Exergoeconomic Analysis of a Variable Area Solar Ejector Refrigeration System under Hot Climatic Conditions

Abstract

1. Introduction

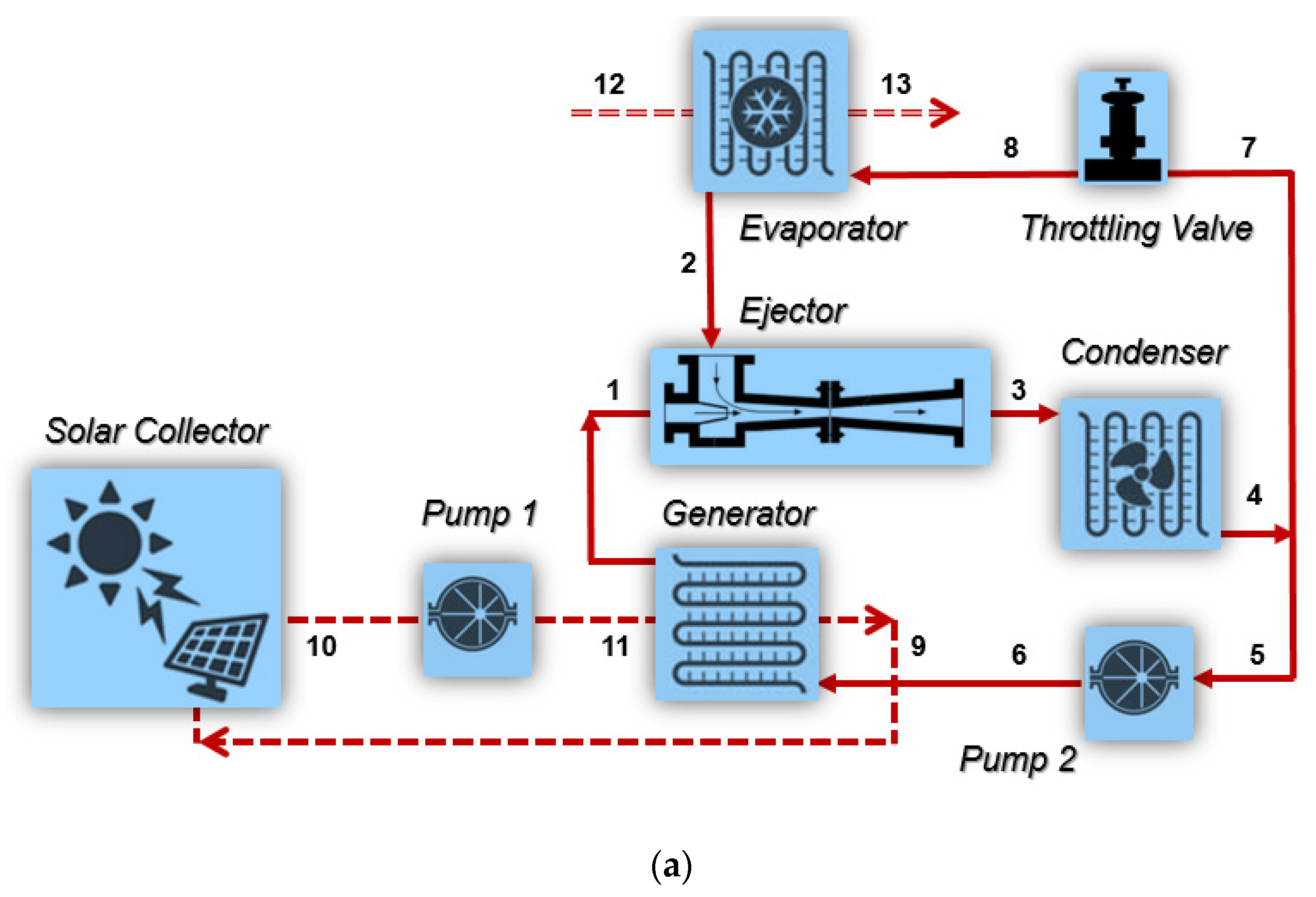

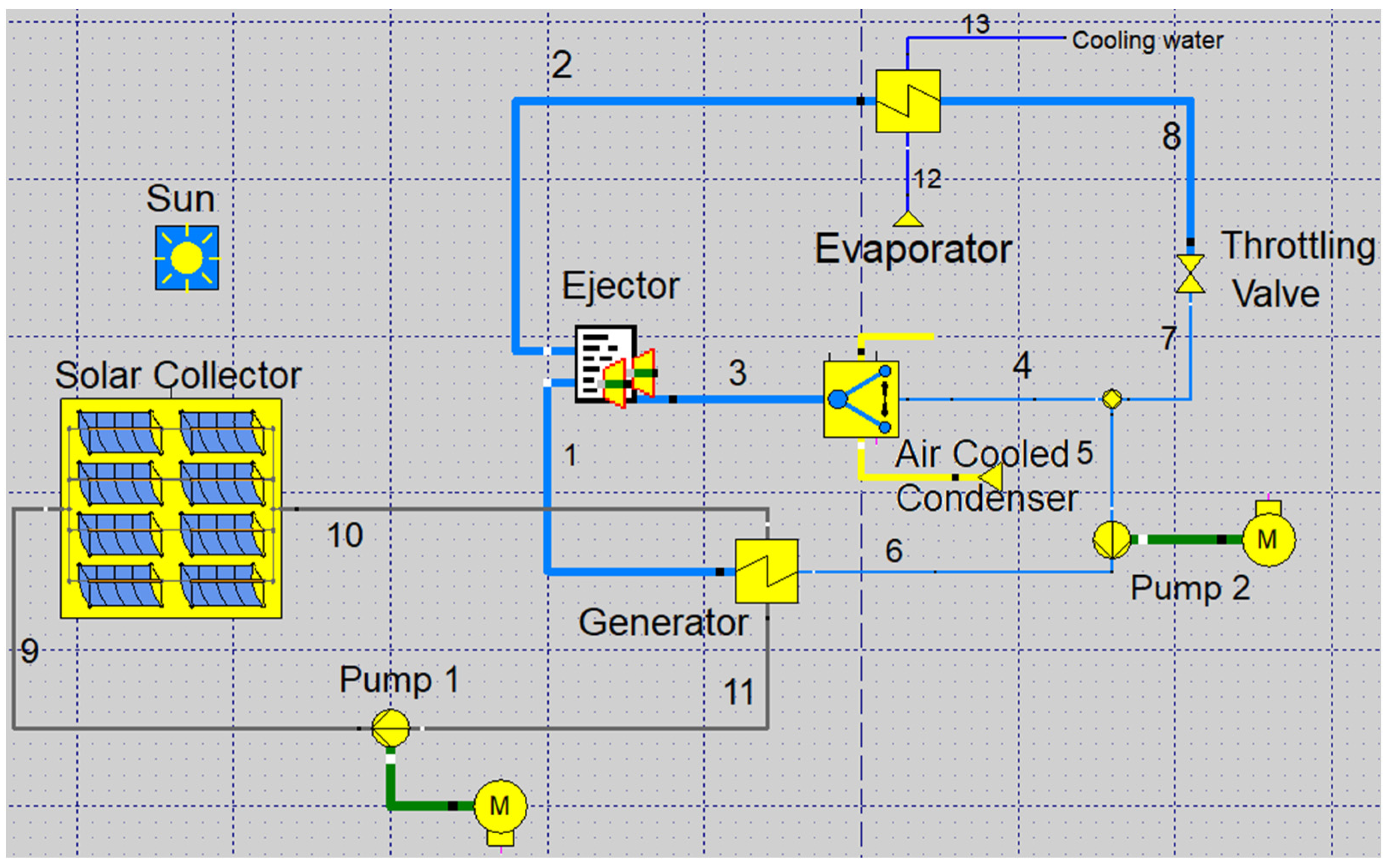

2. Materials and Methods

3. System Modeling and Evaluation

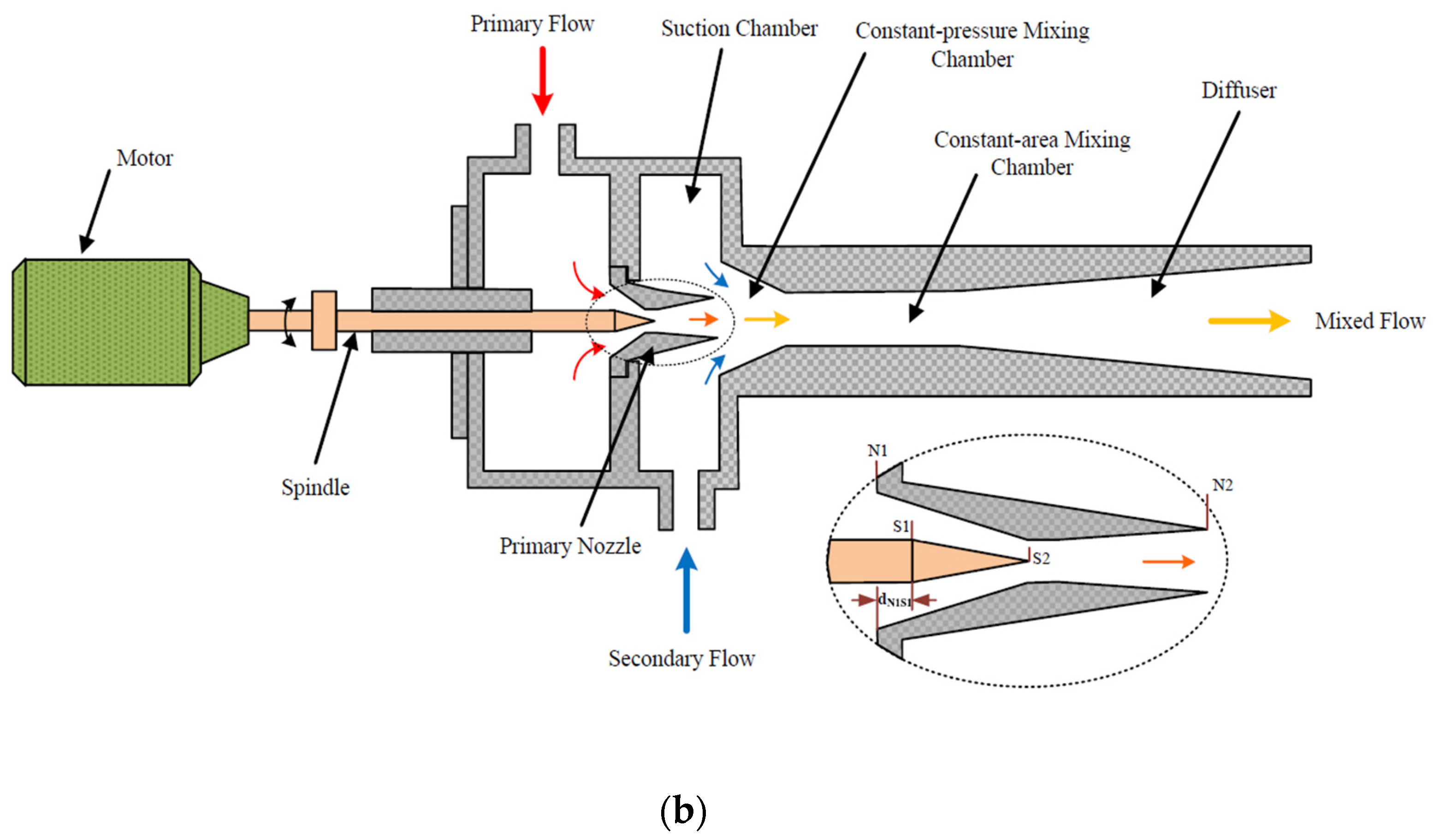

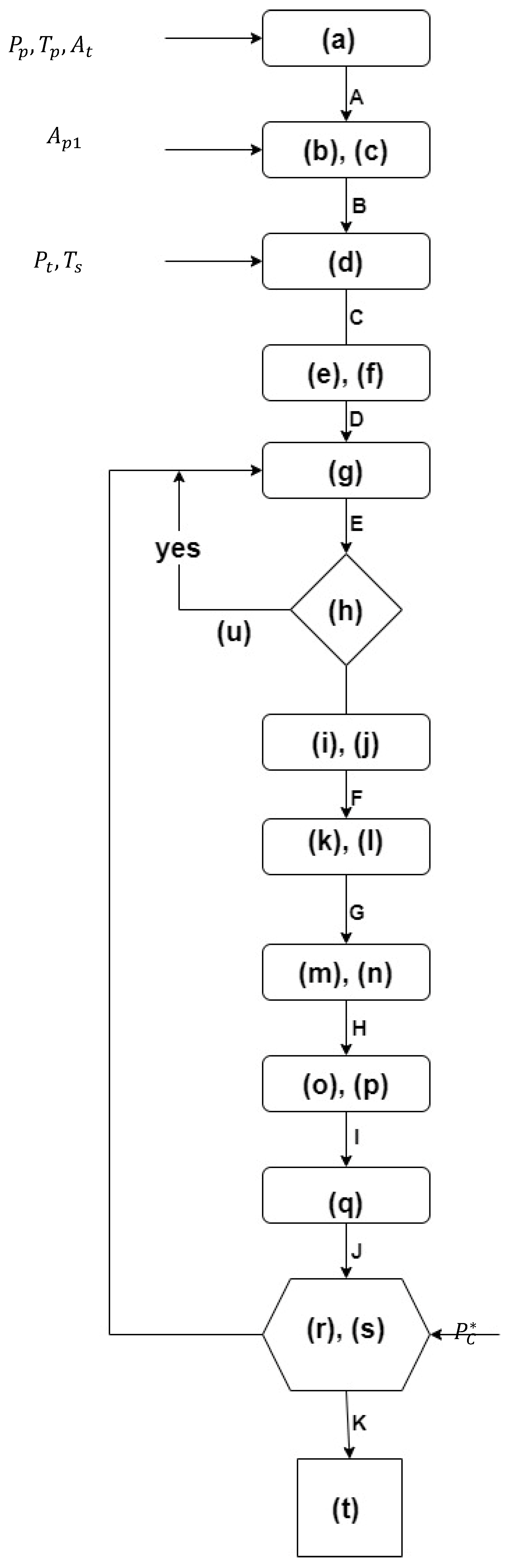

3.1. Ejector Modelling

3.2. System Performance

3.3. Exergy Analysis

- For the entire system

- On the kth component level

- Exergetic efficiency of the entire system

- Exergetic efficiency of the kth component

- The exergy destruction ratio

3.4. Economic Analysis

3.5. Exergoeconomic Analysis

4. Results and Discussion

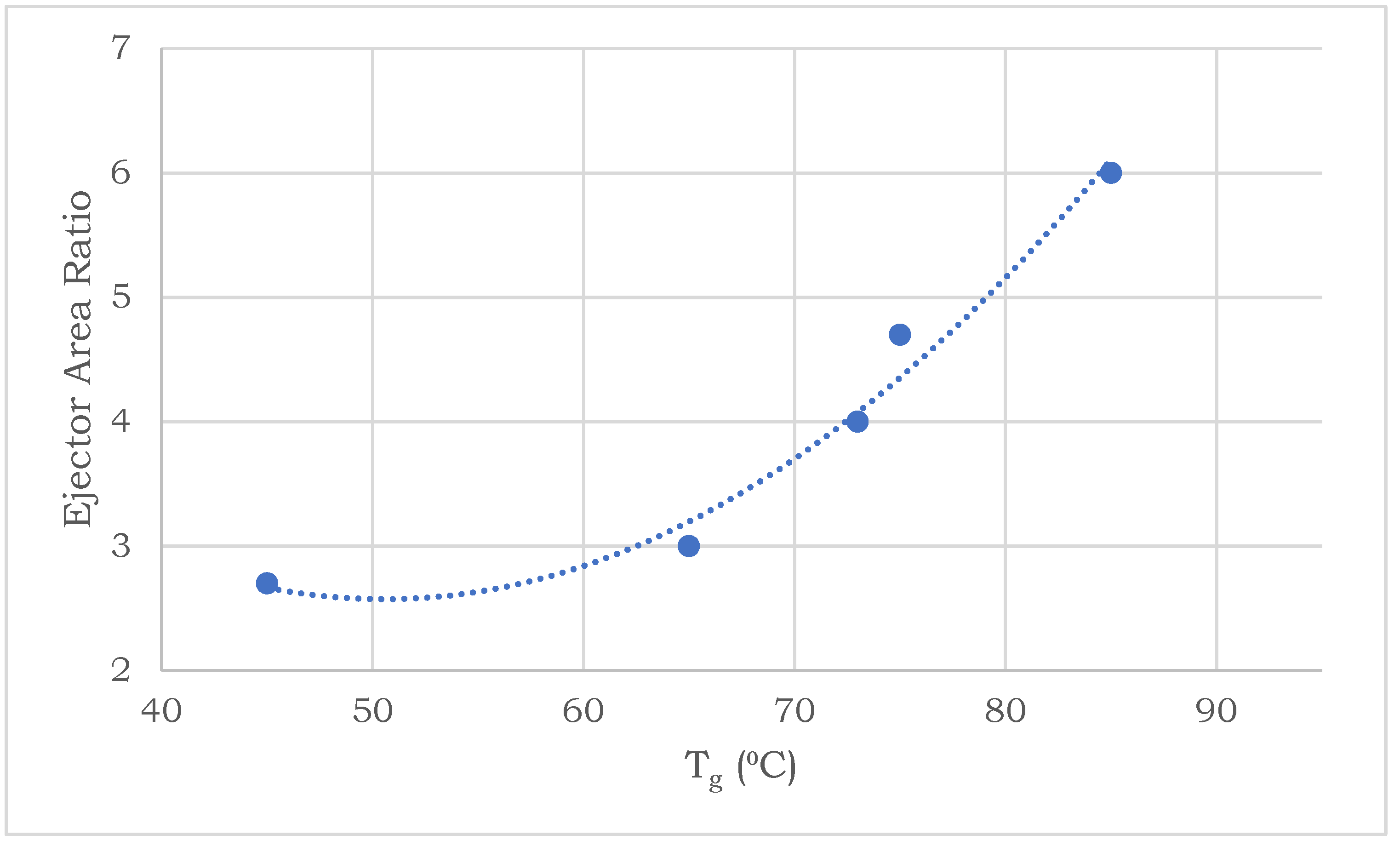

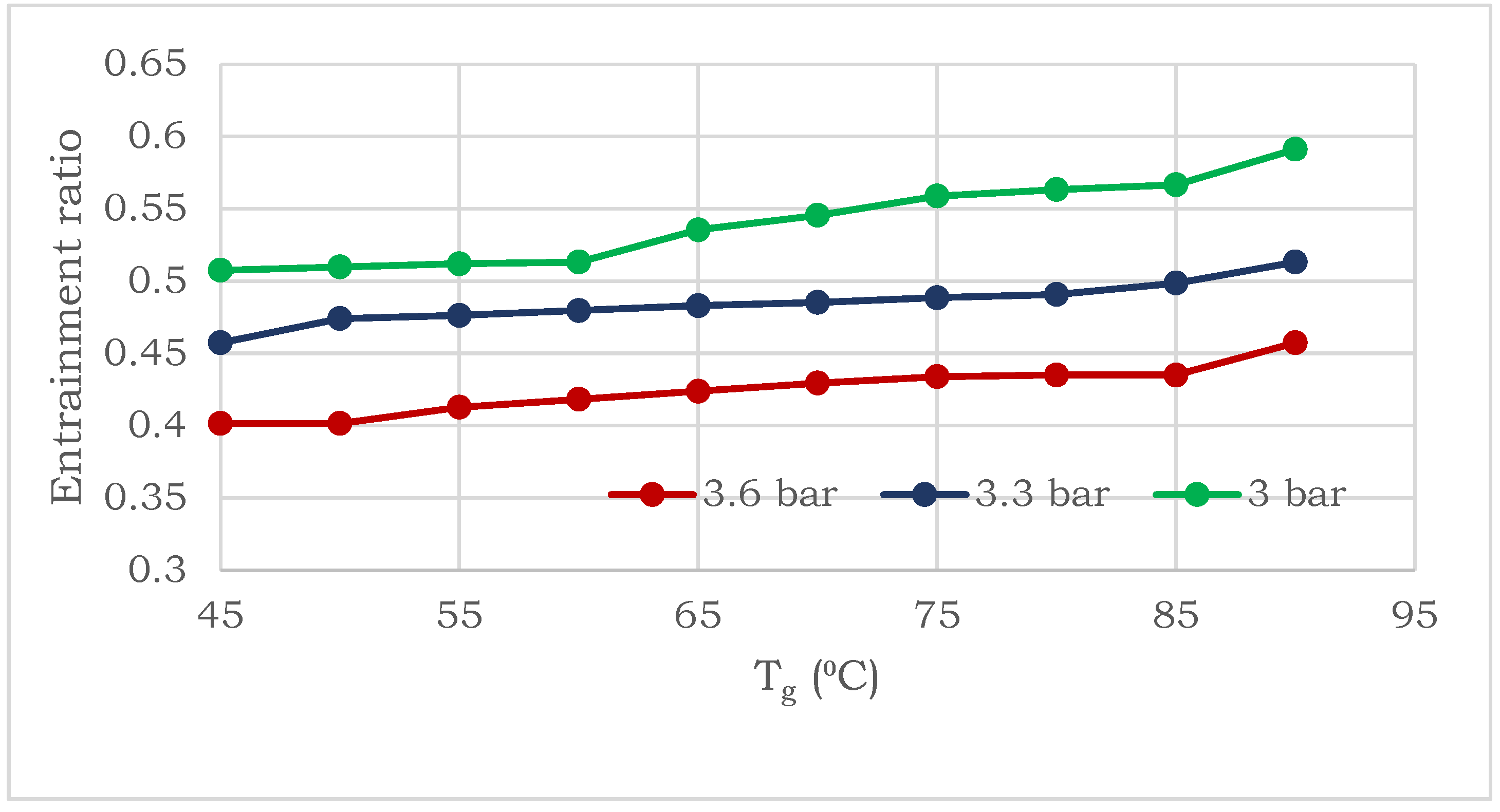

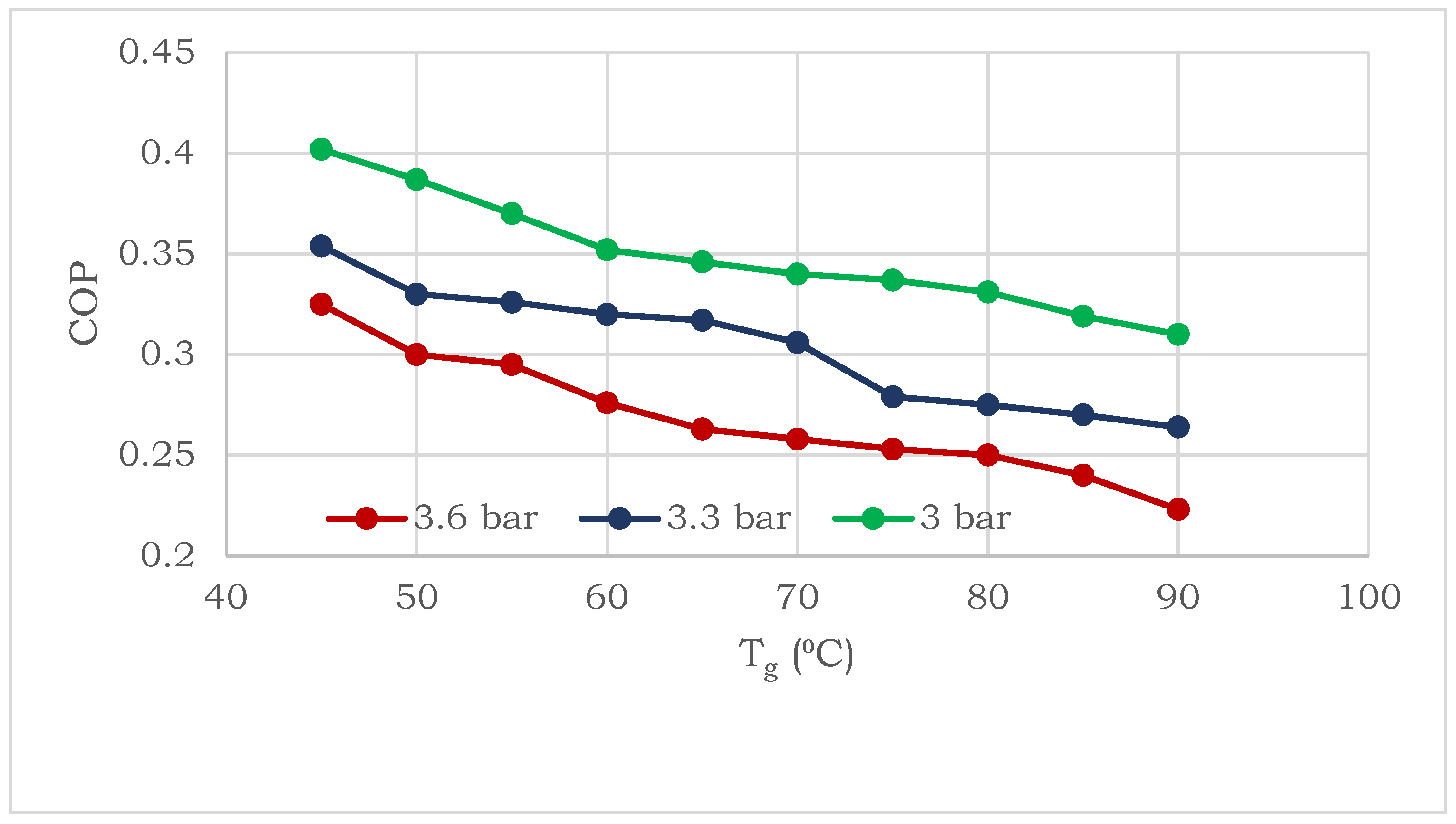

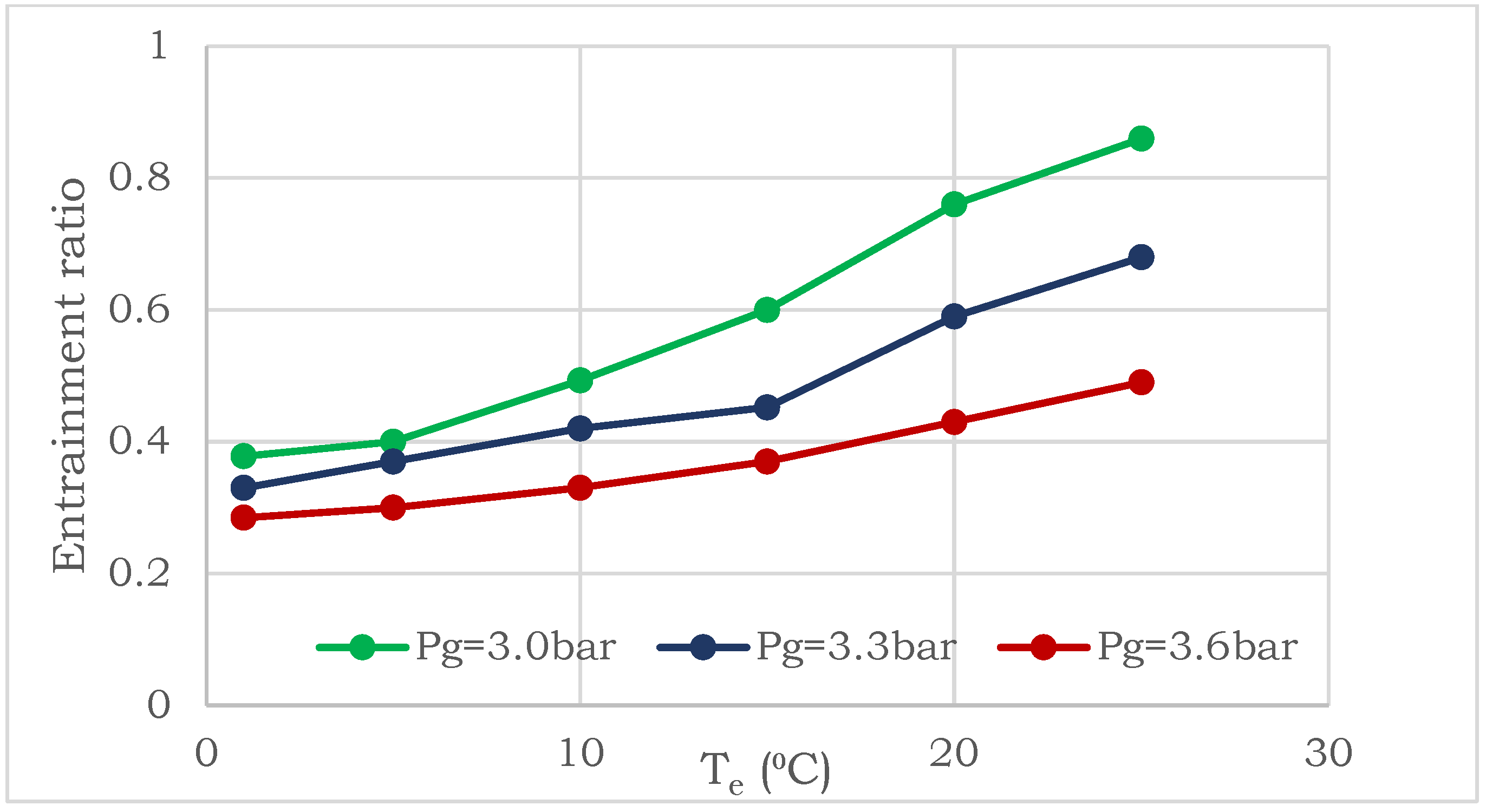

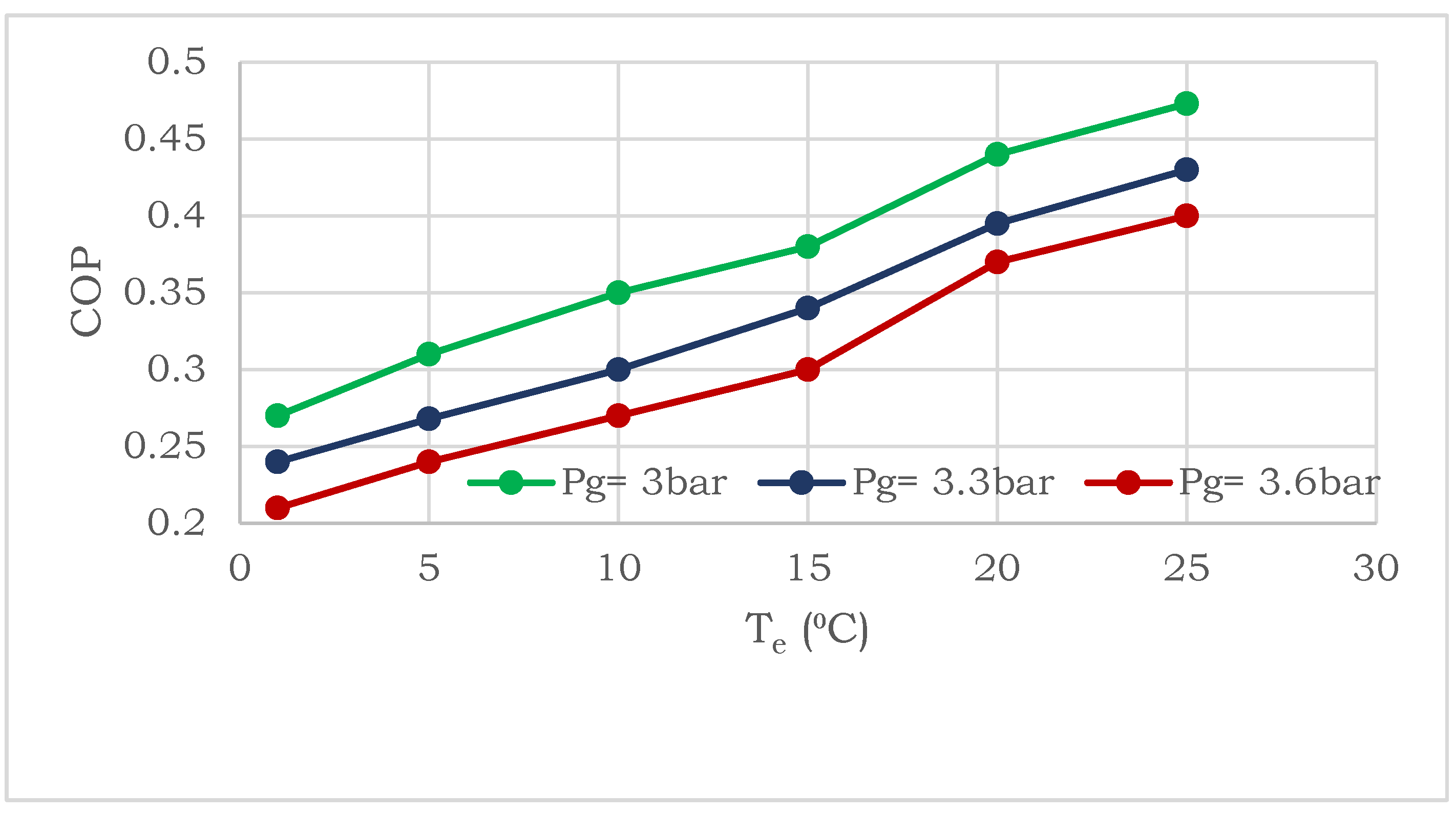

4.1. Sensitivity Energy Analysis

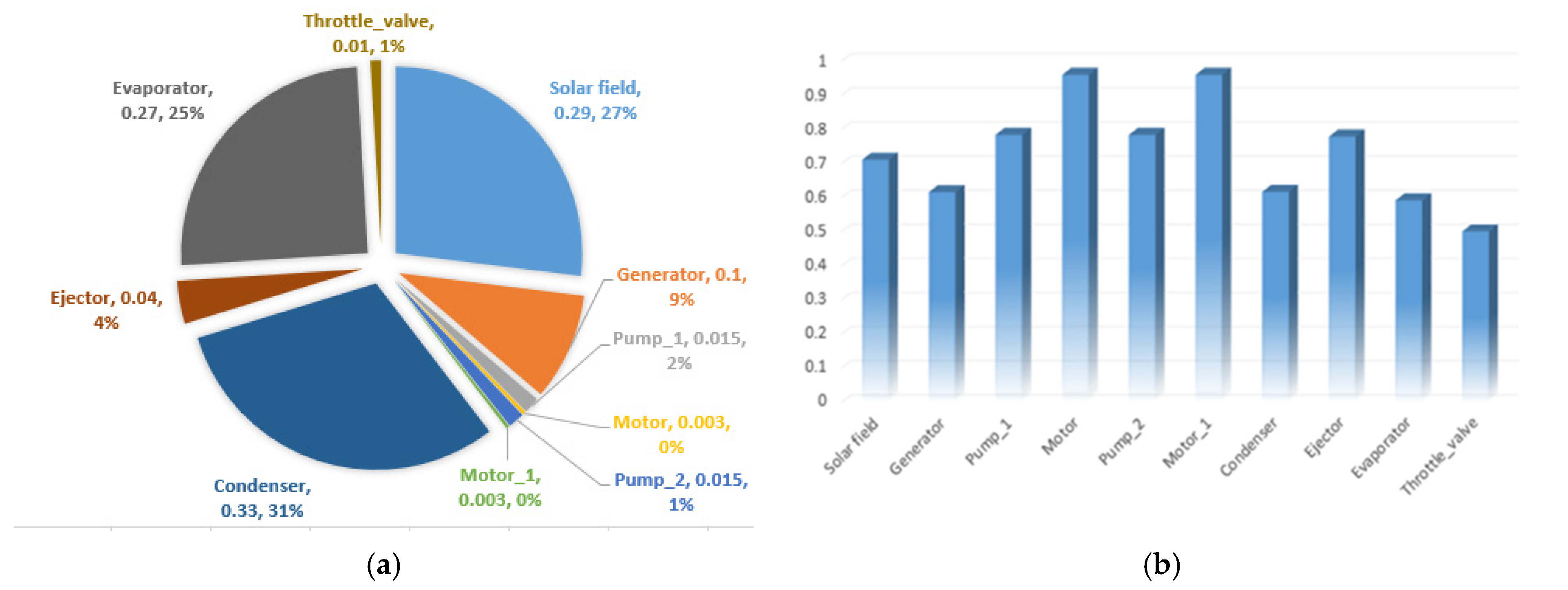

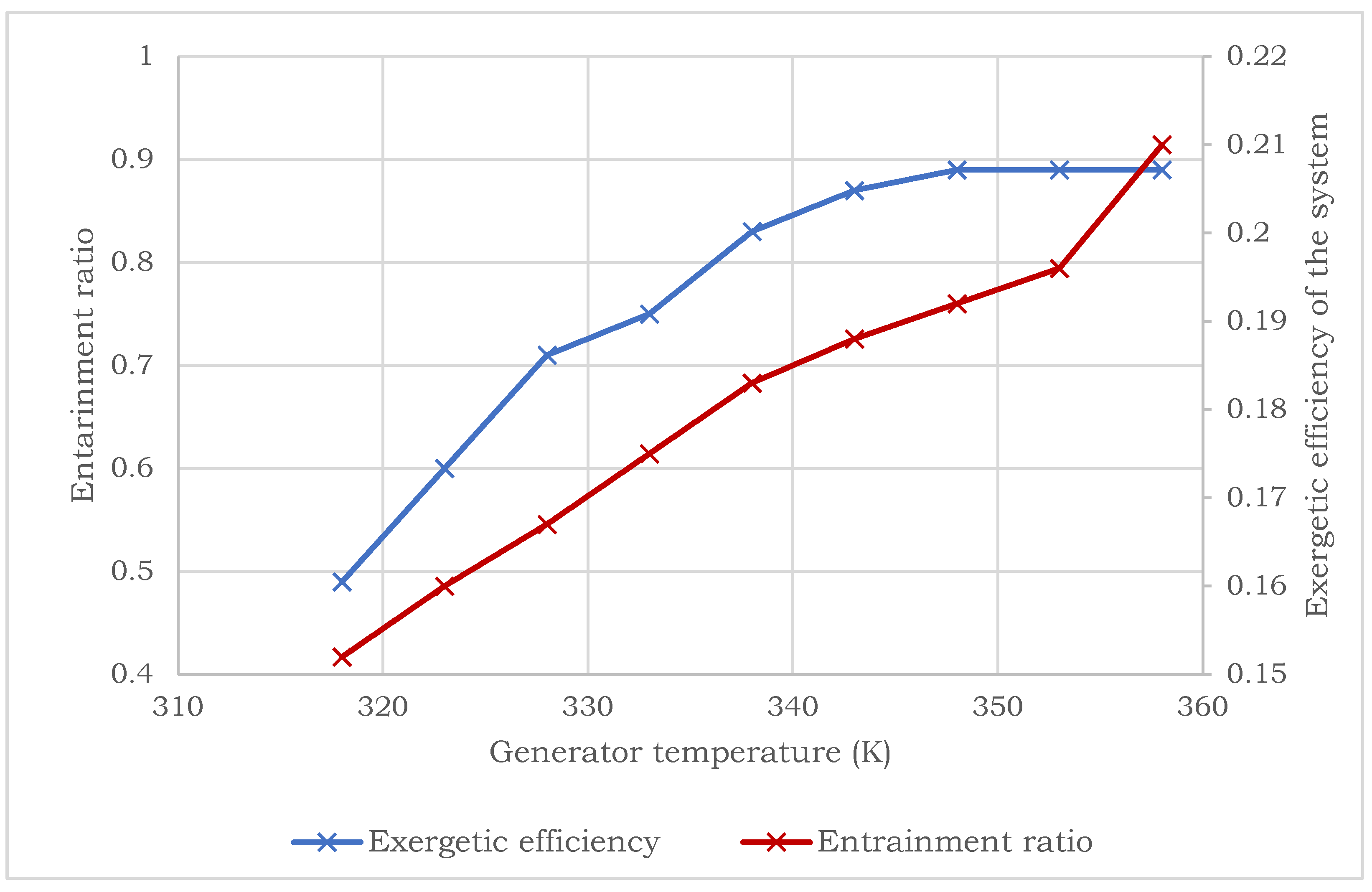

4.2. Exergy Analysis

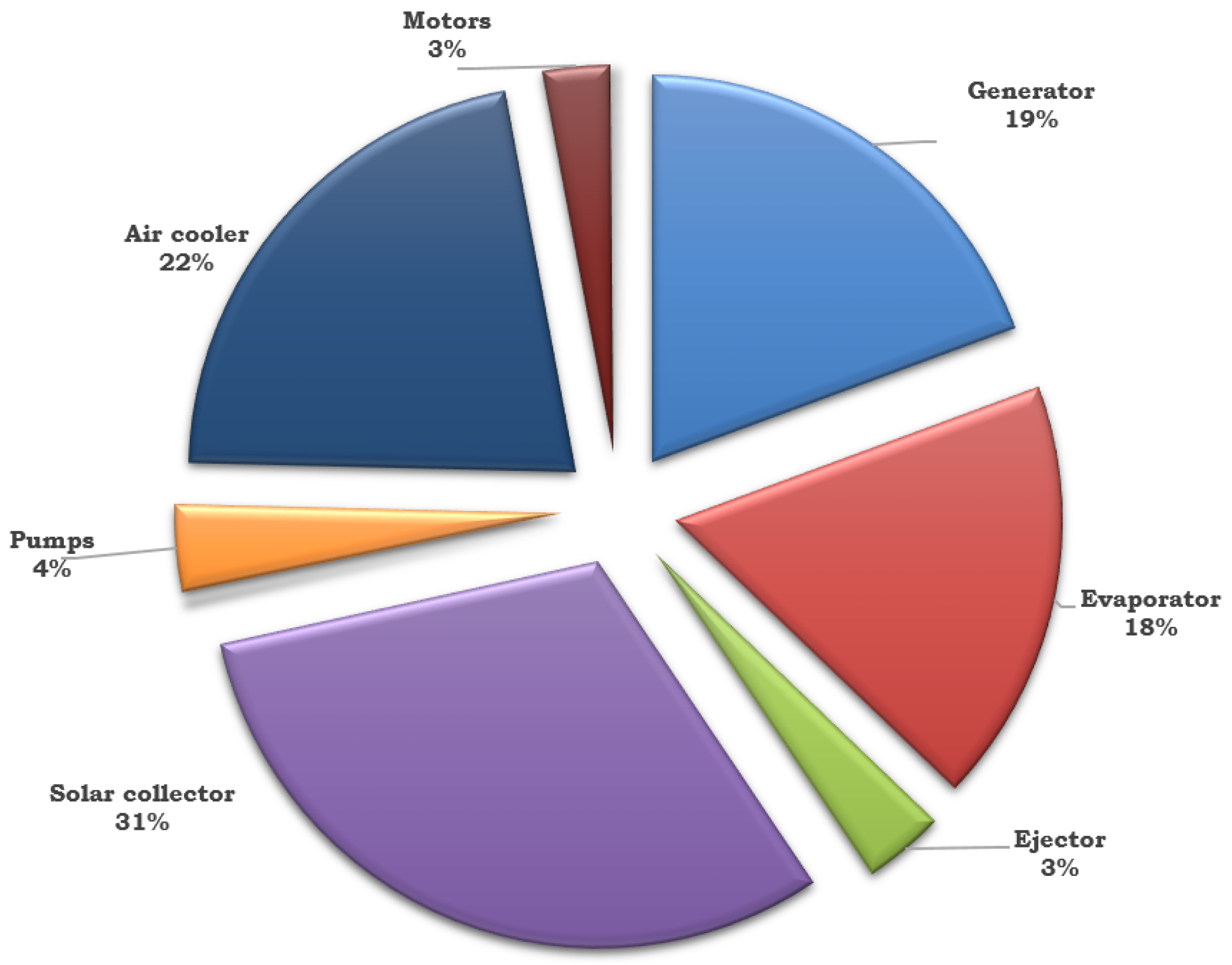

4.3. Economic Analysis

4.4. Exergoeconomic Analysis

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Petinrin, J.; Shaaban, M. Renewable energy for continuous energy sustainability in Malaysia. Renew. Sustain. Energy Rev. 2015, 50, 967–981. [Google Scholar] [CrossRef]

- Li, G.; Li, M.; Taylor, R.; Hao, Y.; Besagni, G.; Markides, C. Solar energy utilisation: Current status and roll-out potential. Appl. Therm. Eng. 2022, 209, 118285. [Google Scholar] [CrossRef]

- Cao, X.; Dai, X.; Liu, J. Building energy-consumption status worldwide and the state-of-the-art technologies for zero-energy buildings during the past decade. Energy Build. 2016, 128, 198–213. [Google Scholar] [CrossRef]

- Alnuaimi, A.; Natarajan, S.; Kershaw, T. The comfort and energy impact of overcooled buildings in warm climates. Energy Build. 2022, 260, 111938. [Google Scholar] [CrossRef]

- Aidoun, Z.; Ameur, K.; Falsafioon, M.; Badache, M. Current Advances in Ejector Modeling, Experimentation and Applications for Refrigeration and Heat Pumps. Part 1: Single-Phase Ejectors. Inventions 2019, 4, 15. [Google Scholar] [CrossRef]

- Besagni, G.; Mereu, R.; Inzoli, F. Ejector refrigeration: A comprehensive review. Renew. Sustain. Energy Rev. 2016, 53, 373–407. [Google Scholar] [CrossRef]

- Tashtoush, B.M.; Al-Nimr, M.A.; Khasawneh, M.A. A comprehensive review of ejector design, performance, and applications. Appl. Energy 2019, 240, 138–172. [Google Scholar] [CrossRef]

- Chen, X.; Omer, S.; Worall, M.; Riffat, S. Recent developments in ejector refrigeration technologies. Renew. Sustain. Energy Rev. 2013, 19, 629–651. [Google Scholar] [CrossRef]

- Riaz, F.; Lee, P.S.; Chou, S.K. Thermal modelling and optimization of low-grade waste heat driven ejector refrigeration system incorporating a direct ejector model. Appl. Therm. Eng. 2019, 167, 114710. [Google Scholar] [CrossRef]

- Yu, W.; Wang, H.; Ge, Z. Comprehensive analysis of a novel power and cooling cogeneration system based on organic Rankine cycle and ejector refrigeration cycle. Energy Convers. Manag. 2021, 232, 113898. [Google Scholar] [CrossRef]

- Hasan, A.; Mugdadi, B.; Al-Nimr, M.A.; Tashtoush, B. Direct and indirect utilization of thermal energy for cooling generation: A comparative analysis. Energy 2021, 238, 122046. [Google Scholar] [CrossRef]

- Atmaca, A.U.; Erek, A.; Ekren, O. Impact of the mixing theories on the performance of ejector expansion refrigeration cycles for environmentally-friendly refrigerants. Int. J. Refrig. 2018, 97, 211–225. [Google Scholar] [CrossRef]

- Yapıcı, R.; Ersoy, H. Performance characteristics of the ejector refrigeration system based on the constant area ejector flow model. Energy Convers. Manag. 2005, 46, 3117–3135. [Google Scholar] [CrossRef]

- Kumar, V.; Singhal, G.; Subbarao, P. Realization of novel constant rate of kinetic energy change (CRKEC) supersonic ejector. Energy 2018, 164, 694–706. [Google Scholar] [CrossRef]

- Chen, W.; Shi, C.; Zhang, S.; Chen, H.; Chong, D.; Yan, J. Theoretical analysis of ejector refrigeration system performance under overall modes. Appl. Energy 2017, 185, 2074–2084. [Google Scholar] [CrossRef]

- Hou, Y.; Chen, F.; Zhang, S.; Chen, W.; Zheng, J.; Chong, D.; Yan, J. Numerical simulation study on the influence of primary nozzle deviation on the steam ejector performance. Int. J. Therm. Sci. 2022, 179, 107633. [Google Scholar] [CrossRef]

- Ünal, S.; Yilmaz, T. Thermodynamic analysis of the two-phase ejector air-conditioning system for buses. Appl. Therm. Eng. 2015, 79, 108–116. [Google Scholar] [CrossRef]

- Van Nguyen, V.; Varga, S.; Soares, J.; Dvorak, V.; Oliveira, A.C. Applying a variable geometry ejector in a solar ejector refrigeration system. Int. J. Refrig. 2020, 113, 187–195. [Google Scholar] [CrossRef]

- Tashtoush, B.; Nayfeh, Y. Energy and economic analysis of a variable-geometry ejector in solar cooling systems for residential buildings. J. Energy Storage 2019, 27, 101061. [Google Scholar] [CrossRef]

- Chen, W.; Huang, C.; Bai, Y.; Chong, D.; Yan, J.; Liu, J. Experimental and numerical investigation of two phase ejector performance with the water injected into the induced flow. Int. J. Adv. Nucl. React. Des. Technol. 2020, 2, 15–24. [Google Scholar] [CrossRef]

- Li, C.; Li, Y.; Cai, W.; Hu, Y.; Chen, H.; Yan, J. Analysis on performance characteristics of ejector with variable area-ratio for multi-evaporator refrigeration system based on experimental data. Appl. Therm. Eng. 2014, 68, 125–132. [Google Scholar] [CrossRef]

- Tashtoush, B.; Algharbawi, A.B.R. Parametric study of a Novel Hybrid Solar Variable Geometry Ejector cooling with Organic Rankine Cycles. Energy Convers. Manag. 2019, 198, 111910. [Google Scholar] [CrossRef]

- Goetzler, W.; Guernsey, M.; Young, J.; Fujrman, J.; Abdelaziz, A. The Future of Air Conditioning for Buildings; Technical Report; US Department of Energy: Washington, DC, USA, 2016. [CrossRef]

- Salimpour, M.R.; Ahmadzadeh, A.; Al-Sammarraie, A.T. Comparative investigation on the exergoeconomic analysis of solar-driven ejector refrigeration systems. Int. J. Refrig. 2018, 99, 80–93. [Google Scholar] [CrossRef]

- Ahmadzadeh, A.; Salimpour, M.R.; Sedaghat, A. Thermal and exergoeconomic analysis of a novel solar driven combined power and ejector refrigeration (CPER) system. Int. J. Refrig. 2017, 83, 143–156. [Google Scholar] [CrossRef]

- Farshi, L.G.; Mahmoudi, S.; Rosen, M. Exergoeconomic comparison of double effect and combined ejector-double effect absorption refrigeration systems. Appl. Energy 2012, 103, 700–711. [Google Scholar] [CrossRef]

- Rashidi, J.; Yoo, C. Exergy, exergo-economic, and exergy-pinch analyses (EXPA) of the kalina power-cooling cycle with an ejector. Energy 2018, 155, 504–520. [Google Scholar] [CrossRef]

- Sadeghi, M.; Mahmoudi, S.; Saray, R.K. Exergoeconomic analysis and multi-objective optimization of an ejector refrigeration cycle powered by an internal combustion (HCCI) engine. Energy Convers. Manag. 2015, 96, 403–417. [Google Scholar] [CrossRef]

- MATLAB and Statistics Toolbox Release; The MathWorks, Inc.: Natick, MA, USA, 2021.

- Sag, N.B.; Ersoy, H.; Hepbasli, A.; Halkaci, H. Energetic and exergetic comparison of basic and ejector expander refrigeration systems operating under the same external conditions and cooling capacities. Energy Convers. Manag. 2015, 90, 184–194. [Google Scholar] [CrossRef]

- Luo, J.; Morosuk, T.; Tsatsaronis, G.; Tashtoush, B. Exergetic and Economic Evaluation of a Transcritical Heat-Driven Compression Refrigeration System with CO2 as the Working Fluid under Hot Climatic Conditions. Entropy 2019, 21, 1164. [Google Scholar] [CrossRef]

- Liu, X.; Yang, X.; Yu, M.; Zhang, W.; Wang, Y.; Cui, P.; Zhu, Z.; Ma, Y.; Gao, J. Energy, exergy, economic and environmental (4E) analysis of an integrated process combining CO2 capture and storage, an organic Rankine cycle and an absorption refrigeration cycle. Energy Convers. Manag. 2020, 210, 112738. [Google Scholar] [CrossRef]

- Singh, A.; Sarkar, J.; Sahoo, R.R. Experimental energy, exergy, economic and exergoeconomic analyses of batch-type solar-assisted heat pump dryer. Renew. Energy 2020, 156, 1107–1116. [Google Scholar] [CrossRef]

- Tsatsaronis, G.; Morosuk, T. Understanding and improving energy conversion systems with the aid of exergy-based methods. Int. J. Exergy 2012, 11, 518–542. [Google Scholar] [CrossRef]

- Thongtip, T.; Aphornratana, S. An experimental analysis of the impact of primary nozzle geometries on the ejector performance used in R141b ejector refrigerator. Appl. Therm. Eng. 2017, 110, 89–101. [Google Scholar] [CrossRef]

- Ruangtrakoon, N.; Thongtip, T. An experimental investigation to determine the optimal heat source temperature for R141b ejector operation in refrigeration cycle. Appl. Therm. Eng. 2020, 170, 114841. [Google Scholar] [CrossRef]

- Saleh, B. Performance analysis and working fluid selection for ejector refrigeration cycle. Appl. Therm. Eng. 2016, 107, 114–124. [Google Scholar] [CrossRef]

- Huang, B.J.; Chang, J.M.; Wang, C.P.; Petrenko, V.A. A 1-D analysis of ejector performance. Int. J. Refrig. 1999, 22, 354–364. [Google Scholar] [CrossRef]

- Elmorsy, L.; Morosuk, T.; Tsatsaronis, G. Exergy-Based Analysis and Optimization of an Integrated Solar Combined-Cycle Power Plant. Entropy 2020, 22, 655. [Google Scholar] [CrossRef]

- Tashtoush, B.; Morosuk, T.; Chudasama, J. Exergy and Exergoeconomic Analysis of a Cogeneration Hybrid Solar Organic Rankine Cycle with Ejector. Entropy 2020, 22, 702. [Google Scholar] [CrossRef]

| Specification | Value |

|---|---|

| Throat diameter | 0.508 mm |

| Area ratio | 2.905 |

| Specific heat ratio | 1.2 |

| Area ratio | 4 |

| Primary stream isentropic efficiency | 0.95 |

| Sec ondary stream isentropic efficiency | 0.85 |

| Frictional losses coefficient of the primary flow | 0.88 |

| Mixed flow frictional losses coefficient | 0.84 |

| Generator pressure | 3.6 bar |

| Generator temperature | 75 °C |

| Evaporator temperature | 11.76 °C |

| Condenser temperature ) | 33 °C |

| Stream No. | Material | Mass Flow Rate | Temperature | Pressure | Specific Enthalpy | Specific Entropy | Specific Physical Exergy |

|---|---|---|---|---|---|---|---|

| [kg/s] | [°C] | [bar] | [kJ/kg] | [kJ/kgK] | [kJ/kg] | ||

| 1 | R141b | 0.030 | 75 | 3.59 | 488.79 | 1.8621 | 53.24 |

| 2 | R141b | 0.157 | 12 | 0.47 | 236.82 | 1.1302 | 1.20 |

| 3 | R141b | 0.187 | 38 | 1.03 | 464.16 | 1.8711 | 26.17 |

| 4 | R141b | 0.187 | 32 | 1.02 | 236.82 | 1.1272 | 2.02 |

| 5 | R141b | 0.030 | 32 | 1.02 | 236.82 | 1.1272 | 2.02 |

| 6 | R141b | 0.030 | 32 | 3.60 | 237.08 | 1.1273 | 2.49 |

| 7 | R141b | 0.157 | 32 | 1.02 | 236.82 | 1.1272 | 2.02 |

| 8 | R141b | 0.157 | 12 | 0.47 | 236.82 | 1.1302 | 1.21 |

| 9 | Water | 17.966 | 85 | 3.50 | 355.75 | 1.1330 | 46.17 |

| 10 | Water | 17.966 | 85 | 3.50 | 356.17 | 1.1342 | 46.27 |

| 11 | Water | 17.966 | 85 | 3.50 | 355.75 | 1.1330 | 46.17 |

| 12 | Water | 15.000 | 30 | 1.00 | 125.83 | 0.4368 | 6.43 |

| 13 | Water | 15.000 | 22 | 1.00 | 93.58 | 0.3290 | 3.61 |

| 14 | Air | 21.194 | 29 | 2.00 | 29.15 | 6.6831 | 54.76 |

| 15 | Air | 21.194 | 31 | 2.00 | 31.16 | 6.6898 | 54.96 |

[°C] | [°C] | ||||||

|---|---|---|---|---|---|---|---|

| Exp | Huang et al. [38] | Present Model | Exp | Huang et al. [38] | Present Model | ||

| 95 | 31.3 | 10.64 | 10.87 | 10.33 | 0.4377 | 0.4627 | 0.4412 |

| 95 | 33.0 | 9.83 | 9.67 | 9.42 | 0.3937 | 0.3774 | 0.3876 |

| 95 | 33.6 | 9.41 | 9.29 | 9.35 | 0.3457 | 0.3476 | 0.3398 |

| 95 | 34.2 | 9.17 | 8.89 | 9.11 | 0.3505 | 0.3253 | 0.3298 |

| 95 | 36.3 | 8.28 | 8.57 | 8.64 | 0.2814 | 0.2983 | 0.2954 |

| 95 | 37.1 | 8.25 | 8.12 | 8.26 | 0.2902 | 0.2658 | 0.2733 |

| 95 | 38.8 | 7.26 | 7.27 | 8.09 | 0.2273 | 0.2078 | 0.2165 |

| 95 | 38.6 | 7.73 | 7.38 | 7.43 | 0.2552 | 0.2144 | 0.2232 |

| 95 | 41.0 | 6.77 | 7.05 | 7.11 | 0.2043 | 0.1919 | 0.2041 |

| 95 | 42.1 | 6.44 | 6.55 | 6.94 | 0.1859 | 0.1554 | 0.1763 |

| 90 | 31.5 | 9.41 | 9.28 | 9.34 | 0.4446 | 0.4178 | 0.4413 |

| 90 | 33.8 | 8.28 | 8.53 | 8.61 | 0.3488 | 0.3552 | 0.3461 |

| 90 | 36.7 | 7.73 | 7.03 | 7.53 | 0.3040 | 0.2395 | 0.2976 |

| 90 | 37.5 | 6.99 | 6.65 | 6.81 | 0.2718 | 0.2093 | 0.2103 |

| 90 | 38.9 | 6.44 | 6.74 | 6.43 | 0.2246 | 0.2156 | 0.2231 |

| 84 | 28.0 | 9.41 | 9.34 | 9.38 | 0.5387 | 0.5215 | 0.5406 |

| 84 | 30.5 | 8.28 | 8.68 | 8.76 | 0.4214 | 0.4605 | 0.4377 |

| 84 | 32.3 | 7.73 | 7.68 | 7.81 | 0.3883 | 0.3704 | 0.3713 |

| 84 | 33.6 | 6.99 | 6.99 | 6.83 | 0.3117 | 0.3042 | 0.3111 |

| 84 | 35.5 | 6.44 | 6.79 | 6.50 | 0.2880 | 0.2880 | 0.2792 |

| 78 | 24.4 | 9.41 | 9.92 | 9.87 | 0.6227 | 0.6944 | 0.6532 |

| 78 | 26.9 | 8.28 | 8.97 | 8.83 | 0.4889 | 0.5966 | 0.4679 |

| 78 | 29.1 | 7.73 | 7.64 | 7.81 | 0.4393 | 0.4609 | 0.4599 |

| 78 | 29.5 | 6.99 | 7.48 | 7.32 | 0.3922 | 0.4422 | 0.4274 |

| 78 | 32.5 | 6.44 | 6.62 | 6.44 | 0.3257 | 0.3525 | 0.3179 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tashtoush, B.; Songa, I.; Morosuk, T. Exergoeconomic Analysis of a Variable Area Solar Ejector Refrigeration System under Hot Climatic Conditions. Energies 2022, 15, 9540. https://doi.org/10.3390/en15249540

Tashtoush B, Songa I, Morosuk T. Exergoeconomic Analysis of a Variable Area Solar Ejector Refrigeration System under Hot Climatic Conditions. Energies. 2022; 15(24):9540. https://doi.org/10.3390/en15249540

Chicago/Turabian StyleTashtoush, Bourhan, Iscah Songa, and Tatiana Morosuk. 2022. "Exergoeconomic Analysis of a Variable Area Solar Ejector Refrigeration System under Hot Climatic Conditions" Energies 15, no. 24: 9540. https://doi.org/10.3390/en15249540

APA StyleTashtoush, B., Songa, I., & Morosuk, T. (2022). Exergoeconomic Analysis of a Variable Area Solar Ejector Refrigeration System under Hot Climatic Conditions. Energies, 15(24), 9540. https://doi.org/10.3390/en15249540