1. Introduction

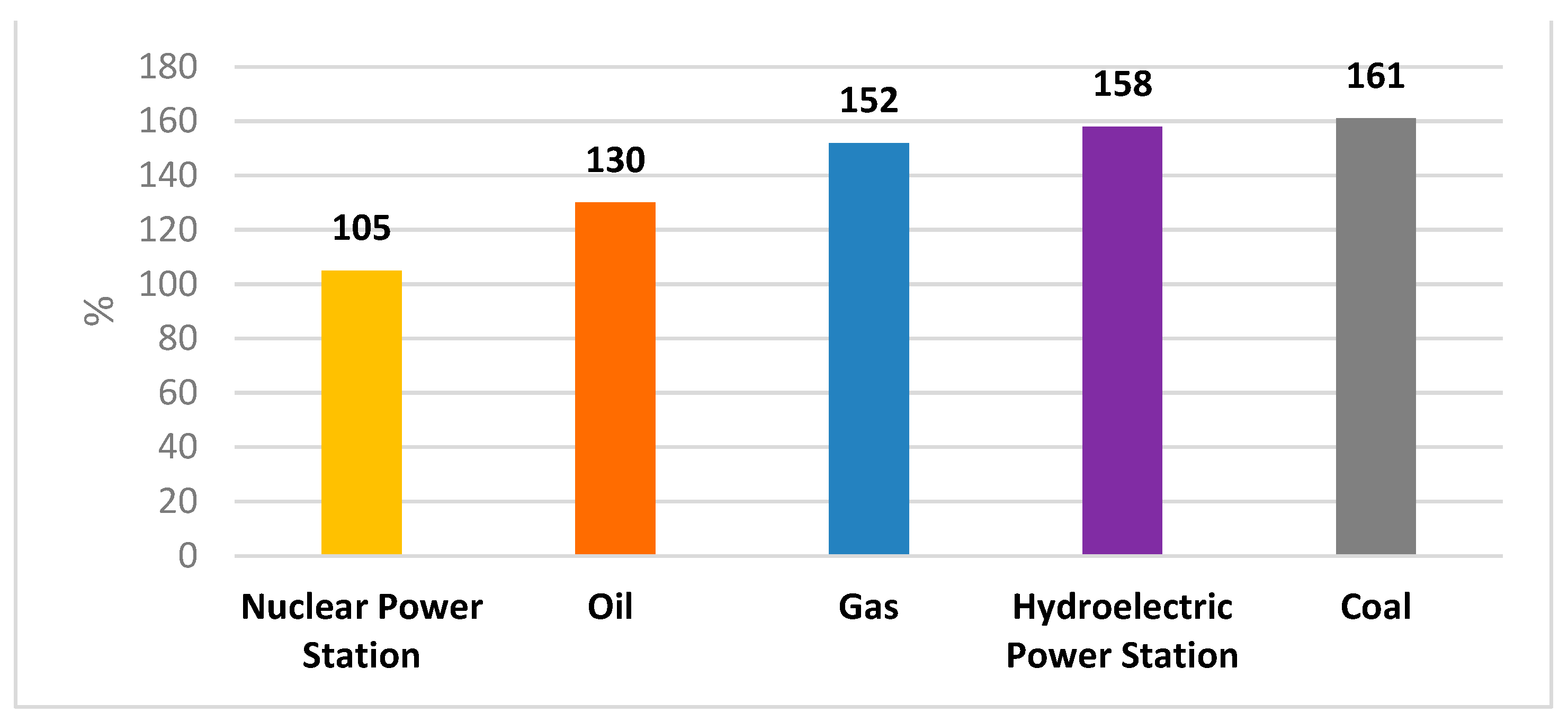

In recent decades, the coal industry has faced a number of global challenges, including competition from alternative energy sources (primarily gas) and the growing influence of environmental factors (labeling coal as a “dirty fuel”), which determined the course of its subsequent history. However, despite all the difficulties associated with environmental issues, social influence, and markets, coal consumption grew by a factor of 1.6 from 2000 to 2018 against the backdrop of a 1.5-fold increase in global energy consumption, which was the highest growth rate among primary energy sources (

Figure 1) [

1].

According to long-term microeconomic forecasts, the world is not ready to give up on coal. Although coal sales and, as a result, coal production will decline in the future as a number of countries aim to phase out coal-fired power, the demand for coal on a global scale will remain stable. The global volume of coal consumption in 2021 will amounted to 8172.6 million tons. Many countries are not yet ready to abandon it in the long term [

2].

In view of the above statement, the coal industry will have to find its competitive niche to respond to the current agenda of sustainable development and the green economy. This can be performed by improving coal use, maximizing value added through advanced processing, and creating new types of products from coal. Many modern technologies for coal production, beneficiation, and processing are already able to increase the value of products through rational and multipurpose resource use, i.e., by means of circular economy models. It is obvious that transitioning to circular business models will enable mining companies to generate social, economic, and environmental effects through creating value chains and improving the quality of end products.

Actually, the attitude towards the mining industry and its place in the circular economic process in the context of the transition to green energy are being reviewed. In 2020, the World Bank report “Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition [

3]” identified 17 minerals that are essential for the transition from clean to renewable energy (lithium, vanadium, aluminum, cobalt, copper, molybdenum, etc.) [

4]. In addition, emerging trends in growth in demand for metals maintain the role of the mining sector in the economies of developing countries [

5], which are the main suppliers of metals needed to create infrastructure for low-carbon energy in the future [

6], primarily for developed countries [

7].

Thus, in Western studies, circularity in the mining sector concerns only the circulation of metals necessary for the development of carbon-free energy technologies (wind, solar generation, etc.). At the same time, the issues of implementing DE in the processes of extracting fuel and energy resources are practically not covered, despite the fact that the relevance of their use in the energy complex of developing countries, including Russia, is very high.

Research conducted by the World Economic Forum (WEF-2015) [

8] proved that large-scale circular economy projects can greatly change the balance between primary and secondary commodity supplies and the trajectories along which mining companies move, which includes product diversification. However, due to the complex nature of production structures in the mineral resources sector and that of products themselves, standard circular economy models cannot be implemented by mining companies. They need to factor in the specific features of the production process and the life cycle of products in the sector. At the same time, it is obvious that circular business models are a practical way to implement the principles of a circular economy, and their inclusion in the business processes of mining companies will lead to transformational growth, including diversification, building up production chains, and merging into production clusters [

9]. This will require a complex assessment of how viable it is to use circular business models, taking into account the character of the mining industry. For this reason, it is necessary to develop the methodological foundations of circularity and practical methods for implementing circular models that will take into account the nature of mining companies.

This thesis is also confirmed in the study [

10], where it is noted: «The results, while confirming that the pursuit of circular schemes can lead to a lower consumption of natural resources, also indicate that a CE still has a marginal effect with respect to the demand for resources linked to economic growth. In other words, it is far from certain that higher recycling or circularity rates necessarily reduce the extraction of primary resources, as global trends, such as increased consumption, could more than offset the gains in circularity. Unless contemporary consumption patterns are reviewed, CE strategies might risk remaining a technical tool that does not change the course of the current unsustainable development» [

10].

The main problem is the lack of theoretical knowledge and a mechanism for organizing circular business models, taking into account industry specifics. The complex nature of production structures and the specifics of the products of enterprises in the mineral resource complex do not allow the implementation of generally accepted circular models without taking into account the peculiarities of the organizational and technological processes of mining and the life cycle of mining products. In this regard, it is necessary to develop the methodological foundations of circularity and practical methods for implementing circular models, taking into account the specifics of mining companies.

The goal of the research is to develop a conceptual framework of options for the implementation and evaluation of circular business models using an interdisciplinary approach and taking into account the specific features of coal companies and the principle of a resource being valuable throughout its whole life cycle.

Research tasks are as follows:

- -

Collect and analyze data on the conditions for rational and multipurpose coal use, coal waste management, and coal processing based on the experience accumulated by mining companies.

- -

Develop circular business models that are adapted to the conditions of the coal industry and take into account the possibility of sustainable development.

A specific feature of coal companies, as an object of the circular economy, should be highlighted: depletion of the resource base and deterioration in the quality of mineral assets; increased capital and resource intensity of production; a specific object of labor (production of extraction), with high liquidity in the market and standardity as a use value; fairly stable technological and economic ties with buyers and suppliers in connection with the use of products for subsequent processing; a high degree of vertical and horizontal integration; increased requirements for industrial and environmental safety.

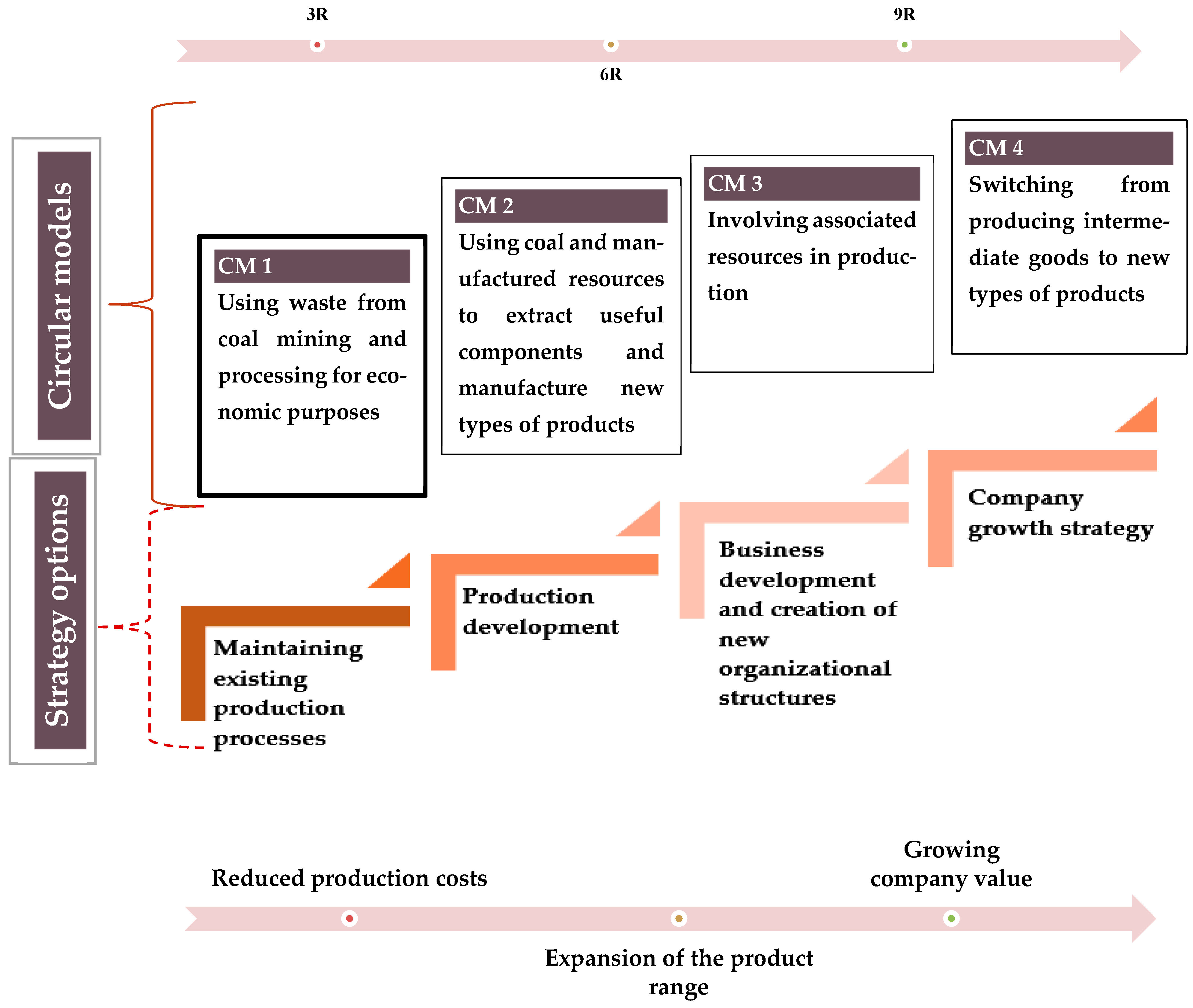

The development of the CE theory and the adaption circular business models in the field of mining and processing of mineral raw materials can become a driver for the technological renewal of mining industries. Circular models based on innovative manufacturing processes will allow the waste or by-products of one industry to be turned into resources for another industry. Mining sites can be subject to a circular approach. This will reduce the amount of accumulated waste in dumps and reduce the rate of accumulation of current waste. A conceptual diagram of options for circular business models, taking into account the specifics of the production chains of coal mining, power and coal and metallurgical companies, will reduce production costs, increase the product range, improve sustainability indicators, and ensure the growth of the company’s value.

The scientific novelty of the research lies in the development of a mechanism for the implementation of reference circular models at the industry level in a specific business environment. A specific feature of coal companies, as an object of the circular economy, should be highlighted: depletion of the resource base and deterioration in the quality of mineral assets; increased capital and resource intensity of production; a specific object of labor (production of extraction), with high liquidity in the market and standards as a use value; fairly stable technological and economic ties with buyers and suppliers in connection with the use of products for subsequent processing; a high degree of vertical and horizontal integration; and increased requirements for industrial and environmental safety.

The Literature Review section discusses the theoretical foundations of the circular economy that form the basis of this research. The section shows how the theory of circular economy evolved, discusses standard business models, and considers the concepts of rational and multipurpose resource use as the basis of circularity for mining companies.

The Materials and Methods section demonstrates the research methodology, which includes analyzing and processing practical experience, defining circularity principles, and transforming standard business models into adapted ones. The section also includes a brief description of the research subject and a diagram of mineral resource distribution.

The Results section contains a description of cases divided into three groups. These groups reflect the specific features of the production process in the mining sector and are in accordance with the principles of standard circular business models. It presents a system of circular business models that are adapted to the conditions of the coal industry.

The Discussion section presents an analysis of the results in the form of discussing the conditions for adopting the models within modern organizational structures in the coal sector and gives an economic assessment of the models. Limitations of the research are also noted.

2. Literature Review

As the global community recognized the need to switch from the traditional linear (“take, make, waste”) model of the economy to the concept of sustainable development, a paradigm shift began in the development of socio-environmental and economic systems. The focus now is on keeping the balance between social, environmental, and economic aspects by achieving the sustainable development goals (SDGs) proposed by the UN in 2015 [

11].

One of the ways to achieve these goals is to make a transition to a circular economy (CE) based on the “take, make, reuse” principle. While the traditional linear model of the economy has an open-loop configuration in which manufacturing end products is associated with large resource costs and anthropogenic pressure, the CE model aims to simulate the mechanisms of a closed, self-healing natural system, reuse products, and recycle them at the end of their life cycle [

12].

The implementation of the CE principles involves creating closed-loop cycles in the production sector. Resources do not leave such cycles and/or are transformed into new goods. Extending the product life cycle, which is characteristic of a circular economy, involves creating value chains in the process of producing, consuming, and processing material resources and products, which in turn creates economic, social, and environmental effects [

12].

Modern CE research is based on the theory of the cyclical nature of production and consumption. Its original 3R principle (reduce, reuse, recycle) [

13] transformed first into 6R (“recover, redesign, remanufacture” were added to reflect all stages of the product life cycle) [

14] and then into 9R (“refuse, refurbish, rethink” were added to reflect the idea of smart consumption) [

15,

16].

As a result of implementing CE principles, production and consumption trends changed. CE has become a logical step in global sustainable development and contributes directly and indirectly to the achievement of the SDGs, including Goal 12 (“Ensure sustainable consumption and production patterns”), Goal 6 (“Ensure access to water and sanitation for all”), Goal 7 (“Ensure access to affordable, reliable, sustainable and modern energy”), and Goal 8 (“Promote inclusive and sustainable economic growth, employment and decent work for all”) [

17,

18].

In practice, CE principles can be implemented by means of five business models: circular supplies, resource recovery, sharing platforms, product life extension, and product as a service [

12,

19,

20,

21].

1. Circular supplies. In this model, non-renewable resources are replaced by renewable ones, which are either fully recyclable or biodegradable. The model is most feasible in the automotive and energy industries. For example, Novelis and Ford Motor Company have created a closed-loop aluminum recycling cycle that has reduced greenhouse gas emissions and energy spent on aluminum recycling by 95% [

20].

2. Resource recovery. New technology and innovations allow for recovering and reusing resources. Through waste reduction, resource losses decrease, and the profitability of production grows. The model is most effective in industries with a wide range of secondary goods and where there is a potential for recovery and waste recycling. For example, DONG Energy and Statoil’s refinery share their process chains by exchanging waste and by-products [

20].

3. Sharing platforms. The model is based on exchanging and sharing goods or assets. It is suitable for industries with low product utilization and/or underutilized production capacities, allowing producers to take advantage of economies of scale by spreading fixed costs. It can be implemented not only in the field of production (business-to-business, or B2B), but also in such models as business-to-consumer (B2C) and consumer-to-consumer (C2C) [

19].

4. Product life extension. It is achieved through product modernization and repair.

5. Product as a service. This model is based on renting or leasing products instead of buying them.

Over the past decade, researchers’ interest in developing theoretical and practical principles for implementing the CE strategy has grown tremendously. The essence of different circular economy models is presented in the works by Ellen MacArthur Foundation [

22], MacArthur E., Waughray D. [

23], Haas W., Krausmann F., Wiedenhofer D., Heinz M. [

24], Sauvé, S., Bernard, S., Sloan, P. [

25], Blomsma F., Brennan G., [

26], Geissdoerfer, Martin and Savaget, Paulo and Bocken, Nancy and Hultink, Erik [

27], Kirchherr, J.; Reike, D.; Hekkert, M. [

28], Alhawari, Omar and Awan, Usama and Bhutta, M. and Ülkü, M. Ali. [

29], Mochalova L.A., Sokolova O.G. [

30], Bobylev S.N., Solov’eva S.V. [

19], Saman Amir [

31].

Blomsma F. and Brennan G. [

26] summarized a number of interpretations of the CE model, the most popular of which is the one proposed by the Ellen MacArthur Foundation. This model is based on the circular flow of environmentally friendly materials and technology. The biological cycle is aimed at preserving the ecosystem by reducing the extraction of natural resources, introducing renewable materials, and reusing production waste and energy. The technical cycle is based on closed supply chains that extend the life cycle of goods and materials, creating new added value. As secondary resources circulate in the technical cycle, it reduces the consumption of raw materials.

Both the models summarized in the work by Blomsma F. and Brennan G. and the model proposed by ERA-MIN 2 [

26,

32] present the mining industry as being connected to rather than part of the CE model [

3]. This simplification does not make it possible to fully assess the potential of the primary link in the system, which is the extraction of natural resources, or opportunities for transformation in the mining sector.

This article aims to assess the potential of the primary link in the chain of resource extraction and consumption. The Ellen MacArthur Foundation forecasts that the CE could yield up to 4.5 trillion USD in economic benefits by 2030 [

6]. How much of this sum can be accounted for by the mining industry?

In the report [

33], Barthel R., Drewell K., and Morrison G. prove that by adopting CE principles, mining companies will be able to maintain their market share and turn the pressure created by the circular agenda into new opportunities or a source of innovative development and modernization. However, it should be noted that there are not many case studies in the field of the circular economy, especially regarding the coal industry.

Articles on the implementation of CE principles in certain economic sectors, such as mining (Geng et al., 2012a [

34]) and the steel industry (Pauliuk et al., 2012 [

35]; Wang et al., 2013 [

36]), are few in number. As noted in [

37], the current methodological framework does not provide for creating sustainable development strategies for mining companies that will take into account modern trends in the circular economy.

Among the fundamental works on the topic are studies by several Russian scientists who, starting in the 1930s, have been discussing issues associated with multipurpose resource use, the development of mining regions, loss optimization in ore extraction and processing, waste disposal, and the use of advanced technologies. Various approaches have been proposed, including full utilization of all useful components and building multipurpose factories [

38,

39].

Multipurpose use of mineral resources consists in extracting several valuable components from ores either simultaneously or sequentially along the whole production chain. The degree of multipurpose use increases as a result of expanding the range of recoverable valuable components, and the utilization rate grows by means of improving recovery degrees. These two parameters depend on whether the range of end products corresponds to the mineralogical and/or chemical composition of the raw materials being processed [

12,

38,

39].

Rational resource use consists in expanding the range of marketable products and, as a result, production volumes, including by means of involving associated minerals. As a result of rational resource use, the value of commercial products is maximized regardless of their applications [

39].

Rational use of mineral resources can be achieved through [

5,

6,

7,

38,

39]:

- -

Reducing losses during the extraction of key useful components and improving the quality of raw materials by means of reducing or diluting.

- -

Improving ore recovery rates and increasing the number of applications of by-products, including overburden, peat, topsoil, groundwater, production waste, etc., if they are available in quantities sufficient for production.

- -

Improving waste recycling rates throughout the whole production chain.

Thus, multipurpose resource use is a special case of rational resource use. This means that it should not be considered something seen only in the final stage of production in the mining sector, which is mineral processing. Multipurpose resource use allows mining companies to provide themselves with additional resource assets and extend the life of the deposit by involving associated minerals in production. Moreover, it often happens that the total value of associated minerals is greater than the value of the key useful component and determines the profitability or feasibility of the project. Issues associated with multipurpose resource use are the focus of research in mining engineering and other sciences [

40]. Requirements regarding the quality of raw materials are constantly changing; the principles for resource classification and the prospects of resource use are being revised.

In Cisternas, L.A. [

41] et al. analyze current efforts to apply CE in mineral processing. Despite the progress made, this review shows that the most significant material flows and environmental impacts occur near mining and processing sites, which are currently limiting closures. In addition, the mining industry is conservative about adopting new technologies or recycling strategies, which is another barrier to CE adoption. «Additionally, mining industries are conservative regarding the adoption of new technologies or processing strategies, which is another hindrance to the implementation of the CE. Thus, and with few exceptions, while some sectors are already facing advanced stages of CE (namely, CE 3.0), the mineral processing field struggles to advance from the basic CE requirements (i.e., CE 1.0 to CE 2.0)» [

41].

In our opinion, one of the reasons for the viscosity of the CE implementation process in mining companies is the lack of a conceptual approach, a well-developed theory, and a practical mechanism for applying classical CE models in a particularly specific mining business environment. The conservatism of the process is observed not only in real production, but also in academic publications, for example, a query on scientific databases for the period 2000–2021 for the term “circular economy” generates a list of 18,540 publications, while for “mining industry” extracted 92 publications. This represents 0.5% of the total, most of which are in 2021, indicating the growing popularity of this issue in the minerals sector. All publications can be divided into two large blocks: solution of local practice-oriented problems on the examples of specific deposits; development of the theory and methodology of CE with elements of linkage to sustainable development, risk management, and the development of models. Most publications are devoted to solving local problems in a particular region: the development of technological solutions to reduce the anthropological load; the search for alternative sources of raw materials due to the natural depletion of the mineral resource base. Conceptual problems of development and implementation of DE models in the mining industry are reflected in only 15% of publications, which indicates the need for further research in this direction.

Articles focused on solving local problems of implementing CE models in the mining industry mainly have a technological bias and contain questions: mining waste management of various types, conditions for their formation, life cycle (tailing dumps, slag, mine water recycling) [

42,

43,

44,

45,

46], technological, innovative solutions, including the use of integrated intelligent systems in the processes of mining, transportation, enrichment [

47,

48].

In a study by Chinese scientists [

49] in the «Discussion on the Model of Mining Circular Economy», the features of coal mining companies are considered, the chain of product processing is described, and waste streams after each processing are identified. «It revealed the connotation of mining circular economy and cleared the specific content of 3R principle. On this basis, it discussed the model of mining circular economy at the enterprise, industry park, and society level according to the present situation of mineral resource recycling in China. Then, with the development of circular economy at enterprise level as an example for constructing a system of circular economy at the coal mine enterprise» [

49]. However, the study does not provide a clear classification of areas for strategy development, and there are no options for circular business models for various types of coal companies.

In a study by de la Torre de Palacios, L., Espí Rodríguez, J.A. [

50], it is stated that mining wastes have different characteristics depending on the stage of their formation. “It is necessary to separate those that are formed during processing or enrichment from those that inevitably accompany the mining cycle in a mine without any mineral content. The latter are much larger in volume and have little chance of being reused under acceptable economic and environmental conditions” [

50]. This study was carried out on the examples of mining in Liberia, that is, it is of a private nature, and it allows us to state that the classification of waste by stages of processing is an important component in terms of determining the legal status of waste and the possibility of using it in one’s own production or in related industries.

The study [

51] noted that the transition to sustainable mining can be achieved through the introduction of a circular economy (CE), and one way forward is through the use of product-service systems. The main idea is that service companies, such as equipment suppliers, should offer intellectual services to mining enterprises, which, according to the authors, should increase the efficiency of both service and mining companies. A similar approach to achieving circularity is reflected in the work of Hristova T. [

52], which assesses the effects and benefits of the introduction of electric vehicles in the mining industry. In our opinion, the results of these works [

52] evaluate the narrow niche of the mining production process only in terms of mechanization and automation; therefore, these proposals can only be used as tools for the mechanism of circular business models.

The main goal of Kalisz et al. [

53] was an overview of the current possibilities of waste management in the mining industry of metal ores, coal, oil, and natural gas. The study includes an analysis and discussion of the possibilities of reusing certain types of waste generated from mining activities, which, in the opinion of the authors, should not only contribute to a more sustainable management of mining waste, but also respond to current efforts to implement the assumptions of a circular economy, which aims to close the cycle.

The conceptual and methodological basis of the CE process is represented by modern works, which discuss the issues of circularity as an element of sustainable development for mining companies [

54], risk management, supply chains, and added value as a result of the application of mechanisms of circular models [

55].

In the article [

54], according to the authors, “the incentive to intensify research that goes beyond the boundaries of the mining industry and introduces the best circular practices at the micro level could be the inclusion of circularity indicators in corporate ESG sustainability reporting, which would reflect the degree of integration of CE elements in corporate strategies. At present, CE approaches in sectors such as mining remain a potential factor in the sustainability of companies. The problem, in particular, lies in the formation of sustainable circular business models that would ensure acceptable profitability of closed supply chains” [

54]. In this study, the issues of the circular economy are fragmented to illustrate the opportunities for sustainable development.

The authors of Upadhyay A. et al. [

55] argue that the mining industry could benefit from learning from other industries regarding CE, which would allow circular economy initiatives to be promoted in a timely manner. In this article, the authors review several circular economy initiatives taken by the mining industries. The purpose of the article is to showcase some common themes for three major mining companies through content analysis; and evaluate identified barriers, drivers and triggers of these circular economy initiatives.

The study by Li H., Wei X., and Gao X. [

56] provides a new policy experience for understanding the policy-driven model for the development of the CE in the mining industry, including changes in the CE policy in the mining industry, as well as the relationship between policy objectives and policy instruments, which contribute to the replication of the experience of the CE policy in the mining industry. The paper notes that policy target setting can be extended to the triple dimension of benefits of “economy-environment-employment” [

56]; the choice of policy instruments should be based on structured learning and feedback mechanisms, determine the effects of combinations of different policy instruments, and dynamically adjust accordingly; moreover, the choice of institutional policy instruments in developing countries deserves more attention and further comparative study between developing and developed countries.

The existing literature is replete with more technical studies of the mining industry. However, there is a gap in the use of a reliable methodology for solving CE problems in the mining industry, which is the subject of [

57]. In the work, on the basis of expert opinion and brainstorming, a classification and clustering of the problems of implementing CE in the mining industry is carried out on the example of developing countries (India). It was revealed that most of the problems lie in a cluster that is important and significant for the industry. Any manipulation of these factors must bring positive results in order to proceed with the adoption of CE. The article says that: «CE adoption in the case company and other mining companies will only be possible if each individual firm identifies challenges and develops suitable strategies to deal with them» [

57].

Based on the analysis of the literature, we can state that the most possible options for implementing CE business models are:

- -

Modern technologies for the extraction of natural materials (coal) that ensure sustainable resource use and ore loss reduction.

- -

Multipurpose use of mineral deposits through utilizing the existing infrastructure for development operations.

- -

Multipurpose use of mineral resources (target components, associated components, and waste), which allows to increase the degree of processing.

3. Materials and Methods

In the course of the study, we used books and articles by researchers from Russia and other countries on topics concerning theoretical issues associated with using circular models in the mining industry and materials covering cases of rational and multipurpose resource use in the coal sector, including mining waste utilization, coal processing, and coal combustion.

The cycle of our research was as follows:

(1) Case-analysis: modern options for the use of resources (minerals) of coal companies according to technological and environmental criteria of circularity. Intermediate result of the stage: an enlarged classification of directions for the rational and integrated use of subsoil, minerals and waste products from coal companies.

(2) Assessment of the specifics of the production cycles of coal companies. The intermediate result of the stage is the identification of types of companies, the stages of product processing in coal, energy-coal and metallurgical companies.

(3) Transformation of reference circular models into industry cicular models by combining directions (1) and stages of production stages (2). The result is a conceptual scheme for the formation of industry basic circular models, taking into account the principle of preserving the value of resources throughout their life cycle.

(4) Analysis of the possibilities of introducing and implementing industry basic circular models (3) within the company. The result is a strategic management mechanism through the implementation of projects from maintenance and reproduction to expansion and growth of the company.

The study uses desk methods for analyzing whether circular models are efficient. We collected, analyzed, and processed secondary information, analyzed practical experience in rational resource use in the mining industry, and used the transformation method to convert basic circular business models into those adapted for the conditions in which coal companies operate.

The methodology for developing circular business models was based on the following principles:

Using resources to the maximum. All mineral resources extracted, including mining and processing waste, are considered as potential raw materials or materials for use in economic activities aimed at producing additional types or volumes of products if appropriate technologies are available.

Minimal involvement of additional resources. Intensive use of mineral resources involves creating additional types of products from raw materials without involving or involving few other natural resources.

Using environmental assessment as one of the key efficiency indicators that determines the choice of a circular model.

Taking into account organizational and technological conditions at coal companies.

Taking into account growth in performance efficiency, strategic growth, and sustainable development in the coal sector.

To discuss organizational and technological conditions, examples of several Russian coal companies are used. They have standard structures that are typical of European, Australian and Asian coal companies.

There are a lot of players in the Russian coal sector, but only five of them provide more than half of domestic coal production. The first group of companies specializes exclusively in coal production. Among them are Siberian Coal Energy Company (SUEK AO), SDS-Ugol, and others. The functioning of coal producers is based on the processes of coal extraction, processing, and transportation. For example, SDS-Ugol operates three open-pit mines, two underground mines, three preparation plants, and a number of service companies. SUEK operates 15 underground mines and 12 open-pit mines in Siberia and the Far East, which produce approximately 28% of all coal in Russia, and 24 power plants serving over 5 million people living in Siberia [

58].

The second group consists of energy companies, which combine coal production and power generation. For example, EuroSibEnergo operates Vostsibugol, a coal-mining company, five hydroelectric power plants, and eleven thermal power stations [

58], i.e., the end products of energy companies are coal and energy.

The third group consists of metal manufacturers, such as Severstal PAO, UMMC OAO, Mechel PAO, and Evraz Group S.A [

59]. They operate on the principle of a full cycle and deal with extracting and preparing coal and ore along with fabricating metal and metal products with high added value and recycling secondary resources. Unlike energy and coal-mining companies, metal manufacturers offer a wide range of products and sell coal, iron ore, steel, cast iron, and rolled metal [

58,

60].

As companies specialize, producing either coal or metals, it determines the complex nature of production structures. In most cases, both Russian companies and companies from other coal-producing countries are holdings (

Table 1) [

58,

59,

60].

For the purpose of adapting five universal business models to the conditions in which coal companies operate, the article uses a macro flow chart for resource distribution from extraction to production.

From the flow chart it follows that the resource mix includes: (1) extracted minerals; (2) ore losses; (3) finished products, and (4) the remains of mineral resources. The latter are partly returned back to the production chain, where they turn into secondary raw materials, and partly used for the production of non-core products, thus becoming by-products. They can also be used by other companies or stored in waste dumps, forming man-made deposits, which can be used for the development and production of marketable products or the provision of services. An important feature of mineral assets is fluctuations in their value. Fluctuations can be caused by both market and technological factors (for example, a new technology for extracting valuable components can affect resource prices).

The Results section considers examples of using coal, its by-products, and waste from mining and processing at different stages. The cases are broken into three groups, which best reflects the specific features of the production process in the mining sector and is in accord with the principles of five standard CE business models, including circular supplies, product life extension, and resource recovery.

The study provides examples of:

- -

Modern technologies for the extraction of natural materials (coal) that ensure sustainable resource use and ore loss reduction.

- -

multipurpose use of mineral deposits through utilizing the existing infrastructure for development operations.

- -

Multipurpose use of mineral resources (target components, associated components, and waste), which allows to increase the degree of processing.

By analyzing examples of rational and multipurpose resource use, we developed configurations of circular business models adapted to the conditions of the coal industry. The models take into account the ways in which resources coal, methane, etc.), can be used, the production stage, and the way the project is implemented with possible effects.

5. Discussion

Circular business models are management tools that create economic conditions for implementing projects in production and other spheres. Business models can increase the investment attractiveness of innovative projects and create new business processes and new value chains that ensure that projects are implemented, which includes using best available technologies (BAT) in the mining industry.

Projects integrated into the production process may include: the introduction of low-waste technological schemes for field development, projects for organizing production in a closed cycle (internal recycling), projects involving the use of waste in auxiliary production, technologies for reclamation, and protection from environmentally hazardous substances contained in waste. As specific tasks of projects integrated into the production process, the following tasks can be considered: reducing costs associated with the placement and storage of waste; saving material and human resources; creating conditions for safe work.

Projects aimed at the development of the company must be coordinated with strategic goals. Such projects are of a diversification nature, as a rule, involve the release of new types of products and the expansion of the range, the production of products with a higher added value. Vertical diversification involves the creation of a continuous technological process of mining, processing and marketing of finished products, that is, the introduction of projects aimed at minimizing the generation of mining and enrichment waste, as well as the processing of generated waste. The implementation of vertical diversification is possible due to the inclusion of new stages in the technological chain: mining, enrichment, metallurgical processing in order to reduce the life cycle of waste. Horizontal diversification is based on the creation of a new product based on existing or new technologies within the company’s profile, the expansion of product distribution channels and the growth of the scale of activities. Unrelated diversification involves going beyond the industry, that is, the formation of new activities—the production of additional products with high added value and entry into new markets. An example of unrelated diversification is projects for the production of materials from mining waste for the construction industry. Through the implementation of diversification projects within the company, the effects of the integrated use of mineral raw materials, the growth of the company’s value, the production of high value-added products, and the reduction of economic and environmental risks are achieved.

Model 1 (using waste from coal mining and processing for economic purposes) can be used within the framework of one company. It does not require a lot of investments and can be implemented as an organizational project. Effects created include saving material resources, reducing material costs, and reducing environmental costs.

Model 2 (using coal and man-made resources to extract useful components and manufacture new types of products) can be used within the framework of one company too. It requires investments in the reconstruction and modernization of production as it forms new production structures. Effects created include savings on new licenses for mining, increase in production volume, entering new markets, introduction of new technologies, and acquiring new knowledge. The model can be modified depending on the characteristics of minerals, the amount of additional investment required for key production processes and infrastructure development, the complexity of production processes, and the complexity of the organizational structure.

Model 3 (involving associated resources in production) can be used within individual projects. It forms independent industrial complexes that require significant investments. Effects created include business diversification, creation of new types of business, and savings on new licenses for mining.

Model 4 (switching from producing intermediate goods to new types of products) can be used within complex projects. It requires significant investments in innovations and forms new organizational structures. Effects created include introduction of new technologies, acquiring new knowledge, transition to a new type of activity, and entry into new markets.

Using adapted circular business models in mining and mineral processing can become a driver for upgrading mining companies [

78,

79]. It is important to develop innovative manufacturing processes that allow the waste or by-products of one industry to be turned into resources for another industry. Mining sites can become targets for a circular mining approach. In addition to the traditional consideration of the impact of mining activities on the environment and society as part of sustainable development strategies, mining companies can implement projects to minimize negative impacts, share best practices, and reduce waste.

It should be recognized that achieving zero waste in the mining industry is quite difficult, in contrast to the example of food waste [

80], due to the specificity of the object. The proposed research [

80] «has incorporated the integration of SC management and CE through the design of inventories under the concept of 3R: “Redirect, reduce, and recycle”. The waste generated in the primary supply chain retailer’s end is redirected to the secondary chain as raw-material. It also helps in reducing the disposal or landfill». With regard to the identification of mining waste the situation is not straightforward. Firstly, the law “On Subsoil” in the Russian Federation does not define the definition—mining waste and associated processing facilities. Secondly, the law defines the use of mining waste as a type of subsoil use, limiting the ability of companies to dispose of waste. One of the tasks we address in our work is to draw attention to the issues of non-universal process and product of mining companies. At the same time, the possibility and necessity to develop and implement projects for the rational use of resources, which will require some effort and commitment of companies. Moreover, since we are talking about coal resources, we emphasize the particular importance of the use of technological innovations in coal chemistry, which will bring the industry to a new level of development: the transition to deep processing of raw materials and expanding the range of products. Our study attempts to assess the possibilities of the coal industry from the 3R to 9R model, as in the extensive subsoil use expediency of such projects is not always obvious.

In our opinion, the resource recovery model holds the greatest potential for coal companies in the field of circularity since new technologies introduced into coal mining processes can reduce coal losses and improve production efficiency by means of reducing mining waste and processing. It also creates opportunities for land reclamation and reducing the negative impact on water, land, and air resources.

Resource recovery models for coal companies can be implemented through a number of programs (or measures) for rational and multipurpose resource use, including through a diversification strategy.

Sharing platform and «product-service» can be used in joint projects for developing mineral deposits or for the exchange or lease of expensive equipment.

Within the resource recovery model applied to waste management, the key methods are recycling, regeneration, and recovery [

78], which corresponds to the 3R concept. Recycling plays an important role by ensuring that mine waste is processed. Waste management in the mining sector is primarily associated with overburden that forms dumps and is limited to 5R [

30]. It is possible to move to the 6R concept (which encompasses all stages of the product life cycle) in managing waste generated by the use of energy and resources or materials from other industries.

The transition to the 9R concept is possible in the following cases:

1. The mining company is part of a vertically integrated company (VIC). Vertical integration makes it possible to achieve consistency among producers along the whole production chain and to add responsible consumption methods to the waste management program.

2. The mining company is part of a conglomerate. A wide range of manufactured products, including end products, makes it possible to add responsible consumption methods to the waste management program.

3. The mining company is part of a circular industrial cluster or eco-industrial symbiosis, which allows for waste reuse and the joint provision and/or use of services, infrastructure facilities, and equipment (within platform sharing, PaaS, and resource recovery models). For example, on 14 July 2021, the government of the Kemerovo Region signed Decree No. 359-r titled “On Approval of the Strategy for the Development of the Cluster for the Multipurpose Processing of Coal and Industrial Waste in the Kemerovo Region (Kuzbass) until 2030” [

79]. The strategic objectives of the cluster include strengthening the competitiveness of the regional economy through adopting R and D results by small and medium-sized businesses; attracting innovations and international experience in the field of multipurpose coal processing (including advanced processing) and waste processing using waste generated by mining, beneficiation, and combustion; geological exploration; upgrading mining companies by developing new technologies suitable for mining deposits characterized by complex geological conditions and developing equipment that allows for optimizing existing production processes; alternative (non-fuel) use of coal (technologies for coal gasification and conversion into liquid fuel); process safety and environmental safety (technologies for managing the human factor and increasing the competence of employees in the coal sector); logistics issues [

79,

81].

Thus, the authors believe that the opinion that the mining sector is potentially suitable for CE models but is not a focus area [

3] is not even questionable; it is untenable. The mining industry has great opportunities to implement CE principles. Moreover, it is in this industry that there is an urgent need to introduce circular business models.

However, reorganizing existing business processes in the transition to a circular economy brings not only additional positive effects but also new risks for a number of industries. Positive effects include a reduction in the consumption of nonrenewable resources; smaller environmental fines; new jobs as a result of the emergence of new sectors of the economy, which leads to an increase in consumer demand; innovation-driven growth of industries and distribution systems, which results in the emergence of new profit centers; consumers get the opportunity to buy more environmentally friendly products, which, in some cases, have lower prices; reduction in CO2 emissions and areas allocated for landfills and waste disposal. At the same time, the reuse of goods will lead to a decrease in sales. Not only manufacturers of end products fall but also companies producing raw materials are at risk. Companies in the commodity sector may face a decrease in demand for their products. However, these risks require additional assessment.

The circular model goes beyond simple waste management and requires the efficient and rational use of natural resources throughout their entire life cycle.

In our opinion, life cycle analysis (LCA) in relation to a mineral is manifested in the number of stages in the production of final products, and in part, we tried to sanctify this through mining companies. The greater the vertical diversification of production, the longer the production chain within one company, but this also does not guarantee the effectiveness of the circular approach. At the same time, if we evaluate the life cycle of the company itself, then taking into account the limited period of operation of mining companies due to the finiteness of minerals in the bowels, the use of circular models can extend the life cycle of the company.

Process optimization can be achieved by: implementing onew projects at existing enterprises (the company independently determines the boundaries of its expansion, modernization); A priori use of innovative schemes for the extraction and processing of mineral raw materials at the design stages of new companies. Including incentives for such an approach should be institutional instruments of a mandatory or stimulating nature on the part of the state. The main drawback of the circular approach system in the mining industry is the absence of strictly regulated requirements from the state. This allows mining companies to use a system of compensation in the form of environmental payments, which is much cheaper than a circular approach.

The conceptual scheme does not imply a system of indicators to assess the level of circularity. The developed and adapted CE models are based on the principles of accounting for environmental efficiency, which is reflected in the analysis of cases where the environmental component is heavily emphasized, but a detailed presentation of environmental and social effects and risks requires further research. The limitation is the lack of integrated economic assessment of the implementation of the CM projects and the lack of assessment of the effects of related industries. Important future developments for the implementation of circular business models will require more work on the development of assessment tools to improve decision-making.

The key limitation of this study is that the proposed models are conceptual in nature and do not take into account conditions that are unique to every company regarding such aspects as technology, management, and finance. The conceptual framework does not provide a system of indicators to assess the degree of circularity. In this study, we limited ourselves to building a general model only. In the future, we plan to evaluate the effectiveness of the circular model. As the main criterion, it is supposed to substantiate the socio-economic and environmental efficiency of the model. The adapted CE models proposed in the article are based on the principles of accounting for environmental efficiency, which is reflected in the analysis of cases, where a major emphasis is placed on the environmental component, but a detailed presentation of environmental and social effects and risks requires further research. Another limitation is the lack of economic assessment of the implementation of CE projects at the macro level and the lack of assessment of the effects produced by related industries.

In the future, more industry examples should be considered in various industrial sectors in order to comprehensively demonstrate the usefulness of the concept. This structure is focused mainly on the analysis of the extractive industry in the implementation of closed models through the mechanisms of the integrated and rational use of natural resources. The study does not consider in detail the resource flows for the extraction and enrichment processes, which will require additional review and analysis. Important future developments for the implementation of circular business models will require more extensive work to develop assessment tools for improved decision-making. The issues of the mechanism for implementing these models in terms of regulatory support and the conditions for stakeholder interaction are subject to detailed consideration, which is important for ensuring the process of transition to the CE.