Latent Thermal Energy Storage Application in a Residential Building at a Mediterranean Climate

Abstract

:1. Introduction

2. The TESSe2b Approach

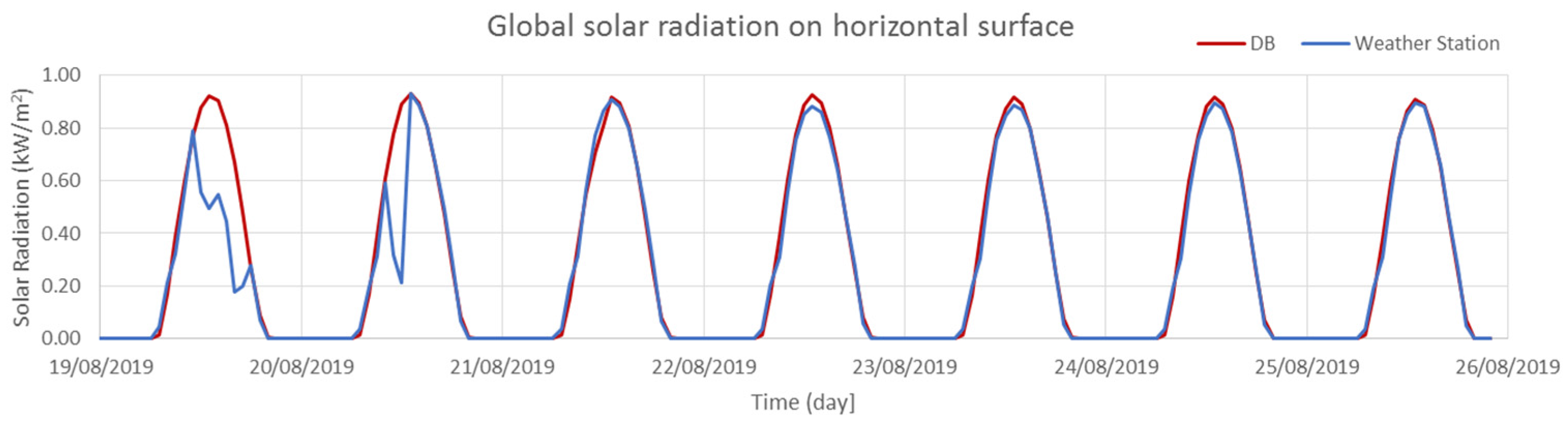

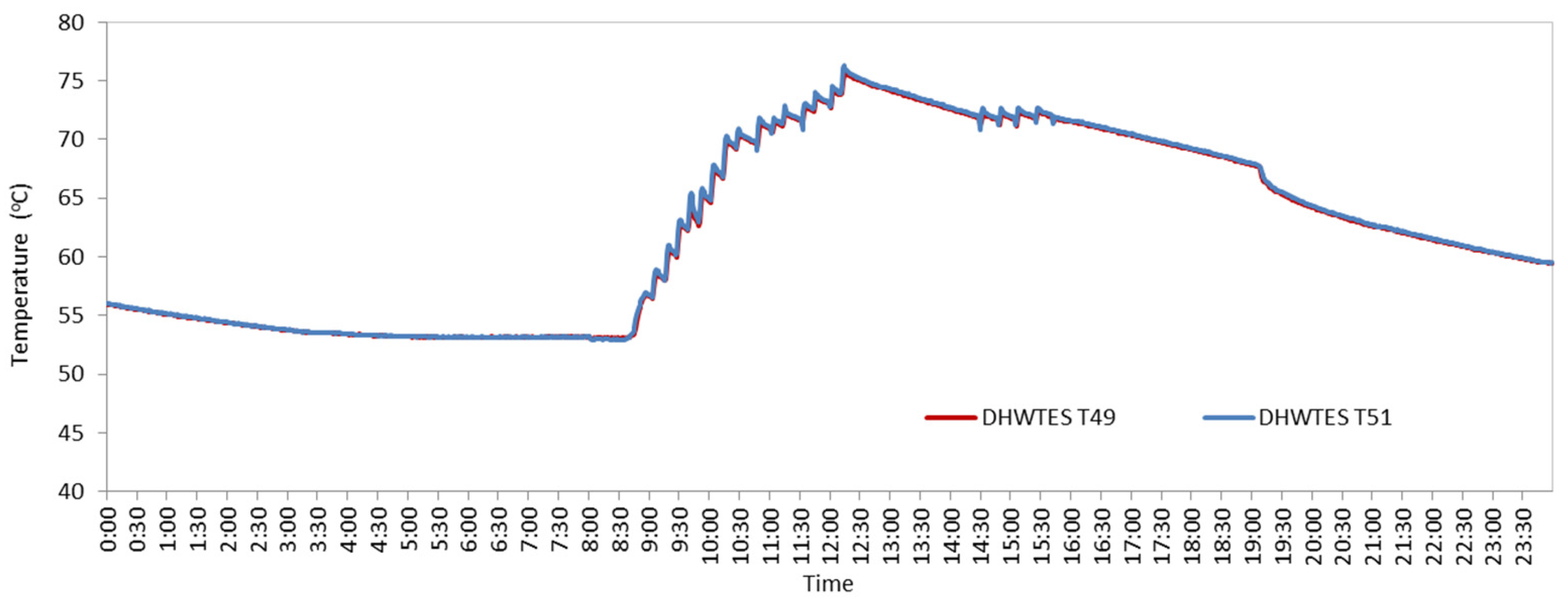

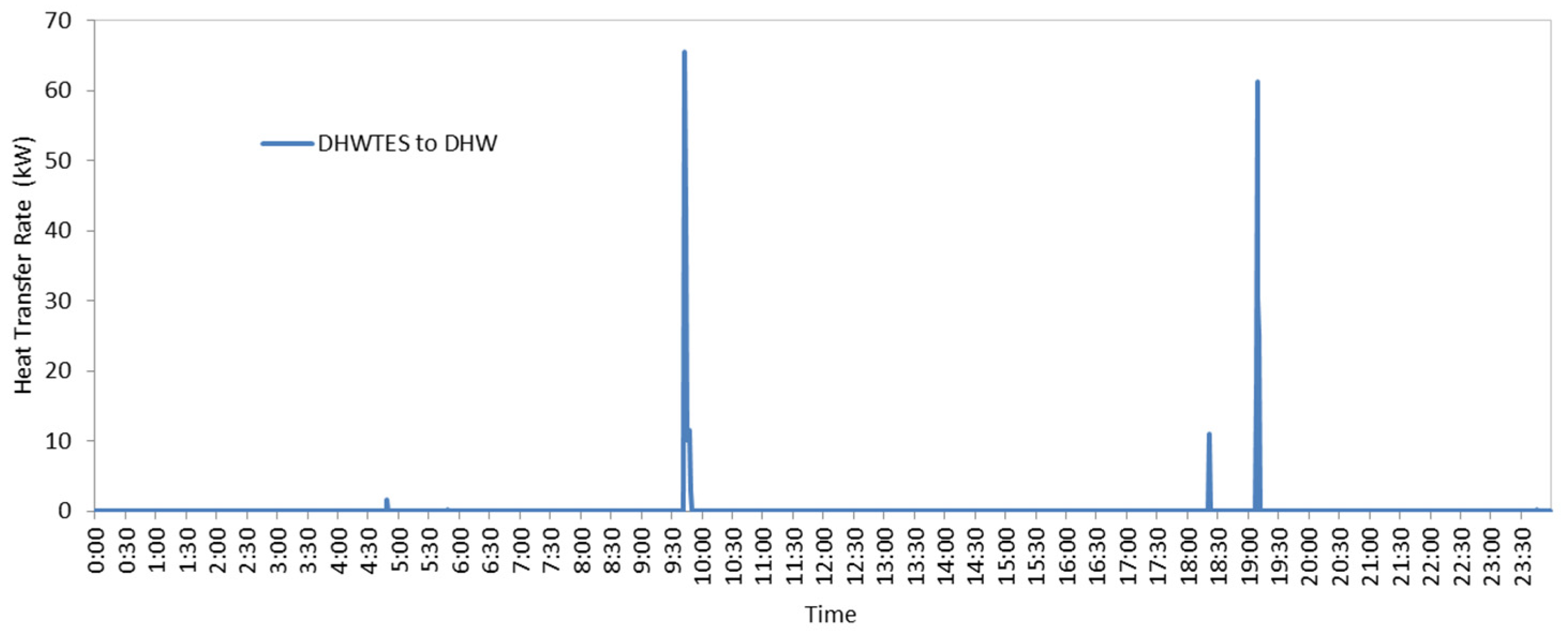

3. TESSe2b System Design for Cyprus Demo Site

3.1. About the Area

3.2. Description of the Building and Its Needs

- Heating season: November to mid-April

- Cooling season: mid-April to September

- Indoor temperatures: 20 °C (heating); 25 °C (cooling);

- Solar Collectors: Flat Panel

- DWH: 4 persons, 160 L per day; 45 °C

- Load Terminal Units for heating and cooling: fan-coils;

- Utilization Schedules and heating or cooling: depending of the room;

- Building total floor area: 221 m2

- There is no thermal insulation in the thermal envelope.

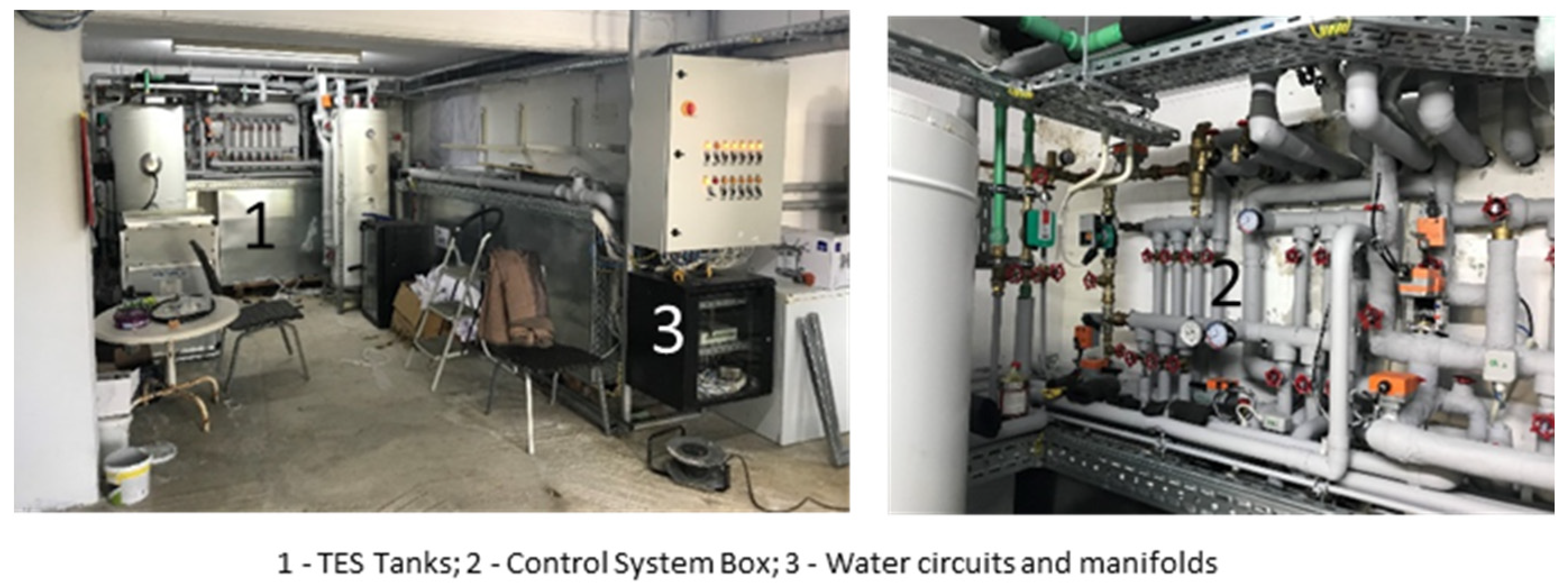

3.3. TESSe2b Implementation

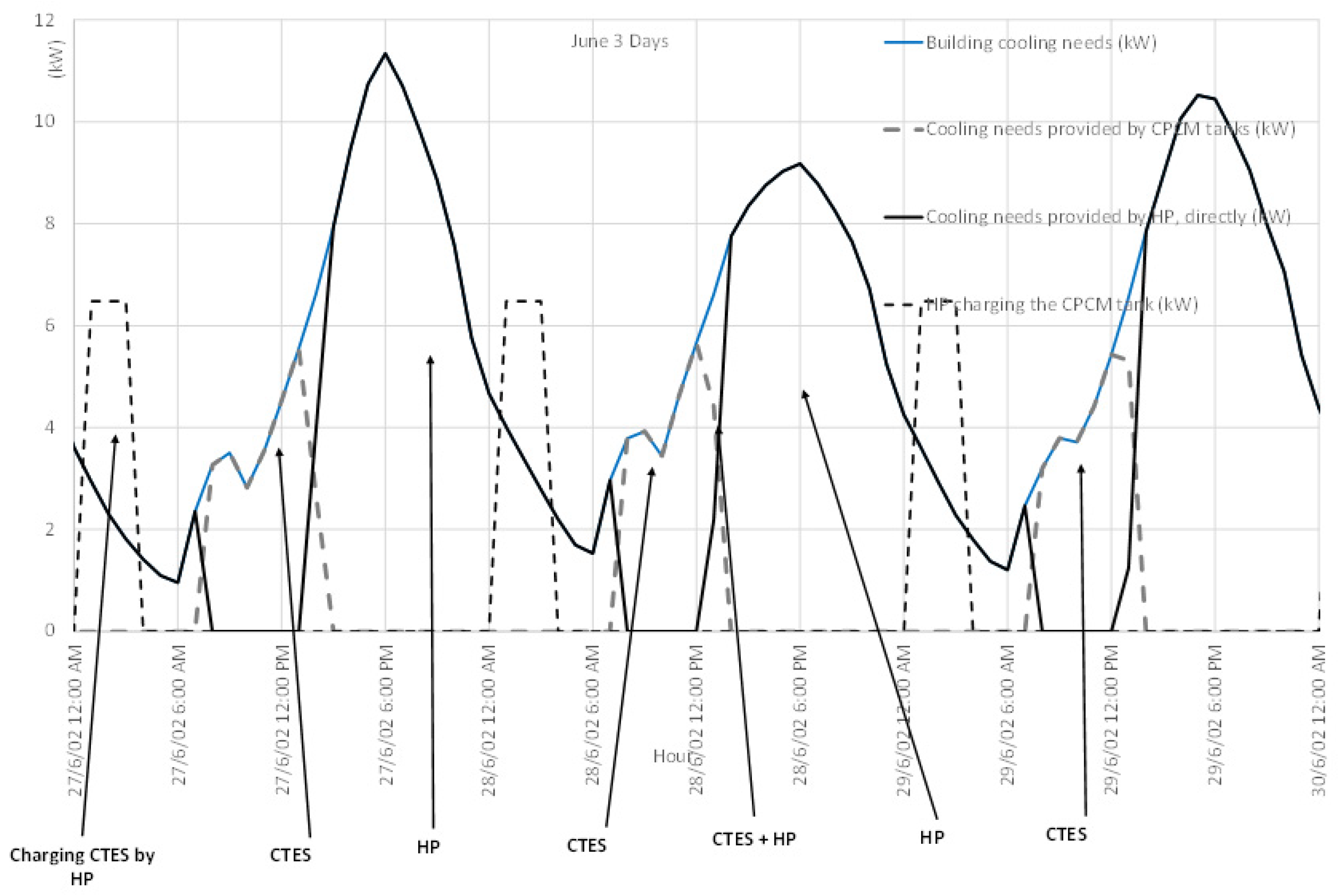

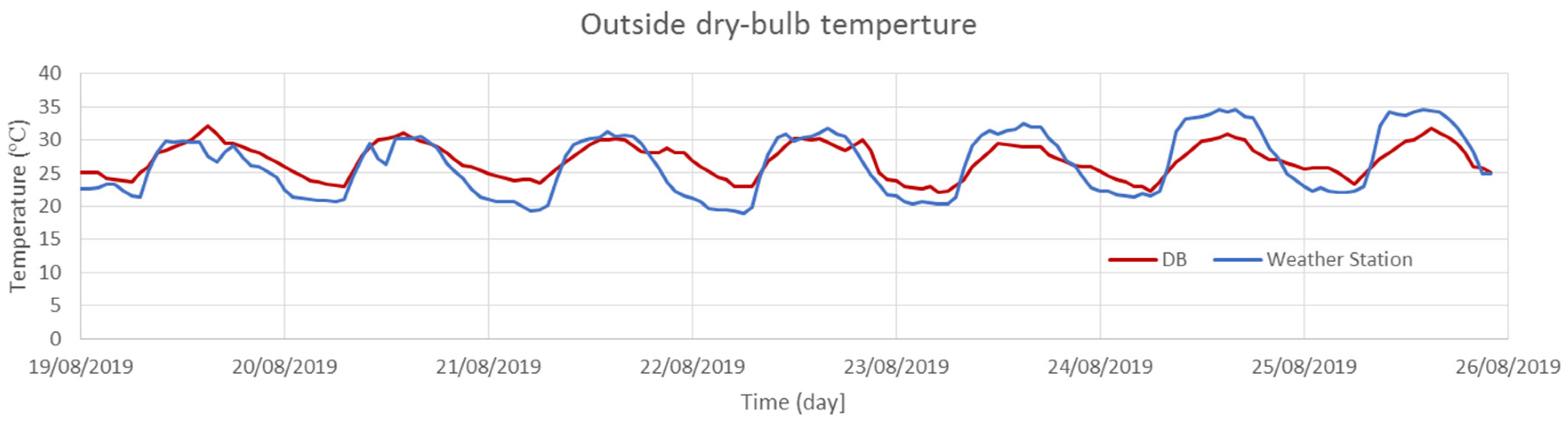

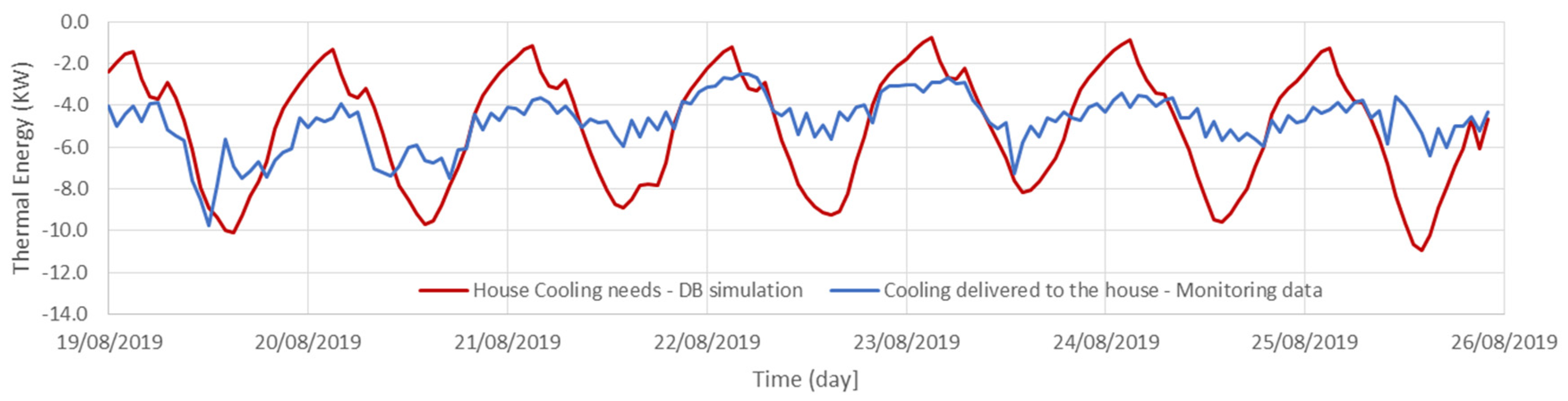

4. Performance Evaluation of TESSe2b System

4.1. Methodology

- SPF1: efficiency of the system, including the electricity consumption of the GSHP;

- SPF2: efficiency of the system, including the electricity consumption of the GSHP and the circulator of the BHEs (circulator CH2);

- SPF3: efficiency of the system, including the electricity consumption of the GSHP and the circulators CH2, CH1 and CL1;

- SPF4: efficiency of the system, including the electricity consumption of the GSHP, the circulators CH2, CH1 and CL1 and the fans of the load terminal units of the building.

- Primary energy conversion factor: oil (1.1) and electrical energy (2.9);

- Emissions TCO2/MWh: oil (0.267) and electrical energy (0.874).

4.2. Conventional System and Tesse2b Calculations: Economic Analysis and Discussion

- Boiler and burner using heat oil of 20 kW for heating;

- Split units of 15.6 kW for cooling;

- Solar system of 9.4 m2: 4 collectors for DHW (supported by a heating element).

- The technical characteristics of the TESSe2b system were the following:

- GSHP of 26.3 kW for heating and 18.6 kW for cooling;

- Solar system of 20m2: 10 collectors for heating and DHW;

- Total of 3 HTES tanks, 3 CTES tanks and 1 DHW-PCM tank.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Renewable Energy Agency. Innovation Outlook—Thermal Energy Storage; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2020. [Google Scholar]

- Douvi, E.; Pagkalos, C.; Dogkas, G.; Koukou, M.K.; Stathopoulos, V.N.; Caouris, Y.; Vrachopoulos, M.G. Phase Change Materials in solar Domestic Hot Water Systems: A Review. Int. J. Thermofluids 2021, 10, 100075. [Google Scholar] [CrossRef]

- Delgado, M.; Lazaro, A.; Mazo, J.; Zalba, B. Review on Phase Change Material Emulsions and Microencapsulated Phase Change Material Slurries: Materials, Heat Trnasfer Studies and Applications. Renew. Sustain. Energy Rev. 2012, 16, 253–273. [Google Scholar] [CrossRef]

- European Association for Storage of Energy and European Energy Research Alliance. Joint EASE/EERA Recommendations for a European Energy Storage Technology Development Roadmap towards 2030; Martens, D., Ed.; EASE/EERA: Brussels, Belgium, 2013. [Google Scholar]

- Pandey, A.; Hossain, M.; Tyagi, V.; Abd Rahim, N.; Selvaraj, J.; Sari, A. Novel Approaches and Recent Developments on Potential Applications Phase Change Materials in Solar Energy. Renew. Sustain. Energy Rev. 2018, 82, 281–323. [Google Scholar] [CrossRef]

- Faraj, K.; Khaled, M.; Faraj, J.; Hackem, F.; Castelain, C. A Review on Phase Change Materials for Thermal Energy Storage in Buildings: Heating and Hybrid Applications. J. Energy Storage 2020, 1, 101913. [Google Scholar] [CrossRef]

- Mehling, H.; Cabeza, L. Heat and Cold Storage with PCM; Springer: New York, NY, USA, 2008. [Google Scholar]

- Agyenim, F.; Hewitt, N.; Eames, P.; Smyth, M. A Review of Materials, Heat Transfer and Phase Change Problem Formulation for Latent Heat Thermal Energy Storage Systems (LHTESS). Renew. Sustain. Energy Rev. 2010, 14, 615–628. [Google Scholar] [CrossRef]

- Aljabr, A.; Chiasson, A.; Alhajjaji, A. Numerical Modeling of the Effects of Micro-Encapsulated Phase Change Materials Intermixed with Grout in Vertical Borehole Heat Exchanger. Geothermics 2021, 96, 102197. [Google Scholar] [CrossRef]

- Yang, W.; Xu, R.; Yang, B.; Yang, J. Experimental and Numerical Investigations on the Thermal Performance of a Borehole Ground Heat Exchanger with PCM Backfill. Energy 2019, 174, 216–235. [Google Scholar] [CrossRef]

- Kocak, B.; Fernadez, A.; Paksoy, H. Review on Sensible Thermal Energy Storage for Industrial Solar Applications and Sustainability Aspects. Solar Energy 2020, 209, 135–169. [Google Scholar] [CrossRef]

- TESSe2b—The Smart Energy Storage. Available online: http://www.tesse2b.eu/ (accessed on 5 November 2021).

- Dogkas, G.; Konstantaras, J.; Koukou, M.K.; Vrachopoulos, M.G.; Pagkalos, C.; Stathopoulos, V.N.; Pandis, P.K.; Lymperis, K.; Coelho, L.; Rebola, A. Development and Experimental Testing of a Compact Thermal Energy Storage Tank using Paraffin Targeting Domestic Hot Water Production Needs. Therm. Sci. Eng. Prog. 2020, 19, 100573. [Google Scholar] [CrossRef]

- Dogkas, G.; Koukou, M.K.; Konstantaras, J.; Pagkalos, C.; Lymperis, K.; Stathopoulos, V.; Coelho, L.; Rebola, A.; Vrachopoulos, M.G. Investigating the Performance of a Thermal Energy Storage Unit with Paraffin as Phase Change Material, Targeting Building’s Cooling Needs: An Experimental Approach. Int. J. Thermofluids 2020, 3–4, 100027. [Google Scholar] [CrossRef]

- Koukou, M.K.; Dogkas, G.; Vrachopoulos, M.G.; Konstantaras, J.; Pagkalos, C.; Stathopoulos, V.N.; Pandis, P.K.; Lymperis, K.; Coelho, L.; Rebola, A. Experimental Assessment of a Full-Scale Prototype Thermal Energy Storage Tank Using Paraffin for Space Heating Application. Int. J. Thermofluids 2020, 1–2, 100003. [Google Scholar] [CrossRef]

- CORESA Savings. Deliverable 7.2-Performance Evaluation Report and Economic Feasibility Study of TESSE2B Solution Small Scale Validation in Cyprus. Center Renew. Energy Sources Sav. 2019, 1, 1–35. [Google Scholar]

- Coelho, L.; Rebola, A.; Passaro, J.; Koukou, M.K.; Vrachopoulos, M.G.; Karytsas, K.; Benou, A.; Goldbrunner, J.; Gaich, H.; Evangelakis, G.; et al. Thermal Energy Storage an Overview of one Advanced System Based on the European TESSE2B Project. In Proceedings of the EinB2019—8th International Conference “Energy in Buildings 2019”, Athens, Greece, 28 September 2019. [Google Scholar]

- Pagkalos, C.; Koukou, M.K.; Vrachopoulos, M.G.; Konstantaras, J.; Dogkas, G.; Stylianou, S.; Stathopoulos, V.; Lymperis, K. Design of Thermoplastic Tanks for Thermal Energy Storage Applications Using Finite Element Analysis. In Proceedings of the EinB2019-8th International Conference “Energy in Buildings 2019”, Athens, Greece, 28 September 2019. [Google Scholar]

- Chalkia, V.; Tachos, N.; Pandis, P.K.; Giannakas, A.; Koukou, M.K.; Vrachopoulos, M.G.; Coelho, L.; Ladavos, A.; Stathopoulos, V.N. Influence of Organic Phase Change Materials on the Physical and Mechanical Properties of HDPE and PP Polymers. RSC Adv. 2018, 48, 27438–27447. [Google Scholar] [CrossRef] [Green Version]

- Cyprus Department of Meteorology, Seasonal Forecasts for South East Europe. Available online: http://www.moa.gov.cy/moa/dm/dm.nsf/seecof_en/seecof_en?OpenDocument (accessed on 1 December 2021).

- DesignBuilder Software Ltd. DesignBuilder Help v7.0. Available online: https://designbuilder.co.uk/helpv7.0/ (accessed on 23 September 2021).

- European Union. Commision Decision of 1 March 2013 Establishing the Guidelines for Member States on Calculating Renewable Energy from Heat Pumps from Different Heat Pump Technologies Pursuant to Article 5 of Directive 2009/28/EC of the European Parliament and the Council. Off. J. Eur. Union 2013, 1, 27–35. [Google Scholar]

| Mode | Capacity (kW) | Capacity per Area (W/m2) | Annual Needs (kWh) | Annual Needs per Area (kW/m2) |

|---|---|---|---|---|

| Heating | 17.0 | 76.9 | 15211 | 68.8 |

| Cooling | 18.6 | 84.2 | 14813 | 67.0 |

| Equivalent Primary Energy—Conventional System | |

|---|---|

| Oil consumption for space heating (kWh) | 18,809.0 |

| Equivalent primary energy for space heating (kWh) | 20,689.9 |

| DHW electricity consumption (kWhe) | 204.2 |

| Equivalent primary energy for DHW (kWh) | 592.3 |

| Electricity consumption for cooling (kWhe) | 7060.4 |

| Equivalent primary energy for Cooling (kWh) | 22,052.8 |

| Total equivalent primary energy (kWh) | 43,335.0 |

| Equivalent Primary Energy—TESSe2b System | |

|---|---|

| Electricity consumption for heating/cooling/DHW (kWh) | 2895.8 |

| Equivalent primary energy for heating/cooling/DHW | 8397.7 |

| Annual Savings | |

|---|---|

| Annual primary energy saving (kWh) | 34,937.2 |

| Annual primary energy saving (%) | 80.6 |

| Annual emissions reduction (TCO2) | 11.8 |

| Maintenance cost of TESSe2b (€) | 160.0 |

| Annual operational & maintenance cost of TESSe2b (€) | 623.3 |

| Maintenance cost of Conventional System (€) | 220.0 |

| Annual operational & maintenance cost of Conventional System (€) | 3237.1 |

| Annual savings from operational & maintenance cost (€) | 2613.7 |

| Annual savings from operational & maintenance cost (%) | 81.7 |

| SPF1 | SPF2 | SPF3 | SPF4 | |

|---|---|---|---|---|

| April | 3.16 | 3.14 | 2.71 | 2.66 |

| May | 3.79 | 3.77 | 2.84 | 2.82 |

| June | 5.77 | 5.67 | 4.29 | 3.80 |

| July | 5.52 | 5.44 | 4.44 | 3.79 |

| August | 5.03 | 4.96 | 4.17 | 3.64 |

| Solar Collectors | Solar Fraction Heating | Solar Fraction Heating + DHW | Heating Needs Shifted Day to Night (Total Solar) | Cooling Needs Shifted Day to Night |

|---|---|---|---|---|

| 10 | 30.5% | 42.3% | 44.8% | 30.3% |

| Variable | Value |

|---|---|

| Number of HTES tanks | 3 |

| Total energy stored (heating) (kWh) | 21.9 |

| Average TES capacity (heating) (kW) | 13.5 |

| Number of CTES tanks | 3 |

| Total energy stored (cooling) (kWh) | 14.5 |

| Average TES capacity (cooling) (kW) | 31.5 |

| Number of DHW_PCM tanks | 1 |

| Total energy stored (DHW) (kWh) | 6.2 |

| Supply water temperature (°C) | 40–50 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coelho, L.; Koukou, M.K.; Dogkas, G.; Konstantaras, J.; Vrachopoulos, M.G.; Rebola, A.; Benou, A.; Choropanitis, J.; Karytsas, C.; Sourkounis, C.; et al. Latent Thermal Energy Storage Application in a Residential Building at a Mediterranean Climate. Energies 2022, 15, 1008. https://doi.org/10.3390/en15031008

Coelho L, Koukou MK, Dogkas G, Konstantaras J, Vrachopoulos MG, Rebola A, Benou A, Choropanitis J, Karytsas C, Sourkounis C, et al. Latent Thermal Energy Storage Application in a Residential Building at a Mediterranean Climate. Energies. 2022; 15(3):1008. https://doi.org/10.3390/en15031008

Chicago/Turabian StyleCoelho, Luis, Maria K. Koukou, George Dogkas, John Konstantaras, Michail Gr. Vrachopoulos, Amandio Rebola, Anastasia Benou, John Choropanitis, Constantine Karytsas, Constantinos Sourkounis, and et al. 2022. "Latent Thermal Energy Storage Application in a Residential Building at a Mediterranean Climate" Energies 15, no. 3: 1008. https://doi.org/10.3390/en15031008

APA StyleCoelho, L., Koukou, M. K., Dogkas, G., Konstantaras, J., Vrachopoulos, M. G., Rebola, A., Benou, A., Choropanitis, J., Karytsas, C., Sourkounis, C., & Chrysanthou, Z. (2022). Latent Thermal Energy Storage Application in a Residential Building at a Mediterranean Climate. Energies, 15(3), 1008. https://doi.org/10.3390/en15031008