Wide Band Gap Devices and Their Application in Power Electronics

Abstract

1. Introduction

2. Why WBG Semiconductor Power Devices?

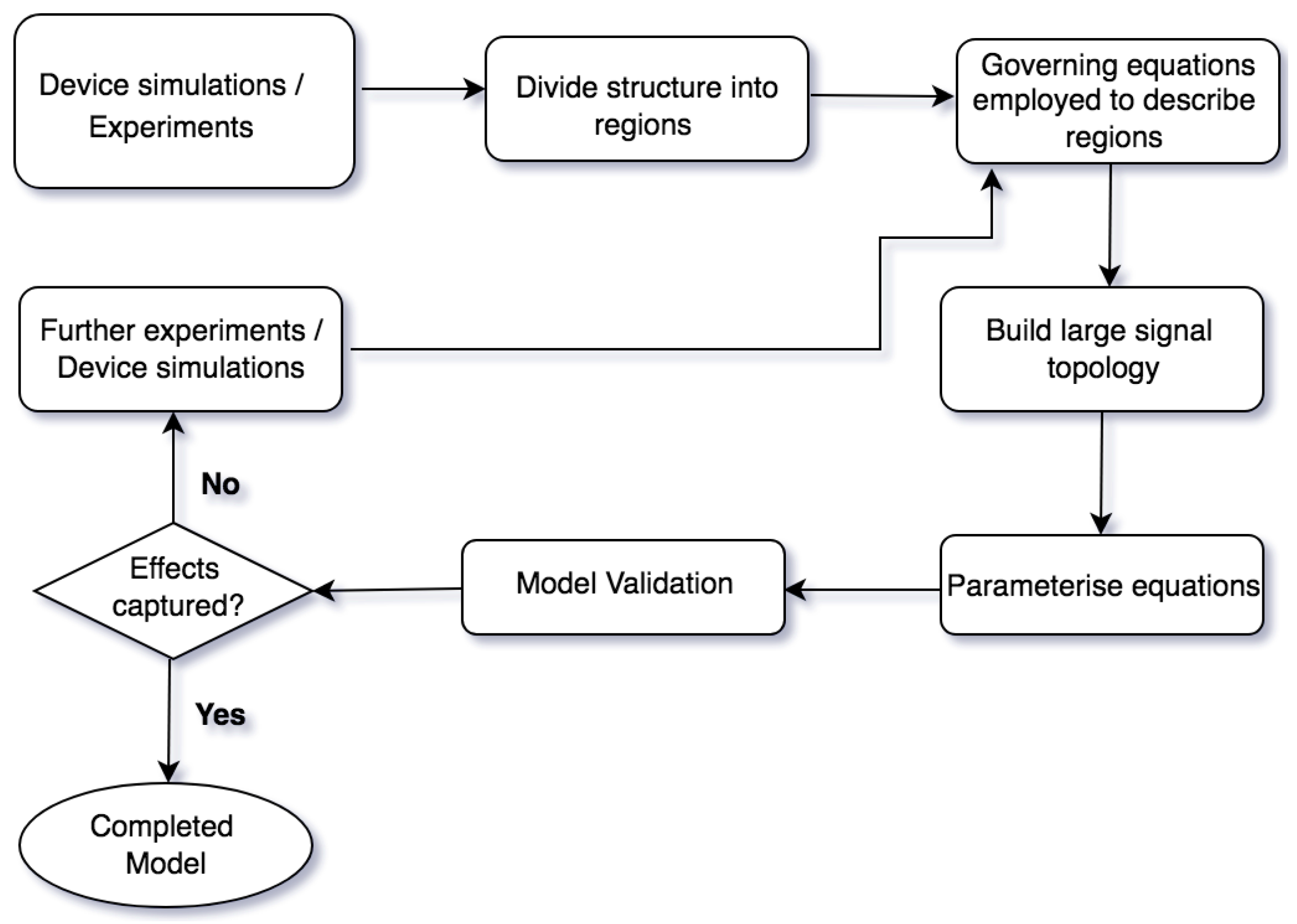

3. Models of Semiconductor Power Devices

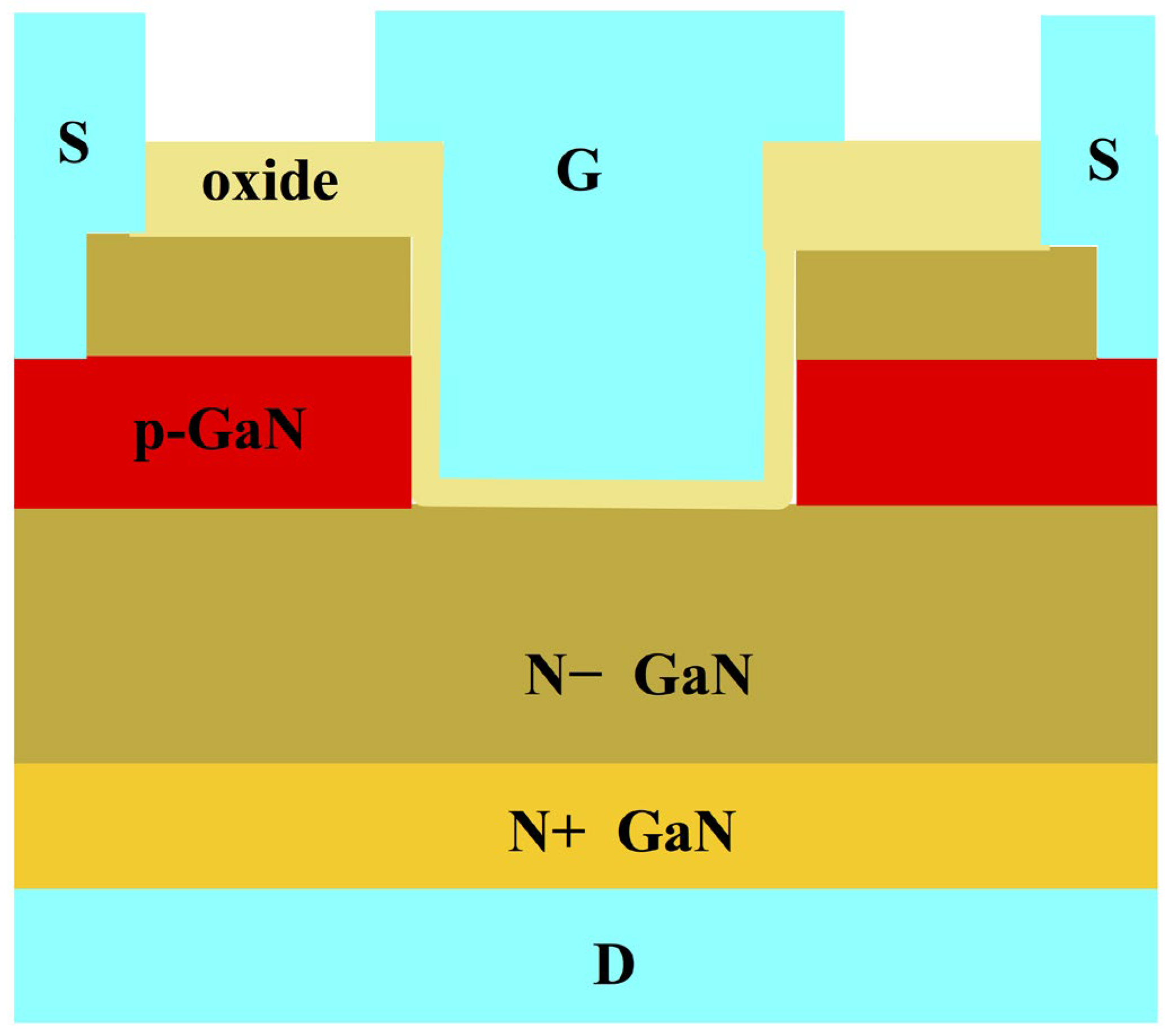

4. SiC and GaN Power Devices

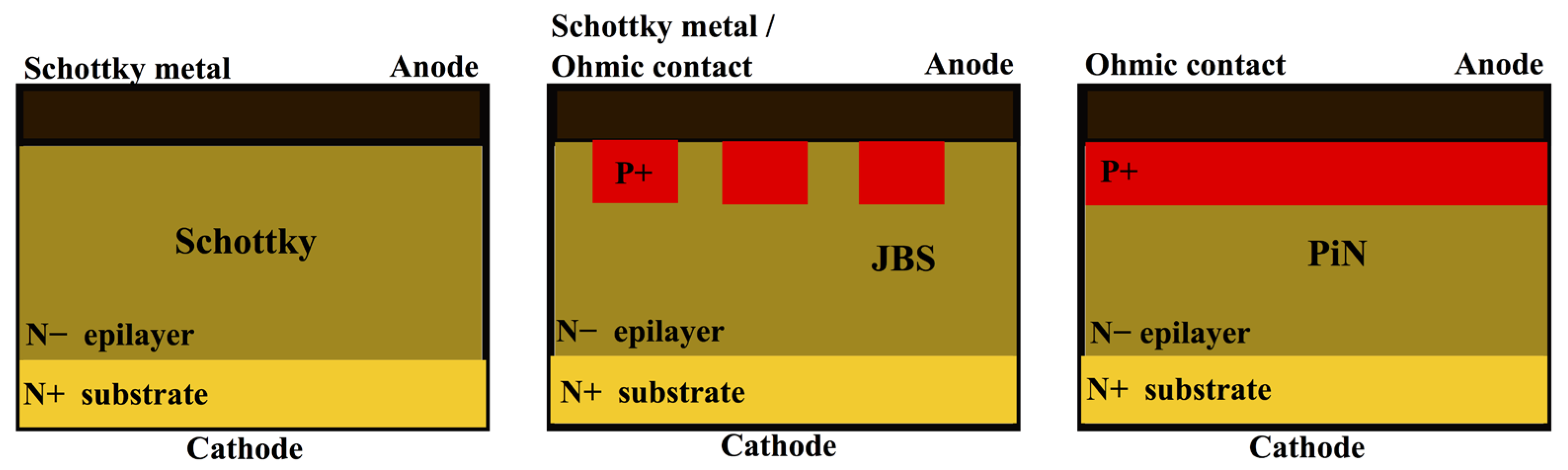

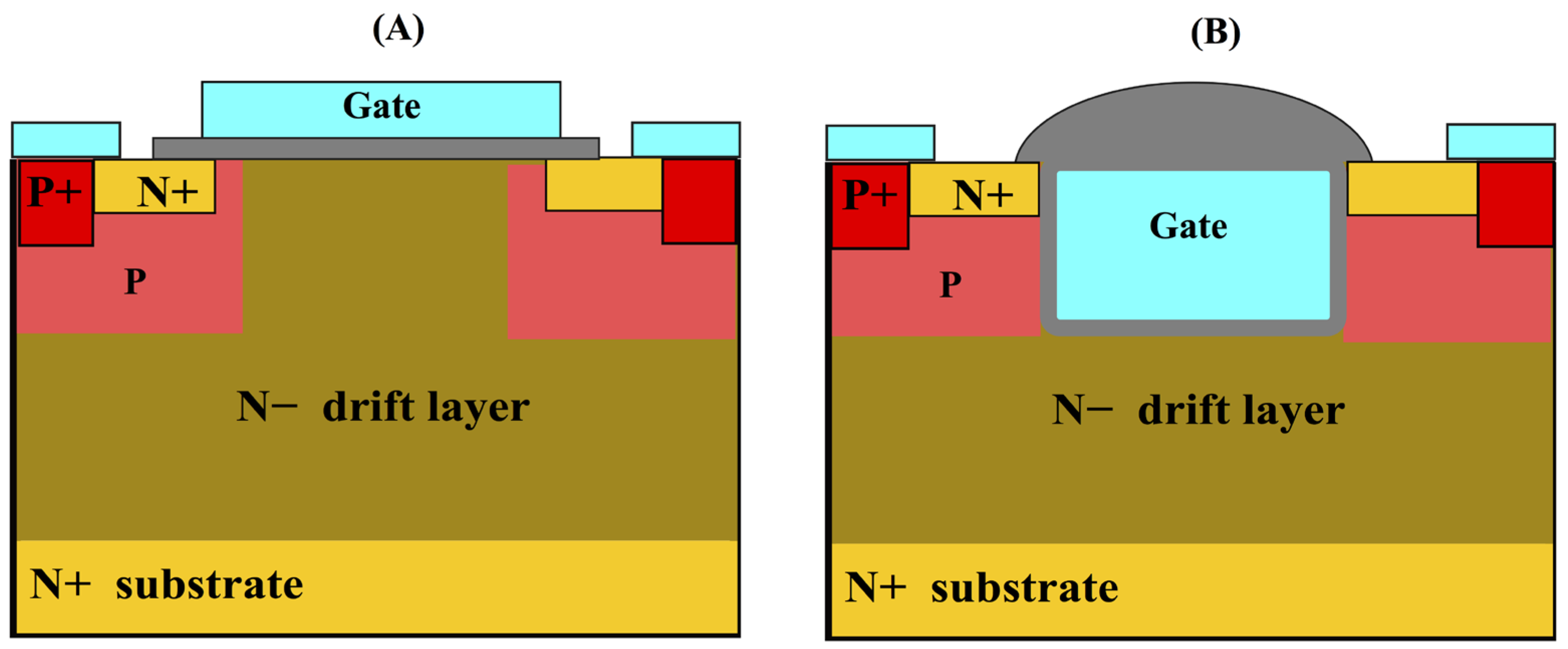

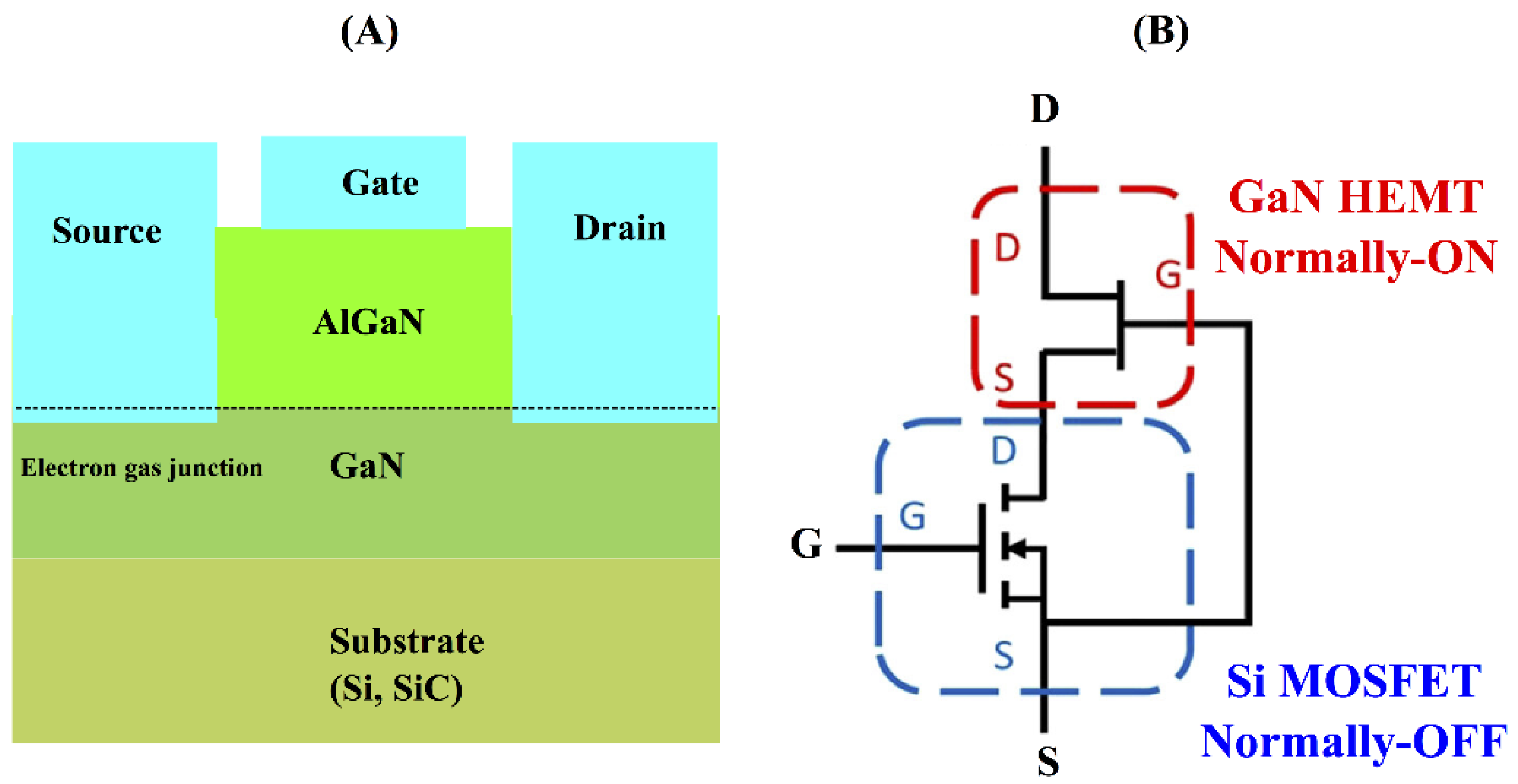

Classification of Semiconductor Power Devices

5. Merits and Challenges of Using WBG Semiconductor Devices

6. Applications of WBG Devices

6.1. Hybrid Application of WBG and Si Devices

- (i)

- (ii)

- (iii)

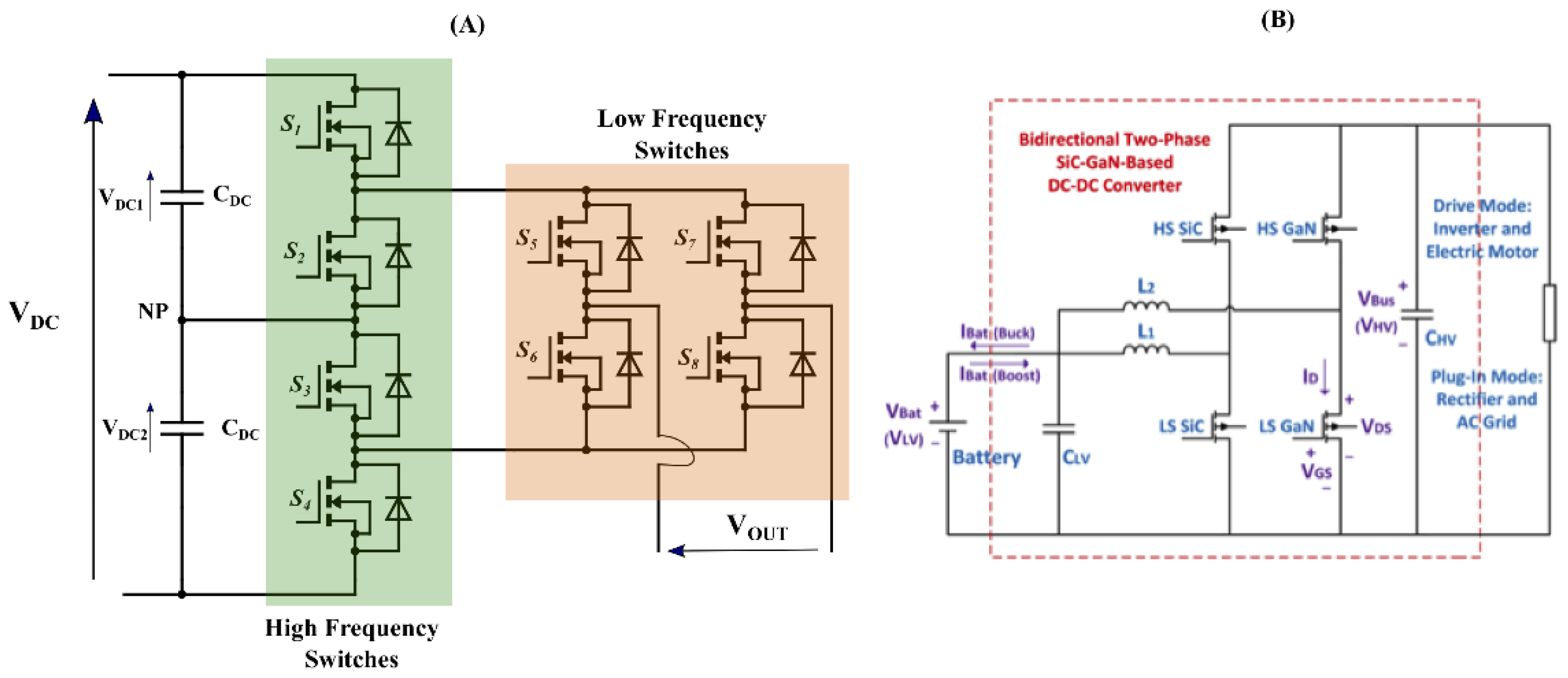

6.2. WBG Devices in Electric Vehicles (EVs)

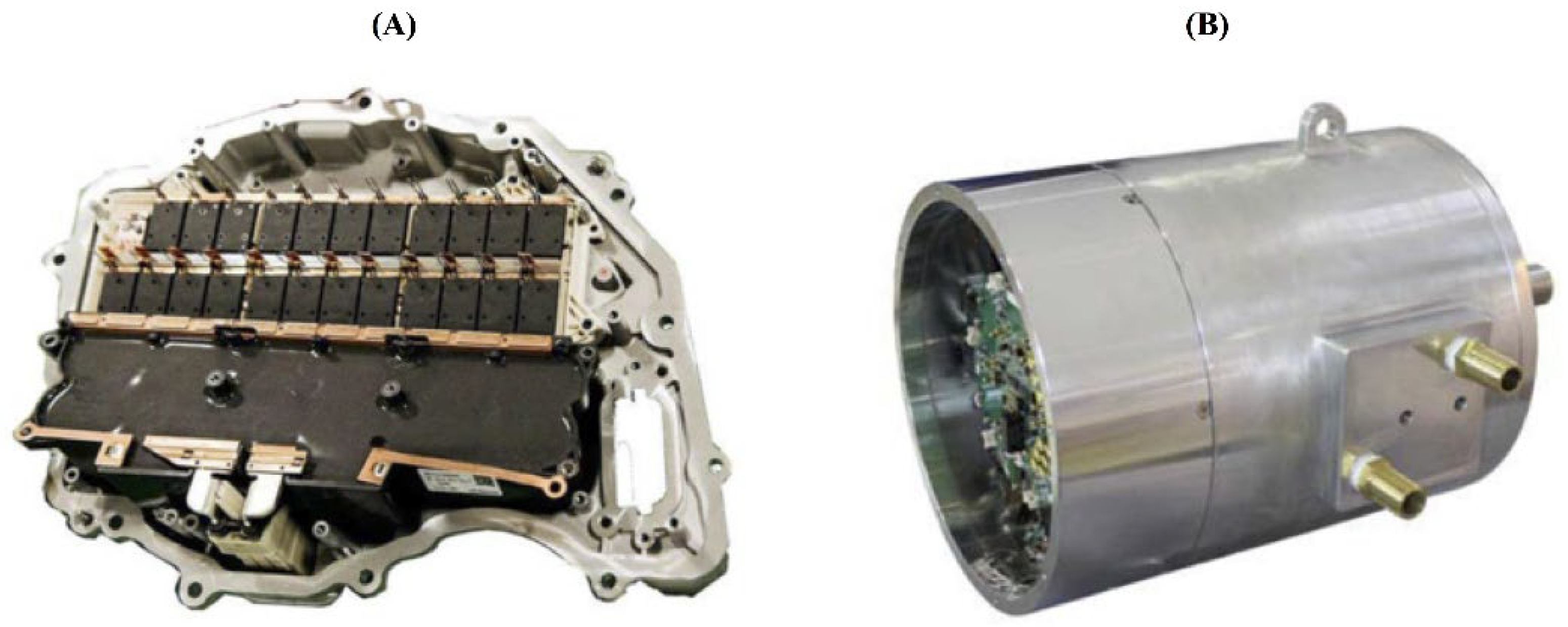

6.3. WBG Devices in Motor Drive Applications

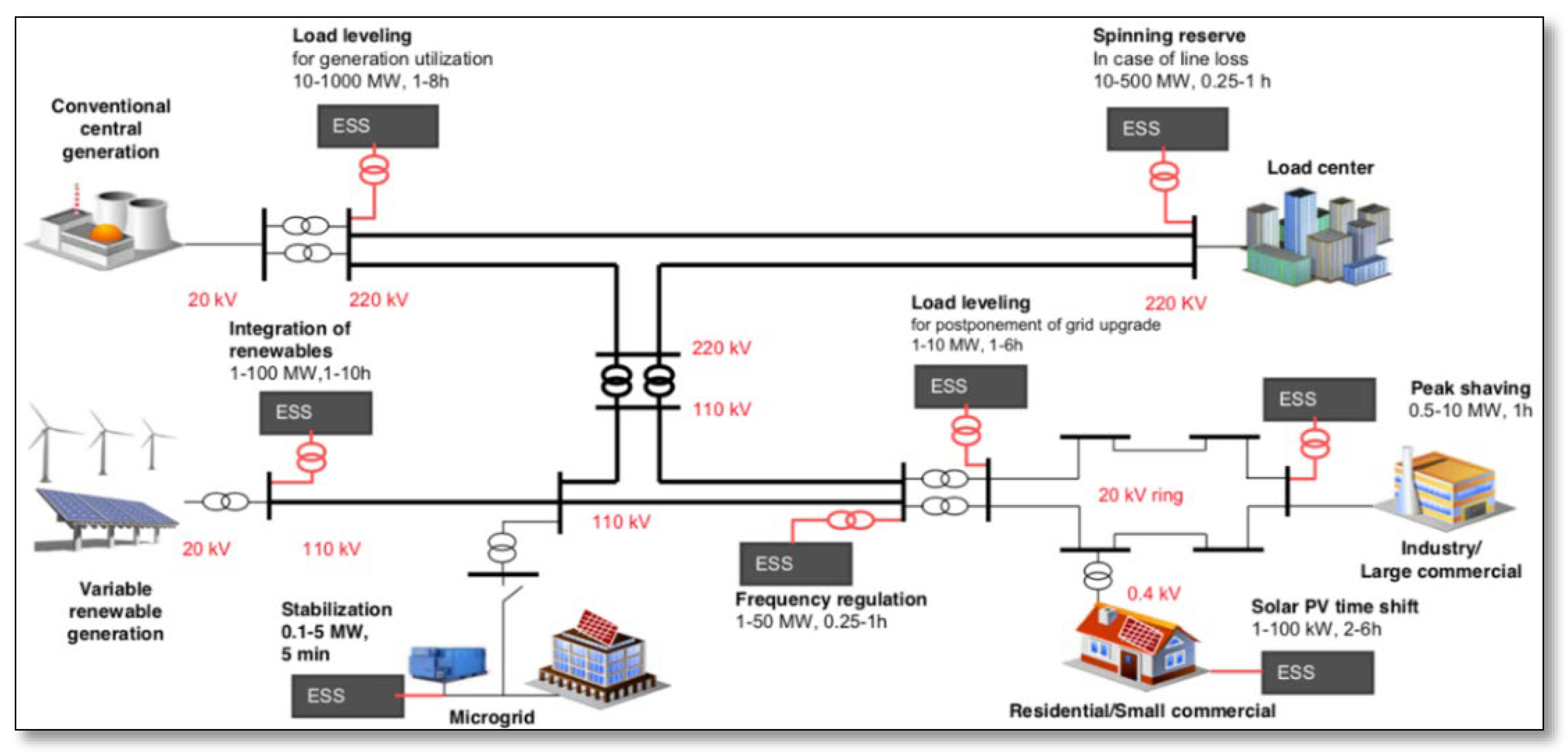

6.4. WBG Devices in Renewable Energy Systems

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Correction Statement

References

- Desogus, G.; Quaquero, E.; Rubiu, G.; Gatto, G.; Perra, C. BIM and IoT Sensors Integration: A Framework for Consumption and Indoor Conditions Data Monitoring of Existing Buildings. Sustainability 2021, 13, 4496. [Google Scholar] [CrossRef]

- Roccaforte, F.; Fiorenza, P.; Greco, G.; Lo Nigro, R.; Giannazzo, F.; Iucolano, F.; Saggio, M. Emerging trends in wide band gap semiconductors (SiC and GaN) technology for power devices. Microelectron. Eng. 2018, 187–188, 66–77. [Google Scholar] [CrossRef]

- Gachovska, T.K.; Hudgins, J.L. SiC and GaN Power Semiconductor Devices. In Power Electronics Handbook; Butterworth-Heinemann: Woburn, MA, USA, 2018; pp. 95–155. [Google Scholar] [CrossRef]

- Cao, Y.; Pomeroy, J.W.; Uren, M.J.; Yang, F.; Kuball, M. Electric field mapping of wide-bandgap semiconductor devices at a submicrometre resolution. Nat. Electron. 2021, 4, 478–485. [Google Scholar] [CrossRef]

- Juneja, S.; Pratap, R.; Sharma, R. Semiconductor technologies for 5G implementation at millimeter wave frequencies—Design challenges and current state of work. Eng. Sci. Technol. Int. J. 2021, 24, 205–217. [Google Scholar] [CrossRef]

- Ren, A.; Wang, H.; Zhang, W.; Wu, J.; Wang, Z.; Penty, R.V.; White, I.H. Emerging light-emitting diodes for next-generation data communications. Nat. Electron. 2021, 4, 559–572. [Google Scholar] [CrossRef]

- García de Arquer, F.P.; Talapin, D.V.; Klimov, V.I.; Arakawa, Y.; Bayer, M.; Sargent, E.H. Semiconductor quantum dots: Technological progress and future challenges. Science 2021, 373, eaaz8541. [Google Scholar] [CrossRef]

- Gatto, G.; Marongiu, I.; Perfetto, A.; Serpi, A. Modelling and predictive control of a Buck-Boost DC-DC converter. In Proceedings of the Speedam 2010, Pisa, Italy, 14–16 June 2010; pp. 1430–1435. [Google Scholar]

- Stefanik, J.; Zygmanowski, M. Power Loss Analysis of Advanced-Neutral-Point-Clamped Converter with SiC MOSFETs and Si IGBTs. In Proceedings of the 2021 IEEE 19th International Power Electronics and Motion Control Conference (PEMC), Gliwice, Poland, 25–29 April 2021; pp. 161–166. [Google Scholar]

- Casula, G.A.; Montisci, G.; Valente, G.; Gatto, G. A Robust Printed Antenna for UHF Wearable Applications. IEEE Trans. Antennas Propag. 2018, 66, 4337–4342. [Google Scholar] [CrossRef]

- Mazumder, S.K.; Kulkarni, A.; Sahoo, S.; Blaabjerg, F.; Mantooth, H.A.; Balda, J.C.; Zhao, Y.; Ramos-Ruiz, J.A.; Enjeti, P.N.; Kumar, P.R.; et al. A Review of Current Research Trends in Power-Electronic Innovations in Cyber–Physical Systems. IEEE J. Emerg. Sel. Top. Power Electron. 2021, 9, 5146–5163. [Google Scholar] [CrossRef]

- Millan, J.; Godignon, P.; Perpina, X.; Perez-Tomas, A.; Rebollo, J. A Survey of Wide Bandgap Power Semiconductor Devices. IEEE Trans. Power Electron. 2014, 29, 2155–2163. [Google Scholar] [CrossRef]

- Castellazzi, A.; Gurpinar, E.; Wang, Z.; Suliman Hussein, A.; Garcia Fernandez, P. Impact of Wide-Bandgap Technology on Renewable Energy and Smart-Grid Power Conversion Applications Including Storage. Energies 2019, 12, 4462. [Google Scholar] [CrossRef]

- Lin, Q.-L.; Liang, H.; Zhou, C.-Q.; Qian, Z.-F.; Sun, Y.-L.; Wang, X.-Y.; Wang, R.-H. Defect-induced magnetism in χ3 borophene. Rare Met. 2022, 41, 3486–3494. [Google Scholar] [CrossRef]

- Roccaforte, F.; Giannazzo, F.; Iucolano, F.; Eriksson, J.; Weng, M.H.; Raineri, V. Surface and interface issues in wide band gap semiconductor electronics. Appl. Surf. Sci. 2010, 256, 5727–5735. [Google Scholar] [CrossRef]

- Kirschman, R.K. High Temperature Electronics; IEEE Press: New York, NY, USA, 1999. [Google Scholar]

- Lamichhane, R.R.; Ericsson, N.; Frank, S.; Britton, C.; Marlino, L.; Mantooth, A.; Francis, M.; Shepherd, P.; Glover, M.; Perez, S.; et al. A wide bandgap silicon carbide (SiC) gate driver for high-temperature and high-voltage applications. In Proceedings of the 2014 IEEE 26th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Waikoloa, HI, USA, 15–19 June 2014; pp. 414–417. [Google Scholar]

- Chen, J.; Du, X.; Luo, Q.; Zhang, X.; Sun, P.; Zhou, L. A Review of Switching Oscillations of Wide Bandgap Semiconductor Devices. IEEE Trans. Power Electron. 2020, 35, 13182–13199. [Google Scholar] [CrossRef]

- Kumar, A.; Losito, M.; Moradpour, M.; Gatto, G. Current Source Gate Driver for SiC MOSFETs in Power Electronics Applications. In Proceedings of the 2022 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Sorrento, Italy, 22–24 June 2022; pp. 523–527. [Google Scholar]

- Nie, Y.; Dai, X.; Wang, J.; Qian, Z.; Wang, Z.; Guo, H.; Yan, G.; Jiang, D.; Wang, R. Facile and scalable fabrication of lithiophilic Cu O enables stable lithium metal anode. J. Energy Chem. 2022, 75, 285–292. [Google Scholar] [CrossRef]

- Molina, M.G. Energy Storage and Power Electronics Technologies: A Strong Combination to Empower the Transformation to the Smart Grid. Proc. IEEE 2017, 105, 2191–2219. [Google Scholar] [CrossRef]

- Arabshahi, H. Comparison of sic and zno field effect transistors for high power applications. Mod. Phys. Lett. B 2011, 23, 2533–2540. [Google Scholar] [CrossRef]

- Farrow, M.R.; Buckeridge, J.; Lazauskas, T.; Mora-Fonz, D.; Scanlon, D.O.; Catlow, C.R.A.; Woodley, S.M.; Sokol, A.A. Heterostructures of GaN with SiC and ZnO enhance carrier stability and separation in framework semiconductors. Phys. Status Solidi 2017, 214, 1600440. [Google Scholar] [CrossRef]

- Raynaud, C.; Tournier, D.; Morel, H.; Planson, D. Comparison of high voltage and high temperature performances of wide bandgap semiconductors for vertical power devices. Diamond Relat. Mater. 2010, 19, 1–6. [Google Scholar] [CrossRef]

- Pu, T.; Younis, U.; Chiu, H.-C.; Xu, K.; Kuo, H.-C.; Liu, X. Review of Recent Progress on Vertical GaN-Based PN Diodes. Nanoscale Res. Lett. 2021, 16, 101. [Google Scholar] [CrossRef]

- Shah, F.M.; Xiao, H.M.; Li, R.; Awais, M.; Zhou, G.; Bitew, G.T. Comparative performance evaluation of temperature dependent characteristics and power converter using GaN, SiC and Si power devices. In Proceedings of the 2018 IEEE 12th International Conference on Compatibility, Power Electronics and Power Engineering (CPE-POWERENG 2018), Doha, Qatar, 10–12 April 2018; pp. 1–7. [Google Scholar]

- Amano, H.; Baines, Y.; Beam, E.; Borga, M.; Bouchet, T.; Chalker, P.R.; Charles, M.; Chen, K.J.; Chowdhury, N.; Chu, R.; et al. The 2018 GaN power electronics roadmap. J. Phys. D Appl. Phys. 2018, 51, 163001. [Google Scholar] [CrossRef]

- Kaminski, N.; Hilt, O. SiC and GaN devices—Wide bandgap is not all the same. IET Circuits Devices Syst. 2014, 8, 227–236. [Google Scholar] [CrossRef]

- Chang, G.A.; Jin, H.; Qin, L.; Zhang, L.; Zeng, X.; Yang, R.; Ma, M.; Arumuga Perumal, S.; Chen, G. Review of wide band-gap semiconductors technology. MATEC Web Conf. 2016, 40, 1006. [Google Scholar] [CrossRef]

- Brueniger, R.D.; Andersen, A.; Wulff, J.; Makoschitz, M.; Krischan, K.; Bergmann, P. Wide Band Gap Technology: Efficiency Potential and Application Readiness Map 4E Power Electronic Conversion Technology Annex (PECTA). Available online: https://www.iea-4e.org/wp-content/uploads/publications/2020/05/PECTA_Report_Total-V10final-May-2020.pdf (accessed on 8 August 2022).

- Santi, E.; Peng, K.; Mantooth, H.A.; Hudgins, J.L. Modeling of Wide-Bandgap Power Semiconductor Devices—Part II. IEEE Trans. Electron Devices 2015, 62, 434–442. [Google Scholar] [CrossRef]

- Kraus, R.; Mattausch, H.J. Status and trends of power semiconductor device models for circuit simulation. IEEE Trans. Power Electron. 1998, 13, 452–465. [Google Scholar] [CrossRef]

- Bottaro, E.; Rizzo, S.A.; Salerno, N. Circuit Models of Power MOSFETs Leading the Way of GaN HEMT Modelling—A Review. Energies 2022, 15, 3415. [Google Scholar] [CrossRef]

- Mantooth, H.A.; Peng, K.; Santi, E.; Hudgins, J.L. Modeling of Wide Bandgap Power Semiconductor Devices—Part I. IEEE Trans. Electron Devices 2015, 62, 423–433. [Google Scholar] [CrossRef]

- Root, D. Future Device Modeling Trends. IEEE Microw. Mag. 2012, 13, 45–59. [Google Scholar] [CrossRef]

- Paula, W.J.; Tavares, G.H.M.; Soares, G.M.; Almeida, P.S.; Braga, H.A.C. Switching losses prediction methods oriented to power MOSFETs—A review. IET Power Electron. 2020, 13, 2960–2970. [Google Scholar] [CrossRef]

- Ahmed, M.R.; Todd, R.; Forsyth, A.J. Predicting SiC MOSFET Behavior Under Hard-Switching, Soft-Switching, and False Turn-On Conditions. IEEE Trans. Ind. Electron. 2017, 64, 9001–9011. [Google Scholar] [CrossRef]

- Xu, Y.; Ho, C.N.M.; Ghosh, A.; Muthumuni, D. A Datasheet-Based Behavioral Model of SiC MOSFET for Power Loss Prediction in Electromagnetic Transient Simulation. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; pp. 521–526. [Google Scholar]

- Santi, E.; Hudgins, J.L.; Mantooth, H.A. Variable Model Levels for Power Semiconductor Devices. In Proceedings of the SCSC07:2007 Summer Computer Simulation Conference, San Diego, CA, USA, 16–19 July 2007; pp. 276–283. [Google Scholar]

- Jun-Ha, L.; Hoong-Joo, L. Circuit model parameter generation with TCAD simulation. In Proceedings of the 7th International Conference on Solid-State and Integrated Circuits Technology, Beijing, China, 18–21 October 2004; pp. 1084–1087. [Google Scholar]

- Campian, I.; Profirescu, O.G.; Ungureanu, A.; Babarada, F.; Lakatos, E.; Amza, C. MOSFET simulation-TCAD tools/packages. In Proceedings of the 2003 International Semiconductor Conference, CAS 2003 Proceedings (IEEE Cat. No.03TH8676), Sinaia, Romania, 28 September–2 October 2003; pp. 235–238. [Google Scholar]

- Liou, J.J.; Ortiz-Conde, A.; Garcia-Sanchez, F. MOSFET simulation using device Simulators. In Analysis and Design of Mosfets; Springer: Boston, MA, USA, 1998; pp. 109–162. [Google Scholar] [CrossRef]

- Ammi, S.; Aissat, A.; Wichmann, N.; Bollaert, S. III-V MOSFET Structure (InP/InAs/InGaAs) I-V Characteristics Using Silvaco TCAD Simulator. In Proceedings of the 1st International Conference on Electronic Engineering and Renewable Energy, Saidia, Morocco, 15–17 April 2018; pp. 207–215. [Google Scholar] [CrossRef]

- Lophitis, N.; Arvanitopoulos, A.; Perkins, S.; Antoniou, M. TCAD Device Modelling and Simulation of Wide Bandgap Power Semiconductors. In Disruptive Wide Bandgap Semiconductors, Related Technologies, and Their Applications; IntechOpen: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef]

- Christen, D.; Biela, J. Analytical Switching Loss Modeling Based on Datasheet Parameters for MOSFETS in a Half-Bridge. IEEE Trans. Power Electron. 2019, 34, 3700–3710. [Google Scholar] [CrossRef]

- Moradpour, M.; Lai, A.; Serpi, A.; Gatto, G. Multi-objective optimization of gate driver circuit for GaN HEMT in electric vehicles. In Proceedings of the IECON 2017—43rd Annual Conference of the IEEE Industrial Electronics Society, Beijing, China, 29 October–1 November 2017; pp. 1319–1324. [Google Scholar]

- Burkart, R.M.; Kolar, J.W. Comparative η– ρ– σ Pareto Optimization of Si and SiC Multilevel Dual-Active-Bridge Topologies with Wide Input Voltage Range. IEEE Trans. Power Electron. 2017, 32, 5258–5270. [Google Scholar] [CrossRef]

- Langmaack, N.; Schobre, T.; Henke, M. Fast and Universal Semiconductor Loss Calculation Method. In Proceedings of the 2019 IEEE 13th International Conference on Power Electronics and Drive Systems (PEDS), Toulouse, France, 9–12 July 2019; pp. 1–4. [Google Scholar]

- Rabkowski, J.; Peftitsis, D.; Nee, H. Silicon Carbide Power Transistors: A New Era in Power Electronics Is Initiated. IEEE Ind. Electron. Mag. 2012, 6, 17–26. [Google Scholar] [CrossRef]

- Jones, E.A.; Wang, F.F.; Costinett, D. Review of Commercial GaN Power Devices and GaN-Based Converter Design Challenges. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 707–719. [Google Scholar] [CrossRef]

- Biswas, S.; Reusch, D.; de Rooij, M. Design of GaN-Based Multilevel Switched Capacitor Converters—Benefits and Challenges. IEEE Trans. Ind. Appl. 2020, 56, 979–988. [Google Scholar] [CrossRef]

- Abdelrahman, A.S.; Erdem, Z.; Attia, Y.; Youssef, M.Z. Wide Bandgap Devices in Electric Vehicle Converters: A Performance Survey. Can. J. Electr. Comput. Eng. 2018, 41, 45–54. [Google Scholar] [CrossRef]

- Kinzer, D. GaN power IC technology: Past, present, and future. In Proceedings of the 2017 29th International Symposium on Power Semiconductor Devices and IC’s (ISPSD), Sapporo, Japan, May 28–June 1 2017; pp. 19–24. [Google Scholar]

- Nouketcha, F.; Lelis, A.; Green, R.; Cui, Y.; Darmody, C.; Goldsman, N. Detailed Study of Breakdown Voltage and Critical Field in Wide Bandgap Semiconductors. In Proceedings of the 2019 IEEE 7th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Raleigh, NC, USA, 29–31 October 2019; pp. 200–207. [Google Scholar]

- Kanamura, M.; Ohki, T.; Kikkawa, T.; Imanishi, K.; Watanabe, K.; Joshin, K. Recent progress in GaN HEMT for high-frequency and high-power applications. In Proceedings of the 2012 IEEE International Symposium on Radio-Frequency Integration Technology (RFIT), Singapore, 21–23 November 2012; pp. 156–158. [Google Scholar]

- She, X.; Huang, A.Q.; Lucia, O.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Donato, N.; Rouger, N.; Pernot, J.; Longobardi, G.; Udrea, F. Diamond power devices: State of the art, modelling, figures of merit and future perspective. J. Phys. D Appl. Phys. 2019, 53, 093001. [Google Scholar] [CrossRef]

- Bodeker, C.; Vogt, T.; Kaminski, N. Stability of silicon carbide Schottky diodes against leakage current thermal runaway. In Proceedings of the 2015 IEEE 27th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Hong Kong, China, 10–14 May 2015; pp. 245–248. [Google Scholar]

- Kimoto, T. Ultrahigh-voltage SiC devices for future power infrastructure. In Proceedings of the 2013 Proceedings of the European Solid-State Device Research Conference (ESSDERC), Bucharest, Romania, 16–20 September 2013; pp. 22–29.

- Bhalla, A. Robustness of SiC JFETs and Cascodes. Available online: https://eepower.com/technical-articles/robustness-of-sic-jfets-and-cascodes/# (accessed on 20 May 2022).

- Shenoy, J.N.; Cooper, J.A.; Melloch, M.R. High-voltage double-implanted power MOSFET’s in 6H-SiC. IEEE Electron Device Lett. 1997, 18, 93–95. [Google Scholar] [CrossRef]

- Garrido-Diez, D.; Baraia, I. Review of wide bandgap materials and their impact in new power devices. In Proceedings of the 2017 IEEE International Workshop of Electronics, Control, Measurement, Signals and their Application to Mechatronics (ECMSM), San Sebastian, Spain, 24–26 May 2017; pp. 1–6. [Google Scholar]

- Pala, V.; Brunt, E.V.; Cheng, L.; O’Loughlin, M.; Richmond, J.; Burk, A.; Allen, S.T.; Grider, D.; Palmour, J.W.; Scozzie, C.J. 10 kV and 15 kV silicon carbide power MOSFETs for next-generation energy conversion and transmission systems. In Proceedings of the 2014 IEEE Energy Conversion Congress and Exposition (ECCE), Pittsburgh, PA, USA, 14–18 September 2014; pp. 449–454. [Google Scholar]

- Cheng, L.; Palmour, J.W. Cree’s SiC power MOSFET technology: Present status and future perspective. In Proceedings of the Ninth Annual SiC MOS Workshop, College Park, MD, USA, 14–15 August 2014. [Google Scholar]

- Meneghini, M.; De Santi, C.; Abid, I.; Buffolo, M.; Cioni, M.; Khadar, R.A.; Nela, L.; Zagni, N.; Chini, A.; Medjdoub, F.; et al. GaN-based power devices: Physics, reliability, and perspectives. J. Appl. Phys. 2021, 130, 181101. [Google Scholar] [CrossRef]

- Huang, X.; Liu, Z.; Li, Q.; Lee, F.C. Evaluation and Application of 600 V GaN HEMT in Cascode Structure. IEEE Trans. Power Electron. 2014, 29, 2453–2461. [Google Scholar] [CrossRef]

- Disney, D.; Hui, N.; Edwards, A.; Bour, D.; Shah, H.; Kizilyalli, I.C. Vertical power diodes in bulk GaN. In Proceedings of the 2013 25th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Kanazawa, Japan, 26–30 May 2013; pp. 59–62. [Google Scholar]

- Fu, H.; Fu, K.; Chowdhury, S.; Palacios, T.; Zhao, Y. Vertical GaN Power Devices: Device Principles and Fabrication Technologies—Part I. IEEE Trans. Electron Devices 2021, 68, 3200–3211. [Google Scholar] [CrossRef]

- Chowdhury, S.; Ji, D. Vertical GaN Power Devices. In Nitride Semiconductor Technology; Wiley: Weinheim, Germany, 2020; pp. 177–197. [Google Scholar] [CrossRef]

- Shenai, K. Future Prospects of Widebandgap (WBG) Semiconductor Power Switching Devices. IEEE Trans. Electron Devices 2015, 62, 248–257. [Google Scholar] [CrossRef]

- Zhang, L.; Yuan, X.; Wu, X.; Shi, C.; Zhang, J.; Zhang, Y. Performance Evaluation of High-Power SiC MOSFET Modules in Comparison to Si IGBT Modules. IEEE Trans. Power Electron. 2019, 34, 1181–1196. [Google Scholar] [CrossRef]

- Nguyen, N.-K.; Nguyen, T.; Nguyen, T.-K.; Yadav, S.; Dinh, T.; Masud, M.K.; Singha, P.; Do, T.N.; Barton, M.J.; Ta, H.T.; et al. Wide-Band-Gap Semiconductors for Biointegrated Electronics: Recent Advances and Future Directions. ACS Appl. Electron. Mater. 2021, 3, 1959–1981. [Google Scholar] [CrossRef]

- Cha, K.-H.; Ju, C.-T.; Kim, R.-Y. Analysis and Evaluation of WBG Power Device in High Frequency Induction Heating Application. Energies 2020, 13, 5351. [Google Scholar] [CrossRef]

- Li, Y.; Liang, T.; Lei, C.; Li, Q.; Li, Z.; Ghaffar, A.; Xiong, J. Study on the Stability of the Electrical Connection of High-Temperature Pressure Sensor Based on the Piezoresistive Effect of P-Type SiC. Micromachines 2021, 12, 216. [Google Scholar] [CrossRef]

- Sullivan, C.R.; Yao, D.; Gamache, G.; Latham, A.; Qiu, J. (Invited) Passive Component Technologies for Advanced Power Conversion Enabled by Wide-Band-Gap Power Devices. ECS Trans. 2019, 41, 315–330. [Google Scholar] [CrossRef]

- Shenai, K. Wide bandgap (WBG) semiconductor power converters for DC microgrid applications. In Proceedings of the 2015 IEEE First International Conference on DC Microgrids (ICDCM), Atlanta, GA, USA, 7–10 June 2015; pp. 263–268. [Google Scholar]

- Huang, A.Q. Wide bandgap (WBG) power devices and their impacts on power delivery systems. In Proceedings of the 2016 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 3–7 December 2016; pp. 20.21.21–20.21.24. [Google Scholar]

- Fuentes, C.D.; Müller, M.; Bernet, S.; Kouro, S. SiC-MOSFET or Si-IGBT: Comparison of Design and Key Characteristics of a 690 V Grid-Tied Industrial Two-Level Voltage Source Converter. Energies 2021, 14, 3054. [Google Scholar] [CrossRef]

- Wang, B.; Dong, S.; Jiang, S.; He, C.; Hu, J.; Ye, H.; Ding, X. A Comparative Study on the Switching Performance of GaN and Si Power Devices for Bipolar Complementary Modulated Converter Legs. Energies 2019, 12, 1146. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, S.; Chu, Y. Comparison of Radiated Electromagnetic Interference (EMI) Generated by Power Converters with Silicon MOSFETs and GaN HEMTs. In Proceedings of the 2019 IEEE Applied Power Electronics Conference and Exposition (APEC), Anaheim, CA, USA, 17–21 March 2019; pp. 1375–1382. [Google Scholar]

- Han, D.; Morris, C.T.; Lee, W.; Sarlioglu, B. A Case Study on Common Mode Electromagnetic Interference Characteristics of GaN HEMT and Si MOSFET Power Converters for EV/HEVs. IEEE Trans. Transp. Electrif. 2017, 3, 168–179. [Google Scholar] [CrossRef]

- Pirino, P.; Losito, M.; Kumar, A.; Gatto, G.; Meo, S.; Frank, W.-T.; Moradpour, M. Multi-Objective Gate Driver Design for a GaN-Based Half-Bridge Converter to Optimize Efficiency and Near-Field EMI. Int. Rev. Electr. Eng. (IREE) 2021, 16, 95. [Google Scholar] [CrossRef]

- Mathur, P.; Raman, S. Electromagnetic Interference (EMI): Measurement and Reduction Techniques. J. Electron. Mater. 2020, 49, 2975–2998. [Google Scholar] [CrossRef]

- Mortazavizadeh, S.A.; Palazzo, S.; Amendola, A.; De Santis, E.; Di Ruzza, D.; Panariello, G.; Sanseverino, A.; Velardi, F.; Busatto, G. High Frequency, High Efficiency, and High Power Density GaN-Based LLC Resonant Converter: State-of-the-Art and Perspectives. Appl. Sci. 2021, 11, 11350. [Google Scholar] [CrossRef]

- Trentin, A.; de Lillo, L.; Empringham, L.; Wheeler, P.; Clare, J. Experimental Comparison of a Direct Matrix Converter Using Si IGBT and SiC MOSFETs. IEEE J. Emerg. Sel. Top. Power Electron. 2015, 3, 542–554. [Google Scholar] [CrossRef]

- Middelstaedt, L.; Lindemann, A. Methodology for analysing radiated EMI characteristics using transient time domain measurements. IET Power Electron. 2016, 9, 2013–2018. [Google Scholar] [CrossRef]

- Schittler, A.C.; Pappis, D.; Zacharias, P. EMI filter design for high switching speed and frequency grid-connected inverters. In Proceedings of the 2016 18th European Conference on Power Electronics and Applications (EPE’16 ECCE Europe), Karlsruhe, Germany, 5–9 September 2016; pp. 1–8. [Google Scholar]

- Ouyang, X.; Huang, W.; Cabrera, E.; Castro, J.; Lee, L.J. Graphene-graphene oxide-graphene hybrid nanopapers with superior mechanical, gas barrier and electrical properties. AIP Adv. 2015, 5, 017135. [Google Scholar] [CrossRef]

- Sankaran, S.; Deshmukh, K.; Ahamed, M.B.; Khadheer Pasha, S.K. Recent advances in electromagnetic interference shielding properties of metal and carbon filler reinforced flexible polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2018, 114, 49–71. [Google Scholar] [CrossRef]

- Akagi, H.; Hasegawa, H.; Doumoto, T. Design and Performance of a Passive EMI Filter for Use With a Voltage-Source PWM Inverter Having Sinusoidal Output Voltage and Zero Common-Mode Voltage. IEEE Trans. Power Electron. 2004, 19, 1069–1076. [Google Scholar] [CrossRef]

- Lee, K.-H.; Kang, B.-G.; Choi, Y.; Chung, S.-K.; Won, J.-S.; Kim, H.-S. Design and Implementation of an Active EMI Filter for Common-Mode Noise Reduction. J. Power Electron. 2016, 16, 1236–1243. [Google Scholar] [CrossRef]

- Biela, J.; Wirthmueller, A.; Waespe, R.; Heldwein, M.L.; Raggl, K.; Kolar, J.W. Passive and Active Hybrid Integrated EMI Filters. IEEE Trans. Power Electron. 2009, 24, 1340–1349. [Google Scholar] [CrossRef]

- Ali, M.; Laboure, E.; Costa, F. Integrated Active Filter for Differential-Mode Noise Suppression. IEEE Trans. Power Electron. 2014, 29, 1053–1057. [Google Scholar] [CrossRef]

- Narayanasamy, B.; Luo, F. A Survey of Active EMI Filters for Conducted EMI Noise Reduction in Power Electronic Converters. IEEE Trans. Electromagn. Compat. 2019, 61, 2040–2049. [Google Scholar] [CrossRef]

- Zhou, Y.; Wang, H.; Chen, W.; Yan, R.; Liu, J.; Zhang, R. The effectiveness comparison of AEF with different sensing method in High Power Converters. In Proceedings of the 2020 IEEE 9th International Power Electronics and Motion Control Conference (IPEMC2020-ECCE Asia), Nanjing, China, 29 November–2 December 2020; pp. 1649–1652. [Google Scholar]

- Luo, F.; Dong, D.; Boroyevich, D.; Mattavelli, P.; Wang, S. Improving High-Frequency Performance of an Input Common Mode EMI Filter Using an Impedance-Mismatching Filter. IEEE Trans. Power Electron. 2014, 29, 5111–5115. [Google Scholar] [CrossRef]

- Bernacki, K.; Wybrańczyk, D.; Zygmanowski, M.; Latko, A.; Michalak, J.; Rymarski, Z. Disturbance and Signal Filter for Power Line Communication. Electronics 2019, 8, 378. [Google Scholar] [CrossRef]

- Wang, S. EMI Modeling and Reduction in Modern Power Electronics Systems. In Proceedings of the 2018 IEEE Symposium on Electromagnetic Compatibility, Signal Integrity and Power Integrity (EMC, SI & PI), Long Beach, CA, USA, July 30–August 3 2018; pp. 1–44. [Google Scholar]

- Zhang, L.; Zheng, Z.; Lou, X. A review of WBG and Si devices hybrid applications. Chin. J. Electr. Eng. 2021, 7, 1–20. [Google Scholar] [CrossRef]

- Amber, L.; Haddad, K. Hybrid Si IGBT-SiC Schottky diode modules for medium to high power applications. In Proceedings of the 2017 IEEE Applied Power Electronics Conference and Exposition (APEC), Tampa, FL, USA, 26–30 March 2017; pp. 3027–3032. [Google Scholar]

- Song, X.; Huang, A.Q.; Lee, M.-C.; Peng, C. High voltage Si/SiC hybrid switch: An ideal next step for SiC. In Proceedings of the 2015 IEEE 27th International Symposium on Power Semiconductor Devices & IC’s (ISPSD), Hong Kong, China, 10–14 May 2015; pp. 289–292. [Google Scholar]

- Deshpande, A.; Luo, F. Comprehensive evaluation of a silicon-WBG hybrid switch. In Proceedings of the 2016 IEEE Energy Conversion Congress and Exposition (ECCE), Milwaukee, WI, USA, 18–22 September 2016; pp. 1–8. [Google Scholar]

- Liu, G.; Bai, K.H.; McAmmond, M.; Brown, A.; Johnson, P.M.; Lu, J. Critical short-timescale transient processes of a GaN+Si hybrid switching module used in zero-voltage-switching applications. In Proceedings of the 2017 IEEE 5th Workshop on Wide Bandgap Power Devices and Applications (WiPDA), Albuquerque, NM, USA, 30 October–1 November 2017; pp. 93–97. [Google Scholar]

- Li, X.; Zeng, Z.; Chen, H.; Shao, W.; Ran, L. Comparative Evaluations and Failure Modes of Wire-Bonding Packaged SiC, Si, and Hybrid Power Modules. In Proceedings of the 2018 1st Workshop on Wide Bandgap Power Devices and Applications in Asia (WiPDA Asia), Xi’an, China, 16–18 May 2018; pp. 16–22. [Google Scholar]

- Li, X.; Li, D.; Chang, G.; Gong, W.; Packwood, M.; Pottage, D.; Wang, Y.; Luo, H.; Liu, G. High-Voltage Hybrid IGBT Power Modules for Miniaturization of Rolling Stock Traction Inverters. IEEE Trans. Ind. Electron. 2022, 69, 1266–1275. [Google Scholar] [CrossRef]

- Langmaack, N.; Tareilus, G.; Henke, M. Silicon Carbide Power Electronics in Fuel Cell and Battery Electric Vehicle Applications. In Proceedings of the SIA Automotive Power Electronics (APE 2017), Paris, France, 28 April 2017. [Google Scholar]

- Langmaack, N.; Tareilus, G.; Henke, M. SiC Drive Inverter using Intelligent Gate Drivers and Embedded Current Sensing. In Proceedings of the SIA Power Train & Electronics (PWTE 2019), Port-Marly, France, 12–13 June 2019. [Google Scholar]

- Langmaack, N.; Tareilus, G.; Henke, M. Power Electronic Components based on Silicon Carbide Devices for Future Vehicle Power Systems. In Proceedings of the SIA Power Train & Energy (PWTE 2020), Port-Marly, France, 16–29 November 2020. [Google Scholar]

- Najjar, M.; Shahparasti, M.; Kouchaki, A.; Nymand, M. Operation and Efficiency Analysis of a Five-Level Single-Phase Hybrid Si/SiC Active Neutral Point Clamped Converter. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 662–672. [Google Scholar] [CrossRef]

- Moradpour, M.; Gatto, G. A New SiC-GaN-Based Two-Phase Interleaved Bidirectional DC-DC Converter for Plug-In Electric Vehicles. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 587–592. [Google Scholar]

- Keshmiri, N.; Wang, D.; Agrawal, B.; Hou, R.; Emadi, A. Current Status and Future Trends of GaN HEMTs in Electrified Transportation. IEEE Access 2020, 8, 70553–70571. [Google Scholar] [CrossRef]

- Kachi, T. GaN devices for automotive application and their challenges in adoption. In Proceedings of the 2018 IEEE International Electron Devices Meeting (IEDM), San Francisco, CA, USA, 1–5 December 2018; pp. 19.15.11–19.15.14. [Google Scholar]

- (H)EV On-Board Battery Charger—Hybrid / Electric Vehicle. Available online: https://www.infineon.com/cms/en/applications/automotive/electric-drive-train/onboard-battery-charger/ (accessed on 5 August 2022).

- Yuan, J.; Dorn-Gomba, L.; Callegaro, A.D.; Reimers, J.; Emadi, A. A Review of Bidirectional On-Board Chargers for Electric Vehicles. IEEE Access 2021, 9, 51501–51518. [Google Scholar] [CrossRef]

- Avron, A. About the SiC MOSFET Modules in Tesla Model 3. Available online: https://www.pntpower.com/tesla-model-3-powered-by-st-microelectronics-sic-mosfets/ (accessed on 20 May 2022).

- Van Do, T.; Trovao, J.P.F.; Li, K.; Boulon, L. Wide-Bandgap Power Semiconductors for Electric Vehicle Systems: Challenges and Trends. IEEE Veh. Technol. Mag. 2021, 16, 89–98. [Google Scholar] [CrossRef]

- Mitsubishi Electric Corporation. Mitsubishi Electric Develops EV Motor Drive System with Built-In Silicon Carbide Inverter. Available online: http://www.mitsubishielectric.com/news/2014/pdf/0213-d.pdf (accessed on 20 May 2022).

- Morya, A.K.; Gardner, M.C.; Anvari, B.; Liu, L.; Yepes, A.G.; Doval-Gandoy, J.; Toliyat, H.A. Wide Bandgap Devices in AC Electric Drives: Opportunities and Challenges. IEEE Trans. Transp. Electrif. 2019, 5, 3–20. [Google Scholar] [CrossRef]

- Narayanasamy, B.; Sathyanarayanan, A.S.; Luo, F.; Chen, C. Reflected Wave Phenomenon in SiC Motor Drives: Consequences, Boundaries, and Mitigation. IEEE Trans. Power Electron. 2020, 35, 10629–10642. [Google Scholar] [CrossRef]

- Diab, M.S.; Yuan, X. A Quasi-Three-Level PWM Scheme to Combat Motor Overvoltage in SiC-Based Single-Phase Drives. IEEE Trans. Power Electron. 2020, 35, 12639–12645. [Google Scholar] [CrossRef]

- Servodrive System Uses Motors with Built-in SiC Devices—Drives and Controls Magazine. Available online: http://drivesncontrols.com/news/fullstory.php/aid/5584/Servodrive_system_uses_motors_with_built-in_SiC_devices.html (accessed on 26 May 2022).

- Langmaack, N.; Tareilus, G.; Mallwitz, R. High Performance Drive Inverter for an Electric Turbo Compressor in Fuel Cell Applications. In Proceedings of the 2020 22nd European Conference on Power Electronics and Applications (EPE’20 ECCE Europe), Lyon, France, 7–11 September 2020; pp. 1–10. [Google Scholar]

- Langmaack, N.; Balasubramanian, S.; Mallwitz, R.; Henke, M. Comparative Analysis of High Speed Drive Inverter Designs using different Wide-Band-Gap Power Devices. In Proceedings of the 2021 23rd European Conference on Power Electronics and Applications (EPE’21 ECCE Europe), Ghent, Belgium, 6–10 September 2021; pp. 1–10. [Google Scholar]

- Langmaack, N.; Lippold, F.; Hu, D.; Mallwitz, R. Analysing Efficiency and Reliability of High Speed Drive Inverters Using Wide Band Gap Power Devices. Machines 2021, 9, 350. [Google Scholar] [CrossRef]

- Mura, P.G.; Baccoli, R.; Innamorati, R.; Mariotti, S. Solar Energy System in A Small Town Constituted of A Network of Photovoltaic Collectors to Produce Electricity for Homes and Hydrogen for Transport Services of Municipality. Energy Procedia 2015, 78, 824–829. [Google Scholar] [CrossRef]

- Baccoli, R.; Kumar, A.; Frattolillo, A.; Mastino, C.; Ghiani, E.; Gatto, G. Enhancing energy production in a PV collector—Reflector system supervised by an optimization model: Experimental analysis and validation. Energy Convers. Manage. 2021, 229, 113774. [Google Scholar] [CrossRef]

- Mura, P.G.; Baccoli, R.; Innamorati, R.; Mariotti, S. An Energy Autonomous House Equipped with a Solar PV Hydrogen Conversion System. Energy Procedia 2015, 78, 1998–2003. [Google Scholar] [CrossRef][Green Version]

- He, J.; Zhao, T.; Jing, X.; Demerdash, N.A.O. Application of wide bandgap devices in renewable energy systems—Benefits and challenges. In Proceedings of the 2014 International Conference on Renewable Energy Research and Application (ICRERA), Milwaukee, WI, USA, 19–22 October 2014; pp. 749–754. [Google Scholar]

- Cicio, D. EssPro™—Battery Energy Storage: The Power to Control Energy. Available online: https://new.abb.com/docs/librariesprovider78/eventos/jjtts-2017/presentaciones-peru/(dario-cicio)-bess---battery-energy-storage-system.pdf?sfvrsn=2 (accessed on 30 May 2022).

- Mookken, J.A.B.; Liu, J. Efficient and Compact 50kW Gen2 SiC Device Based PV String Inverter. In Proceedings of the PCIM Europe 2014, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nurenberg, Germany, 20–22 May 2014; pp. 1–7. [Google Scholar]

- Delmonte, N.C.P.; Santoro, D.; Toscani, A.; Buticchi, G. Development of a GaN based triple-active-bridge for DC nanogrid. In Proceedings of the 20th European Conference on Power Electronics and Applications (EPE’18 ECCE Europe), Riga, Latvia, 17–21 September 2018; pp. 1–9. [Google Scholar]

- Fujii, K.; Noto, Y.; Oshima, M.; Okuma, Y. 1-MW solar power inverter with boost converter using all SiC power module. In Proceedings of the 2015 17th European Conference on Power Electronics and Applications (EPE’15 ECCE-Europe), Geneva, Switzerland, 8–10 September 2015; pp. 1–10. [Google Scholar]

- Umuhoza, J.; Mhiesan, H.; Mordi, K.; Farnell, C.; Mantooth, H.A. A SiC-based power electronics interface for integrating a battery energy storage into the medium (13.8 kV) distribution system. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 2387–2392. [Google Scholar]

- Inverter—Rise and Shine: This Diamond-like Material Is Helping Solar Power Cast a Bigger Shadow. Available online: https://www.ge.com/news/taxonomy/term/2667 (accessed on 30 May 2022).

- Todorovic, M.H.; Carastro, F.; Schuetz, T.; Roesner, R.; Stevanovic, L.; Mandrusiak, G.; Rowden, B.; Tao, F.; Cioffi, P.; Nasadoski, J.; et al. SiC MW PV Inverter. In Proceedings of the PCIM Europe 2016, International Exhibition and Conference for Power Electronics, Intelligent Motion, Renewable Energy and Energy Management, Nuremberg, Germany, 10–12 May 2016; pp. 1–8. [Google Scholar]

- Bose, B.K. Power Electronics in Renewable Energy Systems and Smart Grid; Wiley-Blackwell: Hoboke, NJ, USA, 2019. [Google Scholar] [CrossRef]

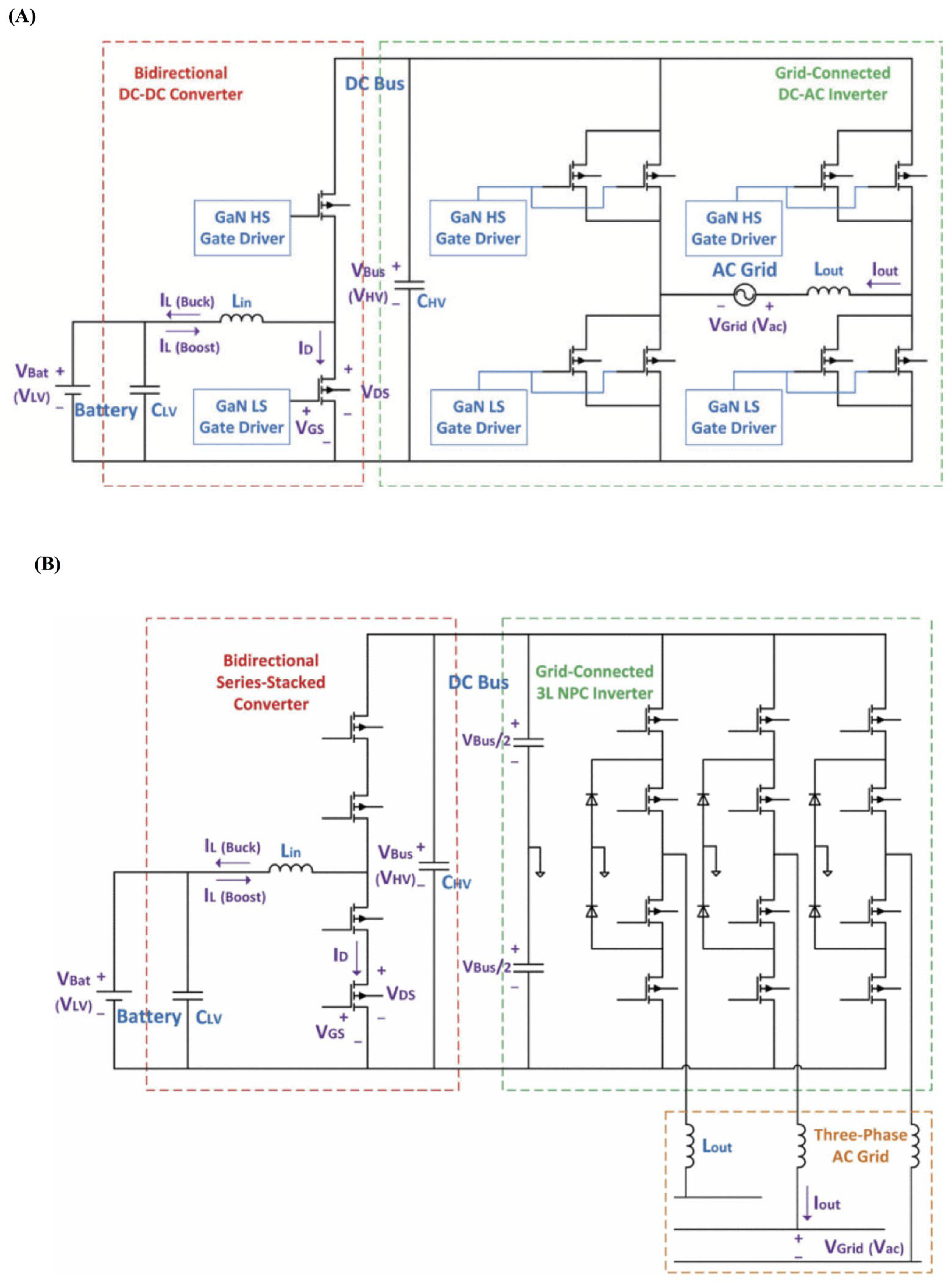

- Moradpour, M.; Ghani, P.; Gatto, G. A GaN-Based Battery Energy Storage System for Residential Application. In Proceedings of the 2019 International Conference on Clean Electrical Power (ICCEP), Otranto, Italy, 2–4 July 2019; pp. 427–432. [Google Scholar]

- Moradpour, M.; Ghani, P.; Pirino, P.; Gatto, G. A GaN-Based Battery Energy Storage System for Three-Phase Residential Application with Series-Stacked Devices and Three-Level Neutral Point Clamped Topology. In Proceedings of the 2019 1st International Conference on Energy Transition in the Mediterranean Area (SyNERGY MED), Cagliari, Italy, 28–30 May 2019; pp. 1–6. [Google Scholar]

| Properties | Si | 6H-SiC | 4H-SiC | GaN | Diamond |

|---|---|---|---|---|---|

| Thermal conductivity (W/cm K) | 1.5 | 4.9 | 4.9 | 1.3 | 22 |

| Band gap (eV) | 1.12 | 3.03 | 3.26 | 3.45 | 5.5 |

| Breakdown field (MV/cm) | 0.3 | 2.5 | 2.2 | 3.3 | 20 |

| Dielectric constant | 11.9 | 9.66 | 9.7 | 8.5–10.4 | 5.5 |

| Electron mobility (cm2/Vs) | 1500 | 400 | 800 | 2000 | 1060 |

| Drift velocity (107 cm/s) | 1.02 | 2.0 | 2.0 | 2.2 | 2.5 |

| Intrinsic carrier concentration (cm−3) | 0.1 | 10−9 | 10−6 | 10−10 | 10−27 |

| Power Devices | Si | SiC | GaN |

|---|---|---|---|

| Diodes | Schottky | Schottky | Schottky |

| Epitaxial | Epitaxial | Epitaxial | |

| Double diffusion | |||

| Transistors | BJT (npn, pnp) | BJT | HEMT |

| MOSFET | MOSFET | MOSFET | |

| IGBT | IGBT | - | |

| - | JFET | JFET |

| Devices | Power Density (kW/L) | Efficiency (%) | Switching Frequency (kHz) | |||

|---|---|---|---|---|---|---|

| Si | WBG | Si | WBG | Si | WBG | |

| Motor Drive | 3.45–11.1 | 12.1–34 | 93–96.4 | 97–99 | 10–20 | 10–20 |

| Onboard converter | 3.9–6 | 22–42 | 91–98 | 94–98.5 | 10–20 | 100–240 |

| Charger | 2–3.9 | 3.3–10.5 | 93–96.5 | 96–98 | 40–100 | 100–500 |

| WBG Devices | Low Inductance | High Speed | High Ambient Temperature |

|---|---|---|---|

| Applications | Motors with large effective airgap; Slotless motors; Low leakage induction machines for high traction | High power density motors fueled by electrification of vehicle; High pole count high speed motors with high torque density; Megawatts level high speed motor | Integrated motor drives; Hybrid electric vehicle; Sub-sea and downhole applications; NASA probes and landers for space exploration |

| Requirements | Pulse width modulation switching frequency of 50–100 kHz | Fundamental frequency of multiple kHz | High junction temperature operations and low losses to reduce cooling requirement |

| Inverter Power Ratings | Grid Connection Type | Application | DC Bus Voltage |

|---|---|---|---|

| <10 kW | Single-phase | Residential | 200–400 VDC |

| 10–100 kW | Three-phase 208 VAC | Small commercial | 300–600 VDC |

| 100–250 kW | Three-phase 480/600 VAC | Large commercial | 600 VDC |

| 250 kW–1 MW | Three-phase 300–600 VAC | Utility | 1000 VDC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kumar, A.; Moradpour, M.; Losito, M.; Franke, W.-T.; Ramasamy, S.; Baccoli, R.; Gatto, G. Wide Band Gap Devices and Their Application in Power Electronics. Energies 2022, 15, 9172. https://doi.org/10.3390/en15239172

Kumar A, Moradpour M, Losito M, Franke W-T, Ramasamy S, Baccoli R, Gatto G. Wide Band Gap Devices and Their Application in Power Electronics. Energies. 2022; 15(23):9172. https://doi.org/10.3390/en15239172

Chicago/Turabian StyleKumar, Amit, Milad Moradpour, Michele Losito, Wulf-Toke Franke, Suganthi Ramasamy, Roberto Baccoli, and Gianluca Gatto. 2022. "Wide Band Gap Devices and Their Application in Power Electronics" Energies 15, no. 23: 9172. https://doi.org/10.3390/en15239172

APA StyleKumar, A., Moradpour, M., Losito, M., Franke, W.-T., Ramasamy, S., Baccoli, R., & Gatto, G. (2022). Wide Band Gap Devices and Their Application in Power Electronics. Energies, 15(23), 9172. https://doi.org/10.3390/en15239172