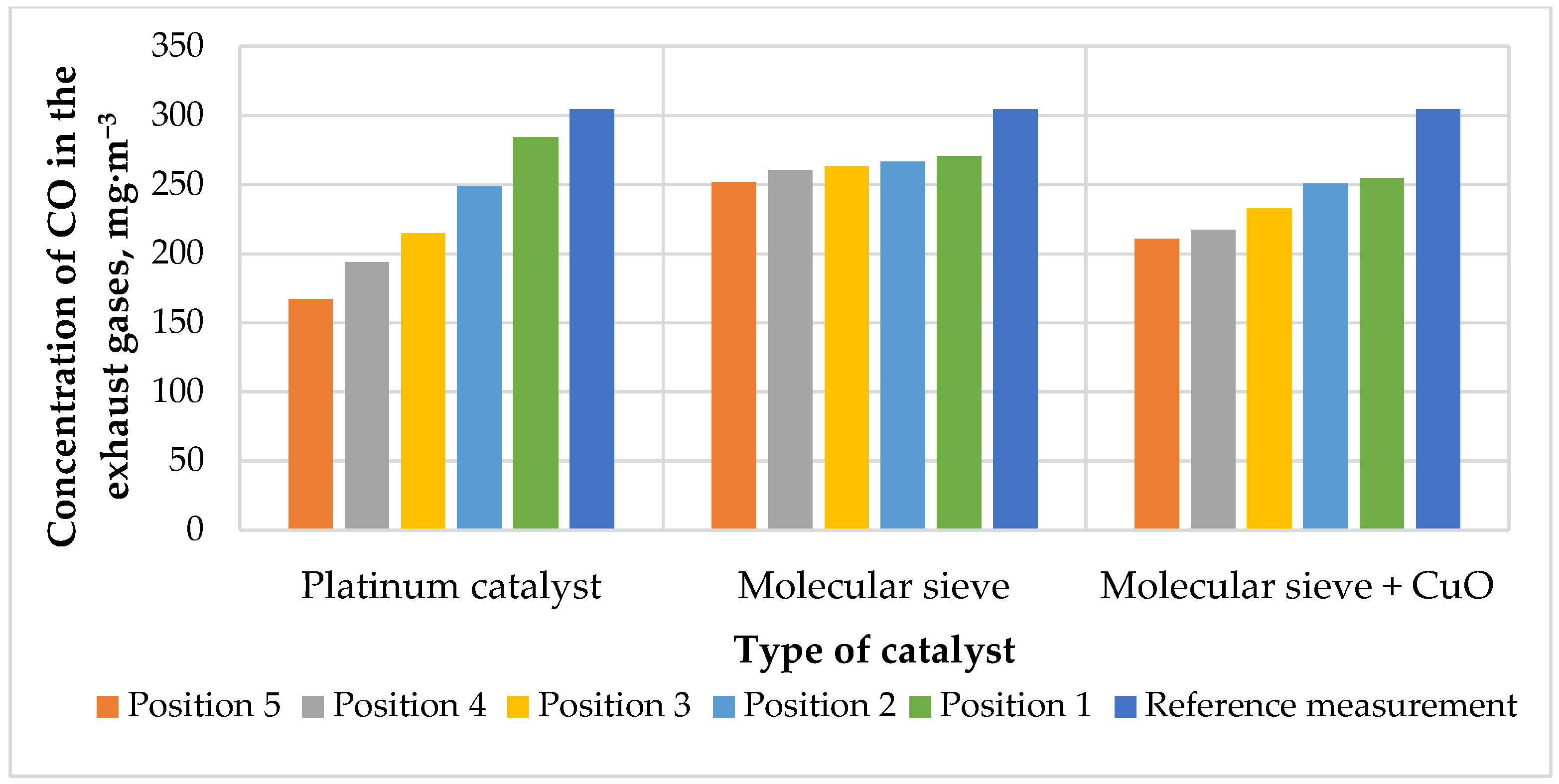

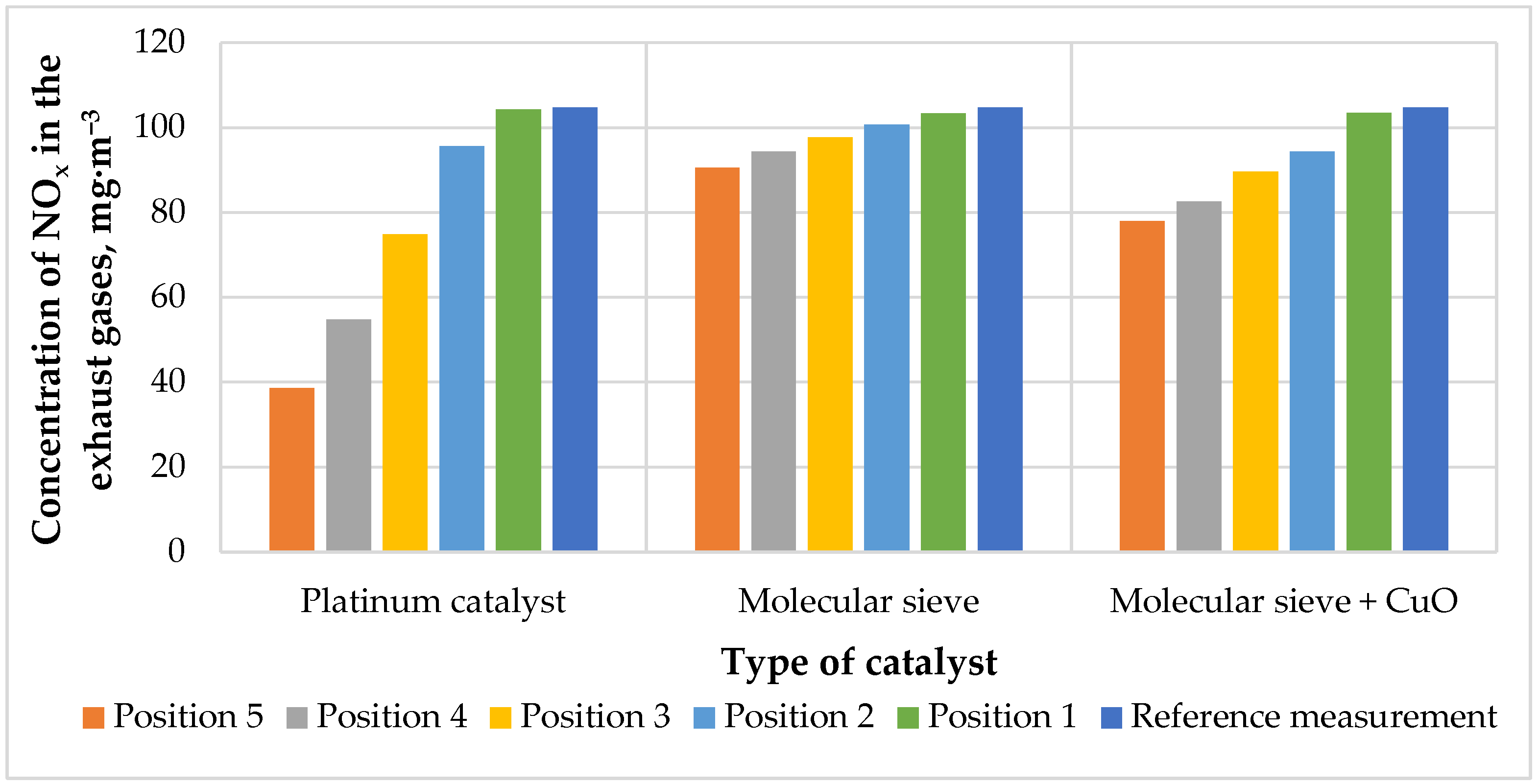

3.2. Exhaust Gases Quality

3.3. Particulate Matter Content in Exhaust Gases

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Jurczyk, Ł.; Koc-Jurczyk, J. Changes in the approach to waste disposal and generation of the leachate. Arch. Gospod. Odpadami Ochr. Sr. 2014, 1, 31–39. [Google Scholar]

- Bove, R.; Lunghi, P. Electric power generation from landfill gas using traditional and innovative technologies. Energy Convers. Manag. 2006, 47, 1391–1401. [Google Scholar] [CrossRef]

- Williams, A.; Jones, J.M.; Ma, L.; Pourkashanian, M. Pollutants from the Combustion of Solid Biomass Fuels. Prog. Energy Combust. Sci. 2012, 38, 113–137. [Google Scholar] [CrossRef]

- European Environment Agency. Air Quality in Europe—2020 Report; European Environment Agency: Copenhagen, Denmark, 2020. [Google Scholar]

- Wielgosiński, G.; Łechtańska, P.; Namiecińska, O. Emission of Some Pollutants from Biomass Combustion in Comparison to Hard Coal Combustion. J. Energy Inst. 2017, 90, 787–796. [Google Scholar] [CrossRef]

- Kuczaj, A. Emission of organic compounds during biomass combustion. Bud. Inżynieria Sr. 2010, 3, 205–214. [Google Scholar]

- Brook, R.D. Cardiovascular effects of air pollution. Clin. Sci. 2008, 115, 175–187. [Google Scholar] [CrossRef] [Green Version]

- Kampa, M.; Castanas, E. Human Health Effects of Air Pollution. Environ. Pollut. 2008, 151, 362–367. [Google Scholar] [CrossRef]

- Boningari, T.; Smirniotis, P.G. Impact of Nitrogen Oxides on the Environment and Human Health: Mn-Based Materials for the NO x Abatement. Curr. Opin. Chem. Eng. 2016, 13, 133–141. [Google Scholar] [CrossRef]

- Stowell, J.; Young-min, K.; Gao, Y.; Fu, J.S.; Chang, H.H.; Liu, Y. The Impact of Climate Change and Emissions Control on Future Ozone Levels: Implications for Human Health. Environ. Int. 2017, 108, 41–50. [Google Scholar] [CrossRef]

- Chen, T.M.; Kuschner, W.G.; Gokhale, J.; Shofer, S. Outdoor Air Pollution: Nitrogen Dioxide, Sulfur Dioxide, and Carbon Monoxide Health Effects. Am. J. Med. Sci. 2007, 333, 249–256. [Google Scholar] [CrossRef]

- Guerreiro, C.B.B.; Horálek, J.; de Leeuw, F.; Couvidat, F. Benzo(a)Pyrene in Europe: Ambient Air Concentrations, Population Exposure and Health Effects. Environ. Pollut. 2016, 214, 657–667. [Google Scholar] [CrossRef]

- Wang, S.L.; Lin, C.Y.; Guo, Y.L.; Lin, L.Y.; Chou, W.L.; Chang, L.W. Infant Exposure to Polychlorinated Dibenzo-p-Dioxins, Dibenzofurans and Biphenyls (PCDD/Fs, PCBs)––Correlation between Prenatal and Postnatal Exposure. Chemosphere 2004, 54, 1459–1473. [Google Scholar] [CrossRef]

- Mocarelli, P.; Patterson, D.G.; Bonzini, M.; Pesatori, A.C.; Caporaso, N.; Landi, M.T. Immunologic Effects of Dioxin: New Results from Seveso and Comparison with Other Studies. Environ. Health Perspect. 2002, 110, 1169–1173. [Google Scholar] [CrossRef] [Green Version]

- The EU Emissions Trading System (EU ETS); European Commission: Brussel, Belgium, 2017.

- 2030 Climate & Energy Framework’; European Commission: Brussel, Belgium, 2014.

- Commission Implementing Decision (EU) 2017/1442; Official Journal of the European Union: Brussel, Belgium, 2017.

- Chyc, M. The role of fuel additives in the fuel combustion process. Res. Rep. Min. Environ. 2012, 1, 5–16. [Google Scholar]

- Doggali, P.; Kusaba, H.; Einaga, H.; Bensaid, S.; Rayalu, S.; Teraoka, Y.; Labhsetwar, N. Low-Cost Catalysts for the Control of Indoor CO and PM Emissions from Solid Fuel Combustion. J. Hazard. Mater. 2011, 186, 796–804. [Google Scholar] [CrossRef]

- Long, H.M.; Li, J.X.; Wang, P.; Gao, G.; Tang, G.W. Emission Reduction of Dioxin in Iron Ore Sintering by Adding Urea as Inhibitor. Ironmak. Steelmak. 2011, 38, 258–262. [Google Scholar] [CrossRef]

- Tic, W.J. System poprawy efektywności energetycznej i ekologicznej spalania paliw stałych. Chemik 2014, 68, 850–855. [Google Scholar]

- Wojtko, P.; Gaze, B.; Knutel, B.; Wacławek, A.; Bukowski, P.; Romański, L. The Use of Catalytic Additives for the Combustion of Sunflower Husk Pellets in a Low-power Boiler. Przemysł Chem. 2021, 5, 90–94. [Google Scholar] [CrossRef]

- International Best Practices Guide for Landfill Gas Energy Projects; Environmental Protection Agency: Washingtion, DC, USA, 2012.

- Zaleska-Bartosz, J. Landfill gas as an energy source. Inst. Naft. Gazu 2014, 14, 932–937. [Google Scholar]

- Ciupek, B.; Urbaniak, R.; Bartoszewicz, J. Koncepcja instalacji energetycznego zagospodarowania biogazu dla dużych składowisk odpadów. Rynek Energii 2018, 6, 55–59. [Google Scholar]

- Popov, V. A new landfill system for cheaper landfill gas purification. Renew. Energy 2005, 30, 1021–1029. [Google Scholar] [CrossRef]

- Best Practice Guidance for Effective Methane Drainage and Use in Coal Mines; Economic Commission for Europe Methane to Markets Partnership: New York, NY, USA, 2010.

- Friedlingstein, P.; O’Sullivan, M.; Jones, M.W.; Andrew, R.M.; Hauck, J.; Olsen, A.; Peters, G.P. Global Carbon Budget 2020. Earth Syst. Sci. Data 2020, 12, 3269–3340. [Google Scholar] [CrossRef]

- Basic Information about Landfill Gass of United States Enwironmental Protection Agency. Available online: https://www.epa.gov/lmop/basic-information-about-landfill-gas (accessed on 10 January 2022).

- Tronconi, E.; Forzatti, P. Adequacy of Lumped Parameter Models for SCR Reactors with Monolith Structure. AIChE J. 1992, 38, 201–210. [Google Scholar] [CrossRef]

- Caton, J.A.; Xia, Z. The Selective Non-Catalytic Removal (SNCR) of Nitric Oxides From Engine Exhaust Streams: Comparison of Three Processes. J. Eng. Gas Turbines Power 2004, 126, 234–240. [Google Scholar] [CrossRef]

- Gaj, K. Primary possibilites of NOx emission abatement from dust boilers. Gospod. Paliwami I Energią 1997, 11, 10–14. [Google Scholar]

- Stelmach, S.; Jastrząb, K. Comparison of Properties of Commercial Active Cokes. Inżynieria I Ochr. Sr. 2013, 16, 373–383. [Google Scholar]

- Zeng, W.; Liu, J.; Ma, H.; Liu, Y.; Liu, A. Experimental Study on the Flame Propagation and Laminar Combustion Characteristics of Landfill Gas. Energy 2018, 158, 437–448. [Google Scholar] [CrossRef]

- Álvarez-Flórez, J.; Egusquiza, E. Analysis of Damage Caused by Siloxanes in Stationary Reciprocating Internal Combustion Engines Operating with Landfill Gas. Eng. Fail. Anal. 2015, 50, 29–38. [Google Scholar] [CrossRef] [Green Version]

- Gaze, B.; Knutel, B.; Jajczyk, M.; Wacławek, A.; Bukowski, P.; Dębowski, M. Analysis of the Use of Catalytic Additives for Combustion with Wood Pellets in a Low-power Boiler. Rynek Energii 2021, 4, 93–98. [Google Scholar]

- Gaze, B. The Concept of Using Urea to Reduce NOx Emissions from Low power Biomass Boilers. Przemysł Chmiczny 2020, 4, 569–573. [Google Scholar] [CrossRef]

- Gaze, B.; Hrywna, D.; Romański, L.; Kułażyński, M. Effect of Fuel Type and Active Substance Addition on Exhaust Gas Emissions from Vehicles Powered by a Spark Ignition Engine. Przemysł Chmiczny 2021, 1, 75–80. [Google Scholar] [CrossRef]

| Parameter | Unit | Value |

|---|---|---|

| Total capacity | m3 | 1,800,000 |

| Total capacity within the crown of the landfill | m3 | 69,000 |

| Mass of deposited waste | Mg | 17,000 |

| Position | Value |

|---|---|

| 1 | 25 cm below the top of the torch |

| 2 | 40 cm below the top of the torch |

| 3 | 55 cm below the top of the torch |

| 4 | 70 cm below the top of the torch |

| 5 | 85 cm below the top of the torch |

| Component | Measurement Method | Range | Precision | Compl. with Standards |

|---|---|---|---|---|

| O2 | paramagnetic | 0–25% | ±0.1% abs. or 3% rel. | EN 14789; OTM-13 |

| CO | chemiluminescence | 0–10,000 ppm | ±3 ppm abs. or 3% rel. | EN 15058; METHOD 10 |

| CO2 | chemiluminescence | 0–25% | ±0.03% abs. or 3% rel. | ISO 12039; OTM-13 |

| NOx | chemiluminescence | 0–1000 ppm | ±3 ppm abs. or 3% rel. | EN14792 |

| SO2 | chemiluminescence | 0–800 ppm | ±5 ppm abs. or 5% rel. | EN14793 |

| Component | Measurement Method | Range | Precision | Compl. with Standards |

|---|---|---|---|---|

| PM | NDIR | 0–300 mg·m−3 | ±1 ppm abs. or 1% rel. | EN14842 |

| CO2 | chemiluminescence | 0–20% | ±0.03% abs. or 3% rel. | ISO 12039 |

| O2 | paramagnetic | 0–22% | ±0.1% abs. or 3% rel. | EN 14789 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaze, B.; Knutel, B.; Zając, K.; Jajczyk, M.; Bukowski, P. Comparison of Selected Technologies to Improve the Quality of Exhaust Gases from Landfill Gas Combustion. Energies 2022, 15, 778. https://doi.org/10.3390/en15030778

Gaze B, Knutel B, Zając K, Jajczyk M, Bukowski P. Comparison of Selected Technologies to Improve the Quality of Exhaust Gases from Landfill Gas Combustion. Energies. 2022; 15(3):778. https://doi.org/10.3390/en15030778

Chicago/Turabian StyleGaze, Błażej, Bernard Knutel, Krzysztof Zając, Mateusz Jajczyk, and Przemysław Bukowski. 2022. "Comparison of Selected Technologies to Improve the Quality of Exhaust Gases from Landfill Gas Combustion" Energies 15, no. 3: 778. https://doi.org/10.3390/en15030778

APA StyleGaze, B., Knutel, B., Zając, K., Jajczyk, M., & Bukowski, P. (2022). Comparison of Selected Technologies to Improve the Quality of Exhaust Gases from Landfill Gas Combustion. Energies, 15(3), 778. https://doi.org/10.3390/en15030778